Page 1

Fitters notes Practical tips

Page

This chapter is devided into two sections:

Installation requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

The installation process. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

© Danfoss A/S (AC-DSL/MWA), 10 - 2006 DKRCC.PF.000.G1.02 / 520H1459 125

Practical tips

Page 2

Page 3

Fitters notes Practical tips - installation requirements

Contents Page

Installation requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Tubing must be kept clean . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Particularly damaging impurities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Problems caused by moisture in the system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Problems caused by atmospheric air. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Problems caused by oil and refrigerant breakdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Problems caused by other impurities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Component and material requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Impurities and moisture. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Copper tubing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Refrigerant requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Compressor oil requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

© Danfoss A/S (AC-DSL/MWA), 10 - 2006 DKRCC.PF.000.G1.02 / 520H1459 127

Practical tips

Page 4

Notes

128 DKRCC.PF.000.G1.02 / 520H1459 © Danfoss A/S (AC-DSL/MWA), 10 - 2006

Page 5

Fitters notes Practical tips - installation requirements

Installation requirements

Tubing must be kept clean

More and more commercial refrigeration systems

and air conditioning plants of a similar size are

built up around hermetic and semihermetic

compressors. These compressors, as compared

to the open type, are normally more vulnerable

to impurities in the refrigerant system and to

incorrect operating conditions.

Therefore, in modern refrigeration systems, there

are special demands on the quality of installation

work and commissioning.

Ac0_0003

A well-dimensioned, correctly installed and

correctly commissioned refrigerant system is

fundamental to a reliable refrigeration system

with a long operating life.

An absolute requirement on the refrigerant

system is that it shall remain completely free of

foreign bodies (impurities).

Installation work must therefore be performed

with a high degree of cleanliness. This applies

especially to systems containing the new

refrigerants.

Particularly damaging

impurities

Problems caused by moisture in

the system

Moisture

Atmospheric air

Soldering ux

Rust, copper oxide, scale

Metal swarf

Unstable oils

Certain uorinated solutions (e.g. R11

or carbon tetrachloride)

Dirt or dust of any description.

Water separation and ice formation

(blockage) in the expansion valve

Acid formation

Ageing and breakdown of the oil

Corrosion

Copper precipitation (dissolved copper

from tubing deposited on bright steel

parts in the compressor)

Damage to the insulating lacquer on

motor windings.

Ac0_0010

Ac0_0037

Ac0_0027

Practical tips

© Danfoss A/S (AC-DSL/MWA), 10 - 2006 DKRCC.PF.000.G1.02 / 520H1459 129

Page 6

Fitters notes Practical tips - installation requirements

Problems caused by

atmospheric air

Problems caused by oil

and refrigerant breakdown

Aeration

Chemical reaction between refrigerant

and oil

Increased condensing pressure.

Ac0_0038

Formation of organic and inorganic acids

Corrosion

Poor lubrication

Abnormal wear

Oil discolouration (darkening)

Sludge formation

Leaking discharge valves because of

oil carbon deposits

Increased discharge gas temperature

Compressor damage

Motor burnout

Ac0_0046

Problems caused by other

impurities

Component and

material requirements

Components

The other impurities mentioned can cause:

Accelerated chemical processes

(breakdown)

Mechanical or electrical faults

High temperature accelerates the breakdown

processes, therefore abnormally high condensing

temperatures and, especially, abnormally high

discharge pipe temperatures must be avoided.

For the reasons just mentioned, a number of

requirements must be met. Some of these are

described in the next chapter.

