Page 1

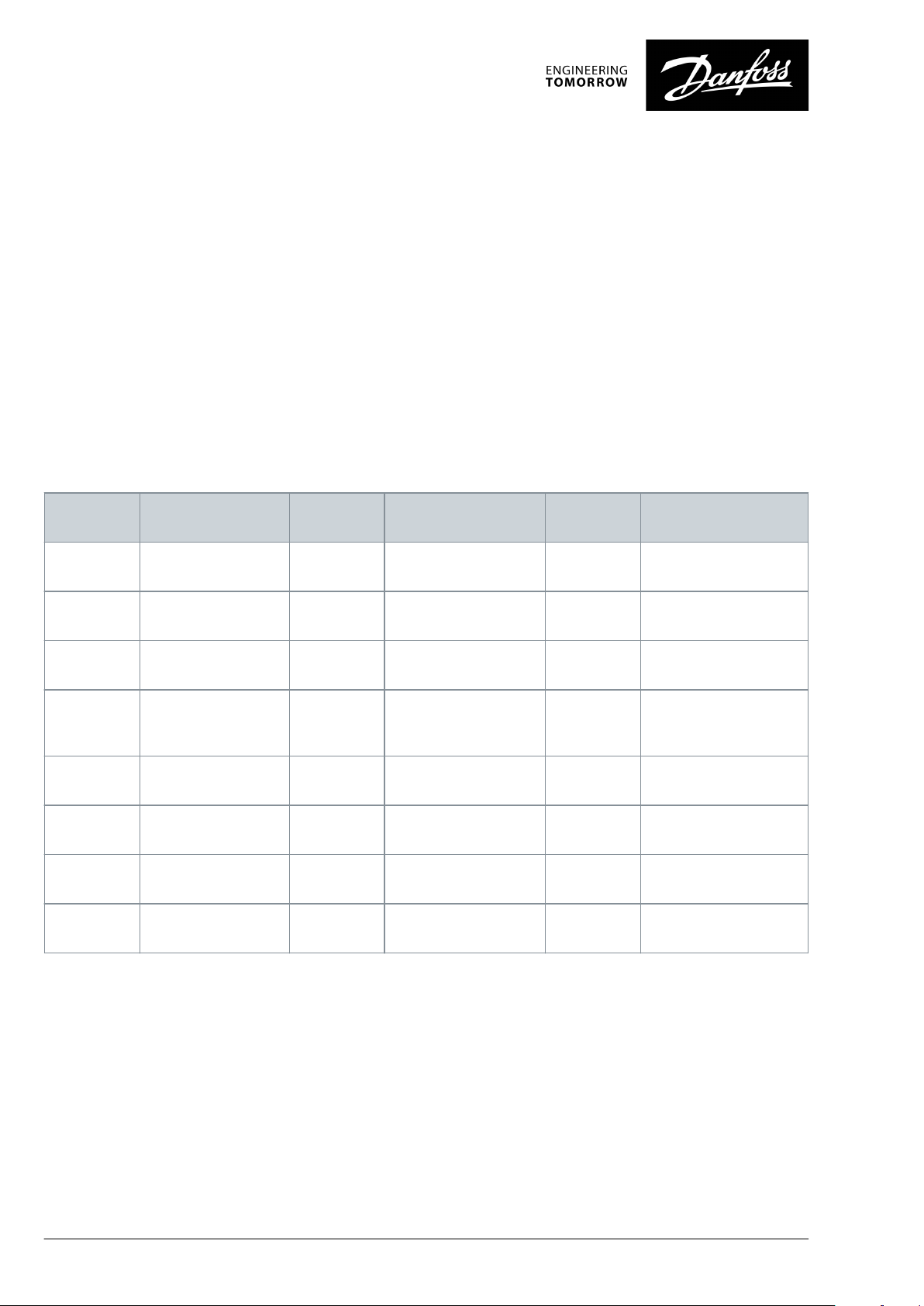

Kit code

number

Kit description

Kit code

number

Kit description

Kit code

number

Kit description

130B1901

Power card, 5.5 kW,

200 V

130B1942

Power card, 18 kW, 500 V

130B1981

Power card, 15 kW, 400 V,

H5 lter

130B1902

Power card, 7.5 kW,

200 V

130B1960

Power card, 11 kW, 600 V

130B1982

Power card, 18 kW, 400 V,

H5 lter

130B1903

Power card, 11 kW,

200 V

130B1961

Power card, 15 kW, 600 V

130B1985

Power card, 15 kW, 500 V,

H5 lter

130B1915

Power card, 11 kW,

400 V FC 102/FC 202

B3

130B1962

Power card, 18 kW, 600 V

130B1986

Power card, 18 kW, 500 V,

H5 lter

130B1920

Power card, 11 kW,

400 V B3

130B1975

Power card, 5.5 kW,

200 V, H5 lter

130B1989

Power card, 11 kW, 600 V,

H5 lter

130B1921

Power card, 15 kW,

400 V

130B1976

Power card, 7.5 kW,

200 V, H5 lter

130B1990

Power card, 15 kW, 600 V,

H5 lter

130B1922

Power card, 18 kW,

400 V

130B1977

Power card, 11 kW, 200 V,

H5 lter

130B1992

Power card, 18 kW, 600 V,

H5 lter

130B1941

