Page 1

Data Sheet

Compressor overflow valve

Type POV

Designed for protecting compressors against excessive pressure

The POV compressor overow valve is used in

conjunction with the BSV safety relief valve and

is specically designed for protecting

compressors against excessive pressure.

Features

• Applicable for the refrigerants HCFC, HFC,

• The Pilot Operated Internal compressor

• POV + BSV is an internal compressor overow

• The system renders full protection of the

• The POV compressor overow valve (main

• Small dimensions mean easy handling and

• Classication: DNV, CRN, BV, EAC etc. To get

R717 (Ammonia), R744 (CO2).

overow valve System POV + BSV is available

in sizes from DN 40 to DN 80.

system thus eliminating the risk of refrigerant

leakage to the atmosphere.

compressor even on increasing back pressure.

valve) has a very large capacity even with

high back pressure when compared to direct

operating back pressure independent

pressure relief valves.

installation.

an updated list of certication on the

products please contact your local Danfoss

Sales Company.

AI183186419402en-001101

Page 2

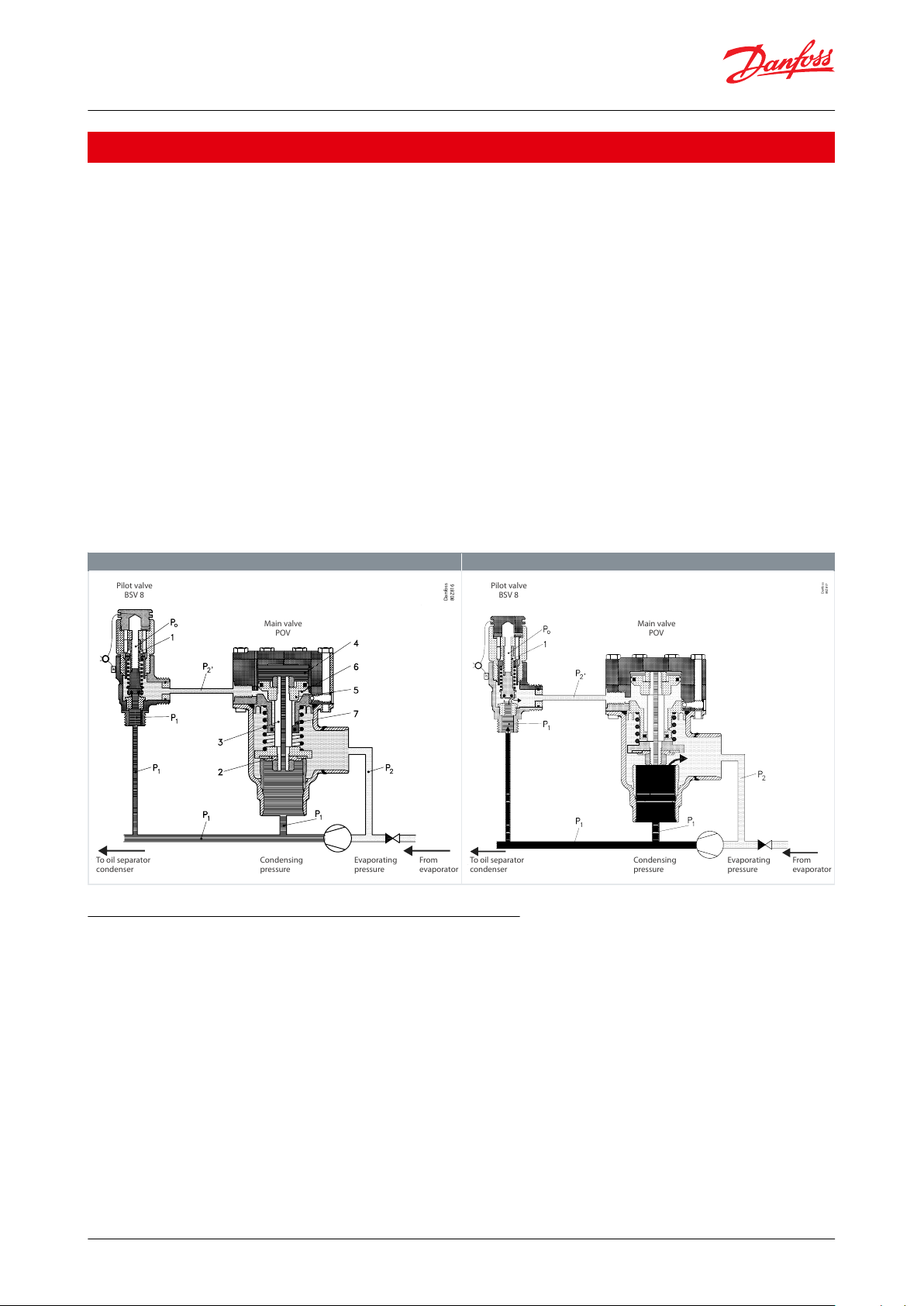

g. 1, Inactive system (closed valve)

g. 2, Active system (open valve)

Pilot valve

BSV 8

Main valve

POV

From

evaporator

To oil separator

condenser

Condensing

pressure

Evaporating

pressure

Danfoss

80Z816

Pilot valve

BSV 8

Main valve

POV

From

evaporator

To oil separator

condenser

Condensing

pressure

Evaporating

pressure

Danfoss

80Z817

Compressor overow valve, Type POV

Function

Pilot valve BSV 8

The pilot valve is actuated by the high pressure P1 and the back pressure P2”. The reference pressure in the stainless

steel bellow (1) P0 is the atmospheric pressure. The eective area of the bellows is equivalent to the area of the valve

seating, so the back pressure P2” does not aect the opening pressure of the valve.

Main valve POV

The main valve is of the normally closed (N.C.) type. The high pressure P1 acts on the valve inlet side of the valve

cone (2). P1 pressure also passes through the piston rod (3) to the upper chamber (4) of the valve, acting on the top

of the piston (5). The area of the piston is larger than the area of the valve seat and this together with the spring

pressure keeps the valve closed.

System BSV 8 + POV

When the pressure P1 reaches the set pressure of the pilot valve, it starts opening. The pressure of the pilot line P2”

and of the lower chamber (6) of the main valve increases. The pressure of the lower chamber is limited by ow

through the nozzle (7). When the ow through the pilot valve exceeds the capacity of the nozzle, the pressure of the

chamber (6) increases, providing the opening of the main valve. When the pressure P1 is reduced, the pilot valve

closes, and the pressure P2” is equalized through the nozzle (7). The spring then closes the main valve. The closing

time is ≤30 seconds.

Table 1: Function

Installation of compressor overow valve POV + BSV

Set pressure

The BSV 8 set pressure is factory set in the range 15 ‑ 25 bar(g) (145 ‑ 363 psig), where 15 bar(g) is the minimum

value for this application Figure 6: Capacity - POV 600.

