Page 1

Applications Manual

Pressure and Speed Limits for

Hydrostatic Units

powersolutions.danfoss.com

Page 2

Applications Manual

Pressure and Speed Limits for Hydrostatic Units

Revision history Table of revisions

Date Changed Rev

May 2015 Danfoss layout - major update 0401

July 1997 D

2 | © Danfoss | May 2015 BLN-9884 | BC00000160en-US0401

Page 3

Applications Manual

Pressure and Speed Limits for Hydrostatic Units

Contents

Introduction

Applications Manuals......................................................................................................................................................................4

Pressure and Speed Limits

Introduction........................................................................................................................................................................................5

Load to Life Relationships............................................................................................................................................................. 5

Pressure Limits for Hydraulic Units............................................................................................................................................ 6

Speed Ratings for Hydraulic Units........................................................................................................................................... 10

Motor Performance at Low Speed

Motor Performance at Low Speed...........................................................................................................................................15

Bypass Valve Speed Limitations

Bypass Valve Speed Limitations............................................................................................................................................... 16

Inlet Vacuum Limits

Inlet Vacuum Limits.......................................................................................................................................................................17

Dynamic Braking

Dynamic Braking............................................................................................................................................................................ 18

Displacement Control:............................................................................................................................................................19

Case Drain Pressure Limits

Case Drain Pressure Limits..........................................................................................................................................................20

©

Danfoss | May 2015 BLN-9884 | BC00000160en-US0401 | 3

Page 4

Applications Manual

Pressure and Speed Limits for Hydrostatic Units

Introduction

Applications Manuals

Content included in these manuals

These applications manuals provide design theory and detailed calculations for building hydraulically

powered machines.

The original document was written as one manual with four sections.

The current set of manuals includes the four documents listed below. The section numbers from the

original document are listed in parenthesis after the current document title.

•

Selection of Driveline Components BLN-9885 (originally Section 1)

•

Pressure and Speed Limits for Hydrostatic Units BLN-9884 (originally Section 2)

•

Transmission Circuit Recommendations BLN-9886 (originally Section 4)

•

Fluids and Lubricants 520L0463 (originally Section 3)

Other Reference Manuals

•

Hydraulic Fan Drive Systems Technical Information 520L0824

•

Hydraulic Fan Drive Systems Design Guidelines 520L0926

4 | © Danfoss | May 2015 BLN-9884 | BC00000160en-US0401

Page 5

Applications Manual

Pressure and Speed Limits for Hydrostatic Units

Pressure and Speed Limits

Introduction

In order to properly size hydrostatic units for power transmission applications, it is necessary to select an

appropriate design pressure and design speed. The selection of these design parameters are affected

by required unit life. The purpose of this guideline is to assist system integrators in the selection of

design pressure and design speed to optimize hydraulic unit utility and to provide satisfactory

transmission life.

Danfoss Power Solutions publishes continuous

speed capabilities. Application decisions are made by considering both typical and extreme operating

conditions. Predicted unit life, based on the design pressure and speed, is compared to the required unit

life for the application. Satisfactory design criteria must be obtained for both normal rated and maximum

values.

(1) The term “continuous” refers to the speed ratings of Danfoss Power System products, but not to their

pressure ratings.

Load to Life Relationships

(1)

ratings and maximum ratings for both pressure and

System pressure is the dominant operating variable affecting hydraulic unit life. High pressure, which

results from high load, reduces life in a manner similar to many mechanical assemblies such as engines

and gear boxes. There are load-life relationships for the rotating group and for the shaft bearings which

must be considered separately.

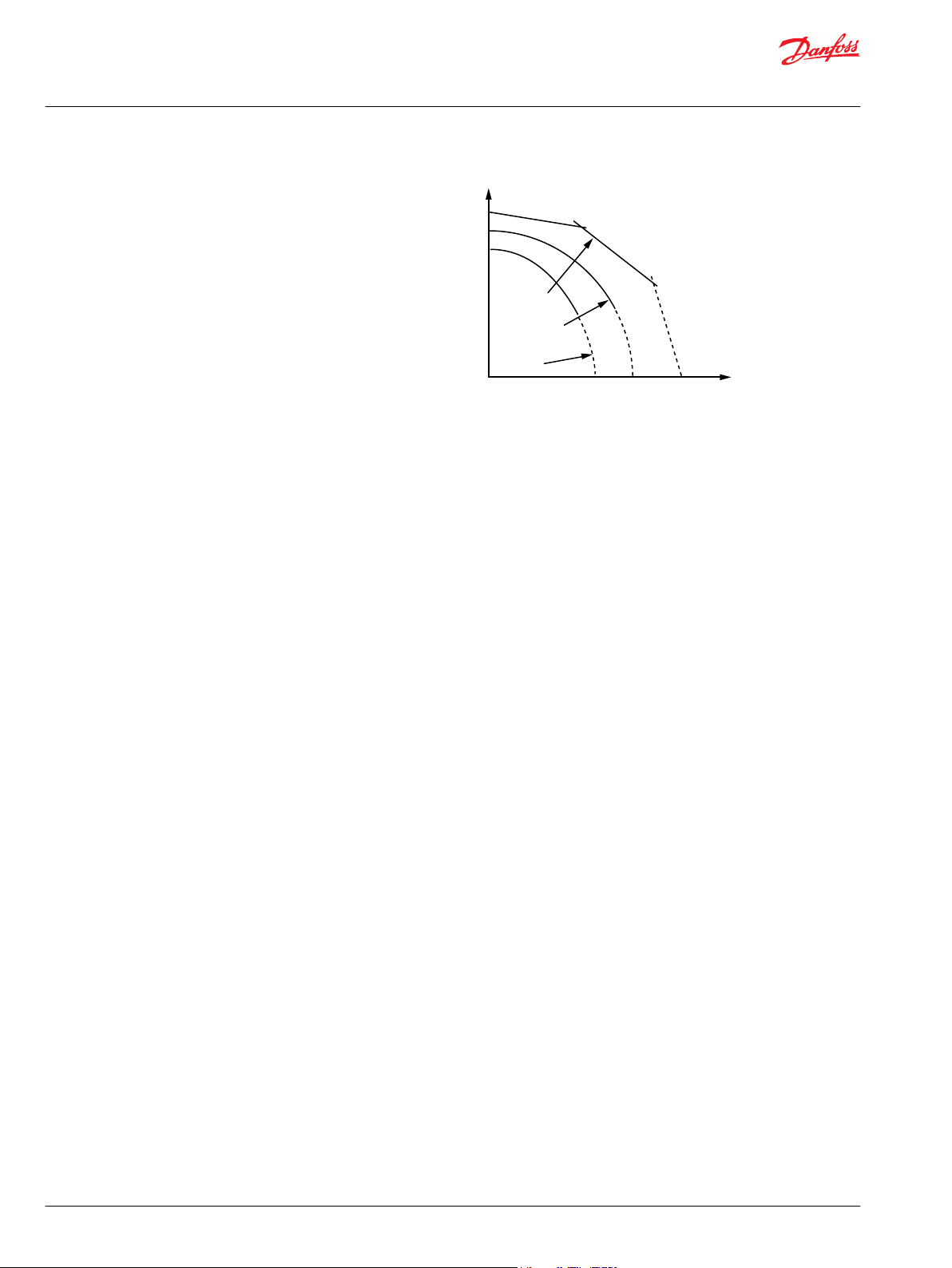

The graph Hydraulic Unit Life vs System Pressure shows the general relationship between life expectancy

and system pressure. The upper limit of hydraulic unit life is established by fatigue and wear of the

rotating group, bearing fatigue, or wear and deterioration of other parts, each with their own load-life

relationship. At high system pressures, fatigue and wear of the rotating group is the limiting factor,

while bearing failure becomes the limiting factor at intermediate pressures. It is important to note the

shallow slope of the life curve at high system pressures which indicates a significant decrease in life with

a slight increase in pressure.