Power card, 15 kW,

500 V

130B1980

Power card, 11 kW, 400 V,

H5 lter

–

–

Installation Guide

Power Card Kit for Enclosure Size B3

1 Introduction

1.1 Description

This Installation Guide explains how to mount the extra foil required when replacing the power card in a B3-enclosure drive produced before 02/03/2020.

The extra foil is requried to attain electrical safety insulation from heat sink to pulse transformer.

1.2 Kit Code Numbers

Table 1: Code Numbers

AN345033032751en-000101 / 130R0938 | 1Danfoss A/S © 2020.09

Page 2

Voltage [V]

Minimum waiting time (minutes)

47152030

40

[kW (hp)]

200–240

1.1–3.7 (1.50–5)

–

5.5–45 (7.5–60)

–––

380–480

1.1–7.5 (1.50–10)

–

11–90 (15–121)

–

–

315–1000 (450–

1350)

400––

–

90–315 (121–450)

––500––

–

110–355 (150–500)

––525––

–

75–315 (100–450)

––525–600

1.1–7.5 (1.50–10)

–

11–90 (15–121)

–––

690––

–

90–315 (100– 350)

–

–

525–690

–

1.1–7.5 (1.50–

10)

11–90 (15–121)

–

400–1400 (500–

1550)

450–1400 (600–

1550)

–

Voltage [V]

Minimum waiting time (minutes)