Ac0_0047

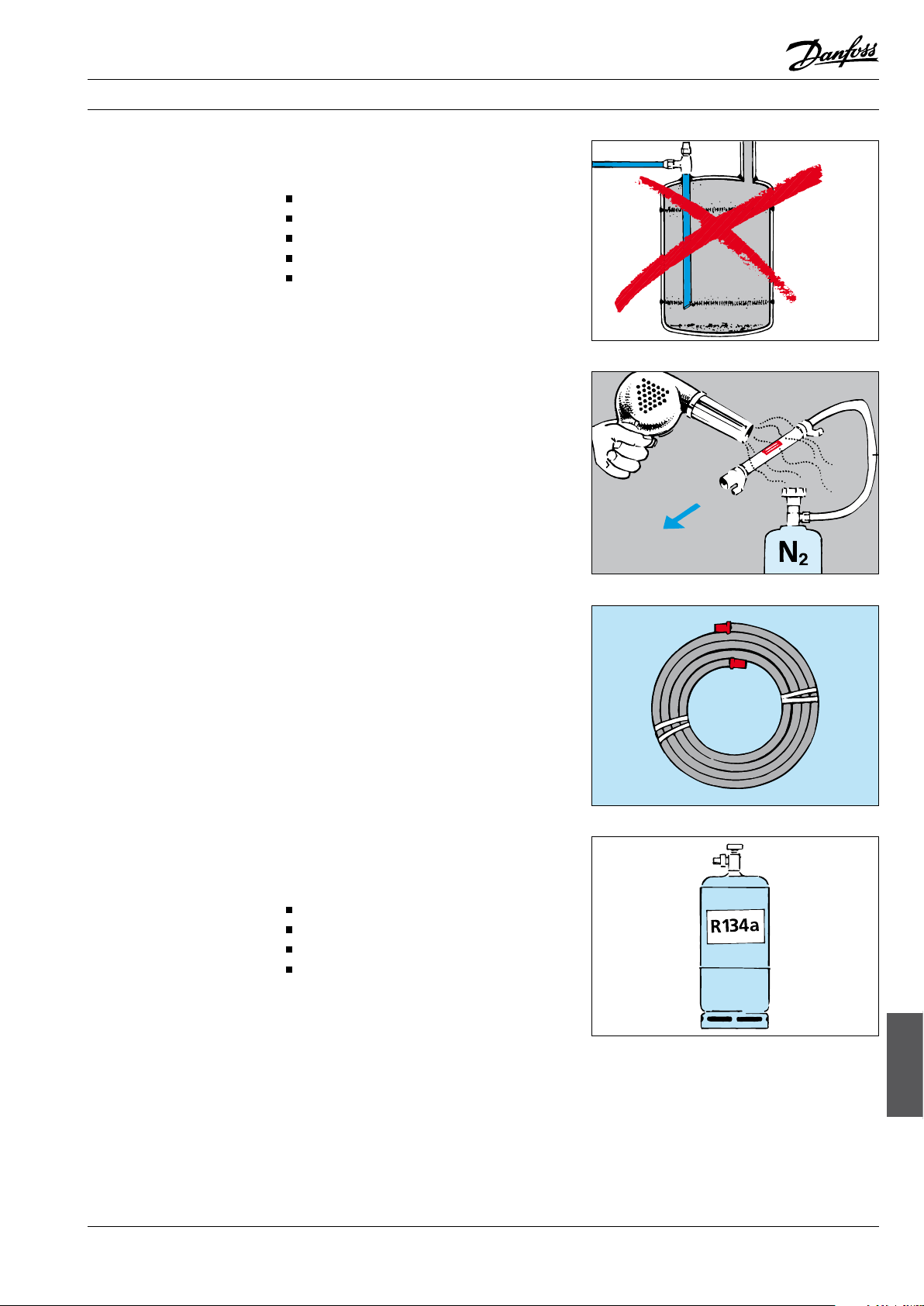

Compressors for refrigeration and heat pump

systems are put through a comprehensive cleaning process by the manufacturer so that, practically speaking, all traces of moisture and other

impurities are removed.

All other components in the system should be of

the same standard.

All components must full cleanliness requirements. In cases of doubt, components should be

checked.

Ac0_0048

130 DKRCC.PF.000.G1.02 / 520H1459 © Danfoss A/S (AC-DSL/MWA), 10 - 2006

Page 7

Fitters notes Practical tips - installation requirements

Impurities and moisture

Impurities that might appear if component

manufacturers are less thorough than they

should be:

Rust and scale (loose or embedded)

Old oil

Flux

Metal swarf

Moisture

Ac0_0001

Moisture in smaller quantities in components

can be removed by simultaneous heating and

blowing through with dry nitrogen (N2).

It is almost pointless to try removing other

impurities. Components containing such impurities should not be used in systems with

halogenous refrigerants.

