Page 1

Data Sheet

Transmission Module

PVBM

Meter-In Meter-Out – Open Circuit Transmission

The Meter-in Meter-out module is designed primarily

for use with transmission hydraulic motors in e.q.

manlifts or demanding winch applications. The terms

Meter-In and Meter- Out relates to the oil flow being

metered into (Meter-In) and out from (Meter-Out) the

transmission motor by the PVG valve.

With the Meter-in Meter-out module both flows in

and out of the transmission motors are controlled at

the same time.

The Meter-in Meter-out module will ensure a stable,

well controlled movement of application when motor

is pushing (i.e. upwards hill) or motor being pulled

(i.e. downward hill) or horizontal movement.

Features

•

Integrated shock/anti-cavitation valve

(A- and B- port)

•

T0 connection

•

BSP/UNF

•

Meter-In compensator

•

Meter-Out compensator on A- and Bport

•

Increased control of negative loads

Comprehensive technical literature online

at powersolutions.danfoss.com

©

Danfoss | Mar 2017 L1117392 | AI00000124en-US0303 | 1

Page 2

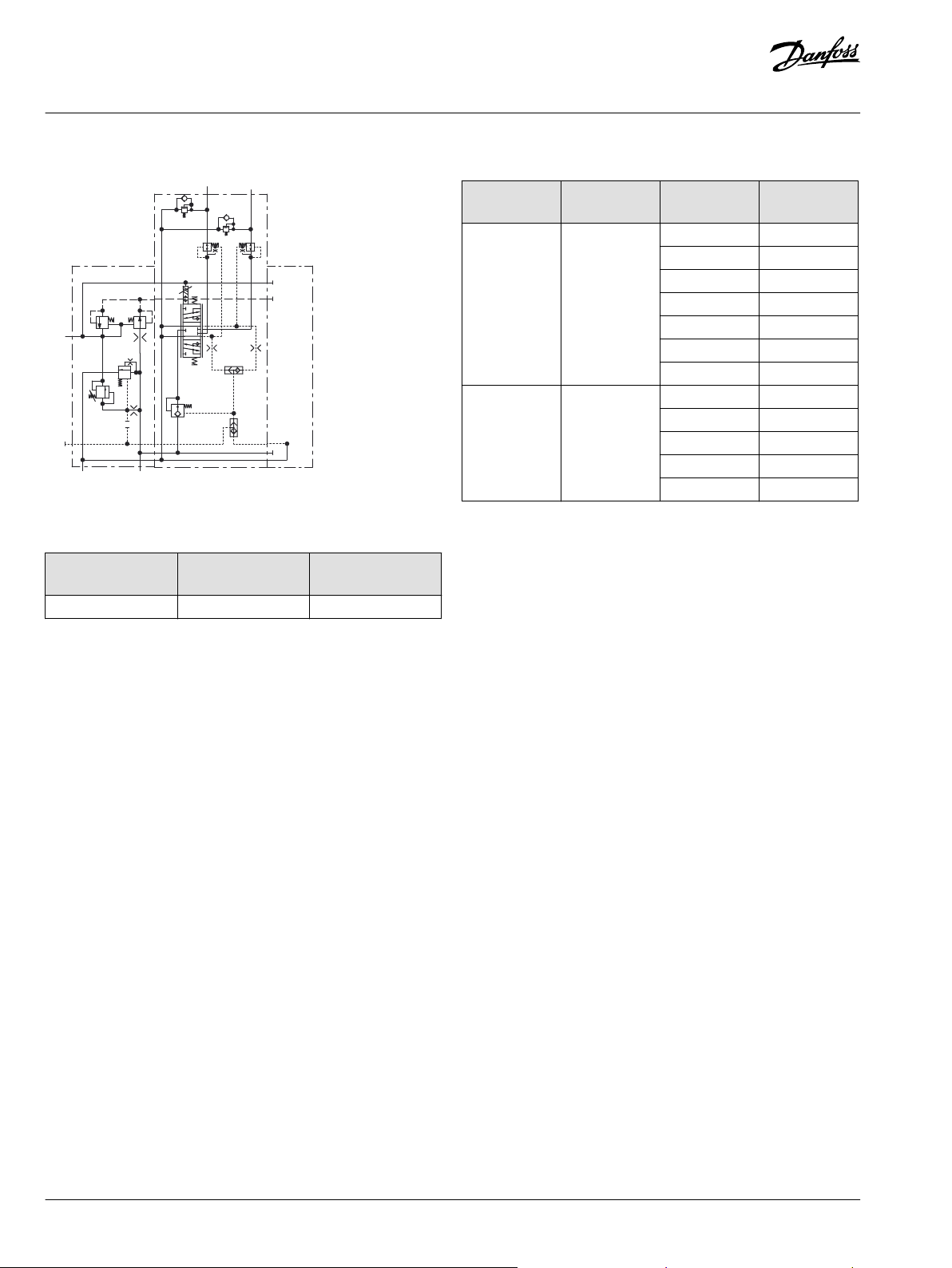

A B

T P

LS

T0

V310 310.A

Data Sheet

Transmission Module PVBM

Schematic

Available spools

Flow

Characteristic

Progressive Closed neutral 5 11187198

Linear Closed neutral 10 11187177

Function in

Neutral

Flow l/min

(Symmetrical)

10 11185988

25 11186235

40 11186436

65 11186450

100 11156265

130 11156268

25 11187390

40 11187500

65 11187659

100 11156300

Part Number

Available modules

Description BSP G1/2 ports Code

No.

PVBM module 157B6268 11018399

SAE 7/8-14 ports

Code No.

Application Awareness

•

With the Meter-In Meter-Out module, stability is determined by ensuring that oil flow into the system is always lower than oil flow out

of the system. This is achieved by means of different spring settings in the Meter-In Meter-Out compensators. As an example, this