47152040

Power Card Kit for Enclosure Size B3

Installation Guide

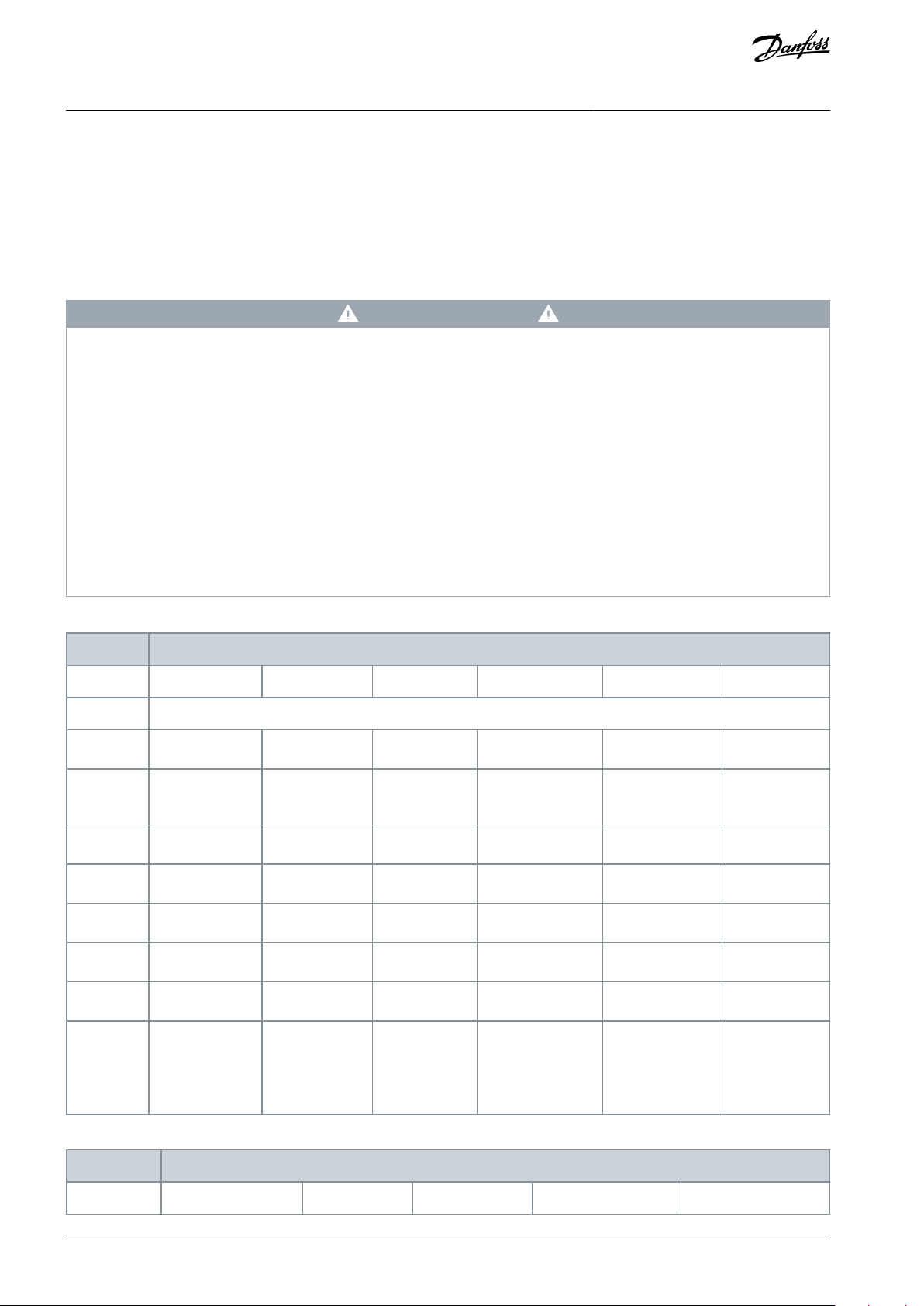

Safety Instructions

2 Safety Instructions

2.1 Qualied Personnel

Only qualied personnel are allowed to install the parts described in this Installation Guide. Make sure to read and save this guide.

2.2 Safety Precautions

Only Danfoss authorized, qualied personnel is allowed to repair this equipment.

W A R N I N G

DISCHARGE TIME

The drive contains DC-link capacitors, which can remain charged even when the drive is not powered. High voltage can be

present even when the warning indicator lights are o.

Failure to wait the specied time after power has been removed before performing service or repair work could result in death or

serious injury.

Stop the motor.

-

Disconnect AC mains, permanent magnet type motors, and remote DC-link supplies, including battery back-ups, UPS, and

-

DC-link connections to other drives.

Wait for the capacitors to discharge fully. The minimum waiting time is specied in the table Discharge time and is also visible

-

on the nameplate on top of the drive.

Before performing any service or repair work, use an appropriate voltage measuring device to make sure that the capacitors

-

are fully discharged.

