Page 1

Design Manual

PLUS+1®

Service Tool

www.danfoss.com

Page 2

Design Manual

PLUS+1® Service Tool

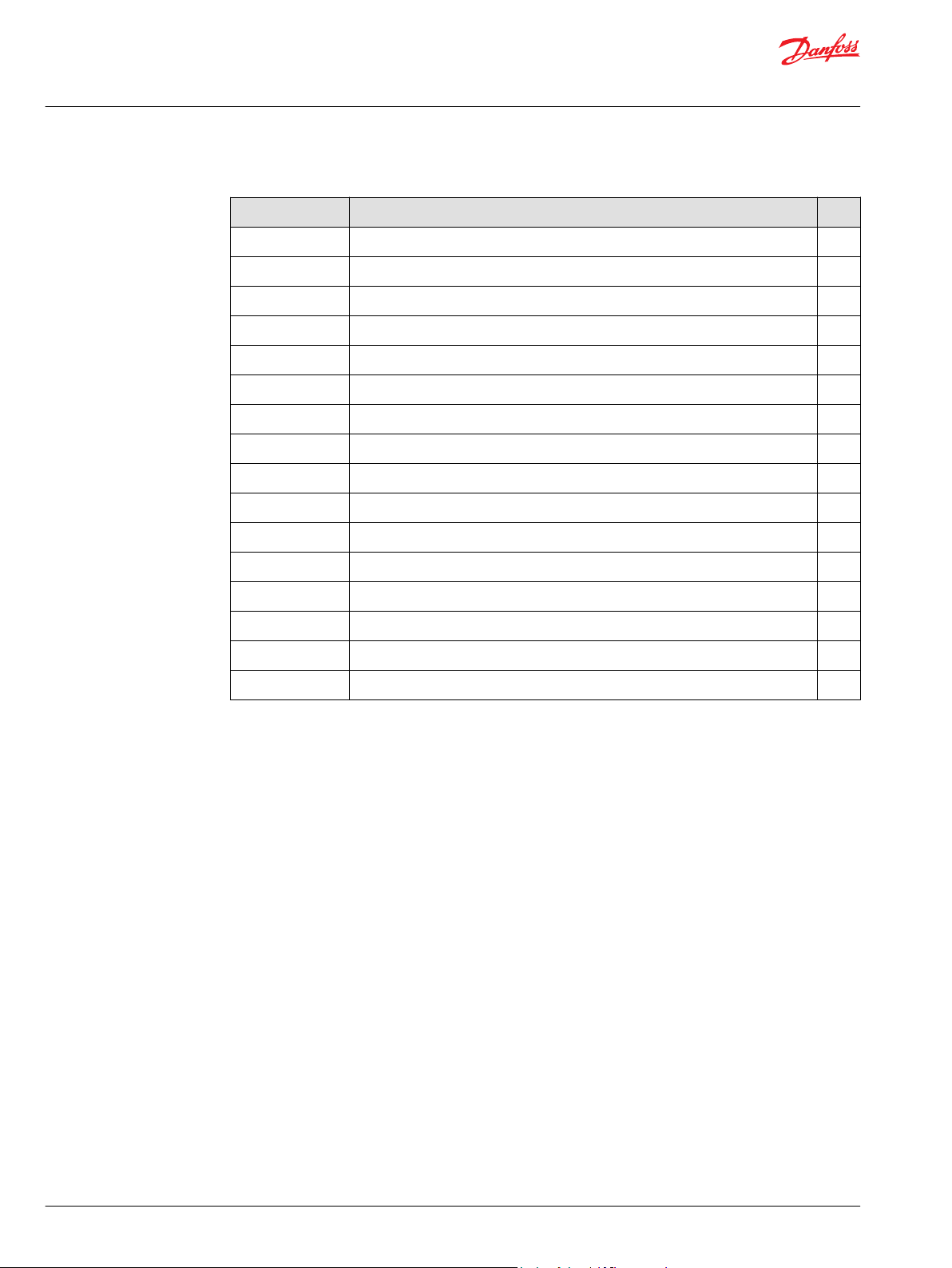

Revision history Table of revisions

Date Changed Rev

February 2021 Supports 12.2 1301

May 2020 Supports 12.1 1202

November 2019 Supports 12.0 1001

April 2019 Supports 11.1 0901

November 2018 Supports 11.0 0801

May 2018 Supports 10.1 0701

October 2017 Supports 10.0 0601

April 2017 Updated to support WebHelp; Supports 9.1 0503

October 2016 Minor change; Supports 9.0 0502

September 2016 Supports 9.0 0501

Changed document number from 'AQ00000160' to 'AQ152986485048' XX

February 2016 Supports 8.0.x and later 0401

August 2015 Supports 7.2.x and later 0301

November 2014 Supports 7.1.x and later CA

December 2013 Conversion to Danfoss layout BA

December 2013 First edition AA

2 | © Danfoss | February 2021 AQ152986485048en-001301

Page 3

Design Manual

PLUS+1® Service Tool

Contents

Introduction

Service applications

Features................................................................................................................................................................................................7

IEC 61508:2010 support tool certification references.........................................................................................................8

Important information to reduce risk....................................................................................................................................... 8

Fault checking and error handling.............................................................................................................................................9

Downloading and testing your applications .........................................................................................................................9

Getting ready..................................................................................................................................................................................... 9

Creating log files overview............................................................................................................................................................9

Log tool page.................................................................................................................................................................................. 10

Environment design......................................................................................................................................................................10

Selecting the page environment..............................................................................................................................................11

Naming the log pages..................................................................................................................................................................11

Arranging log pages..................................................................................................................................................................... 12

Quick navigation between pages............................................................................................................................................ 12

Defining a start page.................................................................................................................................................................... 13

Setting up Tool Key in the Service Application file (P1D)................................................................................................14

ECU Specific Tool Keys............................................................................................................................................................15

License embedded Tool Key set up.........................................................................................................................................17

Working offline • overview..........................................................................................................................................................18

Reconnecting offline files............................................................................................................................................................20

Replacing missing and existing ECU.......................................................................................................................................21

Adding language translations...................................................................................................................................................22

Removing language translations............................................................................................................................................. 22

Editing language translations................................................................................................................................................... 23

Changing the original language...............................................................................................................................................23

Resizing components to fit clipped text................................................................................................................................24

Adding external links....................................................................................................................................................................24

Select hyperlink.........................................................................................................................................................................25

Adding diagnostic data to the service application............................................................................................................26

Editing diagnostic data...........................................................................................................................................................26

CAN Xplorer protocol................................................................................................................................................................... 26

Adding CAN database files in the PLUS+1® Service Tool.................................................................................................27

Signal and Message Attributes................................................................................................................................................. 29

Cycle Time................................................................................................................................................................................... 29

Send Type....................................................................................................................................................................................29

XML files - Danfoss CAN Xplorer database definition.......................................................................................................30

Example........................................................................................................................................................................................33

XML file....................................................................................................................................................................................34

Changing the CAN ID dynamically.......................................................................................................................................... 35

Adding and editing the CAN ID dynamically in XML format.................................................................................... 35

System configuration................................................................................................................................................................... 37

Using Find/Replace Signal Names...........................................................................................................................................38

Example: Find.............................................................................................................................................................................40

Example: Replace......................................................................................................................................................................42

Using Insert Signal Names.......................................................................................................................................................... 43

Example: Insert.......................................................................................................................................................................... 44

Changing Service Application properties.............................................................................................................................45

Creating custom themed modes via enabling disable menus, toolbars and navigator......................................46

Enabling custom page mode.................................................................................................................................................... 46

Reverting back to default in full page mode..................................................................................................................46

Enabling disable menus and toolbars...............................................................................................................................46

Hide virtual ECUs in Normal View............................................................................................................................................ 47

Skip ‘Replace Missing ECU’ ........................................................................................................................................................ 47

Require specific PLUS+1® Service Tool version................................................................................................................... 48

Gateway password........................................................................................................................................................................ 48

Override protocol settings..........................................................................................................................................................49

Creating System Download Packages....................................................................................................................................50

System Download Package Example......................................................................................................................................53

©

Danfoss | February 2021 AQ152986485048en-001301 | 3

Page 4

Design Manual

PLUS+1® Service Tool

Contents

Basic log design page

Basic parameter design page

Advanced log design page

Generic ECU......................................................................................................................................................................................54

Importing and exporting advanced log pages................................................................................................................... 57

Exporting advanced log pages............................................................................................................................................57

Importing advanced log pages........................................................................................................................................... 58

Creating hardware service files.................................................................................................................................................59

Uploading and downloading specific bit values................................................................................................................60

Example: Log a specific bit....................................................................................................................................................60

Example: Set a specific bit..................................................................................................................................................... 60

Design Page (Basic) log page.....................................................................................................................................................62

Design Page (Basic) Log dialog box........................................................................................................................................ 63

Selecting log signal names.........................................................................................................................................................64

Adding Rows to the Log Page...................................................................................................................................................64

Creating graphical overviews....................................................................................................................................................65

Graphical Overview View ........................................................................................................................................................... 65

Bar Graph View ...............................................................................................................................................................................66

Oscilloscope View .........................................................................................................................................................................66

Text view........................................................................................................................................................................................... 67

Creating a list view.........................................................................................................................................................................69

Design Page (Basic) parameter page......................................................................................................................................70

Creating Basic parameter files...................................................................................................................................................72

Parameter views.............................................................................................................................................................................73

Creating a list view.........................................................................................................................................................................75

Setting defaults in parameter pages.......................................................................................................................................77

Creating a Basic graphical view................................................................................................................................................ 80

Advanced Log Design Page Elements....................................................................................................................................82

Components Tab Elements........................................................................................................................................................83

Page Properties...............................................................................................................................................................................83

Advanced Design Settings..........................................................................................................................................................84

Adjusting Component Placement........................................................................................................................................... 86

Resizing Components.............................................................................................................................................................86

Common Component Alignment Tools................................................................................................................................86

Common Component Property Settings.............................................................................................................................. 88

Component Visibility.................................................................................................................................................................... 89

Hide Components • Value Type...........................................................................................................................................90

Hide Components.................................................................................................................................................................... 90

Hide Components • Example................................................................................................................................................92

Show Components...................................................................................................................................................................94

Show Components • Example..............................................................................................................................................95

Multiplier...........................................................................................................................................................................................97

Displayed Digits..............................................................................................................................................................................98

Image Repository...........................................................................................................................................................................99

Using Hyperlinks in Text, Image and Button components...........................................................................................100

Using Hyperlink Component............................................................................................................................................. 100

Removing Hyperlinks ...........................................................................................................................................................101

Using Hide in Normal View...................................................................................................................................................... 101

Using Wizard Design ................................................................................................................................................................. 102

Image Lookup Table...................................................................................................................................................................103

Using the Lookup Tables Tab............................................................................................................................................ 103

Text Lookup Table..................................................................................................................................................................108

Exporting Lookup Tables..........................................................................................................................................................109

Export to CSV format.............................................................................................................................................................110

Importing Lookup Tables......................................................................................................................................................... 112

Import from CSV format.......................................................................................................................................................112

Signals Tab.....................................................................................................................................................................................114

Selector Tab • Text.......................................................................................................................................................................116

4 | © Danfoss | February 2021 AQ152986485048en-001301

Page 5

Design Manual

PLUS+1® Service Tool

Contents

Text Properties........................................................................................................................................................................ 116

Text Inspector Page...............................................................................................................................................................117

Selector Tab • Image...................................................................................................................................................................118

Image Properties.................................................................................................................................................................... 118

Using Image Properties........................................................................................................................................................119

Image Inspector Page...........................................................................................................................................................121

Common Component Property Settings • Panel Component....................................................................................122

Panel Component Set up..........................................................................................................................................................122

Panel Component features.................................................................................................................................................123

Panel Component Properties............................................................................................................................................ 123

Panel Component Alignment............................................................................................................................................124

Panel Component Styles..................................................................................................................................................... 124

Panel definitions.......................................................................................................................................................................... 124

Selector Tab • Input Value.........................................................................................................................................................128

Input Values Properties........................................................................................................................................................128

Additional Settings - Hide Component..........................................................................................................................129

Additional Settings - Hyperlink Table.............................................................................................................................129

Selector Tab • Button..................................................................................................................................................................131

Display Settings...................................................................................................................................................................... 132

Image setting...........................................................................................................................................................................133

Hyperlink setting....................................................................................................................................................................133

Help Data...................................................................................................................................................................................133

Bevel............................................................................................................................................................................................133

Additional Settings................................................................................................................................................................133

Split Image setting.................................................................................................................................................................135

Selector Tab • Standard Log.....................................................................................................................................................136

Standard Log • Signal Scaling............................................................................................................................................ 137

Scale Definition setting........................................................................................................................................................138

Standard Log • Inspector Elements..................................................................................................................................141

Selector Tab • Bargraph.............................................................................................................................................................142

Bargraph Inspector Tab........................................................................................................................................................144

Selector Tab • Oscilloscope...................................................................................................................................................... 145

Creating an Oscilloscope Display.....................................................................................................................................145

Oscilloscope Inspector Tab.................................................................................................................................................150

Selector Tab • Gauge.................................................................................................................................................................. 151

Creating a Gauge Display....................................................................................................................................................152

Gauge Inspector Tab.............................................................................................................................................................160

Selector Tab • Array List.............................................................................................................................................................162

Selecting an Array Element ............................................................................................................................................... 163

Selector Tab – String Parameter.............................................................................................................................................164

Creating a String Parameter Display............................................................................................................................... 165

Advanced parameter design page

Parameter Page............................................................................................................................................................................167

Advanced Design page elements..........................................................................................................................................167

Selector tab components......................................................................................................................................................... 168

Selector Tab • Standard Parameter....................................................................................................................................... 168

Creating parameter tables ...................................................................................................................................................... 170

Import and export..................................................................................................................................................................172

Standard Parameter Inspector Page.....................................................................................................................................173

Selector Tab • Boolean Parameters....................................................................................................................................... 175

Boolean Parameter Properties Elements.......................................................................................................................176

Boolean Parameter Inspector Elements.........................................................................................................................177

Selector Tab • Set Pulse............................................................................................................................................................. 179

Display Settings...................................................................................................................................................................... 180

Image setting...........................................................................................................................................................................180

Split Image setting.................................................................................................................................................................180

Set Pulse Properties...............................................................................................................................................................181

Selector Tab • Graph Component..........................................................................................................................................183

Graph Component Inspector Elements......................................................................................................................... 188

©

Danfoss | February 2021 AQ152986485048en-001301 | 5

Page 6

Design Manual

PLUS+1® Service Tool

Contents

Checkpoints

ECU information signals

Menu and tool bar navigation

Selector Tab – String Parameter.............................................................................................................................................190

Downloading String Parameter values.......................................................................................................................... 190

Help ID - General..........................................................................................................................................................................191

Help ID - Setting up the Service Application.....................................................................................................................192

Creating and connecting checkpoints.................................................................................................................................193

String Component Properties.................................................................................................................................................197

Tool bar parameter description..............................................................................................................................................203

Tool bar log file description.....................................................................................................................................................203

6 | © Danfoss | February 2021 AQ152986485048en-001301

Page 7

Design Manual

PLUS+1® Service Tool

Introduction

Features

Learn the concepts and processes of designing service applications, basic and advanced log pages, and

parameter pages.