means that a motor will run faster in Meter-Out mode than in Meter-In mode.

•

Due to the Meter-out compensators, a backpressure valve is needed to avoid cavitations when running in meter-out situations. The

back pressure setting would be application dependent but typical values are between 5-10 bar. Increased back pressure setting

ensures better protection against cavitations but also decrease energy efficiencies. The hydraulic system would be leaking in neutral

when external forces acts on the working ports. To avoid unwanted movements of the applied motors, therefore external brakes are

needed.

•

Dependent on the application type smooth movement could be requested. PVE’s in combination with a controller and joystick could

be useful to add ramps on the spool and delay on the motor brakes so it doesn’t hit the brakes too hard when returning to neutral.

2 | © Danfoss | Mar 2017 L1117392 | AI00000124en-US0303

Page 3

Data Sheet

Transmission Module PVBM

Technical specifications

Max. pressure Port P continuous, Port A/B 350 bar [5076 psi]

Port T static/dynamic 25/40 bar [362/580 psi]

Port A/B and P 130 l/min [34 US gal/min]

Oil flow, rated Port A/B and P 130 l/min [34 US gal/min]

Spool travel ±7 mm [±0.28 in]

Max. internal leakage A/B→T at 100 bar [1450 psi] and 21 mm2/s 1 l/min [61 in3/min]

Max. internal leakage A/B→T at 200 bar [2900 psi] and 21 mm2/s 1.5 l/min [92 in3/min]

Oil temperature (inlet) Recommended 30 → 60 °C [86 → 140°F]

Minimum -30 °C [-22 °F]

Maximum 90 °C [194 °F]

Ambient temperature -30 → 60 °C [-22 → 140 °F]

Oil viscosity Operating range 12-75 mm2/s [65-347 SUS]

Minimum 4 mm2/s [39 SUS]

Maximum 460 mm2/s [2128 SUS]

Filtration, max. contamination (ISO 4406) 18/16/13

©

Danfoss | Mar 2017 L1117392 | AI00000124en-US0303 | 3

Page 4

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

4 | © Danfoss | Mar 2017 L1117392 | AI00000124en-US0303

Loading...

Loading...