Installation Instructions

Pressure Transmitter Unit PTU 025

®

VLT

Items Supplied

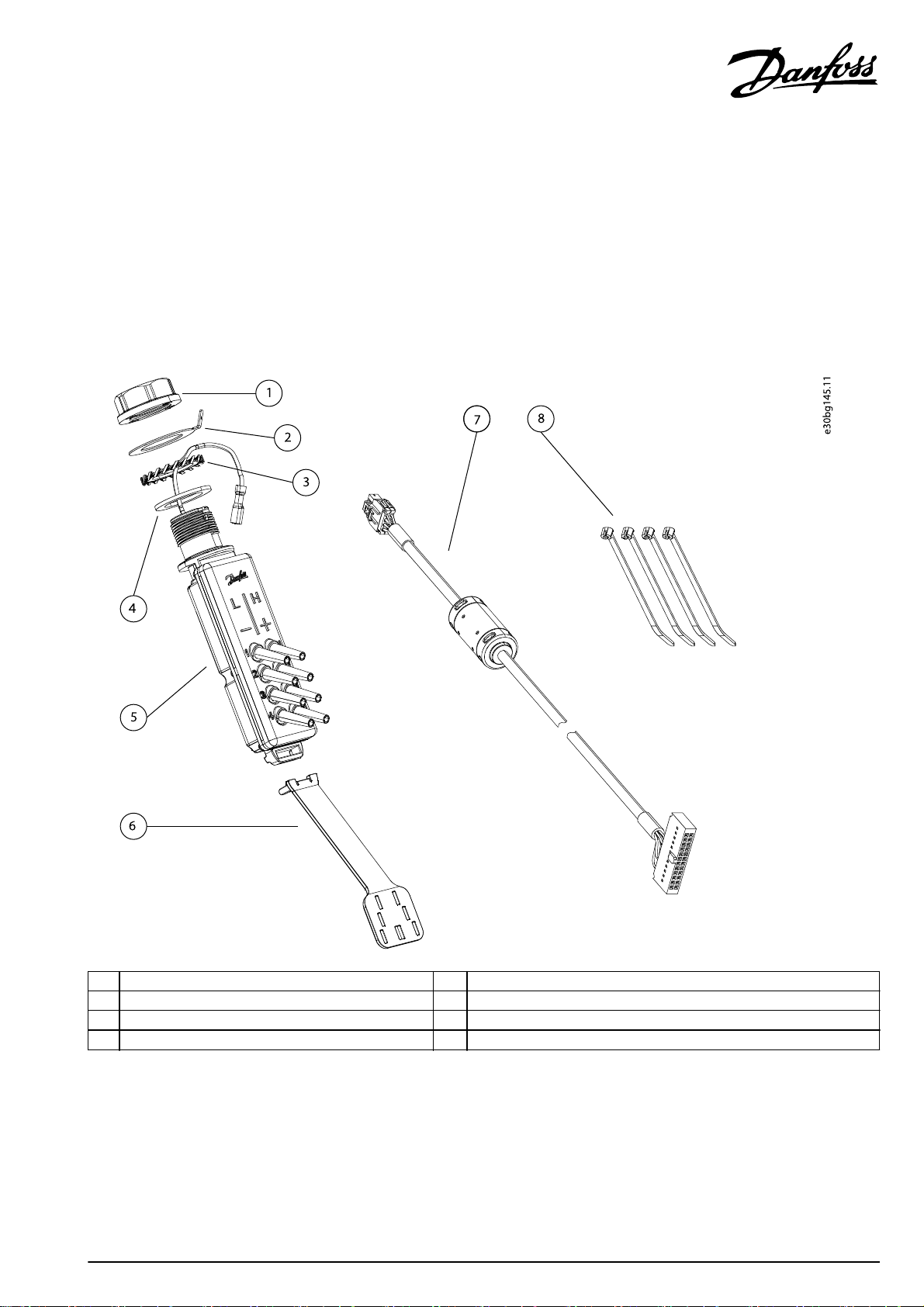

See Illustration 1.1 for the list of supplied items.