For information regarding installation and set-up of the PLUS+1® Service Tool, please refer to:

PLUS+1® Service Tool User Manual, AQ152986484649

https://www.danfoss.com/en/search/?filter=type%3Adocumentation%2Csegment%3Adps

The PLUS+1® Service Tool provides the ability to monitor and tune the operations of controller devices on

a PLUS+1® system. The PLUS+1® GUIDE application developer can use basic service tool building blocks to

develop a custom look and feel service tool.

Standard features of the PLUS+1® Service Tool are:

Bar graph displays

•

Oscilloscope displays for trending and tuning

•

Data export to spreadsheet tools

•

User-defined graphics

•

OEM customizing of the PLUS+1® Service Tool look and feel

•

No programming experience required

•

Work in either online or offline modes

•

Importation of custom graphics to create a proprietary look to the PLUS+1® Service Tool

•

Access to any device on a PLUS+1® network via CAN, using the PLUS+1® USB/CAN communicator

•

Data logging

•

Read and write access for tuning parameters

•

Protection for determining levels of access to PLUS+1® device data

•

Viewing of service record logs maintained in the PLUS+1® device

•

Downloading application files into PLUS+1® controller

•

©

Danfoss | February 2021 AQ152986485048en-001301 | 7

Page 8

Design Manual

PLUS+1® Service Tool

Introduction

IEC 61508:2010 support tool certification references

Contact and reference material are available regarding which versions of PLUS+1® Service Tool carry the

IEC 61508:2010 support tool certification.

Please contact the PLUS+1® Helpdesk.

https://www.danfoss.com/en/products/software/dps/plus1-software-services-support-and-training/plus1support-and-services

For complete details regarding PLUS+1® GUIDE and PLUS+1® Service Tool IEC 61508:2010 support tool

certificates, see:

PLUS+1® GUIDE User Manual, AQ152886483724

https://www.danfoss.com/en/search/?filter=type%3Adocumentation%2Csegment%3Adps

Important information to reduce risk

Your responsibility when designing a PLUS+1® Service Tool application is to include the checking and the

error handling needed to reduce risks in normal and abnormal operating conditions.

The applications that you create with the PLUS+1® Service Tool typically control heavy, powerful, and

mobile off-road equipment such as tractors, cranes, and harvesters.

The PLUS+1® Service Tool has no automatic protections against the risks, such as from bugs in the PLUS

+1® Service Tool software, errors in the PLUS+1® Service Tool user guides, or incompatibilities between

software versions of the PLUS+1® Service Tool.

You must design and test your application to reduce these risks.

8 | © Danfoss | February 2021 AQ152986485048en-001301

Page 9

W

Design Manual

PLUS+1® Service Tool

Introduction

Fault checking and error handling

The following are some items to consider when developing fault checking and error handling for your

application.

Consider:

•

•

•

•

•

•

•

How the machine is normally used

Possible operator errors and their consequences

Industry safety standards and legal requirements

Input and output failures and their consequences including:

Joystick, sensor, and other inputs suddenly going to 100 % or to 0 %

‒

Outputs that control machinery direction, speed, and force suddenly changing direction or going

‒

to 100 % or to 0 %

Decide how likely each failure is

The more likely a failure, the more you need protect against the consequences of the failure

‒

The sequence of events and consequences of a fault or error

The sequence of events and consequences of an emergency stop

Warning

Under normal operating conditions, using this type of machinery always involves risk of personal

injury and equipment damage. Abnormal operating conditions increase the risk of personal injury

and equipment damage.

Downloading and testing your applications

Once you have created an application, you have the responsibility to download and test the application.

You should only download your application to hardware or change software parameters while the

vehicle is not in operation. After downloading, test application operation under normal and abnormal

operating conditions.

You should make sure that:

Individual inputs produce expected outputs.

•

Combinations of inputs do not produce unexpected or dangerous outputs.

•

Fault handling and error checking work as designed.

•

Getting ready

Individual requirements to work with the application examples in this manual:

Fully functional versions of PLUS+1® GUIDE and PLUS+1® Service Tool installed on a PC

•

Working knowledge of PLUS+1® GUIDE environment, including an understanding to use the full

•

capabilities of PLUS+1® Service Tool

The graphical images in this manual may appear different depending on which version of PLUS+1

Service Tool is in use.

®

Creating log files overview

This section describes how to use the PLUS+1® Service Tool to create, run and save controller log pages.

©

Danfoss | February 2021 AQ152986485048en-001301 | 9

Page 10

Design Manual

PLUS+1® Service Tool

Introduction

Log tool page

Environment design

The log tool is a record keeper for the specified tasks selected for monitoring within the controller

application. The log tool page should not be confused with the parameter page, which sets the

application operating values.

Two types of log files can be created:

Basic

•

The basic log files are used to create simple graphical parameter environments.

‒

Advanced

•

The advanced log files allow the user to create a more complex graphical parameter file

‒

environment.

Log and parameter page environments can be graphically customized in PLUS+1®Service Tool by using

two types of environments:

Basic

•

The basic environment can be used for quick and simple graphical overview creation.

‒

Advanced Page Design

•

The advanced environment allows more options and flexibility in creating a custom page

‒

environment.

10 | © Danfoss | February 2021 AQ152986485048en-001301

Page 11

Design Manual

PLUS+1® Service Tool

Service applications

Learn the initial set-up of the start page and other features that allow for more accessibility, such as

"offline mode."

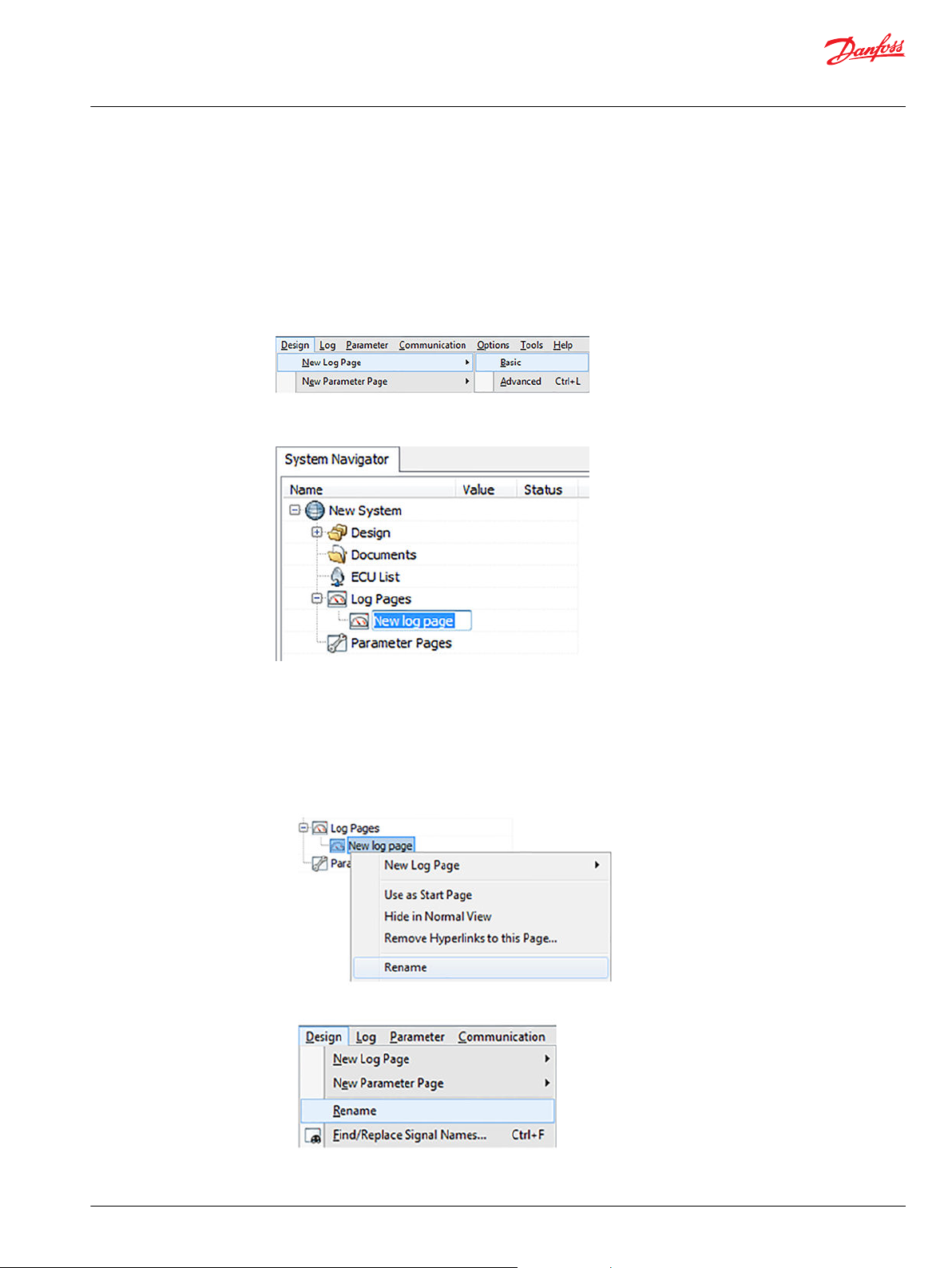

Selecting the page environment

The selection of the page environment is made when creating a new log or parameter page. After

selecting New Log Page or New Parameter Page from the Design menu, a submenu selection appears.

A selection between a Basic or Advanced design page must be made.

A new item, titled New log page or New parameter page will appear under the Log Pages or

Parameter Pages section of the System Navigator.

Naming the log pages

The created log pages can be named now so they can be accessed quickly.

There are two ways to name a log page:

1. Right-click on the New Log Page submenu in the System Navigator, and select Rename from the

pop-up menu.

2. Select Design > Rename from the main PLUS+1® Service Tool menu.

©

Danfoss | February 2021 AQ152986485048en-001301 | 11

Page 12

Design Manual

PLUS+1® Service Tool

Service applications

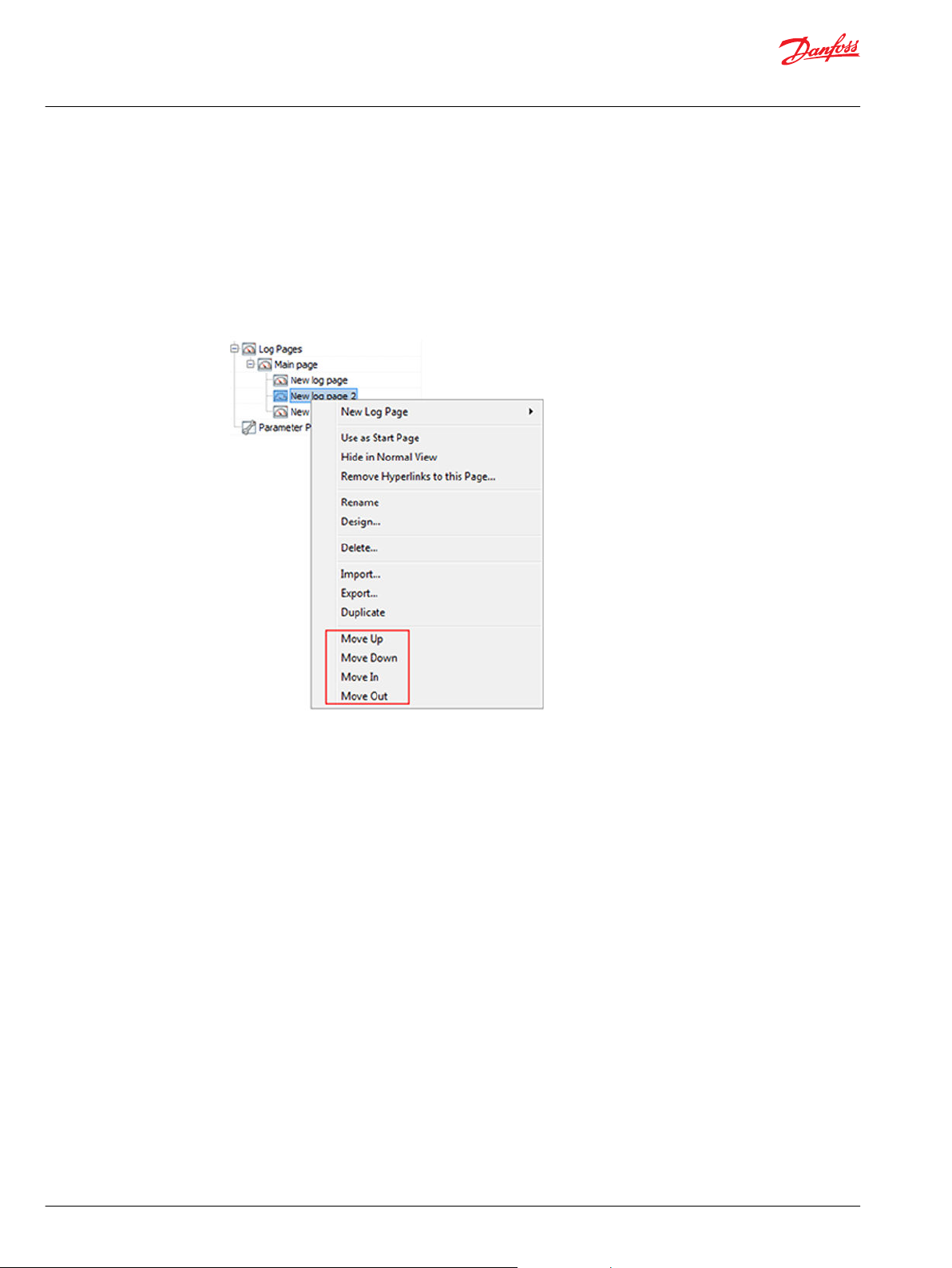

Arranging log pages

Arrange the order of log files within the System Navigator tree by selecting and right-clicking on the log

file to reveal a submenu.

Move Up, Move Down, Move In, or Move Out files within the Log Pages section of the System

Navigator tree.

Files can be also be moved within the section by using drag and drop while holding the Ctrl key.

It is not possible to move log files to the Parameter Page section of the System Navigator tree.

Quick navigation between pages

Navigate quickly through the files using the quick navigation function. Enable quick navigation by

pressing and holding the Shift key while moving up and down the System Navigator tree. Releasing the

Shift key loads the current page selected.

