Page 1

Data Sheet

Liquid level regulating valves

Type PMFL / PMFH and SV

For modulating liquid level control in refrigeration,

freezing and air conditioning plant

For modulating liquid level control in

refrigeration, freezing and air conditioning

plant, a system comprising a liquid level

regulating valve type PMFL or PMFH, controlled

by a pilot oat valve type SV, is used.

PMFL and SV systems are used on the

evaporator side. PMFH and SV systems are used

on the condenser side.

The system is suitable for use with ammonia or

uorinated refrigerants. The PMFL and PMFH

can be used in liquid lines to or from

• evaporators

• separators

• intermediate coolers

• condensers

• receivers

Modulating liquid level regulation provides

liquid injection that is proportional to the

actual capacity. This gives a constant amount of

ashgas, thus ensuring stable regulation and

economic operation because variations in

pressure and temperature are held to a

minimum.

AI242086443737en-001001

Page 2

Liquid level regulating valves, Type PMFL / PMFH and SV

Features

• Applicable to HCFC, HFC and R717 (Ammonia)

• PMFL / PMFH are based on PM valve family housings

• Same ange programme as for PM valve series

• Valve housing in low temperature cast iron (spherical) - EN GJS 400-18-LT

• Manual operation possible

• Position indicator available

• Pressure gauge connection to monitor inlet pressure

• Simple installation

• Main valve top cover can be located in any position without aecting the function

• Classication: DNV, CRN, BV, EAC etc. To get an updated list of certication on the products please contact your

local Danfoss Sales Company

© Danfoss | Climate Solutions | 2021.02 AI242086443737en-001001 | 2

Page 3

to SV float

Subcooling

Pressure

dierence over main valve

bar

psi

bar

psi

K

F

4 – 15

58 – 218

1.2 – 4.0

17 – 58

0 – 8

0 – 14

Normal spring set

Weak spring set

8 – 40

14 – 72

Strong spring set

PMFL

C/w normal (factory mounted) spring set, subcooling 0 – 8 K ~ 0 – 14 F

Pressure

dierence (Dp) over PMFL in bar or psi

< 5 bar

5 – 8 bar

8 – 10 bar

10 – 12 bar

> 12 bar

< 72 psi

72 – 116 psi

116 – 145 psi

145 – 174 psi

> 174 psi

80

No tension

2 – 3

3 – 4.5

4.5 – 6

ca. 7

125

No tension

3 – 5

5 – 7

7 – 9

ca. 10

200

No tension

3 – 5

5 – 7

7 – 9

ca. 10

300

No tension

4 – 6

6 – 9

9 – 12

ca. 14

PMFL

C/w strong spring set, subcooling 8 – 40 K ~ 14 – 72 F

Pressure

dierence (Dp) over PMFL in bar or psi

6 – 9 bar

> 9 bar

87 – 131 psi

> 131 psi

80

4

Max. tension

125

6

Max. tension

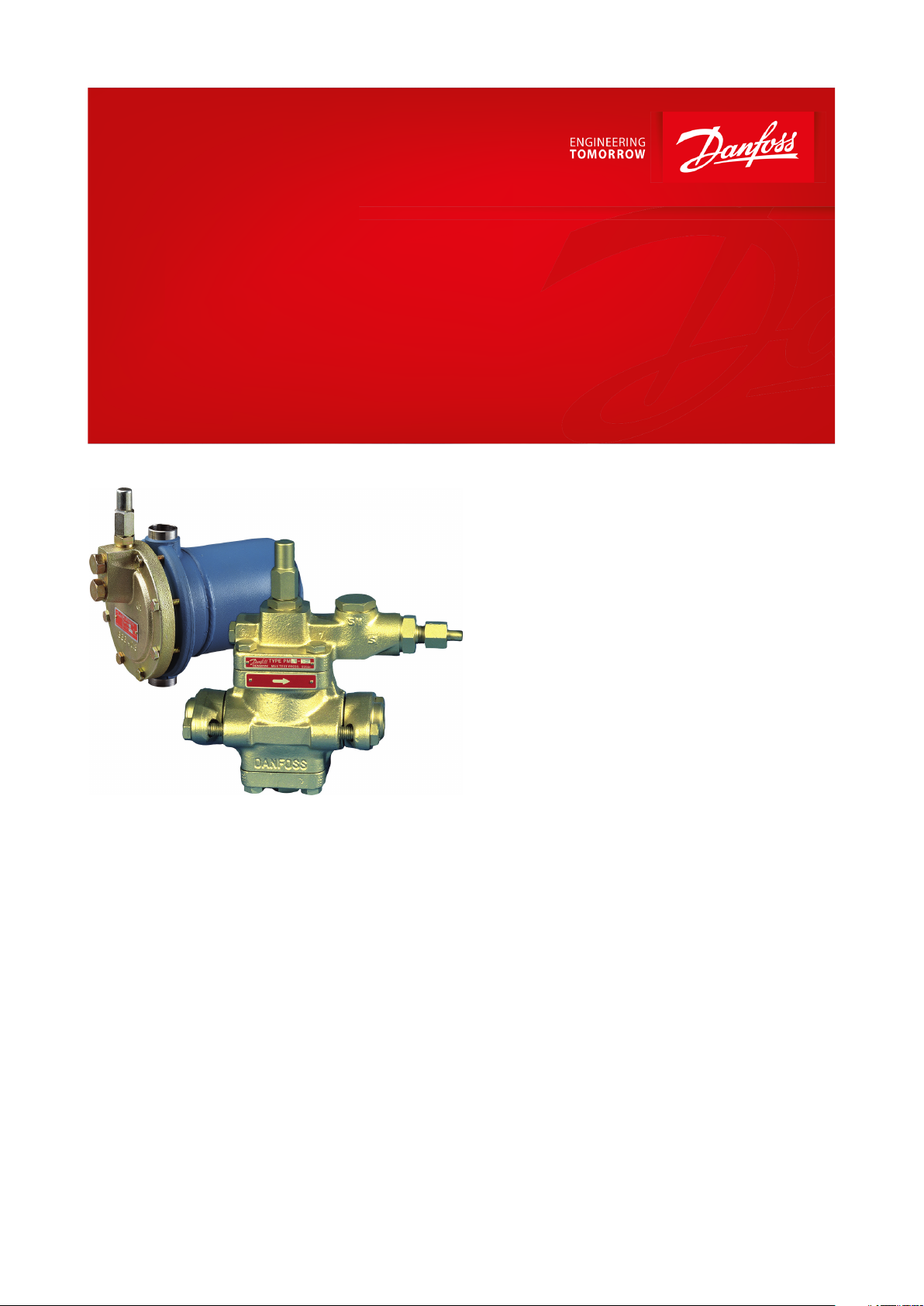

Liquid level regulating valves, Type PMFL / PMFH and SV

Functions

PMFL

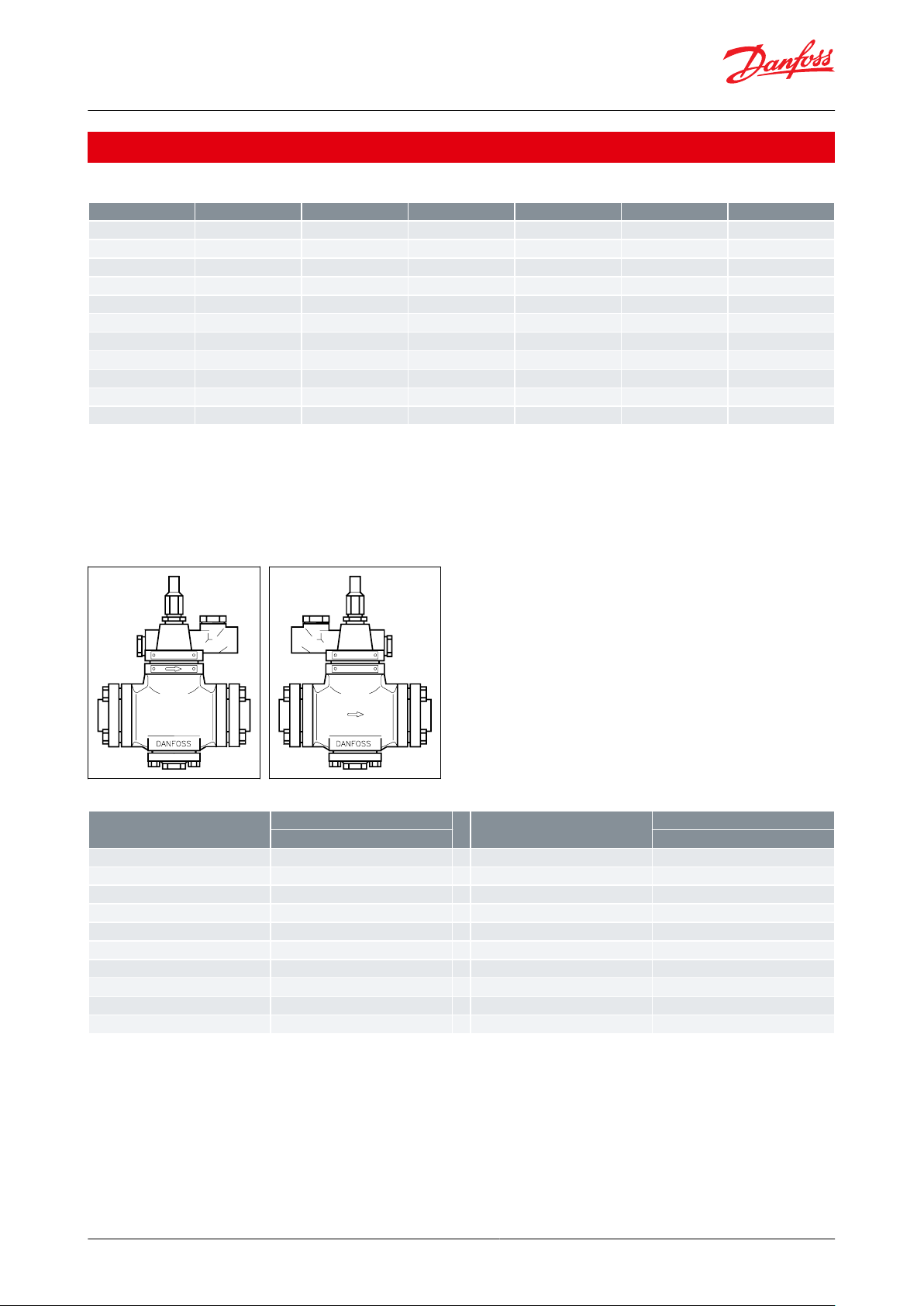

Figure 1: PMFL

When the liquid level inside the oat drops, the oat orice opens. This relieves the higher pressure, ps, acting on