Ac0_0005

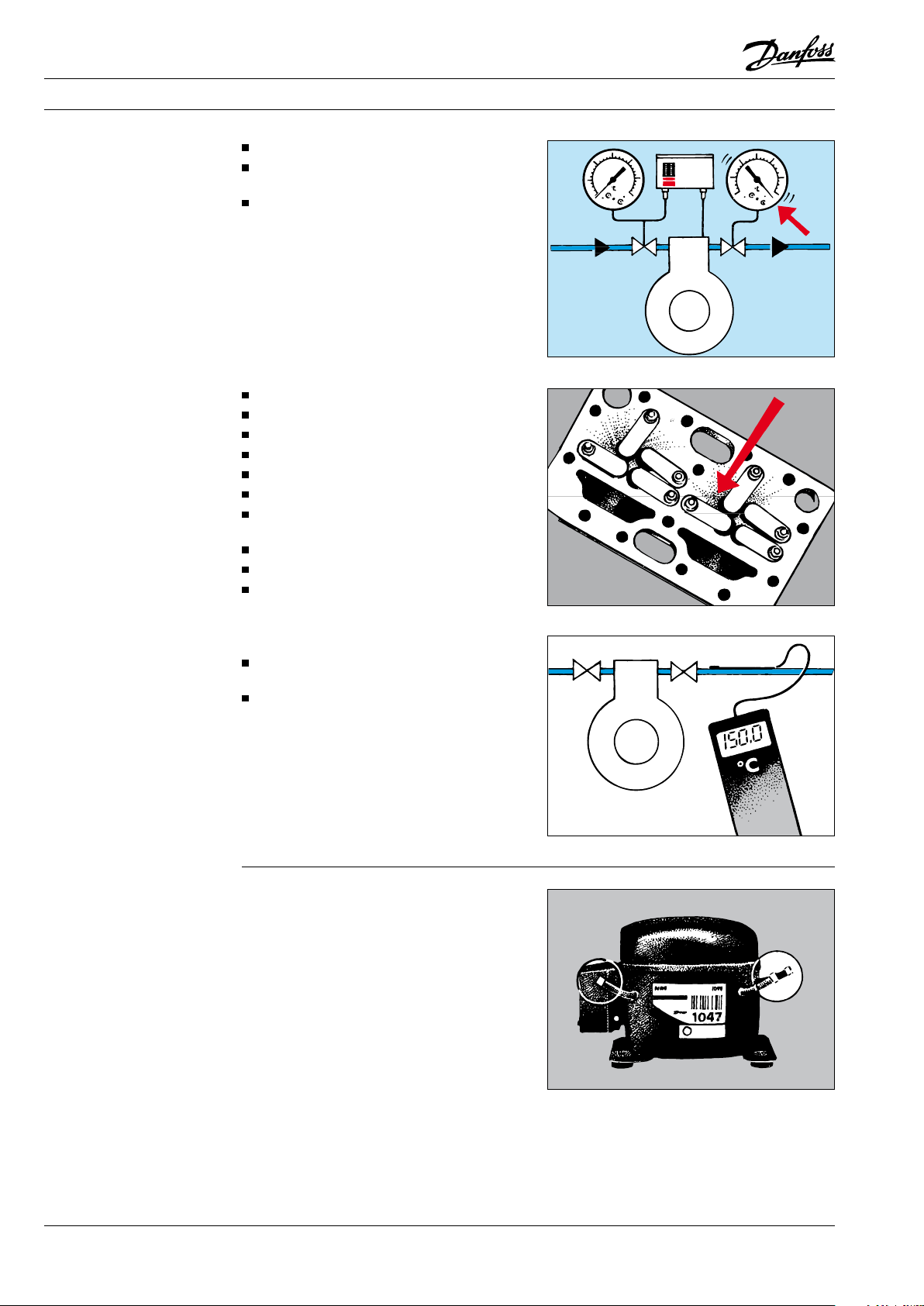

Copper tubing

Refrigerant requirements

Special copper tubing must be used for refrigerant systems, tubing that is completely clean

and dry. In addition, the ends of tubes must be

hermetically sealed.

Tubing other than the type just described must

not be used in refrigerant systems, unless it fulls

the same cleanliness requirements.

All components must remain tightly sealed until

the moment they are installed in the system.

Refrigerants should only be purchased from

accredited distributors.

Refrigerants for hermetic systems must not

contain more than:

10 ppm = 0.001% water

100 ppm = 0.01% high-boiling refrigerant

0 ppm = 0% acid

15000 ppm = 1.5% non-condensable

gases

Care must therefore be exercised when using

regenerated refrigerant.

Ac0_0049

Practical tips

Ac0_0006

© Danfoss A/S (AC-DSL/MWA), 10 - 2006 DKRCC.PF.000.G1.02 / 520H1459 131

Page 8

Fitters notes Practical tips - installation requirements

Compressor oil requirements

Compressor oil must be approved by the

compressor manufacturer and must not contain

more than 25 ppm (0.0025%) water and 0% acid.

