Page 1

User Manual

PLUS+1®

Service Tool

www.danfoss.com

Page 2

User Manual

PLUS+1® Service Tool

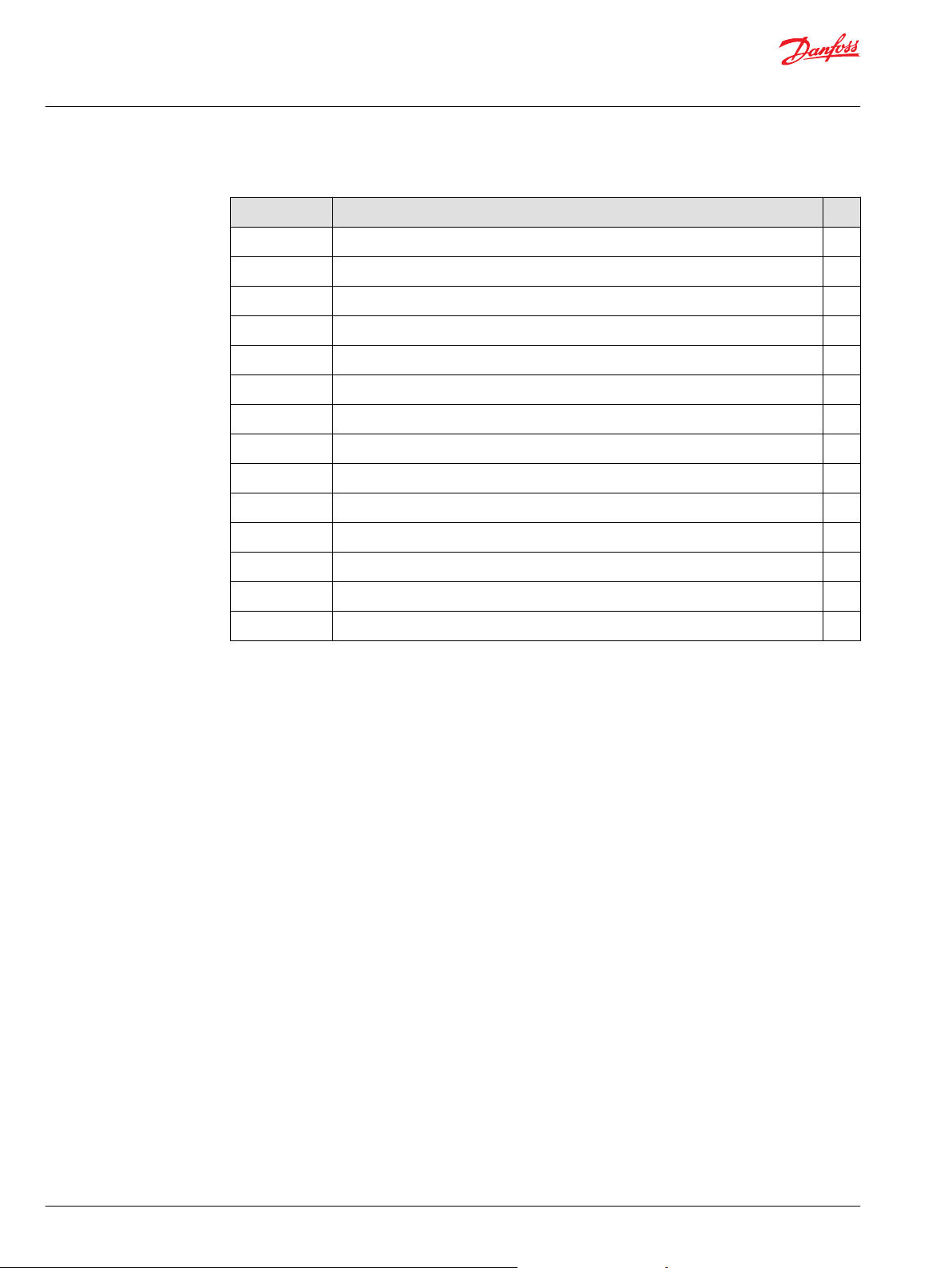

Revision history Table of revisions

Date Changed Rev

February 2021 Supports 12.2 1003

May 2020 Supports 12.1 1002

November 2019 Supports 12.0 0901

April 2019 Supports 11.1 0801

November 2018 Supports 11.0 0701

May 2018 Supports 10.1 0601

October 2017 Supports 10.0 0501

March 2017 Supports 9.1 0401

October 2016 Supports 9.0 0301

August 2015 Supports 7.2.x and later 0200

Changed document number from 'AQ00000194' and 'L1307770' to 'AQ152986484649' 1001

October 2014 Supports 7.1.x and later BA

September 2014 Conversion to Danfoss layout AB

November 2013 First edition AA

2 | © Danfoss | February 2021 AQ152986484649en-001003

Page 3

User Manual

PLUS+1® Service Tool

Contents

General information

IEC 61508:2010 support tool certification references.........................................................................................................5

Important information to reduce risk....................................................................................................................................... 5

Fault checking and error handling.............................................................................................................................................6

Downloading and testing your applications .........................................................................................................................6

Learning about the PLUS+1® Service Tool...............................................................................................................................7

Getting ready..................................................................................................................................................................................... 7

PLUS+1® hardware setup

CAN hardware installation............................................................................................................................................................ 8

CAN hardware installation troubleshooting...........................................................................................................................8

Using the PLUS+1® CG150-2 USB/CAN Gateway Interface Communicator................................................................ 9

Using the PLUS+1® DP Series Display USB/CAN gateway..................................................................................................9

Using the PLUS+1® InterLink gateway....................................................................................................................................10

Using the PLUS+1® InterLink Remote gateway...................................................................................................................11

Using the third party Gateway devices via the RP1210 standard................................................................................ 12

Connection.......................................................................................................................................................................................13

Diagnosing gateway warnings and errors using the RP1210 standard.....................................................................13

Using Reset Gateway in advanced settings..........................................................................................................................13

Managing protocols

Managing Protocols values........................................................................................................................................................ 15

Add new protocols........................................................................................................................................................................16

Protocol options.............................................................................................................................................................................18

PLUS+1 Service Tool window

Start page..........................................................................................................................................................................................20

System Navigator features..........................................................................................................................................................21

Locking and unlocking Diagnostic Navigator pane..........................................................................................................21

Restoring default layouts............................................................................................................................................................ 22

PLUS+1® Service Tool languages

Installing tool languages during setup..................................................................................................................................23

Managing languages in PLUS+1® Service Tool....................................................................................................................23

Selecting the PLUS+1® Service Tool language.................................................................................................................... 23

Selecting the Service Application language........................................................................................................................ 24

Downloading the application

Preparing to Download the Application File to the Controller.....................................................................................26

Downloading system download packages.......................................................................................................................... 29

Mandatory applications/missing ECUs.............................................................................................................................29

Retry downloads.......................................................................................................................................................................30

Parameter settings during the application download.....................................................................................................31

Recover ECU functions.................................................................................................................................................................33

Working with service application files

Introduction to service application files................................................................................................................................35

Log page......................................................................................................................................................................................35

Parameter page.........................................................................................................................................................................35

Manual Load of Service Application Files........................................................................................................................35

Scanning for service application files................................................................................................................................35

Boot loader mode..........................................................................................................................................................................36

Automatic scan for service application files.........................................................................................................................37

Opening hardware service files................................................................................................................................................ 38

Manual installation of diagnostic data files..........................................................................................................................38

Using log pages

Logging controls............................................................................................................................................................................40

Recording log files.........................................................................................................................................................................40

Monitor log files..............................................................................................................................................................................41

Log file playback.............................................................................................................................................................................42

Log file process............................................................................................................................................................................... 43

©

Danfoss | February 2021 AQ152986484649en-001003 | 3

Page 4

User Manual

PLUS+1® Service Tool

Contents

Exporting log files to spreadsheet...........................................................................................................................................43

Using parameter pages

Manual parameter upload and download............................................................................................................................46

Selecting parameter for download..........................................................................................................................................46

Importing parameter values...................................................................................................................................................... 47

Automatic parameter upload function..................................................................................................................................47

Parameter upload and download error messages............................................................................................................ 47

Parameter file export....................................................................................................................................................................48

Parameter file import....................................................................................................................................................................49

Generating parameter reports..................................................................................................................................................50

Parameter memory transfer.......................................................................................................................................................51

Upload parameter values............................................................................................................................................................51

Download parameter values......................................................................................................................................................52

Decrypting P1T files...................................................................................................................................................................... 53

Creating P1T files............................................................................................................................................................................55

Using contextual help in service applications

Contextual help feature...............................................................................................................................................................57

Using the Tool Key

Tool Key function........................................................................................................................................................................... 58

Set up Tool Key information.................................................................................................................................................58

Manually entered Tool Key set up........................................................................................................................................... 59

License embedded Tool Key set up.........................................................................................................................................60

Working in normal view

Application log................................................................................................................................................................................61

Application log file...................................................................................................................................................................61

PLUS+1® Service Tool settings options.................................................................................................................................. 63

Monitoring the CAN bus

Monitor CAN bus messages and bus load............................................................................................................................ 68

Options.............................................................................................................................................................................................. 70

PLUS+1® Service Tool command line mode

Command, Configuration, and Command Modifier Parameters................................................................................. 72

Menu bar

Menu descriptions.........................................................................................................................................................................75

Toolbar

Toolbar descriptions..................................................................................................................................................................... 81

4 | © Danfoss | February 2021 AQ152986484649en-001003

Page 5

User Manual

PLUS+1® Service Tool

General information

IEC 61508:2010 support tool certification references

Contact and reference material are available regarding which versions of PLUS+1® Service Tool carry the

IEC 61508:2010 support tool certification.

Please contact the PLUS+1® Helpdesk.

https://www.danfoss.com/en/products/software/dps/plus1-software-services-support-and-training/plus1support-and-services

For complete details regarding PLUS+1® GUIDE and PLUS+1® Service Tool IEC 61508:2010 support tool

certificates, see:

PLUS+1® GUIDE User Manual, AQ152886483724

https://www.danfoss.com/en/search/?filter=type%3Adocumentation%2Csegment%3Adps

Important information to reduce risk

Your responsibility when designing a PLUS+1® Service Tool application is to include the checking and the

error handling needed to reduce risks in normal and abnormal operating conditions.

The applications that you create with the PLUS+1® Service Tool typically control heavy, powerful, and

mobile off-road equipment such as tractors, cranes, and harvesters.

The PLUS+1® Service Tool has no automatic protections against the risks, such as from bugs in the PLUS

+1® Service Tool software, errors in the PLUS+1® Service Tool user guides, or incompatibilities between

software versions of the PLUS+1® Service Tool.

You must design and test your application to reduce these risks.

©

Danfoss | February 2021 AQ152986484649en-001003 | 5

Page 6

W

User Manual

PLUS+1® Service Tool

General information

Fault checking and error handling

The following are some items to consider when developing fault checking and error handling for your

application.

Consider:

•

•

•

•

•

•

•

How the machine is normally used

Possible operator errors and their consequences

Industry safety standards and legal requirements

Input and output failures and their consequences including:

Joystick, sensor, and other inputs suddenly going to 100 % or to 0 %

‒

Outputs that control machinery direction, speed, and force suddenly changing direction or going

‒

to 100 % or to 0 %

Decide how likely each failure is

The more likely a failure, the more you need protect against the consequences of the failure

‒

The sequence of events and consequences of a fault or error

The sequence of events and consequences of an emergency stop

Warning

Under normal operating conditions, using this type of machinery always involves risk of personal

injury and equipment damage. Abnormal operating conditions increase the risk of personal injury

and equipment damage.

Downloading and testing your applications

Once you have created an application, you have the responsibility to download and test the application.

You should only download your application to hardware or change software parameters while the

vehicle is not in operation. After downloading, test application operation under normal and abnormal

operating conditions.

You should make sure that:

Individual inputs produce expected outputs.

•

Combinations of inputs do not produce unexpected or dangerous outputs.

•

Fault handling and error checking work as designed.

•

6 | © Danfoss | February 2021 AQ152986484649en-001003

Page 7

User Manual

PLUS+1® Service Tool

General information

Learning about the PLUS+1® Service Tool

After successfully creating your first controller application using the PLUS+1® GUIDE, you need to put it to

use now.

Use the PLUS+1® Service Tool to:

Download an application to a controller

•

Log and tune controller performance

•

Download parameters to a controller

•

This manual will help you to understand the following concepts and processes:

The overall concept of the PLUS+1® Service Tool

•

How to download an application file to a controller application

•

How to run log pages

•

How to change controller parameters

•

Getting ready

Individual requirements to work with the applications in this manual:

Fully functional versions of the PLUS+1® GUIDE and PLUS+1® Service Tool programs installed on PC

•

A completed controller application to use within the PLUS+1® Service Tool

•

The following hardware to download these controller applications:

•

One PLUS+1® CG150-2 or PLUS+1® DP series display (or a similar third party CAN communication

‒

device)

One 12 to 24 VDC 55 mA power supply

‒

Working knowledge of the PLUS+1® GUIDE environment, including an understanding to use the full

•

capabilities of the PLUS+1® Service Tool

Proper hardware has be to connected and installed on a computer before you can use the PLUS+1

Service Tool. Connect the controller to the CAN communication device.

The graphical images in this manual may appear slightly different, depending on which version of the

PLUS+1® Service Tool is in use.

®

©

Danfoss | February 2021 AQ152986484649en-001003 | 7

Page 8

User Manual

PLUS+1® Service Tool

PLUS+1® hardware setup

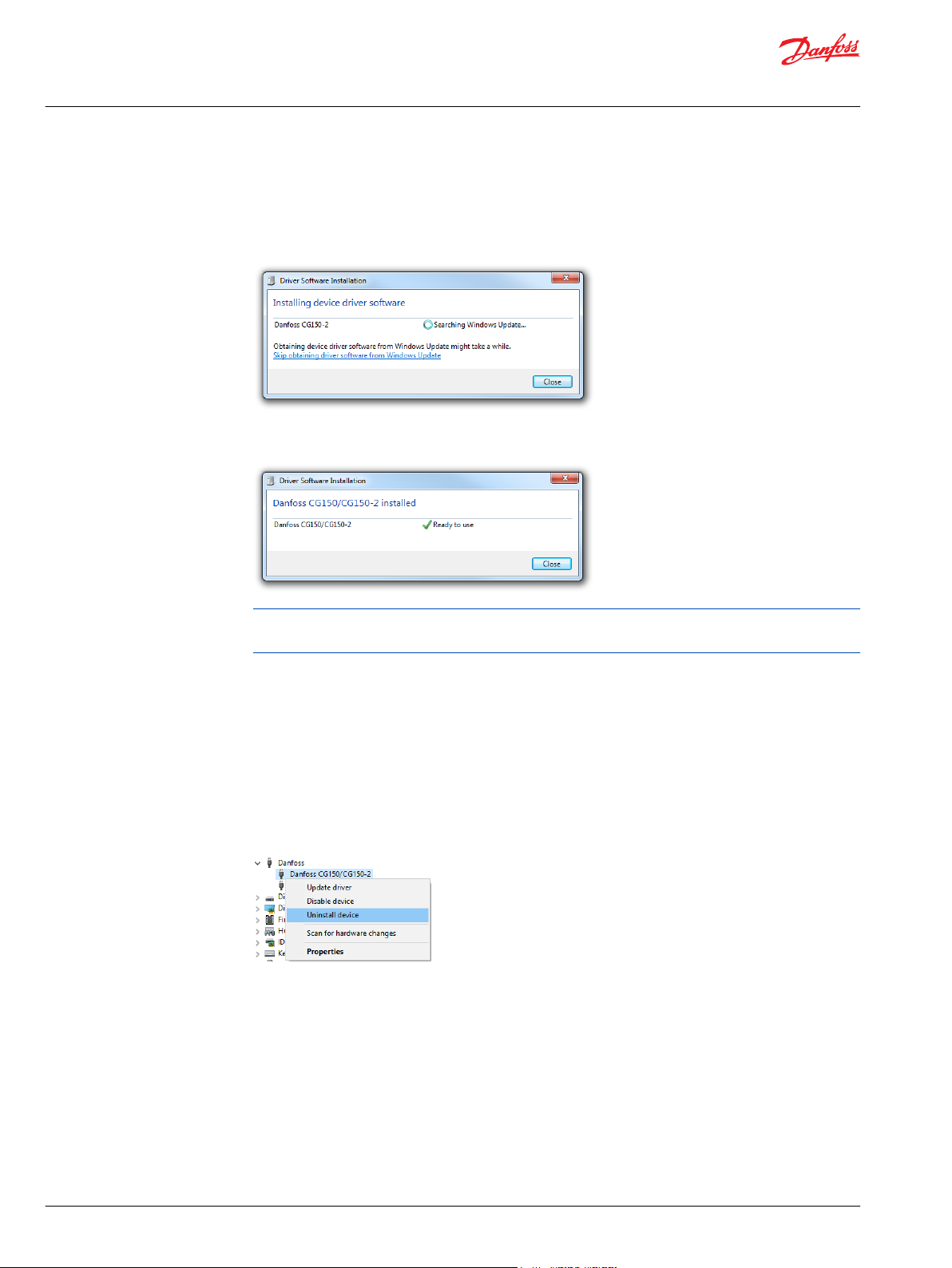

CAN hardware installation

It is necessary to install CAN driver software before using the PLUS+1® Service Tool.

