Page 1

Installation Guide

Danfoss

148F105

148F105

Compressor overflow valve

POV

Installation

148R9525

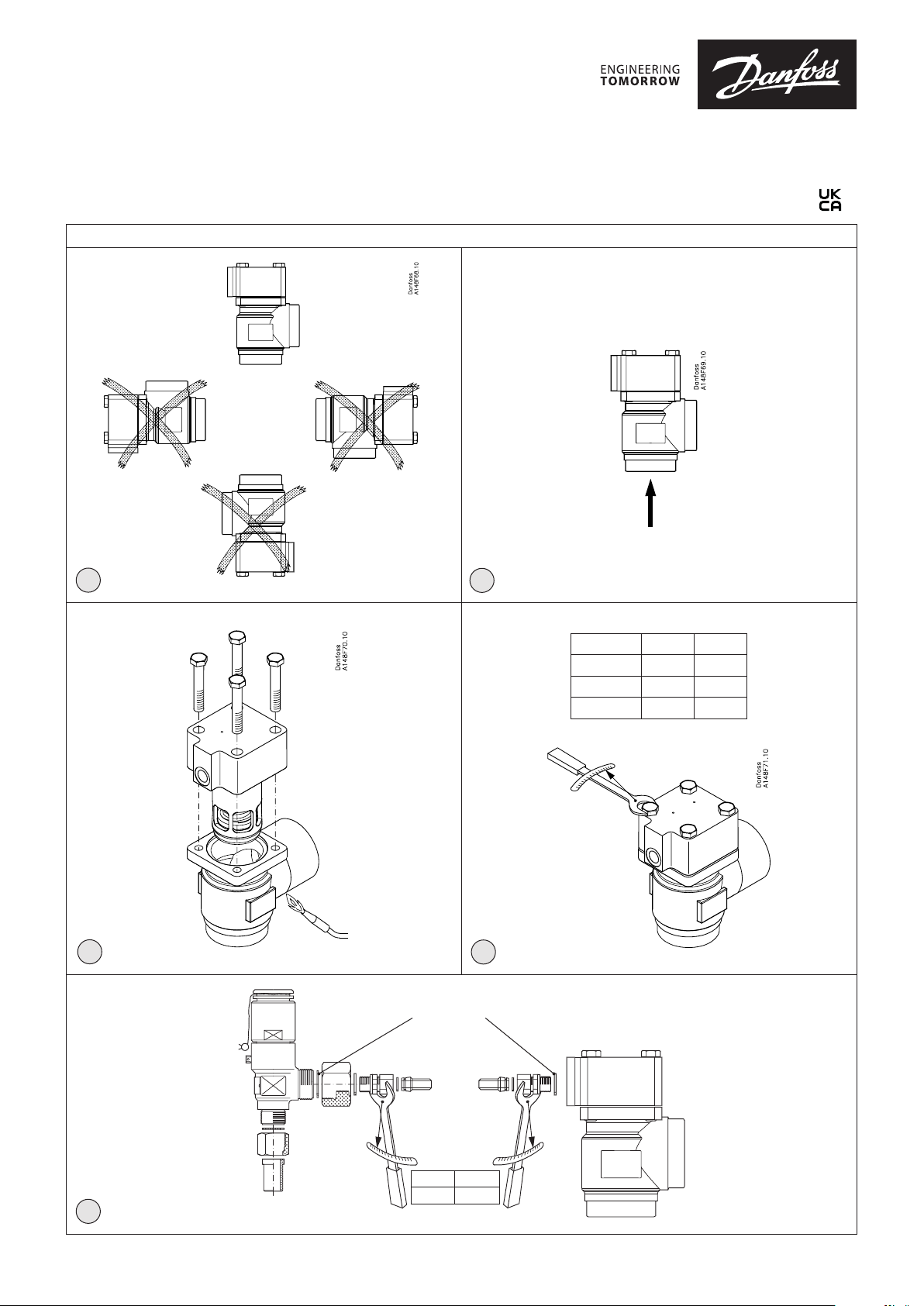

1

2

Nm LB-feet

POV 600 44 32

POV 1050 75 53

POV 2150 44 32

148R9525

3

5

© Danfoss | DCS (hhr) | 2021.01

Alu washer

Nm LB-feet

35 26

4

Danfoss

Info for UK customers only:Danfoss Ltd. Oxford Road, UB9 4LH Denham, UK

AN14978643320301-00701 | 1

Page 2

ENGLISH

Installation

Note!