12 | © Danfoss | February 2021 AQ152986485048en-001301

Page 13

Design Manual

PLUS+1® Service Tool

Service applications

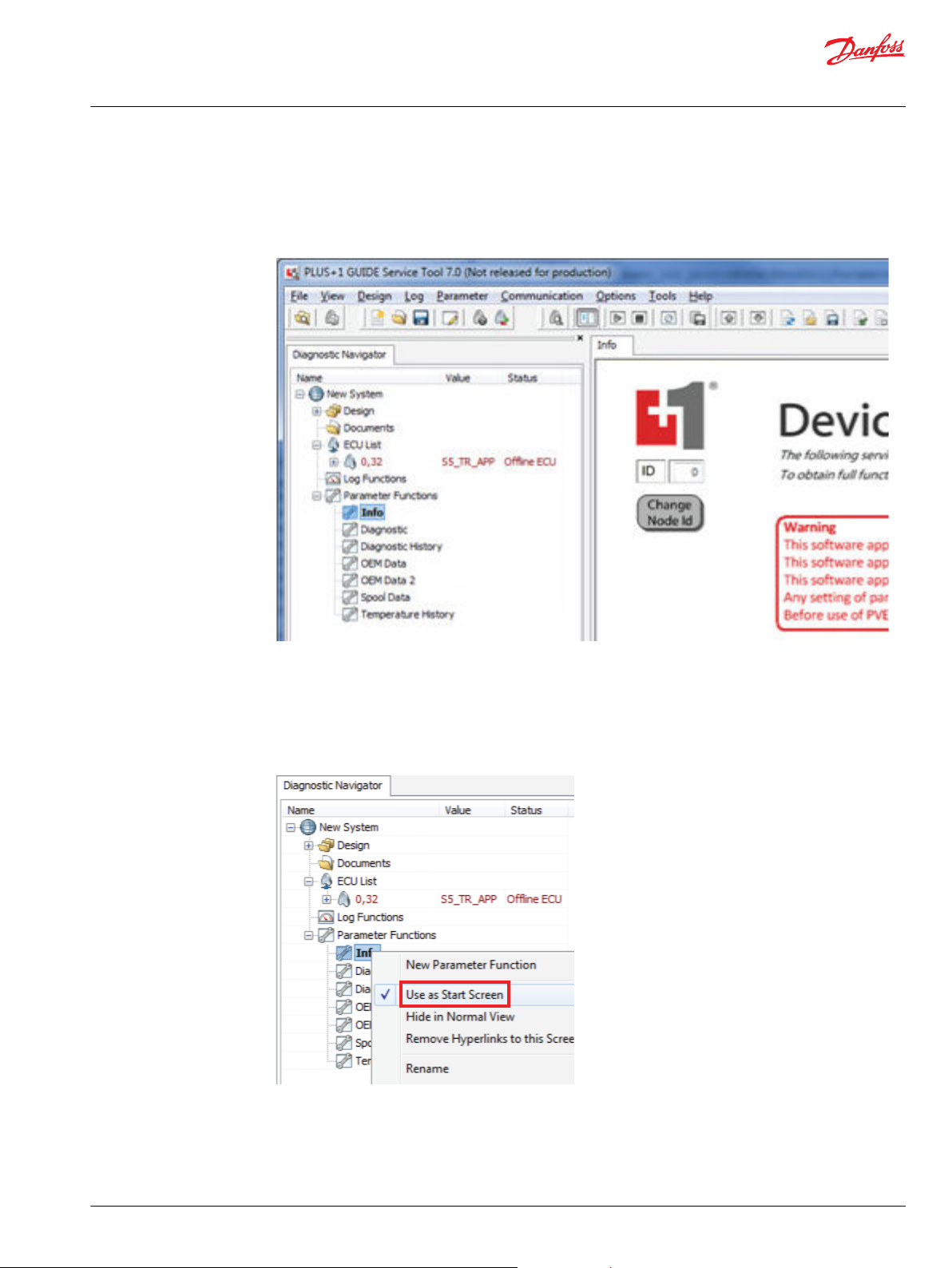

Defining a start page

Define Log and Parameter start pages. The selected start page will be displayed when opening P1D or

P1H files. Start pages can be existing log pages or they can be created using the advanced log design

page to incorporate text and graphics.

Right-click on the Parameter Pages. Select Use as Start page from the drop down menu. A check mark

will be placed to the left of the menu selection. The selected page will now be shown when opening the

P1D or P1H file.

The start page can be deleted or changed by right-clicking on the Parameter Pages and selecting Use as

Start page. This will deselect the selection. Selecting another page to use as the start page will

automatically deselect the previous start page.

©

Danfoss | February 2021 AQ152986485048en-001301 | 13

Page 14

Design Manual

PLUS+1® Service Tool

Service applications

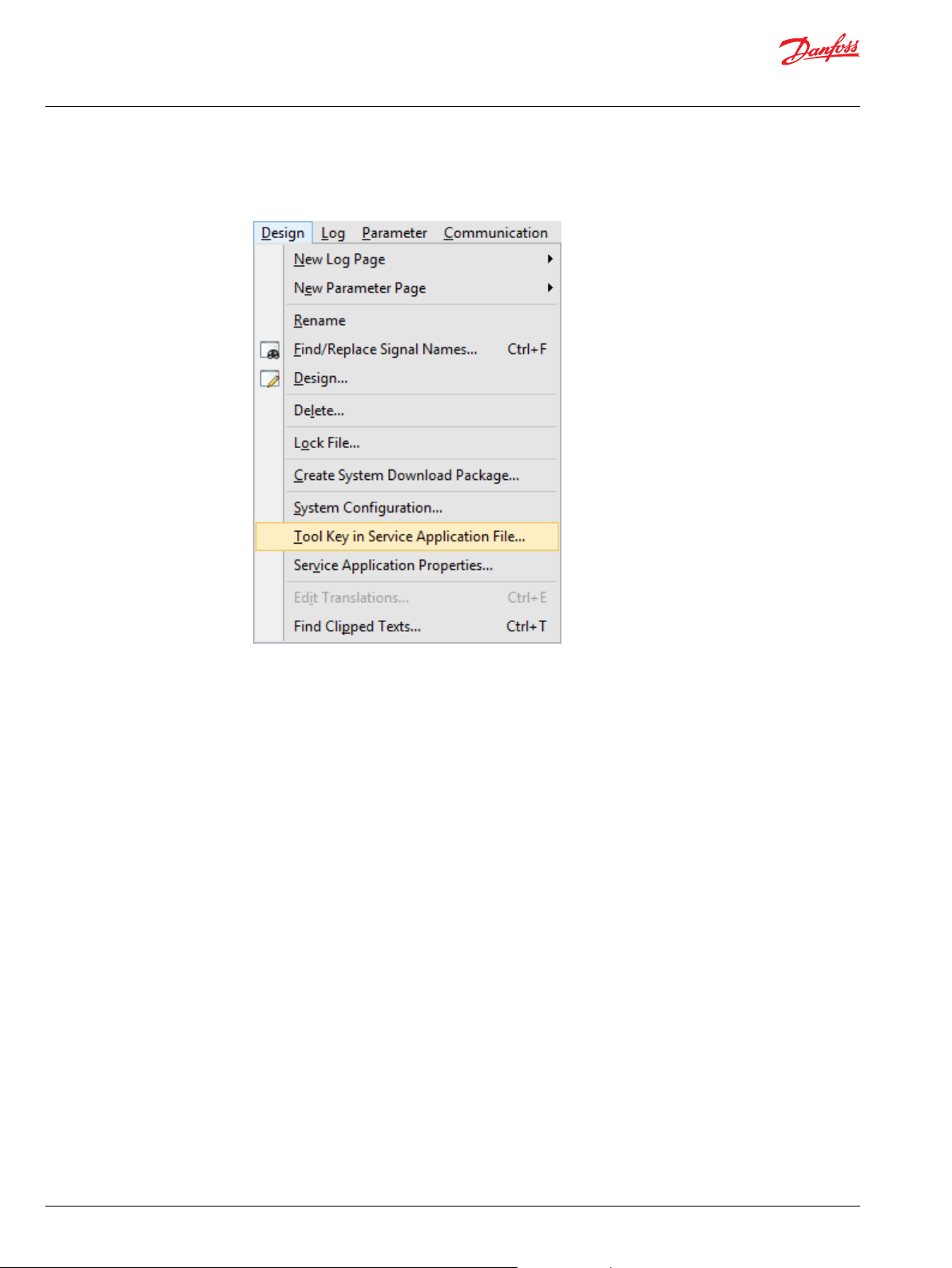

Setting up Tool Key in the Service Application file (P1D)

1. Select Design > Tool Key in Service Application File... to enter a Tool Key.

A Tool Key in Service Application File dialog box appears.

14 | © Danfoss | February 2021 AQ152986485048en-001301

Page 15

Design Manual

PLUS+1® Service Tool

Service applications

2. Enter the name (Description) and password created in the PLUS+1® GUIDE application in the Default

Tool Key section and click OK to close the box.

3. To remove the Tool key in the service application file, click Clear.

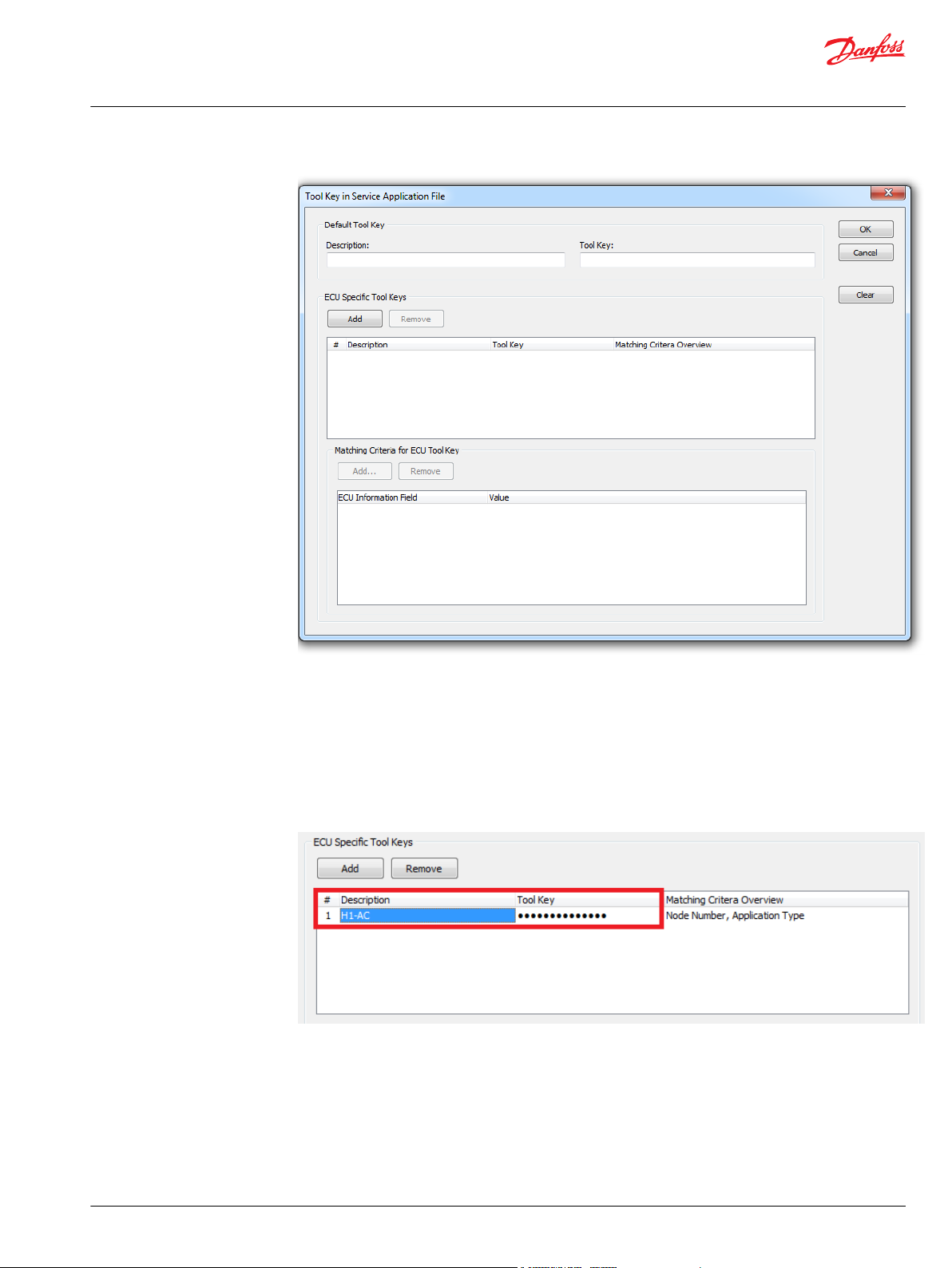

ECU Specific Tool Keys

ECU Specific Tool Keys can be added if the system uses multiple Tool Keys.

1. Click Add in ECU Specific Tool Keys to add a new entry. Enter the name (Description) and password

created in the PLUS+1® GUIDE application.

©

Danfoss | February 2021 AQ152986485048en-001301 | 15

Page 16

Design Manual

PLUS+1® Service Tool

Service applications

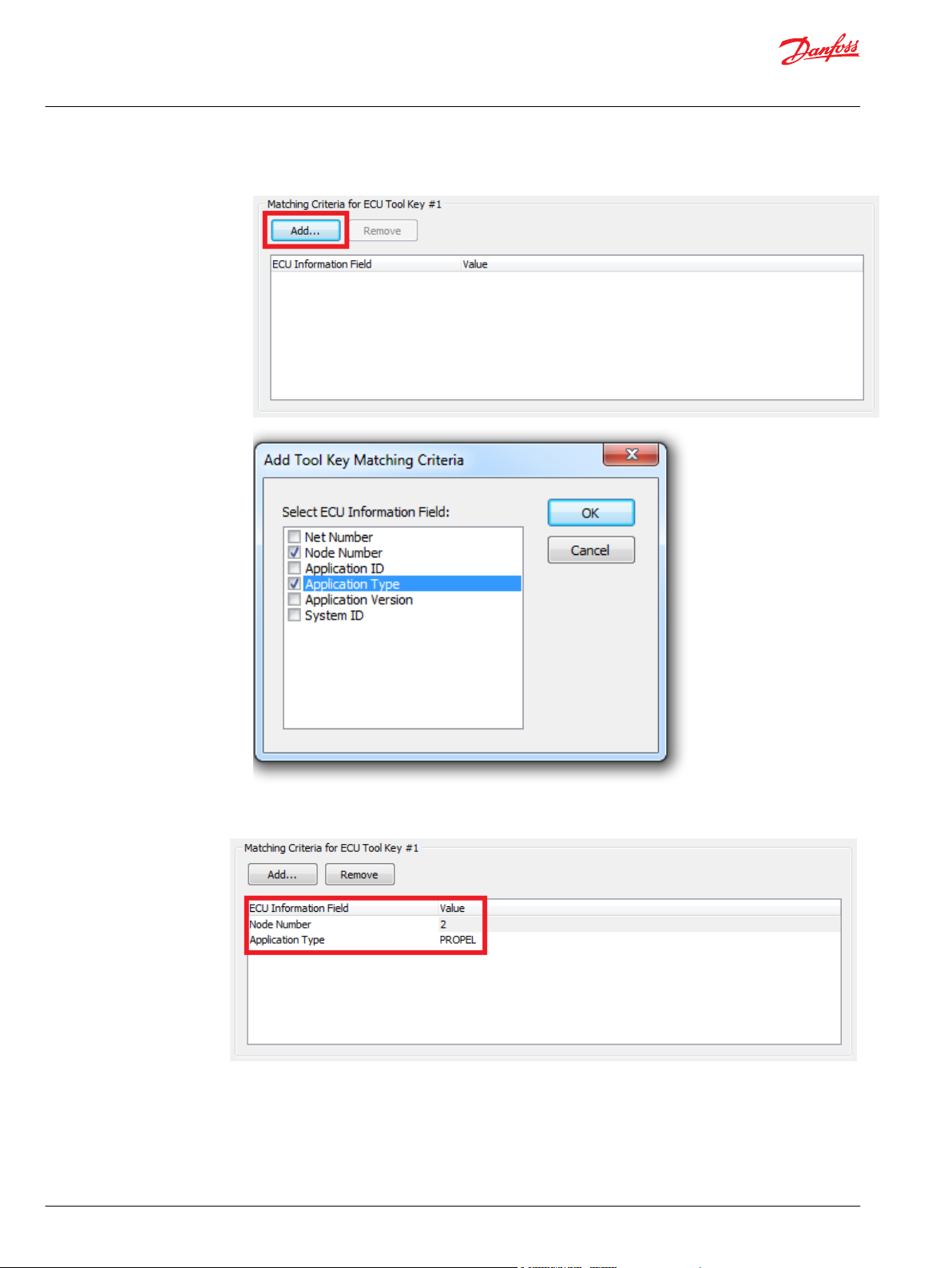

2. Click Add in Matching Criteria for ECU Tool Key to add the condition for using the Tool Key.

In this example, the ECU Specific Tool Key will be used for ECUs that have Node Number 2 and

Application Type is PROPEL.