Standard set pressures

18.0, 21.0, or 25.0 bar(g) (261, 305 or 363 psig). The operational pressure of the plant should be at least 15% below

the set pressure of the pilot valve, and the opening pressure of the pilot valve (pset + 10%) must be below the

reseating pressure of the safety valve protecting the plant. This implies a perfect operation of the plant.

Back pressure

P

is the eective back pressure of the POV main valve P

2-0

outlet line of POV (2).

P

Is normally equal to the evaporating pressure.

2-1

P

must not exceed the limits in Figure 6: Capacity - POV 600.

2-0

Pressure loss in inlet line

© Danfoss | Climate Solutions | 2021.02 AI183186419402en-001101 | 2

= P

2-0

2-1

+ ∆P

where ∆Poutlet is the pressure loss in the

outlet

Page 3

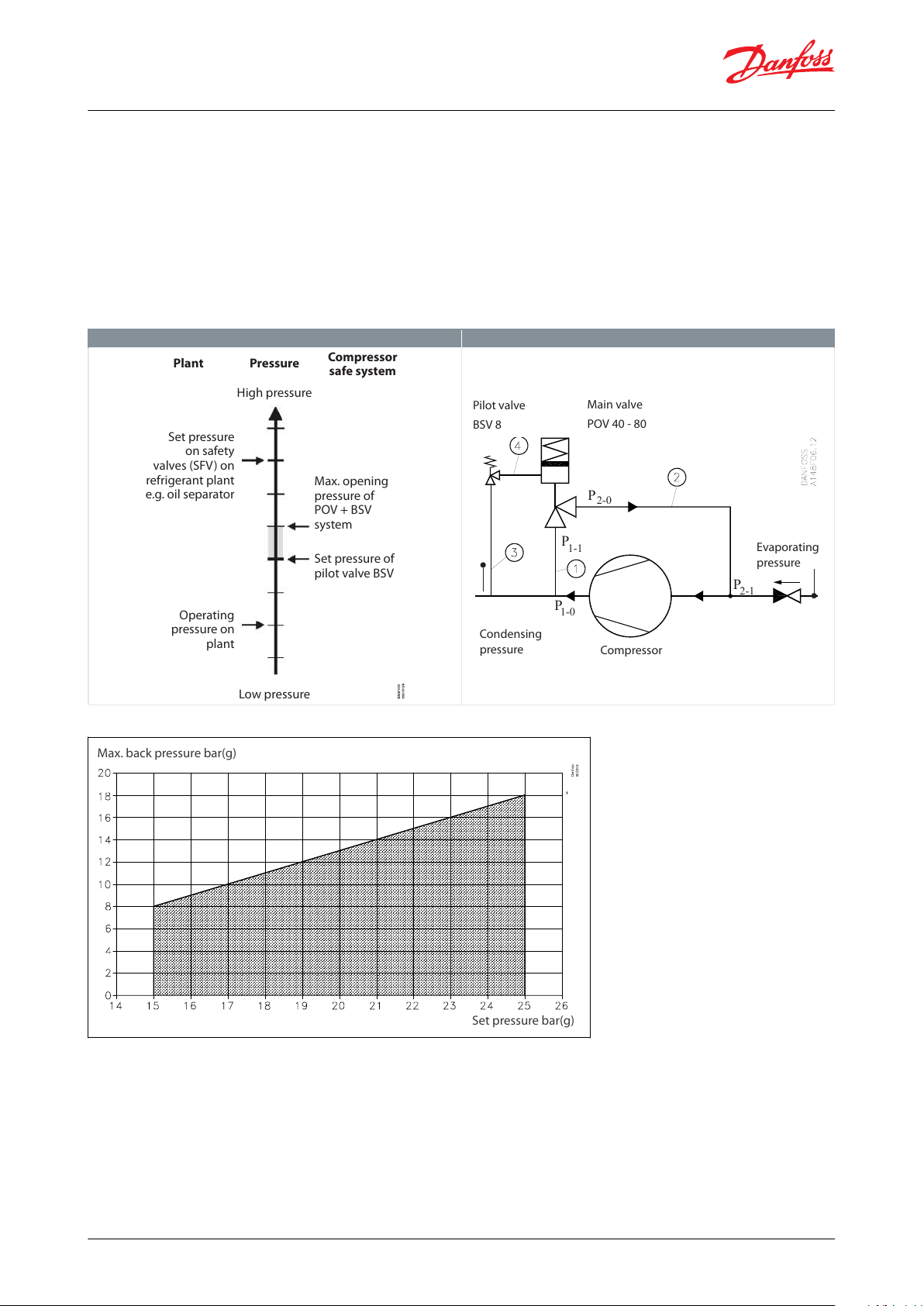

POV + BSV system

Flow diagram

Plant Pressure

Compressor

safe system

Set pressure of

pilot valve BSV

Operating

pressure on

plant

Set pressure

on safety

valves (SFV) on

refrigerant plant

e.g. oil separator

Max. opening

pressure of

POV + BSV

system

High pressure

Low pressure

Figure 1: 3

P

2-1

P

2-0

P

1-1

P

1-0

Pilot valve

BSV 8

Main valve

POV 40 - 80

Compressor

Evaporating

pressure

Condensing

pressure

Max. back pressure bar(g)

Set pressure bar(g)

Danfoss

80Z818

Compressor overow valve, Type POV

The pressure loss in the inlet line of the POV (1) will not aect the function of the POV + BSV system, but a high

pressure drop will reduce the capacity. If the pressure drop in the inlet line ΔP

exceed 3% of the opening

inlet

pressure, the capacity reduction must be taken into consideration by calculation.

Pressure drop in the pilot inlet line

In order to ensure a proper function of the POV + BSV system, the pilot valve must be activated by the plant

pressure. It is important that the inlet line of the pilot valve is mounted in a way which ensures that the pilot

pressure is identical with the plant pressure. If the pilot pressure is mounted in the inlet line of the POV valve, it must

be veried that the pressure drop in the pilot inlet line (3) ΔP

Table 2: Installation of compressor

does not exceed 3% of the opening pressure.

inlet

Figure 2: Fig. 4, range of application of BSV 8 ‑ POV

Important: When locating the inlet line to the pilot valve, it is important that the connection is mounted in the gas

phase and not in an oil phase, if any.

• Pressure drop in the pilot outlet line

• The pressure loss in the BSV outlet line (4) ∆P

• Minimum internal diameter of the pilot outlet line 8 mm (0.314 in.)

• Maximum length of pilot outlet line 1 m (3.25 ft)

© Danfoss | Climate Solutions | 2021.02 AI183186419402en-001101 | 3

is not critical.