the servo piston to the low pressure side causing the PMFL to open. Variations in liquid level will result in variations

in pressure over the piston and variation in the amount of liquid injected. It is important to choose the correct

spring set when designing the plant. The spring set should be selected from the table below:

Table 1: Subcooling

The setting spindle, pos. 60, has not been set from factory. It is imperative that the setting spindle is adjusted before

the valve is put into operation. The outer spring, pos. 23, is preset and the inner spring, pos. 43, is adjusted when

turning the spindle. The following tables shows the adjustment of the inner spring in number of turns of the spindle

as a function of valve size, spring type and pressure dierence:

Table 2: PMFL

Table 3: PMFL

© Danfoss | Climate Solutions | 2021.02 AI242086443737en-001001 | 3

Page 4

PMFL

C/w stong spring set, subcooling 8 – 40 K ~ 14 – 72 F

Pressure dierence (Dp) over PMFL in bar or psi

6 – 16 bar

87 – 232 psi

300

Spring must always be set to max. tension

PMFL

C/w weak spring set, low pressure plants

Pressure dierence (Dp) over PMFL in bar or psi

1.2 – 1.8 bar

1.8 – 2.5 bar

2.5 – 3 bar

3 – 4 bar

17 – 26 psi

26 – 36 psi

36 – 43 psi

43 – 58 psi

80

No tension

3 – 4

4 – 6

Max. tension

125

No tension

4 – 6

6 – 8

Max. tension

200

No tension

4 – 6

6 – 8

Max. tension

300

No tension

5 – 7

5 – 7

Max. tension

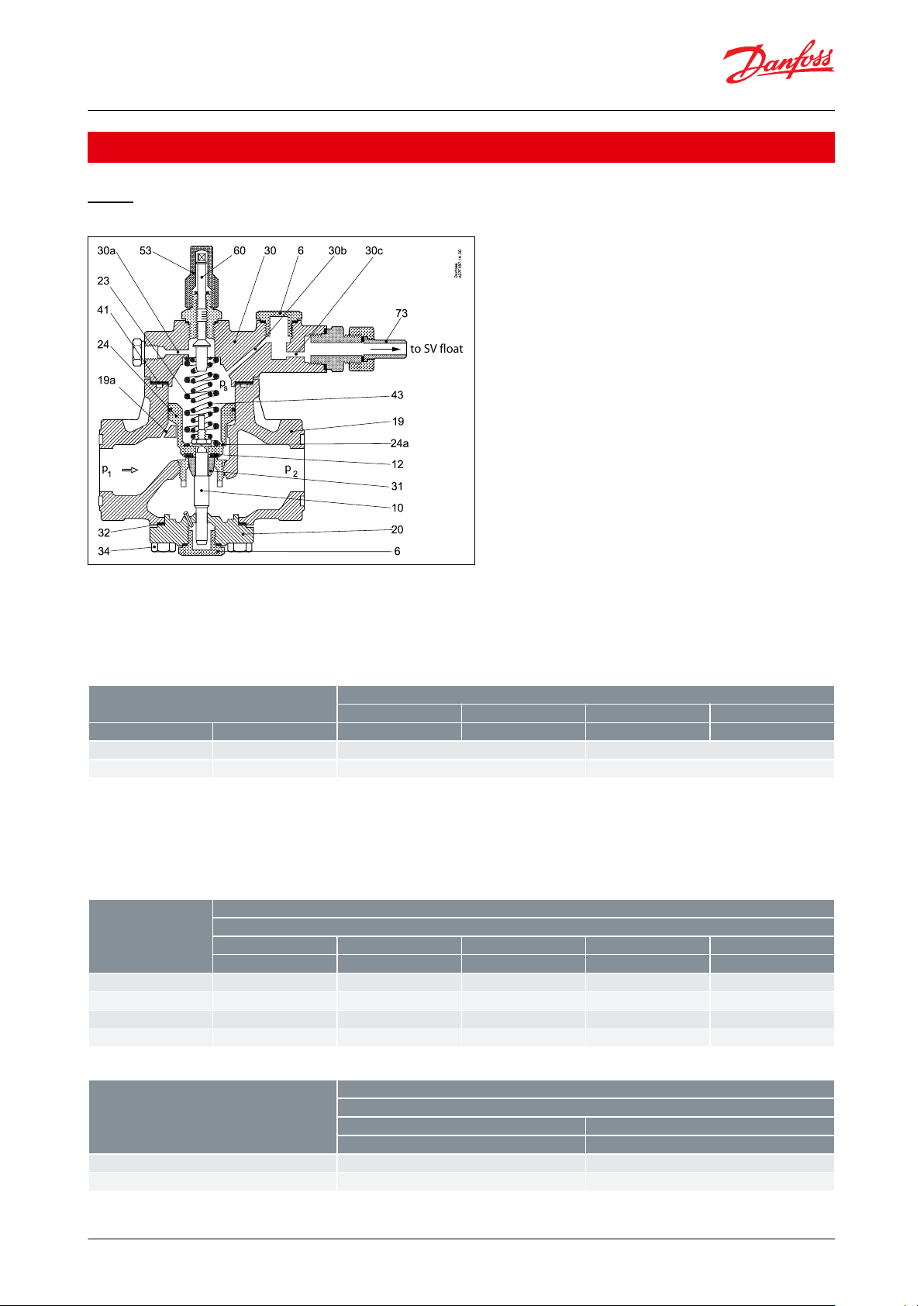

From compressor

To compressor

From evaporator

Condenser

Alarm

Alarm

float switch

Through type receiver

Liquid level

Overflow

valve

Filter

Oil drain

valve

To evaporator

Liquid level regulating valves, Type PMFL / PMFH and SV

Table 4: PMFL

Table 5: PMFL

Figure 2: PMFL function example

The values for spindle turns are an indication for an initial setting only. If a position indicator is used, a more precise

modulation can be achieved when ne tuning the valve setting. If the PMFL is not opening fully, the spring tension

must be reduced. If the PMFL is operating in a ON / OFF function, the spring tension should be increased. The

condenser pressure will have an eect on the ne tuning and large variations in condensing pressure might call for

readjustment. The subcooling is measured just before the PMFL and the pressure dierence is for the valve only

excluding piping and armatures.

The PMFL can be used together with SV 4 as a pilot valve.

The orices determines the Kv (Cv) value of the pilot and the following table can be used as an initial selection guide:

© Danfoss | Climate Solutions | 2021.02 AI242086443737en-001001 | 4

Page 5

PMFL

SV 4 – 6

Ø 2.5

Ø 3 (SV 4)