1. Plug in the PLUS+1® CG150-2 USB cable to the PC USB port. The Hardware Wizard searches for and

installs CAN software. This may take several minutes.

2. Click Close to close the Driver Software Installation dialog.

The following message appears when installation is complete.

USB drivers can be found in the directory: <Program Files>\Danfoss\PLUS1\<Service

Tool Version>\Misc\.

CAN hardware installation troubleshooting

To resolve issues related to the Danfoss PLUS+1®CG150-2 CAN/USB gateway interface communicator,

perform the following procedure:

1. Close the PLUS+1® Service Tool.

2. Enter the Device Manager in Windows® operating system by selecting: Control Panel > System >

Device Manager.

3. Select PLUS+1® CG150-2 or PLUS+1® Display under the Danfoss > Device Manager.

4. Right-click Danfoss CG150-2 or Display and select Uninstall.

8 | © Danfoss | February 2021 AQ152986484649en-001003

Page 9

User Manual

PLUS+1® Service Tool

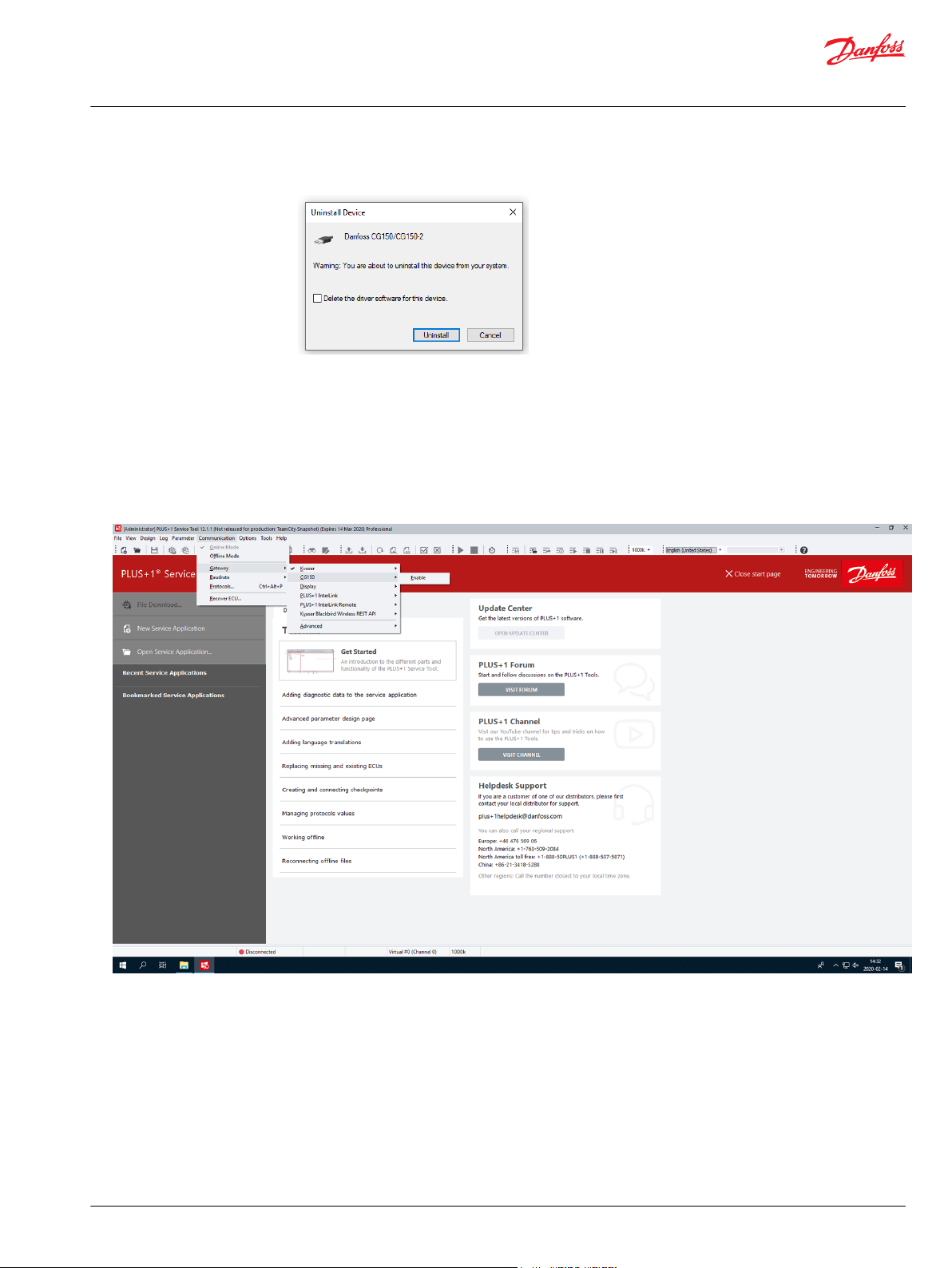

PLUS+1® hardware setup

5. Ensure that the Delete the driver software for this device option is unchecked, then click OK.

6. Unplug the PLUS+1® CG150-2 then plug it back into PC USB port.

The Found New Hardware balloon should appear in the Windows® taskbar. Complete the driver

installation wizard and start the PLUS+1® Service Tool to re-establish connection with the PLUS+1

CG150-2.

Using the PLUS+1® CG150-2 USB/CAN Gateway Interface Communicator

Select Communication > Gateway > CG150-2 from the PLUS+1® Service Tool window menu.

®

Using the PLUS+1® DP Series Display USB/CAN gateway

PLUS+1® DP Series Displays with USB connectivity can be used as a CAN gateway.

Make sure that the display is connected using a supported USB cable (see product documentation).

©

Danfoss | February 2021 AQ152986484649en-001003 | 9

Page 10

User Manual

PLUS+1® Service Tool

PLUS+1® hardware setup

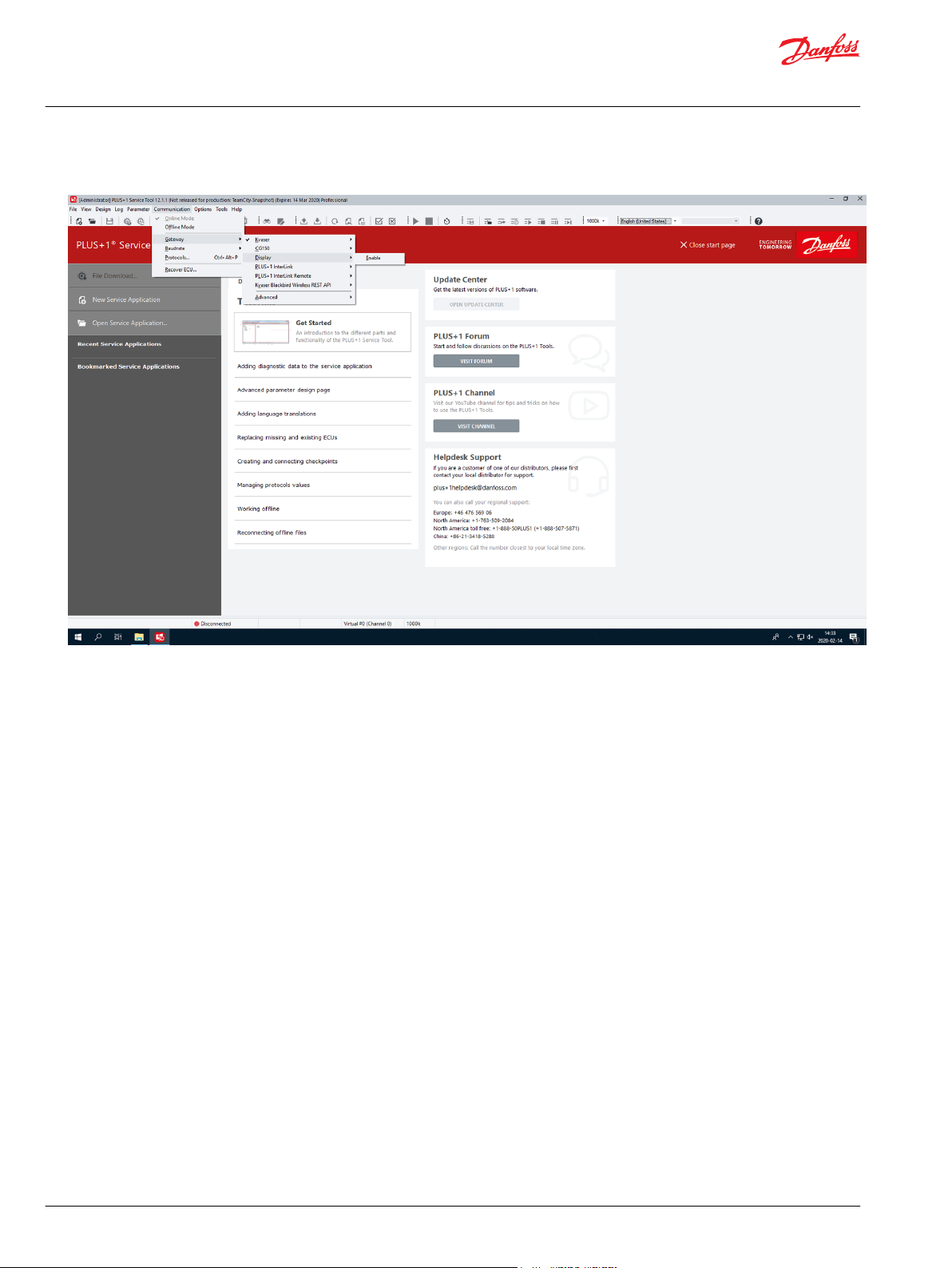

Select Communication > Gateway > Enable from the PLUS+1® Service Tool window menu.

Diagnose will be a choice under Gateway to select to examine any detected errors and warnings.

Using the PLUS+1® InterLink gateway

PLUS+1® products with PLUS+1® InterLink capabilities can be used as a gateway.

1. Make sure that the device is accessible through Wi-Fi/Ethernet/Bluetooth/USB (see product

documentation).

10 | © Danfoss | February 2021 AQ152986484649en-001003

Page 11

User Manual

PLUS+1® Service Tool

PLUS+1® hardware setup

2. Select Communication > Gateway > PLUS+1 InterLink from the PLUS+1® Service Tool window

menu.

The PLUS+1® Service Tool will search for available PLUS+1® InterLink devices, and these devices will

be available as channels.

3. After selecting the desired channel, a Gateway Password dialog will show up if the gateway is

password protected. Enter the correct password and press the Connect button to connect.

4. Check the Remember password check box to save the password.

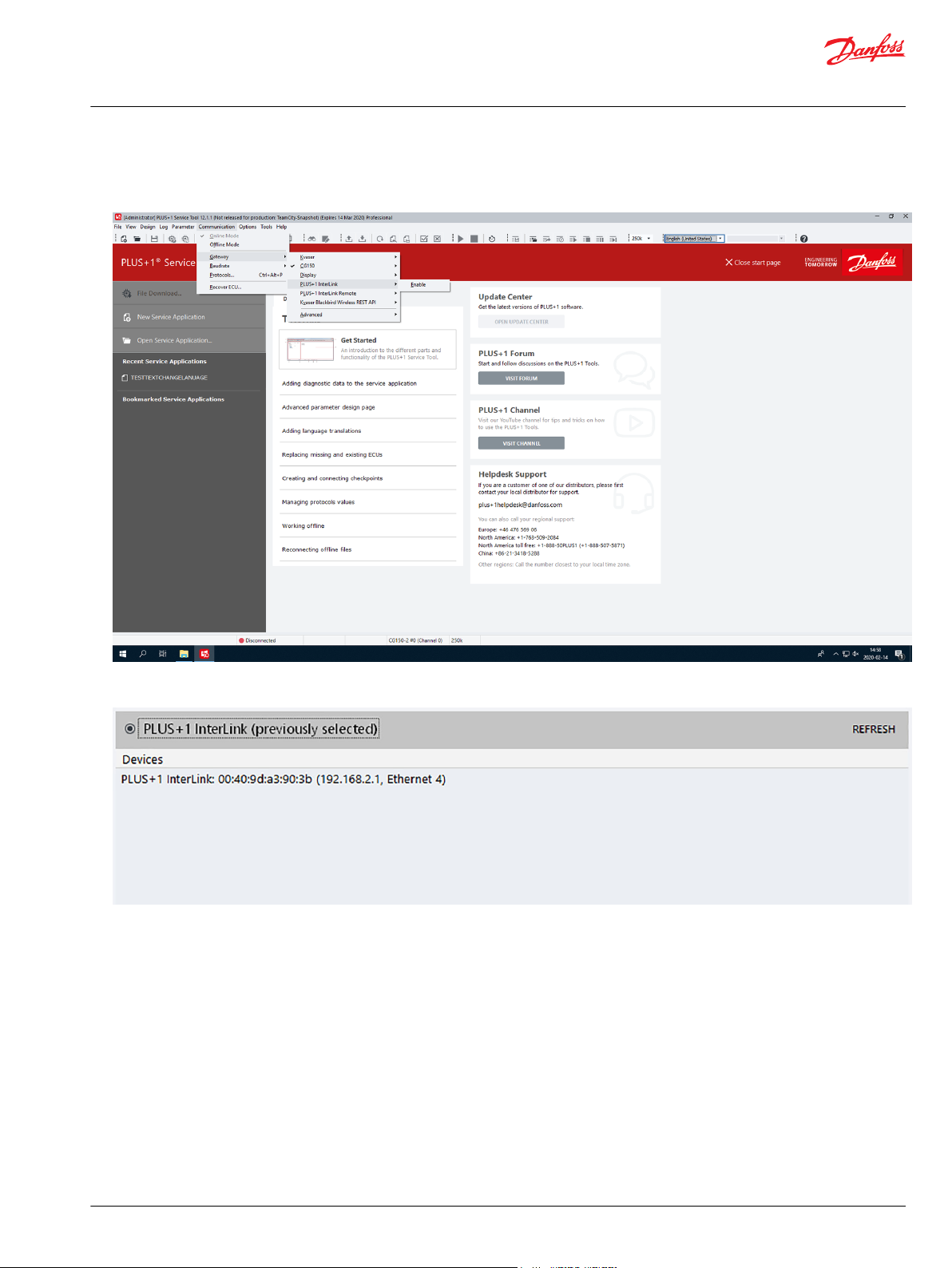

Using the PLUS+1® InterLink Remote gateway

PLUS+1® products with PLUS+1® InterLink Remote capabilities can be used as a gateway.