16 | © Danfoss | February 2021 AQ152986485048en-001301

Page 17

Design Manual

PLUS+1® Service Tool

Service applications

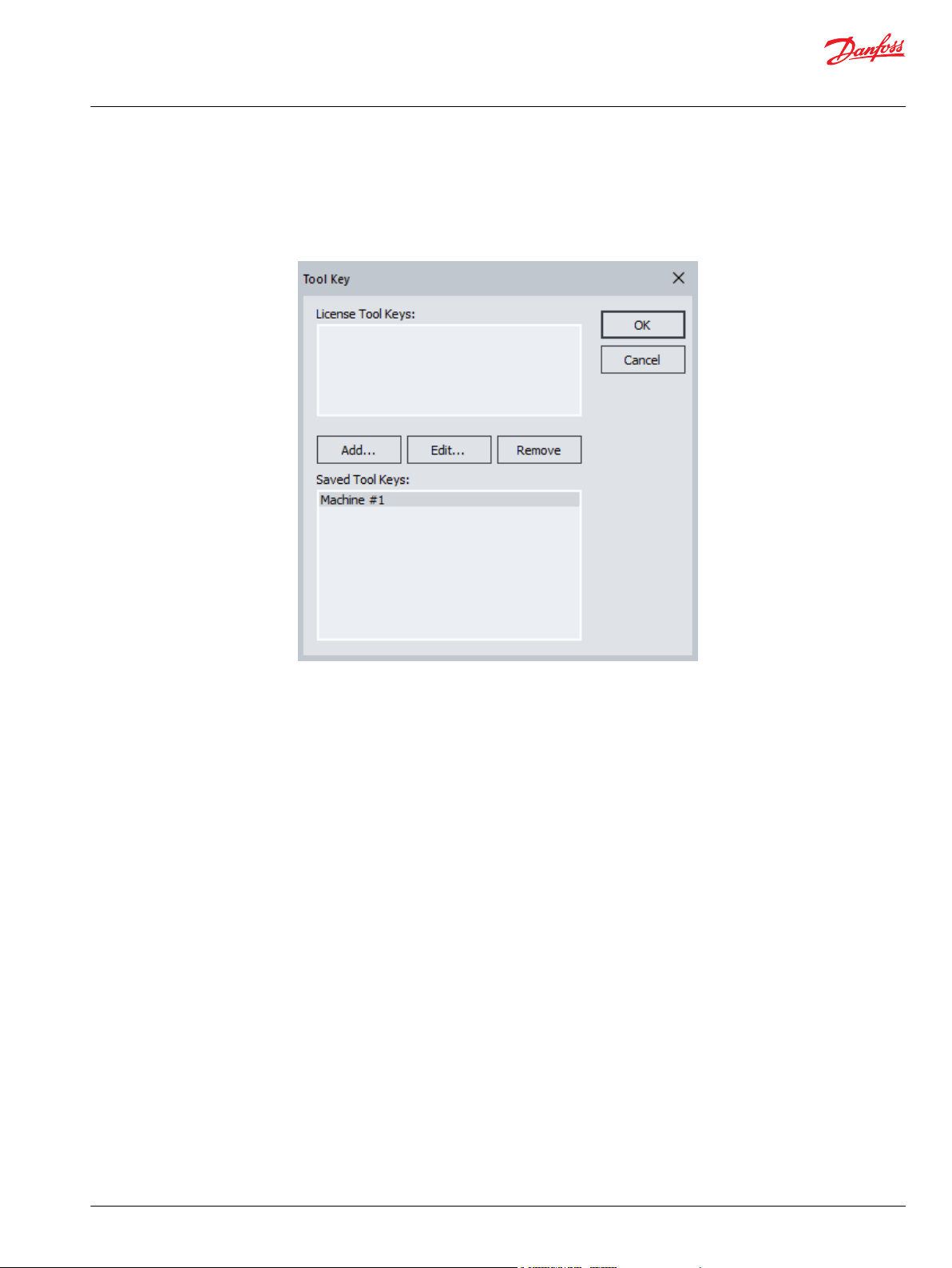

License embedded Tool Key set up

Tool keys embedded in the active license will appear in the License Tool Keys field of the Tool Key

dialog box.

1. Select Tool Key and click OK to activate the selected Tool Key.

2. Select Add....

The Tool key is now active.

©

Danfoss | February 2021 AQ152986485048en-001301 | 17

Page 18

Design Manual

PLUS+1® Service Tool

Service applications

Working offline • overview

Most work in the PLUS+1® Service Tool is done in a controller-connected online mode, but it is possible to

work in an offline mode as well.

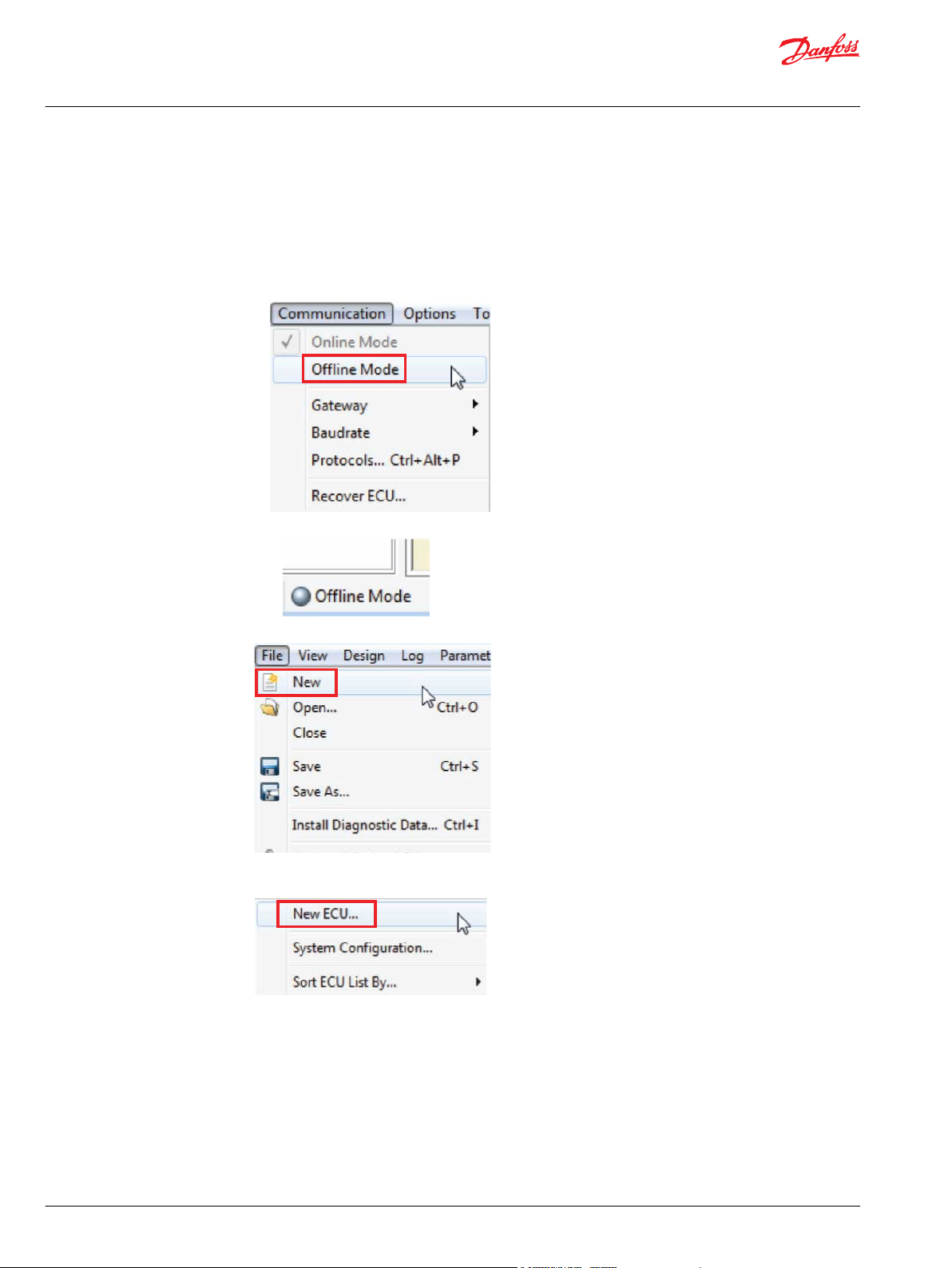

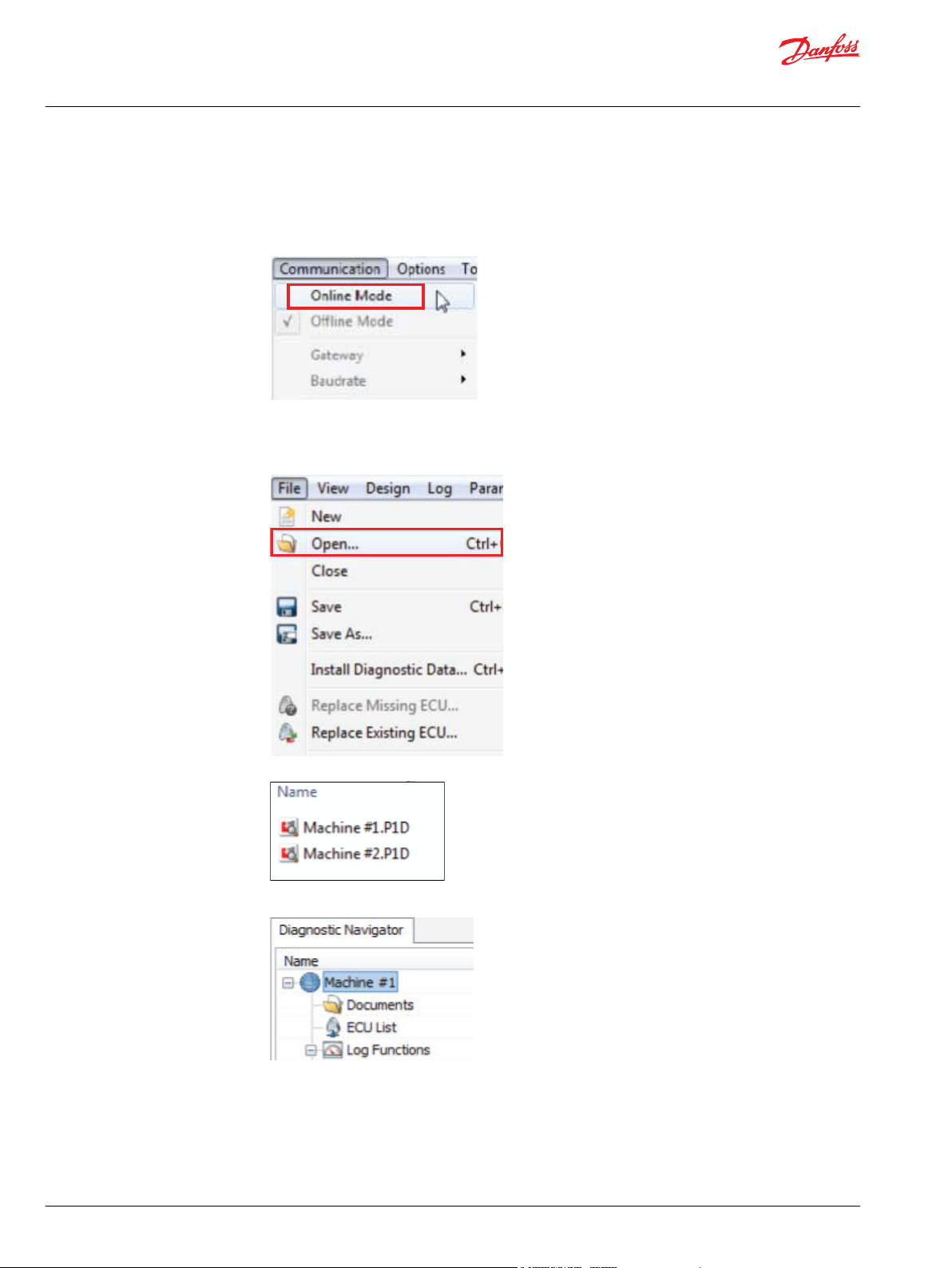

1. Set up the PLUS+1® Service Tool in the Offline Mode.

a) Open the PLUS+1® Service Tool.

b) Select Communication > Offline Mode in the menu bar.

Offline Mode is indicated in the connection status bar at the bottom center of the PLUS+1® Service

Tool

2. Select File > New in the menu bar to create a new system in the System Navigator.

3. In the System Navigator, click on New ECU..., then right-click on the ECU list icon to create a new

ECU to add to the System Navigator.

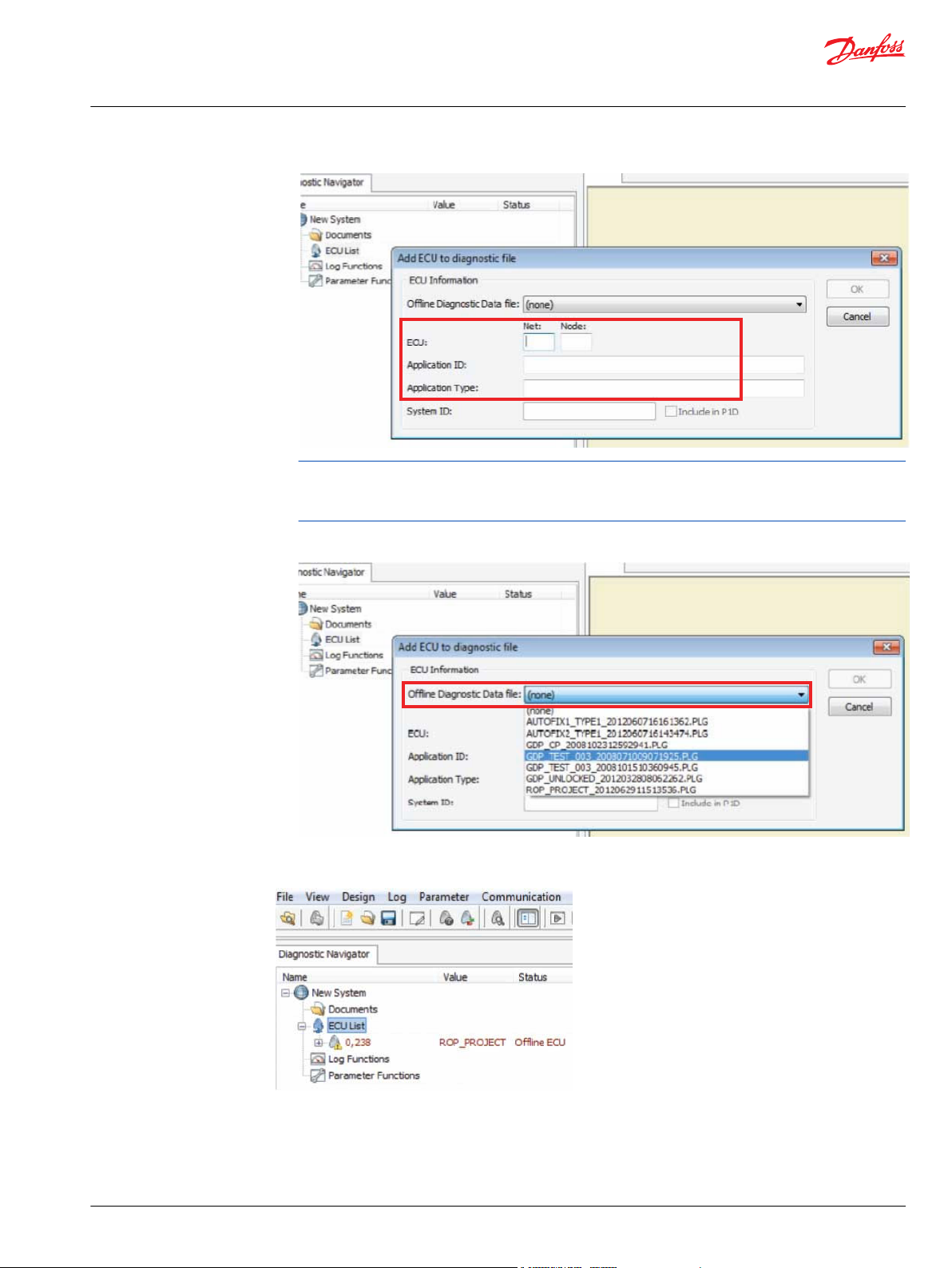

4. The Add ECU to service application file dialog box is displayed.

a) Enter Net, Node, Application ID and Application Type information.