P-outlet

Page 4

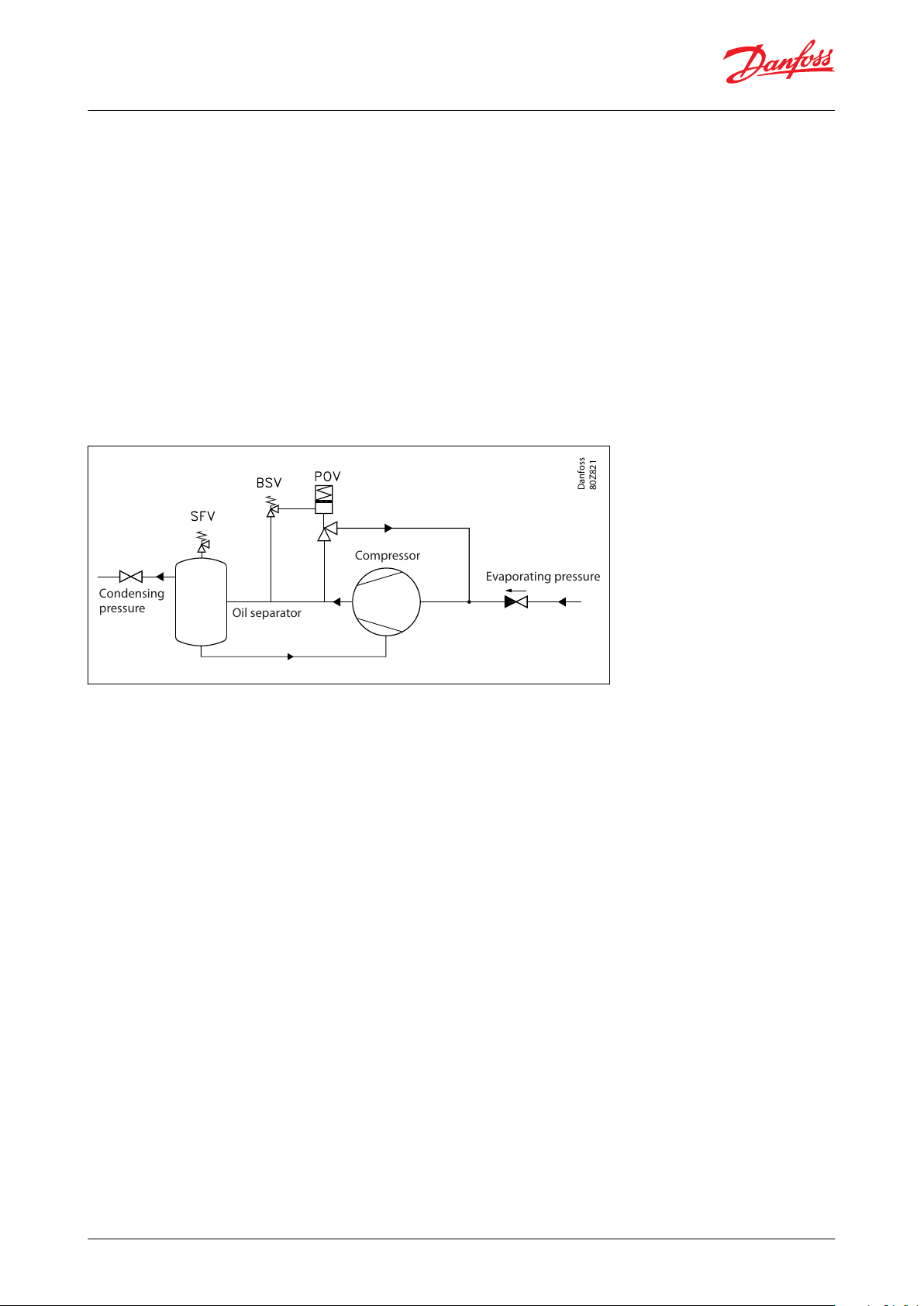

Evaporating pressure

Compressor

Condensing

pressure

Oil separator

Danfoss

80Z821

Compressor overow valve, Type POV

Note: The guidelines mentioned above are securing a safe function of the POV + BSV system, but there might be

restrictions from national authorities.

NOTE:

Valve type POV is categorized as a compressor overow accessory (not as a safety accessory). Hence a safety

valve (e.g. SFV) has to be installed to protect the system against excessive pressure.

Fig. 5 shows a typical application of the POV + BSV system. In the example a non return valve has been mounted in

the suction line, as well as a shut-o valve in the pressure line. It is good practise and a demand from the authorities

of most countries to mount a safety valve on the oil separator.

If the shut-o valve in the pressure line is closed, and aIl regulation equipment fails, the pressure after the

compressor will rise, and the BSV + POV system is activated. Provided that the required motor eect is present, there

will be a rise in temperature caused by the compression work, followed by a rise in pressure. Therefore, the safety

relief valve of the oil separator must, besides being dimensioned for “normal” heat input, also be dimensioned for

heat input, corresponding to the eect of the motor.

Figure 3: Installation of compressor overow valve POV + BSV

© Danfoss | Climate Solutions | 2021.02 AI183186419402en-001101 | 4

Page 5

Compressor overow valve, Type POV

Media

Refrigerants

Applicable for the refrigerants HCFC, HFC, R717 (Ammonia), R744 (CO2). Flammable hydrocarbons are not

recommended. For further information please contact your local Danfoss Sales Company

New refrigerants

Danfoss products are continually evaluated for use with new refrigerants depending on market requirements.

When a refrigerant is approved for use by Danfoss, it is added to the relevant portfolio, and the R number of the

refrigerant (e.g. R513A) will be added to the technical data of the code number. Therefore, products for specic

refrigerants are best checked at store.danfoss.com/en/, or by contacting your local Danfoss representative.

© Danfoss | Climate Solutions | 2021.02 AI183186419402en-001101 | 5

Page 6

Features

Description

Pressure setting range

15 - 25 bar(g) (218 ‑ 363 psig)

Strength test

50 bar(g) (725 psig)

Leakage test

25 bar(g) (363 psig)

PB/MWP

40 bar (580 psig)

Temperature range

–50/+150 °C (–58/+302 °F)

ø

Compressor overow valve, Type POV

Product specication

Pressure and temperature data

Table 3: Pressure and temperature data

Design

Control/Identication

All pilot valves (BSV 8 Safety Relief Valves) are adjusted, tested and sealed before leaving Danfoss A/S. For that

reason Danfoss can only guarantee correct operation, as long as the seal remains unbroken.

Transport/Handling

POV and BSV are supplied separately from Danfoss. BSV safety valves are tted with special protection covers and

packed in purpose made cartons. POV valves are provided with protection covers. It is important that the protective

covers remain tted until the valve is installed. To ensure the exact and precise operation of the valve it must be

handled with care.

Re-calibration/servicing

In certain countries the authorities demand that the valves are readjusted at least once a year (see local rules).

Capacity

The design and construction of the compressor overow valve has been tested and approved by TÜV. This test

comprises control of the function of the valve as well as measuring of the capacity, which is the basis of the curves

and tables on the following pages.

Installations

To ensure exact operation of the valve it should be installed with the spring housing upwards (refer to "Installation

of compressor overow valve POV + BSV" on the following pages).

When the valve is mounted, it is important to avoid the inuence of static, dynamic and thermal stress.