1. Select Communication > Gateway > PLUS+1®InterLink Remote from the PLUS+1® Service Tool

window menu.

©

Danfoss | February 2021 AQ152986484649en-001003 | 11

Page 12

User Manual

PLUS+1® Service Tool

PLUS+1® hardware setup

2. Click Log in to log in or sign up for a Danfoss Profile. Once authenticated the device list will display

the list of your PLUS+1® InterLink Remote devices and the state of each device. Click Refresh to the

update the state of the available devices.

3. Click OK to connect to the selected device.

By default, routing to all CAN interfaces is enabled. This means that any PLUS+1® device connected to the

CAN interfaces of the remote gateway will be accessible in PLUS+1® Service Tool. This functionality can be

configured in the CAN Interface Routing list before connecting to the device.

Using the third party Gateway devices via the RP1210 standard

The PLUS+1® Service Tool supports the generic communication standards RP1210B & RP1210A for any

compliant third party gateway. These recommended practice standards were written by the Technology

and Maintenance Council (TMC).

12 | © Danfoss | February 2021 AQ152986484649en-001003

Page 13

User Manual

PLUS+1® Service Tool

PLUS+1® hardware setup

Connection

RP1210B gateways may not support all baudrates that the built-in gateways support.

•

RP1210B gateways can be used if they support the generic CAN protocol.

‒

RP1210A gateways only supports baudrates equal to 250k.

•

RP1210A gateways can be used if they:

Support the generic CAN protocol

‒

Support blocking calls

‒

Use the same endianness (byte order) for CAN messages as RP1210B

‒

Activate RP1210 gateways by selecting the appropriate DeviceID in the submenu under the gateway

•

submenu. All possible device IDs will be listed for selection. Devices do not need to be connected to

the computer to be listed.

When an RP1210B or RP1210A gateway has been properly installed, it will be automatically added to the

list of installed gateways under Communication > Gateway after the PLUS+1® Service Tool is restarted.

The name of the new gateway consists of the name of the standard implemented (RP1210B or RP1210A)

plus the name of the gateway vendor as written in the vendor supplied .ini file. The order of gateways in

the list is determined by the global RP121032.ini file.

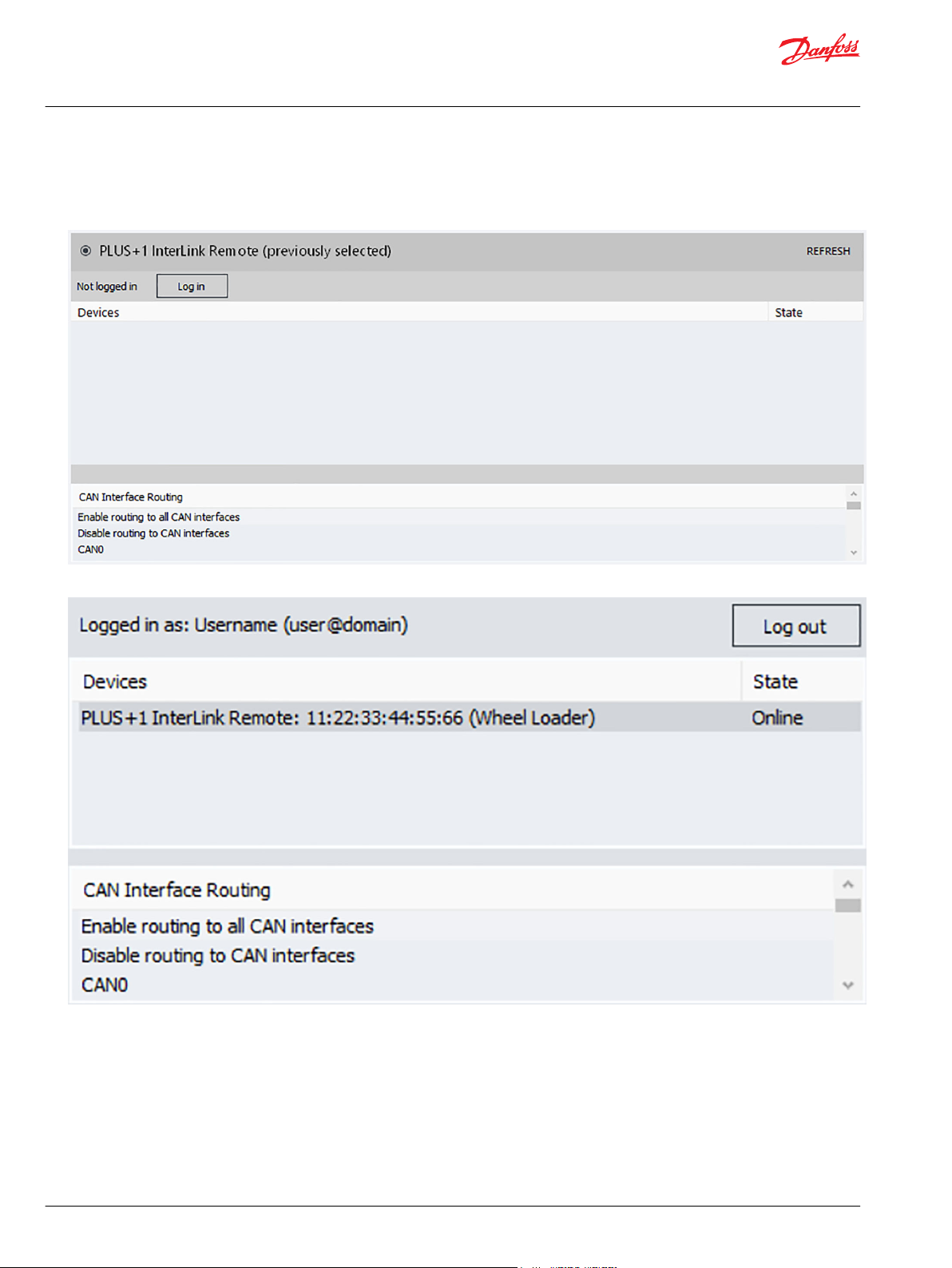

Diagnosing gateway warnings and errors using the RP1210 standard

Configure an RP1210 gateway using its .ini file. It is important that the .ini file follows the standard.

If the PLUS+1® Service Tool has problems reading the .ini file, an error or a warning message will occur. If

an error is found, it will not be possible to use the gateway from the PLUS+1® Service Tool. If warnings are

found it will still be possible to use the gateway, but a communication slowdown will occur. This

slowdown can be overridden by the user. See Using Reset Gateway in advanced settings on page 13 to fix

a gateway error manually.

Diagnose will be a choice under Gateway to select to examine any detected errors and warnings.

Advanced users may wish to use the View RP1210 parse log to troubleshoot RP1210 gateways that may

not be working well with the PLUS+1® Service Tool.

Select Communication > Gateway > Advanced > RP1210 Log from the PLUS+1® Service Tool window

menu.

The contents shown in the RP1210 Parse Results window is generated from the code and never stored

in a specific file.

A gateway that does not implement RP1210B, but only RP1210A will generate a warning message.

Using Reset Gateway in advanced settings

Reset Gateway can be used to:

©

Danfoss | February 2021 AQ152986484649en-001003 | 13

Page 14

User Manual

PLUS+1® Service Tool

PLUS+1® hardware setup

Search for gateway changes

•

Manually fix a gateway error that is not automatically detected

•

14 | © Danfoss | February 2021 AQ152986484649en-001003

Page 15

User Manual

PLUS+1® Service Tool

Managing protocols

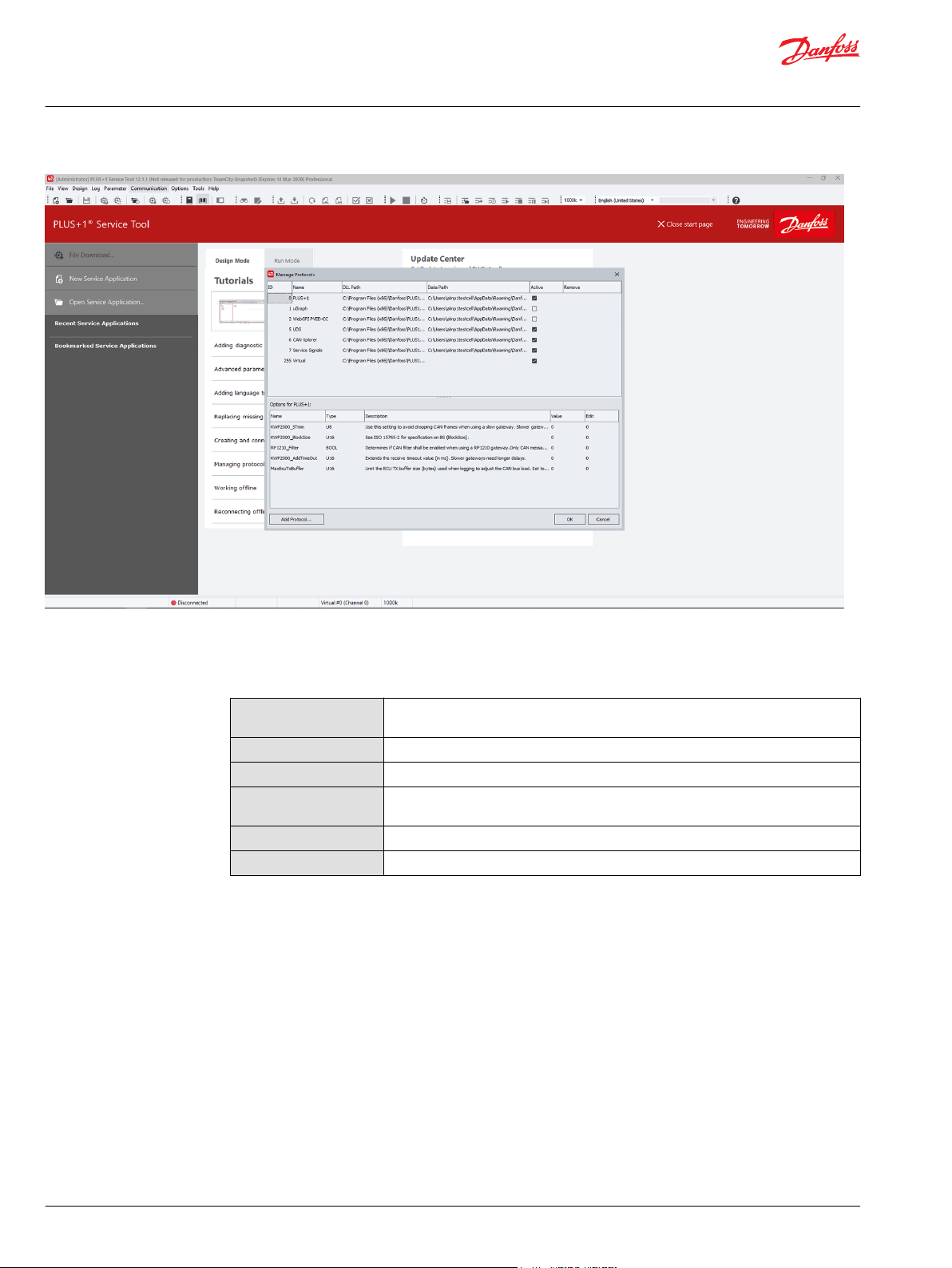

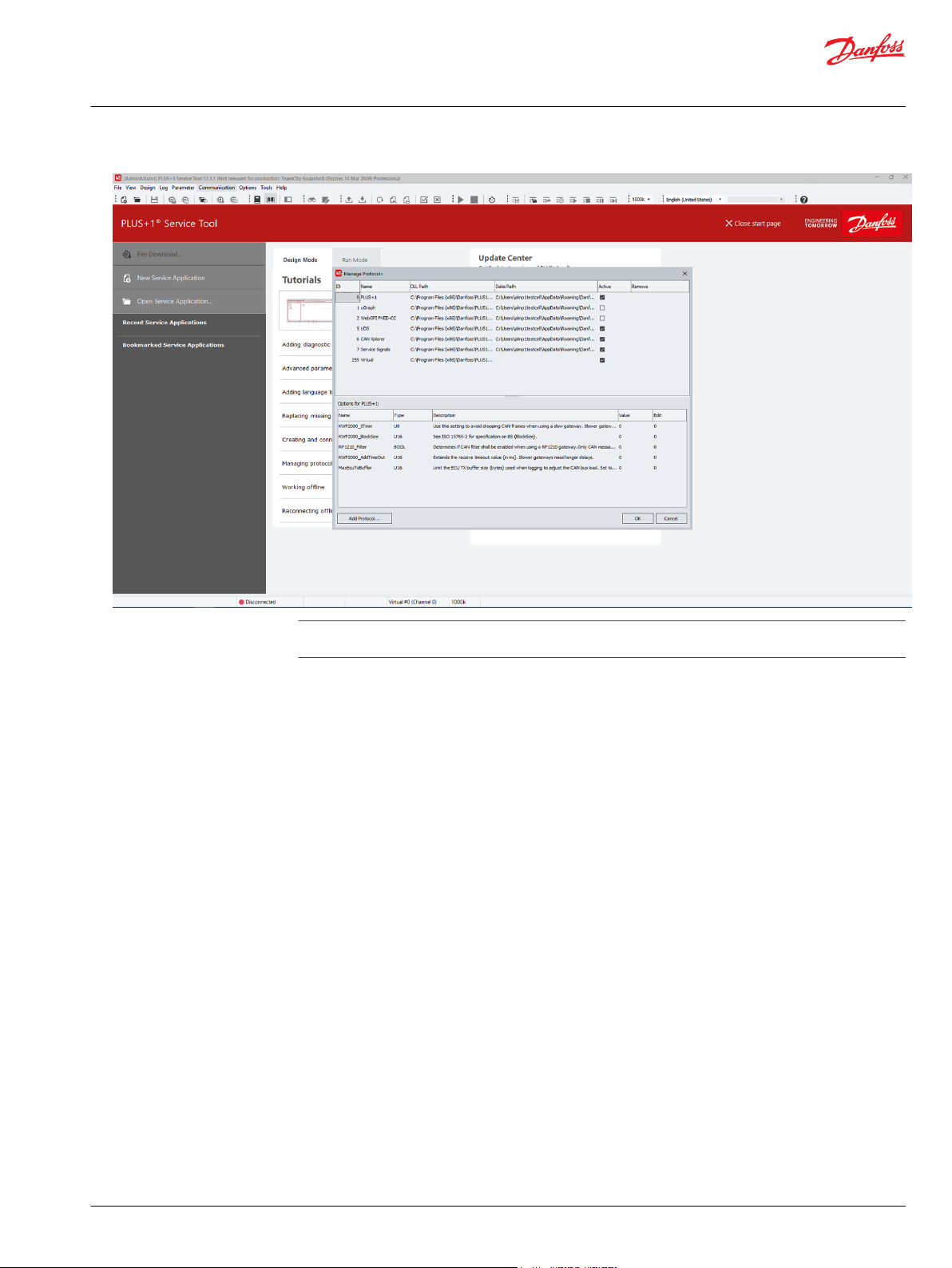

Managing Protocols values

Protocols must be installed and selected before they can be used. This can be done in the Manage

Protocols window. More than one protocol can be used at a time.