80X125X200X300

X

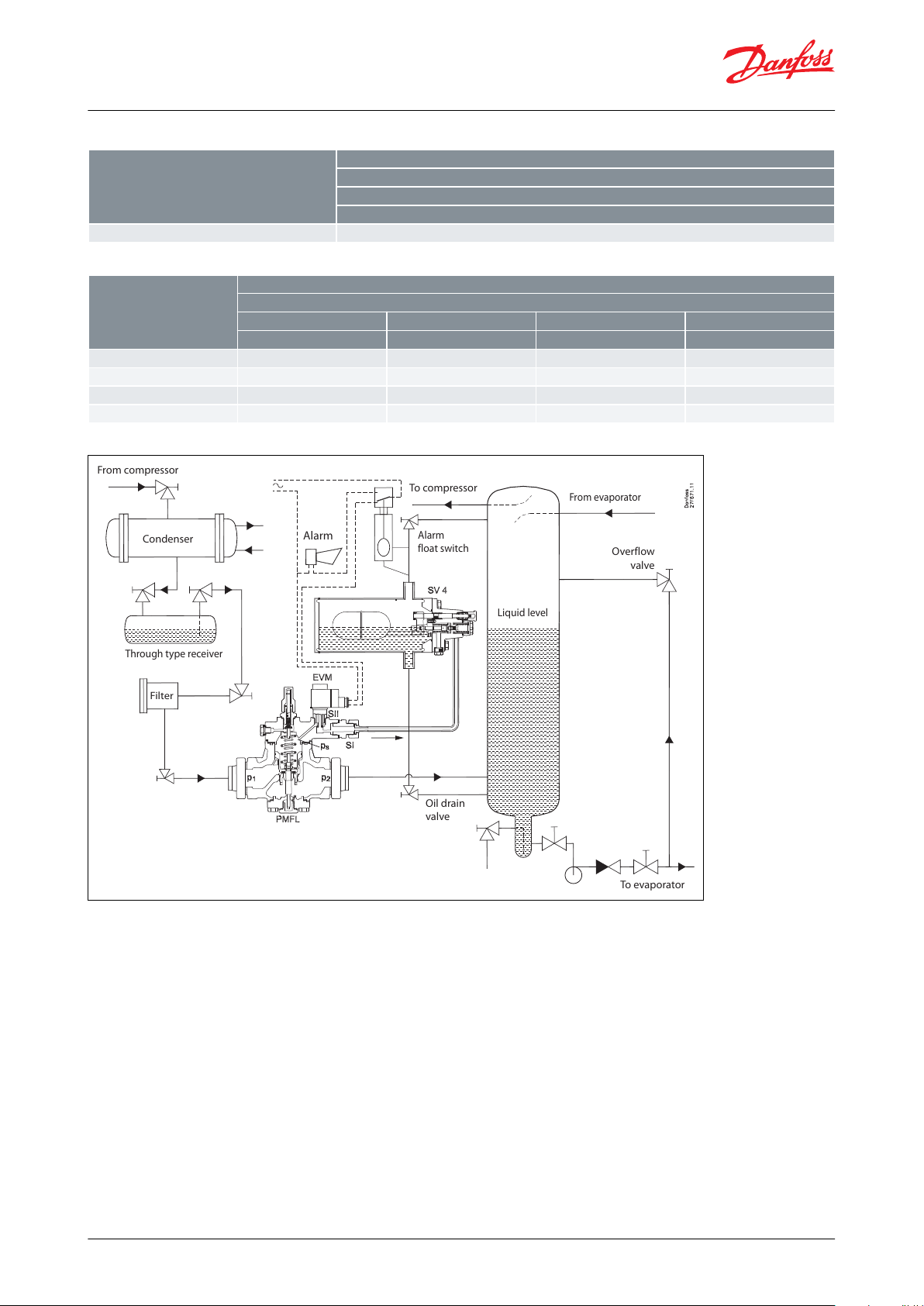

Inlet to SV 4 from PMFL

Liquid level regulating valves, Type PMFL / PMFH and SV

Table 6: PMFL

The nal choice of orice may vary depending on refrigerant and pressure levels. Smaller pressure levels needs a

bigger orice. Pressure dierence levels below 3 bar (43 psi) need SV 4 – 6 with Ø3 mm orice.

SV oats for PMFL

SV 4 can be used for PMFL low pressure control system. The oat must be connected as shown.

Figure 3: SV oats for PMFL

NOTE:

Only one inlet connection possible for SV 4.

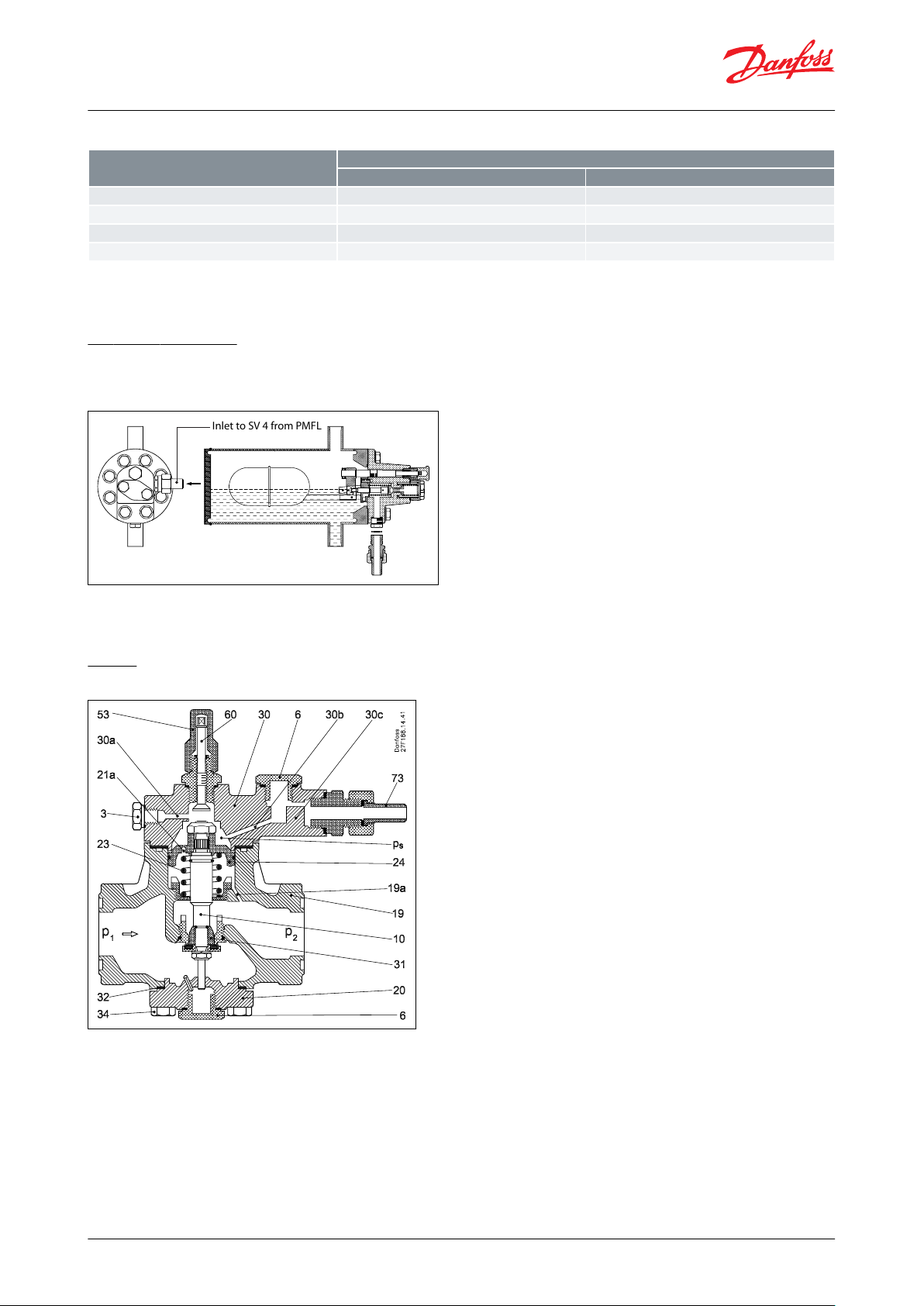

PMFH

Figure 4: PMFH

If the liquid level inside the SV oat rises, the oat orice opens and relieves pressure through the pilot line to the

top of the PMFH, increasing the pressure, ps, moving the pushrod downwards and opening the PMFH. The pilot line

is connected in the topcover at SI. Override of the pilot signal can be made by using an EVM valve at SII. It is

important to choose the correct spring set when designing the plant. The spring set should be selected from the

table below:

© Danfoss | Climate Solutions | 2021.02 AI242086443737en-001001 | 5

Page 6

Pressure dierence over main valve

bar

psi

bar

psi

0 – 4.5

0 – 65

> 4.5

> 65

Weak spring set

Normal spring set

SV 3 (1)

From low stage

compressor(s)

Tohigh stage

compressor(s)

From high stage

compressor(s)

To

low stage

separator

Condenser

Alarm

float

switch

Intermediate

pressure

vessel

Liquid trap

receiver

Filter

To

compressor

cooling

Alarm

S-connection

P-connection

Liquid level regulating valves, Type PMFL / PMFH and SV

Table 7: spring set selection

The PMFH can be used together with either SV 1 or 3 with the SV mounted with the bleed valve downwards, refer to

the drawing below. This reverses the opening so that rising oat opens the orice.

Figure 5: PMFH function example

NOTE:

High pressure oat system (for explanatory purposes only)

SV 1 - 3

SV 1 – 3 oat has 2 dierent pilot connections: S-port (series connection with PMFH) or P-port (parallel connection

with the PMFH).

P-port:

When using the P-port, it is possible to force open the PMFH valve to a fully open position. This is practical for

service purposes or to conrm if the oat has sucient capacity for the PMFH and the operating conditions.

However, when P-port connection is used it is possible to overll a system due to constant bleeding or unautorised

tampering. In this case, it is advisable to introduce a shut o when the liquid level reaches a preset point. Shut o

can be done via an electrical switch if an EVM valve is mounted in the SII port in the top of the PMFH. It is only

advisable to use the P-port at low pressure dierence.

S-port:

The S-port oers the advantage of a preorice which divides the pressure drop and any wear possibility due to

cavitation. S-port connection must be used at high pressure dierences, dp > 10 bar (145 psi). The Kv (Cv) value of

the SV is higher using P-port than using S-port. A higher P-band can thus be obtained.

© Danfoss | Climate Solutions | 2021.02 AI242086443737en-001001 | 6

Page 7

Liquid level regulating valves, Type PMFL / PMFH and SV

Media

Refrigerants

Applicable to HCFC, HFC and R717 (Ammonia).

New refrigerants

Danfoss products are continually evaluated for use with new refrigerants depending on market requirements.

When a refrigerant is approved for use by Danfoss, it is added to the relevant portfolio, and the R number of the

refrigerant (e.g. R513A) will be added to the technical data of the code number. Therefore, products for specic

refrigerants are best checked at store.danfoss.com/en/, or by contacting your local Danfoss representative.