Table 2: Discharge Time, VLT® HVAC Drive FC 102

Table 3: Discharge Time, VLT® Refrigeration Drive FC 103

AN345033032751en-000101 / 130R09382 | Danfoss A/S © 2020.09

Page 3

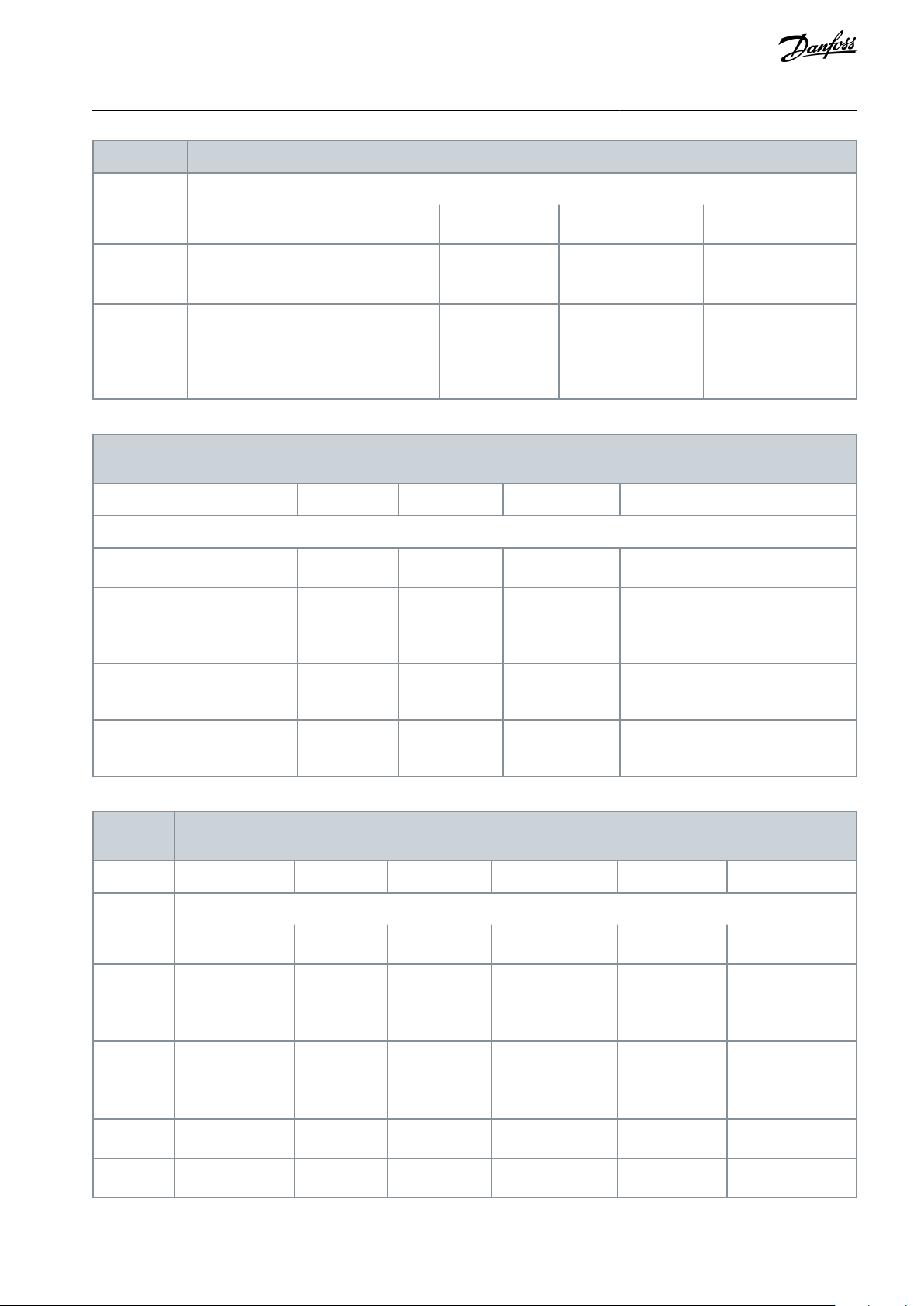

Voltage [V]

