Page 1

Fact sheet | VLT® Pressure Transmitter PTU 025

Optimized airflow control

saves energy and improves indoor climate

Optimize indoor climate

Optimizing indoor climate in for instance

office buildings or hospitals will ensure

a healthy work environment for optimal

staff performance and increase overall

well-being for both staff and patients by

ensuring access to clean and fresh air.

The VLT® HVAC Drive FC 102 has a built-in

airflow controller. Combining the control

with the filter monitoring, via the

VLT® Pressure Transmitter PTU 025, will

create a solution that is easy to install and

that provides great indoor climate with

minimal energy consumption.

Save energy and costs

Cut operation costs by ensuring airflow

based on the actual demand and system

design – whether this is based on the

airflow through the fan or the pressure in

the connected air distribution system.

The control solution can handle different

control logics from simple pressure

measurement to advanced flow or pressure

control in air-handling units (AHUs)/roof

top units (RTUs).

Four PID loops for full control

The FC 102 has a total of four PID loops to

support different air conditioning needs

in the AHU/RTU, e.g. heating, cooling,

humidification, or energy recovery.

The advanced, programmable smart logic

controller with four independent control

loops will cover many simple AHU/RTU

control solutions.

Easy to install

The VLT® Pressure Transmitter is fast and

easy to install, commission and operate.

Avoid complexity in installation and system

integration thanks to the simplicity of this

compact design. It is built specifically for

AHU and RTU applications, for reliable

operation both indoors and outdoors.

Communicate seamlessly

When combined into a single unit,

the VLT® Pressure Transmitter and the

VLT® HVAC Drive ensure that airflow

and pressure level are handled by

the drive according to predefined

control parameters and sensor inputs.

Communication to the connected network

or building management system (BMS) is

automatic and seamless.

Mount VLT® Pressure Transmitter PTU 025 directly

onto the VLT® HVAC Drive FC 102 enclosure, and

connect easily to achieve seamless BMS integration.

Ensure

clean

air and win the

benefits of an optimal

indoor climate

Features Benefits

Optimizes energy consumption by aiding correct

airflow and pressure in air distribution system.

Easy to install, with dedicated software for airflow

control in different combinations.

Three additional PID controllers for special

requirements in the actual application, like integrated

controller for air conditioning in AHUs and RTUs,

for instance heating or cooling.

Connects to building management system (BMS)

via network, analog interface, or digital and

relay outputs.

4 pressure sensors. Monitoring of filter and airflow in one unit.

Reduces operating costs to demand.

Complexity reduction.

Easy control and monitoring on the local control

panel of the VLT® HVAC Drive or via fieldbus network.

Reduce installation cost and complexity with the

built-in software features.

Easy to harvest, correlate and present

performance data.

drives.danfoss.com

Page 2

Electrical connection

The VLT® Pressure Transmitter PTU

025 module is easily integrated into

the VLT® HVAC Drive, and suitable for

IP55/66 enclosures. It is easily mounted

onto the enclosure of the VLT® HVAC

Drive, and suitable for retrofitting

existing drives.

Ordering number

Order with code number 134B5925. Includes pressure transmitter with tube relief

and internal C-option connection cable with cable binder.

Specifications

System integration

Sensors 1 and 2; working area of 0-500 Pa.

Pressure sensor inputs

Pressure sensor outputs

Control method

Communication

Compatibility

Control parameterization

Differential air pressure flow control

Pressure level flow control

Performance

Measuring accuracy

Environment

Temperature Range -25 to +50 °C

IP class IP66

Sensor 3; working area of 0-1000 Pa.

Sensor 4; working area of 0-2500 Pa.

5 mm pressure tube tap connection and holder

for the tubes.

Pressure signals on fieldbus and digital output,

relay or as analogue values.

Airflow control with closed-loop PID regulator on

air volume or pressure level in air channel.

Data communication via different fieldbus

networks.

VLT® HVAC Drive FC 102 with minimum software

version 5.12. Retrofit solution with minimum MK II

new control card for older version.

Internal connection to C-option slot on

VLT® HVAC Drive FC 102.

Use the capacity K-factor, provided by the

AHU/RTU manufacture for the fan, to control

the demanded airflow, or provide detailed

information of the AHU/RTU to calculate the flow.

Define the pressure level the AHU/RTU must

provide to the air distribution ducting.