Actual life is also affected by a combination of factors relating to fluid quality as shown in Hydraulic Unit

Life vs System Pressure by the curves corresponding to less-than-ideal fluid quality. Factors relating to fluid

quality include temperature, contamination (heat, hard particle, water, chemical, and entrained air),

viscosity, and lubrication properties. Most of these factors are also influenced by operating pressure.

System design should take these factors into account. Technical Information Manuals (Hydraulic Fluids

and Lubricants 520L0463, Experience with Biodegradable Hydraulic Fluids 520L0465, and Design Guideline

for Hydraulic Fluid Cleanliness 520L0467) cover this subject in more detail.

©

Danfoss | May 2015 BLN-9884 | BC00000160en-US0401 | 5

Page 6

Rotating group

Fatigue & Wear

Bearing Fatigue

Other Components

Normal Limit

of Unit Life

Marginal Fluid

Quality

Poor Fluid

Quality

Life Expectancy (Time)

System Operating

Pressure

Applications Manual

Pressure and Speed Limits for Hydrostatic Units

Pressure and Speed Limits

Hydraulic Unit Life vs System Pressure

Pressure Limits for Hydraulic Units

The following definitions of hydraulic unit pressure capability and associated life requirements are

provided to assist in sizing transmission components. Contact a Danfoss Power Solutions representative

with your machine parameters if there is a question regarding typical load cycles.

In closed circuit hydrostatic units, System Pressure is the differential (delta) pressure between the high

and low pressure work ports. It is the measure of the pressure available to accept or provide torque

through the conversion of mechanical to/from hydraulic power. Zero System Pressure is the condition

where both sides of the hydrostatic loop are at equal pressure, typically at Charge Pressure. System

Pressure is the dominant operating variable affecting hydraulic unit life and performance. High system

pressure, which results from high load, reduces expected life. Hydraulic unit life depends on the speed

and normal operating, or weighted average, pressure which can only be determined from a duty cycle

analysis.

In open circuit units, System Pressure is the gauge pressure of the working port since the low pressure

reference is zero gage pressure at the reservoir.

In closed circuit hydrostatic units, it is common to provide a flow source at a moderate pressure to

provide makeup flow (charge flow) for the hydrostatic loop. The pressure of this flow source is called

Charge Pressure and is usually measured in terms of delta pressure above case pressure. The lower

pressure side of the hydrostatic power loop will typically be at, or near, charge pressure. In open circuit

systems, charge pressure may be considered to be the pressure available to the inlet of the pump or the

outlet of the motor. It may be either below atmospheric (0 Gauge Pressure) or above. If the charge

pressure is above atmospheric, it is often known as Boost Pressure for a pump or Back Pressure for a

motor.

In closed circuit units, Minimum Pressure is the gauge pressure that must be maintained in the working

ports under all operating conditions to avoid excessive cavitation and to provide lubrication for sliding

components. Minimum pressure is typically less than Charge Pressure. Minimum Pressure limits are

identified in the Technical Information Bulletin for each product. Unless otherwise specified, Minimum

Pressure is defined as 10 bar [150 psig].

In open circuit units, Minimum Inlet Pressure is the minimum allowable absolute pressure in the pump

suction line. The minimum inlet pressure must be evaluated in both steady state, and transient

conditions; note that when pump displacement increases, inlet pressure is reduced due to acceleration of

fluid in the inlet line.

6 | © Danfoss | May 2015 BLN-9884 | BC00000160en-US0401

Application Pressure is the highest intermittent pressure defined for a given application; and is the high

pressure relief, pressure limiter, or pressure compensator setting typically defined within the order code

of the pump or motor. It is determined by the maximum machine load demand. Application Pressure is

the "applied" System Pressure (delta pressure) at which the driveline generates the maximum calculated

pull or torque, or at which maximum loads move in the application. Application Pressure is typically

determined from the maximum design loads of the vehicle driveline or work function components.

Application Pressure is assumed to occur for a small percentage of operating time, usually less than 2% of

the total.

Page 7

Applications Manual

Pressure and Speed Limits for Hydrostatic Units

Pressure and Speed Limits

For systems with pressure limiter valves acting to avoid frequent overloads, it may be necessary to select

a reduced maximum design pressure below that normally allowed because time at maximum Application

Pressure may be excessive.

Maximum Working Pressure is the highest recommended Application Pressure. Maximum Working

Pressure is the highest standard pressure setting allowed within the product code. Systems with

Application Pressures at, or below, the Maximum Working Pressure should yield predicted (calculated)

unit life given proper component sizing. Maximum Working Pressure limits are identified in the Technical

Information manual for each product. Application Pressures above Maximum Working Pressure will only

be considered with duty cycle analysis and factory approval. (Factory approval means Engineering

approval is needed.)

Maximum Pressure is the highest allowable System Pressure under any circumstance. System Pressures

above Maximum Pressure may result in damage to the hydrostatic unit which could result in reduction in

useful life below what would be predicted by existing design/life analysis tools; and/or a permanent

reduction in the performance or efficiency of the hydrostatic unit.