HVAC Drive FC 102

1 M25 nut 5 Pressure Transmitter Unit PTU 025

2 M25 ground washer connection 6 Tube relief plate

3 M25 star washer 7 Interface cable for the C-option port

4 M25 gasket 8 Cable binders

Tab le 1.1

Illustration 1.1 Pressure Transmitter Unit PTU 025 and Items Supplied

Danfoss A/S © 12/2017 All rights reserved. MI08A102

Installation Instructions

Pressure Transmitter Unit PTU 025

®

HVAC Drive FC 102

VLT

To order the unit, use the following ordering number:

NOTICE

The PTU 025 unit can be installed in IP55 and IP66

Model Ordering number

PTU 025, 4 inputs 134B5925

Table 1.2 Ordering Numbers

enclosures, and can be connected with the frequency

converter using the C-option interface. This instruction is

applicable for a frequency converter in a standard conguration without any modications.

Safety Instructions

For important information about safety precautions for installation, refer to the product-specic operating guide.

WARNING

DISCHARGE TIME

The frequency converter contains DC-link capacitors, which can remain charged even when the frequency converter is not

powered. High voltage can be present even when the warning LED indicator lights are o. Failure to wait the specied time

after power has been removed before performing service or repair work can result in death or serious injury.

Stop the motor.

•

Disconnect AC mains and remote DC-link power supplies, including battery back-ups, UPS, and DC-link connections to

•

other frequency converters.

Disconnect or lock PM motor.

•

Wait for the capacitors to discharge fully. The minimum duration of waiting time is specied in Ta b le 1 .3.

•

Before performing any service or repair work, use an appropriate voltage measuring device to make sure that the

•

capacitors are fully discharged.

Voltage [V] Minimum waiting time (minutes)

4 7 15 20 30 40

200–240 1.1–3.7 kW

(1.50–5 hp)

380–480 1.1–7.5 kW

(1.50–10 hp)

400 – – – 90–315 kW

500 – – – 110–355 kW

525 – – – 75–315 kW

525–600 1.1–7.5 kW

(1.50–10 hp)

690 – – – 90–315 kW

525–690 – 1.1–7.5 kW

Table 1.3 Discharge Time, VLT® HVAC Drive FC 102

–5.5–45 kW

(7.5–60 hp)

– 11–90 kW

(15–121 hp)

– 11–90 kW

(15–121 hp)

11–90 kW

(1.50–10 hp)

(15–121 hp)

–––

– – 315–1000 kW

(121–450 hp)

(150–500 hp)

(100–450 hp)

–––

(100– 350 hp)

–400–1400 kW

(450–1350 hp)

––

––

––

––

–

(500–1550 hp)

450–1400 kW

(600–1550 hp)

