Page 1

User Manual

PLUS+1® GUIDE

Software

www.danfoss.com

Page 2

User Manual

PLUS+1® GUIDE Software

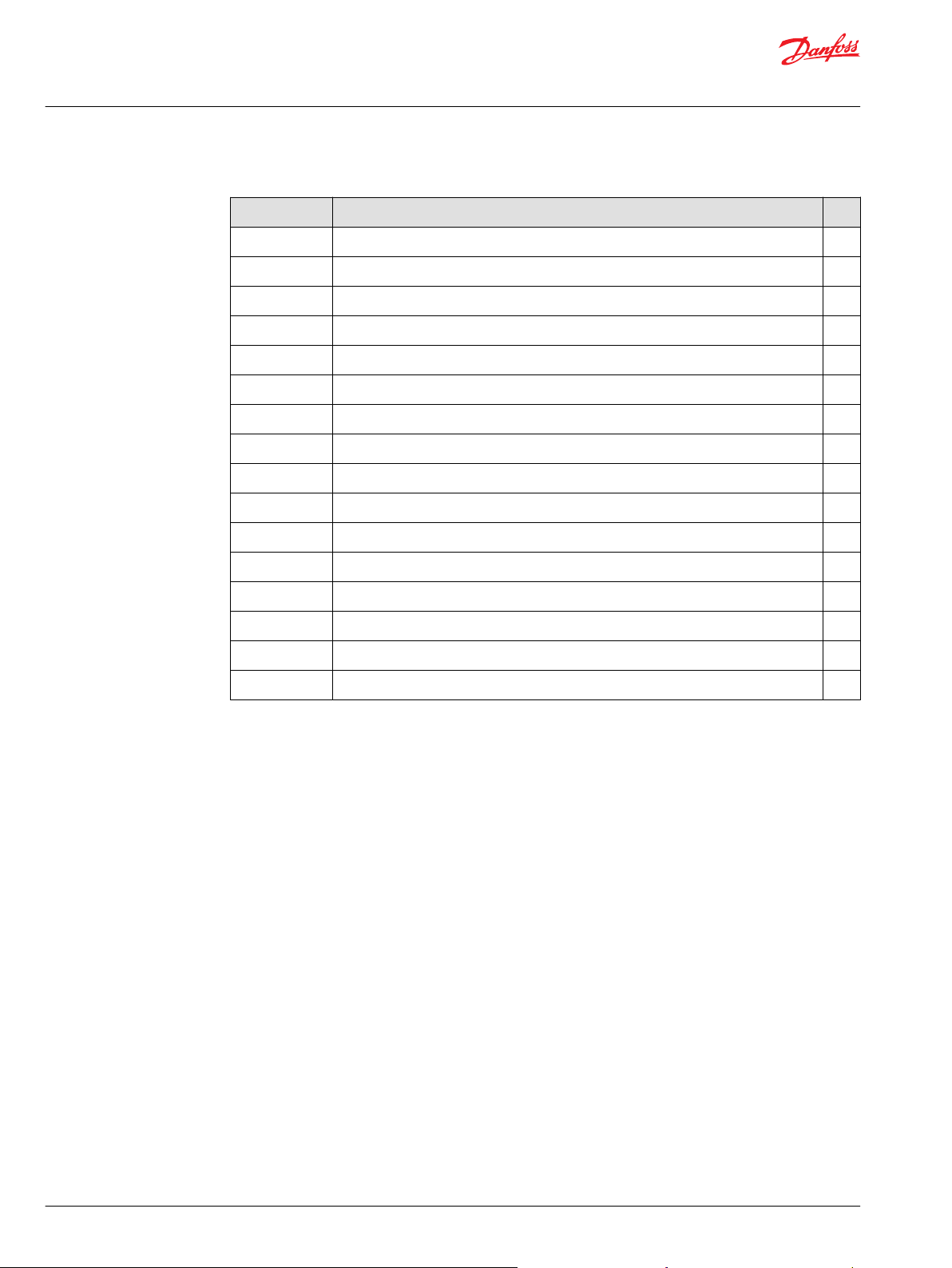

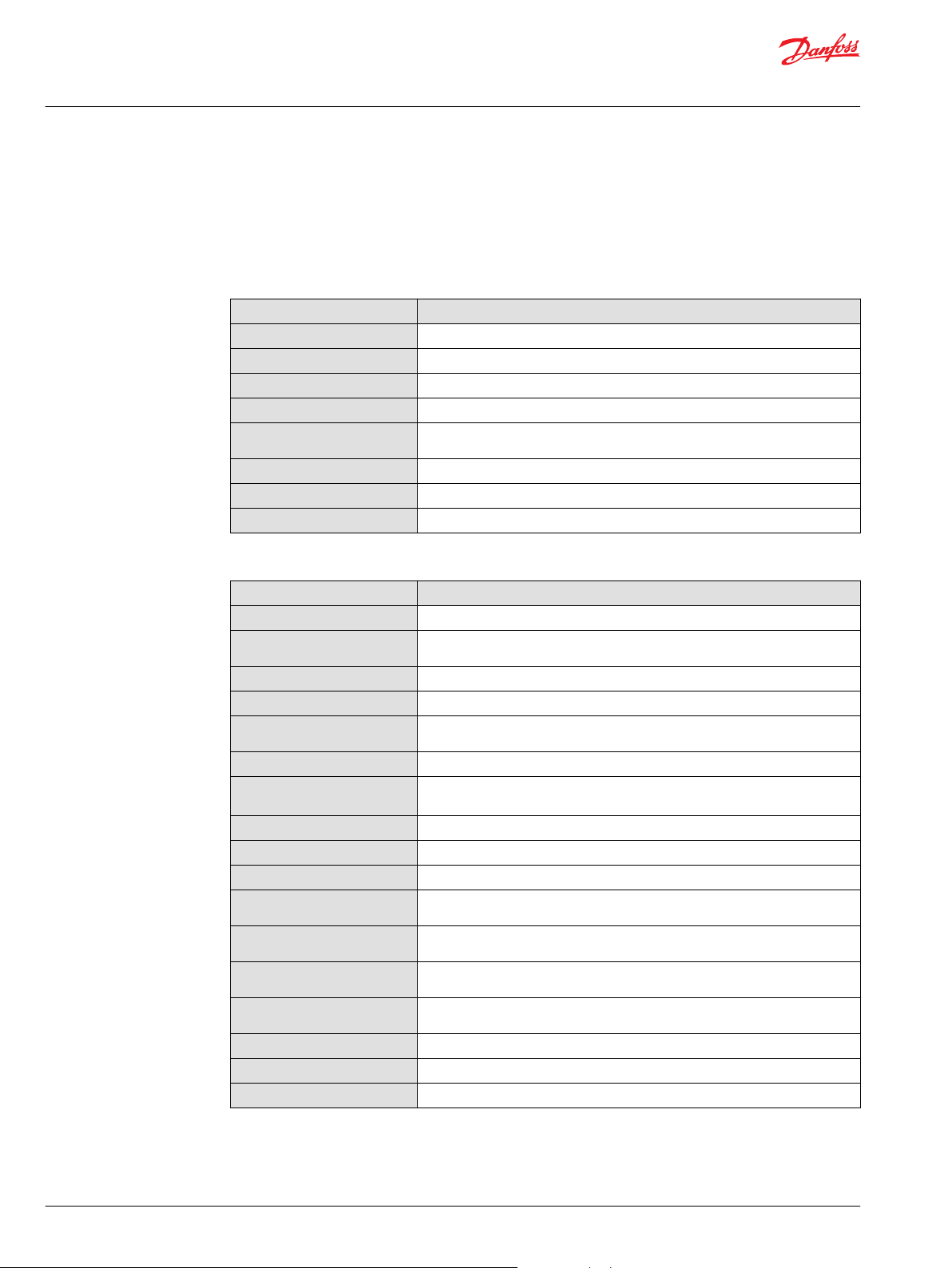

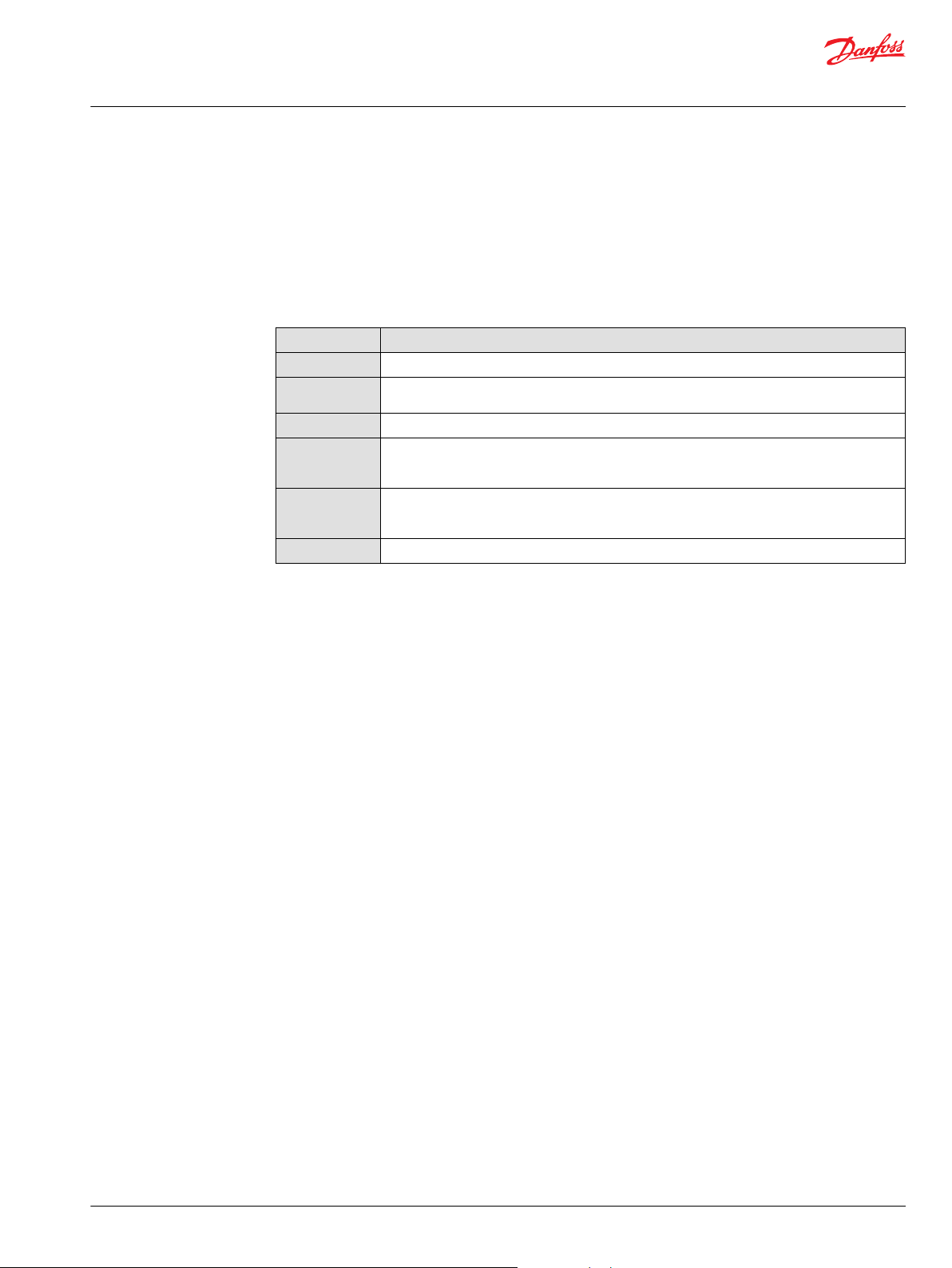

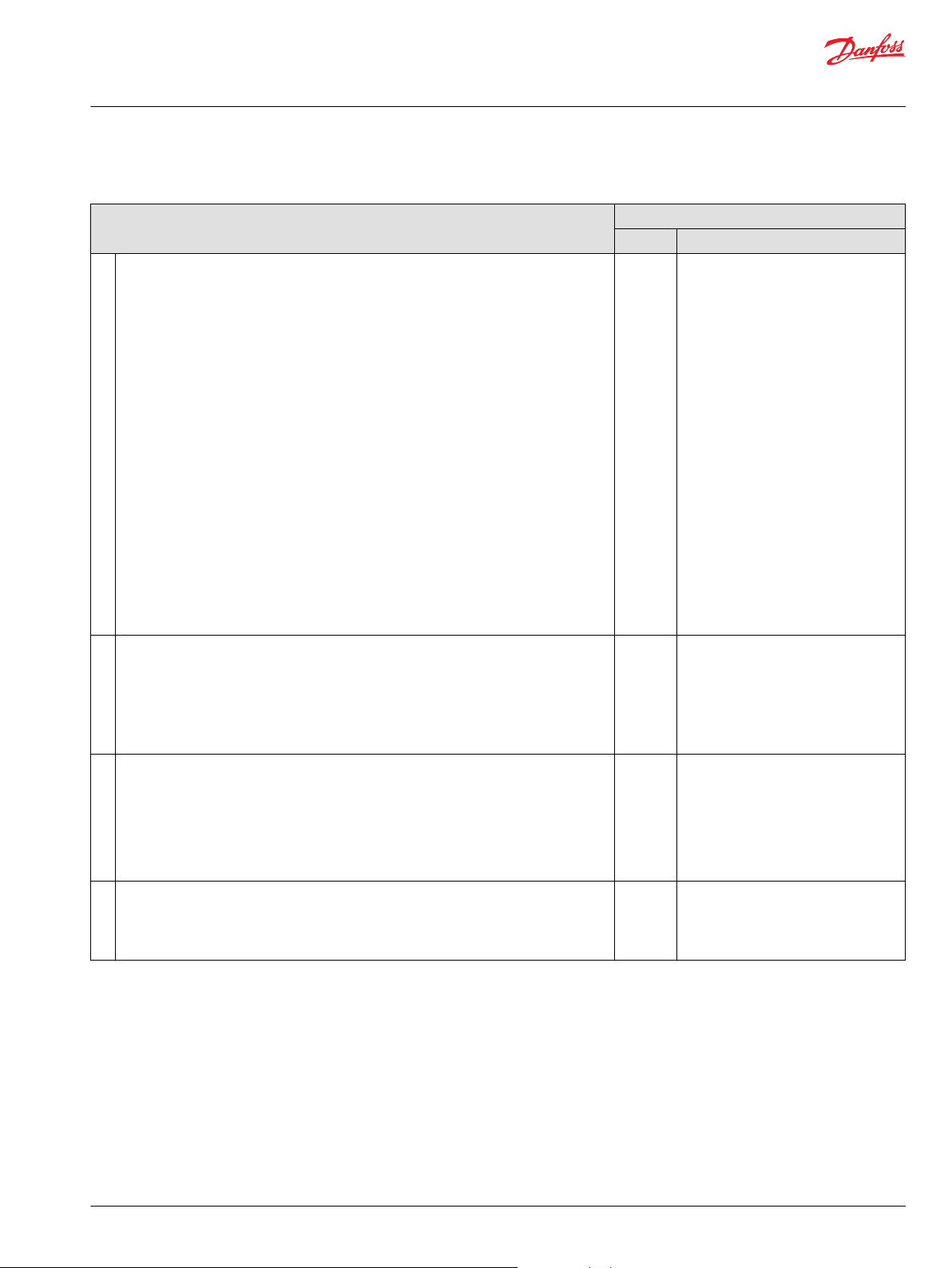

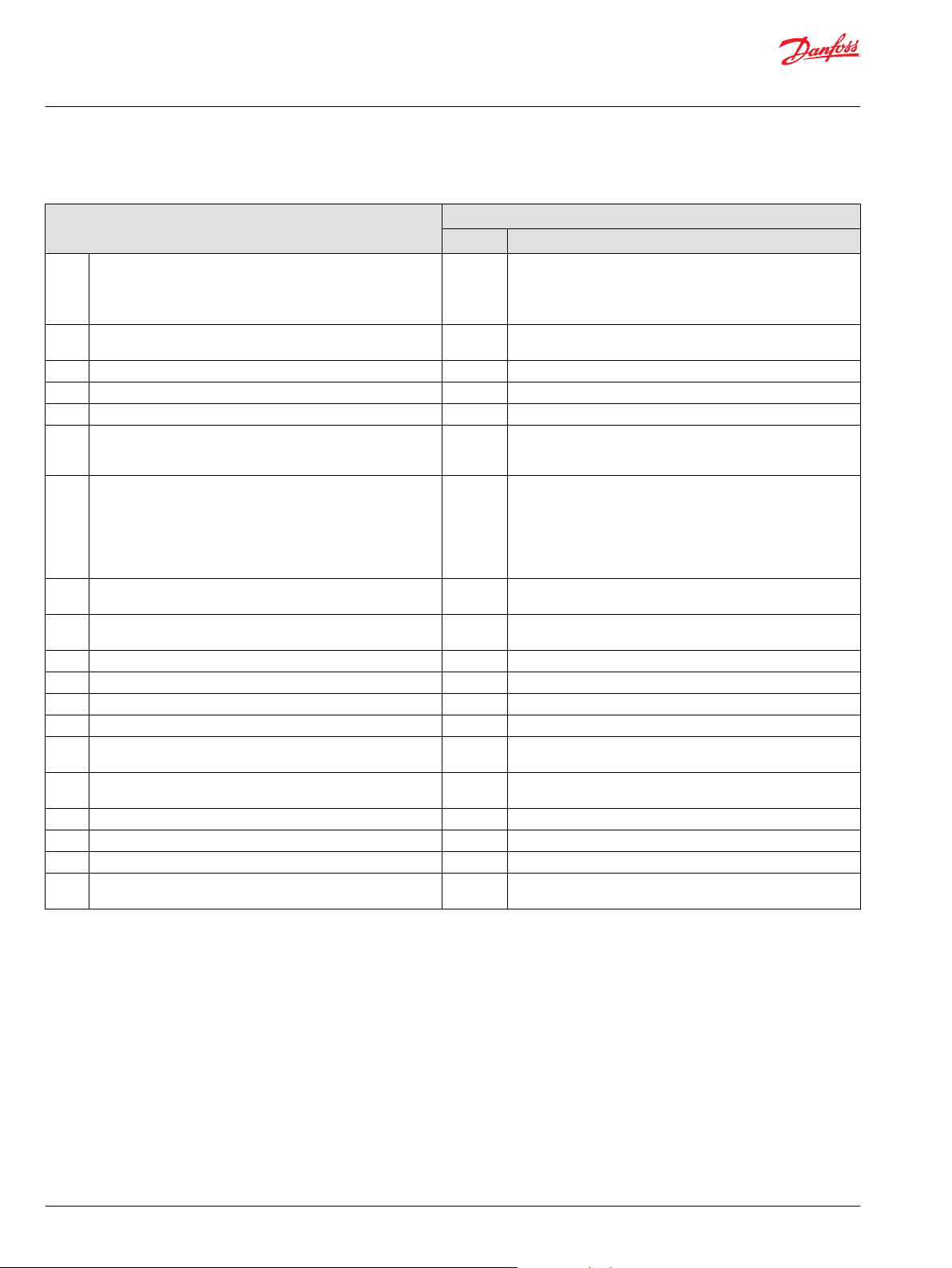

Revision history Table of revisions

Date Changed Rev

February 2021 Updated to support 12.2 2301

June 2020 supports 12.1 and later 2201

June 2020 Changed document number from 'AQ00000026' and '10100824' to 'AQ152886483724' 2102