The PLUS+1® Service Tool also supports the use of communication protocols other than the standard

PLUS+1® protocol, but not all PLUS+1® features may be functional if a different protocol is used.

To manage communication protocols, select: Communication > Protocols....

This opens the Manage Protocols window, see below:

©

Danfoss | February 2021 AQ152986484649en-001003 | 15

Page 16

User Manual

PLUS+1® Service Tool

Managing protocols

Add new protocols

Selecting Add Protocol opens the window, where all installed protocols can be seen and managed. The

Manage Protocols window displays the following values:

Manage Protocols Values

ID

Name

DLL Path

Data Path

Active Selection Box

Remove

All protocols have an assigned ID number from 0 to 255. PLUS+1® protocol is always 0

and Virtual is always 255.

Protocol name.

Location folder of actual DLL file.

Location of a created folder where protocol-related information can be stored. This

location can be changed by the user.

Check box checked: protocol is active.

Link to remove protocol from system.

1. Add new protocols by clicking the Add Protocol button in the lower left corner of the Manage

Protocols window.

2. Select a protocol DLL in the Select Protocol DLL dialog and click Select to confirm the choice.

The added protocol will now appear in the protocols list of the Manage Protocols window with an

assigned ID number.

3. Use the Manage Protocols window to check data path, activate, remove or modify options for the

protocol. When finished, click OK.

The protocol is added and ready for use.

16 | © Danfoss | February 2021 AQ152986484649en-001003

Page 17

User Manual

PLUS+1® Service Tool

Managing protocols

When using multiple protocols in a system, make sure that the protocols will not interfere with each

other. High bus load may occur when using many protocols at the same time.

©

Danfoss | February 2021 AQ152986484649en-001003 | 17

Page 18

User Manual

PLUS+1® Service Tool

Managing protocols

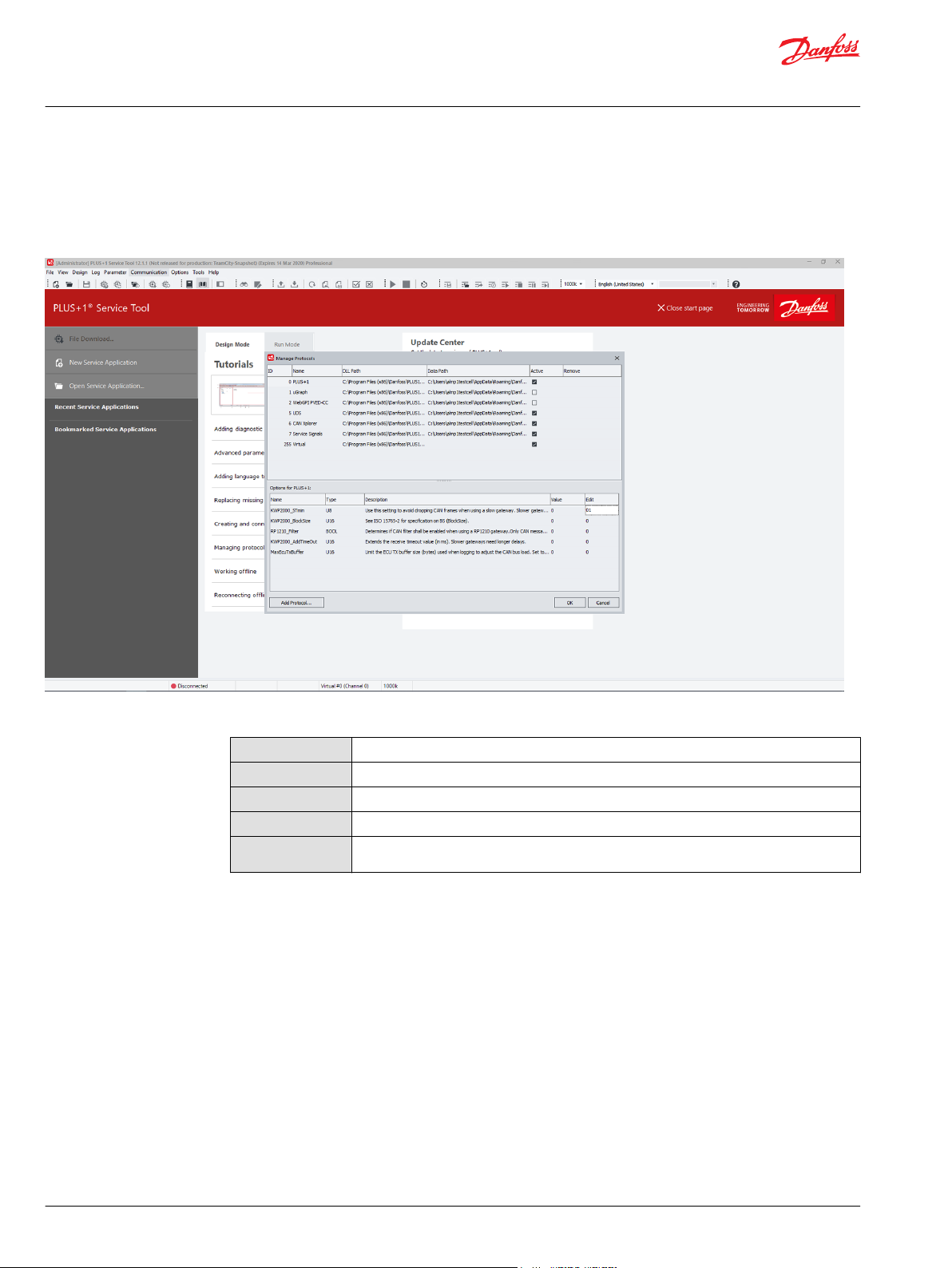

Protocol options

Protocol option values can be changed. In the Manage Protocols window, select a protocol in the list to

view the protocol options displayed in the bottom part of the dialog. The options and information for

each protocol will vary.

Options for protocol window

Name

Type

Description

Value

Edit

The name of the option.

Setting type.

A short description of the setting.

The current value of the setting.

The editable properties of the setting. If field is empty, the setting is not editable (see editing

properties for more information).

Click the value in the Edit field to edit the option value. Click OK to save and use the updated option

values.

18 | © Danfoss | February 2021 AQ152986484649en-001003

Page 19

User Manual

PLUS+1® Service Tool

PLUS+1 Service Tool window

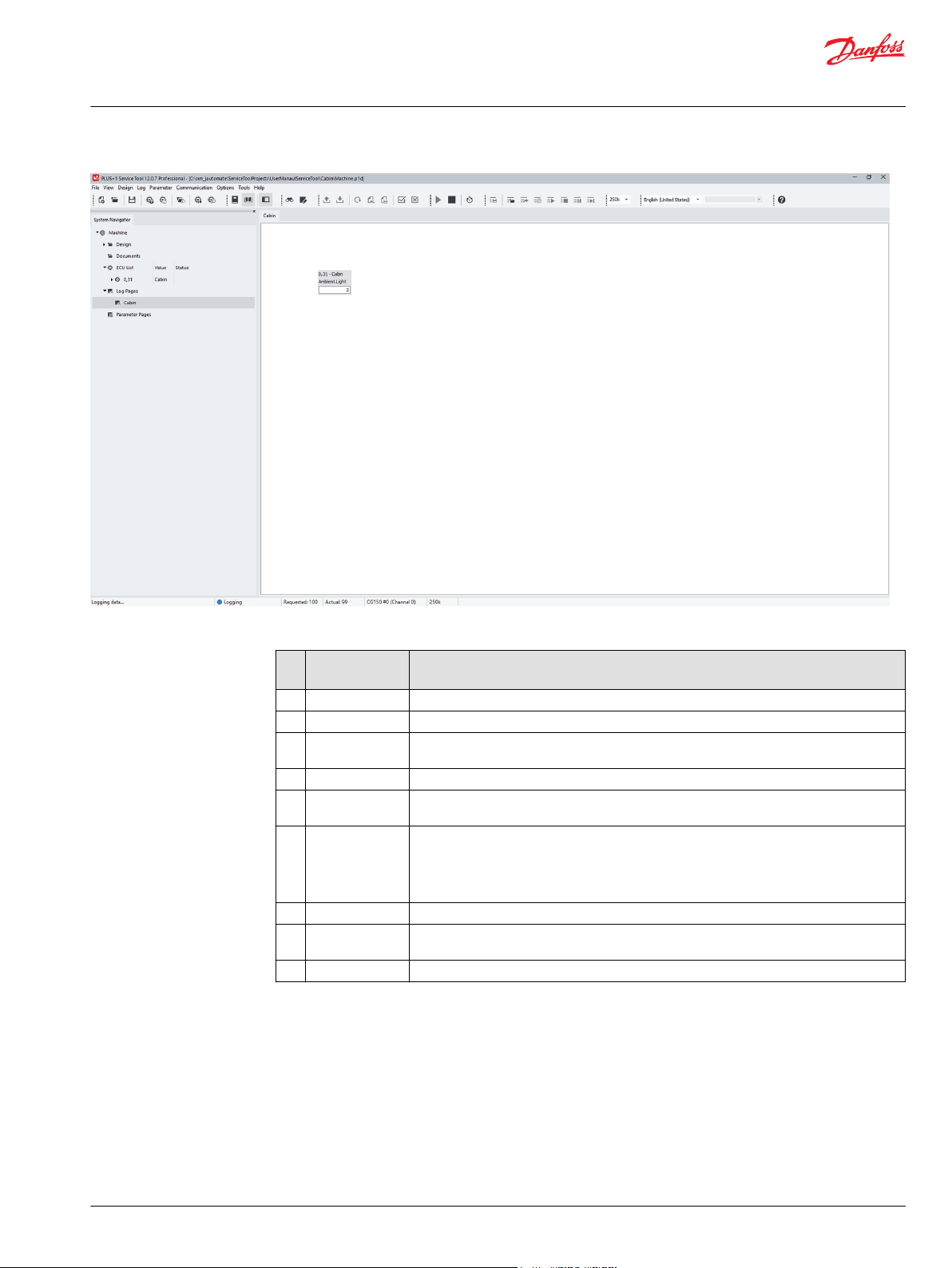

PLUS+1® Service Tool Window Description

ItemName Description

1. Menu bar Use to access PLUS+1® Service Tool commands and information.

2. Toolbar Use to access common PLUS+1® Service Tool commands and information.

3. System Navigator Use to show a tree view of all hardware and software applications within the PLUS+1

4. Work area The area where all PLUS+1® Service Tool functions are performed.

5. Service function

status

6. Controller

connection status

7. Log period status Displays the requested and actual log period settings in the application.

8. CAN device

information

9. CAN baudrate Displays the baudrate setting for the CAN/USB gateway interface communicator.

Service Tool.

Displays information of current PLUS+1® Service Tool function.

Green — Controller connected

•

Blue — Logging or Downloading

•

Yellow — Searching for connection

•

Red — Controller disconnected or gateway error

•

Displays connected CAN/USB gateway interface communicator information.