Minimum waiting time (minutes)

[kW (hp)]

200–240

0.25–3.7 (0.34–5.0)

–

5.5–37 (7.5–50)

–

–

380–480

0.25–7.5 (0.34–10)

–

11–75 (15–100)

110–315 (150–450)

355–450 (500–600)

355–560 (500–750)

525–600

0.75–7.5 (1.0–10)

–

11–75 (15–100)

–

–

525–690

–

1.5–7.5 (2–10)

11–75 (15–100)

55–400 (75–550)

450–630 (600–750)

450–800 (600–1075)

Voltage

[V]

Minimum waiting time (minutes)

47152030

40

[kW (hp)]

200–240

0.25–3.7 (0.34–5.0)

–

5.5–37 (7.5–50)

–––

380–480

0.25–7.5 (0.34–10)

–

11–75 (15–100)

110–315 (150–

450)

–

315–1000 (450–

1350)

355–560 (500–750)

525–600

0.75–7.5 (1–10)

–

11–90 (15–121)

–

400–1400

(550–1550)

–

525–690

–

1.1–7.5 (1.5–

10)

11–90 (10–125)

75–400 (100–

550)

–

450–800 (600–

1075)

Voltage

[V]

Minimum waiting time (minutes)

47152030

40

[kW (hp)]

200–240

0.25–3.7 (0.34–5)

–

5.5–37 (7.5–50)

–––

380–500

0.25–7.5 (0.34–10)

–

11–75 (15–100)

90–200 (150–350)

250–500 (450–

750)

250–800 (450–

1350)

315–500 (500–750)

400––

–

90–315 (125–450)

––500––

–

110–355 (150–450)

––525––

–

55–315 (75–400)

––525–600

0.75–7.5 (1–10)

–

11–75 (15–100)