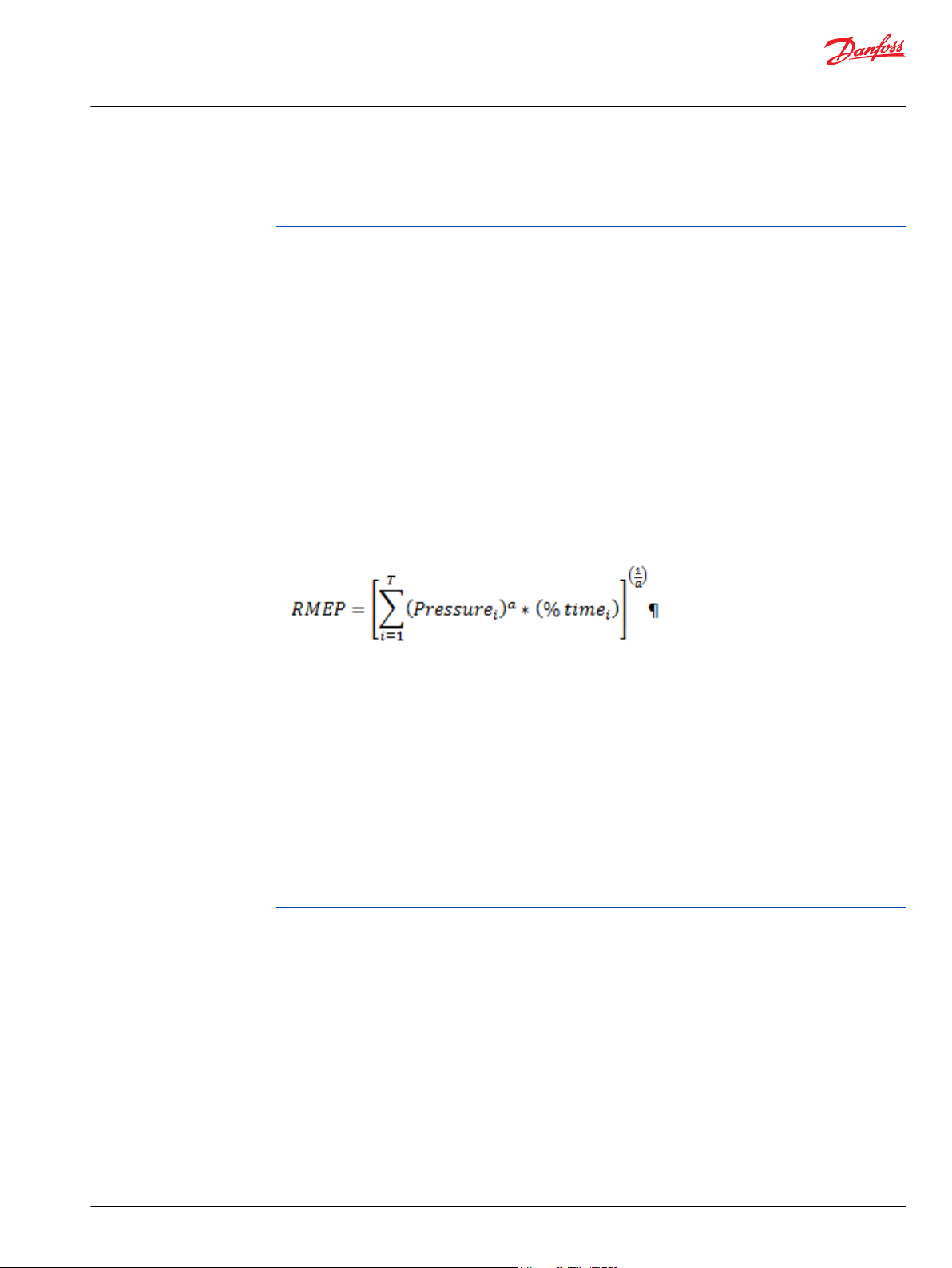

Root Mean Effective Pressure is the time weighted average for a pressure duty cycle using a specified

weighting exponent relative to the internal components under consideration. RMEP is a calculated

System Pressure equivalent for a specific duty cycle. It can be used to compare the relative severity of

loading cycles and used for component life predictions.

The formula for calculating the RMEP value is shown below:

Where:

RMEP = Root Mean Effective Pressure

Pressure = System Pressure average for the time step

% time = Total time for the time step expressed as a decimal percent

a = cumulative fatigue damage exponent for the unit or the component under consideration

a = 8 for rotating groups and shafts in bending fatigue

•

a = 3 for ball bearings

•

a = 10/3 for tapered or cylindrical rolling element bearings

•

The exponent of 8 is derived from mechanical fatigue and is appropriate for the all rotating components

except bearings. The exponents of 3 and 10/3 are derived from the bearing industry standard practice.

©

Danfoss | May 2015 BLN-9884 | BC00000160en-US0401 | 7

Page 8

System Pressure Line

Design Input

Power

Output Flow

Rated

Design Tractive Effort

at Maximum Design

Speed

NLHI

Full Load Speed

Max.