© Danfoss | Climate Solutions | 2021.02 AI242086443737en-001001 | 7

Page 8

610121919a20232424a3030a.b.c

3143445360

73

Description

Values

Max. working pressure

PMFL / H: MWP = 28 bar

SV: MWP = 28 bar

Max. test pressure

PMFL / H: Max. test pressure = 42 bar

SV: Max. test pressure = 42 bar

Temperature of media

-60 °C – 120 °C

to SV float

Seal plug

Valve spindle

Valve seat

Valve body

Channel in valve body

Bottom cover

Main spring

Servo piston

Channel in servo piston

Top cover

Channels in top cover

Valve cone

Supplementary spring

Manometer connection

Spindle cap

Setting spindle

Pilot connection

Liquid level regulating valves, Type PMFL / PMFH and SV

Product specication

Pressure and temperature

Table 8: Pressure and temperature data

NOTE:

Max. working pressure is limited to

MWP = 21 bar when media temperatures are:

below -20 °C for valves made of GGG-40.3 and

below -10 °C for valves made of GG-25.

Material specication

PMFL

Figure 6: PMFL

© Danfoss | Climate Solutions | 2021.02 AI242086443737en-001001 | 8

Page 9

36101919a2021a23243030a.b.c

31

536073

Manometer connection

Seal plug

Valve spindle

Valve body

Channel in valve body

Bottom cover

Channel in servo piston

Main spring

Servo piston

Top cover

Channels in top cover

Valve cone

Spindle cap

Manual opening

Pilot connection

Description

Values

Refrigerant

R 717 (NH

3

)

Evaporator capacity

Q

e

= 600 kW

Evaporating temperature

t

e

= -10 °C (∼ pe = 2.9 bar abs.)

Condensing temperature

t

c

= 30 °C (∼ pc = 11.9 bar abs.)

Liquid temperature ahead of valve

t

l

= 20 °C at max. capacity

Subcooling

Δtsub = tc - tl = 30 °C - 20 °C = 10 K

Calculations do not take into account pressure loss in pipelines.

Pressure drop across valve

Δp = p

c

- pe = 11.9 - 2.9 bar = 9 bar

Correction factor for 10 K subcooling

0.98

Corrected capacity

600 kW × 0.98 = 588 kW

Liquid level regulating valves, Type PMFL / PMFH and SV

PMFH

Figure 7: PMFH

Sizing

Sizing example for PMFL

Table 9: Sizing example for PMFL

NOTE:

The corrected capacity can be found in the capacity table. It will be seen from the table that valve type PMFL 80-4

should be chosen. Refering to “ordering table”, code number 027F0053 can be found. For details of anges,

accessories and pilot valve, see Ordering section.

Since Δp = 9 bar and Δt

set must be used. The pilot line is connected to SV at connection S. In the ordering table the code number for the

spring set can be found: 027F0118.

= 10 K, it will be seen from the “C/w strong spring set” for PMFL that a “STRONG” spring

sub

© Danfoss | Climate Solutions | 2021.02 AI242086443737en-001001 | 9

Page 10

Description

Values

Refrigerant

R 717 (NH3)

Evaporator capacity

Qe = 2200 kW

Evaporating temperature

te = -10 °C (∼ pe = 2.9 bar abs.)

Condensing temperature

tc = 30 °C (∼ 11.9 bar abs.)

Liquid temperature ahead of valve

tl = 20 °C

Subcooling

Δtsub = tc - tl = 30 °C - 20 °C = 10 K

Calculations do not take into account pressure loss in pipelines.

Pressure drop across valve

Δp = pc - pe = 11.9 - 2.9 bar = 9 bar

Correction factor for 10 K subcooling

0.98

Corrected capacity

2200 kW × 0.98 = 2156 kW

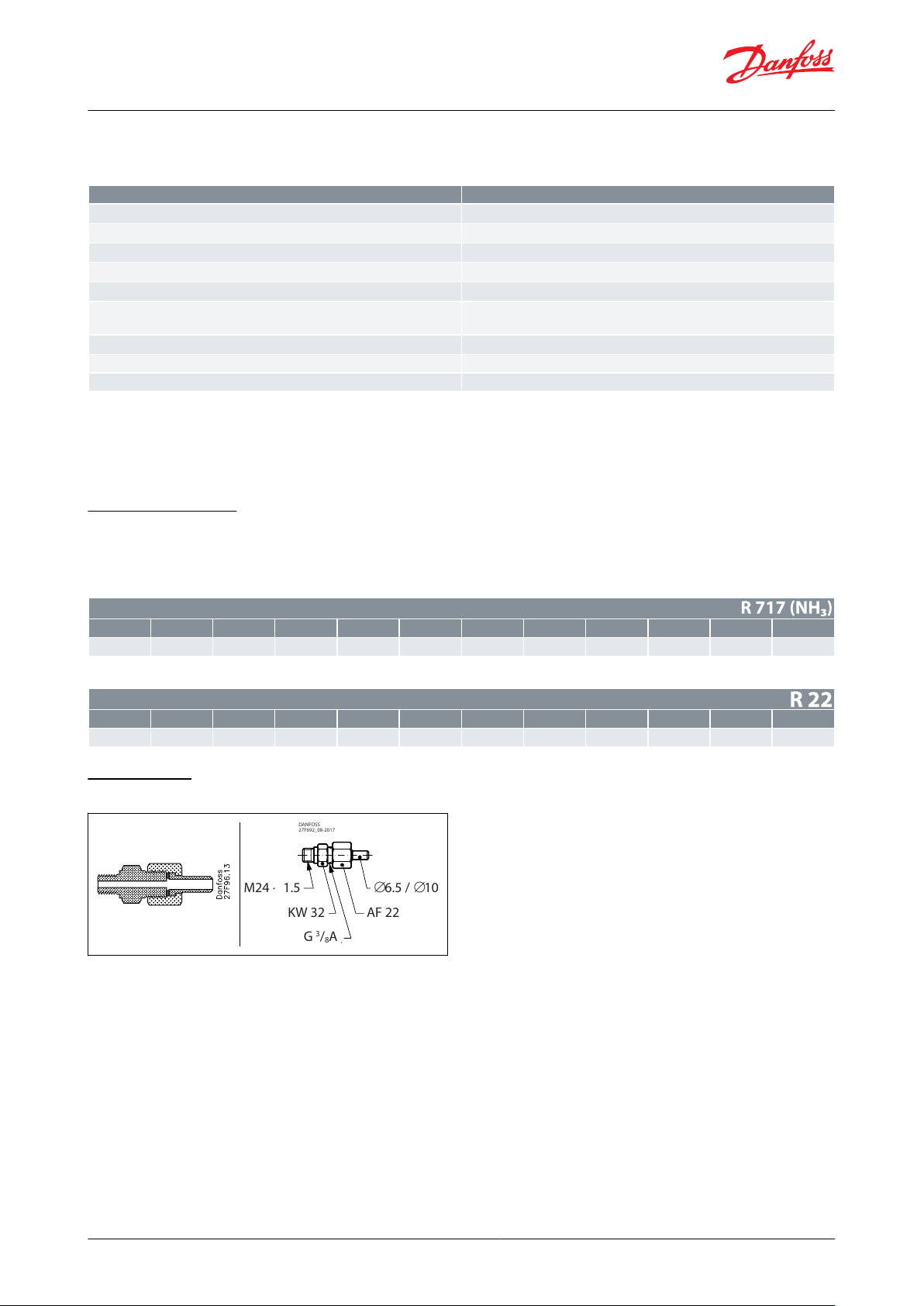

∆t K24101520253035404550k

1.0110.98

0.96

0.94

0.92

0.91

0.89

0.87

0.86

0.85

∆t K24101520253035404550k

1.0110.96

0.93

0.9

0.87

0.85

0.83

0.8

0.78

0.77

DANFOSS

27F692_08-2017

M24 × 1.5

KW 32

G3/8A

AF 22

∅6.5 / ∅10

Liquid level regulating valves, Type PMFL / PMFH and SV

Sizing example for PMFH

Table 10: Sizing example for PMFH

NOTE:

The corrected capacity can be found in the capacity table. It will be seen from the table that valve type PMFH 80-7

should be chosen. In the ordering table the code number for the valve can be found: 027F3060 for CE-approved

valve. For details of anges, accessories and pilot valve, see Ordering section.

Correction factors

When dimensioning, multiply the evaporator capacity by a correction factor k dependent on the subcooling Δt

just ahead of the valve. The corrected capacity can then be found in the capacity table.