Pressure compensated to altitude, and absolute

accuracy of ± 2.5% of sensor FS value and

temperature range.

SENSOR 4

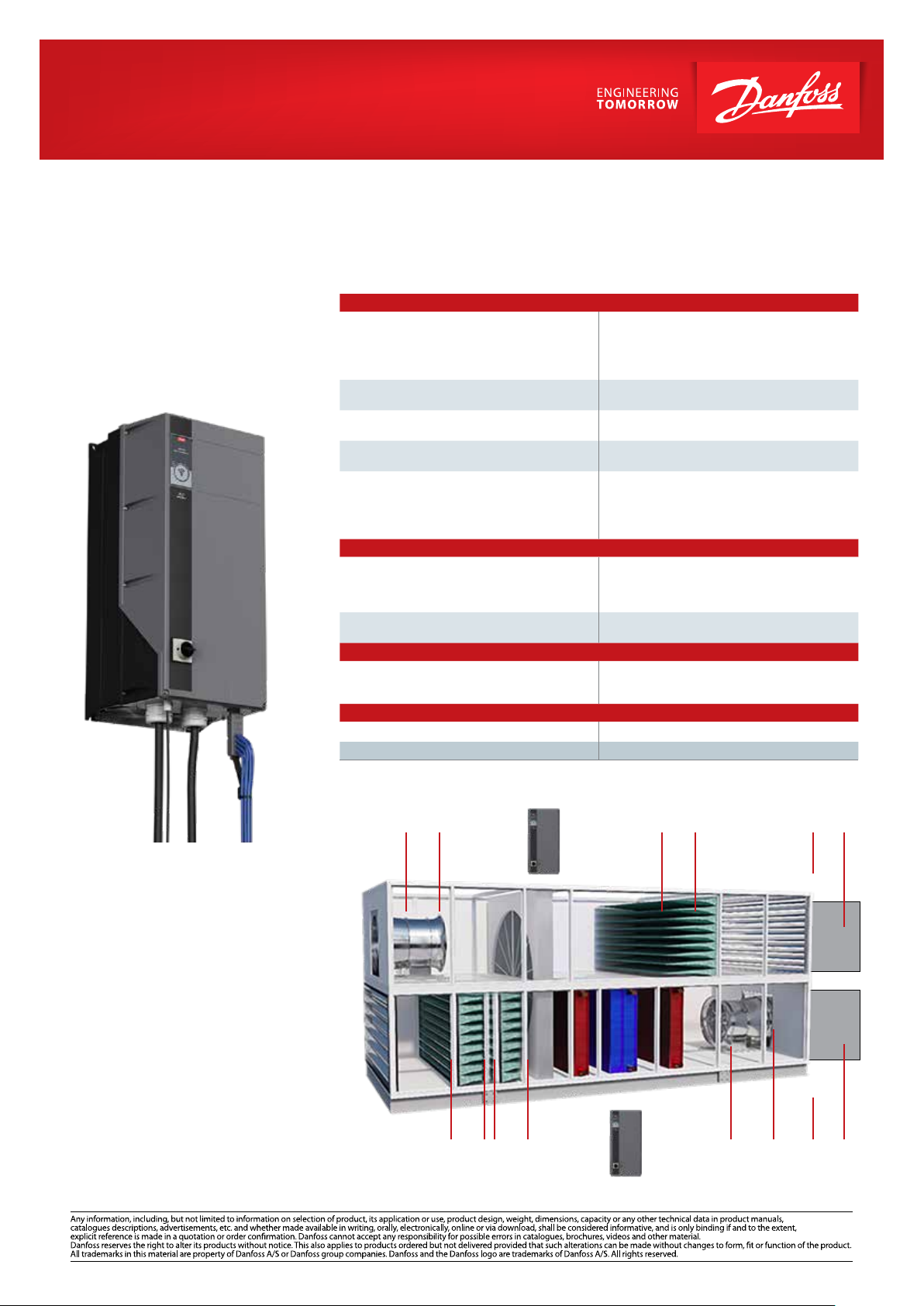

Example of installation: The supply and exhaust

air strings in the AHU are controlled by separate

VLT® HVAC Drives measuring in total seven pressure

DKDD.PFM.104.A1.02 © Copyright Danfoss Drives | 2021.08

points in the AHU.

SENSOR 1

SENSOR 2

SENSOR 1

SENSOR 4

SENSOR 3 SENSOR 3

Loading...

Loading...