Application

System

Pressure

Applications Manual

Pressure and Speed Limits for Hydrostatic Units

Pressure and Speed Limits

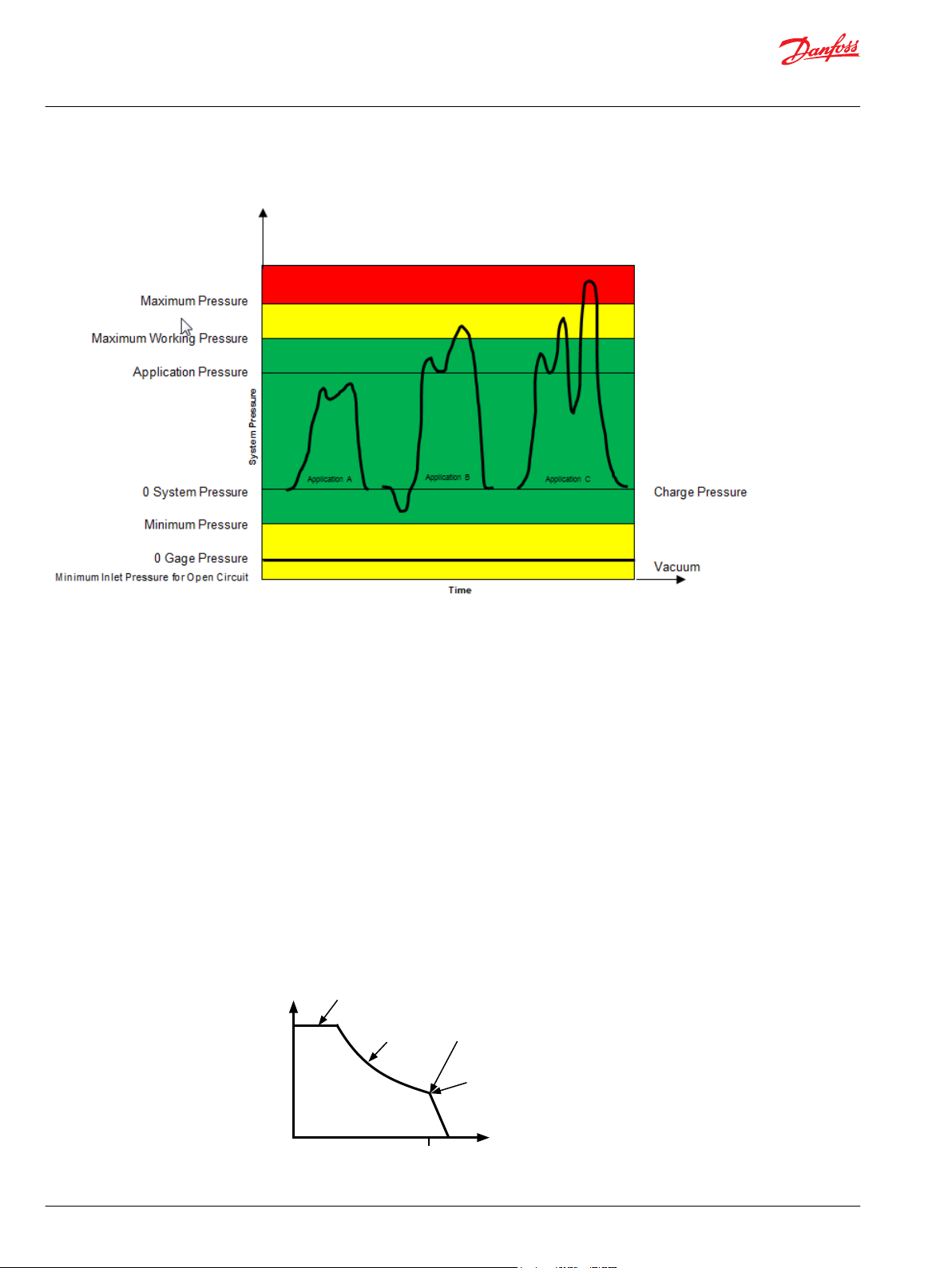

Pressure versus Time chart showing key pressure terms

Application A - The System Pressure duty cycle stays under the Application Pressure. The unit in this

application should have satisfactory predicted life provided the fluid viscosity, quality and cleanliness are

maintained.

Application B - The delta system pressure starts out within the maximum working pressure but has a

spike above Maximum Working Pressure. The trace also shows a spike below charge pressure, but still

above the minimum pressure. The unit in this application would perform as expected, but has the

potential of having a somewhat shorter predicted life, dependent upon the total amount of time spent

near Maximum Pressure.

Application C - The system delta pressure trace shows a spike significantly above Maximum Pressure. The

unit in this application may suffer damage and have its expected life significantly shortened; and/or no

longer provide expected performance.

Normal working pressure is the pressure expected when performing “normal” work functions. It is the

average pressure across the normal work load range.

The normal working pressure occurs at a regularly occurring load condition. Its design value can be

established by calculating system pressure at the design input power and maximum pump displacement

(see the following graph). For machines with variable load cycles, the design input power may be

estimated by deducting the average power to the other functions from the maximum available engine

power.

8 | © Danfoss | May 2015 BLN-9884 | BC00000160en-US0401

Page 9

Applications Manual

Pressure and Speed Limits for Hydrostatic Units

Pressure and Speed Limits

The preferred method of selecting an Application Pressure requires duty cycle information for the

application. A duty cycle is a means of quantifying the pressure and speed demands of a particular

system on a percent time basis. The duty cycle data is weighted to reflect the preponderant influence of

pressure on unit life. Using the rotating group and shaft bearing load-life tools developed by Danfoss

Power Solutions for the various product families, the optimum Application Pressure can be selected

based on the required life expectancy for the application.

If an external side load is expected on the shaft, its magnitude and direction with respect to the

swashplate must be known when calculating expected bearing life.

It is very important that the duty cycle information be as accurate as possible due to the exponential

effect that pressure has on the life of the rotating group.

In the absence of duty cycle data, allowable pressure limits for design can usually be established based

on the maximum and normal working load in the drive. This assumes that the duty cycle falls within a

typical band width. By using this approach, two “pressure limit” values can be used to predict a successful

application when machine life requirements are known.

The following table is provided to aid the engineer in understanding and selecting appropriate design

pressure for a given component life requirement. These values are derived from the load-life relationship

for the rotating groups of the various Danfoss Power Solutions product families at 1800 rpm shaft speed

and no external shaft loads. Unit life is given in terms of L20 hours (80% survival) for the rotating group

based on published recommendations for fluid cleanliness and viscosity. Using these guidelines, the

system must meet both the maximum and continuous pressure limits to be considered acceptable.

Prototype test programs to verify operating pressures and predicted unit life are strongly recommended

prior to finalizing any hydrostatic drive design.

©

Danfoss | May 2015 BLN-9884 | BC00000160en-US0401 | 9

Page 10

1500 15 3200 [220] 25 3675 [253] L25 4150 [286] 28 4150 [286] 42 4900 [338] 45 4500 [310] 60 4900 [338] 60 >4150 [286]

35 4150 [286] L30 3650 [252] 32 3650 [252] 55 4900 [338] 53 3900 [269] 80 4900 [338] 80 >4150 [286]

44 4025 [277] L35 2875 [198] 41 4150 [286] 75 4900 [338] 60 4500 [310] 110 4900 [338] 110 >4150 [286]

PV046 3675 [253] K38 3650 [252] 51 3650 [252] 100 4900 [338] 68 3900 [269] 160 4900 [338] 160 >4150 [286]

MV046 3675 [253] K45 2875 [198] 130 4900 [338] 69 4900 [338] 250 4900 [338] 250 >4150 [286]

MF046 3450 [238] 180 4900 [338] 78 4900 [338]

250 4900 [338] 89 4900 [338]

100 4900 [338]

115 4900 [338]

130 4900 [338]

147 4900 [338]

165 4900 [338]

210 4900 [338]

250 4900 [338]

5000 15 2750 [190] 25 3175 [219] L25 3600 [248] 28 3600 [248] 42 4225 [291] 45 3850 [265] 60 4225 [291] 60 >3600 [248]

35 3600 [248] L30 3125 [215] 32 3125 [215] 55 4225 [291] 53 3375 [233] 80 4225 [291] 80 >3600 [248]

44 3450 [238] L35 2475 [171] 41 3600 [248] 75 4225 [291] 60 3850 [265] 110 4225 [291] 110 >3600 [248]

PV046 3175 [219] K38 3125 [215] 51 3125 [215] 100 4225 [291] 68 3375 [233] 160 4225 [291] 160 >3600 [248]

MV046 3175 [219] K45 2475 [171] 130 4225 [291] 69 4225 [291] 250 4225 [291] 250 >3600 [248]

MF046 2975 [205] 180 4225 [291] 78 4225 [291]

250 4225 [291] 89 4225 [291]

100 4225 [291]

115 4225 [291]

130 4225 [291]

147 4225 [291]

165 4225 [291]

210 4225 [291]

250 4225 [291]

15000 15 2400 [165] 25 2775 [191] L25 3125 [215] 28 3125 [215] 42 3650 [252] 45 3350 [231] 60 3650 [252] 60 >3125 [215]

35 3125 [215] L30 2725 [188] 32 2725 [188] 55 3650 [252] 53 2925 [202] 80 3650 [252] 80 >3125 [215]

44 3000 [207] L35 2150 [148] 41 3125 [215] 75 3650 [252] 60 3350 [231] 110 3650 [252] 110 >3125 [215]