October 2019 supports 12.0 and later 2001

September 2019 Major update - supports 12.0 and later 1901

May 2019 Major update - supports 11.1 and later 1901

October 2018 Major update - supports 11.0 and later 1801

May 2018 Major update - Supports 10.1x and later 1703

November 2017 Major update - Supports 10.0x and later 1601

April 2017 Major update - Supports 9.1.x and later 1503

December 2016 Minor revision to document layout only 1502

October 2016 Major update - Supports 9.0.x and later 1501

February 2016 Major update - Supports 8.0.x and later 1401

August 2015 Major update - Supports 7.2.x and later 1300

December 2014 Supports 7.1.x and later MC

December 2013 LA

2 | © Danfoss | February 2021 AQ152886483724en-002301

Page 3

User Manual

PLUS+1® GUIDE Software

Contents

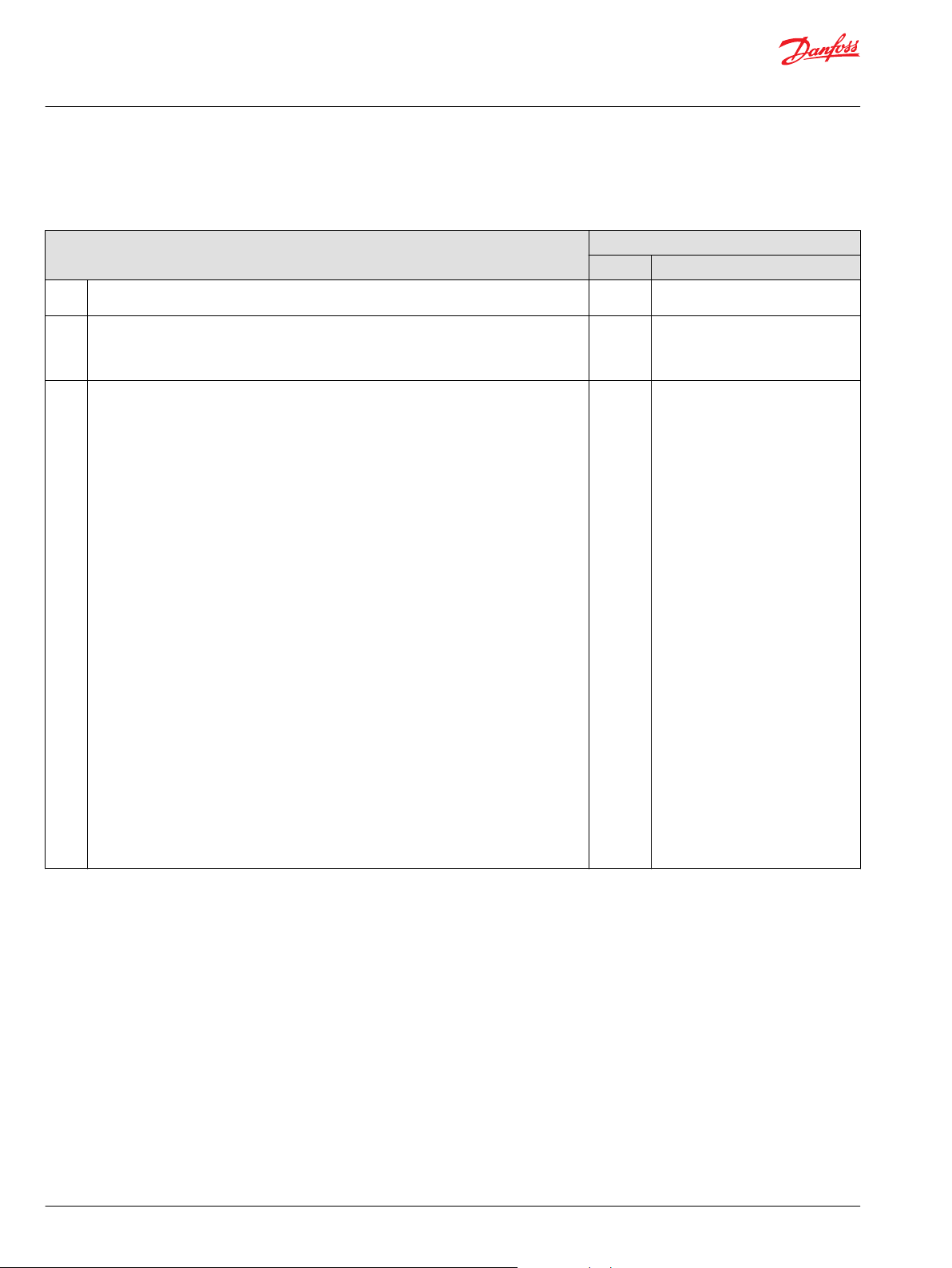

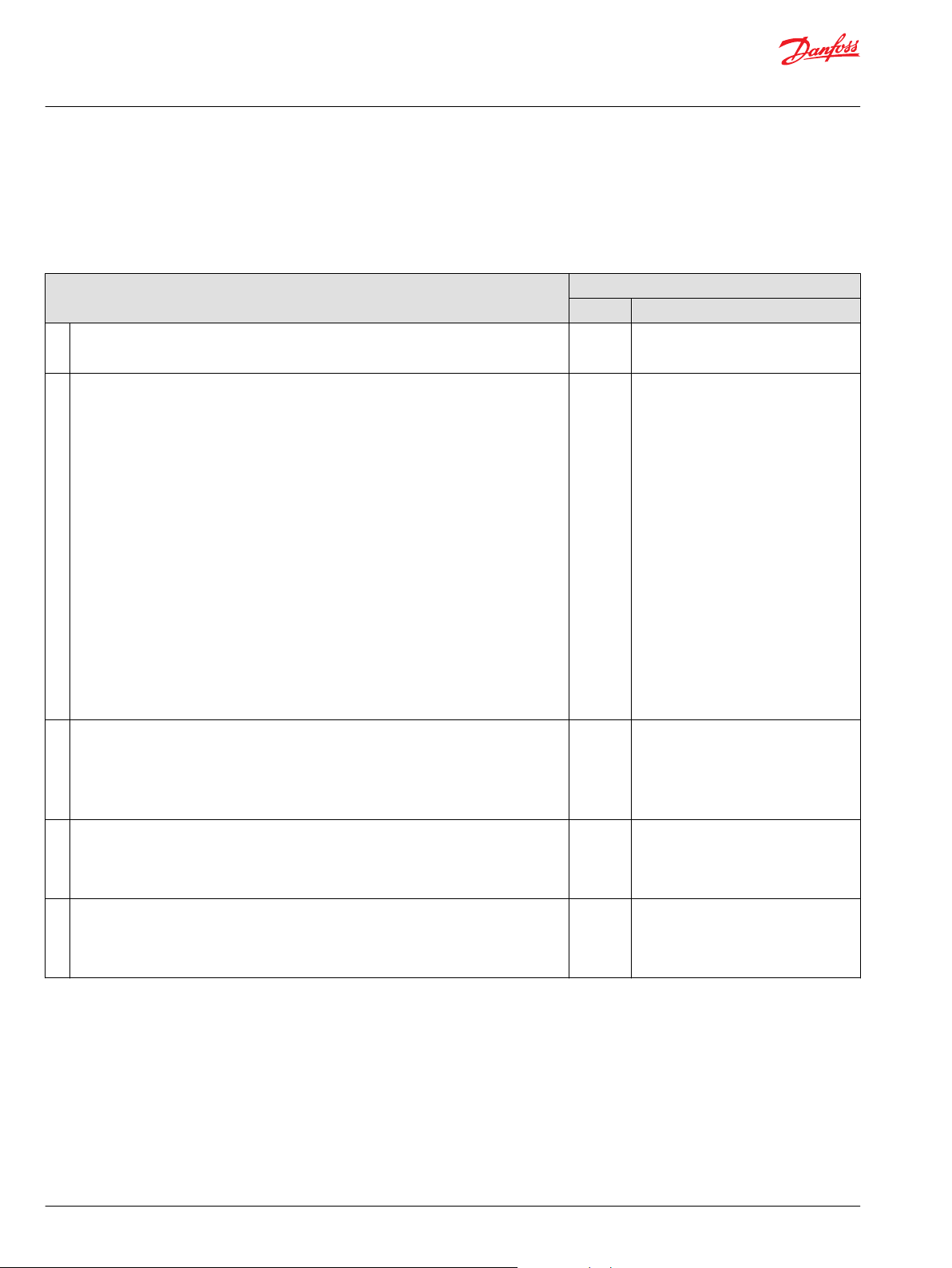

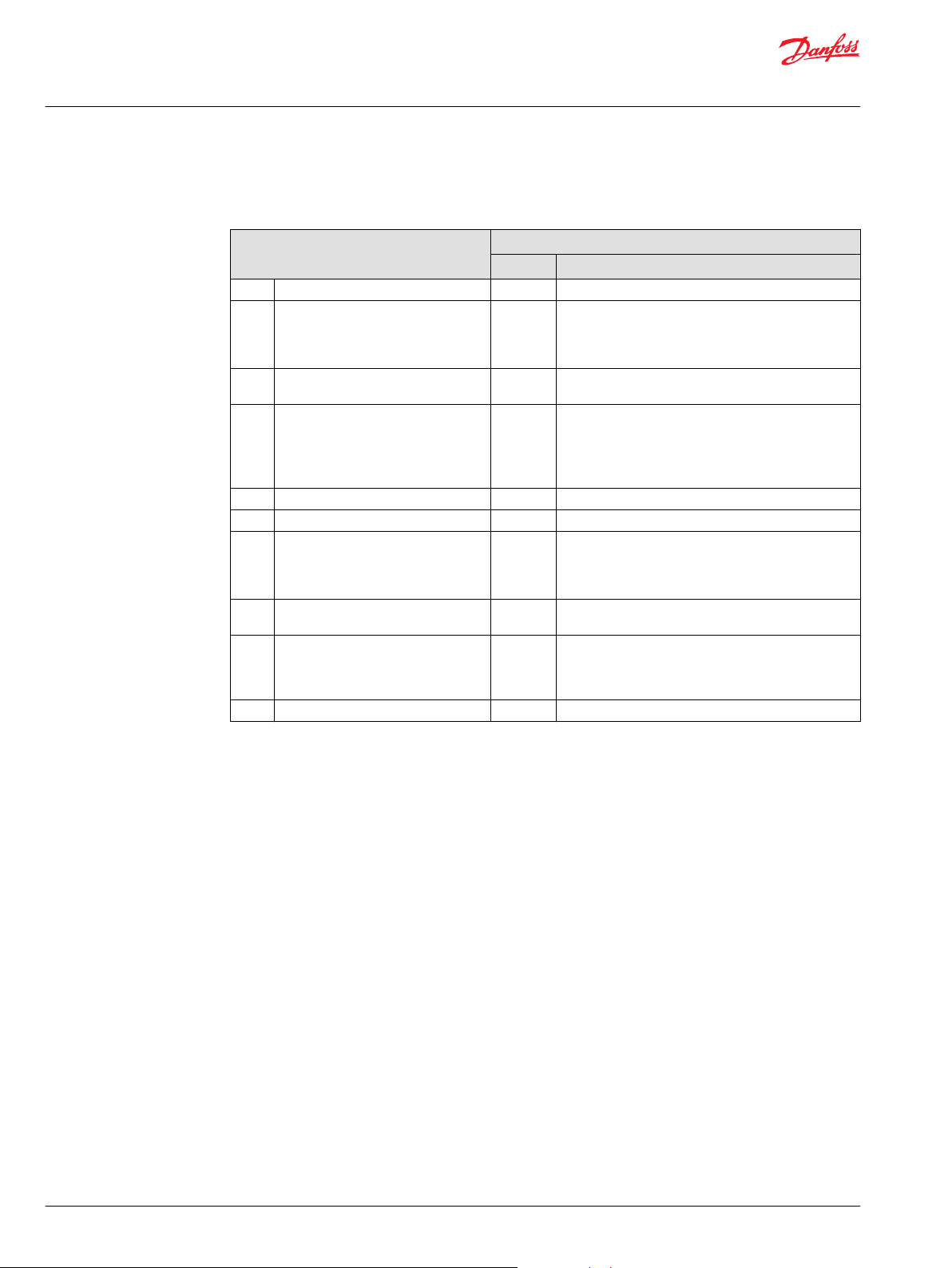

IEC 61508:2010 Certified Support Tool

About IEC 61508:2010 Certification........................................................................................................................................ 14

SIL2 compilation requirements.................................................................................................................................................16

Additional SIL2 certification requirements...........................................................................................................................17

Responsibilities for IEC 61508 and ISO 13849-1 requirements..................................................................................... 18

Terminology............................................................................................................................................................................... 18

Features........................................................................................................................................................................................18

Prerequisites...............................................................................................................................................................................19

Division of Responsibility between Danfoss and the User............................................................................................. 20

General Software Safety Life Cycle Requirements.............................................................................................................21

Software Safety Requirements Specification.......................................................................................................................22

Validation Plan for Software Aspects of System Safety....................................................................................................24

General Software and Design Requirements.......................................................................................................................25

Requirements for Software Architecture Design................................................................................................................28