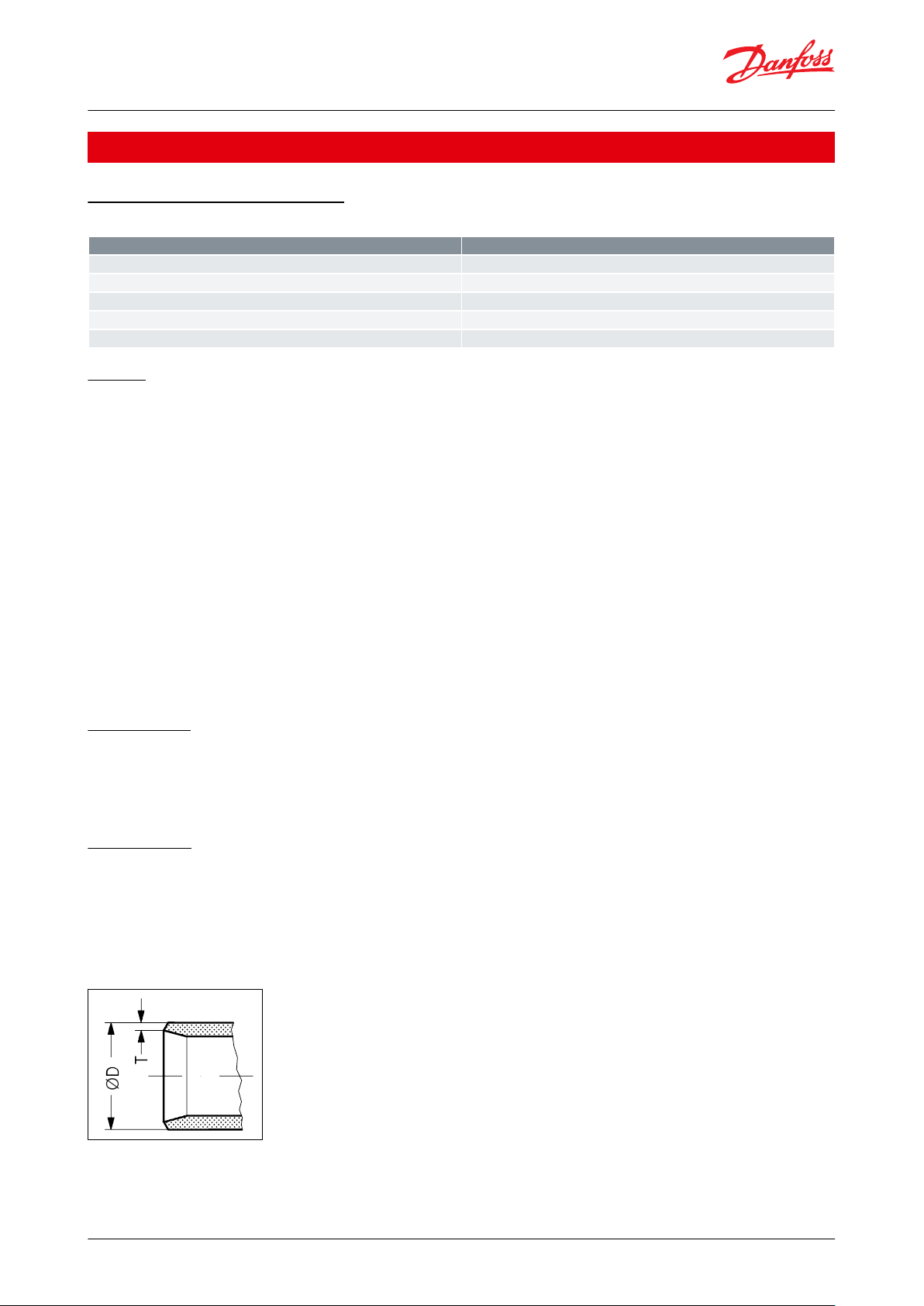

Connections

Available with the following connections:

• Welding DIN (2448)

• Welding ANSI (B 36.10):

◦ DN 40, Schedule 80

◦ DN 65 - 80, Schedule 40

Figure 4: DIN

© Danfoss | Climate Solutions | 2021.02 AI183186419402en-001101 | 6

Page 7

Version

Size

SizeøDTøDTmmin.mmmm

in.

in.

POV 600401

1

⁄2

48.3

2.6

1.902

0.103

POV 1050652

1

⁄2

76.1

2.930.11

POV 2150803

88.9

3.2

3.5

0.13

Version

Size

SizeøDTøDT

Schedule

mm

in.mmmm

in.

in.

POV 600401

1

⁄2

48.3

5.1

1.902

0.201

Schedule 80

POV 1050652

1

⁄2

73

5.2

2.87

0.2

Schedule 40

POV 2150803

88.9

5.5

3.5

0.22

Schedule 40

Version

Nominal size

Flow diameter

Flow area

De-rated,

certied coef‐

ficient of discharge

Inlet

Outlet

d0A0K

dr

POV 600

40 mm

40 mm

32.6 mm

835 mm

2

0.735

1½ in.

1½ in.

1.28 in.

1.28 in

2

POV 1050

65 mm

65 mm

39.8 mm

1244 mm

2

0.859

2½ in.

2½ in.

1.56 in.

1.93 in

2

POV 2150

80 mm

80 mm

59 mm

2734 mm

2

0.799

3 in.

3 in.

2.32 in.

4.24 in

2

Compressor overow valve, Type POV

Table 4: Welding DIN (2448)

Figure 5: ANSI

Table 5: Welding ANSI (B 36.10)

Capacity

The values in the table are based on saturated gas and with 50K superheat. If other operating conditions have to be

taken into consideration, the formulas or the Danfoss computation program (Coolselector®2) can be used.

Table 6: Table 1

The discharge capacity of the compressor overow valves are based on (IS0 4126‑1/EN 1268‑1 / prEN 1313 6 (1998)).

qm = 0.2883 × C × A0 × Kdr × Kb ×

P

V

© Danfoss | Climate Solutions | 2021.02 AI183186419402en-001101 | 7

Page 8

q

m

C

A0K

dr

K

b

v

p

set

p

atm

P

Discharge capacity (kg/h)

Discharge function depending of the actual refrigerant (κ) see table 2 (‑)

Flow area of the compressor overow valve (mm2).

De-rated coecient of discharge (Kdr = Kd × 0.9), (the Kdr is certied by TÜV) see table 1. (‑)

Correction factor for sub‑critical ow. (-) Kb = 1.0 when the back pressure is lower than approx. 0.5 × relieving

pressure (Pb < 0.5 × p). For all BSV safety valves Kb = 1.0

Specic volume of the vapour. (m3/kg)

Set pressure, the predetermined pressure at which a compressor overow valve under operation starts to

open (pset is indicated on the metal plate on the safety relief valve). (bar gauge)

Atmospheric pressure. (1 bar)

Relieving pressure, p = pset × 1.1 + Patm (bar absolute)

Refrigerant number

Isentropic exponent

K

Discharge function

C

R 22

1.17

2.54

R 134a

1.12

2.50

R 404A

1.12

2.49

R 410A

1.17

2.54

R 717 (Ammonia)

1.31

2.64

R 744 (CO

2

)

1.30

2.63

Air

1.40

2.70

Compressor overow valve, Type POV

For further details see the above mentioned ISO or EN standards.