PV046 2750 [190] K38 2725 [188] 51 2725 [188] 100 3650 [252] 68 2925 [202] 160 3650 [252] 160 >3125 [215]

MV046 2750 [190] K45 2150 [148] 130 3650 [252] 69 3650 [252] 250 3650 [252] 250 >3125 [215]

MF046 2600 [179] 180 3650 [252] 78 3650 [252]

250 3650 [252] 89 3650 [252]

100 3650 [252]

115 3650 [252]

130 3650 [252]

147 3650 [252]

165 3650 [252]

210 3650 [252]

250 3650 [252]

Displacement (cc/rev) & Root Mean Effective Pressure, at Full Displacement, Psid [dbar]

Series 15

Series 40

Series 51

H1B

Required Life

(L20 Hours)

KV/LV

Series 42

Series 90

H1P

W

Applications Manual

Pressure and Speed Limits for Hydrostatic Units

Pressure and Speed Limits

Design Pressure Recommendations as a Function of Required Life

Speed Ratings for Hydraulic Units

10 | © Danfoss | May 2015 BLN-9884 | BC00000160en-US0401

The applied speed of hydraulic units is limited by several design and application factors which have

varying effects on life. In general, hydraulic unit life varies inversely proportional to speed at, or below,

the (continuous) speed limit. Operation at speeds in excess of the continuous speed limit causes less than

normal life but is permissible at less than full power. The maximum speed limit cannot be exceeded

without significant reduction in life and without risking immediate failure resulting in a loss of hydrostatic

power.

Warning

Danfoss Power Solutions strongly recommends that a secondary means of braking be provided to stop a

runaway load caused by block lift or any other condition..

Speed capability is affected by flow rate and mechanical loading of the rotating group, and therefore, is a

function of hydraulic unit displacement (swashplate angle). The graph Speed Ratings for Piston Pumps and

Motors shows the typical speed rating versus displacement relationship for axial piston and bent axis

Page 11

W

Applications Manual

Pressure and Speed Limits for Hydrostatic Units

Pressure and Speed Limits

hydraulic units. In general, speed capability increases as displacement decreases, up to a peak value at

intermediate displacements.

The Rated Continuous Speed Limit is the highest speed recommended at full power conditions. This

rating defines the highest speed at which normal life can be expected. Continuous full power operation

applies at the conditions defined by continuous pressure.

Operation above the rated speed limit is expected at reduced power, as engine speed increase (for

pumps) and reduced volumetric loss (for motors) will produce increased motor/vehicle speed at low, or

negative, power. Some reduction of life would be expected at full power when operating above the rated

speed limit. For normal systems, working power level, and resulting system pressures will be low when

applied properly, and time above the rated speed limit will be low.

The rated speed limit varies with swashplate angle up to the reduced angle continuous maximum value.

The upward sloping speed characteristic is derived from the kinematic design parameters of axial piston

pumps and motors. They define the conditions at which normal operation is expected, based on

sufficient charge pressure. Normally, pumps are not applied at reduced angle speed ratings because they

frequently must operate at the highest speed and maximum angle simultaneously.

The maximum speed rating is the highest operating speed recommended and cannot be exceeded

without severe reduction of unit life, or without risking premature failure and loss of drive. Operating

conditions between continuous and maximum speed limits should be restricted to less than full power

and to limited periods of time. For most drive systems, maximum motor speed occurs during downhill

braking or negative power conditions.

The maximum speed rating varies with swashplate angle up to the reduced angle maximum value. At

this speed, conditions of marginal lubrication may exist when system pressure is low. Also, rotational

forces are high and may cause abnormal mechanical loading and stress on the rotating group.

For all axial and bent axis units, exceeding the maximum speed limit is a safety concern when the

transmission is providing retarding power. At high swashplate angles, the maximum speed is limited by

block lift which causes a loss of drive power. This could allow dangerously high, and uncontrollable,

output speed. Operation above the maximum speed limit must be avoided under all modes of operation

including engine speed-up and reduced volumetric loss during downhill braking.

Warning

Danfoss Power Solutions strongly recommends that a secondary means of braking be provided to stop a

runaway load caused by block lift or any other condition.

©

Danfoss | May 2015 BLN-9884 | BC00000160en-US0401 | 11

Page 12

Max Disp

Swash Angle

Full Angle

Rated

(Continuous)

Speed

Full Angle

Maximum

Speed

Intermittent

Operation

Continuous

Full Power

Operation

Reduced

Angle

Maximum

Speed

Reduced

Angle Rated

(Continuous)

Speed

Operation Not Permitted

Block

Lift Limit

P108902

Applications Manual

Pressure and Speed Limits for Hydrostatic Units

Pressure and Speed Limits

Speed Ratings for Piston Pumps and Motors

The highest permissible rated (continuous) and maximum speed limits for Danfoss Power Solutions

closed circuit piston pumps and motors are provided in the table Figure : Speed Ratings for Closed Circuit

Pumps and Motors on page 13. Variable motors have speed ratings for both “maximum” and “minimum”

displacements. The “minimum” displacement speed limit applies at approximately half of full

displacement, but this varies with product family and frame size. Minimum displacement speed ratings

are not provided for pumps, because pumps are typically expected to operate at fixed input speeds at full

displacement.

12 | © Danfoss | May 2015 BLN-9884 | BC00000160en-US0401

Page 13

spmu sP rotoMdexi sF rotoMelbairaV

p.siDllu p.F siDdecudeR

tcudorP detaR xaM detaR xaM detaR xaM detaR xaM

09seireS

240 0024 0064 0024 0064 --- --- --- --550 0093 0524 0093 0524 0093 0524 0064 0015

570 0063 0593 0063 0593 0063 0593 0524 0074

001 0033 0563 0033 0563 --- --- --- --031 0013 0043 0013 0043 --- --- --- --081 0062 0582 --- --- --- --- --- --052 0032 0052 --- --- --- --- --- ---

02seireS

12 0053 0083 0053 0083 0053 0083 0044 0525

22 0023 0093 0023 0093 0023 0093 0004 0584

32 0092 0533 0092 0533 0092 0533 0073 0554

42 0072 0013 0072 0013 0072 0013 0543 0014

52 0042 0592 0042 0592 0042 0592 0013 0573

62 0012 0052 0012 0052 0012 0052 0082 0043

72 0091 0502 0091 0502 0091 0502 0542 0592

15seireS

060 --- --- --- --- 0063 0044 0065 0007

080 --- --- --- --- 0013 0004 0005 0526

011 --- --- --- --- 0082 0063 0054 0065

061 --- --- --- --- 0052 0023 0004 0005

052 --- --- --- --- 0022 0072 0043 0524

24seireS

82 0043 0093 --- --- --- --- --- --14 0043 *0093 --- --- --- --- --- ---

04seireS

52M 0004 0005 0004 0005 0004 000 05 075

53M 0063 0054 0063 0054 0063 005 04 035

44M 0033 0014 0033 0014 0033 001 04 584

64M 0004 0014 0063 0063 0004 001 04 005

51seireS

51 0004 0024 0004 0024 --- --- --- ---

07seireS

L01-PDB 0063 0063 --- --- --- --- --- --L12-PDB 0063 0063 --- --- --- --- --- ---

* Any operation above rated speed requires application approval

P108903

Applications Manual

Pressure and Speed Limits for Hydrostatic Units

Pressure and Speed Limits

Speed Ratings for Closed Circuit Pumps and Motors

©

Danfoss | May 2015 BLN-9884 | BC00000160en-US0401 | 13

Page 14

Applications Manual

Pressure and Speed Limits for Hydrostatic Units

Pressure and Speed Limits

The following equations are provided to calculate motor speed limits for intermediated displacements.