Requirements for Support Tools and Programming Languages..................................................................................29

Requirements for Detailed Design and Development.....................................................................................................31

Requirements for Code Implementation.............................................................................................................................. 32

Requirements for Software Module Testing........................................................................................................................ 33

Requirements for Software Integration Testing.................................................................................................................33

Programmable Electronics Integration (Hardware and Software)...............................................................................34

Software Operation and Modification Procedures............................................................................................................35

Software Safety Validation..........................................................................................................................................................36

Software Modification..................................................................................................................................................................37

Software Verification.................................................................................................................................................................... 38

Functional Safety Assessment...................................................................................................................................................41

Appendix A — IEC 61508............................................................................................................................................................41

Software Safety Requirements Specification................................................................................................................. 41

Software Design and Development—Software Architecture Design...................................................................41

Software Design and Development—Support Tools and Programming Language.......................................43

Software Design and Development—Detailed Design..............................................................................................43

Software Design and Development—Software Module Testing and Integration...........................................44

Programmable Electronics Integration (Hardware and Software)......................................................................... 45

Software Aspects of System Safety Validation...............................................................................................................45

Modification................................................................................................................................................................................46

Software Verification...............................................................................................................................................................47

Functional Safety Assessment............................................................................................................................................. 47

Appendix B — IEC 61508............................................................................................................................................................ 47

Design and Coding Standards............................................................................................................................................. 47

Dynamic Analysis and Testing............................................................................................................................................. 48

Functional and Black-Box Testing...................................................................................................................................... 49

Failure Analysis..........................................................................................................................................................................49

Modeling......................................................................................................................................................................................49

Performance Testing............................................................................................................................................................... 50

Semi-Formal Methods.............................................................................................................................................................50

Static Analysis............................................................................................................................................................................ 51

Modular Approach...................................................................................................................................................................51

EN ISO 13849-1:2015.....................................................................................................................................................................52

Safety-Related Application SoftWare (SRASW)..............................................................................................................53

Software-Based Parameterization......................................................................................................................................56