Important!

For back pressure higher than 0.5 × p, the Danfoss computer program (DIRcalc™) or the above mentioned standard

must be used when calculating the capacity.

Table 7: Table 2. Properties of Refrigerants

Figure 6: Capacity - POV 600

qm = 0.2883 × C × A0 × Kdr × Kb ×

P

V

© Danfoss | Climate Solutions | 2021.02 AI183186419402en-001101 | 8

Page 9

P

set

P

C

v

qmKbdoAoKdrSet pressure in bar(g)

Relieving pressure in bar(g)

Discharge function

Specic volume of the vapour at the relieving pressure P in m3/kg

Discharge capacity in kg/h

Correction factor for sub-critical ow

Flow diameter seat mm

2

Flow area seat in mm

2

De-rated coecient of discharge at dened lifting height

P

set

P

R22

q

m

R134a

q

m

R404a

q

m

R717

q

m

bar(g)

psig

bar(g)

psigvkg/h

lb/minvkg/h

lb/minvkg/h

lb/minvkg/h

lb/min1014512174

0.01974

11077

407

0.01655

11907

437

0.01629

11953

439

0.10753

4933

18111160

13.1

190

0.01797

12130

446

0.01502

13059

480

0.0147

13147

483

0.09867

5380

19812174

14.2

206

0.01638

13228

486

0.01383

14169

521

0.01346

14305

526

0.0913

5823

21413189

15.3

222

0.01514

14281

525

0.01273

15330

563

0.01233

15514

570

0.08461

6279

23114203

16.4

238

0.014

15376

565

0.01172

16475

605

0.01128

16793

617

0.079

6728

24715218

17.5

254

0.01311

16414

603

0.01094

17685

650

0.01048

17997

661

0.07383

7189

26416232

18.6

270

0.01229

17477

642

0.01007

19004

698

0.00973

19256

708

0.06998

7613

28017247

19.7

286

0.01152

18578

683

0.0094

20243

744

0.00902

20582

756

0.06636

8045

29618261

20.8

302

0.0108

19716

724

0.00888

21400

786

0.00842

21889

804

0.06213

8544

31419276

21.9

318

0.01012

20899

768

0.00828

22741

836

0.00786

23247

854

0.05898

8998

3312029023334

0.00961

21978

808

0.00775

24089

885

0.00738

24586

903

0.0562

9446

34721305

24.1

350

0.00908

23145

850

0.00727

25459

935

0.00688

26066

958

0.0535

9910

36422319

25.2

365

0.00861

24305

893

0.00685

26820

985

0.00645

27528

1011

0.05121

10358

38123334

26.3

381

0.0081

25599

941

0.00645

28235

1037

0.00606

29013

1066

0.049

10818

39724348

27.4

397

0.00768

26834

986

0.00606

29733

1092

0.00565

30670

1127

0.04687

11290

41525363

28.5

413

0.00738

27918

1026

0.00574

31158

1145

0.0053

32295

1187

0.04514

11733

43126377

29.6

429

0.00699

29235

1074

0.00541

32707

1202

0.00496

34022

1250

0.04348

12183

44827392

30.7

445

0.0067

30410

1117

0.00506

34442

1266

0.00463

35862

1318

0.0415

12700

46728406

31.8

461

0.00634

31817

1169

0.00479

36028

1324

0.00429

37918

1393

0.0401

13149

48329421

32.9

477

0.00607

33075

1215

0.00453

37683

1385

0.00401

39892

1466

0.0387

13615

5003043534493

0.00579

34426

1265

0.00422

39690

1458

0.00371

42161

1549

0.0373

14098

51831450

35.1

509

0.00552

35824

1316

0.00392

41842

1537

0.00339

44814

1647

0.03612

14556

53532464

36.2

525

0.00523

37376

1373

0.00365

44036

1618

0.003

48378

1778

0.03482

15056

55333479

37.3

541

0.00499

38841

1427

0.00337

46520

1709

0.00206

59262

2178

0.0337

15535

57134493

38.4

557

0.00475

40393

1484

0.00306

49534

1820

0.03276

15987

58735508

39.5

573

0.00452

41997

1543

0.00275

52994

1947

0.03158

16514

60736522

40.6

589

0.00428

43755

1608

0.00221

59933

2202

0.03083

16945

62337537

41.7

605

0.00408

45418

1669

0.02972

17491

64338551

42.8

621

0.00389

47124

1731

0.02901

17935

65939566

43.9

637

0.00365

49269

1810

0.02815

18440

6784058045653

0.00345

51308

1885

0.0274

18923

695

Compressor overow valve, Type POV

Table 8: Capacity - POV 600

© Danfoss | Climate Solutions | 2021.02 AI183186419402en-001101 | 9

Page 10

P

set

P

Air(20 °C)

q

m

R410a

q

m

R744

(CO2)

q

m

bar(g)

psig

bar(g)