®

©

Danfoss | February 2021 AQ152986484649en-001003 | 19

Page 20

User Manual

PLUS+1® Service Tool

PLUS+1 Service Tool window

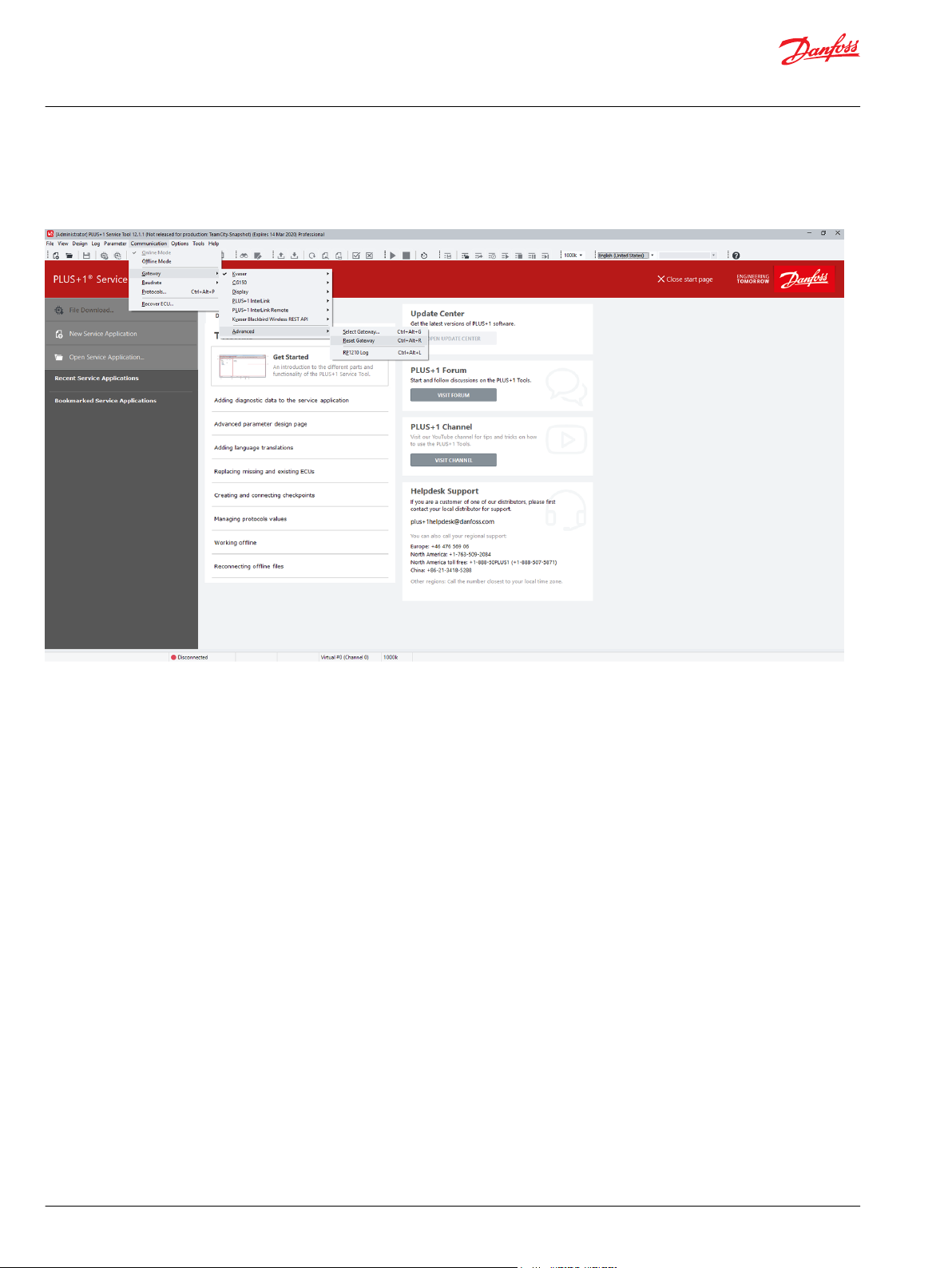

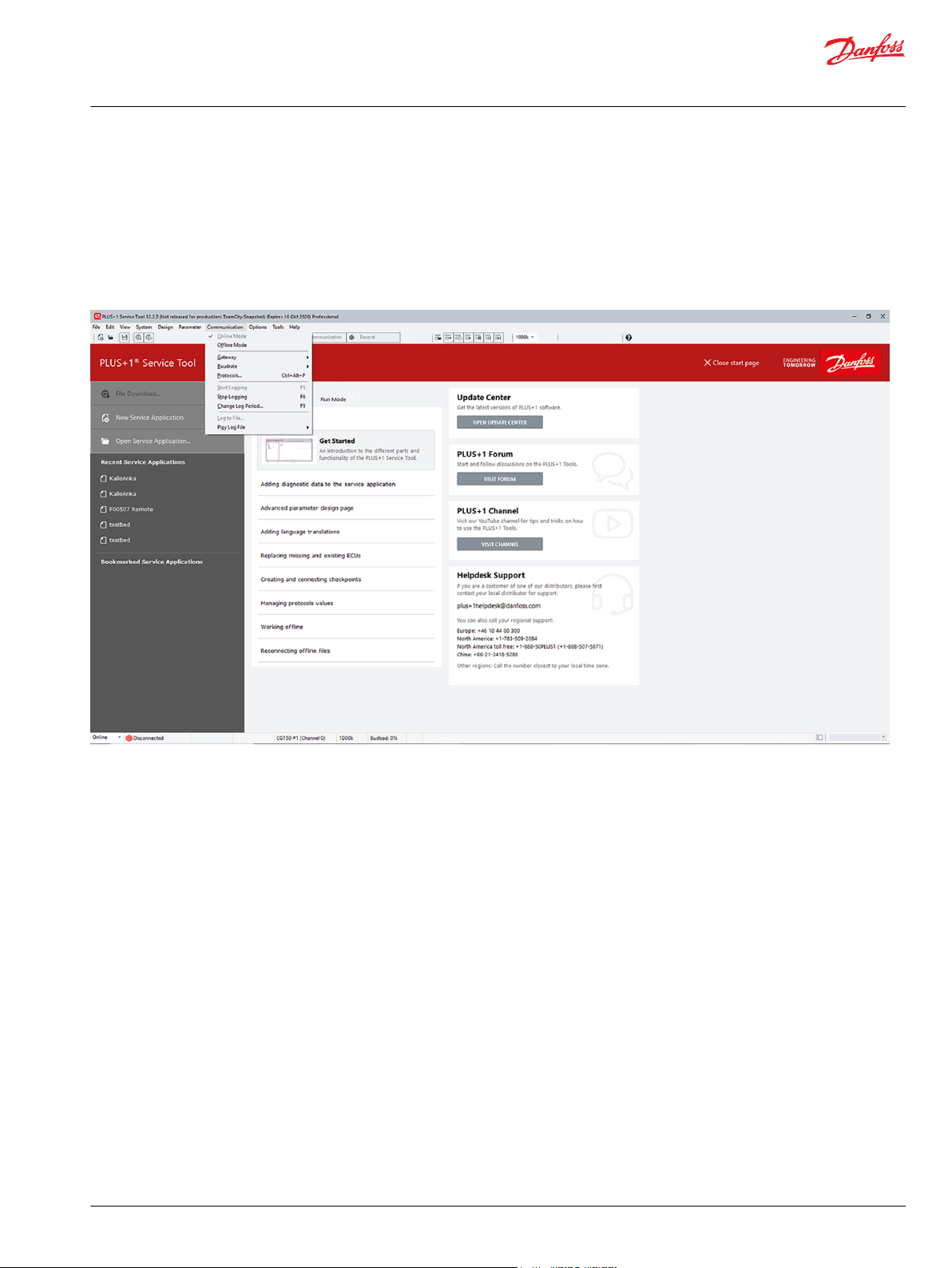

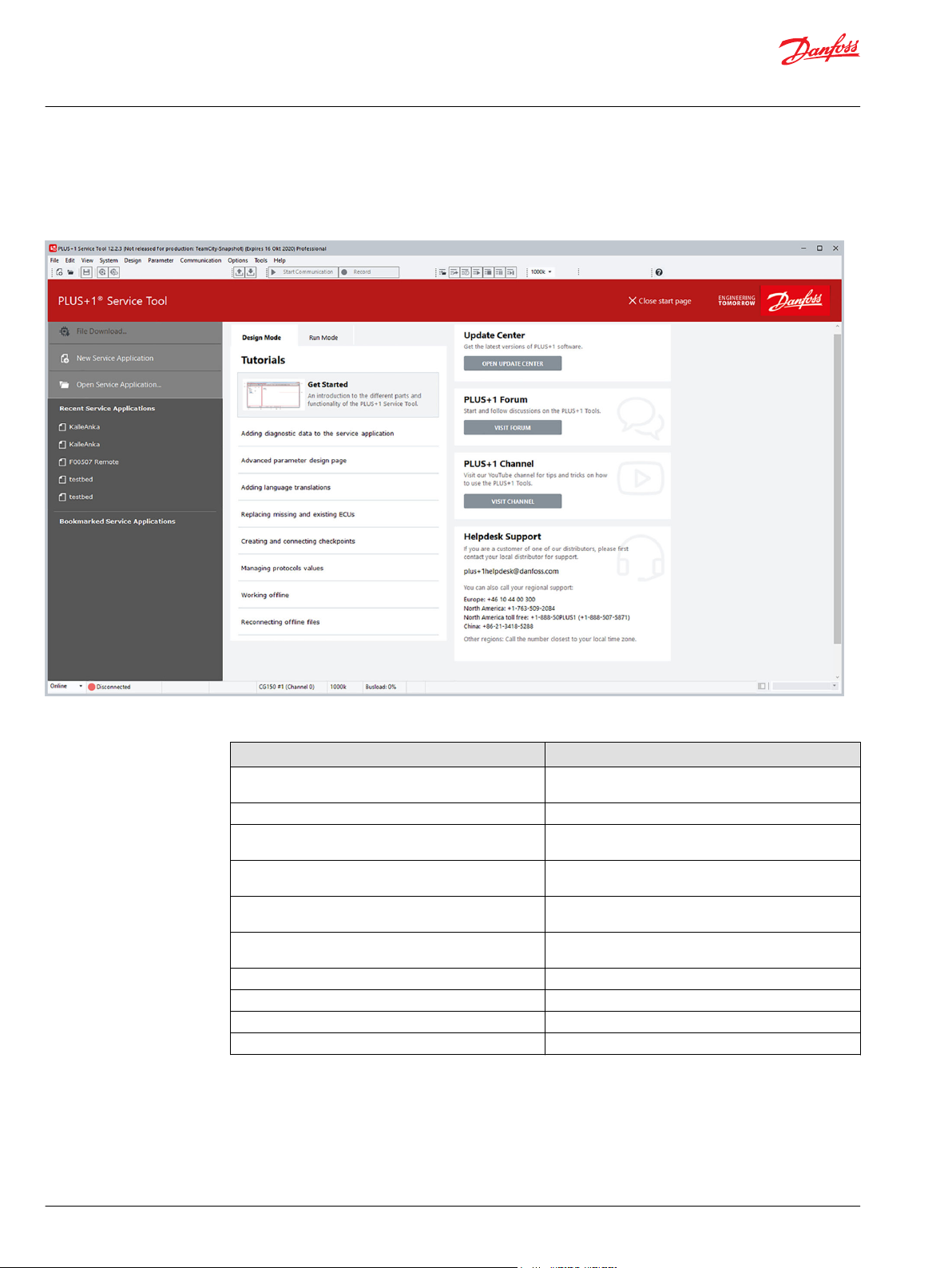

Start page

The start page is available by default when no Service Application is open in PLUS+1® Service Tool. It can

be disabled in Options under General (or new page number if changed).

PLUS+1 Service Tool start page

Item Description

File Download… Displays the Open Download File dialog. Once a file is

New Service Application Creates a new empty Service Application.

Open Service Application... Displays the Open Service Application dialog. Use this

Recent Service Applications A list of recently opened Service Applications. Select a

Bookmarked Service Applications A list of bookmarked Service Applications. Select a

Tutorials A list of tutorial links into the HTML version of the user

Update Center Shortcut to start the PLUS+1® Update Center.

PLUS+1® Forum Shortcut to the PLUS+1® Forum online.

PLUS+1® Channel Shortcut to the PLUS+1R YouTube channel.

Helpdesk Support Contact information to PLUS+1® Helpdesk.

selected, the Download File dialog is displayed.

dialog to locate and open Service Application files.

Service Application to open from this list.

Service Application to open from this list.

and design manuals.

20 | © Danfoss | February 2021 AQ152986484649en-001003

Page 21

User Manual

PLUS+1® Service Tool

PLUS+1 Service Tool window

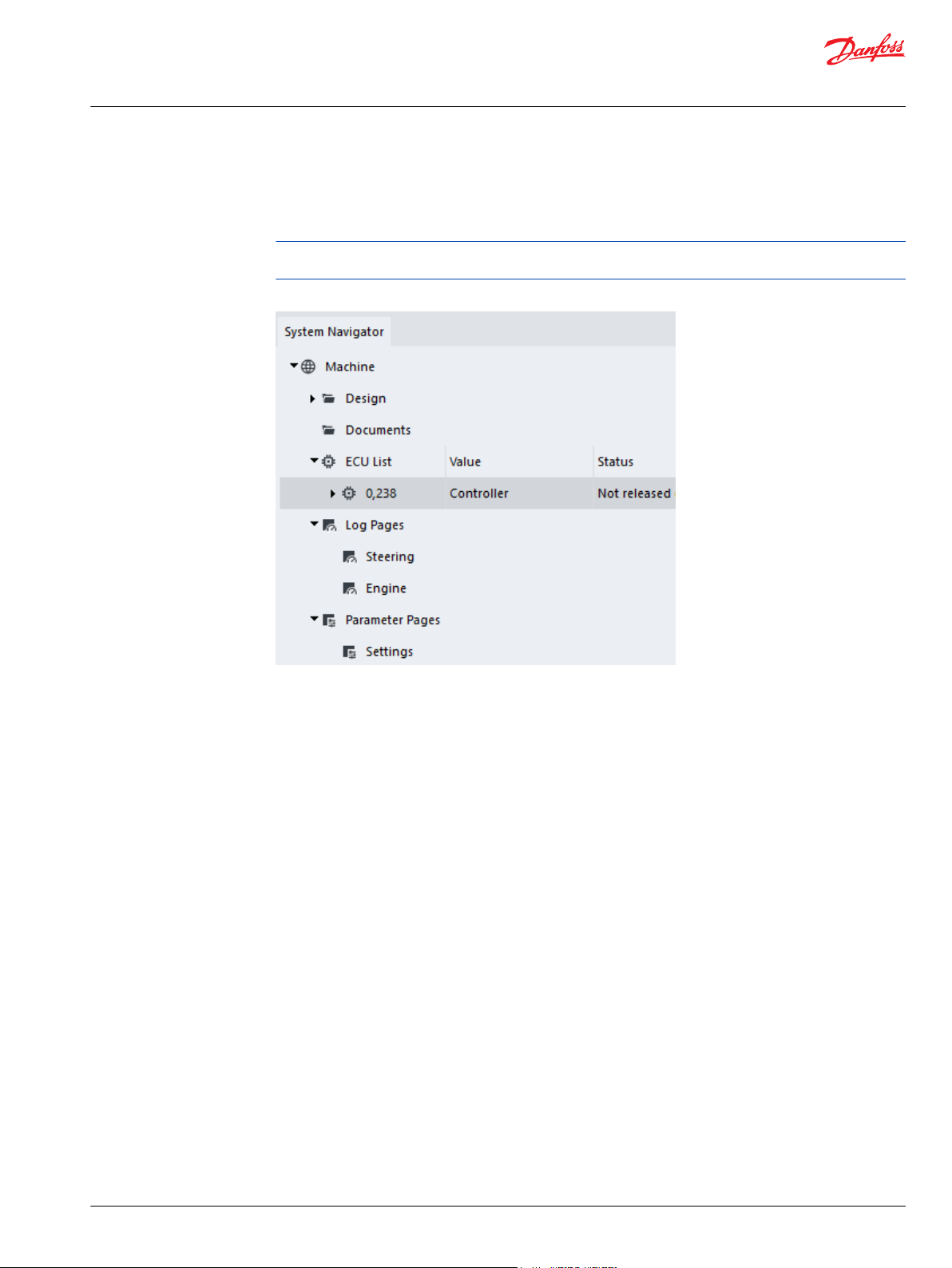

System Navigator features

The System Navigator section of the PLUS+1® Service Tool window contains and displays important

information for the PLUS+1® Service Tool.

It is possible to copy the ECU list information to the clipboard, by right-clicking the ECU List node and

selecting the menu item Copy ECU List to clipboard.

The System Navigator area is the starting point for all PLUS+1® Service Tool functions.

Use the System Navigator to:

Set and display system information

•

Store and access documents (right click on Documents icon to add, remove or hide documents in

•

Normal view)

Set and display ECU information

•

Display Net, node and hardware information

•

Create, open and arrange Log and Parameter pages

•

Store and display PLUS+1® Service Tool activity history

•

Information in the System Navigator is arranged in a hierarchical style. Sections can be expanded or

minimized as needed.

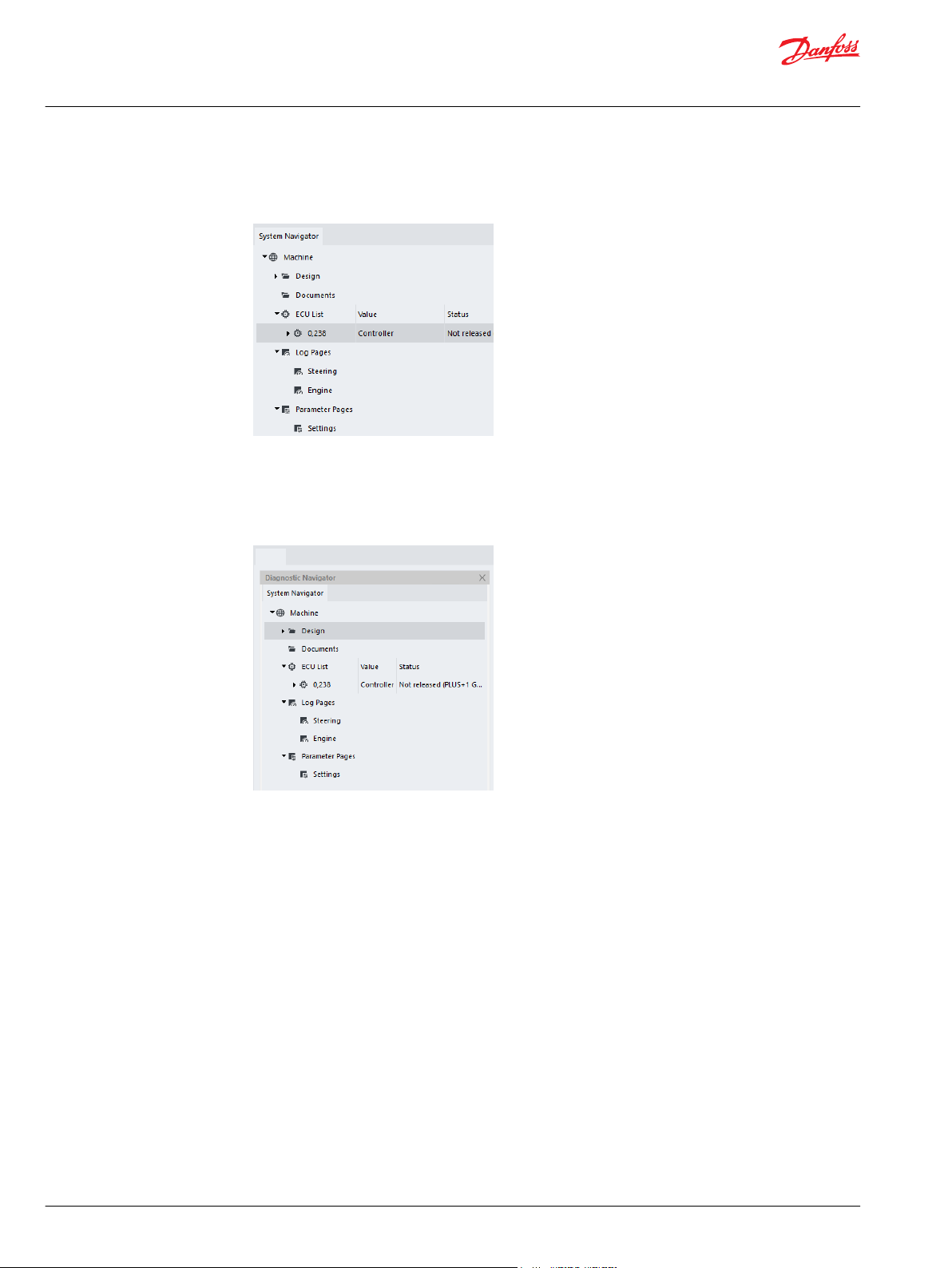

Locking and unlocking Diagnostic Navigator pane

Unlock the Diagnostic Navigator pane

©

Danfoss | February 2021 AQ152986484649en-001003 | 21

Page 22

User Manual

PLUS+1® Service Tool

PLUS+1 Service Tool window

Lock the Diagnostic Navigator pane

1. Drag the pane by the undocking bar to separate it from the main window.

Drag to unlock (docked)

2. Double-click on the title bar at the top of the window.

The Navigator pane snaps to its default position.