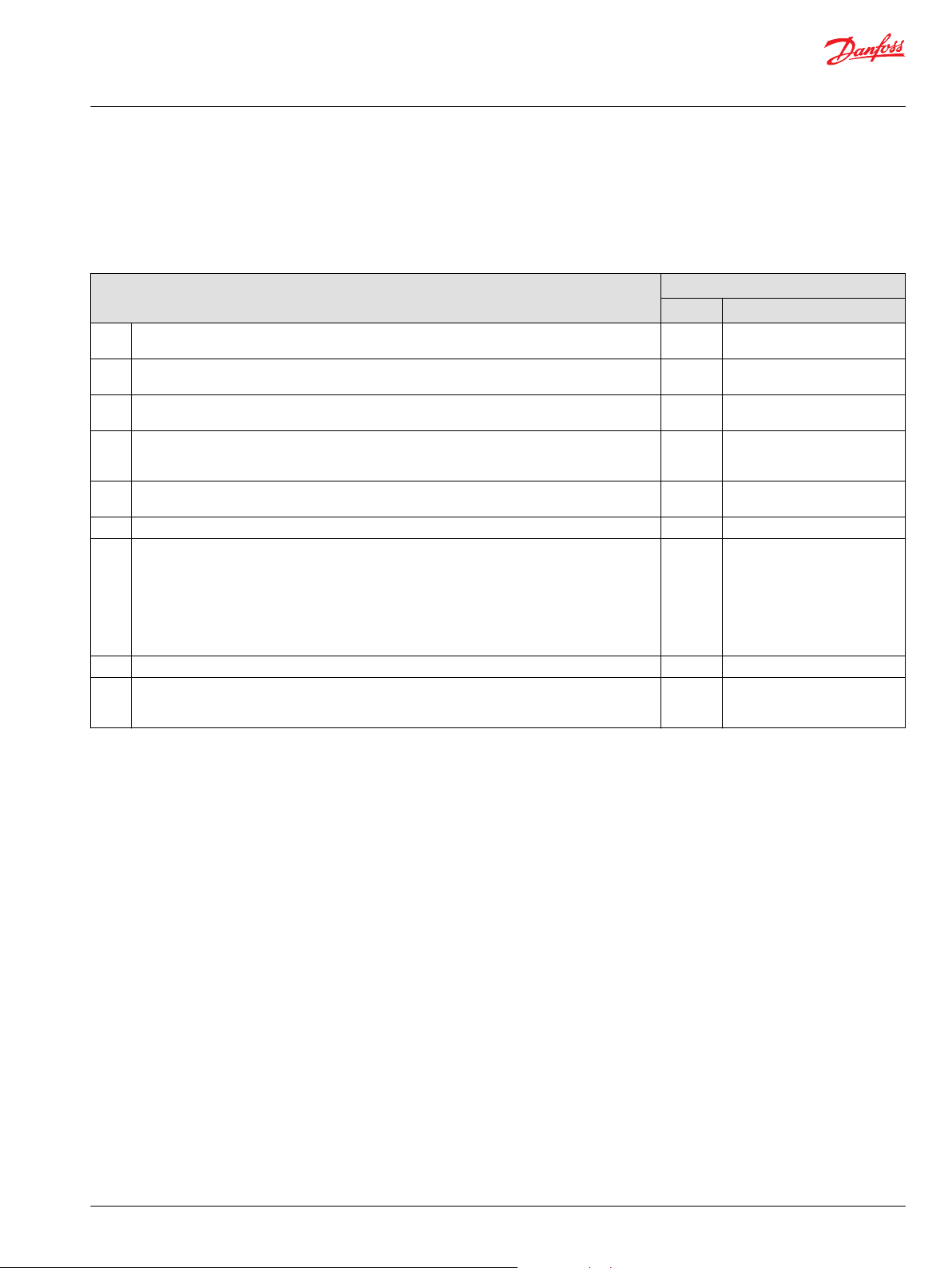

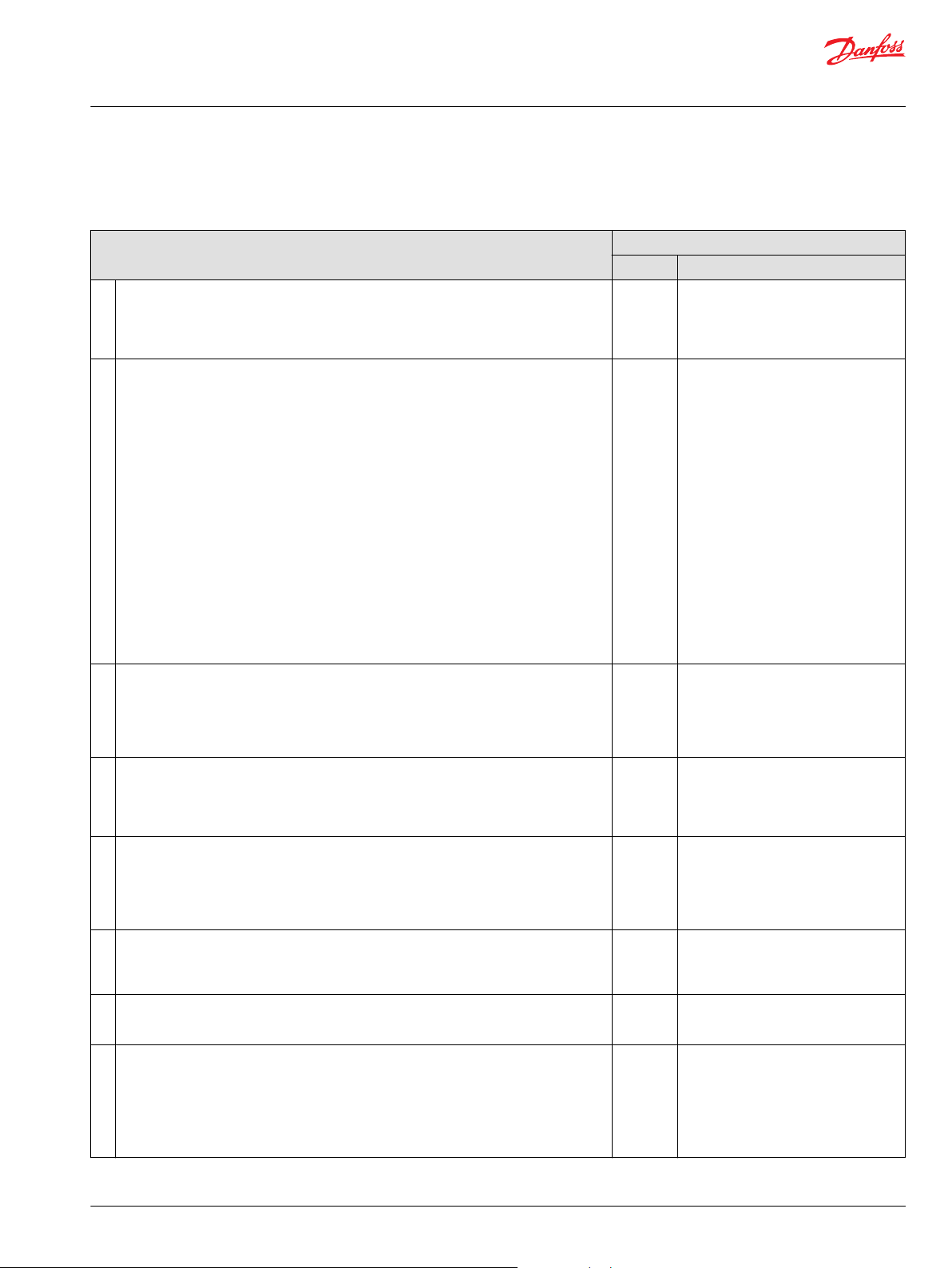

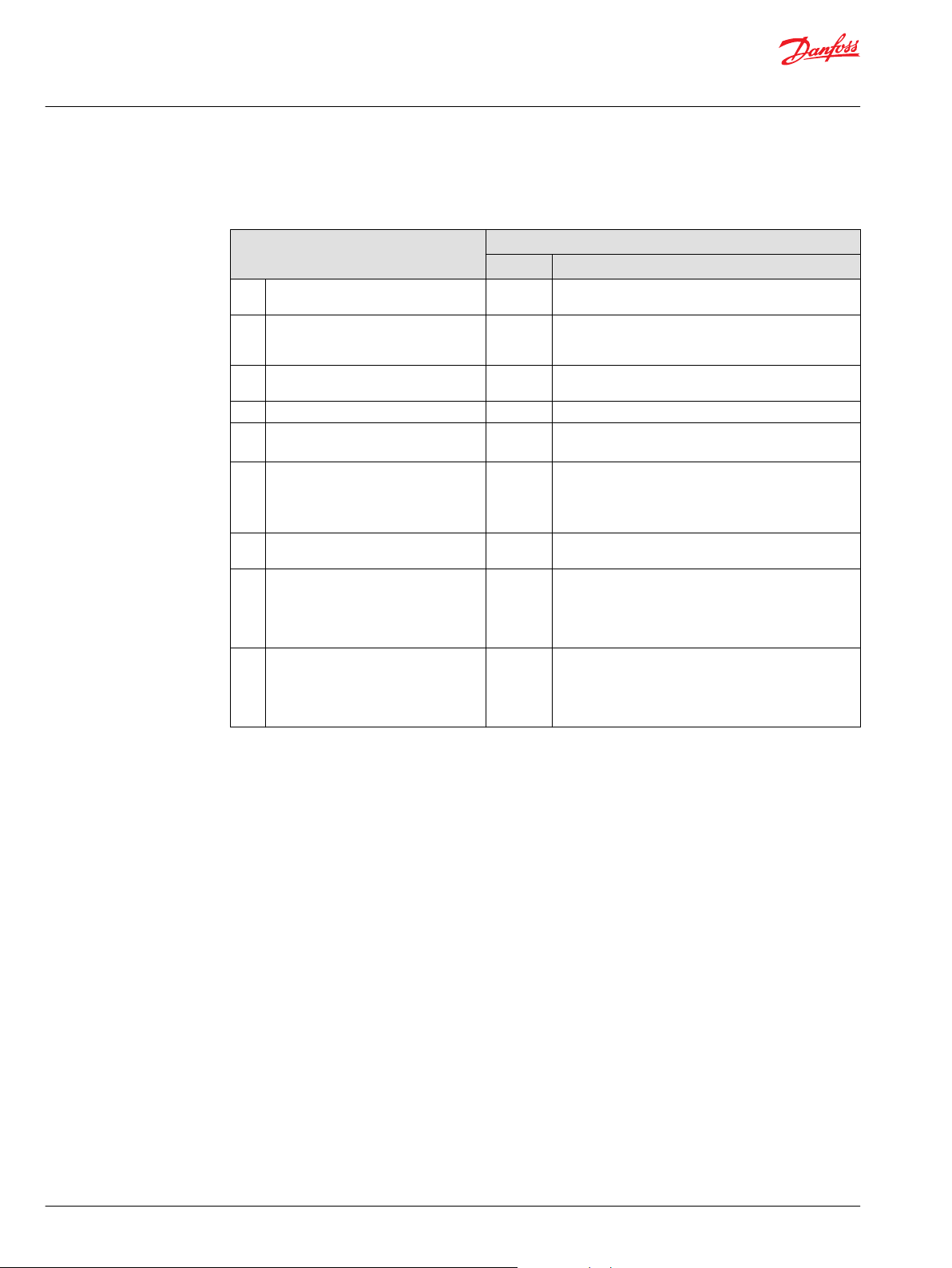

Licensing

PLUS+1 GUIDE License.................................................................................................................................................................57

Upgrade Features.......................................................................................................................................................................... 57

User Interface

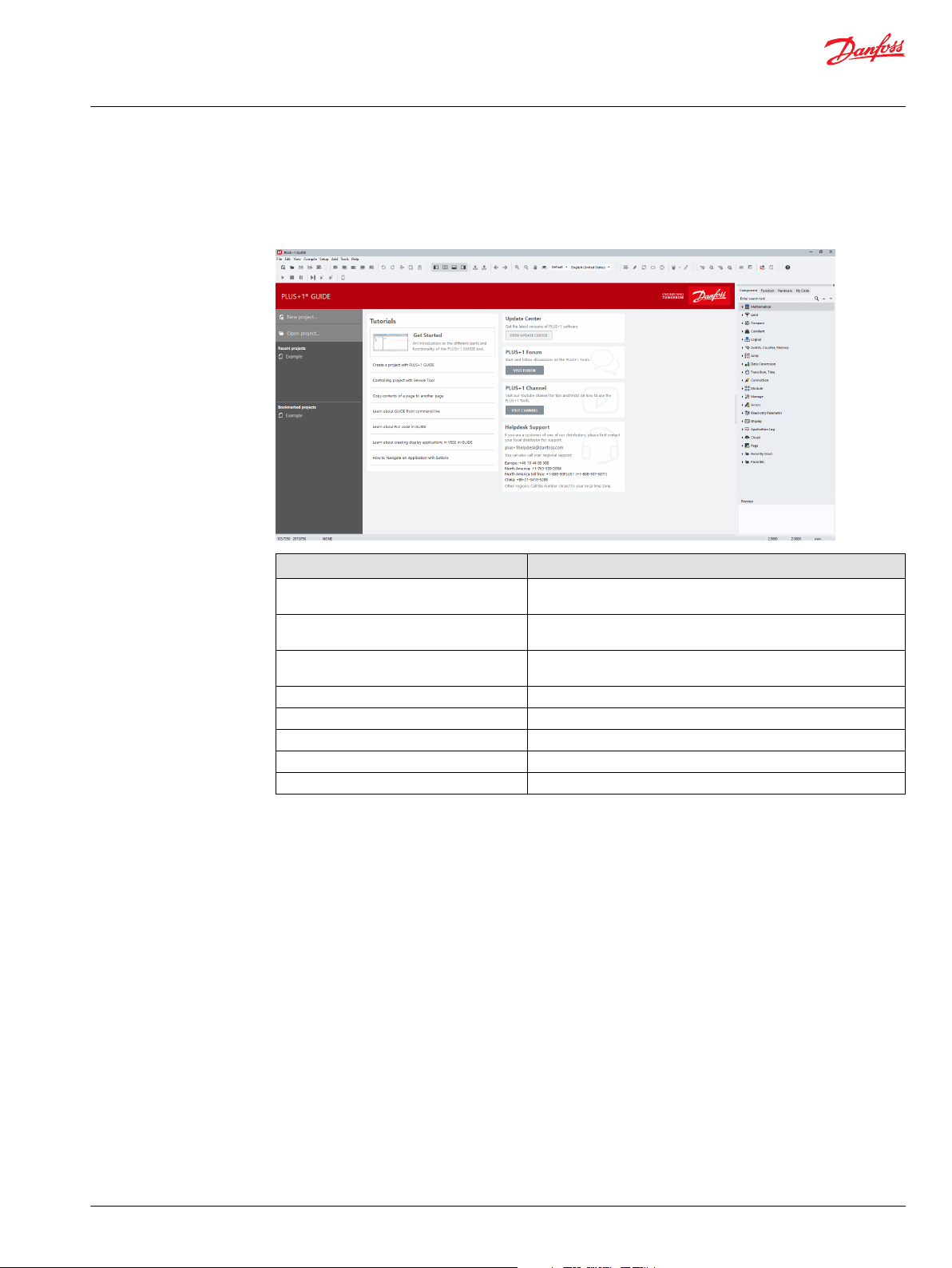

Overview........................................................................................................................................................................................... 59

Start Page.................................................................................................................................................................................... 61

Languages........................................................................................................................................................................................ 61

Menus.................................................................................................................................................................................................62

File Menu..................................................................................................................................................................................... 63