Ac0_0007

132 DKRCC.PF.000.G1.02 / 520H1459 © Danfoss A/S (AC-DSL/MWA), 10 - 2006

Page 9

Fitters notes Practical Tips - The installation process

Contents Page

Installation process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Planning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Location of main components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Installation of refrigeration system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Piping installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Location of other components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Compressors in parallel installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Important installation processes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Component storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Pipe cutting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Pipe cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Silver soldering (brazing). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Phosphor solder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Use of inert gas when soldering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Economic soldering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Be careful with the temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Flare connections (copper piping) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Evacuation, ushing and charging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Necessary equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Vacuum pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Vacuum hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

First evacuation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

System vacuum test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Flushing and provisional leak testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Second evacuation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Provisional setting of safety equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Checking the electrics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Refrigerant charging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Condensing pressure too high . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Setting and testing safety equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Setting and testing regulation equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Setting the high-pressure control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Setting the low-pressure control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

© Danfoss A/S (AC-DSL/MWA), 10 - 2006 DKRCC.PF.000.G1.02 / 520H1459 133

Practical tips

Page 10

Notes

134 DKRCC.PF.000.G1.02 / 520H1459 © Danfoss A/S (AC-DSL/MWA), 10 - 2006

Page 11

Fitters notes Practical Tips - The installation process

Installation process

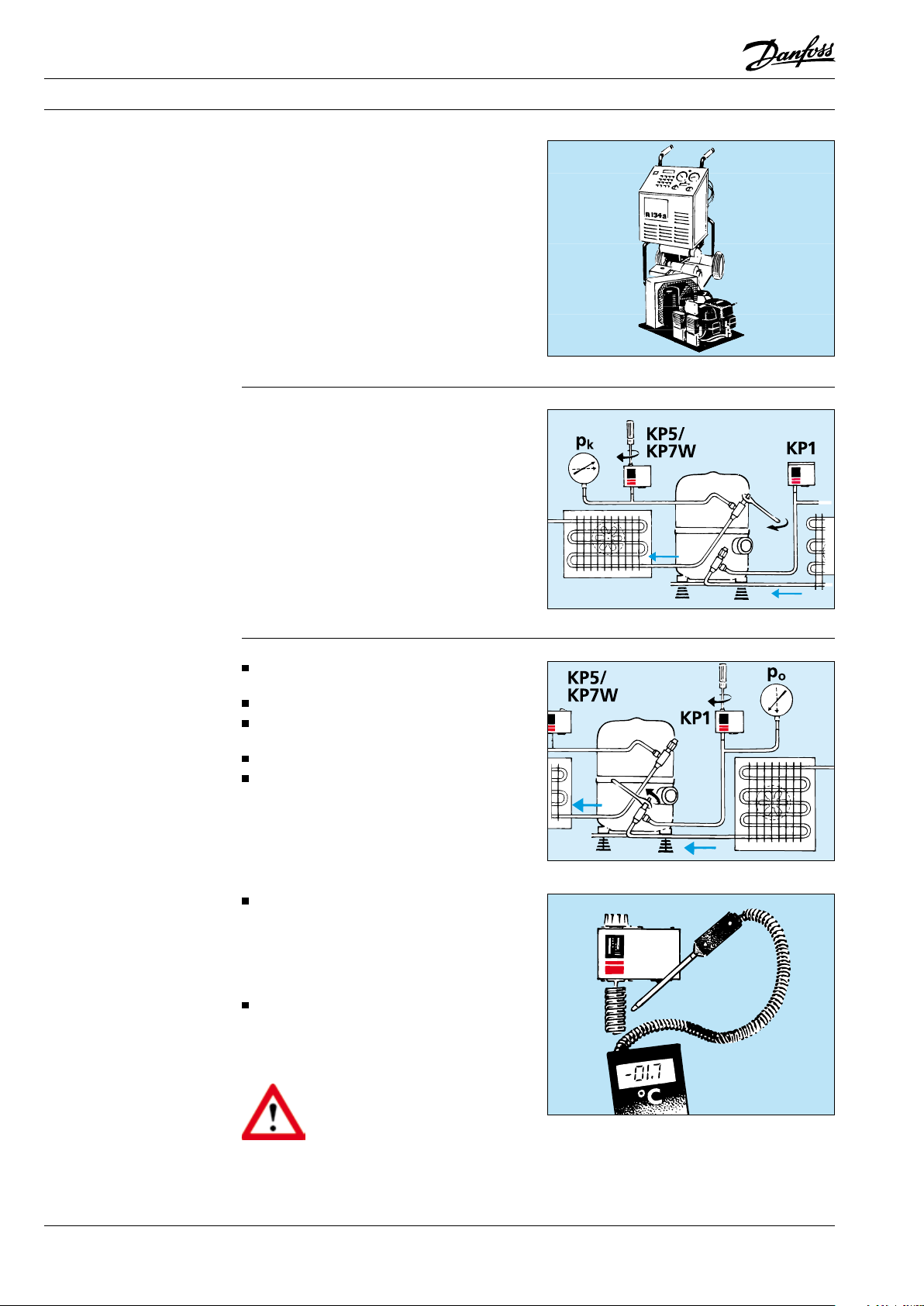

Planning

Process:

Planning of component location and

tubing layout

Setting up of main components

Piping and component installation

Evacuation

Flushing

Pressure testing

Leak testing

Charging

Setting safety equipment

Testing safety equipment

Setting controls

Testing the complete system and

readjusting controls, etc.

