Page 1

Installation Guide

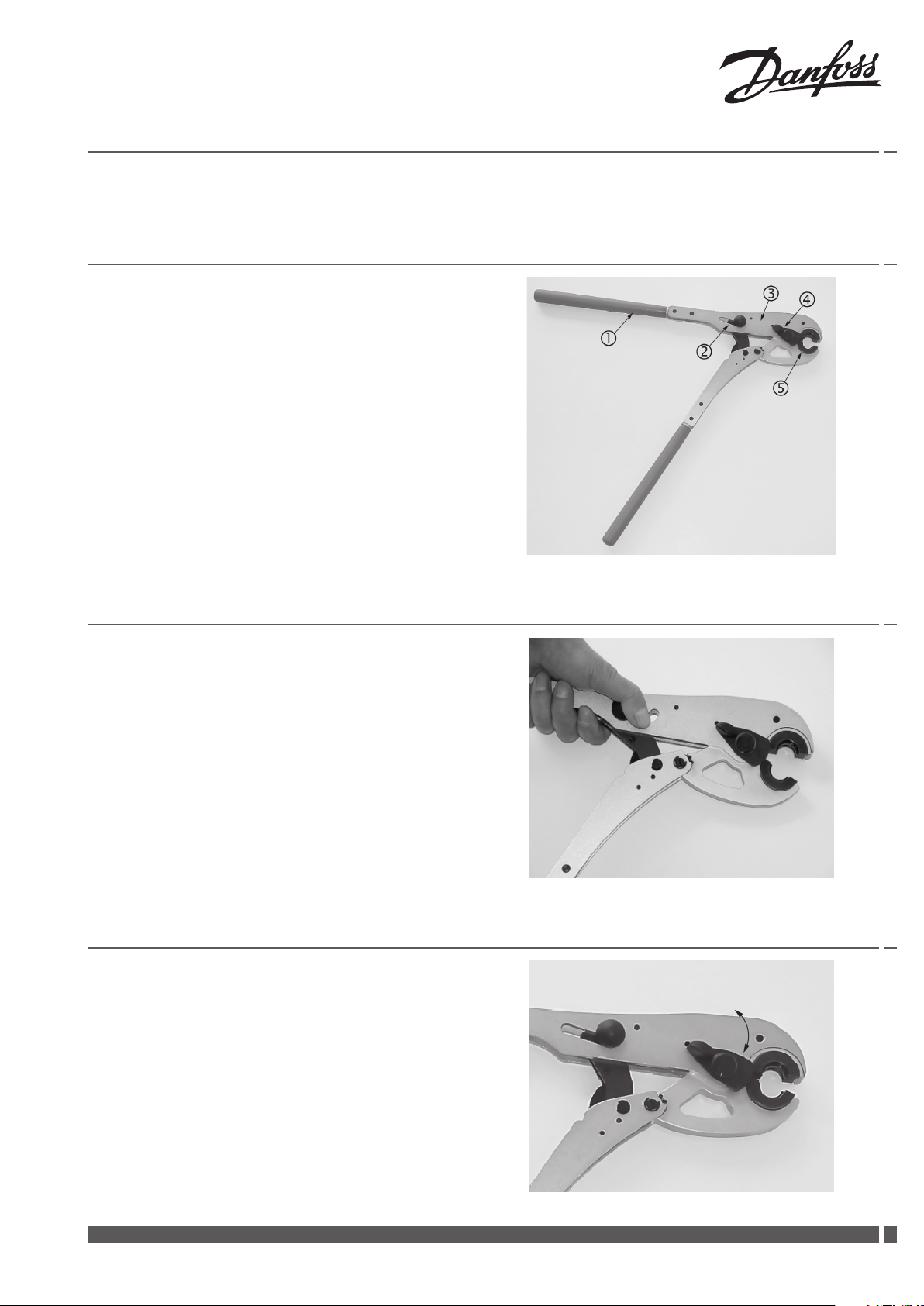

Pressing tool

1 Introduction

The pressing tool is designed for use with the Danfoss composite

pipe tting system. The tool has easily replaceable jaw inserts for

pressing alternatively 16 and 20 mm tube ttings.

The pressing tool is designed with a safety feature which ensures

the tool levers cannot be opened before the pressing of the tting is

completed. Thereby a tight seal in the tting is secured.