2

Danfoss A/S © 12/2017 All rights reserved. MI08A102

Installation Instructions

Pressure Transmitter Unit PTU 025

®

HVAC Drive FC 102

VLT

Mechanical installation

Prepare the hole for the installation

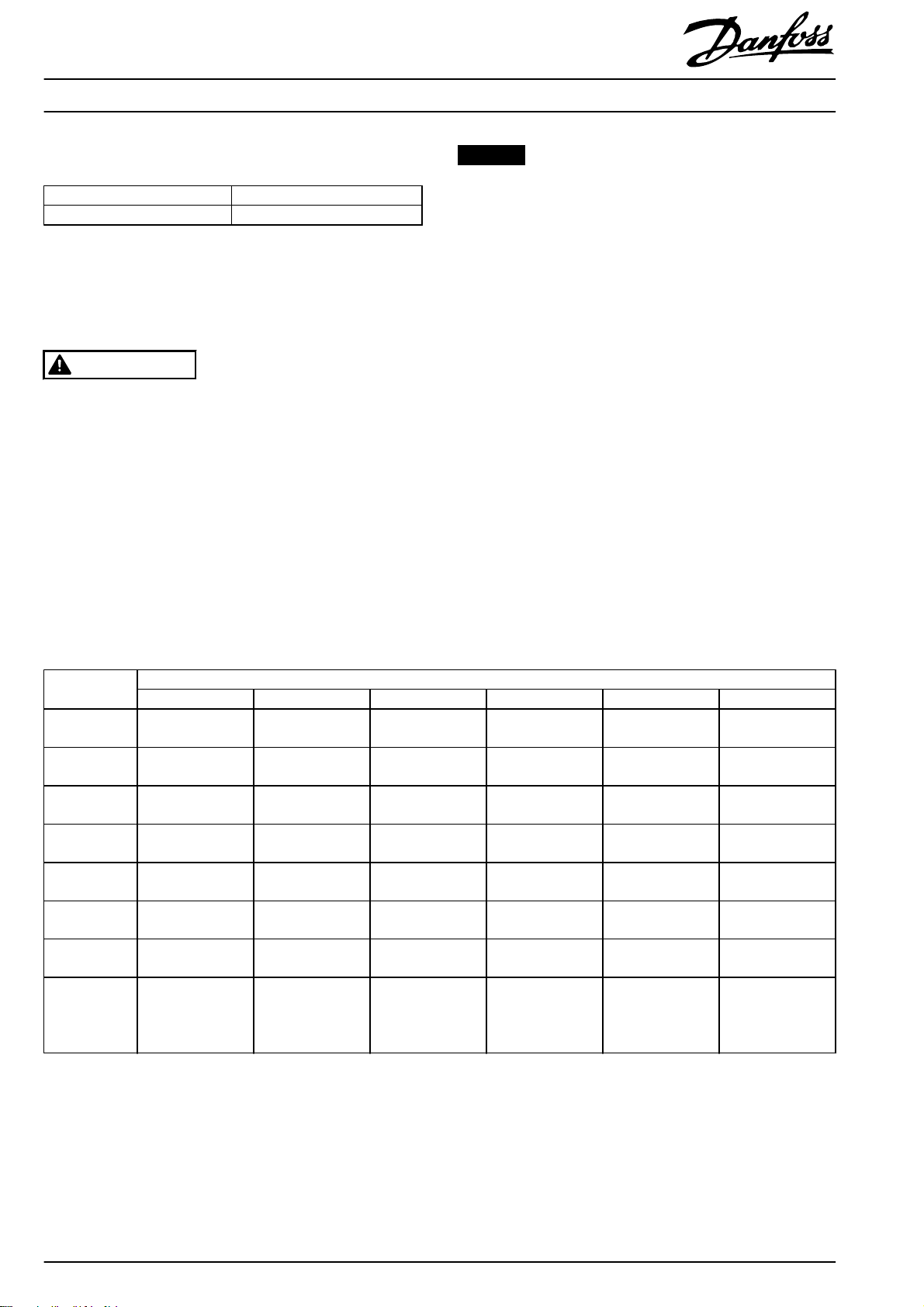

The options to mount the PTU 025 unit on an IP55/66

enclosure include the following:

Factory-installed M25 tread.

•

Using the knock-out plate.

•

Making a new hole in the connection plate. Hole

•

diameter: 25 mm (0.98 in).

Illustration 1.3 The Nut, The Ground Connection, The Washer, The

Gasket

Illustration 1.2 PTU 025 Installation Hole

For grounding purpose, ensure that there is a good electrical

connection between the PTU 025 mounting star washer and

the enclosure.

Installing the Unit

To install PTU 025:

1. Place the gasket between the PTU 025 unit and the

enclosure. This is necessary for the IP55/66 rating.

2. Inside the enclosure, place the star washer, the

ground connection, and the nut. See Illustration 1.3.

3. Put the ground wire inside the enclosure through the

star washer, the ground connection, and the nut.

4. Rotate the unit to the required position. The unit can

be rotated 360°.

5. Fasten the nut with the momentum 5 Nm. The unit

cannot be rotated after fastening the nut. See

Illustration 1.4.

Illustration 1.4 Positioning the Unit

MI08A102 Danfoss A/S © 12/2017 All rights reserved.