Ac0_0061

Installation must be planned so that

Damage to building sections, including

cold room insulation, is minimal.

Components are located functionally

correctly (e.g. adequate air ow to

compressor, condenser, evaporator).

Pipe runs are as short as feasibly possible.

Location of main components

Installation of refrigeration

system

Main components (compressor, condenser,

evaporator, etc.) must be mounted securely in

position, using the accompanying brackets and in

accordance with the manufacturer’s instructions.

The compressor must always be secured to

a horizontal base. If vibration dampers are

supplied, they must also be tted.

Installation must be as rapid as possible so that

signicant quantities of moisture, air or other

impurities have little chance of collecting in the

system.

Compressors and lter driers should therefore be

installed last, immediately before evacuating and

charging the system.

All openings into the refrigerant system - with

absolutely no exception - must be completely

sealed against air and water vapour for the

duration of any pauses that might occur in

installation work.

Ac0_0008

Ac0_0009

Practical tips

Ac0_0004

© Danfoss A/S (AC-DSL/MWA), 10 - 2006 DKRCC.PF.000.G1.02 / 520H1459 135

Page 12

Fitters notes Practical Tips - The installation process

Piping installation

As far as possible, piping must be horizontal or

vertical. The exceptions are:

Suction lines, which can be given a slight fall

towards the compressor.

Discharge lines, which can have a slight fall

away from the compressor.

Pipe xing brackets, clips, etc. must be pitched

to suit the pipe diameter and load from components mounted in the lines.

If vibration dampers are tted to the compressor,

then suitable vibration eliminators should be

tted to suction and discharge piping.

Ac0_0002

Oil locks must be mounted in vertical suction

lines at a pitch of 1.5 to 5 m depending on

running time per cycle. In systems with

large load variations it can be necessary to

introduce double risers.

Suction lines must also be installed to take

account of oil return to the compressor.

In systems with varying loads, the demands

are particularly critical at low loads.

Location of other components

Ac0_0011

All components should be installed so that they

are easily accessible for service and possible

repair.

Controls and safety equipment must be located

so that testing and adjustment can easily be

performed using ordinary tools.

Ac0_0012

136 DKRCC.PF.000.G1.02 / 520H1459 © Danfoss A/S (AC-DSL/MWA), 10 - 2006

Page 13

Fitters notes Practical Tips - The installation process

Compressors in parallel

installation

Compressors in parallel must be installed with

oil equalization between compressor crankcases,

otherwise whichever compressor(s) run most

will „steal“ oil from the other compressor(s). Oil

equalization can be introduced by installing an

equalizing tube between oil sumps. In systems

with one equalizing tube, the tube must be

installed between compressor oil sumps and

must be of such a diameter that both oil and

refrigerant vapour are able to ow through it

unhindered.

With two equalizing tubes (g. 1)

One tube must be installed between compressor

oil sumps, the other between compressor vapour

chambers (crankcases). When installing oil

equalization in either of the forms described, the

compressors must be set up in exactly the same

horizontal plane.

Oil level controls (g. 2)

Oil equalization is also possible using oil level

regulators.

If these are used, the compressors can be

installed at dierent levels. However, level

controls are much more expensive than

equalizing pipes.

The following components are necessary with oil

level regulation:

Oil separator (1)

Pressure equalizing valve (2)

Oil reservoir (3)

Oil lter (4)

Oil level regulator (5)

Remember that each compressor must be

protected with a high-pressure control, e.g. KP7.

Important installation processes

Component storage

The processes that might give rise to

contamination of refrigerant systems

are:

Component storage

Pipe cutting

Cleaning pipe ends

Soldering

Flare connections

All components must have a temperature not

lower than that of their surroundings - before

they are opened. This prevents condensation in

the components.

For example, components must not be installed

immediately after they have been brought from a

cold service van into a warm room.

Ac0_0036

Practical tips

Ac0_0013

© Danfoss A/S (AC-DSL/MWA), 10 - 2006 DKRCC.PF.000.G1.02 / 520H1459 137

Page 14

Fitters notes Practical Tips - The installation process

Pipe cutting

Pipe cleaning

Tubing must be cut with a pipe cutter or be sawn.

Never use any kind of lubricant/coolant.