–––

Power Card Kit for Enclosure Size B3

Installation Guide

Table 4: Discharge Time, VLT® AQUA Drive FC 202

Safety Instructions

Table 5: Discharge Time, VLT® AutomationDrive FC 301/FC 302

AN345033032751en-000101 / 130R0938 | 3Danfoss A/S © 2020.09

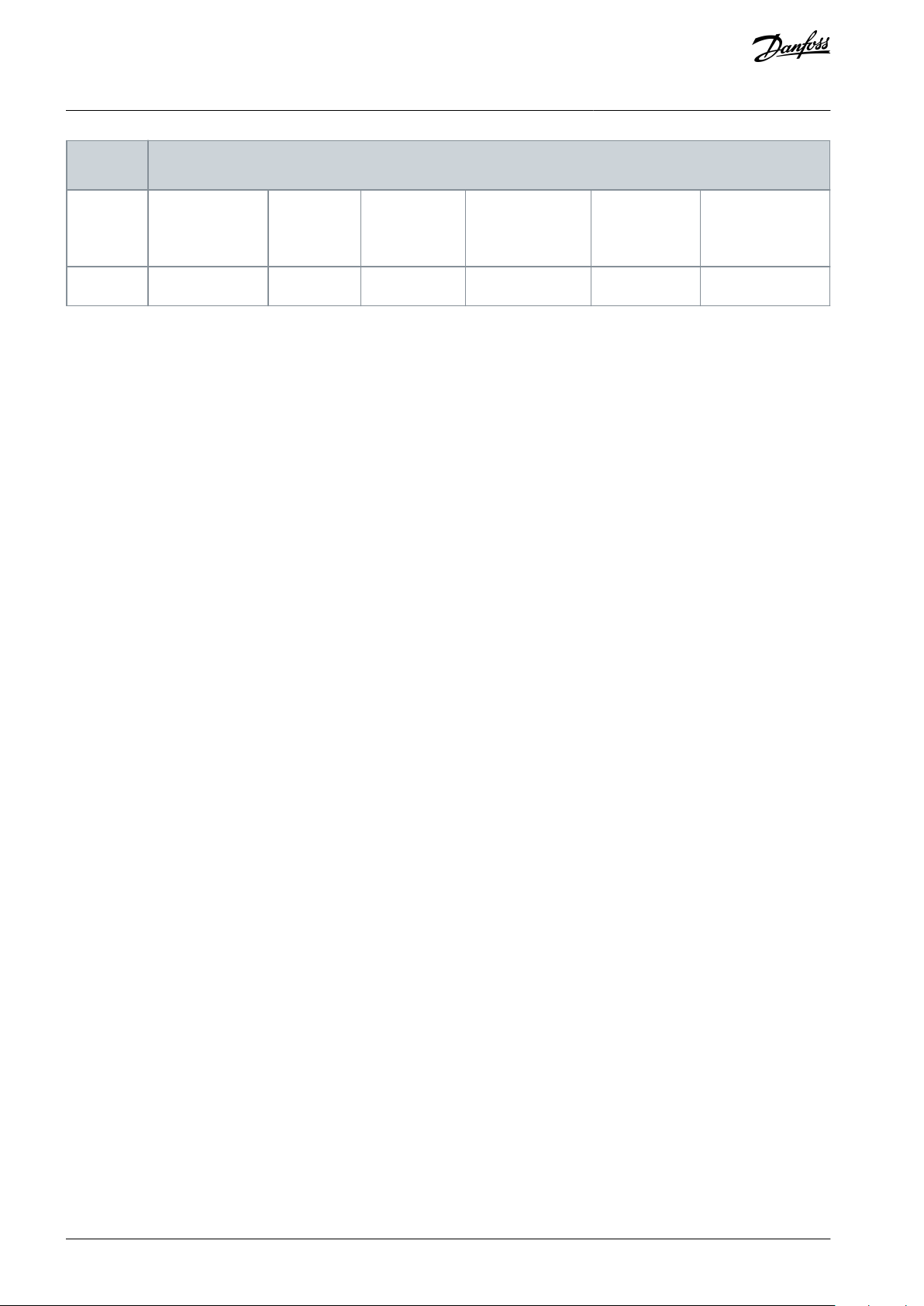

Page 4

Voltage

[V]

Minimum waiting time (minutes)

525–690

–

1.5–7.5 (2–

10)

11–75 (15–100)

37–315 (50–450)

355–1200 (450–

1550)

355–2000 (450–

2050)

355–710 (400–950)

690––

–

55–315 (75–400)