(Application ID is the controller application name created in the PLUS+1® GUIDE application.)

.

18 | © Danfoss | February 2021 AQ152986485048en-001301

Page 19

Design Manual

PLUS+1® Service Tool

Service applications

It is important that both the Application ID and the Application Type name are entered exactly as

created in the PLUS+1® GUIDE application to ensure that files will reconnect properly when returning

to online mode.

5. Select an offline PLG file from the pull down menu. A valid and existing PLG file must be selected or it

will not be possible to create an offline ECU. Click OK to finish creating the offline ECU.

The application ID now appears in the System Navigator. It is now possible to create log and parameter

pages offline.

©

Danfoss | February 2021 AQ152986485048en-001301 | 19

Page 20

Design Manual

PLUS+1® Service Tool

Service applications

Reconnecting offline files

1. Set up the PLUS+1® Service Tool in online mode to reconnect log and parameter files.

a) Open the PLUS+1® Service Tool.

b) Select Communication > Online Mode in the PLUS+1® Service Tool menu bar.

Program will automatically scan system and open connected ECU by default.

2. Open Offline Work.

a) Select File > Open n the PLUS+1® Service Tool menu bar.

b) Select a P1D service application file from Open dialog box and click OK.

The offline log and parameter file are now online.

20 | © Danfoss | February 2021 AQ152986485048en-001301

Page 21

Design Manual

PLUS+1® Service Tool

Service applications

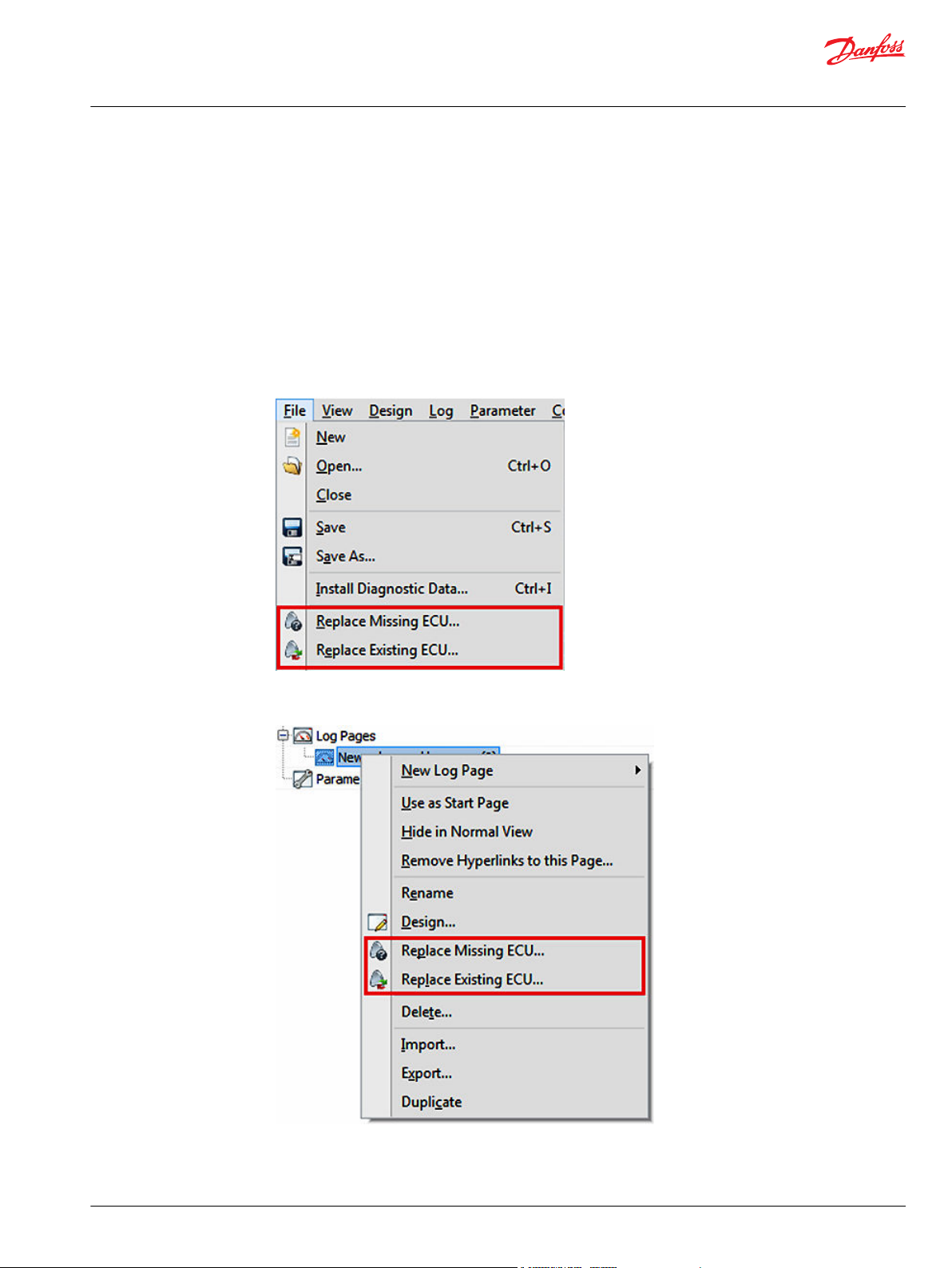

Replacing missing and existing ECU

If the ECU is not compatible with current P1D files, it may be necessary to select Replace Missing ECU...

and/or Replace Existing ECU.... These functions are used when an ECU node and net cannot be found or

need to be replaced.

The function scans the system for available ECU nodes that can be used to link service application files to

the PLUS+1® Service Tool application and presents a list for the user to choose from.

The functions will alert the user when an ECU is unavailable or when there is no missing ECU in the

service application file.

To replace ECU in all service pages select from the menu:

File > Replace Missing ECU... and/or File > Replace Existing ECU....

To only replace ECU in a specific service page with option to include subpages, select Replace Missing

ECU... and/or Replace Existing ECU... from the pop-up menu by right-clicking on a service page.

©

Danfoss | February 2021 AQ152986485048en-001301 | 21

Page 22

Design Manual

PLUS+1® Service Tool

Service applications

Adding language translations

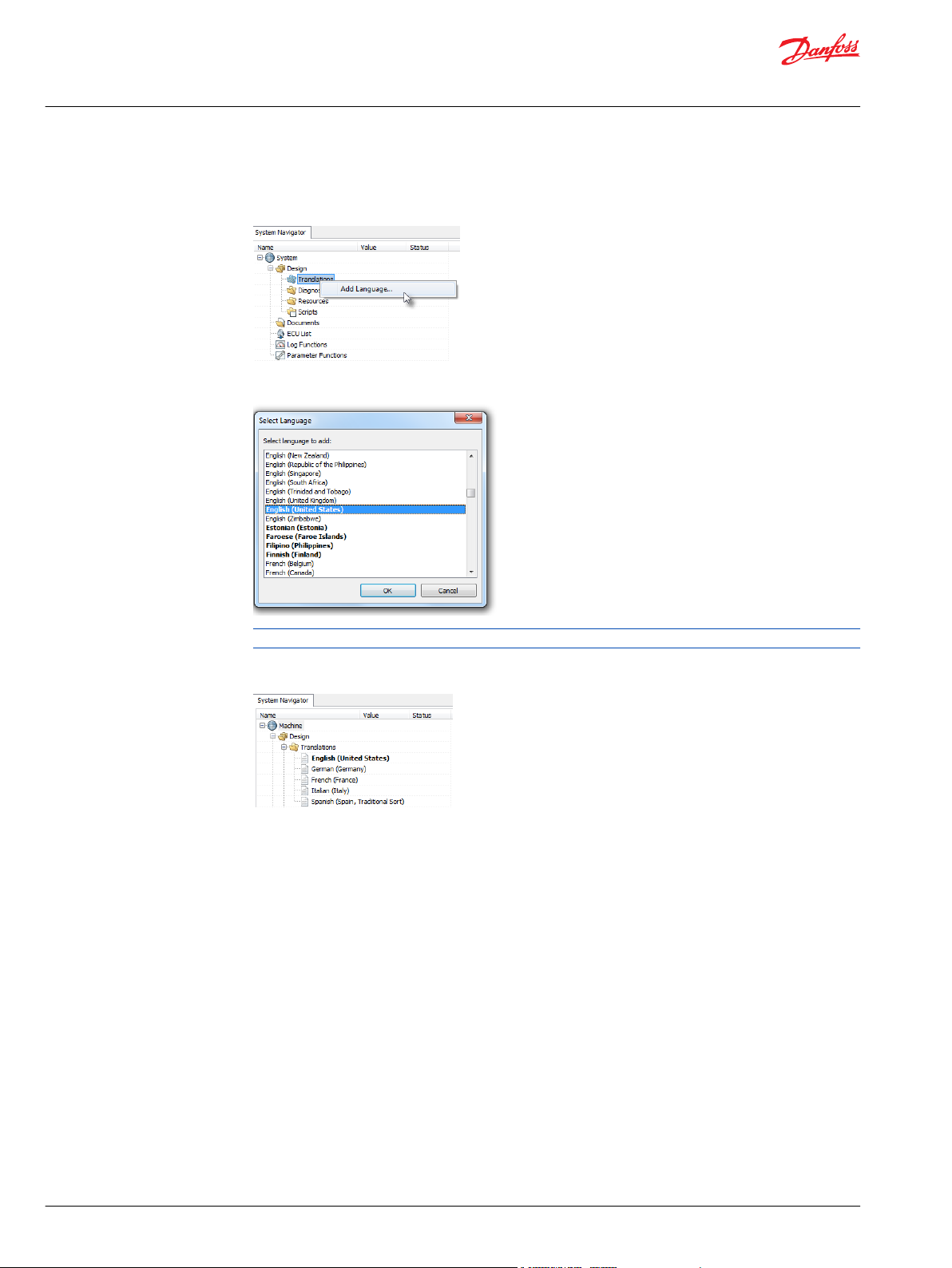

1. Right-click the Design > Translations node and select Add Language…

2. Select the desired language in the selection dialog.

3. Optional: Right-click the language you want as the original language and select Set as Original

Removing language translations

The first translation language that is added is set as the original language as default.

Language.

Right-click the language and select Remove Language.

22 | © Danfoss | February 2021 AQ152986485048en-001301

Page 23

Design Manual

PLUS+1® Service Tool

Service applications

Editing language translations

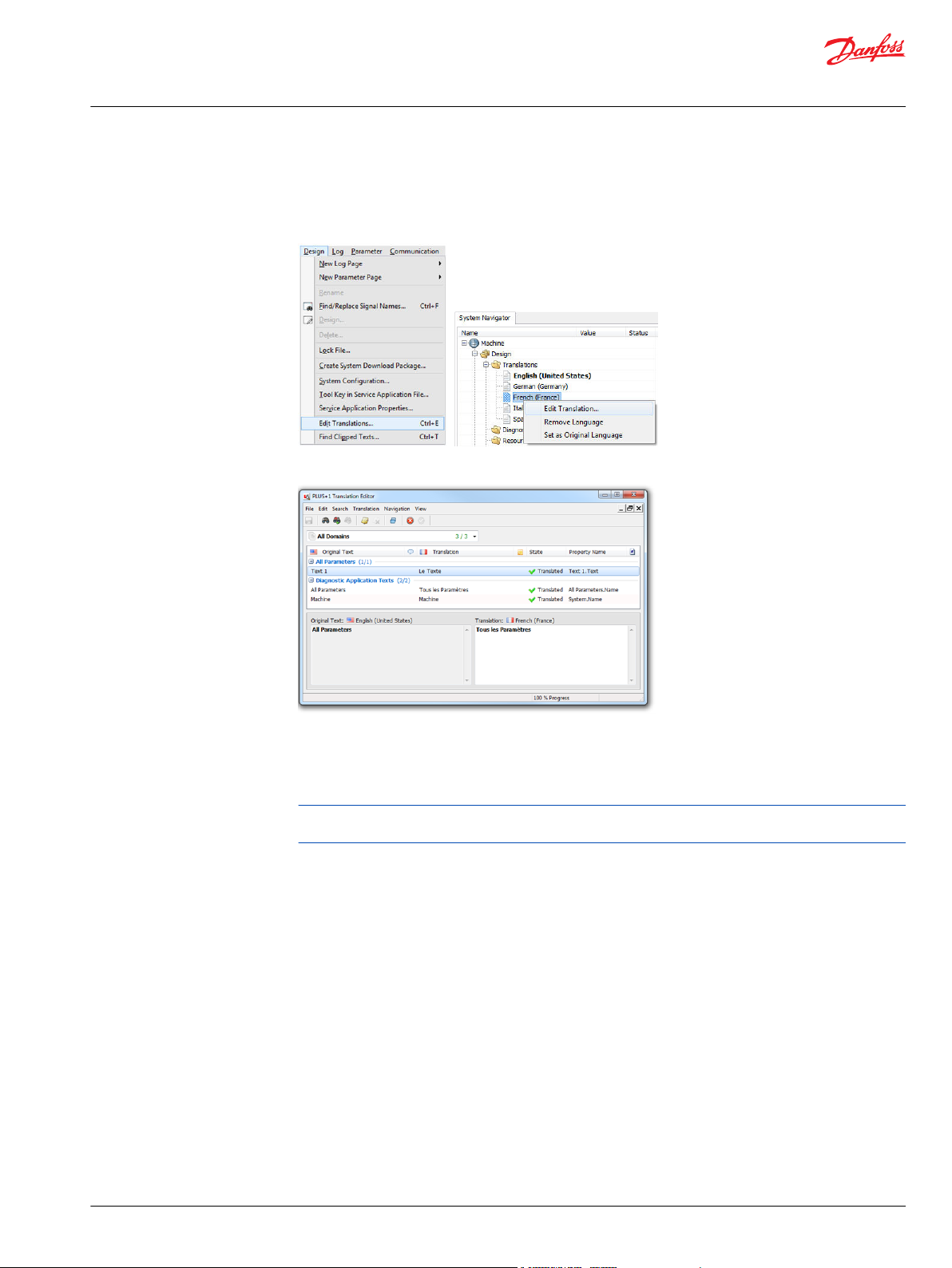

1. Select the menu item Design > Edit Translations…

Alternatively, right-click a language and select Edit Translation... or double-click a language.