Table 11: R 717 (NH3)

Table 12: R 22

Connections

Figure 8: Pilot connection (weld / solder)

sub

© Danfoss | Climate Solutions | 2021.02 AI242086443737en-001001 | 10

Page 11

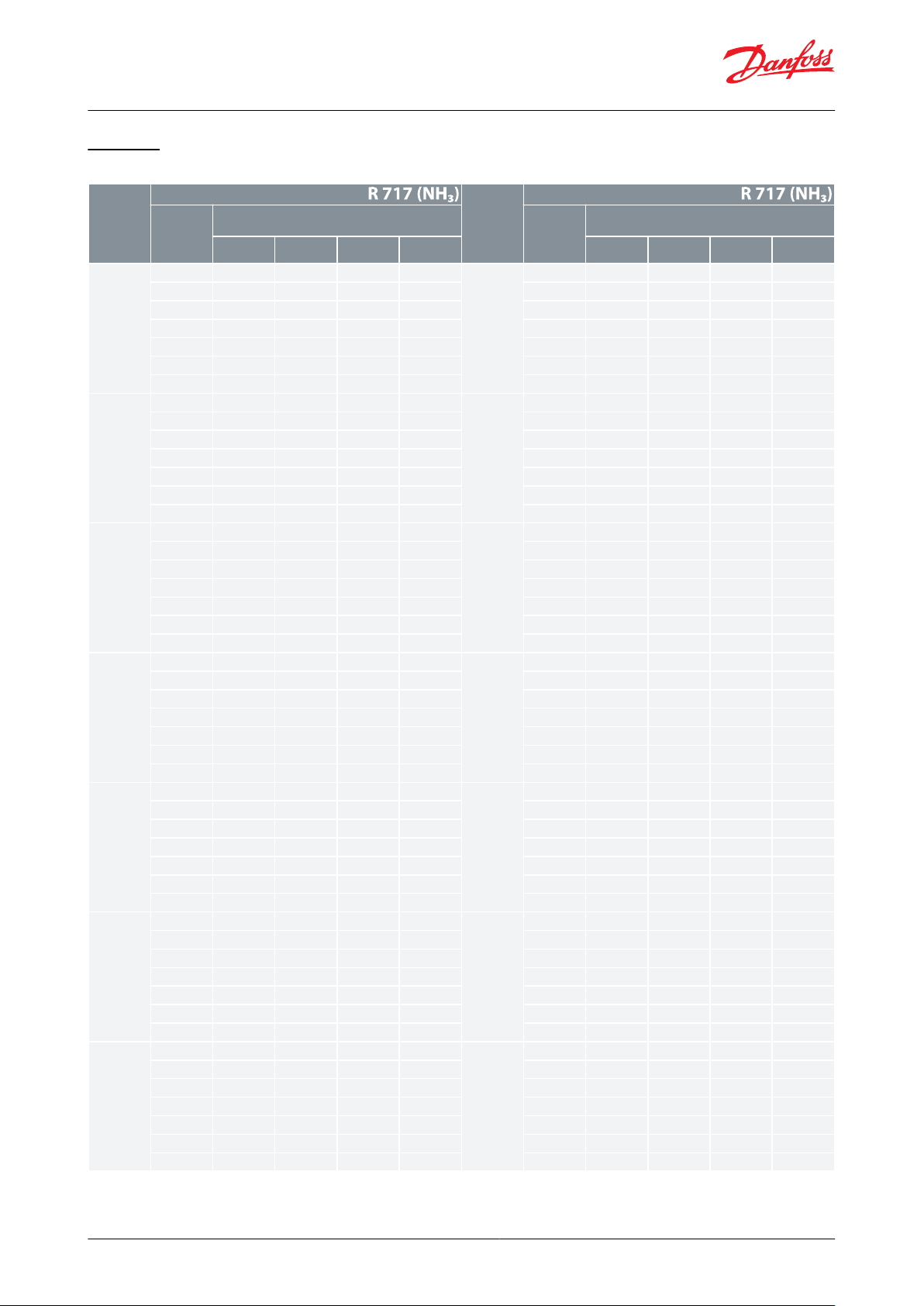

Type

Type

Evaporat‐

ing tem‐

perature t

e

°C

Rated capacity in kW at pressure drop across valve

∆p bar

Evaporat‐

ing tem‐

perature t

e

°C

Rated capacity in kW at pressure drop across valve

∆p bar

0.8

1.2

1.624812

16

PMFL 80-1

1050606976

PMFL 80-1

10

104

140

1610516271790

107

142

165

176

-1053647381

-10

110

143

166

178

-2054657482

-20

111

143

166

179

-3055667583

-30

111

143

165

179

-4056677986

-40

111

142

162

177

-5056677582

-50

109

140

160

175

PMFL 80-2

108097

111

123

PMFL 80-2

PMFH 80-2

10

167

224

257083

101

115

1270172

227

264

281

-1085103

118

130

-10

176

228

265

284

-2086105

119

132

-20

177

238

264

285

-3088106

120

133

-30

177

227

262

284

-4089107

120

132

-40

175

225

258

281

-5090106

119

131

-50

173

222

253

277

PMFL 80-3

10

127

154

176

194

PMFL 80-3

PMFH 80-3

10

264

353

4040131

159

182

2010271

356

414

440

-10

134

163

186

205

-10

276

357

416

444

-20

137

164

188

207

-20

278

356

413

445

-30

139

167

188

207

-30

276

353

407

443

-40

140

166

187

205

-40

272

349

400

438

-50

139

164

184

201

-50

267

343

393

431

PMFL 80-4

10

206

250

286

316

PMFL 80-4

PMFH 80-4

10

427

571

6510214

259

295

3270438

573

664

704

-10

219

264

301

333

-10

444

572

665

709

-20

222

267

303

334

-20

445

568

657

709

-30

224

267

301

330

-30

439

561

647

704

-40

223

263

295

323

-40

429

552

635

696

-50

219

257

288

315

-50

420

543

624

685

PMFL 80-5

10

325

394

449

496

PMFL 80-5

PMFH 80-5

10

667

887

10100336

406

463

5110679

883

1020

1080

-10

344

413

470

518

-10

685

874

1020

1080

-20

347

414

468

514

-20

680

864

1000

1080

-30

345

407

458

502

-30

666

852

984

1070

-40

338

396

444

486

-40

649

837

966

1060

-50

327

383

429

470

-50

632

823

948

1040

PMFL 80-6

10

565

682

773

851

P MFL 80-6

PMFH 80-6

10

1130

1490

16700584

700

792

86901130

1460

1690

1780

-10

591

705

795

871

-10

1130

1430

1670

1780

-20

587

692

777

850

-20

1110

1410

1640

1770

-30

571

666

746

816

-30

1080

1380

1610

1760

-40

546

636

712

781

-40

1050

1360

1570

1730

-50

520

608

684

751

-50

1020

1340

1540

1710

PMFL 80-7

10

881

1060

1190

1300

PMFL 80-7

PMFH 80-7

10

1690

2220

24800909

1080

1210

131001670

2150

2500

2610

-10

910

1070

1190

1300

-10

1660

2090

2470

2610

-20

887

1030

1150

1250

-20

1630

2050

2410

2610

-30

844

975

1090

1190

-30

1580

2010

2350

2590

-40

794

921

1030

1130

-40

1530

1970

2300

2550

-50

750

875

984

1080

-50

1490

1940

2250

2510

Liquid level regulating valves, Type PMFL / PMFH and SV

Capacity

Table 13: Capacity in kW

© Danfoss | Climate Solutions | 2021.02 AI242086443737en-001001 | 11

Page 12

Type

Type

Evaporat‐

ing tem‐

perature t

e

°C

Rated capacity in kW at pressure drop across valve

∆p bar

Evaporat‐

ing tem‐

perature t

e

°C

Rated capacity in kW at pressure drop across valve

∆p bar

0.8

1.2

1.624812

16

PMFL 125

10

1400

1690

1910

2100

PMFL 125

PMFH 125

10

2770

3650

410001450

1730

1950

214002770

3570

4140

4350

-10

1460

1740

1950

2140

-10

2770

3500

4090

4350

-20

1450

1700

1930

2080

-20

2720

3430

4010

4340

-30

1400

1630

1820

1990

-30

2650

3370

3920

4300

-40

1330

1550

1730

1900

-40

2570

3320

3840

4240

-50

1260

1480

1660

1830

-50

2490

3260

3770

4180

PMFL 200

10

2250

2710

3060

3360

PMFL 200

PMFH 200

10

4410

5810

653002320

2770

3120

342004420

5680

6590

6920

-10

2340

2780

3120

3410

-10

4400

5550

6510

6920

-20

2310

2710

3030

3310

-20

4330

5450

6370

6900

-30

2220

2590

2890

3160

-30

4210

5360

6240

6830

-40

2110

2480

2750

3020

-40

4080

5260

6110

6740

-50

2000

2340

2630

2900

-50

3960

5170

5990

6640

PMFL 300

10

3420

4110

4650

4990

PMFL 300

PMFH 300

10

6690

8810

988003530

4210

4740

518006690

8600

9980

10500

-10

3560

4210

4730

5170

-10

6660

8400

9850

10500

-20

3500

4100

4590

5010

-20

6550

8240

9650

10400

-30

3370

3910

4370

4780

-30

6360

8100

9430

10300

-40

3190

3710

4160

4560

-40

6170

7960

9240

10200

-50

3030

3540

3980

4380

-50

5990

7820

9050

10000

PMFH 500

10

10700

14100

15800010700

13700

15900

16700

-10

10600

13400

15700

16700

-20

10400

13100

15400

16700

-30

10100

12900

15000

16500

-40

9830

12700

14700

16300

-50

9540

12400

14400

16000

Type

Type

Evaporat‐

ing tem‐

perature t

e

°C

Rated capacity in kW at pressure drop across valve

∆p bar

Evaporat‐

ing tem‐

perature t

e

°C

Rated capacity in kW at pressure drop across valve

∆p bar

0.8

1.2

1.624812

16

PMFL 80-1

1011131517

PMFL 80-1

1022283132012141618023293233

-1012151718

-1024303234

-2012151719

-2025303234

-3013151719

-3025303233

-4013161819

-4025303232

-5013161819

-5024293132

PMFL 80-2

1018222527

PMFL 80-2

PMFH 80-2

1036465152019232629038475253

-1020242730

-1039485254

-2020242830

-2040485254

-3021252831

-3040485253

-4021252831

-4040485152

-5021252831

-5039474951

Liquid level regulating valves, Type PMFL / PMFH and SV

Capacity

Table 14: Capacity in kW