psigvkg/h

lb/minvkg/h

lb/minvkg/h

lb/min1014512174

0.0679

6349

233

0.02213

10461

384

0.03196

9014

33111160

13.1

190

0.0622

6931

255

0.02022

11435

420

0.0293

9836

36112174

14.2

206

0.05738

7513

276

0.01848

12453

458

0.0269

10688

39313189

15.3

222

0.05325

8095

297

0.0169

13517

497

0.02514

11476

42214203

16.4

238

0.04968

8676

319

0.01569

14525

534

0.02352

12283

45115218

17.5

254

0.04656

9258

340

0.01457

15570

572

0.02201

13117

48216232

18.6

270

0.04381

9840

362

0.01353

16657

612

0.02061

13974

51317247

19.7

286

0.04136

10422

383

0.01275

17659

649

0.01932

14854

54618261

20.8

302

0.03917

11004

404

0.01201

18696

687

0.01825

15704

57719276

21.9

318

0.03721

11586

426

0.01132

19760

726

0.01726

16570

6092029023334

0.03543

12168

447

0.0106

20927

769

0.01645

17394

63921305

24.1

350

0.03381

12750

468

0.00995

22110

812

0.0156

18283

67222319

25.2

365

0.03233

13332

490

0.00944

23212

853

0.01485

19162

70423334

26.3

381

0.03098

13914

511

0.00887

24463

899

0.0142

20019

73624348

27.4

397

0.02974

14496

533

0.00847

25552

939

0.01355

20918

76925363

28.5

413

0.02859

15078

554

0.00795

26899

988

0.01299

21789

80126377

29.6

429

0.02753

15660

575

0.00758

28074

1032

0.01239

22736

83527392

30.7

445

0.02654

16242

597

0.00722

29295

1076

0.01185

23677

87028406

31.8

461

0.02562

16824

618

0.00687

30565

1123

0.01145

24515

90129421

32.9

477

0.02477

17406

640

0.00653

31888

1172

0.01093

25521

9383043534493

0.02396

17988

661

0.00621

33242

1221

0.01059

26358

96831450

35.1

509

0.02321

18570

682

0.00589

34681

1274

0.01015

27355

100532464

36.2

525

0.02251

19152

704

0.00558

36185

1330

0.00978

28301

104033479

37.3

541

0.02184

19734

725

0.0053

37688

1385

0.00948

29179

107234493

38.4

557

0.02122

20316

746

0.00508

39059

1435

0.0091

30217

111035508

39.5

573

0.02063

20898

768

0.00478

40839

1501

0.00875

31254

114836522

40.6

589

0.02007

21479

789

0.00455

42437

1559

0.00847

32206

118337537

41.7

605

0.01954

22062

811

0.0043

44241

1626

0.0082

33172

121938551

42.8

621

0.01904

22643

832

0.00409

45957

1689

0.00794

34153

125539566

43.9

637

0.01856

23225

853

0.00385

47973

1763

0.00768

35169

12924058045653

0.01811

23808

875

0.00362

50089

1840

0.00743

36201

1330

Compressor overow valve, Type POV

Table 9: Capacity - POV 600 (Continued)

Figure 7: Capacity - POV 1050

qm = 0.2883 × C × A0 × Kdr × Kb ×

P

V

© Danfoss | Climate Solutions | 2021.02 AI183186419402en-001101 | 10

Page 11

P

set

P

C

v

qmKbdoAoKdrSet pressure in bar g

Relieving pressure in bar(g)

Discharge function

Specic volume of the vapour at the relieving pressure P in m3/kg

Discharge capacity in kg/h

Correction factor for sub-critical ow

Flow diameter seat mm

2

Flow area seat in mm

2

De-rated coecient of discharge at dened lifting height

P

set

P

R22

q

m

R134a

q

m

R404a

q

m

R717

q

m

bar(g)

psig

bar(g)

psigvkg/h

lb/minvkg/h

lb/minvkg/h

lb/minvkg/h

lb/min1014512174

0.01974

19295

709

0.01655

20741

762

0.01629

20822

765

0.10753

8593

31611160

13.1

190

0.01797

21129

776

0.01502

22748

836

0.0147

22902

841

0.09867

9372

34412174

14.2

206

0.01638

23042

847

0.01383

24681

907

0.01346

24918

916

0.0913

10144

37313189

15.3

222

0.01514

24878

914

0.01273

26703

981

0.01233

27024

993

0.08461

10938

40214203

16.4

238

0.014

26785

984

0.01172

28698

1054

0.01128

29252

1075

0.079

11719

43115218

17.5

254

0.01311

28592

1051

0.01094

30807

1132

0.01048

31350

1152

0.07383

12523

46016232

18.6

270

0.01229

30444

1119

0.01007

33104

1216

0.00973

33542

1232

0.06998

13261

48717247

19.7

286

0.01152

32362

1189

0.0094

35262

1296

0.00902

35853

1317

0.06636

14015

51518261

20.8

302

0.0108

34344

1262

0.00888

37279

1370

0.00842

38130

1401

0.06213

14883

54719276

21.9

318

0.01012

36405

1338

0.00828

39613

1456

0.00786

40495

1488

0.05898

15674

5762029023334

0.00961

38285

1407

0.00775

41961

1542

0.00738

42828

1574

0.0562

16455

60521305

24.1

350

0.00908

40317

1481

0.00727

44348

1630

0.00688

45405

1668

0.0535

17264

63422319

25.2

365

0.00861

42338

1556

0.00685

46718

1717

0.00645

47953

1762

0.05121

18043

66323334

26.3

381

0.0081

44593

1638

0.00645

49185

1807

0.00606

50540

1857

0.049

18844

69224348

27.4

397

0.00768

46744

1718

0.00606

51793

1903

0.00565

53425

1963

0.04687

19666

72325363

28.5

413

0.00738

48632

1787

0.00574

54275

1994

0.0053

56257

2067

0.04514

20438

75126377

29.6

429

0.00699

50925

1871

0.00541

56975

2093

0.00496

59265

2178

0.04348

21223

78027392

30.7

445

0.0067

52974

1946

0.00506

59997

2205

0.00463

62470

2295

0.0415

22123

81328406

31.8

461

0.00634

55424

2036

0.00479

62760

2306

0.00429

66051

2427

0.0401

22905

84229421

32.9

477

0.00607

57614

2117

0.00453

65642

2412

0.00401

69489

2553

0.0387

23716

8713043534493

0.00579

59969

2203

0.00422

69138

2540

0.00371

73442

2699

0.0373

24557

90231450

35.1

509

0.00552

62404

2293

0.00392

72886

2678

0.00339

78063

2868

0.03612

25356

93232464

36.2

525

0.00523

65107

2392

0.00365

76708

2819

0.003

84273

3096

0.03482

26226

96433479

37.3

541

0.00499

67660

2486

0.00337

81035

2978

0.00206

103232

3793

0.0337

27061

99434493

38.4

557

0.00475

70363

2585

0.00306

86286

3170

0.03276

27848

102335508

39.5

573

0.00452

73157

2688

0.00275

92314

3392

0.03158

28767

105736522

40.6

589

0.00428

76220

2801

0.00221

104400

3836

0.03083

29517

108537537

41.7

605

0.00408

79116

2907

0.02972

30468

112038551

42.8

621

0.00389

82087

3016

0.02901

31243

114839566

43.9

637

0.00365

85825

3154

0.02815

32121

11804058045653

0.00345

89377

3284

0.0274

32963

1211

Compressor overow valve, Type POV

Table 10: Capacity - POV 1050

© Danfoss | Climate Solutions | 2021.02 AI183186419402en-001101 | 11

Page 12

P

set

P

Air(20 °C)

q

m

R410a

q

m

R744 (CO2)

q

m

bar(g)

psig

bar(g)