©

Danfoss | February 2021 AQ152886483724en-002301 | 3

Page 4

User Manual

PLUS+1® GUIDE Software

Contents

Edit Menu.....................................................................................................................................................................................66

View Menu...................................................................................................................................................................................68

Compile Menu........................................................................................................................................................................... 70

Setup Menu.................................................................................................................................................................................71

Add Menu....................................................................................................................................................................................72

Tools Menu..................................................................................................................................................................................73

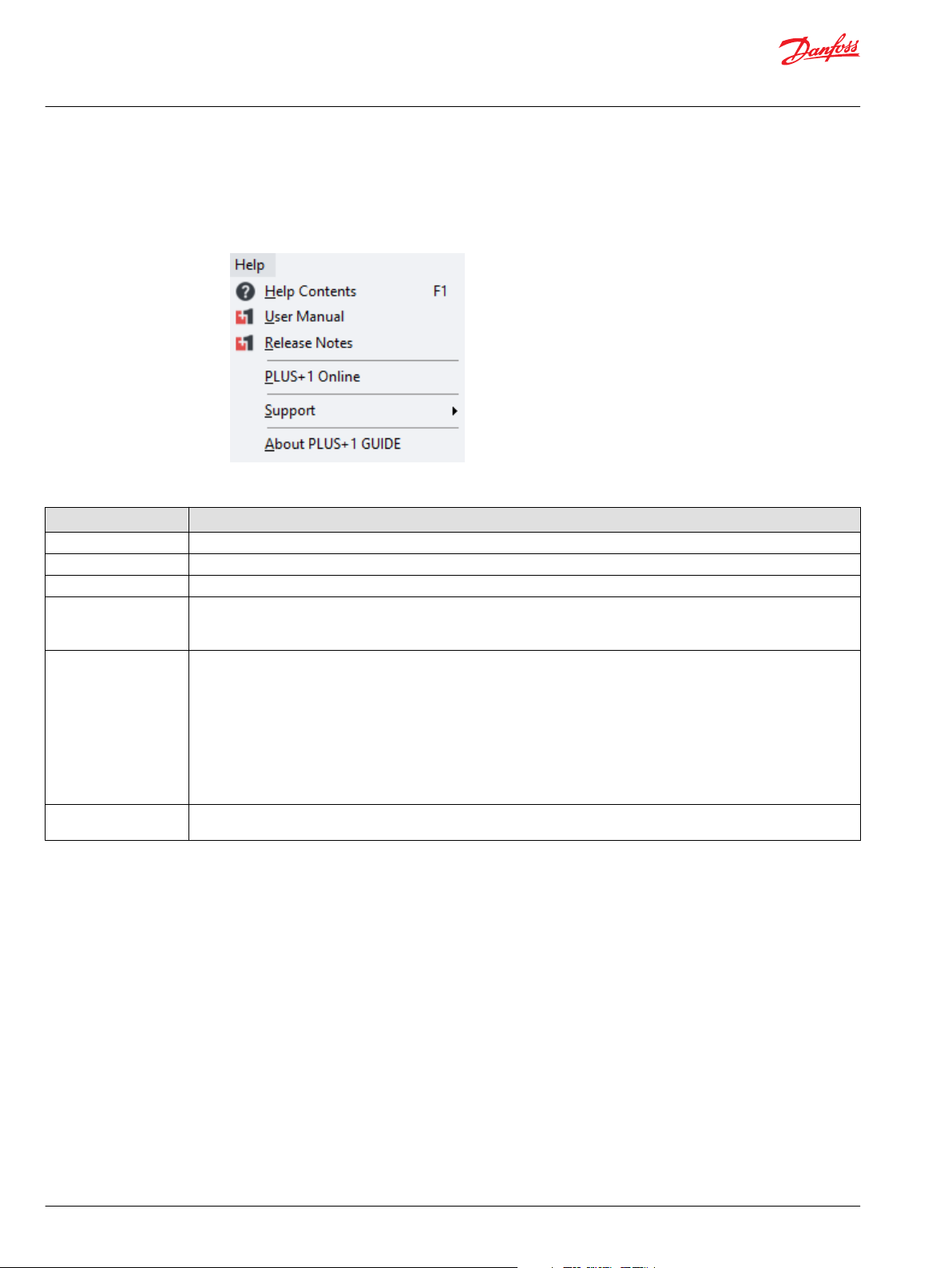

Help Menu...................................................................................................................................................................................74