Double-click to dock (undocked)

Hide the Diagnostic Navigator pane

3. Toggle either the Diagnostic Navigator button in the status bar or Diagnostic Navigator in the View

menu.

Display the Diagnostic Navigator pane

4. Move the mouse cursor to the left side of the PLUS+1® Service Tool window or click the System

Navigator button on the toolbar again.

Restoring default layouts

Select View > Default Layout to restore the PLUS+1® Service Tool window settings to the default

layout.

22 | © Danfoss | February 2021 AQ152986484649en-001003

Page 23

User Manual

PLUS+1® Service Tool

PLUS+1® Service Tool languages

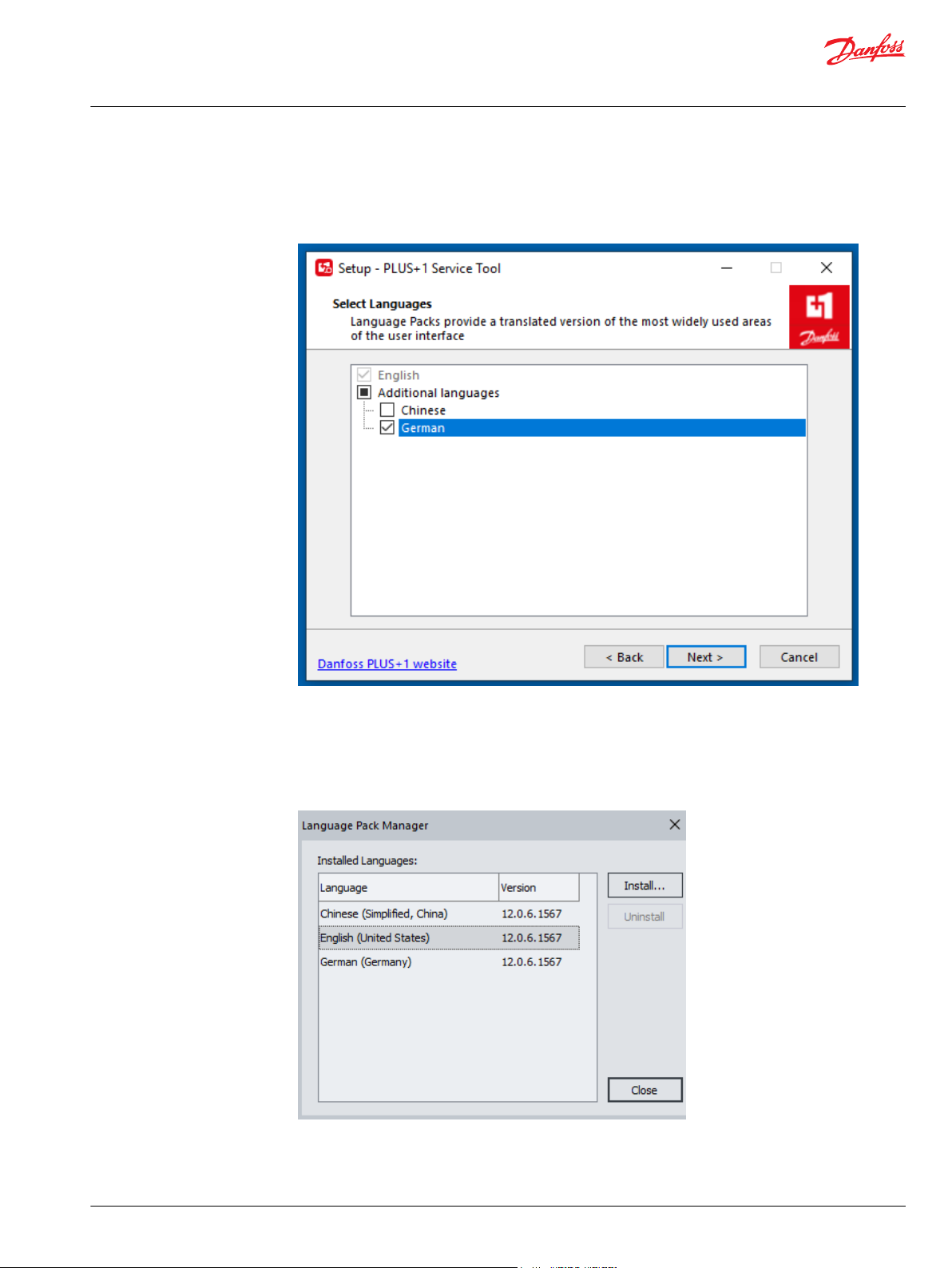

Installing tool languages during setup

When setting up the PLUS+1® Service Tool, install additional languages in the Select Languages

page.

Managing languages in PLUS+1® Service Tool

1. In the PLUS+1® Service Tool, select Tools > Language > Language Manager.

2. Select language to install or uninstall.

You cannot uninstall the default language (English).

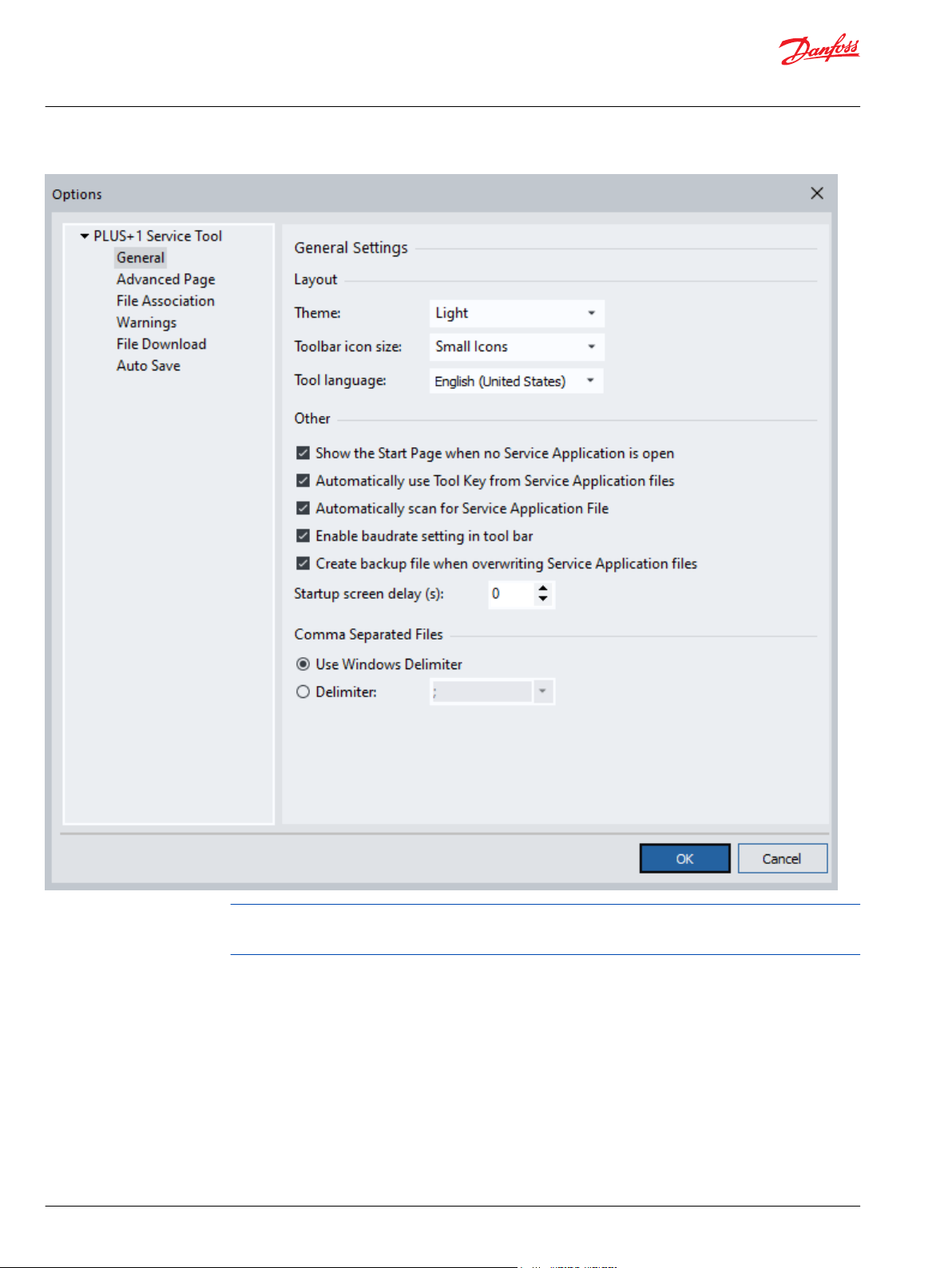

Selecting the PLUS+1® Service Tool language

To select the preferred PLUS+1® Service Tool language, select Tool language in the General Settings.

©

Danfoss | February 2021 AQ152986484649en-001003 | 23

Page 24

User Manual

PLUS+1® Service Tool

PLUS+1® Service Tool languages

To select the default language (English), select Options > Language > Default Tool Language.

This can also be done by selecting Ctrl+Alt+F.

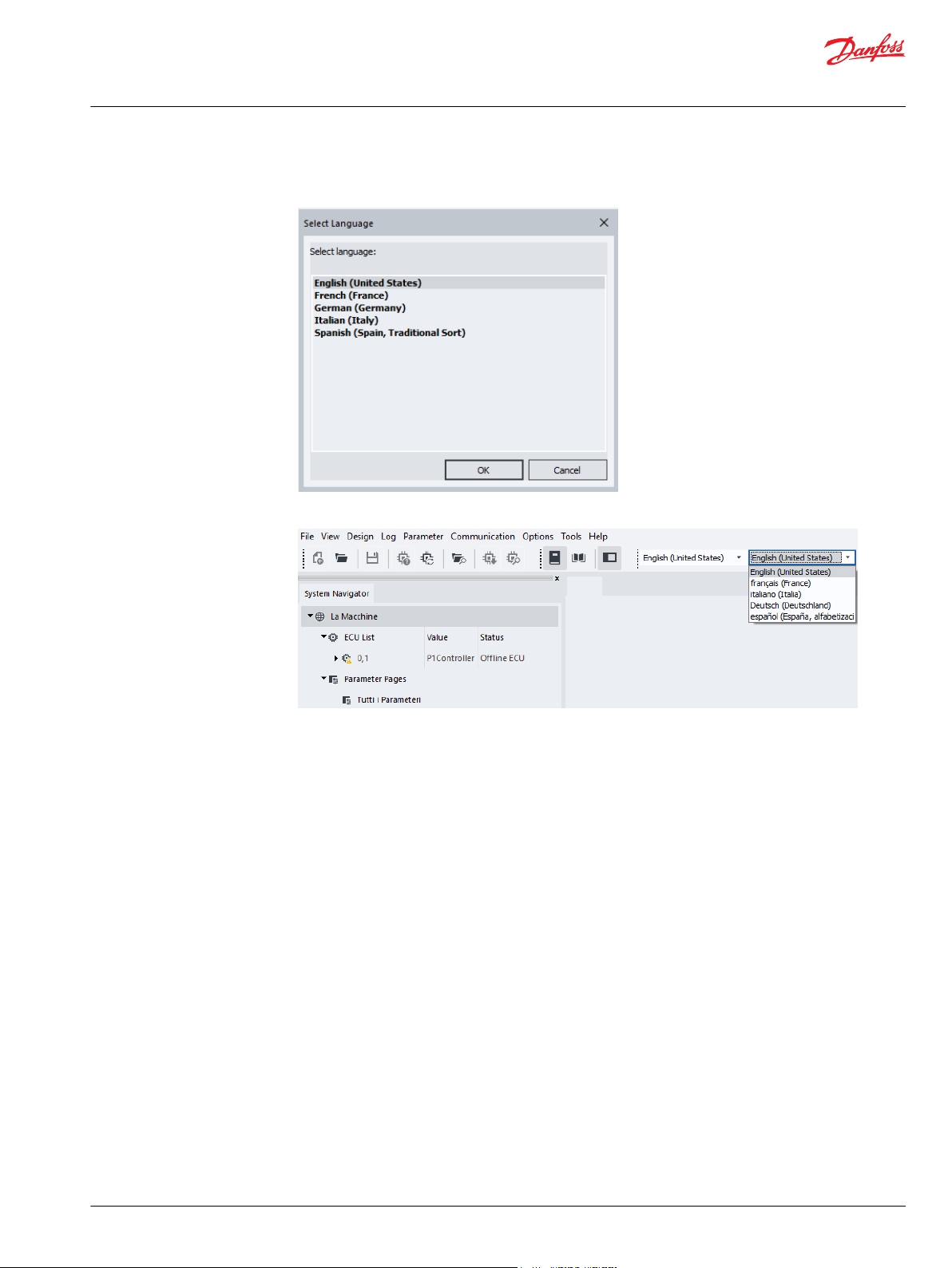

Selecting the Service Application language

24 | © Danfoss | February 2021 AQ152986484649en-001003

Page 25

User Manual

PLUS+1® Service Tool

PLUS+1® Service Tool languages

When a multilingual Service Application is active and the tool is in Normal View, select Tools >

Language > Select Service Application Language.

Alternatively, you can select the preferred language in the drop-down list of the toolbar.

©

Danfoss | February 2021 AQ152986484649en-001003 | 25

Page 26

User Manual

PLUS+1® Service Tool

Downloading the application

Preparing to Download the Application File to the Controller

1. Click the File Download button in the PLUS+1® Service Tool window toolbar.

This can also be done by selecting File > File Download or Ctrl+D command.

2. Browse in the Open dialog box and click the file name of your application, then click Open.

It is possible to select multiple download files.

3. Select the target ECU in the ECU dropdown menu and click Next.

The download file is now ready for downloading.

26 | © Danfoss | February 2021 AQ152986484649en-001003

Page 27

User Manual

PLUS+1® Service Tool

Downloading the application

4. Check the Show report after download checkbox to get a report of the download.

It is possible to configure the PLUS+1® Service Tool to automatically save download reports to a

specific folder. If this functionality is enabled, the Show report after download checkbox will not be

available.