© Danfoss | Climate Solutions | 2021.02 AI242086443737en-001001 | 12

Page 13

Type

Type

Evaporat‐

ing tem‐

perature t

e

°C

Rated capacity in kW at pressure drop across valve

∆p bar

Evaporat‐

ing tem‐

perature t

e

°C

Rated capacity in kW at pressure drop across valve

∆p bar

0.8

1.2

1.624812

16

PMFL 80-3

1029353943

PMFL 80-3

PMFH 80-3

1057728082030364146060748284

-1031374347

-1062768285

-2032394448

-2063768285

-3033394448

-3063768183

-4034404549

-4062757981

-5034404448

-5061737779

PMFL 80-4

1047576471

PMFL 80-4

PMFH 80-4

1094118

130

133049596774098121

133

136

-1051617077

-10

101

123

133

138

-2052637178

-20

102

123

132

137

-3054647278

-30

101

122

130

134

-4054647278

-4099120

127

131

-5055647177

-5097117

124

127

PMFL 80-5

107489

102

112

PMFL 80-5

PMFH 80-5

10

147

184

202

20607894107

1170153

188

205

211

-108096

110

121

-10

157

190

205

212

-208399

112

122

-20

157

189

203

210

-308499

112

122

-30

156

187

199

206

-408499

110

120

-40

152

184

195

200

-508497

108

117

-50

148

179

189

194

PMFL 80-6

10

129

156

177

194

P MFL 80-6

PMFH 80-6

10

251

310

341

3450135

162

184

2020260

314

343

352

-10

140

167

188

206

-10

263

315

341

353

-20

142

168

189

205

-20

262

313

335

348

-30

143

167

186

202

-30

257

308

328

340

-40

141

163

181

196

-40

249

302

320

331

-50

137

158

175

189

-50

241

294

312

321

PMFL 80-7

10

202

242

273

299

PMFL 80-7

PMFH 80-7

10

381

466

510

5150211

251

283

3080390

467

510

524

-10

216

256

286

311

-10

393

465

504

523

-20

218

255

283

307

-20

389

461

495

516

-30

215

249

275

298

-30

378

454

483

503

-40

209

240

265

286

-40

366

444

471

489

-50

200

230

254

275

-50

353

433

458

473

PMFL 125

10

321

386

437

479

PMFL 125

PMFH 125

10

620

763

837

8470336

402

455

4980639

770

842

864

-10

346

412

464

507

-10

647

771

835

865

-20

352

415

464

505

-20

643

767

821

853

-30

352

410

455

494

-30

628

755

804

834

-40

346

399

442

478

-40

609

739

784

810

-50

335

386

426

461

-50

589

720

762

785

PMFL 200

10

515

618

700

767

PMFL 200

PMFH 200

10

990

1220

1330

13500538

645

728

79601020

1230

1340

1380

-10

555

660

742

810

-10

1030

1230

1330

1380

-20

563

663

740

805

-20

1020

1220

1310

1360

-30

561

653

725

786

-30

1000

1200

1280

1330

-40

550

635

702

760

-40

969

1170

1250

1290

-50

532

612

677

732

-50

937

1150

1210

1250

Liquid level regulating valves, Type PMFL / PMFH and SV

© Danfoss | Climate Solutions | 2021.02 AI242086443737en-001001 | 13

Page 14

Type

Type

Evaporat‐

ing tem‐

perature t

e

°C

Rated capacity in kW at pressure drop across valve

∆p bar

Evaporat‐

ing tem‐

perature t

e

°C

Rated capacity in kW at pressure drop across valve

∆p bar

0.8

1.2

1.624812

16

PMFL 300

10

782

940

1060

1170

PMFL 300

PMFH 300

10

1500

1850

2020

20500819

980

1110

121001550

1860

2030

2080

-10

843

1000

1130

1230

-10

1560

1860

2010

2090

-20

855

1010

1120

1220

-20

1550

1850

1980

2060

-30

851

990

1100

1190

-30

1510

1820

1930

2010

-40

833

961

1060

1150

-40

1470

1780

1890

1950

-50

804

925

1020

1110

-50

1420

1730

1830

1890

PMFH 500

10

2410

2950

3240

327002480

2970

3250

3330

-10

2500

2970

3210

3330

-20

2480

2950

3160

3290

-30

2420

2900

3090

3210

-40

2340

2840

3010

3120

-50

2260

2770

2930

3020

Type

H1 mm

H2 mm

H3 mm

H4 mm

H5 mm

L mm

L1 mm

L5 max.

B1 mm

B2 mm

B3 mm

Weight

excl. sol‐

enoid

valve kg

10 Wmm20 W

mm

PMFL

PMFH

80

66

162

79

113

176

177

106

130

140

75

87

7.0

125

72

178

96

128

193

240

170

130

140

84

82

94

11.3

200

79

187

105

138

202

254

170

130

140

94

89

102

14.2

300

95

205

123

155

220

288

200

130

140

104

106

113

19.8

PMFH

500

109

227

146

176

242

342

250

130

140

127

113

135

28.3

Liquid level regulating valves, Type PMFL / PMFH and SV

Dimensions and weights

Figure 9: PMFL / PMFH

Table 15: Dimensions and weights

© Danfoss | Climate Solutions | 2021.02 AI242086443737en-001001 | 14

Page 15

Valve type

R 717

R 22

R 134a

R 404A

R 12

R 502

PMFL/H 80-1

139

27.8

22.13317.4

30

PMFL/H 80-2

209

41.8

35.3

49.7

27.8

45.2

PMFL/H 80-3

3487053.1

82.7

41.8

75.2

PMFL/H 80-4

558

105

88.9

12470113

PMFL/H 80-5

835

174

133

207

105

188

PMFL/H 80-6

1395

278

221

330

174

300

PMFL/H 80-7

2080

435

353

569

278

470

PMFL/H 125

3480

700

552

831

435

755

PMFL/H 200

5580

1050

889

1243

700

1130

PMFL/H 300

8350

1740

1333

2068

1050

1880

PMFL/H 500

13900

2780

2210

3300

1740

3000

Valve type

Code no.

Valve type

Code no.

EN GJS 400-18-LT

EN GJS 400-18-LT

PMFL 80-1

027F3054

PMFH 80-2

027F3065

PMFL 80-2

027F3055

PMFH 80-3

027F3066

PMFL 80-3

027F3056

PMFH 80-4

027F3067

PMFL 80-4

027F3057

PMFH 80-5

027F3068

PMFL 80-5

027F3058

PMFH 80-6

027F3069

PMFL 80-6

027F3059

PMFH 80-7

027F3070

PMFL 80-7

027F3060

PMFH 125

027F3071

PMFL 125

027F3061

PMFH 200

027F3072

PMFL 200

027F3062

PMFH 300

027F3073

PMFL 300

027F3063

PMFH 500

027F3074

Liquid level regulating valves, Type PMFL / PMFH and SV

Ordering

Table 16: Rated capacity in kW (1 kW = 0.284 TR)

NOTE:

The rated capacity is given at

Evaporating temperature te = 5 °C,

Condensing temperature tc = 32 °C and

Liquid temperature tl = 28 °C.