An editor dialog is shown, where the texts can be edited.

Changing the original language

2. Select the text line in the list, and add or edit the text in the lower-right edit window (double-click the

text item or click the translation edit field to enter edit mode).

The editor dialog also features import and export functionality under File > Import… and File >

Export…)

The original language is always shown in Design View. Select Normal View to enable the language

selection for the Service Application and see the Service Application in the different languages.

Right-click the desired language and select Set as Original Language.

If any text items are empty for the selected language, the text from the previous original language

will be used for these items.

©

Danfoss | February 2021 AQ152986485048en-001301 | 23

Page 24

Design Manual

PLUS+1® Service Tool

Service applications

Resizing components to fit clipped text

Components in the Service Application may contain text that is too long to fit the component. This text is

clipped text. It can be helpful to find clipped text and resize components in the Service Application so the

text fits.

Clipped text can be resized in multilingual and monolingual Service Applications.

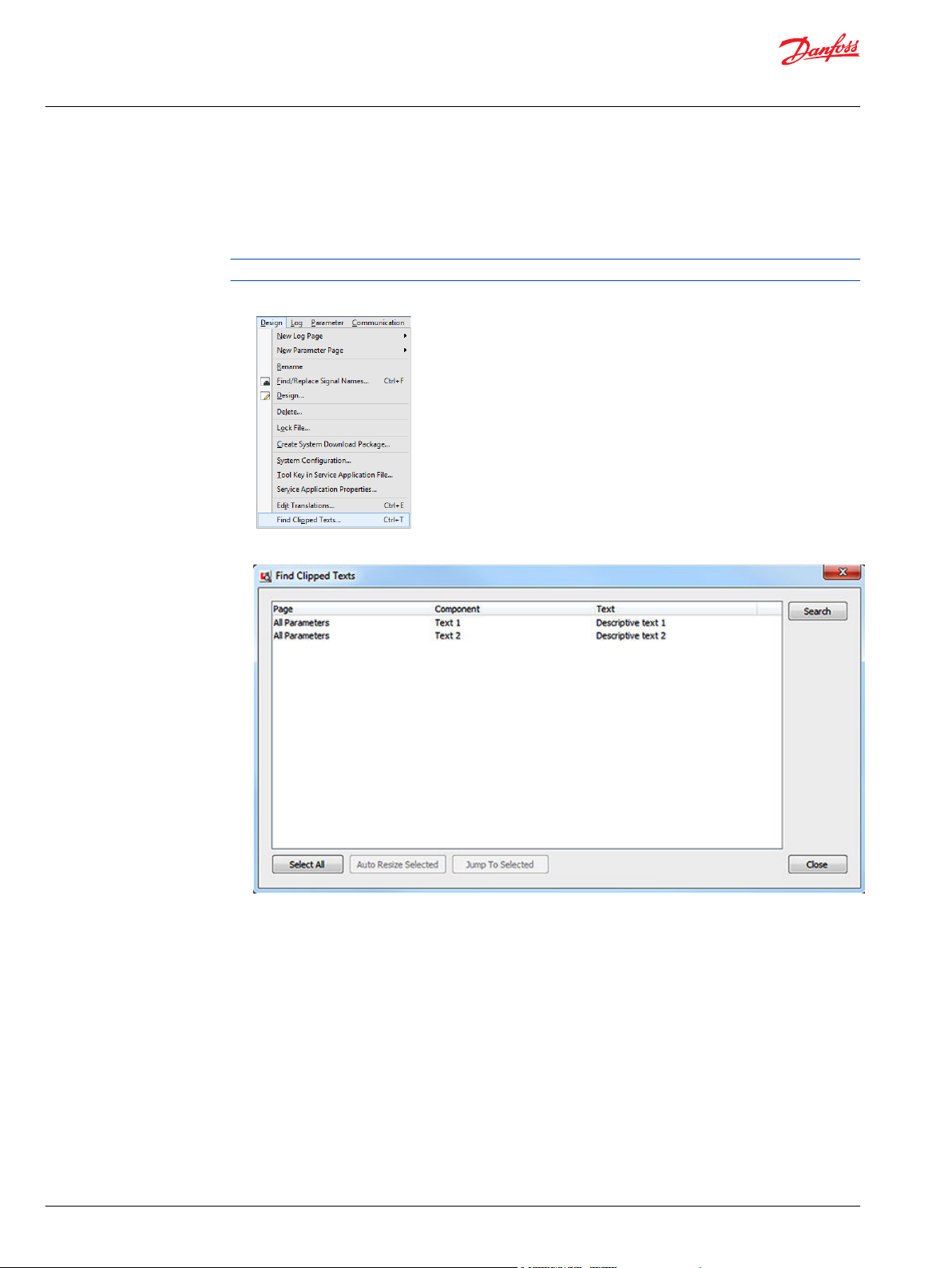

1. Select Design > Find Clipped Texts… to display the search dialog.

2. Press Search to start the search for clipped texts.

3. Press Auto Resize Selected to automatically resize the selected components to fit all texts.

Press Select All to select all lines. Alternatively, hold Ctrl while selecting a line to select multiple lines.

4. Optional: Press Jump To Selected to enter design mode and highlight the affected component.

Only one line may be selected.

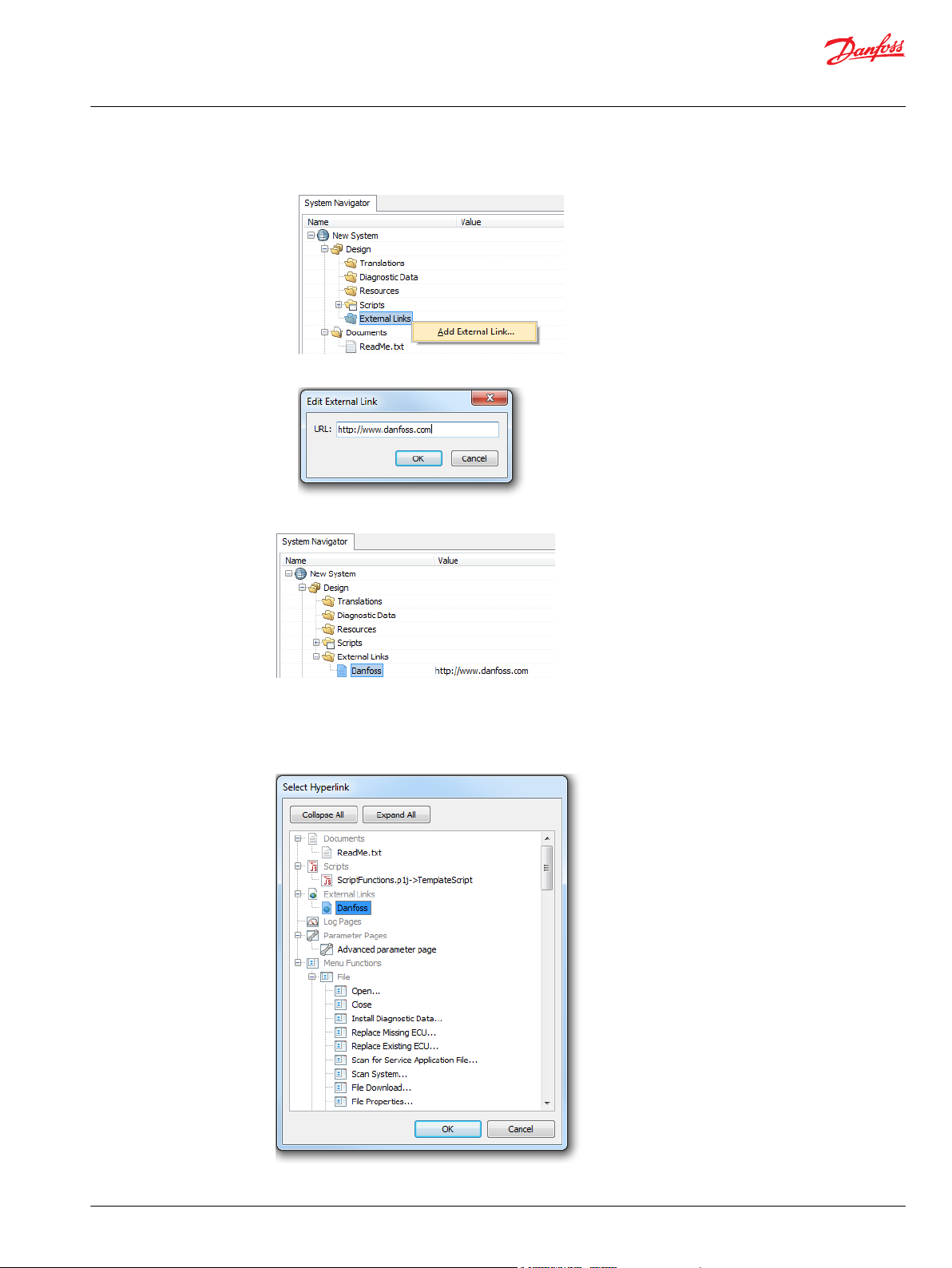

Adding external links

To add an external link to a website or to a PLUS+1® GUIDE project, follow these steps.

24 | © Danfoss | February 2021 AQ152986485048en-001301

Page 25

Design Manual

PLUS+1® Service Tool

Service applications

1. Right-click the External Links node in the System Navigator.

2. Enter the desired link.

The link is now available under External Links.

Select hyperlink

Advanced Page components like Text, Image and Button components can hyperlink to external links. The

link will open in the associated program.

©

Danfoss | February 2021 AQ152986485048en-001301 | 25

Page 26

Design Manual

PLUS+1® Service Tool

Service applications

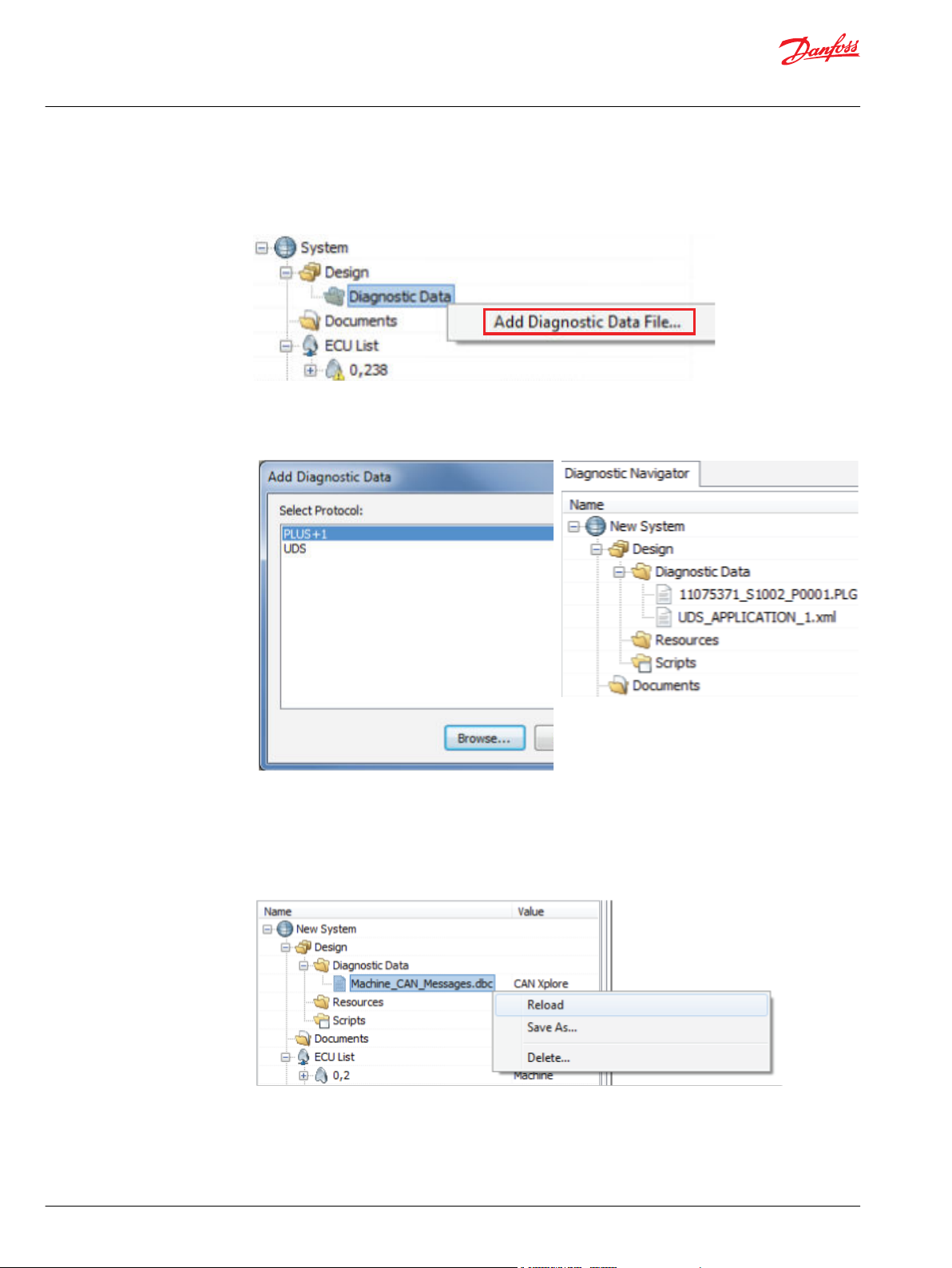

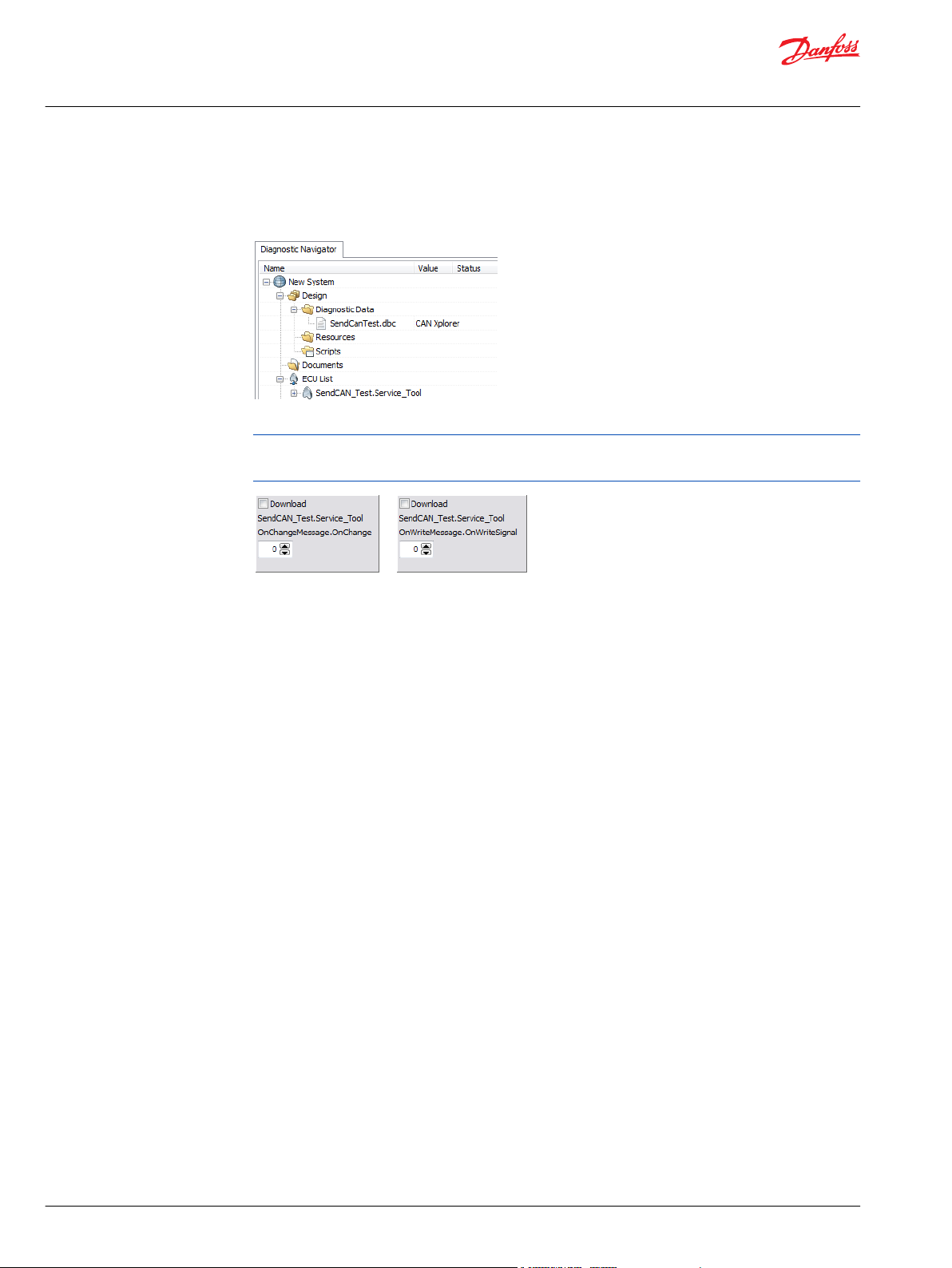

Adding diagnostic data to the service application

1. In the System Navigator, click on Design, right-click on Diagnostic Data, and select Add

Diagnostic Data File... to add to the diagnostic application.