psigvkg/h

lb/minvkg/h

lb/minvkg/h

lb/min1014512174

0.0679

11059

406

0.02213

18223

670

0.03196

15701

57711160

13.1

190

0.0622

12073

444

0.02022

19919

732

0.0293

17134

63012174

14.2

206

0.05738

13087

481

0.01848

21693

797

0.0269

18617

68413189

15.3

222

0.05325

14100

518

0.0169

23547

865

0.02514

19990

73514203

16.4

238

0.04968

15114

555

0.01569

25301

930

0.02352

21397

78615218

17.5

254

0.04656

16128

593

0.01457

27122

997

0.02201

22849

84016232

18.6

270

0.04381

17141

630

0.01353

29016

1066

0.02061

24343

89417247

19.7

286

0.04136

18155

667

0.01275

30761

1130

0.01932

25875

95118261

20.8

302

0.03917

19169

704

0.01201

32568

1197

0.01825

27356

100519276

21.9

318

0.03721

20183

742

0.01132

34421

1265

0.01726

28864

10612029023334

0.03543

21197

779

0.0106

36453

1339

0.01645

30299

111321305

24.1

350

0.03381

22210

816

0.00995

38515

1415

0.0156

31849

117022319

25.2

365

0.03233

23224

853

0.00944

40434

1486

0.01485

33380

122723334

26.3

381

0.03098

24238

891

0.00887

42613

1566

0.0142

34873

128124348

27.4

397

0.02974

25251

928

0.00847

44510

1635

0.01355

36438

133925363

28.5

413

0.02859

26265

965

0.00795

46856

1722

0.01299

37955

139526377

29.6

429

0.02753

27279

1002

0.00758

48903

1797

0.01239

39606

145527392

30.7

445

0.02654

28293

1040

0.00722

51030

1875

0.01185

41244

151528406

31.8

461

0.02562

29307

1077

0.00687

53243

1956

0.01145

42703

156929421

32.9

477

0.02477

30321

1114

0.00653

55548

2041

0.01093

44457

16343043534493

0.02396

31334

1151

0.00621

57906

2128

0.01059

45914

168731450

35.1

509

0.02321

32348

1189

0.00589

60412

2220

0.01015

47651

175132464

36.2

525

0.02251

33361

1226

0.00558

63033

2316

0.00978

49299

181133479

37.3

541

0.02184

34375

1263

0.0053

65651

2412

0.00948

50828

186834493

38.4

557

0.02122

35389

1300

0.00508

68040

2500

0.0091

52637

193435508

39.5

573

0.02063

36403

1338

0.00478

71140

2614

0.00875

54443

200036522

40.6

589

0.02007

37416

1375

0.00455

73924

2716

0.00847

56101

206137537

41.7

605

0.01954

38430

1412

0.0043

77066

2832

0.0082

57784

212338551

42.8

621

0.01904

39444

1449

0.00409

80055

2942

0.00794

59492

218639566

43.9

637

0.01856

40458

1487

0.00385

83566

3071

0.00768

61263

22514058045653

0.01811

41472

1524

0.00362

87253

3206

0.00743

63061

2317

Compressor overow valve, Type POV

Table 11: Capacity - POV 1050 (Continued)

Figure 8: Capacity - POV 2150

qm = 0.2883 × C × A0 × Kdr × Kb ×

P

V

© Danfoss | Climate Solutions | 2021.02 AI183186419402en-001101 | 12

Page 13

P

set

P

C

v

qmKbdoAoKdrSet pressure in bar(g)

Relieving pressure in bar(g)

Discharge function

Specic volume of the vapour at the relieving pressure P in m3/kg

Discharge capacity in kg/h

Correction factor for sub-critical ow

Flow diameter seat mm

2

Flow area seat in mm

2

De-rated coecient of discharge at dened lifting height

P

set

P

R22

q

m

R404a

q

m

R717

q

m

bar(g)

psig

bar(g)

psigvkg/h

lb/minvkg/h

lb/minvkg/h

lb/min1014512174

0.01974

39440

1449

0.01629

42561

1564

0.10753

17564

64511160

13.1

190

0.01797

43190

1587

0.0147

46812

1720

0.09867

19157

70412174

14.2

206

0.01638

47098

1731

0.01346

50934

1871

0.0913

20735

76213189

15.3

222

0.01514

50851

1868

0.01233

55239

2030

0.08461

22358

82114203

16.4

238

0.014

54749

2012

0.01128

59793

2197

0.079

23955

88015218

17.5

254

0.01311

58444

2147

0.01048

64080

2355

0.07383

25597

94116232

18.6

270

0.01229

62230

2287

0.00973

68562

2519

0.06998

27106

99617247

19.7

286

0.01152

66149

2431

0.00902

73285

2693

0.06636

28646

105318261

20.8

302

0.0108

70200

2579

0.00842

77940

2864

0.06213

30421

111819276

21.9

318

0.01012

74413

2734

0.00786

82774

3041

0.05898

32038

11772029023334

0.00961

78257

2875

0.00738

87543

3217

0.0562

33635

123621305

24.1

350

0.00908

82411

3028

0.00688

92811

3410

0.0535

35287

129722319

25.2

365

0.00861

86540

3180

0.00645

98018

3602

0.05121

36882

135523334

26.3

381

0.0081

91150

3349

0.00606

103306

3796

0.049

38518

141524348

27.4

397

0.00768

95546

3511

0.00565

109203

4013

0.04687

40199

147725363

28.5

413

0.00738

99406

3653

0.0053

114992

4225

0.04514

41776

153526377

29.6

429

0.00699

104094

3825

0.00496

121141

4451

0.04348

43380

159427392

30.7

445

0.0067

108281

3979

0.00463

127692

4692

0.0415

45220

166228406

31.8

461

0.00634

113289

4163

0.00429

135011

4961

0.0401

46820

172029421

32.9

477

0.00607

117767

4327

0.00401

142040

5219

0.0387

48477

17813043534493

0.00579

122580

4504

0.00371

150120

5516

0.0373

50197

184431450

35.1

509

0.00552

127557

4687

0.00339

159565

5863

0.03612

51829

190432464

36.2

525

0.00523

133083

4890

0.003

172258

6329

0.03482

53608

197033479

37.3

541

0.00499

138300

5082

0.00206

211011

7753

0.0337

55313

203234493

38.4

557

0.00475

143826

5285

0.03276

56922

209235508

39.5

573

0.00452

149537

5495

0.03158

58801

216136522

40.6

589

0.00428

155797

5725

0.03083

60334

221737537

41.7

605

0.00408

161717

5942

0.02972

62278

228838551

42.8

621

0.00389

167790

6165

0.02901

63861

234639566

43.9

637

0.00365

175430

6446

0.02815

65657

24124058045653

0.00345

182690

6713

0.0274

67378

2476

Compressor overow valve, Type POV

© Danfoss | Climate Solutions | 2021.02 AI183186419402en-001101 | 13

Page 14

P

set

P

Air(20 °C)

q

m

R410a

q

m

R744 (CO2)

q

m

bar(g)

psig

bar(g)