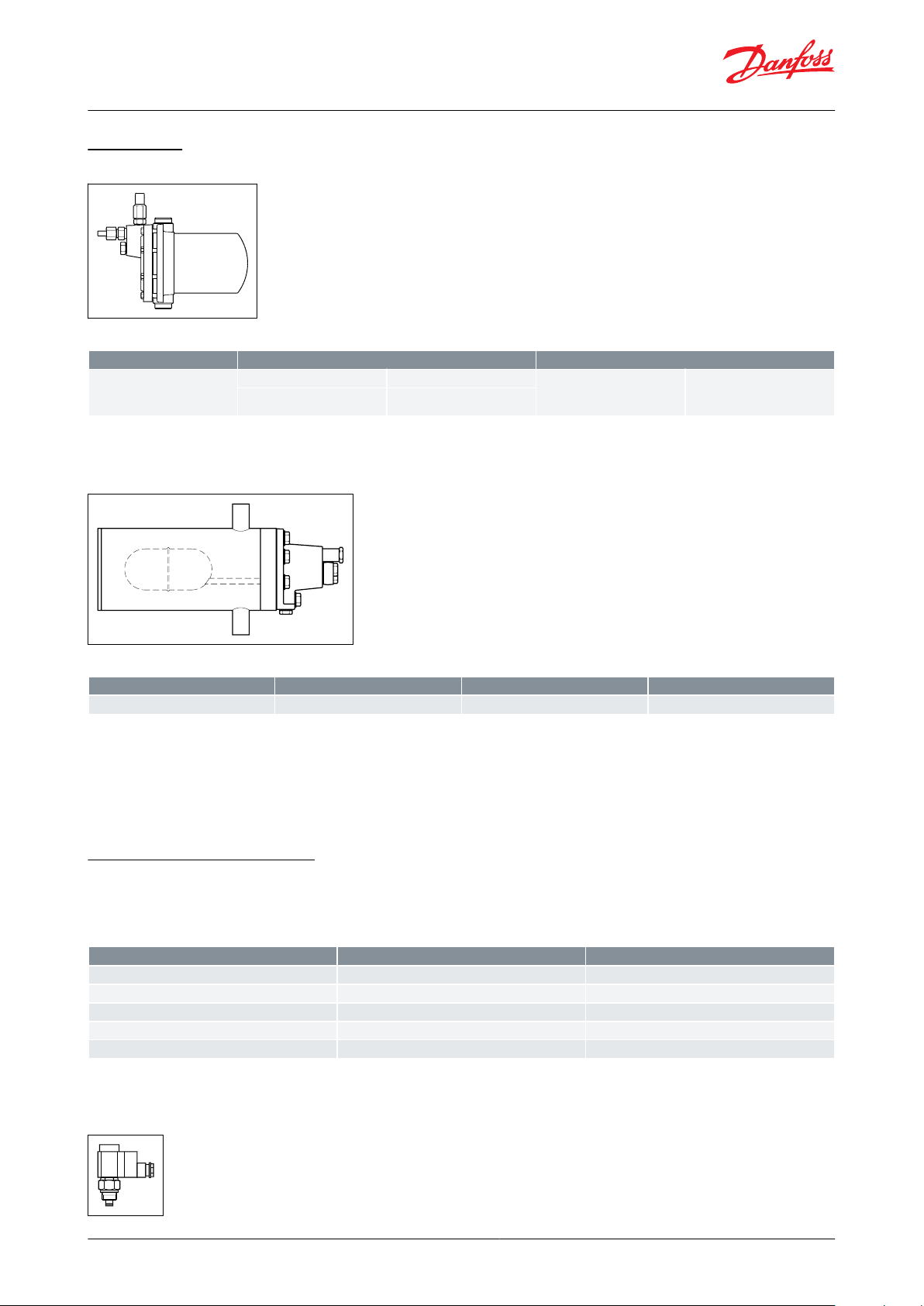

Figure 10: Main valve Figure 11: Main valve

Table 17: Main valve

NOTE:

The code nos. stated apply to main valves type PMFL or PMFH incl. ange gaskets, ange bolts, blanking plug and

pilot connection with Ø6.5 / Ø10 mm weld nipple.

© Danfoss | Climate Solutions | 2021.02 AI242086443737en-001001 | 15

Page 16

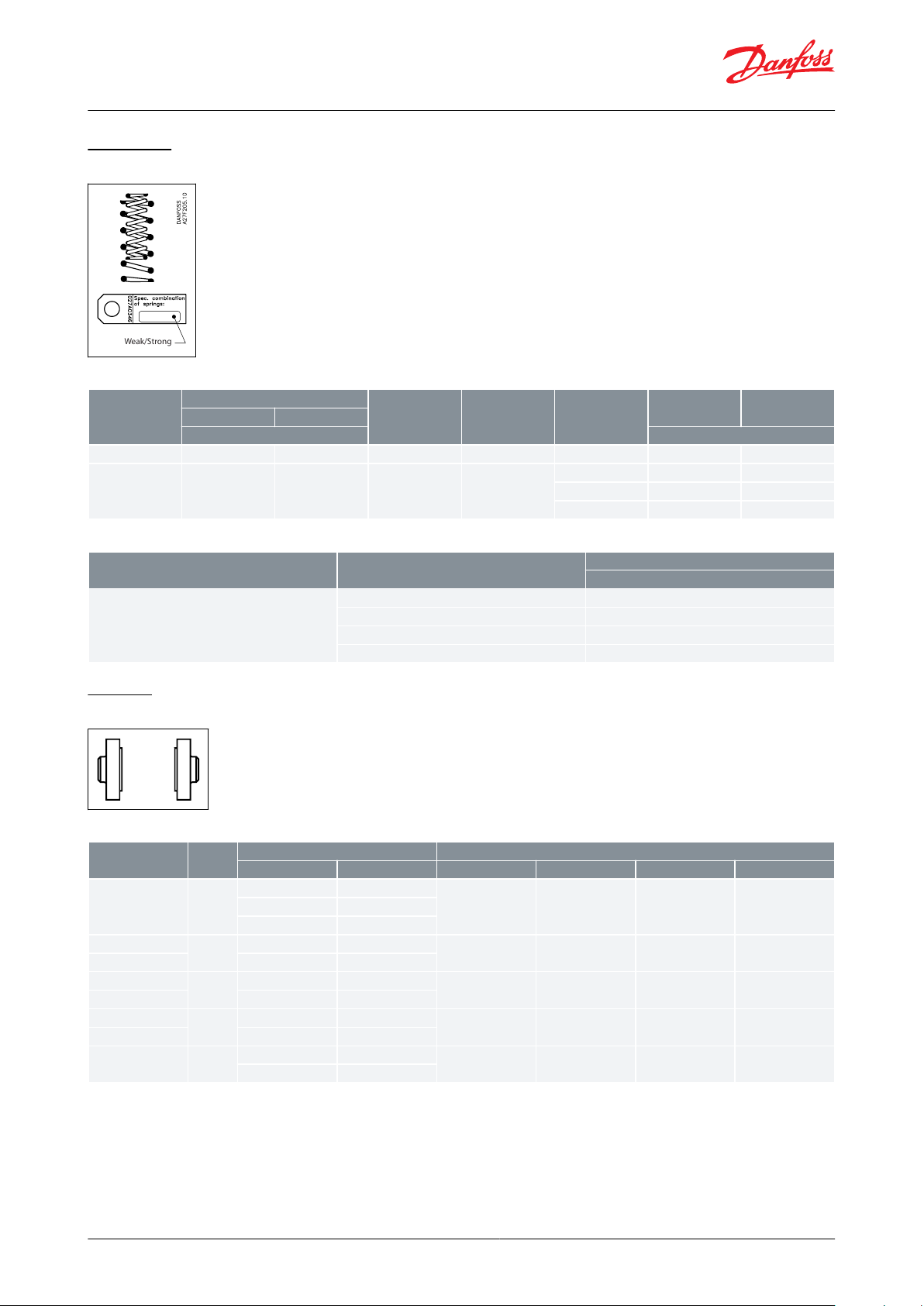

Weak/Strong

Subcooling ∆tu K

Pressure drop ∆p in PMFL

Pilot connection

on SV 1 – 3 only

Pos.

Type PMFL

"WEAK"

"STRONG"

4 – 15 bar

1.2 – 4 bar

Spring set

Code no.

0 – 8

STANDARD

WEAKP23 + 43

80-1 – 80-7

027F0123

027F0118

8 – 40

STRONGSd

125

027F0124

027F0119

200

027F0125

300

027F0126

027F0121

Pressure drop in PMFH ∆p bar

Type

WEAK

Code no.

1 – 4

PMFH 80.1 – 7

027F2190

PMFH 125

027F2191

PMFH 200

027F2192

PMFH 300

027F2193

Valve type

Flange

type

Weld

anges

Solder

anges

in.

Code no.

(1)

in.

Code no.

(1)

mm

Code no.

(1)