Remove internal and external burrs with a special

deburring tool.

Avoid copper swarf entering the pipe.

Use calibration tools to ensure the correct

diameter and roundness.

Ac0_0014

Blow through the pipe using a blast of dry

compressed air or dry nitrogen.

Never use ordinary compressed air; it contains

too much moisture. Never blow through piping

by mouth.

Piping which has been prepared for later use

must be laid ready, with sealed ends, together

with the other components.

Ac0_0015

Silver soldering (brazing)

Silver solder consists of 30% silver, copper, zinc

and tin. The melting range is just over 655°C to

about 755°C.

Silver solder will bind only with clean, nonoxidized metal surfaces.

Clean the pipe ends with a special brush and

apply ux at once, immediately before soldering.

Silver soldering ux must be suspended in spirit,

never water.

Ac0_0016

Smear a thin layer of ux around the soldering

point after the parts have been joined.

Silver solder can then be used to permanently

join dierent materials, e.g. brass/copper and

iron/copper.

Ac0_0017

138 DKRCC.PF.000.G1.02 / 520H1459 © Danfoss A/S (AC-DSL/MWA), 10 - 2006

Page 15

Fitters notes Practical Tips - The installation process

Phosphor solder

Use of inert gas when soldering

Phosphor solder consists of 2-15% silver with

copper and phosphor. The melting range is about

640°C to 740°C.

Flux must not be used when making phosphor

solder connections.

Phosphor solder can only be used to join copper

to copper.

At the high temperatures used in soldering,

oxidation products (scale) form immediately if

the pipe comes into contact with atmospheric air

while soldering is taking place.

An inert gas must therefore be blown through

the system during soldering. Send a slight ow of

dry nitrogen or another kind of inert gas through

the tubing.

Do not begin soldering until there is no more air

in the component(s) concerned.

Start the operation with a strong ow of inert

gas.

Closely observe that no air ow goes into the

pipe with inert gas ow.

Reduce the ow to a minimum when soldering is

started.

Maintain this slight ow of shielding gas during

the whole soldering process.

Soldering must be performed with oxygen and

gas, with a slight oxygen decit and a relatively

large burner jet.

The solder must not be applied until the melting

temperature is reached on the parts being

connected.

Ac0_0018

Ac0_0019

Economic soldering

Never use more solder than necessary, otherwise

there is a risk of blocking the pipe partially or

completely.

Solder quickly so that the oxygen absorption

property of the ux is not impaired, i.e. for no

longer than about 15 seconds.

Ac0_0020

© Danfoss A/S (AC-DSL/MWA), 10 - 2006 DKRCC.PF.000.G1.02 / 520H1459 139

Practical tips

Page 16

Fitters notes Practical Tips - The installation process

Be careful with the temperature

Flare connections

(copper piping)

The temperature must not be higher than

necessary.

Therefore draw the ame back slowly when the

melting temperature is reached.

External ux residue must be removed by

brushing with hot water.

Alloys based on tin or lead are not recommended

as solders for refrigerant systems.

Ac0_0021

Use only approved refrigeration copper piping.

Cut ends at right angles to the piping.

Remove all internal and external burrs.

Make the are the right size, neither too small nor

too large.

Do not compress the are so severely that it

becomes hard.

Leave nal tightening up until actual installation.