2. Select the protocol where the diagnostic data file shall be installed. Browse for the file and click OK to

add the file. The files available under this node will be active for the applicable protocol once

installed.

Editing diagnostic data

1. To edit diagnostic data files added to the service application, double-click the file to open the file in

the associated program.

2. After editing the file, save it and right-click on the file in the System Navigator and select Reload, to

make the changed file active.

CAN Xplorer protocol

CAN Xplorer is a protocol that can be used to log and send generic CAN messages on the CAN bus. The

content of the CAN messages are mapped to PLUS+1® Service Tool signals and parameters using CAN

database definition files.

26 | © Danfoss | February 2021 AQ152986485048en-001301

Page 27

Design Manual

PLUS+1® Service Tool

Service applications

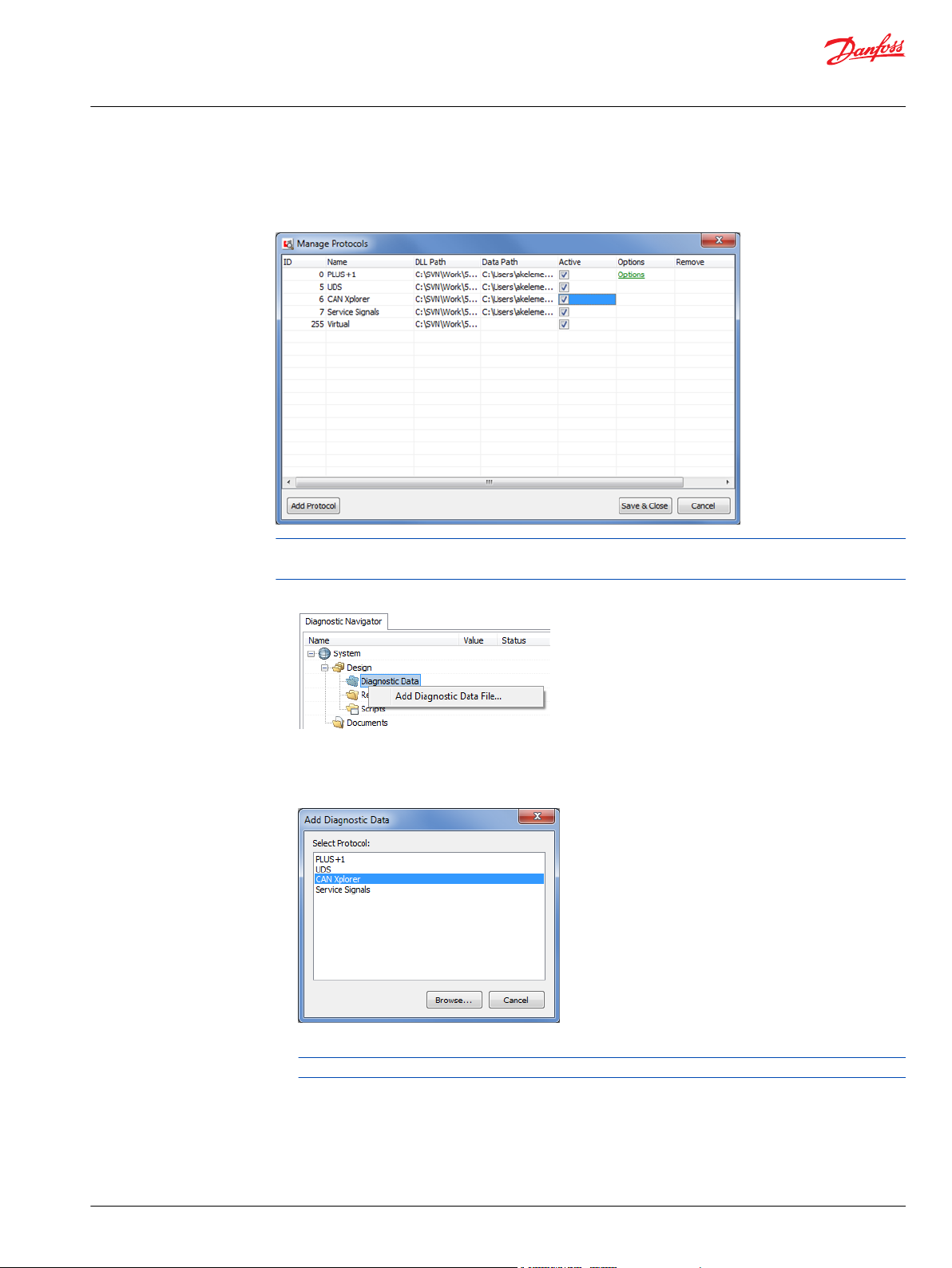

Adding CAN database files in the PLUS+1® Service Tool

Ensure the CAN Xplorer protocol is active in the Protocol Manager.

PLUS+1® Service Tool Professional Add-on License is required to install diagnostic data files for the CAN

Xplorer protocol.

1. Right-click the Diagnostic Data node under the Design node in the System Navigator.

2. Select Add Diagnostic Data File….

A protocol selection dialog will show up.

3. Select CAN Xplorer protocol, and click Browse….

4. Select the DBC file you want to add, and click Open.

DBC file format 1.0.5 is supported.

©

Danfoss | February 2021 AQ152986485048en-001301 | 27

Page 28

Design Manual

PLUS+1® Service Tool

Service applications

The diagnostic data file now is added and activated. The nodes defined in the DBC file will show up as

ECUs in the ECU List.

The signals in the messages will appear named as <Message Name>.<Signal Name>.

5. Select ECU and signals/parameters in the normal manner in PLUS+1® Service Tool pages.

Signals that are defined as sent by the selected ECU/node are available as readable signals.

Signals that are defined as received by the selected ECU/node are available as writable parameters.

28 | © Danfoss | February 2021 AQ152986485048en-001301

Page 29

Design Manual

PLUS+1® Service Tool

Service applications

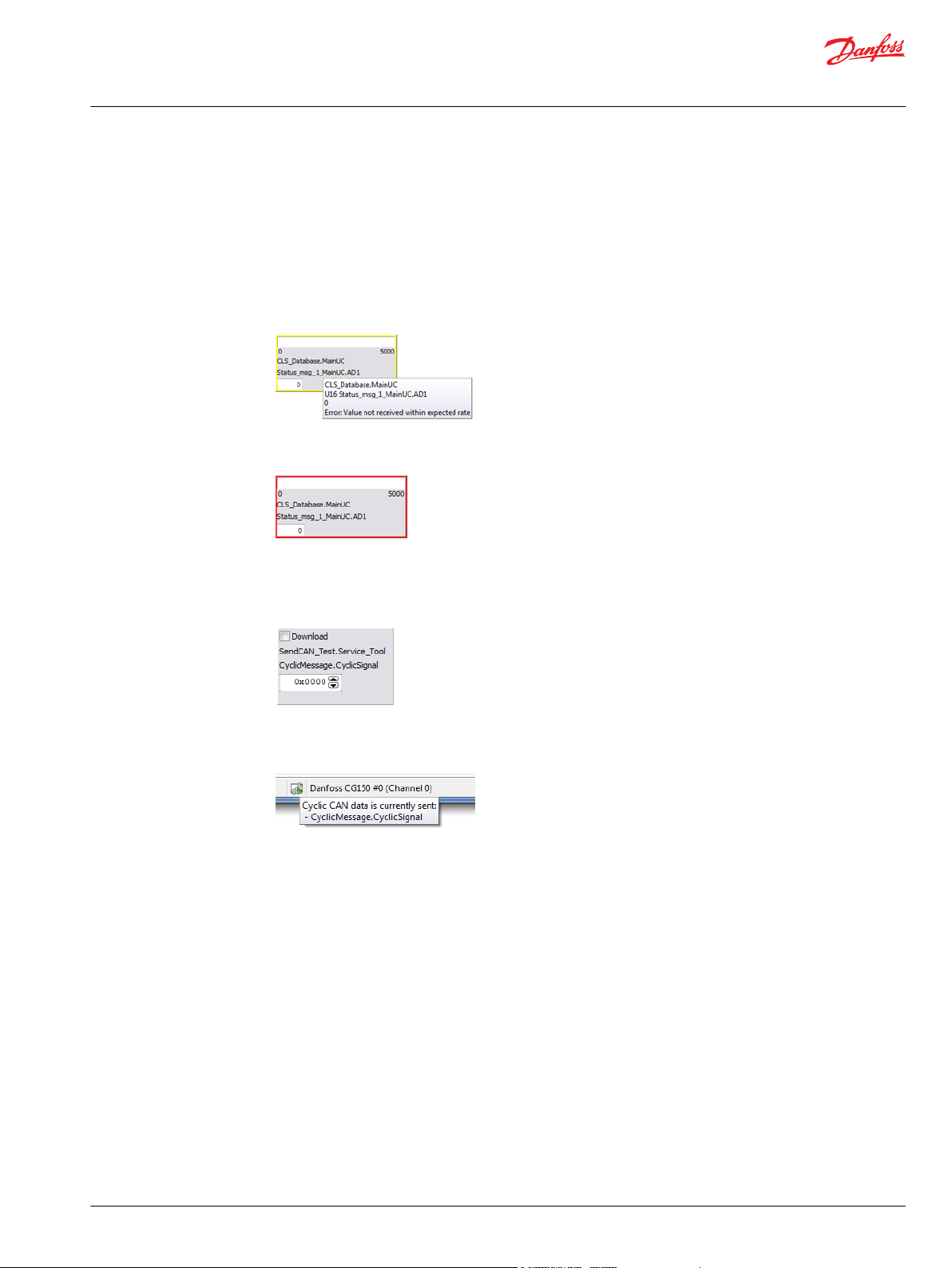

Signal and Message Attributes

Cycle Time

In DBC files, use the attribute GenMsgCycleTime to set a cycle time for a message. GenMsgSendType

must be set to Cyclic for this attribute to be used.

When logging signals from the message, the component will have a yellow border if the signal or

message is not received within the set rate.

The component will have a red border if a message has not been received since scanning the node/

system.

When selecting a page where cyclic parameters are available, the corresponding CAN messages and

current values are sent automatically. The initial values, defined in the DBC file, will be sent until different

values have been downloaded to the cyclic parameters. If no initial value is defined, the initial value in the

PLUS+1® Service Tool will be 0.

An icon is available in the status bar when cyclic CAN data is sent. Place the mouse cursor over the icon to

see which signals/parameters are sent.

Send Type

Use the attribute GenMsgSendType to define when a signal/message is sent (by downloading a value to

the signal in the PLUS+1® Service Tool).

OnWrite: The signal/message is sent each time a signal value is downloaded in the PLUS+1® Service

•

Tool

OnChange: The signal/message is sent if the value of the downloaded signal is different from the

•

previously downloaded value

Cyclic: When selecting a page containing a signal that is Cyclic, the PLUS+1® Service Tool will

•

automatically start to send the signal/message with the set rate as long as the page is selected

©

Danfoss | February 2021 AQ152986485048en-001301 | 29

Page 30

Design Manual

PLUS+1® Service Tool

Service applications

XML files - Danfoss CAN Xplorer database definition

Other than DBC files, an XML file format is also supported as diagnostic data files for the CAN Xplorer

protocol.

This file format supports some features that are not supported in the DBC file format, such as having

signals from other messages as conditionals, and also having signals as Offset together with a shift mask

as Factor. This can be used to be able to decode J1939 DM2 messages, for instance.