PMFL 80 /PMFH 80

12

3

⁄4

027N1220

7

⁄8

1

1

⁄8

027L1223

027L1229

22

28

027L1222

027L1228

1

027N1225

1

1

⁄4

027N1230

PMFL 125 /

23

1

1

⁄4

027N2332

1

3

⁄8

027L2335

35

027L2335

PMFH 125

1

1

⁄2

027N2340

PMFL 200 /

24

1

1

⁄2

027N2440

1

5

⁄8

027L2441

42

027L2442

PMFH 2002027N2450

PMFL 300 /

25

2

027N2550

2

1

⁄8

027L2554

54

027L2554

PMFH 300

2

1

⁄2

027N2565

PMFH 500

26

2

1

⁄2

027N2665

2

5

⁄8

027L2666

76

027L2676

3

027N2680

Liquid level regulating valves, Type PMFL / PMFH and SV

Spring set

Figure 12: Spring set

Table 18: Special spring set for PMFL

Table 19: Special spring set for PMFH

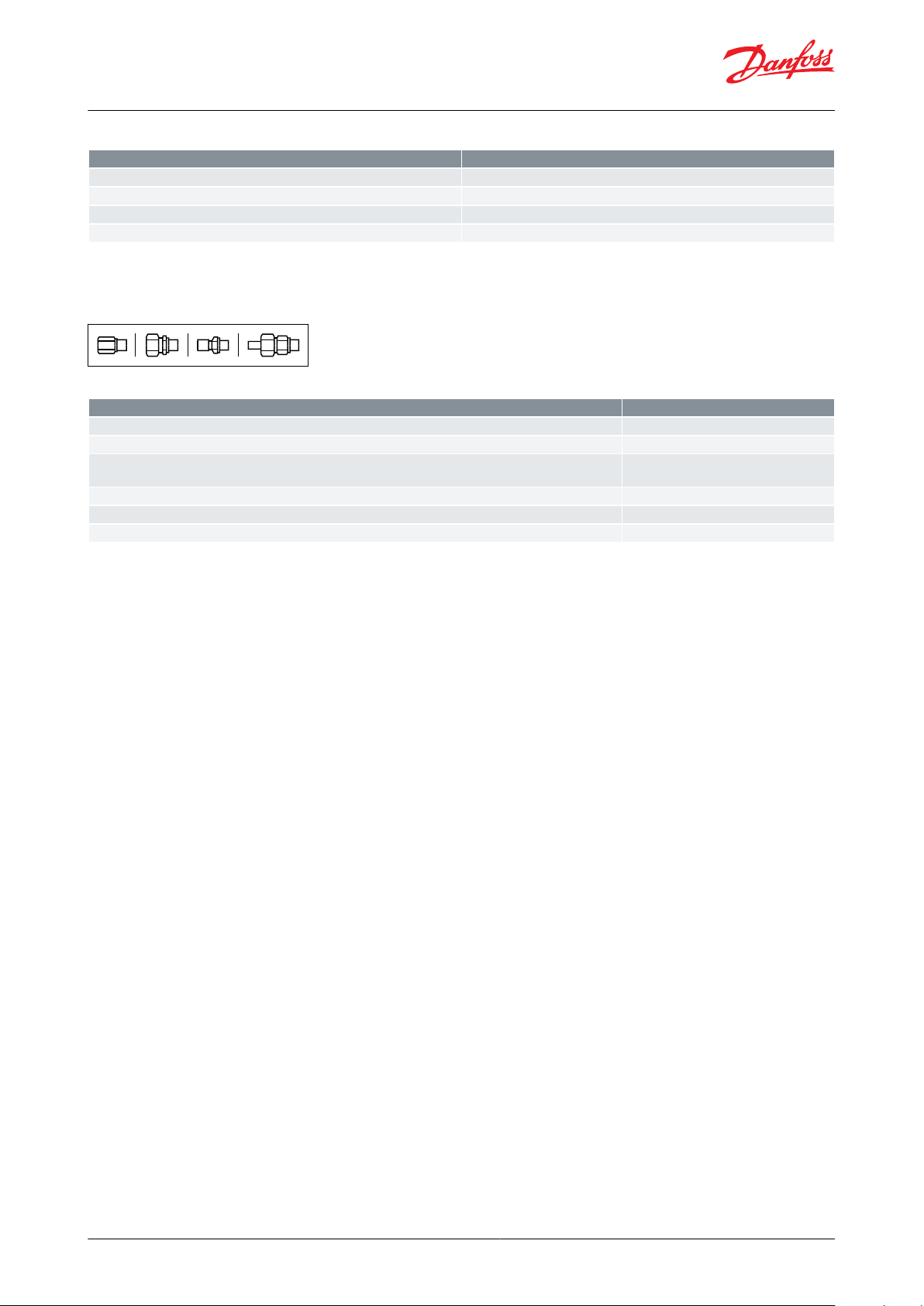

Flanges

Figure 13: Flanges

Table 20: Flanges

(1)

(1)

Code no. applies to one

Code no. applies to one

NOTE:

For dimension sketch of ange see spare part catalogue.

ange set consisting of one inlet and one outlet ange

ange set consisting of one inlet and one outlet ange

NOTE:

Stainless steel: anges, bolts for anges and top and bottom covers, see spare parts catalogue.

© Danfoss | Climate Solutions | 2021.02 AI242086443737en-001001 | 16

Page 17

Type

Connection

Code no.

Float pilot valve type SV

Balance tube liquid / vapour

Pilot line

SV 1:

027B2021

027B2021CE

(2)

SV 3:

027B2023

027B2023CE

(2)

1 in. Weld

Ø 6.5 / Ø 10 mm weld

(3)

Valve type

Orice diameter

Code no.

Code no. without housing

(4)

SV 4

Ø 3.0 mm

027B2024

(5)

027B2014

(5)

Orice

diameter

K

v

Code no.

(1)

Ø 1.0 mm

0.026

027B2080

Ø 1.5 mm

0.06

027B2081

Ø 2.0 mm

0.1

027B2082

Ø 2.5 mm

0.16

027B2083

Ø 2.8 mm

0.2

027B2084

Liquid level regulating valves, Type PMFL / PMFH and SV

Pilot valves

Figure 14: Pilot valves SV 1 – 3

Table 21: Pilot valves SV 1 – 3

(2)

(2)

Approved and CE-marked in accordance with Pressure Equipment Directive - 97/23/EC

Approved and CE-marked in accordance with Pressure Equipment Directive - 97/23/EC

(3)

(3)

3

3

⁄8 in. are connection can be supplied under code no. 027B2033.

⁄8 in. are connection can be supplied under code no. 027B2033.

Figure 15: Pilot valves SV 4

Table 22: Pilot valves SV 4

(4)

(4)

Flange for mounting without housing Code no. 027B2027

Flange for mounting without housing Code no. 027B2027

(5)

(5)

Approved and CE-marked in accordance with Pressure Equipment Directive - 97/23/EC

Approved and CE-marked in accordance with Pressure Equipment Directive - 97/23/EC

NOTE:

The code nos. stated apply to liquid level regulators type SV 4, SV 5 and SV 6 with two 1” weld connections for

balance tubes and two

1

⁄2” weld joints for liquid and evaporator connections respectively.

Spare parts and accessories

Smaller orices for the SV 4 are available as spare parts.

Seal kit: 027B2070

Table 23: Special orice code no. for SV 4

(1)

(1)

The code no. includes

The code no. includes

Figure 16: Pilot valve kits (EVM and coil)

orice and all necessary gaskets

orice and all necessary gaskets

© Danfoss | Climate Solutions | 2021.02 AI242086443737en-001001 | 17

Page 18

Coils, 10 W AC

AC: 027B1122xx where xx can be

110 V, 60 Hz

21

220 V, 50 Hz

31

220 V, 50 / 60 Hz

32

240 V, 50 Hz

33

Description

Code no.

Pressure gauge connection Ø 6.5 / Ø 10 mm weld / solder

027B2035

Pressure gauge connection ⁄ in. are (self-closing) (Must not be used in ammonia plant)

027B2041

Pressure gauge connection - 6 mm

Cutting ring connection - 10 mm

027B2063

027B2064

Pressure gauge connection -

1

⁄4 NPT

027B2062

Manual operating unit for PMFL. Can be tted in place of the regulator bottom plug

027F0128

⁄ in. are pilot connection for SV

027B2033

Liquid level regulating valves, Type PMFL / PMFH and SV

Table 24: Pilot valve kits (EVM and coil)

NOTE:

Can be screwed on to the PMFL or PMFH instead of the blanking plug.

Figure 17: Optional accessories

Table 25: Optional accessories

© Danfoss | Climate Solutions | 2021.02 AI242086443737en-001001 | 18

Page 19

Type

File name

Document type

Document topic

Approval authority

PMFH

Д-DK.БЛ08.B.03759

EAC Declaration

Machinery & Equipment

RU

PMFH/L

033F0685.AK

EU Declaration

EMCD/PED

Danfoss

033F0686.AH

Manufacturers Declaration

PED

Danfoss

033F0691.AE

Manufacturers Declaration

RoHS

Danfoss

Д-DK.БЛ08.B.00189_18

EAC Declaration

EMCRUД-DK.БЛ08.В.00191_18

EAC Declaration

Machinery & Equipment

RU

Д-DK.РА01.B.72054_20

EAC Declaration

PEDRU033F0474.AC

Manufacturers Declaration

ATEX

Danfoss

0B22768.5267890YTN

Pressure - Safety Certicate

CRN

TSSA

0045 202 1204 Z 00354 19 D 001(00)

Pressure - Safety Certicate

PED

TÜV

SA7200

Mechanical - Safety Certicate

ULSV033F0685.AK

EU Declaration

EMCD/PED

Danfoss

033F0691.AE

Manufacturers Declaration

RoHS

Danfoss

Д-DK.БЛ08.B.01120_19

EAC Declaration

EMCRUД-DK.БЛ08.В.00191_18

EAC Declaration

Machinery & Equipment

RU

Д-DK.РА01.B.72054_20

EAC Declaration

PEDRUUA.1O146.D.00069-19

UA Declaration

PED

LLC CDC EURO-TYSK

UA.TR-089.1112.01-19

Pressure - Safety Certicate

PED

LLC CDC EURO-TYSK

033F0473.AD

Manufacturers Declaration

ATEX

Danfoss

0045 202 1204 Z 00354 19 D 001(00)

Pressure - Safety Certicate

TÜV

SV 1-3

SA7200

Mechanical - Safety Certicate

UL

SV 4-6

19.10327.266

Marine - Safety Certicate

RMRS

The PMFL / PMFH valves are approved and CE marked in accordance with Pressure Equipment Directive 97/23/EC. For further details / restrictions - see Installation guide.

PMFL / PMFH-valves

(1)

Nominal bore

DN≤ 25 (1 in.)

DN 32-125 mm (1

1

⁄4 - 5 in.)/

DN 150 mm (6 in.)

Classied for

Fluid group I

Catagory

Article 3, paragraph 3

II

III

Liquid level regulating valves, Type PMFL / PMFH and SV

Certicates, declarations, and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Table 26: Valid approvals

Table 27: Pressure Equipment Directive (PED)

Table 28: Compliance

(1)

(1)

CE is only applicable to the EN GJS 400-18-LT

CE is only applicable to the EN GJS 400-18-LT

© Danfoss | Climate Solutions | 2021.02 AI242086443737en-001001 | 19

Page 20

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Spare Parts

Get access to the Danfoss spare parts and service kit catalog right from your smartphone. The app

contains a wide range of components for air conditioning and refrigeration applications, such as

valves, strainers, pressure switches, and sensors.

Download the Spare Parts app for free at www.danfoss.com/en/service-and-support/downloads.

Coolselector®2 - nd the best components for you HVAC/R system

Coolselector®2 makes it easy for engineers, consultants, and designers to nd and order the best

components for refrigeration and air conditioning systems. Run calculations based on your operating

conditions and then choose the best setup for your system design.

Download Coolselector®2 for free at coolselector.danfoss.com.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its

products without notice. This also applies to products already on order provided that such alterations can be made without subsequential

changes being necessary in specications already agreed. All trademarks in this material are property of the respective companies. Danfoss and

the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.02 AI242086443737en-001001 | 20

Loading...

Loading...