5. Click Start Download to download the application.

©

Danfoss | February 2021 AQ152986484649en-001003 | 27

Page 28

C

User Manual

PLUS+1® Service Tool

Downloading the application

A progress bar is shown while downloading

It is recommended that there are no other applications running on your PC while downloading the

application file. This will speed the file transfer process up and help to avoid possible system and

application conflicts.

Caution

To avoid possible system and application conflicts, do not disconnect or power off the system during

the download process. The PLUS+1® Service Tool will automatically rescan the controller when the

download is completed.

If the target OS version does not match the file OS version when attempting to download, a

•

warning message will be shown in the Application File Information in the Download File to ECU

window:

If the target application file type does not match the file application type for the file that is to be

•

downloaded, a warning message dialog box will appear:

28 | © Danfoss | February 2021 AQ152986484649en-001003

Page 29

User Manual

PLUS+1® Service Tool

Downloading the application

When the download is completed, the application is ready for testing.

6. Click the Save Report button when the download is finished to create a report file.

Downloading system download packages

When using system download packages, there will be a list of individual downloads (1-∞) in the list. It is

possible to check/uncheck individual downloads, depending if they are mandatory or not.

1. Click Next to see eventual parameter settings.

2. Click Start Download to start all downloads.

Mandatory applications/missing ECUs

Applications might be mandatory in a package. It is not possible to deselect these applications during the

download sequence.

©

Danfoss | February 2021 AQ152986484649en-001003 | 29

Page 30

User Manual

PLUS+1® Service Tool

Downloading the application

If no valid ECU is found for the mandatory application, it will not be possible to continue the system

download.

Retry downloads

It is possible to retry a failed download. The successful downloads will be unchecked by default, and the

failed download will remain checked.

30 | © Danfoss | February 2021 AQ152986484649en-001003

Page 31

User Manual

PLUS+1® Service Tool

Downloading the application

Press the Retry Download button to retry the failed downloads.

Parameter settings during the application download

Parameter Settings - Values dialog window will appear when downloading applications with common

parameters.

•

The upper field shows information about the current application and the application to be

downloaded.

•

The lower field shows changes in the parameter structure.

The Status icons display more detailed information about the parameter. Only parameter values that are

checked in the Parameter Values dialog box will be downloaded during file download.

©

Danfoss | February 2021 AQ152986484649en-001003 | 31

Page 32

User Manual

PLUS+1® Service Tool

Downloading the application

If restricted parameters exist, a warning message will be displayed.

•

•

•

Use the Parameter Setting pull-down selection to define parameter setting behavior:

Restricted parameters will be transferred automatically.

New restricted parameters will be set to zero.

Restricted parameters with changed parameter type will be transferred if the value is valid within the

new parameter type; otherwise the parameter value will be set to zero.

Automatic selection will transfer values where the memory locations have been changed.

•

Set to Zero will set all parameter values to zero (parameter values with restricted access will be

•

transferred to the new application).

User Defined is automatically selected when custom changes are made. All fields that are white (not

•

grey) are possible to change manually

An option is available whether to always display the parameter settings dialog, or only when the

parameter structure is changed.

32 | © Danfoss | February 2021 AQ152986484649en-001003

Page 33

User Manual

PLUS+1® Service Tool

Downloading the application

Recover ECU functions

The correct Tool Key for the current application must be supplied before the download to be able to

transfer the parameter values automatically. If not, a warning dialog will be displayed. If you continue the

download, parameter values will not be transferred to the new application.

The Recover ECU is now available for all protocols (where supported), and not only the PLUS+1

®

protocol. A protocol field has been added to the Recover ECU dialog.

©

Danfoss | February 2021 AQ152986484649en-001003 | 33

Page 34

User Manual

PLUS+1® Service Tool

Downloading the application

It is also possible to install diagnostic data files for all protocols (where supported).

To use the Recover ECU functionality with a display or RP1210 gateway it is required to have at least 3

units attached to the CAN Bus: The diagnostic interface, the ECU to recover, and at least one hardware

that can do acknowledge on the CAN messages sent by the PLUS+1® Service Tool.

34 | © Danfoss | February 2021 AQ152986484649en-001003

Page 35

User Manual

PLUS+1® Service Tool

Working with service application files

Introduction to service application files

In order to interface with an ECU application, a service application file is needed. Service application files

can contain both Log and Parameter pages.

There are two ways to open service application files in the PLUS+1® Service Tool application.

•

Manual load service application files

•

Scan for service application files

Log page

Use the Log page to:

Monitor application activity

•

Enable data logging to file

•

Export log data to Microsoft Excel

•

Parameter page

Use the Parameter page to:

Download and upload PLUS+1® GUIDE profiles and parameters

•

Import and export created parameter files

•

Generate database reports of parameter values

•

®

Manual Load of Service Application Files

1. Select File > Open

2. Select System Application files to load to the System Navigator.

Scanning for service application files Use Scan for Service Application File... to load service application files:

©

Danfoss | February 2021 AQ152986484649en-001003 | 35

Page 36

User Manual

PLUS+1® Service Tool

Working with service application files

1. Select File > Scan for Service Application File...

If the connected system contains a System ID, that System ID will be used to find matching service

application files. All service application files that contain an exact matching System ID will be

displayed in the results dialog.

If only one matching file is found, this file will be opened automatically.

Matching files are added to the list while searching.

2. To open a matching file and close the search dialog, select the desired file in the list and select Open.

Refer to the PLUS+1® GUIDE User Manual, AQ152886483724 for instructions how to enter System IDs

into PLUS+1® GUIDE.

The PLUS+1® Service Tool will search for service application files in the following locations:

Any service application file that has been previously opened

•

Files in the My Documents Danfoss\PLUS1\GUIDE Service Tool\Service

•

Application Files Folder

If no System ID is available in the connected system, files will be matched using the Net/Node

Number, Application ID, and Application Type of the file and connected system. An exact match of all

ECUs in the file and system is required.

Boot loader mode

After downloading an application, the system is scanned for new diagnostic data to load.

If the connection is broken during the application download, the ECU will go into boot loader mode.

36 | © Danfoss | February 2021 AQ152986484649en-001003

Page 37

User Manual

PLUS+1® Service Tool

Working with service application files

When the ECU is in boot loader mode the ECU will be displayed red in the System Navigator.

Downloading a valid application will take the ECU out of boot loader mode.

Automatic scan for service application files

The PLUS+1® Service Tool can be set to automatically open the correct P1D after scanning the system in

normal view.

The option Automatically scan for Service Application File must be enabled in the PLUS+1® Service

Tool settings for this feature to be active.

When enabled, the Scan for Service Application File function on the File Menu will be activated after

each system scan.

1. Enable the feature by selecting Automatically scan for Service Application File in the General

section of the Options dialog box.

2. Click OK to save your selection and close the Options dialog box.

©

Danfoss | February 2021 AQ152986484649en-001003 | 37

Page 38

User Manual

PLUS+1® Service Tool

Working with service application files

The Automatically Scan for Service Application File will only be activated if the connected system

contains a System ID.

Opening hardware service files

There are two ways to open hardware service files in the PLUS+1® Service Tool application:

•

The PLUS+1® Service Tool can scan for hardware service files

•

Files can be manually loaded

1. Open the PLUS+1® Service Tool.

2. In the System Navigator, right-click on the ECU and select option.

Scan for Hardware Service File...

•

Load Hardware Service File...

•

Manual installation of diagnostic data files

In the PLUS+1® Service Tool, diagnostic data files are automatically installed when a P1H/P1D or LHX file is

opened.

Diagnostic data files can also be installed manually by selecting File > Install Diagnostic Data.

1. Click Install Diagnostic Data...

Active communication protocols that support Install Diagnostic Data files are listed.

38 | © Danfoss | February 2021 AQ152986484649en-001003

Page 39

User Manual

PLUS+1® Service Tool

Working with service application files

2. Select from the list of active protocols to display the installed diagnostic data files.

3. Select a data file to install or uninstall.

A new file can be added by leaving all selections unchecked and clicking Install.

4. After clicking install, select a file to install from the Open window. Click Open to install.

An installation dialog window will confirm the status of the file installation. Unsuccessful installations

will be shown in red with the reason for the failed installation.

©

Danfoss | February 2021 AQ152986484649en-001003 | 39

Page 40

User Manual

PLUS+1® Service Tool

Using log pages

Logging controls

1. In the menu bar of the main PLUS+1® Service Tool window, select Communication > Start

Communication to begin log activity.

2. To stop logging, select Communication > Stop Communication.

3. Logging can be monitored in any or all of the four log file views chosen in the Design Diagnostic

Page. Click through the tabs to change log views.

Recording log files

4. Logging controls can also be accessed through the button controls above the Log view work area.

Button controls above the Log view area

Button Description

Start logging / Stop logging toggle button

/

Record to file

1. Record log files by using the record to file function. Select Communication > Record to File from the

PLUS+1® Service Tool window menu. When the recording has been started, log data recording will be

automatically saved.

40 | © Danfoss | February 2021 AQ152986484649en-001003

Page 41

User Manual

PLUS+1® Service Tool

Using log pages

2. When recording is stopped, select or create a log file to save in the Select logfile window.

Monitor log files

Any logging activity will be recorded in a log file. Logfiles (*.LDF) for basic pages will be stored as

LDF/LHF files.

Log files for advanced pages will be stored as LDF/GEN files in the selected log folder.

1. Verify Log to File activity by monitoring Log status box in lower left hand of PLUS+1® Service Tool

window.

©

Danfoss | February 2021 AQ152986484649en-001003 | 41

Page 42

User Manual

PLUS+1® Service Tool

Using log pages

2. To play saved log files select Log > Play Log File > Open from the PLUS+1® Service Tool window

menu bar or click the Open Saved Log File icon from the PLUS+1® Service Tool window toolbar.

3. Select the file from the Open dialog window and click Open.

Log file playback

Choose either one:

Select Log > Play Log File > Play in the PLUS+1® Service Tool window menu

•

Click the Play icon from the PLUS+1® Service Tool window toolbar.

•

Menu view

Only data is displayed during playback of basic log pages. Images, if added, are not displayed.

Log file playback information (activity status, file name, date and time stamp) is displayed in the

bottom left-hand corner of the PLUS+1® Service Tool window.

42 | © Danfoss | February 2021 AQ152986484649en-001003

Page 43

User Manual

PLUS+1® Service Tool

Using log pages

Log file process

Log file playback can be controlled by using the Change Position in Log File, Play, Stop, Pause and

Step Forward in Log File controls.

Toolbar view

There are two ways to open logged file:

1. Select from the PLUS+1® Service Tool window menu Log > Play Log File > Open

2. Click from the Log File toolbar Open > Saved Log File

3. Select Log File in the Open dialog box, and click Open.

The Log File is now open in the PLUS+1® Service Tool window.

Exporting log files to spreadsheet

Log files can be exported to any CSV format spreadsheet program (such as, Microsoft Excel® and Google

Docs™). The PLUS+1® Service Tool defaults to Microsoft Excel® csv delimiters for exporting database files.

Default delimiter

©

Danfoss | February 2021 AQ152986484649en-001003 | 43

Page 44

User Manual

PLUS+1® Service Tool

Using log pages

1. Export one of two ways:

From the PLUS+1® Service Tool window menu select Log > Play Log file > Export...

•

PLUS+1® Service Tool window menu example

From the Log File tool bar click on Export.

•

2. Save As dialog box , click Select the file for export in the Save.

The file will be exported and saved as a .csv file to the Log folder of the application.

3. Click OK

The file is now ready to be opened with Microsoft Excel®.

Selecting a different delimiter

Options > Settings in the PLUS+1® Service Tool window menu.

44 | © Danfoss | February 2021 AQ152986484649en-001003

Page 45

User Manual

PLUS+1® Service Tool

Using log pages

©

Danfoss | February 2021 AQ152986484649en-001003 | 45

Page 46

User Manual

PLUS+1® Service Tool

Using parameter pages

Manual parameter upload and download

1. Use the Parameter Upload and Parameter Download functions to enter and verify operating values to

the controller.

2. Upload parameter values to the PLUS+1® Service Tool from the controller by selecting Parameter >

Upload from the PLUS+1® Service Tool window menu.

Parameters can also be uploaded using the Upload button from the toolbar.

3. Download parameter values from the PLUS+1® Service Tool to the controller by selecting Parameter

> Download in the PLUS+1® Service Tool window menu.

Parameters can also be downloaded using the Download button from the toolbar.

In a basic parameter, controller values are updated in the ECU values fields of the Design Screen

(Basic) pane of the PLUS+1® Service Tool window.

Selecting parameter for download

1. Download parameter values by checking the Download check box for each parameter to download,

Upload or Download parameters from or to ECU

Only Parameters selected for download will be downloaded.

and press the Download parameter button in the toolbar.

Basic Parameter List view

Advanced Parameter Page view

When changing a parameter value, the check box will automatically be checked.

Unchecked parameter values will not be downloaded.

46 | © Danfoss | February 2021 AQ152986484649en-001003

Page 47

User Manual

PLUS+1® Service Tool

Using parameter pages

2. Press the Check All button to check all parameters in the list.

3. Press the Uncheck All button to uncheck all parameters in the list.

4. Press the Set default button to set all parameter values to the default value (specified in design

mode).

Use a period (.), a comma (,) or the decimal symbol from the Windows regional settings when

entering decimal values.

Importing parameter values

When importing parameters, an error dialog will show up if any values (from file) are not within the

parameter range set by the designer.

Automatic parameter upload function

ECU parameter values are automatically uploaded when a parameter page is selected.

If Cancel is selected, parameter values will be set to the default settings. A notification message will be

displayed.

If the ECU is not connected, parameters will not be automatically uploaded.

Parameter upload and download error messages

If errors occur during parameter upload and/or download, error messages will be displayed.

In basic pages, parameters containing errors will be marked by red exclamation circle.

©

Danfoss | February 2021 AQ152986484649en-001003 | 47

Page 48

User Manual

PLUS+1® Service Tool

Using parameter pages

In advanced pages, parameters components containing errors will be shown in the tool tip.

If the property “Indicate changed value” has been enabled by the designer, the parameter edit field

background will turn yellow when the edit value differs from the current ECU value.

Parameter file export

1. Created parameter files can be imported or exported from a local PC by selecting Parameter > File

Import and File Export functions.

These files are called parameter data files and are saved in an xml file format.

Parameter data files contain the ECU, signal name and value together with a version number on the

file format.

48 | © Danfoss | February 2021 AQ152986484649en-001003

Page 49

User Manual

PLUS+1® Service Tool

Using parameter pages

2. Save the parameter data file using the Save As dialog box:

Parameter file import

Only the currently displayed and available parameter values can be saved.

If the user does not have access to the parameter, the parameter cannot be saved.

1. Import files by selecting Parameter > File Import from the Menu Bar or click on File Import from the

PLUS+1® Service Tool window toolbar.

2. Select the desired file for value import.

©

Danfoss | February 2021 AQ152986484649en-001003 | 49

Page 50

User Manual

PLUS+1® Service Tool

Using parameter pages

Generating parameter reports

Only values for displayed signal names in the current parameter page will be changed.

The imported file data uses signal names to reference imported value locations.

If no signal name match is found, data will remain unchanged. Parameter values that are locked will

remain unchanged.

Database readable reports of parameter activity can be generated using the Generate Report function.

1. In the PLUS+1® Service Tool window menu select Parameter > Generate Report or from the toolbar

click on the Generate Report icon.

or

2. Name the file in the Generate Report dialog box.

The file will be saved as a .csv file.