1. Tool lever

2. Slider

3. Tool head

4. Closure

5. Pressing jaws

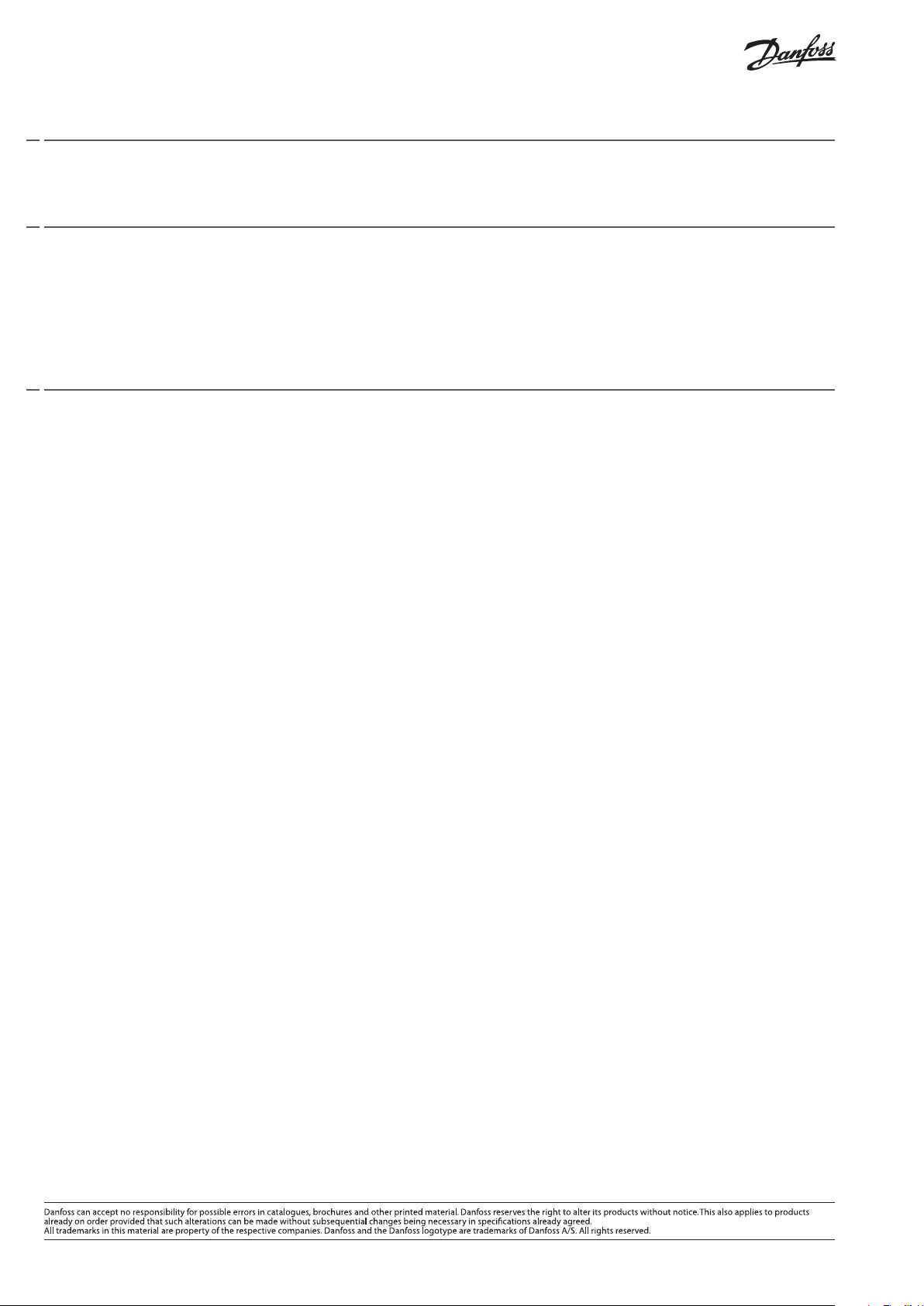

2 Function

Press levers rmly together and the jaws can be opened.

Place the open jaws around the press tting (If there is a lack of

work space, the jaws can be opened without moving levers simply

by pulling back the slider).

Press the levers until they are pressed completely together.

Once the levers have been pressed completely together the jaws

can be opened again.

3 Replacing jaw inserts

Turn the closure so the jaws can be opened.

Place the pressing tool on a surface with the closure turning up.

Open the jaws and replace the jaw inserts.

Turn the closure to locked position to prevent inserts from falling

out.

1Danfoss Floor Heating Hydronics VICTD302 05/2015

Page 2

Installation Guide Pressing tool

4 Service and cleaning

The pressing tool should always be cleaned after use.

The tool should be checked every 4 weeks, to ensure that the jaws close completely.

All moving parts should be oiled regularly

To ensure functionality the tool should always be stored in a clean and dust free environment.

5 Warranty

The pressing tool is only to be used with Danfoss composite pipe ttings.

Any damage caused by throwing or hitting the pressing tool will void the warranty.

Any modications to the tool will void the warranty and Danfoss will not be responsible for consecutive damage to installations or

ttings.

The pressing tool should only be used in compliance with valid safety regulations such as the German UVV and similar European 89/92/

EWG.

VICTD302

Produced by Danfoss Floor Heating Hydronics © 05/2015

Loading...

Loading...