File format (XSD):

<?xml version="1.0" encoding="UTF-8"?>

<xs:schema xmlns:xs="http://www.w3.org/2001/XMLSchema"

elementFormDefault="qualified" attributeFormDefault="unqualified">

<xs:element name="System">

<xs:complexType>

<xs:sequence>

<xs:element name="Network" minOccurs="0"

maxOccurs="unbounded">

<xs:complexType>

<xs:sequence>

<xs:element name="Node" minOccurs="0"

maxOccurs="unbounded">

<xs:complexType>

<xs:attribute name="Name"/>

</xs:complexType>

</xs:element>

<xs:element name="Msg" minOccurs="0"

maxOccurs="unbounded">

<xs:complexType>

<xs:complexContent>

<xs:extension

base="SignalType">

<xs:attribute name="Name"

use="required"/>

<xs:attribute name="Id">

<xs:annotation>

<xs:documentation>bit 32 = Ext CAN</xs:documentation>

</xs:annotation>

</xs:attribute>

<xs:attribute name="Mask">

<xs:annotation>

<xs:documentation>1=must match, 0=don't care</xs:documentation>

</xs:annotation>

</xs:attribute>

<xs:attribute

name="Length"/>

<xs:attribute

name="TxNode"/>

</xs:extension>

</xs:complexContent>

</xs:complexType>

</xs:element>

</xs:sequence>

<xs:attribute name="Name"/>

</xs:complexType>

</xs:element>

<xs:element name="FileFormat">

<xs:complexType>

<xs:attribute name="Name" use="required"

fixed="001A"/>

<xs:attribute name="Released"

type="xs:boolean"/>

</xs:complexType>

30 | © Danfoss | February 2021 AQ152986485048en-001301

Page 31

Design Manual

PLUS+1® Service Tool

Service applications

</xs:element>

</xs:sequence>

<xs:attribute name="Name"/>

</xs:complexType>

</xs:element>

<xs:complexType name="SignalType">

<xs:sequence>

<xs:element name="Signal" maxOccurs="unbounded">

<xs:complexType>

<xs:sequence>

<xs:element name="Decode">

<xs:complexType>

<xs:attribute name="Start"

use="required"/>

<xs:attribute name="Length"

use="required"/>

<xs:attribute name="Sign"/>

<xs:attribute name="Endian"/>

<xs:attribute name="DataSource">

<xs:annotation>

<xs:documentation>CANdata

(default) or CANid </xs:documentation>

</xs:annotation>

</xs:attribute>

</xs:complexType>

</xs:element>

<xs:element name="Scale" minOccurs="0">

<xs:complexType>

<xs:attribute name="Offset"/>

<xs:attribute name="Factor"/>

</xs:complexType>

</xs:element>

<xs:element name="Range" minOccurs="0">

<xs:complexType>

<xs:attribute name="Min"/>

<xs:attribute name="Max"/>

</xs:complexType>

</xs:element>

<xs:element name="Info" minOccurs="0">

<xs:complexType>

<xs:attribute name="Unit"/>

</xs:complexType>

</xs:element>

<xs:element name="RxNode" minOccurs="0"

maxOccurs="unbounded">

<xs:complexType>

<xs:attribute name="Name"/>

</xs:complexType>

</xs:element>

<xs:element name="Condition"

type="ConditionType" minOccurs="0"/>

<xs:element name="Traffic" minOccurs="0">

<xs:complexType>

<xs:attribute name="Type">

<xs:annotation>

<xs:documentation>Cyclic,

OnChange, OnWrite</xs:documentation>

</xs:annotation>

</xs:attribute>

<xs:attribute name="Rate">

<xs:annotation>

<xs:documentation>ms

(Cyclic)</xs:documentation>

</xs:annotation>

</xs:attribute>

</xs:complexType>

</xs:element>

©

Danfoss | February 2021 AQ152986485048en-001301 | 31

Page 32

Design Manual

PLUS+1® Service Tool

Service applications

</xs:sequence>

<xs:attribute name="Name" use="required"/>

<xs:attribute name="Type" use="optional"/>

<xs:attribute name="InitValue"/>

</xs:complexType>

</xs:element>

</xs:sequence>

</xs:complexType>

<xs:complexType name="ConditionType">

<xs:sequence>

<xs:element name="Case" minOccurs="0"

maxOccurs="unbounded">

<xs:complexType>

<xs:attribute name="SignalName" use="required"/>

<xs:attribute name="Min" use="required"/>

<xs:attribute name="Max" use="required"/>

</xs:complexType>

</xs:element>

<xs:element name="Condition" minOccurs="0"

maxOccurs="unbounded">

<xs:complexType>

<xs:complexContent>

<xs:extension base="ConditionType"/>

</xs:complexContent>

</xs:complexType>

</xs:element>

</xs:sequence>

<xs:attribute name="Logic"/>

</xs:complexType>

</xs:schema>

32 | © Danfoss | February 2021 AQ152986485048en-001301

Page 33

Design Manual

PLUS+1® Service Tool

Service applications

Example

This XML file contains a node titled Node with two messages with one signal each defined.

Two signals will be available for this node in the PLUS+1® Service Tool.

•

Message1.Signal1 is available as a readable signal. It is defined as cyclic with the rate of 100.

•

Message2.Signal2 is available as a writable signal with the initial value of 127.

Message1.Signal1 will be updated when the CAN message below is received by the PLUS+1® Service Tool

while logging.

You can edit the value for Message2.Signal2 and download the parameter value to send the CAN

message from the PLUS+1® Service Tool.

©

Danfoss | February 2021 AQ152986485048en-001301 | 33

Page 34

Design Manual

PLUS+1® Service Tool

Service applications

XML file

<?xml version="1.0" encoding="UTF-8"?>

<System xmlns:xsi="http://www.w3.org/2001/XMLSchema-instance"

xsi:noNamespaceSchemaLocation="CANMsgFormat.xsd">

<FileFormat Name="001A" Released="true"/>

<Network Name="Database">

<Node Name="Node" Address="31"/>

<Msg Name="Message1" Id="31" Length="1" TxNode="Node">

<!-- Message1.Signal1 will be available as a readable U8

signal.-->

<!-- The matching CAN message received on the CAN bus...-->

<!-- ... will update the value of this signal in PLUS+1

Service Tool.-->

<Signal Name="Signal1">

<Decode Start="0" Length="8" Endian="Little" Sign="Unsigned"/>

<Scale Factor="1" Offset="0"/>

<Range Min="0" Max="0"/>

</Signal>

</Msg>

<Msg Name="Message2" Id="2147483695" Length="1">

<!-- Message2.Signal2 will be available as a writable S8 signal->

<!-- Message2 will be sent on the CAN bus when downloading...-->

<!-- ... a value to this parameter in PLUS+1 Service Tool.-->

<Signal Name="Signal2" InitValue="127">

<Decode Start="0" Length="8" Endian="Little" Sign="Signed"/>

<Scale Factor="1" Offset="0"/>

<Range Min="0" Max="0"/>

<RxNode Name="Node"/>

</Signal>

</Msg>

<Msg Name="Message3" Id="2147483711" Length="2">

<!-- Message3.Signal3 will be available as a writable U16 signal

-->

<!-- Message3 will be sent on the CAN bus when downloading... -->

<!-- ... a value to this parameter in PLUS+1 Service Tool. -->

<Signal Name="Signal3" InitValue="65535">

<Decode Start="0" Length="16" Endian="Little" Sign="Unsigned"/>

<Scale Factor="1" Offset="0"/>

<Range Min="0" Max="0"/>

<RxNode Name="Node"/>

</Signal>

</Msg>

</Network>

</System>

34 | © Danfoss | February 2021 AQ152986485048en-001301

Page 35

Design Manual

PLUS+1® Service Tool

Service applications

Changing the CAN ID dynamically

The CAN ID and Type (standard/extended) for defined messages can be changed dynamically in the PLUS

+1® Service Tool. The CAN ID is set to the defined ID initially, and also reset to the defined ID when the

DBC file is reloaded in the PLUS+1® Service Tool.

For all nodes that receives or transmits a message, the CAN ID and Type for the message will be available

as two additional writable parameters, named <Message>.XplorerCanId (bit 0-28) and

<Message>.XplorerCanExt (bit 31).

1. Optional: Writing a signal with the default ID/EXT.

2. Changing the ID/EXT for the message.

3. Writing a signal with updated ID/EXT.

Adding and editing the CAN ID dynamically in XML format

When using DBC files the parameters will be added automatically, but when using XML files you will have

to add these messages manually.

©

Danfoss | February 2021 AQ152986485048en-001301 | 35

Page 36

Design Manual

PLUS+1® Service Tool

Service applications

Example:

…

<Node Name="ReceivingNode"/>

<Msg Name="DemoMessage" Id="1" Length="8">

<Signal Name="XplorerCanId">

<Decode DataSource="CANid" Start="0" Length="29"

Endian="Little" Sign="Unsigned"/>

</Signal>

<Signal Name="XplorerCanExt">

<Decode DataSource="CANid" Start="31" Length="1"

Sign="Unsigned"/>

<RxNode Name="ReceivingNode"/>

</Signal>

…

Multiple nodes may be added as <RxNode> attributes.

36 | © Danfoss | February 2021 AQ152986485048en-001301

Page 37

Design Manual

PLUS+1® Service Tool

Service applications

System configuration

When a service application is created, it is possible that all hardware may be required by the application

system. System configuration allows the user to adjust hardware settings and requirements for a specific

application.

Access System Configuration by one of these two ways:

1. In the Menu Bar, select Design > System Configuration

2. In the System Navigator, right-click on the ECU icon > System Configuration

The System Configuration window is displayed with the following edit options available:

System configuration

ECU

Display Style

Scan Check

Tooltip

Displays ECU information

Select Bold or Normal font style that will be displayed in the System Navigator

Select that ECU is required, optional or if no check is required

Enter tooltip that will be displayed if ECU is missing

©

Danfoss | February 2021 AQ152986485048en-001301 | 37

Page 38

Design Manual

PLUS+1® Service Tool

Service applications

Using Find/Replace Signal Names...

PLUS+1® Service Tool pages can be easily reused and organized without compiling conflicts or manually

selecting and renaming signals by using the find/replace function of the PLUS+1® Service Tool.

Use Find/Replace Signal Names... to search, replace or insert signal names used in an open P1D file.

Design > Find/Replace Signal Names....

Use the Find tab to search for specific signal.

Use the search criteria to refine the search process.

All matching results from both Basic and Advanced Pages will be listed along with other signal

information in the Search Results field located at the bottom of the window.

The find/replace functionality is also accessible from Advanced Page design.

The Find/Replace Signal Names window contains three tabs:

1. Find

2. Replace

3. Insert

38 | © Danfoss | February 2021 AQ152986485048en-001301

Page 39

Design Manual

PLUS+1® Service Tool

Service applications

Replace settings

ECU

page

Panel

Find What

ECU options

ECU

Any ECU

Page options

Selected page

Selected and Subpages

Any page

Case options

Search all pages

Not case sensitive

Select from pull down list of all available controller ECU

Select individual page to search on

Select the panel(s) to search on. Multiple panels can be selected by holding

the Ctrl button while selecting panels. When no panels are selected, the

search will be done in the whole page.

Enter search word or phrase

Select to search only selected ECU

Select to search any ECU

Search only selected page

Search selected page and subpages linked to selected page

Search all pages

Must match signal name case

Ignore signal name case

©

Danfoss | February 2021 AQ152986485048en-001301 | 39

Page 40

Design Manual

PLUS+1® Service Tool

Service applications

Search results

Match whole signal name

Match from start of signal name

Match any part of signal name

Search name must match exactly

Search name must partially match signal name

Search name can match any part of signal name.

Example: Find

1. Enter the signal name to find in the Find What field.

2. Optional: Use the Find options and Case options to widen the search possibilities if unsure of the

exact signal name.

3. Click Search.

Search Results field will list all possible search matched.

4. Widen or narrow searches by changing search criteria.

40 | © Danfoss | February 2021 AQ152986485048en-001301

Page 41

Design Manual

PLUS+1® Service Tool

Service applications

5. Use the Replace tab to Replace Names to find and replace text in existing signal names.

It is possible to go directly to the signal by clicking to highlight the selected signal and clicking the Go

to Design button. This will open the page where the signal is located.

Replace settings

ECU

page

Panel

Find What

Replace With

Select from pull down list of all available controller ECU

Select individual page to search on

Select the panel(s) to search on.

Multiple panels can be selected by holding the Ctrl button while selecting

panels.

When no panels are selected, the search will be done in the whole page.

Enter search word or phrase

Enter replacement text

ECU options

ECU

Any ECU

Select to search only selected ECU

Select to search any ECU

Find Options

Match whole signal names

Match from start of signal name

Match any part of signal name

Find only exact signal name

Find all from start of signal name

Find any part start of signal name

©

Danfoss | February 2021 AQ152986485048en-001301 | 41

Page 42

Design Manual

PLUS+1® Service Tool

Service applications

Case options

Search all pages

Not case sensitive

Must match signal name case

Ignore signal name case

Advanced Page Parameter options

Retain Global Parameter Settings

Skip (use existing)

The resulting signal will keep its global settings (min/max/default values,

and unit/comment).

The resulting signal will get the (global) signal settings from the replaced

signal.

Example: Replace

1. In the Find What field, enter the signal name to find.

2. Optional: Use the Find options and Case options to widen the search possibilities if unsure of the

exact signal name.

3. Click Search.

The search operation will list all possible matches to the search.

4. Select the signal to be changed and ensure that the full signal name is entered in the Find What field.

5. In the Replace With field enter the replacement text information.

The new information can be previewed in the Name after Change column of the Replace Preview

field.

The Status column shows whether the new signal name is valid or not.

6. Select the Change checkbox in the Replace Preview to enable name change.

7. Click the Change button to perform the change.

Multiple lines may be selected by holding the Ctrl button and clicking the lines to select.

Click the right mouse button to get a menu to check the selected lines.

42 | © Danfoss | February 2021 AQ152986485048en-001301

Page 43

Design Manual

PLUS+1® Service Tool

Service applications

Using Insert Signal Names

Use the Insert tab to insert text into existing signal names. An example of using Insert can be used to add

a namespace to a page that previously did not have one.

Replace settings

ECU Selection

page Selection

Panel Selection

Insert What

ECU options

ECU

Any ECU

Placement options

Insert first in signal name

Insert last in signal name

Select from pull down list of all available controller ECU

Select individual page to search on

Select the panel(s) to search on. Multiple panels can be selected by holding

the Ctrl button while selecting panels.

When no panels are selected, the search will be done in the whole page.

Enter word or phrase to insert

Select to search only selected ECU

Select to search any ECU

Insert before signal name

Insert after signal name

©

Danfoss | February 2021 AQ152986485048en-001301 | 43

Page 44

Design Manual

PLUS+1® Service Tool

Service applications

Example: Insert

1. In the Insert What field, enter desired text to insert.

2. Optional: Use the search criteria to refine signal selection.

The Insert Preview field will list all instances when the search criteria matches.

3. Click the change box in the Insert Preview window for each of the signal names where the text will

be inserted.

4. Click the Change button to update.

The new text will be inserted for the selected signals.

44 | © Danfoss | February 2021 AQ152986485048en-001301

Page 45

Design Manual

PLUS+1® Service Tool

Service applications

Changing Service Application properties

Different settings are available for Service Application files in the Service Application Properties window.

In the PLUS+1® Service Tool menu bar, select Design > Service Application Properties...

©

Danfoss | February 2021 AQ152986485048en-001301 | 45

Page 46

Design Manual

PLUS+1® Service Tool

Service applications

Creating custom themed modes via enabling disable menus, toolbars and navigator

In normal and design default modes, all menu items and toolbars are displayed and enabled for use.

Occasions may arise when it would be beneficial to have all menus and toolbars hidden. This can be

enabled by using Disable Menus and Toolbars in Normal View.

Use this mode to lock customized pages for end-user activity. Disable menus and toolbars in normal view

mode creates limited access environments that can only be altered by the developer, minimizing

potential errors in settings and parameters.

When Disable Menus and Toolbars in Normal View mode is enabled, all menus and toolbars will be

hidden. It is also possible to enable or disable all menu shortcut keys when in full page mode. Enable

Disable System Navigator in Normal View to disable the System Navigator in Normal View.

Disable Menus and Toolbars in Normal View mode is enabled in the Service Application File

Properties window.

Enabling custom page mode

Before selecting Disable menus and toolbars in Normal View, consider in full page mode, all menus

and toolbars are hidden. This means that all default navigation will not be accessible.

Functions must be programmed so that the user can perform certain tasks without the aid of the menu or

toolbars. Without the menu and toolbar functions, the user will be unable to perform many basic tasks

such as scanning the system and downloading files.

Reverting back to default in full page mode

Follow these steps to revert back to enable menus, toolbars, shortcut keys when in full page mode.

1. Close the PLUS+1® Service Tool application.

2. Open the PLUS+1® Service Tool application.

3. Select View > Design View from the menu bar.

4. Open P1D file.

The P1D file now has menus, toolbars, and shortcut keys fully functional in full page mode.

Enabling disable menus and toolbars

In the Service Application File Properties-General Settings window, there are check boxes for

enabling Disable menus and toolbars in Normal View and Disable shortcut keys in full page mode.

46 | © Danfoss | February 2021 AQ152986485048en-001301

Page 47

Design Manual

PLUS+1® Service Tool

Service applications

1. Select from settings, either:

2. Click OK to save.

3. Close the Service Application Properties-General Settings window.

Menus and toolbars will be hidden and not functional in full page mode. Shortcut keys will not be

functional if Disable shortcut keys was also selected.

Hide virtual ECUs in Normal View

Enable ‘Hide virtual ECUs in Normal View’ to hide ECU nodes using the CAN Xplorer and Service Signals