Valve type POV is categorized as

a compressor overflow accessory

(not as a safety accessory). Hence

a safety valve (e.g. SFV) has to be

installed to protect the system

against excessive pressure.

Refrigerants

Applicable to HCFC, HFC, R717 (Ammonia)

and R744 (CO₂).

Flammable hydrocarbons are not

recommended. The valve is only

recommended for use in closed circuits. For

further information please contact Danfoss.

Temperature range

POV: -50/+150 °C (-58/+302 °F)

Pressure range

The valves are designed for a max. working

pressure of 40 barg (580 psig).

Only materials and welding methods

compatible with the valve housing material

must be applied. The valve should be

cleaned internally to remove welding

debris on completion of welding and

before the valve is reassembled.

Avoid welding debris and dirt in the

threads of the housing and the top.

Removing the top can be omitted provided

that:

The temperature in the area between the

valve body and top as well as in the area

between the seat and the teflon cone

during welding does not exceed

+150 °C/+302 °F. This temperature depends

on the welding method as well as on

any cooling of the valve body during the

welding itself (cooling can be ensured by,

for example, wrapping a wet cloth around

the valve body). Make sure that no dirt,

welding debris etc. get into the valve

during the welding procedure.

Be careful not to damage the teflon cone

ring.

Installation

The POV valve is used in conjunction with

the BSV back pressure independent safety

relief valve and is specifically designed for

protecting compressors against excessive

pressure (fig. 5).

See technical leaflet for further installation

instructions.

The valve should be installed with the

spring housing upwards (fig. 1). By

mounting of the valve it is important to

avoid the influence of thermic and dynamic

stress (vibrations).

The valve is designed to withstand a high

internal pressure. However, the piping

system should be designed to avoid liquid

traps and reduce the risk of hydraulic

pressure caused by thermal expansion. It

must be ensured that the valve is protected

from pressure transients like “liquid

hammer” in the system.

Recommended flow direction

The valve should be installed with the flow

towards the valve cone as indicated by the

arrow on fig. 2.

Flow in the opposite direction is not

acceptable.

Welding

The top should be removed before welding

(fig. 3) to prevent damage to the O-rings

between the valve body and top, as well as

the teflon gasket in the valve seat. Do not

use high-speed tools for dismantling and

reassembling. Be sure that grease on bolts

is intact before reassembling.

The valve housing must be free from

stresses (external loads) after installation.

Assembly

Remove welding debris and any dirt from

pipes and valve body before assembly.

Tightening

Tighten the top with a torque wrench to

the values indicated in the table (fig. 4). Do

not use high-speed tools for dismantling

and reassembling. Be sure that grease on

bolts is intact before reassembling.

Colours and identification

Precise identification of the valve is made

via the ID label on the top, as well as by the

stamping on the valve body. The external

surface of the valve housing must be

prevented against corrosion with a suitable

protective coating after installation and

assembly.

Protection of the ID label when painting

the valve is recommended.

In cases of doubt, please contact Danfoss.

Danfoss accepts no responsibility for

errors and omissions. Danfoss Industrial

Refrigeration reserves the right to make

changes to products and specifications

without prior notice.

2 | AN14978643320301-000701

© Danfoss | DCS (hhr) | 2021.01

Page 3

FRANÇAIS

Installation

Remarque!

La vanne de type POV est

considérée comme un accessoire

de décharge du compresseur

(et non comme un accessoire

de sécurité). Une soupape de

sécurité (par exemple SFV) doit

être installé pour protéger le

système contre une pression

excessive.

Fluides frigorigènes

La vanne est utilisable avec les fluides

frigorigènes HCFC, HFC, R717 (ammoniac)

et R744 (CO₂).

Une utilisation avec des hydrocarbures

inflammables est déconseillée. Cette

vanne est préconisée uniquement pour les

circuits fermés. Merci de contacter Danfoss

pour de plus amples informations.