psigvkg/h

lb/minvkg/h

lb/minvkg/h

lb/min1014512174

0.0679

22605

831

0.02213

37249

1369

0.03196

32094

117911160

13.1

190

0.0622

24677

907

0.02022

40716

1496

0.0293

35022

128712174

14.2

206

0.05738

26750

983

0.01848

44342

1629

0.0269

38055

139813189

15.3

222

0.05325

28822

1059

0.0169

48131

1768

0.02514

40861

150114203

16.4

238

0.04968

30894

1135

0.01569

51717

1900

0.02352

43737

160715218

17.5

254

0.04656

32966

1211

0.01457

55438

2037

0.02201

46704

171616232

18.6

270

0.04381

35038

1287

0.01353

59310

2179

0.02061

49757

182817247

19.7

286

0.04136

37110

1364

0.01275

62878

2310

0.01932

52890

194318261

20.8

302

0.03917

39183

1440

0.01201

66570

2446

0.01825

55917

205519276

21.9

318

0.03721

41254

1516

0.01132

70359

2585

0.01726

58999

21682029023334

0.03543

43327

1592

0.0106

74513

2738

0.01645

61933

227621305

24.1

350

0.03381

45399

1668

0.00995

78726

2893

0.0156

65101

239222319

25.2

365

0.03233

47471

1744

0.00944

82648

3037

0.01485

68230

250723334

26.3

381

0.03098

49543

1820

0.00887

87103

3201

0.0142

71281

261924348

27.4

397

0.02974

51615

1897

0.00847

90981

3343

0.01355

74481

273725363

28.5

413

0.02859

53687

1973

0.00795

95776

3519

0.01299

77582

285126377

29.6

429

0.02753

55760

2049

0.00758

99961

3673

0.01239

80956

297527392

30.7

445

0.02654

57832

2125

0.00722

104308

3833

0.01185

84305

309828406

31.8

461

0.02562

59904

2201

0.00687

108831

3999

0.01145

87287

320729421

32.9

477

0.02477

61977

2277

0.00653

113543

4172

0.01093

90872

33393043534493

0.02396

64048

2353

0.00621

118362

4349

0.01059

93850

344831450

35.1

509

0.02321

66121

2430

0.00589

123485

4537

0.01015

97401

357932464

36.2

525

0.02251

68192

2506

0.00558

128842

4734

0.00978

100769

370333479

37.3

541

0.02184

70265

2582

0.0053

134195

4931

0.00948

103894

381734493

38.4

557

0.02122

72337

2658

0.00508

139076

5110

0.0091

107593

395335508

39.5

573

0.02063

74410

2734

0.00478

145413

5343

0.00875

111285

408936522

40.6

589

0.02007

76480

2810

0.00455

151104

5552

0.00847

114673

421437537

41.7

605

0.01954

78554

2886

0.0043

157526

5788

0.0082

118114

434038551

42.8

621

0.01904

80625

2962

0.00409

163636

6013

0.00794

121605

446839566

43.9

637

0.01856

82697

3039

0.00385

170813

6276

0.00768

125225

46014058045653

0.01811

84770

3115

0.00362

178349

6553

0.00743

128900

4736

POV 600, POV 1050

POV 2150

Compressor overow valve, Type POV

Table 12: Capacity - POV 2150 (Continued)

Dimensions and weights

Table 13: Dimensions

© Danfoss | Climate Solutions | 2021.02 AI183186419402en-001101 | 14

Page 15

Valve size

A

B

C1C2C

3

ØD

Weight

POV 600 1

1

⁄2 in

mm55130

1887388

5 kgin2.2

5.1

7.4

2.8

3.5

11.0 lb

POV 1050 2

1

⁄2in.

mm70137

18490105

6 kgin2.8

5.4

7.2

3.5

4.1

13.2 lb

POV 2150 3 in.

mm90174

219

130

11 kgin3.5

6.9

8.6

5.1

24.2 lb

Compressor overow valve, Type POV

Table 14: Dimensions and weight

Specied weights are approximate values only.

© Danfoss | Climate Solutions | 2021.02 AI183186419402en-001101 | 15

Page 16

Type

Code no.

POV 600 BUTT WELD DIN DN 40

2417+232

POV 600 BUTT WELD ANSI DN 40

2417+047

POV 1050 BUTT WELD DIN DN 65

148F3026

POV 1050 BUTT WELD ANSI DN 65

148F3027

POV 2150 BUTT WELD DIN DN 80

148F3033

POV 2150 BUTT WELD ANSI DN 80

148F3034

Size

Type

Code no.mmin.

For system POV + BSV

–

15

½

Set of ttings

148H3453

POV 600

POV 1050, POV 2150

No

Part

MaterialENISO

ASTM

1

Housing

Steel

P285QH

LF2, A350

2

O-ring

Chloroprene (Neoprene)

EN 10222-4

3

Spring ring

Steel

4

Telfon washer

PTFE(Teon)

5

Spring

Steel6Seeger

Steel

7

Glide ring

PTFE(Teon)

Compressor overow valve, Type POV

Ordering

Table 15: Ordering

Nipples and gaskets

Attention: Fittings for connections must be ordered separately

Table 16: Dimensions and weight

IMPORTANT:

Where products need to be certied according to specic certication societies or where higher pressures are

required, the relevant information should be included at the time of order.

Material specication

Table 17: Material specication

Table 18: Material specication

© Danfoss | Climate Solutions | 2021.02 AI183186419402en-001101 | 16

Page 17

No

Part

MaterialENISO

ASTM

8 - 12

O-ring

Chloroprene (Neoprene)

13

Glide ring

PTFE(Teon)

14

O-ring

Chloroprene (Neoprene)

15

Top cover

Steel

Grade A, A662

16

Bolt

Stainless steel

P275NL1

A2-70

Grade B8

Compressor overow valve, Type POV

© Danfoss | Climate Solutions | 2021.02 AI183186419402en-001101 | 17

Page 18

File name

Document type

Document topic

Approval authority

EAC RU Д-DK.БЛ08.B.03706

EAC Declaration

Machinery & Equipment

EAC

TÜV 0045 202 1204 Z 00354 19 D

001(00)

Pressure - Safety Certicate

TÜV

GMPI TSX71002520151142

Manufacturing Permission

GMPI

EAC RU C-DK.БЛ08.B.01096_20

Pressure - Safety Certicate

PED

EAC

MD 033F0691.AE

Manufacturers Declaration

RoHS

Danfoss

033F0473.AD

Manufacturers Declaration

ATEX

Danfoss

POV valves

Nominal bore

DN40 mm (1½ in.)

DN40 mm (1½ in.)

Classied

for

Fluid group I

Category

I

II

Compressor overow valve, Type POV

Certicates, declarations and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Table 19: Valid approvals

Pressure Equipment Directive (PED)

Pressure Equipment Directive (PED)

POV valves are approved according to the European standard specied in the Pressure Equipment Directive and are

CE marked. For further details / restrictions - see Installation Instruction.

Table 20: Pressure Equipment Directive (PED)

© Danfoss | Climate Solutions | 2021.02 AI183186419402en-001101 | 18

Page 19

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Spare Parts

Get access to the Danfoss spare parts and service kit catalog right from your smartphone. The app

contains a wide range of components for air conditioning and refrigeration applications, such as

valves, strainers, pressure switches, and sensors.

Download the Spare Parts app for free at www.danfoss.com/en/service-and-support/downloads.

Coolselector®2 - nd the best components for you HVAC/R system

Coolselector®2 makes it easy for engineers, consultants, and designers to nd and order the best

components for refrigeration and air conditioning systems. Run calculations based on your operating

conditions and then choose the best setup for your system design.

Download Coolselector®2 for free at coolselector.danfoss.com.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its

products without notice. This also applies to products already on order provided that such alterations can be made without subsequential

changes being necessary in specications already agreed. All trademarks in this material are property of the respective companies. Danfoss and

the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.02 AI183186419402en-001101 | 19

Loading...

Loading...