3

Installation Instructions

Pressure Transmitter Unit PTU 025

®

HVAC Drive FC 102

VLT

Electrical Installation

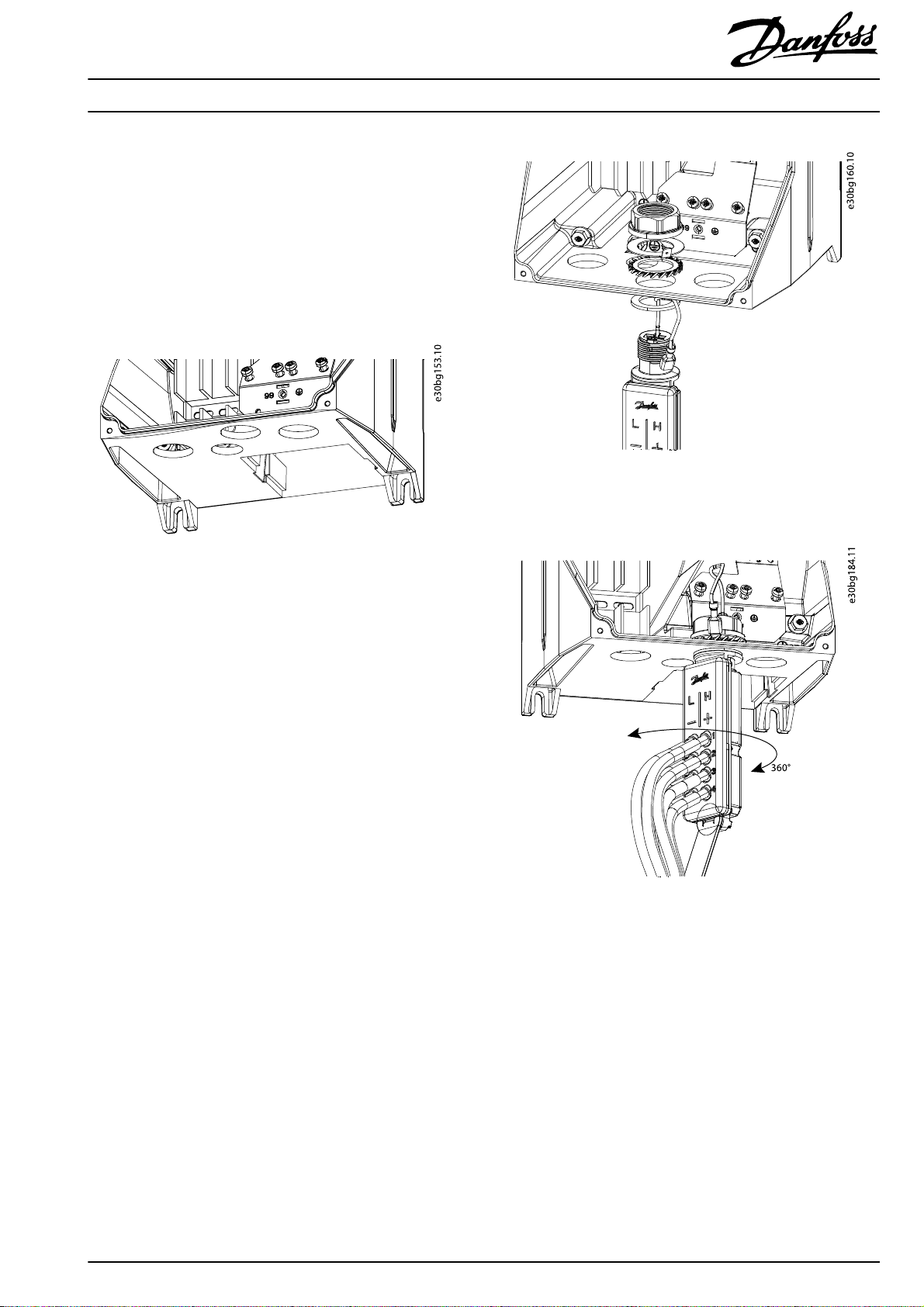

1. Connect the PTU 025 unit to the C-option port.

Ensure that the connectors are secure in sockets on

both ends and secure the cable inside the enclosure

with cable binders. See Illustration 1.5.

2. Wire the outputs for the related signals and statuses.

3. Mount the front cover of the frequency converter.

4. Power up the frequency converter. Ensure that the

frequency converter

identies

the PTU 025 unit.

Illustration 1.5 PTU 025 Electrical Connection to the C-option Port

4

Danfoss A/S © 12/2017 All rights reserved. MI08A102

Installation Instructions

Pressure Transmitter Unit PTU 025

®

HVAC Drive FC 102

VLT

Pressure Signals on Outputs

The frequency converter can be congured to transmit the pressure values on analog output or active status on digital and relay

outputs. Perform the

conguration

In/Out. See the wiring diagram in Illustration 1.6.

in parameter group 5-** Main Menu - Digital In/Out and parameter group 6-** Main Menu - Analog

Illustration 1.6 Wiring Diagram

MI08A102 Danfoss A/S © 12/2017 All rights reserved.