Evacuation, ushing and

charging

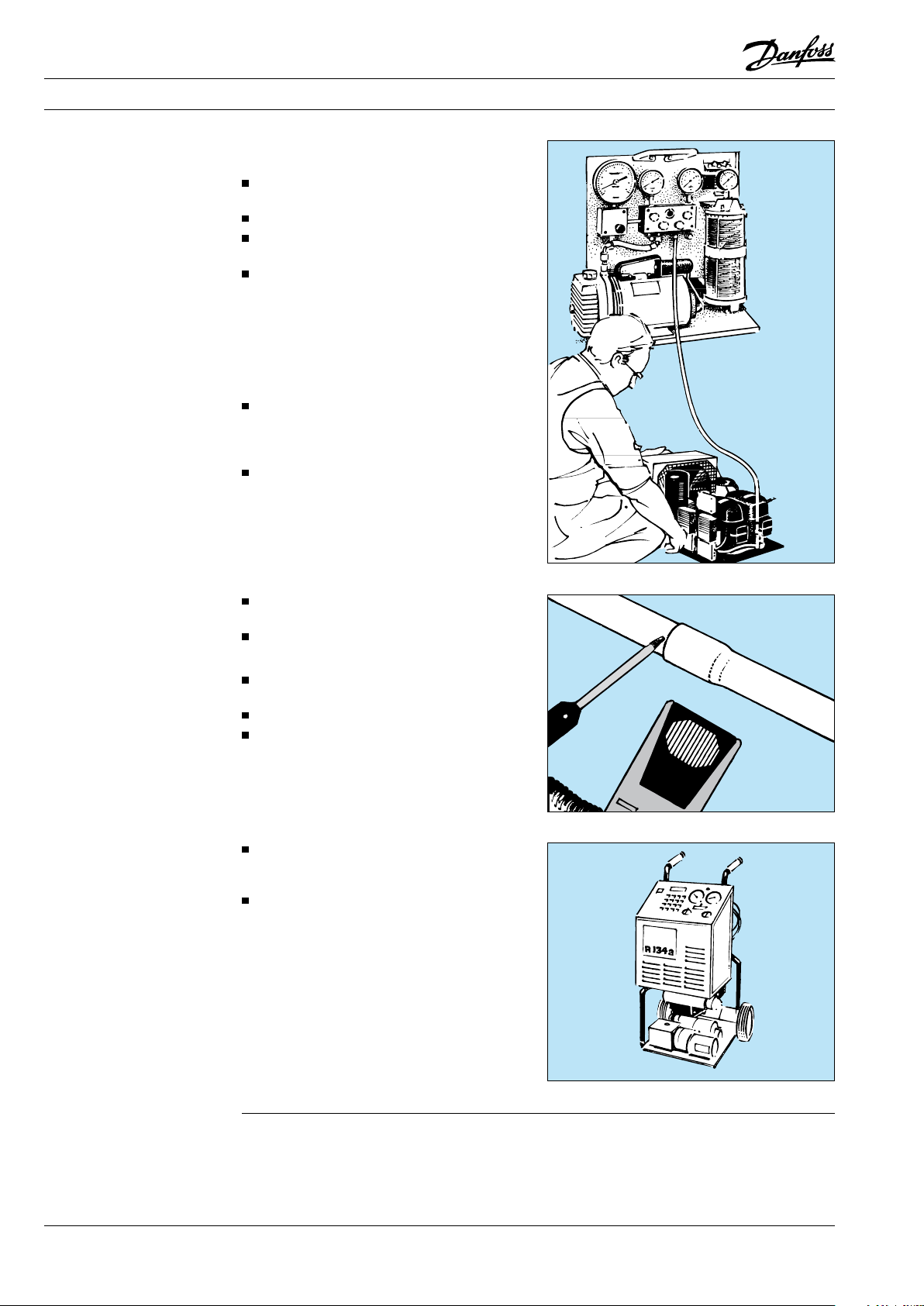

Necessary equipment

Ac0_0022

Steps to follow:

On completing installation work, the next steps

are:

Evacuation and refrigerant charging

Leak testing

Starting up and adjustment.

Faults, which occur after the system has been

started, can necessitate:

Repair of the system.

Vacuum pump

Vacuum gauge

Charging bottle (or service cylinder

containing refrigerant)

(Vacuum pump, vacuum gauge and

charging bottle can be obtained

assembled as an evacuation and

charging board.)

Charging hoses

Leak detector

Remove moisture, atmospheric air and inert gas

from the system when evacuating.

Ac0_0023

140 DKRCC.PF.000.G1.02 / 520H1459 © Danfoss A/S (AC-DSL/MWA), 10 - 2006

Page 17

Fitters notes Practical Tips - The installation process

Vacuum pump

Vacuum hoses

The vacuum pump should be capable of quickly

bringing the system pressure down to about 0.05

mbar.

Pump capacity, e.g. 20 l/minute. Eective

evacuation requires large pipe diameters.

Therefore evacuation through “Schraeder”

valves is not advisable. Use a “Quick Connector”

for compressors with process tube or use the

process connectors on the compressor suction

and perhaps the discharge stop valve.

The valve spindle must be in its mid position.

Ac0_0024

Vacuum hoses and tubes must be as short as

possible and the diameter suciently large.

Normally, an ordinary 1/4" charging hose not

more than 1 m in length can be used.

Evacuate in two stages with refrigerant ushing

between.

The process of evacuation, ushing and charging

is described below.

Checking the vacuum pump and hoses

a) Mount the charging hoses between

charging board and compressor. Shut o the

connections between charging hoses and

compressor.

b) Start the pump and allow it to suck the

pressure down as far as possible.

c) Shut o the pump from the rest of the system.

d) Stop the pump.

e) Read o and register the pressure on the

vacuum gauge. The pressure must not be

more than 0.05 mbar.

f) Check to ensure that the vacuum can be

maintained. If not, replace charging hoses

and/or leaking valves and/or vacuum oil in the

vacuum pump.