Although the calculated values will exceed the tabulated values at lower swashplate angles, speed limits

from the table should never be exceeded. The equations are valid for “maximum” as well as “rated” speed

limits and are provided for convenience of calculation.

Axial Piston Motors

NV = NM (TM / TV)

or

NV = NM (DM / DV)

where:

NV = Motor speed limit at reduced angle (RPM)

NM= Motor speed limit at maximum swashplate angle from Table 2 (RPM)

TV = Tangent of reduced swashplate angle

TM = Tangent of maximum swashplate angle

Tan 15° = 0.268 (Series 15 and Series 40-M25)

•

Tan 16° = 0.287 (Series 40-M35 and Series 40-M44)

•

Tan 17° = 0.306 (Series 90 and Series 40-M46)

•

Tan 18° = 0.325 (Series-20, Series 42, and H1P)

•

1/2

1/2

DM= Motor displacement at maximum angle (cc/rev or in3/rev)

DV = Motor displacement at reduced angle (cc/rev or in3/rev)

Bent Axis Motors

NV = NM (SM / SV)

or

NV = NM (DM / DV)

where:

NV = Motor speed limit at reduced angle (RPM)

NM= Motor speed limit at maximum angle from Table 2 (RPM)

SV = Sine of reduced angle

SM = Sine of maximum angle, Sin 32° = 0.530 (Series 51 and H1B)

DM= Motor displacement at maximum angle (cc/rev or in3/rev)

DV = Motor displacement at reduced angle (cc/rev or in3/rev)

14 | © Danfoss | May 2015 BLN-9884 | BC00000160en-US0401

Page 15

Applications Manual

Pressure and Speed Limits for Hydrostatic Units

Motor Performance at Low Speed

Motor Performance at Low Speed

Some applications require controlled motor operation at low speeds. Generally, speeds less than 5% of

rated are considered “slow” for axial piston motors. For bent axis motors, speeds less than 2-3% of rated

are considered “slow”. Like high speed applications, a common requirement for low speed operation is

continuous smooth output shaft rotation. However, axial piston type motors have inherent limitations

which may provide unacceptable performance at low speeds.

The main limitation is related to the interaction of the pistons as they transition from high to low pressure

across the valve plate. As each piston makes the transition, there is a variation in the motor’s total

displacement. Even if system pressure remains constant, the variation in displacement results in a “torque

ripple” at the motor output shaft, which is generally described as shaft cogging. As system pressure

increases, the speed at which cogging occurs also increases. Other system parameters affecting this

inherent phenomenon include inertia of the load, load fluctuations, and bulk modulus of the system (line

diameter and length, line type, and fluid compressibility).

Another inherent limitation to low speed operation, common to all types of driveline components, is

simply mechanical friction. For piston motors, this is largely a function of the design of the unit and the

manufacturing tolerances of the rotating group parts.

As a rule of thumb, most Danfoss Power Solutions axial piston motors will operate smoothly down to

~150 rpm. Some axial piston motors may run smoothly at less than 150 rpm, but performance must be

verified for the specific application. Danfoss Power Solutions does not recommend that any axial piston

motor be size to operate continuously at speeds less than 100 rpm.

The H1B and Series 51 variable displacement bent axis motors have demonstrated smooth performance

at speeds down to 50 rpm in most applications, but acceptability must be judged based on specific

application requirements.

Because the limitation to low speed operation is inherent to all piston type motors, Danfoss Power

Solutions cannot offer “special hardware” to improve low motor speed performance. Low speed

applications should be critiqued carefully at the design phase and thoroughly tested for acceptable

performance at the prototype phase.

©

Danfoss | May 2015 BLN-9884 | BC00000160en-US0401 | 15

Page 16

Applications Manual

Pressure and Speed Limits for Hydrostatic Units

Bypass Valve Speed Limitations

Bypass Valve Speed Limitations

Most Danfoss Power Solutions axial piston pumps have a bypass valve which allows system fluid to be

cross-ported between the main “A” and “B” ports when pump input shaft rotation is not possible. This

valve requires manual engagement and disengagement via an external device on the pump, such as an

adjustment screw or plunger. The intent of this valve is to allow a vehicle using a closed loop propel

circuit to be moved a short distance at slow speeds. Typically, this translates to loading a vehicle onto a

trailer, getting a malfunctioning machine away from the work area, or out of a traffic lane.

Cross-port bypassing is required to prevent hydraulic lockup as the motor becomes a flow source while

the vehicle is being moved (assuming the motor remains coupled to the ground via tires or tracks). The

bypass valve should not be used or referred to as a “towing valve” which implies high speed and long

duration usage.

Vehicle speed limitations associated with cross-port bypassing are a function of flow rate and duration of

time. Exceeding one, or both, of these criteria can lead to failure of the transmission. Flow rate is critical

because the bypass valve may become saturated due to its pressure rise rate creating excessive heat. The

temperature rise of the fluid as it passes thru the bypass valve is proportional to the square of the flow

rate. (i.e., if you double the flow rate, you will increase the temperature rise rate by 4-times).

Duration is critical because there will be no charge fluid to makeup leakage in the circuit, and the system

lines will become evacuated. Because the flow rate being bypassed is a function of the motor

displacement, final drive ratio, and rolling radius; it is impossible to publish strict speed ratings for the

bypass mode. Also, the circuit design will affect how quickly system fluid is lost to leakage. However, the

following rule of thumb for flow rate and duration has been used successfully to quantify the limitations

during a bypass mode.

Do not operate the transmission in bypass mode at more than 10~15% of rated motor speed and

do not exceed a duration of 3~5 minutes, depending on the product. Refer to the product specific

Technical Information Manuals for details and limits.

During normal transmission operation, the bypass valve must remain fully closed. Partial opening of the

valve will cause sluggish performance and will create excessive heat in the system.

The bypass function is standard on all Series 90 pumps, Series 40 pumps and H1P pumps. It is an optional

feature on Series 42 pumps and Series 15 pumps. Please refer to the technical information bulletins for

the specific pump families for details on the use of the bypass function.

The bypass function is not available for Tandem H1 Pumps.