5

Installation Instructions

Pressure Transmitter Unit PTU 025

®

HVAC Drive FC 102

VLT

Mounting the Pressure Tubes

PTU 025 has 5 mm (0.2 in) tube connection taps. Attach high-pressure input tubes to the taps labeled H +, and the low-pressure

tubes on the L - taps. To prevent clogging of sensors, attach tubes to all connection taps. See Illustration 1.7.

Illustration 1.7 Mounting Pressure Tubes

NOTICE

Put a tube connection on all pressure transmitter taps to minimize the amount of dirt entering the unit. The minimum tube

length is 80 mm (3.1 in). If a sensor uses the surrounding pressure level, cut the tube at a place farther than the tube relief

plate.

6

Danfoss A/S © 12/2017 All rights reserved. MI08A102

Installation Instructions

Pressure Transmitter Unit PTU 025

®

HVAC Drive FC 102

VLT

Parameter Conguration

After PTU 025 is installed, power up the frequency converter.

The LCP shows alarm A80, Drive initialized, which indicates that

the frequency converter detected the new device. Press [Reset]

to reset the alarm.

Illustration 1.8 Alarm A80, Drive Initialized

Use the LCP or MCT 10 Set-up Software to congure PTU 025.

The PTU 025 option can be

congured

purposes:

Monitoring of the pressure transmitter signals.

•

Showing the readouts on the LCP or transmitting

•

them via the

Integration of the pressure monitoring into a system

•

eldbus.

solution.

PID closed-loop control based on airow or pressure

•

levels.

Signals from all PTU 025 sensors are active all the time and

the frequency converter can show the values on the LCP

continuously. Use parameters in parameter group 31-2*

Readouts to monitor

LCP or

congure

lters, airow,

warnings or alarms. Values in parameter

group 31-2* Readouts are also available via the eldbus.

MCT 10 Set-up Software and the frequency converter check

whether the entered pressure values are within the operating

ranges of sensors. The LCP shows a warning if the entered

pressure value is outside the operating range.

Use parameter 31-30 Press Sens Cmp State in the smart logic

control to achieve application-specic functionality. Use

parameters in parameter group 13-9* User-dened Alerts and

Readouts to congure application-specic messages, warnings,

and alarms. For more information, see the programming guide.

for the following

and pressure levels on the

31-** Pressure Sensor Option

Parameters related to the PTU 025 option.

31-2*

Each pressure-related status has its own below-level and

above-level trigger thresholds. The thresholds can be activated

individually. When the actual pressure level exceeds the

threshold level, the frequency converter waits for the value in

parameter 31-23 On Delay Time, and then performs a status

change of a status. When the actual pressure goes below the

threshold level, the value in parameter 31-24 Reset Delay Time

denes when the status is reset. The value in

parameter 31-25 Pressure lter time constant adjusts the

dynamic of the reaction to the actual pressure input, to ensure

reliable and stable status generation.

Conguration

31-20 Pressure/Speed Curve

Select the type of the pressure/speed curve.

Each pressure sensor can have a dierent setting.

For options [1] Linear and [2] Square root, the pressure threshold

at 0 speed equals 10% of the value entered in

parameter 31-21 Below level threshold or parameter 31-22 Above

level threshold.See Illustration 1.9.

Illustration 1.9 Pressure/Speed Dependency

Option: Function:

[0]

*

[1] Linear The pressure threshold is

[2] Square root The pressure threshold

31-21 Below level threshold

Range: Function:

#* [ -2500 - 2500 Pa] Enter the below-level threshold.

None The pressure threshold is

constant and does not

depend on speed.

proportional to the speed.

depends on the speed.

The dependency is

quadratic.

MI08A102 Danfoss A/S © 12/2017 All rights reserved.

7

Installation Instructions

Pressure Transmitter Unit PTU 025

®

HVAC Drive FC 102

VLT

31-22 Above level threshold

Range: Function:

#* [ -2500 - 2500 Pa] Enter the above-level threshold.

31-23 On Delay Time

Range: Function:

60 s* [0 - 3600 s] Enter the on delay time.

31-24 Reset Delay Time

Range: Function:

9999 s* [0 - 9999 s] Enter the reset delay time.

31-25 Pressure lter time constant

Range: Function:

1 s* [0.01 - 60 s] Enter the pressure lter time constant. A

longer value make the pressure signal more

stable but less dynamic. A shorter value

allows to eliminate signal spikes and keep

control more dynamic.