Toolbar...............................................................................................................................................................................................75

Dialogs............................................................................................................................................................................................... 78

Options.........................................................................................................................................................................................78

PLUS+1 GUIDE Settings.................................................................................................................................................... 78

General Settings.................................................................................................................................................................. 79

Auto Pop-ups Settings.......................................................................................................................................................80

Preview Settings.................................................................................................................................................................. 81

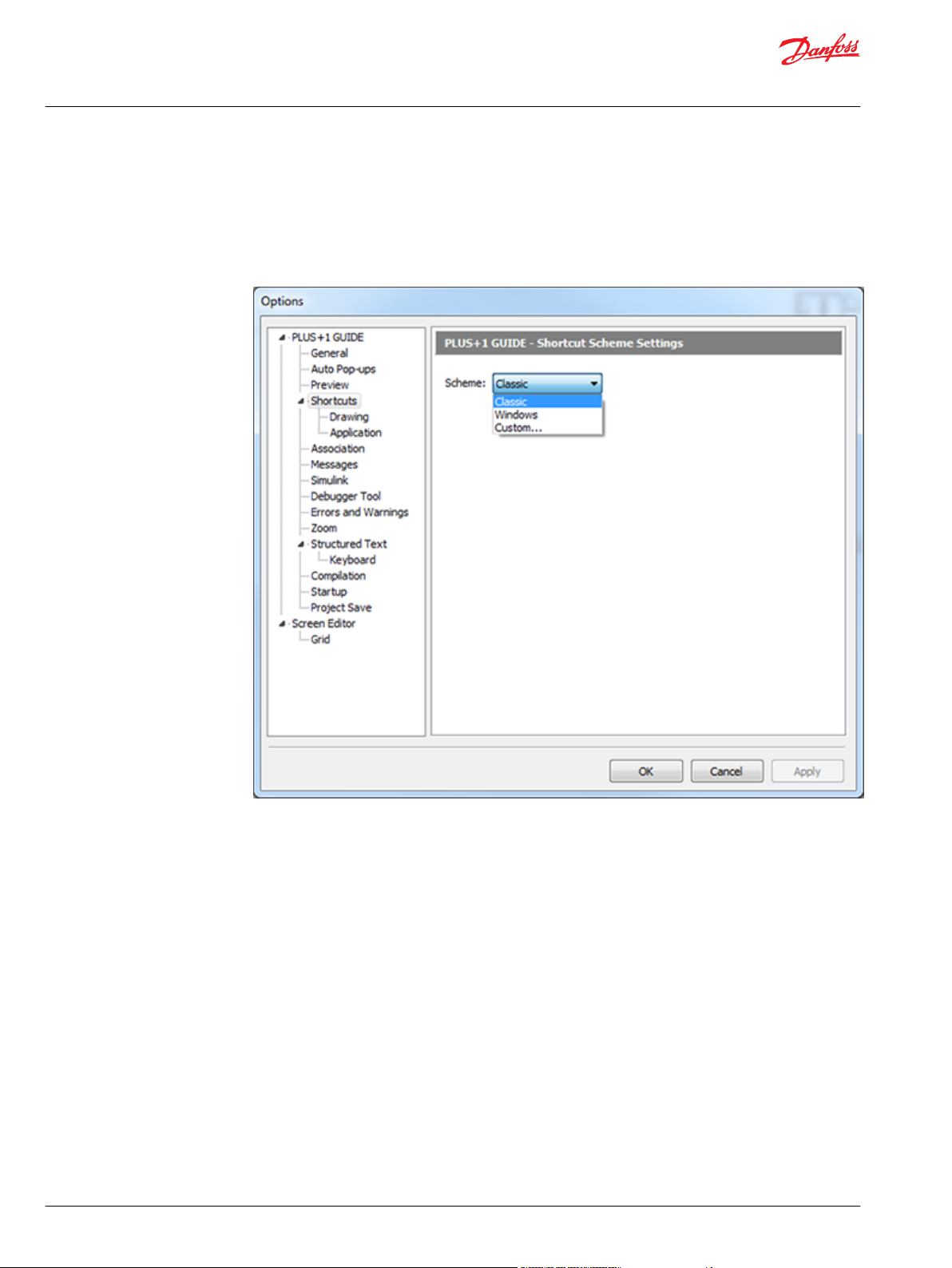

Shortcuts Scheme Settings..............................................................................................................................................82

File Association Settings...................................................................................................................................................88

Messages................................................................................................................................................................................90

Simulink Settings.................................................................................................................................................................91

Debugger Tool Settings....................................................................................................................................................92

Errors, Warnings and Hints Settings.............................................................................................................................93

Zoom Settings...................................................................................................................................................................... 98

PLC Settings........................................................................................................................................................................100

Compilation Settings.......................................................................................................................................................104

Project Open/Close Settings.........................................................................................................................................105

Search Settings..................................................................................................................................................................106

Screen Editor Settings.....................................................................................................................................................107

Layouts................................................................................................................................................................................. 108

Print.............................................................................................................................................................................................109

Project View..............................................................................................................................................................................110

Parameter Overview..............................................................................................................................................................111

Logical Net................................................................................................................................................................................113

Dependencies..........................................................................................................................................................................115

Comment Editor..................................................................................................................................................................... 116

Search/Replace....................................................................................................................................................................... 119

Search....................................................................................................................................................................................119

Replace................................................................................................................................................................................. 134

Page Interface Editor.............................................................................................................................................................141

Page Interface Editor Window Menus.......................................................................................................................142

Page Interface Editor—File Menu...............................................................................................................................143

Page Interface Editor—Edit Menu..............................................................................................................................144

Page Interface Editor—View Menu............................................................................................................................145

Page Interface Editor—Setup Menu..........................................................................................................................146

Page Interface Editor—Add Menu............................................................................................................................. 147

Page Interface Editor—Tools Menu...........................................................................................................................147

Page Interface Editor Window Toolbar.....................................................................................................................148

About Pages, Page Top views, and the Page Interface Editor Window........................................................150

How to Add Page with the Page Command...........................................................................................................152

How to Add a Basic Page................................................................................................................................................153

How to Change an Old Page.........................................................................................................................................154

Traceability Properties..........................................................................................................................................................155

Tabs...................................................................................................................................................................................................156

Hardware...................................................................................................................................................................................156

Search Window..................................................................................................................................................................158

Project Manager..................................................................................................................................................................... 159

About the Project Manager and Hardware tabs....................................................................................................161

How to Remove Items from the Project Manager Tab........................................................................................162

Page Navigator........................................................................................................................................................................163

Component.............................................................................................................................................................................. 164

Function.....................................................................................................................................................................................165