Ac0_0025

Practical tips

Ac0_0026

© Danfoss A/S (AC-DSL/MWA), 10 - 2006 DKRCC.PF.000.G1.02 / 520H1459 141

Page 18

Fitters notes Practical Tips - The installation process

First evacuation

System vacuum test

Evacuation from suction side of compressor and

possibly also the discharge side.

Charging hose(s) mounted between charging

board and compressor.

All valves, incl. solenoid valves, open.

Automatic regulating valves at maximum

opening.

Evacuate system, if possible down to the

pressure previously indicated by the vacuum

gauge.

To be performed as described under „Checking

the vacuum pump and hoses“.

If any leakage is detected:

Approximately localize the leakage by

shutting o sections of the system.

Retighten are and/or ange connections.

Repeat evacuation.

Repeat the test until vacuum is maintained or

continue with the next point.

Ac0_0028

Flushing and provisional leak

testing

Second evacuation

Apply refrigerant pressure to the system

(approx. 2 bar overpressure).

Leak-test all connections.

If leakage is detected:

Use a recycling unit and vacuum pump to

remove refrigerant from the system.

Repair the leakage.

Repeat the process until no system leakage

remains.

Ac0_0030

If overpressure remains on the system,

use the recycling unit to empty it of

refrigerant.

Then evacuate again as described under

“First evacuation”.

This will further remove any air and moisture

remaining in the refrigerant system.

Ac0_0029

142 DKRCC.PF.000.G1.02 / 520H1459 © Danfoss A/S (AC-DSL/MWA), 10 - 2006

Page 19

Fitters notes Practical Tips - The installation process

Provisional setting of safety

equipment

Checking the electrics

Check and set high-pressure control and any

other safety equipment, incl. motor protector

(setting in accordance with scale values).

Ac0_0031

Check all wiring.

Test the control system with compressor

motor disconnected.

Check the direction of rotation of the motor.

Swap two phases if necessary.

Ac0_0032

Refrigerant charging

After nal evacuation, the system can be charged

with refrigerant.

A charging board can be used for the purpose

and will, with sucient accuracy, dose the correct

quantity of refrigerant for the system. High

accuracy is needed in systems without receiver.

If the system has a charging valve, refrigerant

can be supplied in the form of liquid to the liquid

line. Otherwise the refrigerant can be supplied as

vapour to the compressor suction stop valve with

the compressor running.

Caution:

Too little superheating during the charging

process can cause liquid hammer in the

compressor.

Charging must be continued until no vapour

formation appears in the sight glass - unless

vapour formation is due to other faults, see the

section “Trouble shooting - Fault location”.

If the necessary quantity of refrigerant is not

known, use the method last described.

Here however, it is necessary the whole time

to check that the condensing pressure and

suction pressure remain normal and that the

Thermostatic expansion valve superheat is not

too low.

Ac0_0033

Ac0_0034

Practical tips

© Danfoss A/S (AC-DSL/MWA), 10 - 2006 DKRCC.PF.000.G1.02 / 520H1459 143

Page 20

Fitters notes Practical Tips - The installation process

Condensing pressure too high

Setting and testing safety

equipment

Conditions

Too high a condensing pressure during the

charging process can mean that the system has

been overcharged with refrigerant and must be

partly drained.

Always use the recycling unit if it becomes

necessary to drain o refrigerant.

Ac0_0035

Final setting and testing of safety equipment

must be performed with all mechanical and

electrical equipment installed and the system

running.

The functions must be checked with accurate

instruments. See also the chapter “Trouble

Shooting” , section “Measuring Instruments“

with reference to the instructions for the equipment concerned.

Setting and testing

regulation equipment

Procedure

Setting the high-pressure control

Setting the low-pressure control

Ac0_0039

If a constant-pressure valve is installed, make a

coarse setting.

Set the expansion valve superheat.

Using a pressure gauge, set the constant

pressure valve.

Set the capacity regulator, if installed.

Set the thermostats (using a thermometer).

Ac0_0062

Increase the condensing pressure to

permissible maximum and use a pressure

gauge to set the high-pressure control.

Reduce the suction pressure to the

permissible minimum and use a pressure

gauge to set the low-pressure control.

Attention:

When making the above settings,

constantly check whether the system

Ac0_0045

is operating normally (pressure, etc.).

Finally - ensure that correct refrigerant identi-

cation labels are axed to the system in order

that correct future servicing is ensured.

144 DKRCC.PF.000.G1.02 / 520H1459 © Danfoss A/S (AC-DSL/MWA), 10 - 2006

Loading...

Loading...