31-2* Readouts

Parameters in this group contain the actual pressure levels and

the status information. The LCP can be congured to show the

values of these parameters in

dierent

toggle function allows to show multiple pressure signals in the

same LCP line. The number is followed by the hash sign (#).

See Illustration 1.9.

Use parameter 0-20 Display Line 1.1 Small to

parameter 0-24 Display Line 3 Large to congure the LCP to

show

dierent

pressure values.

display lines. The

31-27 Pressure Sensor 2

Range: Function:

0 Pa* [-500 - 500 Pa] Shows the readout of pressure sensor 2.

31-28 Pressure Sensor 3

Range: Function:

0 Pa* [-1000 - 1000 Pa] Shows the readout of pressure sensor

3.

31-29 Pressure Sensor 4

Range: Function:

0 Pa* [-2500 - 2500 Pa] Shows the readout of pressure sensor

4.

31-30 Press Sens Cmp State

Range: Function:

0* [0 -

255]

Shows the pressure sensor state. The state is an 8-

digit binary value, where 1 indicates an active status

and 0 indicates an inactive status. Reading from

right to left, the rst 4 digits indicate the alarms for

the below-level threshold, and the last 4 digits the

alarms for the above-level threshold. For instance,

counting from right to left, sensor 1 for the below-

level threshold is at position 1, and sensor 1 for the

above-level threshold is at position 5. See

Illustration 1.9.

NOTICE

When using this parameter in the smart logic

controller, the output status signal for the

below-level threshold and for the above-level

threshold is the same for a specic sensor.

For example, in the following cases the

output status signal is the same:

The below-level threshold for sensor

•

1 is active.

The above-level threshold for sensor

•

1 is active.

Illustration 1.9 Pressure Sensor Data on the LCP

31-26 Pressure Sensor 1

Range: Function:

0 Pa* [-500 - 500 Pa] Shows the readout of pressure sensor 1.

8

Danfoss A/S © 12/2017 All rights reserved. MI08A102

31-31 Press Sens toggle

Range: Function:

[0 - 4] Shows the pressure values on all sensors. The

readout switches between sensors in a loop, going

from sensor 1 to sensor 4. The sensor number is

followed by a hash sign, see Illustration 1.9.

Installation Instructions

Pressure Transmitter Unit PTU 025

®

HVAC Drive FC 102

VLT

Application Integration

PTU 025 is designed for central air handling units with 1 or more lters in the inlet/outlet part and with fan control based on the

or pressure level in the ventilation system. Separate frequency converters with separate pressure transmitter units control

airow

the inlet and outlet. PTU 025 has 4 pressure inputs. See the pressure ranges in Tab l e 1. 4. Sensors 3 and 4 can be congured for

either lter monitoring or PID control of the airow or the pressure level.

Illustration 1.10 Application Integration Example

#Range Typical function

1 0–500 Pa Filter monitoring

2 0–500 Pa Filter monitoring

3 0–1000 Pa Filter monitoring or PID control of the airow or the pressure level

4 0–2500 Pa Filter monitoring or PID control of the airow or the pressure level

Table 1.4 PTU 025 Sensors and their Functions

Integrating pressure signals into a system solution

The pressure values can be read as analog values on the

analog output or as pulses on digital outputs. Use

parameter 5-30 Terminal 27 Digital Output,

parameter 5-31 Terminal 29 Digital Output, and

parameter 5-40 Function Relay to send the sensor status to the

relay or digital outputs. For more information about using the

pressure values in applications and in the smart logic control,

see the programming guide.

PID closed-loop control based on the airow or pressure

level

Use parameters in parameter group 20-0* Feedback to use the

pressure values for the frequency converter’s closed-loop PID

controller.

Use parameters in parameter group 22-** Application Functions

to congure the monitoring of HVAC applications based on

airow. For more information, see the operating guide and the

programming guide.

MI08A102 Danfoss A/S © 12/2017 All rights reserved.

9

Dimensional Drawings

Illustration 1.11 Dimensional Drawings

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products already on

order provided that such alterations can be made without subsequential changes being necessary in specifications already agreed. All trademarks in this mate rial are property of the respective companies. Danfoss

and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

Danfoss A/S

Ulsnaes 1

DK-6300 Graasten

vlt-drives.danfoss.com

MI08A102130R0803 12/2017

*MI08A102*

Loading...

Loading...