–

–

Power Card Kit for Enclosure Size B3

Installation Guide

Safety Instructions

AN345033032751en-000101 / 130R09384 | Danfoss A/S © 2020.09

Page 5

e30bi299.10

e30bi280.10

1

e30bi283.10

Power Card Kit for Enclosure Size B3

Installation Guide

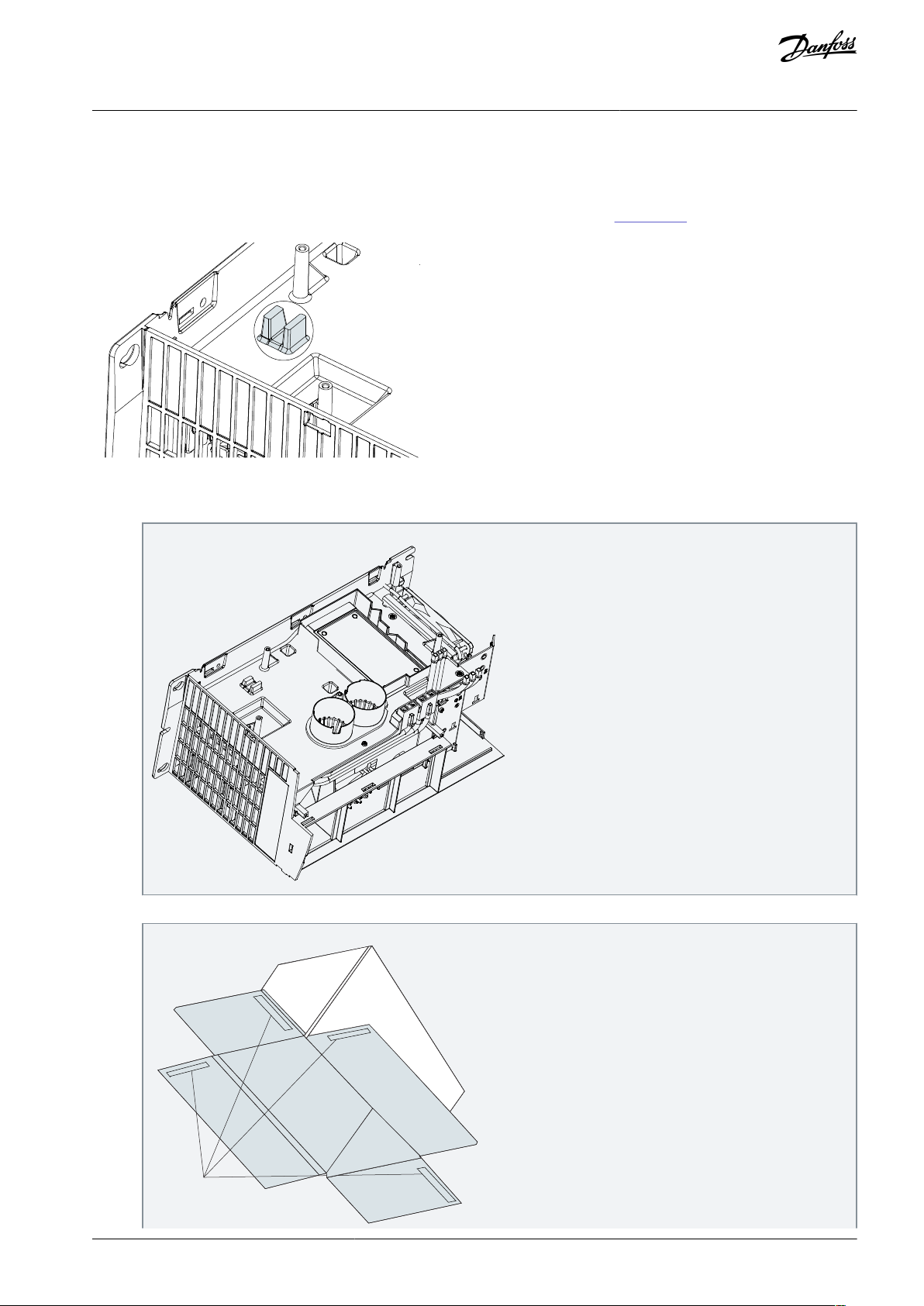

3 Installation

3.1 Mounting the Foil

The foil with code number 134B7292 is only to be mounted when the heat sink looks as in Illustration 1.

Procedure

1.

Disassemble the power card.

Installation

2.

Remove the peel-o sheet from the double-sided tape of the foil.

AN345033032751en-000101 / 130R0938 | 5Danfoss A/S © 2020.09

Page 6

1

Double-sided tape

1

e30bi284.10

1

Foil mounted correctly

e30bi282.10

Power Card Kit for Enclosure Size B3

Installation Guide

3.

Fix the foil on top of the heat sink, over the 2 anges

4.

Mount the new power card.

Installation

, and make sure that the foil sticks rmly to the heat sink.

Danfoss A/S

Ulsnaes 1

-6300 Graasten

DK

vlt-drives.danfoss.com

Danfoss can accept no responsibility for possible errors in catalogs, brochures and other printed material. Danfoss reserves the right to alter its products without notice.

his also applies to products already on order provided that such alterations can be made without subsequential changes being necessary in specications already

T

agreed. All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

*130R0938*

AN345033032751en-000101 / 130R09386 | Danfoss A/S © 2020.09

*M0023701*

Loading...

Loading...