16 | © Danfoss | May 2015 BLN-9884 | BC00000160en-US0401

Page 17

Applications Manual

Pressure and Speed Limits for Hydrostatic Units

Inlet Vacuum Limits

Inlet Vacuum Limits

Flow enters the charge pump through the charge inlet. Unless this inlet is pressurized, a vacuum will exist

due to the resistance to flow through the inlet line leading to the inlet port of the charge pump.

The degree of inlet vacuum affects the ability of the charge pump to fill properly. Starving the charge

pump can cause the inlet fluid to reach its “air release” pressure level which results in cavitation.

Cavitation is the formation and collapse of vapor and/or air bubbles in the fluid. When the bubbles

collapse, they pit or erode the metal surfaces on which they are in contact resulting in reduced

Volumetric Efficiency. Charge pumps are usually less susceptible to erosion damage because of the

reduced pressure in the charge cavity. Typically, damage occurs at the valve plate, cylinder block and

piston slippers due to the high pressures in the system circuit. Volumetric losses can become so extreme

that the charge pump will be unable to meet the demands of the system. Loss of charge pressure can

cause serious degradation of system performance as well as component failure.

As a general recommendation, continuous inlet vacuum should not exceed 6 inches of Hg. for any

gerotor style charge pump during normal operation. Intermittent limits for cold start situations are more

a function of the capability of the charge pump. Danfoss Power Solutions medium and high power pump

families are generally capable of achieving upwards of 24 inches Hg. for short duration events. Series 15

products are capable of vacuums on the order of 20 inches Hg. for short duration events. Refer to the

product specific Technical Information Manuals for details and limits.

Normal operating inlet vacuum in the range of 6 to 10 inches Hg is generally associated with a suction

filter in need of replacement.

Inlet suction specifications are based on the use of mineral base fluids at sea level. Fluids with a higher

specific gravity than mineral base fluids, such as fire resistant or synthetic fluids; are more resistant to

flow and are more likely to cause cavitation. Some of these fluids may require inlet vacuum limits on the

order of 3 inches Hg for continuous operation. Please refer to Hydraulic Fluids and Lubricants 520L0463,

Experience with Biodegradable Hydraulic Fluids 520L0465, and Design Guideline for Hydraulic Fluid

Cleanliness 520L0467 for more details on the subject.

Operation at altitudes above sea level also changes charge pump inlet vacuum limits. As a rule of thumb,

for every one thousand feet above sea level, the inlet vacuum limit should be reduced by 1 inch Hg.

Pressurized reservoirs can be used to compensate for lost atmospheric pressure in closed circuit hydraulic

systems. Refer to the product specific Technical Information Manuals for details and specific inlet

vacuum limits.

©

Danfoss | May 2015 BLN-9884 | BC00000160en-US0401 | 17

Page 18

Applications Manual

Pressure and Speed Limits for Hydrostatic Units

Dynamic Braking

Dynamic Braking

By definition, a closed circuit hydrostatic transmission is capable of transmitting power through both the

“A” and “B” sides of the power loop. In a typical mobile vehicle system, there are two modes of power

transmission: propel and braking. Propel implies that the power is transmitted from the engine (or prime

mover), to the pump through to the motor, through the final drive gears and wheels, and finally to the

ground. Power transmitted during the braking mode is opposite from the propel mode. Braking implies

that the power from vehicle inertia is transmitted from the ground, through the wheels and final drive

gears, to the motor, to the pump and back into the engine. All closed circuit hydrostatic systems with

duty cycles that include accelerations and decelerations for a load are subjected to both the propel and

braking modes of operation. On mobile equipment applications, the braking mode will typically be

encountered when the vehicle is commanded to decelerate quickly or when it travels down an incline of

sufficient grade to overcome the rolling resistance of the vehicle. These modes of operation are often

referred to as “dynamic braking” and “downhill braking”, respectively.

It is important to note that, although dynamic braking is an inherent feature of closed circuit hydrostatic

systems, the pump and motor only act to transmit the power; and that the braking power of the vehicle is

limited to the braking power of the engine. The ability of the vehicle to dynamically brake is only a

function of the power absorption capability of the engine while remaining within the maximum speed

limits of the engine, pump, and motor. Most engines have the capacity to absorb 10~15% of their rated

power. Braking power transmission above the absorption capability of the engine may cause the engine

to over-speed and risk premature failure. Consult the engine supplier for the braking power absorption

capability.

Some high inertia applications may require the addition of a special dynamic braking valve to prevent

engine over-speed. The Integrated Speed Limitation Valve improves vehicle deceleration while

protecting the engine from failure due to over-speed. Please consult H1 Axial Piston Pump 115/130

147/165 ISL Integrated Speed Limitation 11053026 for additional information that applies to the H1 Series

of pumps. It is recommended that a test program to verify safe, and controllable, performance during all

modes of dynamic and downhill braking is completed.

Although the closed circuit hydrostatic system is capable of transmitting dynamic braking power back to

the engine, the loss of hydrostatic driveline power in any mode of operation may cause the loss of

hydrostatic braking capability. Therefore, a braking system which is independent of the hydrostatic

transmission must be provided which is adequate to stop and hold the vehicle should the condition

develop.

As implied above, the roles of the pump and motor are reversed during dynamic braking. The motor

become a flow source, while the pump receives the flow and offers some resistance to it based on its

displacement and engine frictional load. The resistance, or course, determines the system pressure in the

braking loop. The pump transmits hydraulic power (flow at pressure) back to the engine where it is

dissipated as frictional heat.

During a downhill operating mode, the vehicle will experience an increase in travel speed for two

reasons. The first reason involves volumetric leakage of the pump and motor. In the propel mode (as

defined above) normal pump and motor leakage reduce the output speed (i.e., vehicle speed) relative to

the input speed. However, during downhill braking, when the pump and motor roles are reversed, the

leakage acts to increase the vehicle speed.

The second, and most significant issue, involves the internal forces acting on the swashplate as a result of

braking pressure in the power loop. In the propel mode, internal swashplate forces act to reduce the

displacement of the pump. The magnitude of the resultant force or moment is a function of system

pressure, input speed, and servo spring force, swashplate angle and valve plate design. In the braking

mode, however, the swashplate forces act to increase the displacement of the pump. If the pump

displacement increases, the motor can rotate faster since more flow is accepted by the pump, with the

net result being increased vehicle speed.

18 | © Danfoss | May 2015 BLN-9884 | BC00000160en-US0401

Page 19

Applications Manual

Pressure and Speed Limits for Hydrostatic Units

Dynamic Braking

Displacement Control:

The mechanical feedback mechanism in the displacement control ultimately limits the amount of pump

swashplate angle increase, which is called over-travel. However, the pump displacement control, like

most controls, has a dead-band within which no error signal will be received from the feedback

mechanism. Thus, the control will regulate swashplate position only after the swashplate has traveled

outside of the dead-band. In other words, the displacement control limits the amount of swashplate

over-travel, but cannot eliminate it completely. While the pump is operating within the dead-band

during a downhill condition, the resulting effect on vehicle performance is generally considered

unfavorable.