The file can be opened by many common database applications, such as Microsoft Excel®.

50 | © Danfoss | February 2021 AQ152986484649en-001003

Page 51

User Manual

PLUS+1® Service Tool

Using parameter pages

Parameter memory transfer

Parameter memory values can be transferred from one controller to another using the Parameter

memory transfer feature.

All parameters referenced in the diagnostic data (except those that are write-protected) can be uploaded

and downloaded regardless of user access level.

The memory value that is transferred is from the NV (non-volatile) memory value and not the VAL (value)

signal.

For more information on the difference between NV and VAL values, reference the PLUS+1® GUIDE User

Manual, AQ152886483724.

Upload parameter values

1. Right-click the current ECU of an open application in the PLUS+1® Service Tool window. Select ECU

Parameter Transfer to open a submenu.

2. Select Upload all parameter values.

©

Danfoss | February 2021 AQ152986484649en-001003 | 51

Page 52

User Manual

PLUS+1® Service Tool

Using parameter pages

3. In the ECU Parameter Transfer - Upload dialog window name the file and click Save.

The parameters will be stored as a .P1T file.

Download parameter values

1. Right-click the current ECU and select ECU Parameter Transfer.

2. Select Download all parameter values.

52 | © Danfoss | February 2021 AQ152986484649en-001003

Page 53

User Manual

PLUS+1® Service Tool

Using parameter pages

3. In the ECU Parameter Transfer - Download dialog window select desired .P1T file and click Open.

The parameter values will then be transferred to the current ECU.

Decrypting P1T files

This will download all available parameters into the current ECU.

It is only possible to download parameter values to an application which matches the parameter set in

the .P1T file.

If a parameter cannot be uploaded or downloaded, a Parameter Upload/Parameter Download Error

dialog window will be displayed. Specific parameter and error information will be listed.

Only .P1T files created in PLUS+1® Service Tool 10.0 or later can be decrypted.

1. Decrypt a .P1T file to view the ECU and parameter information by selecting the menu item File > ECU

Parameter Transfer > Decrypt ECU Parameter Transfer file...

©

Danfoss | February 2021 AQ152986484649en-001003 | 53

Page 54

User Manual

PLUS+1® Service Tool

Using parameter pages

2. In the ECU Parameter Transfer - Decrypt dialog window select desired .P1T file and click Open.

3. In the next ECU Parameter Transfer - Decrypt dialog window name the file and click Save. Two

output formats are available, .CSV and .JSON.

If the ECU application, from which the .P1T file was created, required a Tool Key, then the same Tool Key

must be active in the PLUS+1® Service Tool to be able to decrypt the .P1T file.

The content in the decrypted information will depend on the access levels in the active license.

54 | © Danfoss | February 2021 AQ152986484649en-001003

Page 55

User Manual

PLUS+1® Service Tool

Using parameter pages

Creating P1T files

P1T files can be created based on a decrypted .CSV or .JSON file.

1. Select the menu item File > ECU Parameter Transfer > Create ECU Parameter Transfer file…

2. In the ECU Parameter Transfer - Create dialog window select desired .CSV or .JSON file and click

Open.

If the input file does not contain a Tool Key (or if it is invalid) a dialog will show up, where a Tool Key

can be added (recommended).

©

Danfoss | February 2021 AQ152986484649en-001003 | 55

Page 56

User Manual

PLUS+1® Service Tool

Using parameter pages

3. In the next ECU Parameter Transfer - Create dialog window name the file and click Save.

56 | © Danfoss | February 2021 AQ152986484649en-001003

Page 57

User Manual

PLUS+1® Service Tool

Using contextual help in service applications

Contextual help feature

Service applications may contain contextual help. Contextual help is available when the screen cursor is

placed over an advanced page component subject and a question mark is displayed.

Press F1 to display the help topic relevant to the "context" in which the user pressed the key.

For example, pressing F1 in an editor could display a topic on editing, pressing F1 in a configuration

dialog could display a topic on the features of that dialog.

Tool Key Set Up

©

Danfoss | February 2021 AQ152986484649en-001003 | 57

Page 58

User Manual

PLUS+1® Service Tool

Using the Tool Key

Tool Key function

Use the Tool key function to provide customized application protection. For information on license

embedded Tool Key options, consult your nearest Danfoss technical sales representative.

There are three ways to set up the Tool Key:

Manually entered

•

Included or embedded in the Service Application File (P1D)

•

License embedded

•

Set up Tool Key information

When downloading the application with Tool Key for the first time it will be necessary to set up the Tool

Key information in the PLUS+1® Service Tool.

1. When no Tool key information is found when attempting a download, the following warning

messages will appear:

2. Enter Tool Key information by first clicking OK to close the Incorrect Tool Key error message.

3. Next, select Options > Tool Key... from the PLUS+1® Service Tool window menu to open the Tool Key

dialog box.

58 | © Danfoss | February 2021 AQ152986484649en-001003

Page 59

User Manual

PLUS+1® Service Tool

Using the Tool Key

Manually entered Tool Key set up

1. In the Tool Key dialog box select Add.

A sub dialog box appears.

2. Enter the Tool Key name (description) and the Tool Key password that was created in the PLUS+1

GUIDE application. Click OK to close box.

The Tool Key has successfully been entered.

®

©

Danfoss | February 2021 AQ152986484649en-001003 | 59

Page 60

User Manual

PLUS+1® Service Tool

Using the Tool Key

3. Select OK to save and close.

License embedded Tool Key set up

Tool keys embedded in the active license will appear in the License Tool Keys field of the Tool Key

dialog box.

1. Select Tool Key and click OK to activate the selected Tool Key.

2. Select Add....

The Tool key is now active.

60 | © Danfoss | February 2021 AQ152986484649en-001003

Page 61

User Manual

PLUS+1® Service Tool

Working in normal view

Application log

Record application activity for supported applications and controllers in the Application log function of

the PLUS+1® Service Tool. The Application Log writes application-specified information to a flash memory

file (PLA file) that can be accessed in the Diagnostic Navigator section of the PLUS+1® Service Tool.

Application data logging writes data to the memory of a Danfoss PLUS+1® controller. The PLUS+1

Service Tool program accesses this data. The program writes data first to an encrypted .p1a (PLUS+1

®

®

application data log) file and then, with proper access rights, writes to a CSV (comma-separated value)

file.

Access to application log information can be controlled within the PLUS+1® GUIDE software program.

You can use access components to restrict the PLUS+1® Service Tool program's access to the application

data log and its contents.

For more information, see the Application Data Logging chapter of the PLUS+1® GUIDE User Manual,

AQ152886483724.

Application log file

©

Danfoss | February 2021 AQ152986484649en-001003 | 61

Page 62

User Manual

PLUS+1® Service Tool

Working in normal view

1. Double-click to open the encrypted log file.

The file will automatically decode to create and save to an ASCII file.

The Application Log file can now be decoded into a csv file that can be accessed by many

spreadsheet applications.

2. Select in the PLUS+1® Service Tool window menu bar: File > Decode Application Log File...

62 | © Danfoss | February 2021 AQ152986484649en-001003

Page 63

User Manual

PLUS+1® Service Tool

Working in normal view

3. Select the file to be decoded

An Application Log File that matches the user access level is created.

PLUS+1® Service Tool settings options

Use PLUS+1® Service Tool settings to access general and advanced page setting options. In the main

menu bar select Options > Settings to open the Options window.

General

Use the General settings screen to set Tool Key, setup screen display, PLUS+1® Service Tool background

color, and Export Log options.

©

Danfoss | February 2021 AQ152986484649en-001003 | 63

Page 64

User Manual

PLUS+1® Service Tool

Working in normal view

General settings options

Theme

Toolbar icon size

Show start page is no Service

Application is open

Automatically use tool key from

Service Application File

Automatically scan for service

application file

Enable baudrate setting in status bar

Create backup file when overwriting

Service Application files

Startup screen delay

Export log file

Use to select light or dark appearance in user interface.

Use to select icon size displayed in tool bar.

Select check box to display the start page when no Service Application is

open.

Select check box to always use the tool key embedded in the *.P1D file.

Select to automatically scan for service application files after automatic

system scan is completed.

Select to enable manual baudrate setting.

Select check box to automatically create a *.P1D backup file.

Enter time that startup screen will be display at start up.

Select to choose delimiter for log file export. The default is Windows

Advanced Screen

In the Advanced Page Design - Settings select Display tooltip on components and Display help cursor

on help enabled components cursor options.

64 | © Danfoss | February 2021 AQ152986484649en-001003

Page 65

User Manual

PLUS+1® Service Tool

Working in normal view

Advanced page setting options

Display tooltip on components

Time to display tooltip(s)

Display help cursor on help

enabled components

File association

Select to enable visible tooltip functionality when mouse is over tool tip

function screen items.

The time the tool tip is shown (1 to 60 seconds).

Select to display help cursor hand image when mouse is over help enabled

components.

File association setting options

Check or uncheck box

If checked, will check at startup if this version of PLUS+1® Service Tool is

the default associated application for P1D, P1H, and LHX file extensions.

File download

Use the File Download setting to select either to always display a parameter settings message or to only

display a message when downloading a file.

©

Danfoss | February 2021 AQ152986484649en-001003 | 65

Page 66

User Manual

PLUS+1® Service Tool

Working in normal view

Warnings

Check box to display a warning message if opening a P1D/P1H file with an older file format.

66 | © Danfoss | February 2021 AQ152986484649en-001003

Page 67

User Manual

PLUS+1® Service Tool

Working in normal view

©

Danfoss | February 2021 AQ152986484649en-001003 | 67

Page 68

User Manual

PLUS+1® Service Tool

Monitoring the CAN bus

Use the CAN Monitor to monitor all CAN bus messages and bus load. Messages are displayed in either

decimal or hexadecimal format and can be logged to a file.

CAN Monitor is a basic general-purpose CAN bus log tool, it is not a substitute for a full-scale CAN

analyzer tool.

To use the CAN Monitor you need to have an Express or Professional license installed in the License

Manager.

Monitor CAN bus messages and bus load

1. Select menu item Tools > CAN Monitor > .

The PLUS+1® CAN Monitor is a standalone window that can be used along side the PLUS+1® Service

Tool.

Tool Bar buttons

1

2

3

4

5

Start Start monitoring the CAN bus.

Stop Stop monitoring the CAN bus.

Log to file Log all CAN bus messages to file. The current settings will be applied

to the file content.

Options Open the Options dialog.

Close Close the CAN Monitor window.

68 | © Danfoss | February 2021 AQ152986484649en-001003

Page 69

User Manual

PLUS+1® Service Tool

Monitoring the CAN bus

CAN messages in main log panel

6

7

8

9

10

11

12

Chn Active channel ID in the PLUS+1® Service Tool.

Identifier CAN message identifier.

Flg CAN message flag, empty for standard CAN messages, X for

extended.

DLC Data length code, the amount of data bytes in the message.

D...0...1...2...3...4...5...6...D...7 The content in the CAN message data bytes.

Time The CAN message time stamp, displayed in seconds since the

logging was started.

Dir The CAN message direction R, when received by the PLUS+1

Service Tool and T when sent from the PLUS+1® Service Tool.

®

The status bar shows the current bus load.

2. Right-click the main panel to show a menu where you can switch to Fixed Positions mode, (for more

information, see Options on page 70), copy the logged content to clipboard and clear the log

window.

©

Danfoss | February 2021 AQ152986484649en-001003 | 69

Page 70

User Manual

PLUS+1® Service Tool

Monitoring the CAN bus

Options

Press the Options button to display the Options dialog.

General options

Numeric base Select decimal or hexadecimal format

Fixed Positions Check option to enable Fixed Positions mode. In this mode, each CAN ID will be

displayed on a single line and change the content each time a message with the

same CAN ID is received/sent.

70 | © Danfoss | February 2021 AQ152986484649en-001003

Page 71

User Manual

PLUS+1® Service Tool

Monitoring the CAN bus

Pass filter options

Enable CAN ID pass filter Check option to enable the pass filter

Lower limit Lower limit of CAN message ID’s that shall pass the filter.

Upper limit Upper limit of CAN message ID’s that shall pass the filter.

Lower and Upper limits can be entered in either decimal or hexadecimal (for example ‘$FF’ or ‘0xFF’)

format.

©

Danfoss | February 2021 AQ152986484649en-001003 | 71

Page 72

User Manual

PLUS+1® Service Tool

PLUS+1® Service Tool command line mode

Use the PLUS+1® Service Tool command line interface to perform tasks, such as testing a continuous

integration (CI) build agent.

P1Diagnostics

The executable is named Plus1_Diag.exe and it can be found in the /P1Tools/P1Diagnostics

installation folder.

Plus1_Diag can be run in 3 modes: GUI, CLI and GUI+CLI.

EXE modes

Modes Description

GUI PLUS+1® Service Tool will provide a standard Windows

CLI PLUS+1® Service Tool will provide a command line

GUI+CLI PLUS+1® Service Tool will provide a combined interface

desktop user interface.

interface, without graphical elements.

where information will be provided both in the graphical

and the command line interfaces.

Command, Configuration, and Command Modifier Parameters

Command Parameters

Name Description

-run-script <P1J file> <Script function>

-download-file-to-ecu <Application file>

-decrypt-p1t <P1T file> <Decrypted output file>

-create-p1t <Decrypted input file> <P1T file>

Run the specified script function and then terminate.

This command requires exactly two parameters, a P1J file

and a script function.

If the script is run successfully, then the exit code will be

zero (0).

Otherwise, the exit code will be one (1).

Download the specified file to the connected system and

then terminate.

The application(s) will automatically be matched to the

available ECU(s). No attempt to download any file will be

done unless the mapping is clear.

This command requires exactly 1 application download

file.

If file download succeeds, then the exit code will be zero

(0).

Otherwise, the exit code will be one (1).

Decrypt the P1T file and then terminate.

This command requires exactly 2 parameters, a P1J file

and a CSV/JSON output file.

If the decryption succeeds, then the exit code will be zero

(0).

Otherwise, the exit code will be one (1).

Create a P1T file and then terminate.

This command requires exactly 2 parameters, a CSV/JSON

input file and a P1T output file name.

If the creation succeeds, then the exit code will be zero

(0).

Otherwise, the exit code will be one (1).

72 | © Danfoss | February 2021 AQ152986484649en-001003

Page 73

User Manual

PLUS+1® Service Tool

PLUS+1® Service Tool command line mode

Command Parameters (continued)

Name Description

-export-p1log-to-csv <Input file> <Output file>

-extract-application-xml <Input p1d file> <Output path>

--version

/?--help

Export the specified P1log/LDF file to CSV format and

then terminate.

This command requires exactly 2 parameters, a P1log or

LDF file and a CSV output file.

If the export succeeds, then the exit code will be zero (0).

Otherwise, the exit code will be one (1).

Extracts the application file from the specified p1d file to

xml format.

This command requires exactly 2 parameters, a P1D file

and a output path where the application XML file is

stored.

If the export succeeds, then the exit code will be zero (0).

Otherwise, the exit code will be one (1).

Prints the PLUS+1® Service Tool version.

Must not be combined with any other parameter.

Prints information about CLI usage.

Must not be combined with any other parameter.

Configuration Parameters

Name Description

-use-gateway <Gateway name> Specifies which gateway to select when starting the PLUS

-use-channel <Channel name> Specifies which gateway channel to select when starting

-use-baudrate <Baud rate> Starts the PLUS+1® Service Tool in normal view.

-normal-view Starts the PLUS+1® Service Tool in normal view.

-design-view Starts the PLUS+1® Service Tool in design view.