4 | © Danfoss | February 2021 AQ152886483724en-002301

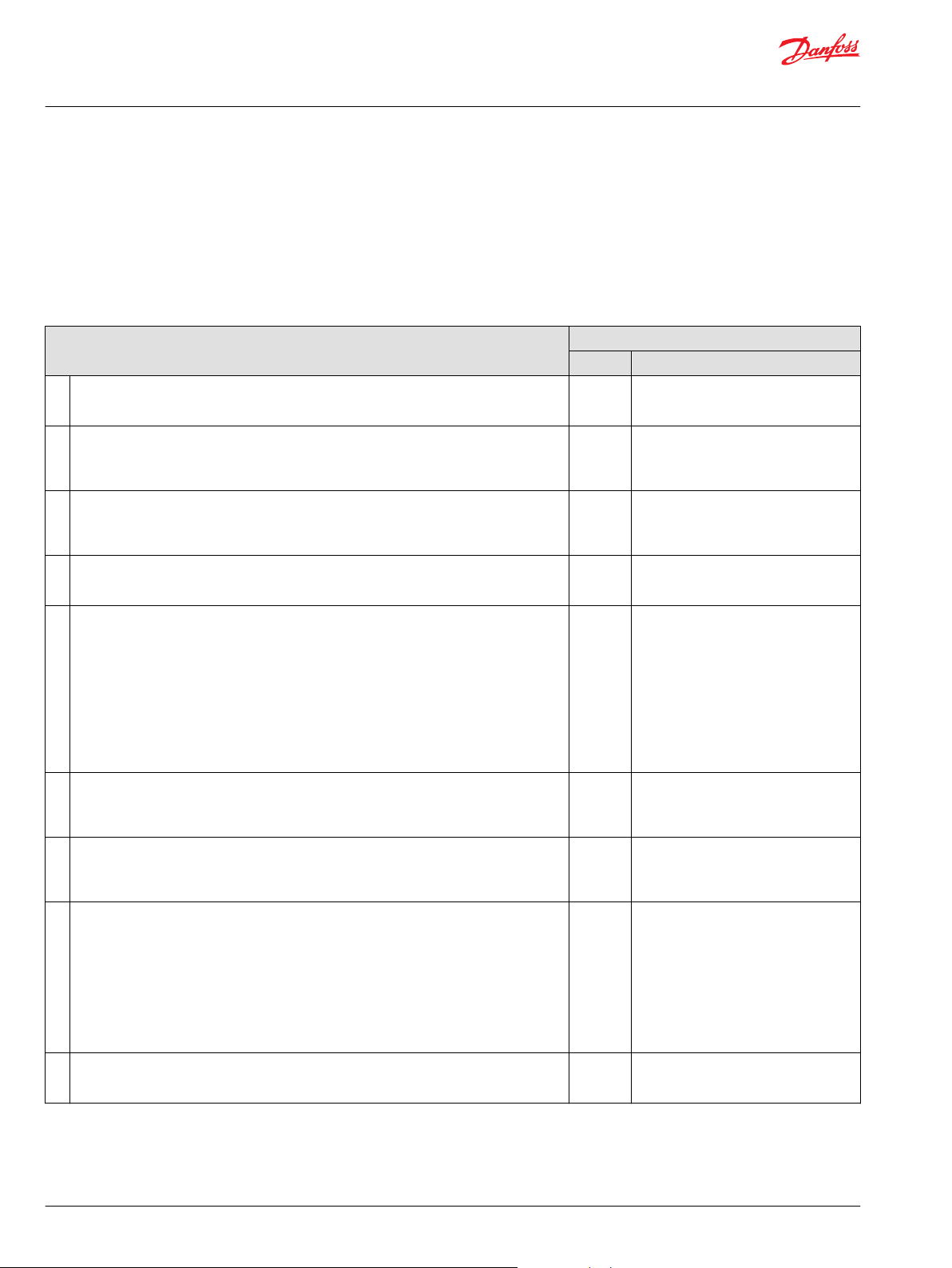

Page 5

User Manual

PLUS+1® GUIDE Software

Contents

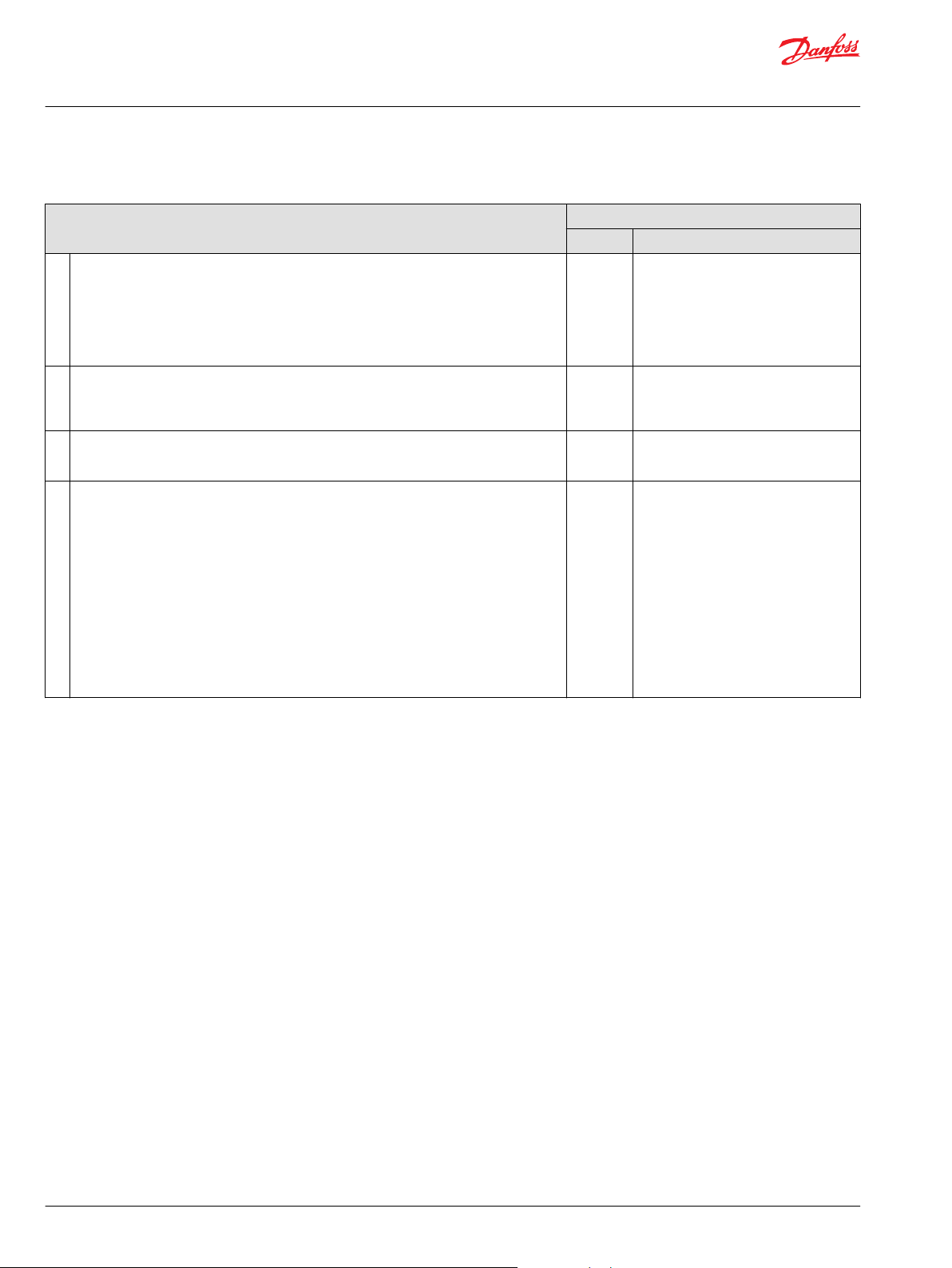

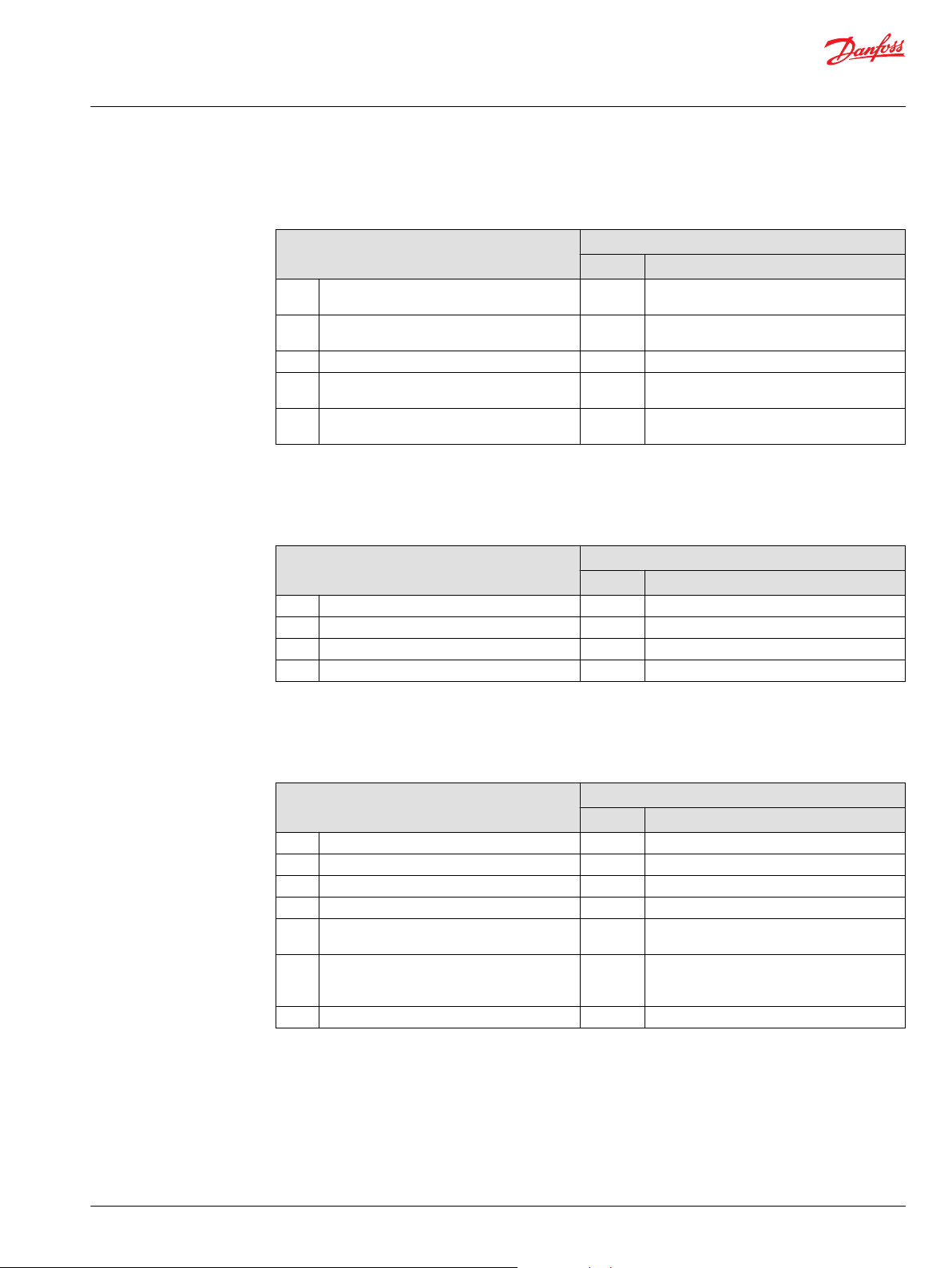

File Types

Programming

My Code.....................................................................................................................................................................................166

Inspector....................................................................................................................................................................................168

Compiler Messages................................................................................................................................................................169

Test Tool..........................................................................................................................................................................................170

About Creating Test Cases for a Page.............................................................................................................................171

Test Case Manager Window—Menus and buttons...................................................................................................173

About Generating a Test Case Definition Table for a Page.....................................................................................174

Test Case Definition table................................................................................................................................................... 175

About Test Case Execution and Test Results................................................................................................................177

About Test Case Results.......................................................................................................................................................178

About the Test Manager Tab View...................................................................................................................................179

Debugger Tool..............................................................................................................................................................................181

Debugger Tool Elements.....................................................................................................................................................182

About Breakpoints and Net Values............................................................................................................................ 184

About the Display of Net Values..................................................................................................................................185

About Set Breakpoints....................................................................................................................................................186

About Breakpoints and Debugger Tool buttons...................................................................................................187

Debug Window.......................................................................................................................................................................189

Debug Window—Local Variables tab.......................................................................................................................190

Debug Window—Watches tab....................................................................................................................................191

Debug Window—Call Stack tab..................................................................................................................................193

Debug Window—Breakpoints tab.............................................................................................................................194

Debug Window—Loop Input tab...............................................................................................................................195

Debug Window—Loop Output tab...........................................................................................................................197

Generate FMU...............................................................................................................................................................................198

Limitations................................................................................................................................................................................198

How to generate an FMU.................................................................................................................................................... 198

Generated FMU Properties................................................................................................................................................. 199

Co-Simulation step size.................................................................................................................................................. 200

OS Signals............................................................................................................................................................................200

Non-volatile memory...................................................................................................................................................... 200

Set Pulse...............................................................................................................................................................................200

Repeat/Until........................................................................................................................................................................200

Unique signal names.......................................................................................................................................................200

Simulated CAN interface..................................................................................................................................................... 200

CAN Database.................................................................................................................................................................... 201

Select CAN port................................................................................................................................................................. 201

Set default bit value.........................................................................................................................................................202

PLUS+1 GUIDE File Types......................................................................................................................................................... 203

STRING Types................................................................................................................................................................................ 204

How to Specify a STRING Value.........................................................................................................................................205

Escape Sequences..................................................................................................................................................................205

STRING Examples................................................................................................................................................................... 206

PLC Functions..........................................................................................................................................................................207

VBSE Control Codes...............................................................................................................................................................207

Using STRING in C Code Files and C Code POUs.........................................................................................................207

PLUS+1 GUIDE Graphical Code.............................................................................................................................................. 208

Hardware Templates.............................................................................................................................................................208

Route Names............................................................................................................................................................................209

Data Types................................................................................................................................................................................ 210

About Overflow Conditions..........................................................................................................................................211

About the Time Base data type................................................................................................................................... 212

About the Array Data Type............................................................................................................................................213

PLUS+1 GUIDE Components..............................................................................................................................................214

About the Hardware - Dependency of Components...........................................................................................214

Context-sensitive Help for Components..................................................................................................................214

©

Danfoss | February 2021 AQ152886483724en-002301 | 5

Page 6

User Manual

PLUS+1® GUIDE Software

Contents

Screen Editors

About Component Descriptions.................................................................................................................................215

About Execution Order...................................................................................................................................................216

About Capped Components.........................................................................................................................................219

General Menu.....................................................................................................................................................................220

Mathematical Menu.........................................................................................................................................................222

Limit Menu.......................................................................................................................................................................... 242