There are two ways to improve the downhill speedup characteristics of a pump: reduce the deadband of

the displacement control or increase the internal swashplate forces. Because downhill speedup tends to

be more pronounced in larger, heavier vehicles, Danfoss Power Solutions has addressed these issues with

the Series 90 and H1 pump families.

Danfoss Power Solutions has also created a special set of hardware identified as a “Downhill Kit” that

improves the internal forces during the downhill condition for the Series 90 pump family. The “Downhill

Kit” includes nested servo springs (one spring nested inside another) and a special valve plate. The

“Downhill Kit” improves the ability of a vehicle to minimize downhill speedup, but does not eliminate the

potential for speedup on severe grades. This situation can only be considered during the design phase of

the vehicle powertrain.

Because the downhill kit increases the neutral return forces on the swashplate, the actual charge pressure

must be at least 24 bar (350 psi) to allow the pump to reach full displacement.

Because it is difficult to quantify all of the parameters associated with downhill speedup, it is difficult for

the designer to predict whether to be concerned for a given application. In general, however,

applications involving large inertial loads on off-highway grades should be critiqued carefully for

downhill performance.

©

Danfoss | May 2015 BLN-9884 | BC00000160en-US0401 | 19

Page 20

Applications Manual

Pressure and Speed Limits for Hydrostatic Units

Case Drain Pressure Limits

Case Drain Pressure Limits

Both steady state and transient case pressure limits can have an impact on the success of the application

of the hydrostatic pump and/or motor in the system. It is rare that case pressure will affect the

performance of the system in a measurable way; but, it can have an impact on the success of the shaft

seals and various seals/gaskets to prevent external leakage.

Case pressure may be above, or below, ambient pressures; depending on where the internal case

pressure is referenced. For example, case pressure above, or below, ambient atmospheric pressure may

impact the seals/gaskets at the various joints between housings and end caps.

Likewise, case pressure above, or below, the pressure in the driveline coupling cavity can have an impact

on the shaft seals' performance. In general, individual shaft seals are designed to seal against an internal

pressure that is greater than the external pressure. If the external pressure is greater than the internal

pressure, then the fluid in the external cavity, air, or other forms of contaminant can enter the case cavity.

Some Danfoss Power Solutions products have minimum case pressure limits to ensure that all of the

internal components are lubricated over the entire operating spectrum of the system. In other products,

only the maximum case pressure limits are considered.

Please consult the specific product Technical Information Bulletins for the maximum, and minimum, case

pressure limits for all Danfoss Power Solutions products in the system.

In some applications, particularly those with small diameter and/or long case drain hoses; case pressure

can be influenced significantly by both viscosity of the fluid and by rapid changes in flow velocity. Under

cold start conditions, when the viscosity is highest; the pressure in the case cavity can be reduced by

reducing the velocity of the fluid in the hose and/or the length of the hose.

Short duration, transient, pressures should also be considered by the system designer. If there is a sudden

acceleration of the fluid in the case drain line, for any reason; then there will be a transient pressure

change inside the case cavity of the pump, or motor. If there is a positive acceleration of the fluid in the

case drain line, there will be a short duration, transient pressure rise above the normal operating

pressure. These pressure pulses can have the effect of reducing the life of the shaft seal. If there is a

negative acceleration of the fluid in the case drain line, there will be a short duration, transient pressure

drop below the normal operating pressure. These pressure pulses can have the effect of drawing

contaminant (fluid, air, water, or abrasive particles) into the case cavity across the sealing interface of the

shaft seal.

For an incompressible fluid, the peak value of the pressure required to accelerate the fluid in a circular

passage if related to the mass density of the fluid, the length of the line, the diameter of the line and the

fluid’s acceleration. Reducing the line length will reduce the transient pressure linearly; increasing the

diameter of the line will reduce the transient pressure by the square of the ratio of diameters considered.

Frequently, the line length is constrained by the location of the various components in the vehicle; but, it

may be relatively easy to change the line diameter to keep case pressure within the limits defined in the

product technical information manuals.

20 | © Danfoss | May 2015 BLN-9884 | BC00000160en-US0401

Page 21

Applications Manual

Pressure and Speed Limits for Hydrostatic Units

©

Danfoss | May 2015 BLN-9884 | BC00000160en-US0401 | 21

Page 22

Applications Manual

Pressure and Speed Limits for Hydrostatic Units

22 | © Danfoss | May 2015 BLN-9884 | BC00000160en-US0401

Page 23

Applications Manual

Pressure and Speed Limits for Hydrostatic Units

©

Danfoss | May 2015 BLN-9884 | BC00000160en-US0401 | 23

Page 24

Danfoss

Power Solutions GmbH & Co. OHG

Krokamp 35

D-24539 Neumünster, Germany

Phone: +49 4321 871 0

Danfoss

Power Solutions ApS

Nordborgvej 81

DK-6430 Nordborg, Denmark

Phone: +45 7488 2222

Danfoss

Power Solutions (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239 6000

Danfoss

Power Solutions Trading

(Shanghai) Co., Ltd.

Building #22, No. 1000 Jin Hai Rd

Jin Qiao, Pudong New District

Shanghai, China 201206

Phone: +86 21 3418 5200

Products we offer:

Comatrol

www.comatrol.com

Turolla

www.turollaocg.com

Hydro-Gear

www.hydro-gear.com

Daikin-Sauer-Danfoss

www.daikin-sauer-danfoss.com

Bent Axis Motors

•

Closed Circuit Axial Piston

•

Pumps and Motors

Displays

•

Electrohydraulic Power

•

Steering

Electrohydraulics

•

Hydraulic Power Steering

•

Integrated Systems

•

Joysticks and Control

•

Handles

Microcontrollers and

•

Software

Open Circuit Axial Piston

•

Pumps

Orbital Motors

•

PLUS+1® GUIDE

•

Proportional Valves

•

Sensors

•

Steering

•

Transit Mixer Drives

•

Danfoss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and

electronic components. We specialize in providing state-of-the-art technology and solutions

that excel in the harsh operating conditions of the mobile off-highway market. Building on

our extensive applications expertise, we work closely with our customers to ensure

exceptional performance for a broad range of off-highway vehicles.

We help OEMs around the world speed up system development, reduce costs and bring

vehicles to market faster.

Danfoss – Your Strongest Partner in Mobile Hydraulics.

Go to www.powersolutions.danfoss.com for further product information.

Wherever off-highway vehicles are at work, so is Danfoss. We offer expert worldwide support

for our customers, ensuring the best possible solutions for outstanding performance. And

with an extensive network of Global Service Partners, we also provide comprehensive global

service for all of our components.

Please contact the Danfoss Power Solution representative nearest you.

Local address:

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

©

Danfoss | May 2015 BLN-9884 | BC00000160en-US0401

Loading...

Loading...