Plage de température

POV : -50/+150 °C (-58/+302 °F)

Plage de pression

Les vannes sont conçues pour une pression

max. de service de 40 barg (580 psig).

Installation

La vanne POV est utilisée avec la vanne

de sécurité indépendante de la contrepression BSV. Elle est spécifiquement

conçue pour protéger les compresseurs de

tout excès de pression (fig. 5).

Voir la fiche technique pour plus

d'instructions d'installation.

Installer la vanne de sorte que le boîtier du

ressort soit orienté vers le haut (fig. 1). Lors

du montage de la vanne, il est important

d’éviter les contraintes thermiques et

dynamiques (vibrations).

Cette vanne est conçue pour supporter

une pression interne élevée. Toutefois, la

tuyauterie doit être conçue pour éviter

les pièges à liquide et réduire le risque

de pression hydraulique causée par la

dilatation thermique. Veiller à ce que la

vanne soit protégée des variations de

pression au sein du système comme les

coups de bélier.

Soudage

Retirer le chapeau avant de souder (fig.

3) afin de ne pas endommager les joints

toriques entre le corps de vanne et le

chapeau, ainsi que le joint en téflon du

siège de vanne.

Ne pas utiliser d’outils à grande vitesse

pour le démontage et le montage.

S’assurer que les boulons sont bien graissés

avant de procéder au montage. Seuls des

matériaux et des méthodes de soudage

compatibles avec le matériau du boîtier de

la vanne doivent être utilisés. L’intérieur de

la vanne doit être nettoyé pour éliminer les

débris de soudage une fois le soudage

effectué et avant le montage de la vanne.

Éviter que des débris de soudage et des

salissures ne pénètrent dans les filetages

du boîtier et le chapeau.

Le chapeau peut rester en place

uniquement si :

Pendant le soudage, la température dans

la zone comprise entre le corps de vanne

et le chapeau, ainsi que dans la zone située

entre le siège et le cône en téflon n’excède

pas +150 °C/+302 °F. Cette température est

fonction de la méthode de soudage ainsi

que du refroidissement du corps de vanne

pendant le soudage (le refroidissement

peut être réalisé, par exemple, en

enveloppant le corps de vanne d’un

chiffon humide). Veiller à ce qu’aucune

salissure, aucun débris de soudage, etc. ne

s’introduisent dans la vanne pendant le

soudage.

Veiller à ne pas endommager la bague du

cône en téflon.

Aucune contrainte (charges externes) ne

doit être exercée sur le boîtier de la vanne

après l’installation.

Montage

Éliminer les débris de soudage et les

salissures des conduites et du corps de

vanne avant de procéder au montage.

Serrage

Serrer le couvercle avec une clé

dynamométrique en respectant les valeurs

prescrites dans le tableau (fig. 4). Ne pas

utiliser d’outils à grande vitesse pour le

démontage et le montage. S’assurer que

les boulons sont bien graissés avant de

procéder au montage.

l’aide d’un revêtement adéquat à l’issue de

l’installation et du montage.

Il est préconisé de protéger l’étiquette

d’identification lors de l’application de la

peinture sur la vanne.

En cas de doute, merci de contacter

Danfoss.

Danfoss décline toute responsabilité quant

aux éventuelles erreurs et omissions. La

société Danfoss Industrial Refrigeration se

réserve le droit de modifier les produits et

spécifications sans préavis.

Sens du débit recommandé

La vanne doit être installée avec le débit en

direction du cône de vanne, comme illustré

par la flèche à la fig. 2.

Un débit dans le sens opposé n’est pas

admis.

© Danfoss | DCS (hhr) | 2021.01

Couleurs et identification

La référence précise de la vanne figure sur

l’étiquette d’identification sur le dessus du

chapeau et sur l’estampillage du corps de

vanne. La surface extérieure du boîtier du

flotteur doit être protégée de la corrosion à

AN14978643320301-00701 | 3

Page 4

© Danfoss | DCS (hhr) | 2021.01

AN14978643320301-00701 | 4

Loading...

Loading...