Compare Menu..................................................................................................................................................................248

Constant Menu.................................................................................................................................................................. 260

Logical Menu......................................................................................................................................................................266

Switch, Counter, Memory Menu..................................................................................................................................279

Array Menu..........................................................................................................................................................................297

Data Conversion Menu...................................................................................................................................................313

Transition, Time Menu.................................................................................................................................................... 319

Connection Menu.............................................................................................................................................................332

Module Menu.....................................................................................................................................................................367

Manage Menu....................................................................................................................................................................373

Access Menu.......................................................................................................................................................................380

Read-only Parameter Menu.......................................................................................................................................... 393

Display Menu......................................................................................................................................................................398

Application Log Menu.....................................................................................................................................................400

Cloud Menu.........................................................................................................................................................................404

Page Layout Guidelines....................................................................................................................................................... 409

Port Label Abbreviations................................................................................................................................................411

Port Label Unit Abbreviations......................................................................................................................................412

IEC61131-3 PLC Languages..................................................................................................................................................... 412

About PLC Data Types..........................................................................................................................................................412

About POUs..............................................................................................................................................................................413

Create New PLC Unit and POU.....................................................................................................................................413

Import Existing PLC Unit................................................................................................................................................ 417

Edit ST....................................................................................................................................................................................418

Edit FBD/LD.........................................................................................................................................................................419

Querying Components................................................................................................................................................... 421

FBD/LD Networks..............................................................................................................................................................422

EN/ENO Components......................................................................................................................................................422

Use PLUS+1 GUIDE to Call Program Organizational Units (POUs)..................................................................423

Call from PLUS+1 GUIDE — Inside the POU Component.................................................................................. 424

SFC POUs..............................................................................................................................................................................424

About Global Variables........................................................................................................................................................ 425

C Code in PLUS+1 GUIDE..........................................................................................................................................................425

General Considerations Regarding C Code in a PLUS+1 GUIDE Environment................................................426

About Compatibility........................................................................................................................................................ 426

Accessing C Code Generated by PLUS+1 GUIDE from C Code POUs or C Code Files..............................426

Supported HWDs.............................................................................................................................................................. 427

#include directives........................................................................................................................................................... 428

About C Data Types...............................................................................................................................................................428

C Code POUs............................................................................................................................................................................429

C Code Files..............................................................................................................................................................................431

Precompile Analysis.........................................................................................................................................................432

Programming Tips and Tricks................................................................................................................................................. 433

Issue Indicators.............................................................................................................................................................................433

Classic Screen Editor...................................................................................................................................................................435

Classic Screen Editor Elements..........................................................................................................................................436

Define Areas Page..................................................................................................................................................................438

Define Areas Page—Inspector Tab............................................................................................................................ 439

Define Areas Page—About the Enable Property.................................................................................................. 440

Define Areas Page—About the Order Property.................................................................................................... 441

Define Areas Page—About the Corner Property.................................................................................................. 444

Define Screen Page................................................................................................................................................................445

6 | © Danfoss | February 2021 AQ152886483724en-002301

Page 7

User Manual

PLUS+1® GUIDE Software

Contents

Define Screen Page—Add Library Items..................................................................................................................446

Define Screen Page—Inspector Tab..........................................................................................................................447

Define Screen Page—Image Register....................................................................................................................... 452

Define Screen Page—Text Register........................................................................................................................... 455

Vector-Based Screen Editor......................................................................................................................................................456

Elements of the Vector-Based Screen Editor................................................................................................................457

Danfoss Recommends the SVG Format....................................................................................................................457

About Screen Definitions and the Screen Editor Window......................................................................................458

About Show Screen Components and Screen Definitions..................................................................................... 459

Screen Editor Window..........................................................................................................................................................460

Project Library Tab............................................................................................................................................................460

External Library Tab......................................................................................................................................................... 463

Edit Image Window .........................................................................................................................................................464

Edit Text Window..............................................................................................................................................................467

Common Properties Windows.....................................................................................................................................472

Screen Manager Tab........................................................................................................................................................473

Inspector Tab......................................................................................................................................................................480

Toolbar..................................................................................................................................................................................483

Design Area.........................................................................................................................................................................484

Data Types................................................................................................................................................................................ 487

Integer, Boolean and Color .......................................................................................................................................... 487

Text and Image..................................................................................................................................................................488

String.....................................................................................................................................................................................488

Text and String Rendering..................................................................................................................................................488

Code Point Set................................................................................................................................................................... 489

Edit Code Point Range.................................................................................................................................................... 490

Control Codes.....................................................................................................................................................................491

Zero-width Glyphs............................................................................................................................................................491

Missing Glyphs...................................................................................................................................................................491

Font Output Format.........................................................................................................................................................491

Screen Definitions and Widgets........................................................................................................................................492

Screen Definition Properties.........................................................................................................................................493

Using Widgets....................................................................................................................................................................495

Layout.........................................................................................................................................................................................496

Screen Definition Layout................................................................................................................................................497

Layout Manager................................................................................................................................................................ 497

Manual Layout................................................................................................................................................................... 499

Call POU.....................................................................................................................................................................................500

Internal Connections.............................................................................................................................................................501

Signal Assignment Table................................................................................................................................................502

Connect Bus........................................................................................................................................................................502

Add and Connect Bus......................................................................................................................................................504

Configure Object Interface............................................................................................................................................506

Invalid Connections......................................................................................................................................................... 512

About the Show Screen Component and the Query Screen Component Window...................................... 515

About the Query Screen Component Window and Screen Definition Signals............................................... 516

About the Query Screen Component Window and Screen Definition Buses..................................................518

About the Query Screen Component Window and KPH Screen Definition..................................................... 520

About the Query Screen Component Window and MPH Screen Definition....................................................521

About Exporting and Importing Screen Definitions................................................................................................. 522

Import Screen Definitions—Import Screens Window.........................................................................................523

Import Screen Definitions—Screen Library Placement Window....................................................................524

Import Screen Definitions—Import Duplicate Library Items Window..........................................................525

Import Screen Definitions—Import Window......................................................................................................... 526

About Exporting and Importing Library Objects........................................................................................................527

Import Library Objects—Import Duplicate Library Items..................................................................................528

Import Screen Definitions—Import Window......................................................................................................... 529

Touch Display Functionality...............................................................................................................................................529

Local Touch Coordinates................................................................................................................................................531

©

Danfoss | February 2021 AQ152886483724en-002301 | 7

Page 8

User Manual

PLUS+1® GUIDE Software

Contents

Application Data Logging

Tutorials

Generic Viewport....................................................................................................................................................................531

Overview of Application Data Logging...............................................................................................................................532

Classic Application Log..............................................................................................................................................................532

Basic Elements of Application Data Logging...............................................................................................................532

Define Application Log Areas Page.................................................................................................................................534

Define Application Log Areas Page/Inspector Tab...............................................................................................535

Define Application Log Page/Text Register tab.................................................................................................... 538

Define Application Log Page............................................................................................................................................. 539

Define Application Log Page/Add Texts.................................................................................................................. 540

Define Application Log Page/Inspector Tab—Data Write Properties...........................................................541

Define Application Log Page/Inspector Tab—DataValue Properties............................................................542

Application Log 2........................................................................................................................................................................ 542

Application Log Definitions................................................................................................................................................542

Write Applog............................................................................................................................................................................543

Application Log 2 Editor......................................................................................................................................................543

Application Log 2 Editor Window...............................................................................................................................543

Text Component Properties..........................................................................................................................................545

Using Application Log 2.......................................................................................................................................................546

Defining Texts.................................................................................................................................................................... 546

Application Log Definition Interface......................................................................................................................... 546

Putting It Together...........................................................................................................................................................547

How to Read the Contents of an Application Data Log................................................................................................ 548

About the Properties that Determine Data Logging Values.................................................................................. 550

Learning About the PLUS+1 GUIDE Software...................................................................................................................551

Before You Start......................................................................................................................................................................551

Mouse and Keyboard Actions............................................................................................................................................551

Lesson 1: Create an Application.............................................................................................................................................552

1. Start the PLUS+1 GUIDE software and create a new PLUS+1 project folder............................................... 552

2. Get the PLUS+1 GUIDE window ready to select the hardware files................................................................553

3. Click and drag the MC24-10 Hardware Description and Template to the Project Manager tab..........554

4. Enter the Application of the template and select the components needed to construct an

oscillator............................................................................................................................................................................ 555

5. Wire together the components that you have placed in the Application page.........................................556

6. Use the Edit Value window to apply values to the 3 Digit Auto-type and Time Base constants..........557

7. Wire the output of the Oscillator component to the Outputs bus..................................................................558

8. Navigate to the OS page.................................................................................................................................................559

9. Delete the constant True applied to the LED_GREEN..........................................................................................560

10. Route the Green_LED signal to the LED_GREEN port........................................................................................561

11. Compile the application into an LHX format file that you can download..................................................562

12. Compress the project files into P1P format file and exit PLUS+1 GUIDE....................................................563

Lesson 2: Download an Application..................................................................................................................................... 563

PLUS+1 Service Tool window............................................................................................................................................ 565

Using the PLUS+1® CG150-2 USB/CAN Gateway Interface Communicator.................................................566

Preparing to Download the Application File to the Controller........................................................................567

Downloading the File to the Controller and Exit PLUS+1 Service Tool........................................................ 571

PLUS+1—How-To....................................................................................................................................................................... 572

How to Select...........................................................................................................................................................................573

How to Undo Your Mistakes...............................................................................................................................................573

How to Zoom with Mouse Clicks......................................................................................................................................574

How to Zoom with the Mouse Wheel.............................................................................................................................574

How to Zoom with Keystrokes.......................................................................................................................................... 574

How to Delete a Single Item...............................................................................................................................................575

How to Delete Many Items................................................................................................................................................. 576

How to Delete a Signal-to-Bus Connection..................................................................................................................577

How to Copy the Entire Contents of a Page to another Page................................................................................579

How to Refresh a View..........................................................................................................................................................581

8 | © Danfoss | February 2021 AQ152886483724en-002301

Page 9

User Manual

PLUS+1® GUIDE Software

Contents

How to View a Full Page...................................................................................................................................................... 581

How to Pan a View by Right-Clicking and Dragging.................................................................................................581

How to Pan a View by Right-Clicking..............................................................................................................................581

How to Navigate an Application with Buttons............................................................................................................582

How to Navigate an Application with the Page Navigator Tab............................................................................ 582

How to Show and Hide Tabs..............................................................................................................................................583

How to Install a Hardware Description...........................................................................................................................584

How to Change Properties with the Inspector Tab................................................................................................... 586

How to Change Properties with the Pop-up Edit Window..................................................................................... 587

How to Create a Custom Keyboard Shortcut Scheme..............................................................................................588

How to Reset a Custom Keyboard Shortcut Scheme to either the Classic or the Windows.......................590

How to Create a Page from Scratch.................................................................................................................................591

How to use View Logical Net Tool....................................................................................................................................599

How to Create Read-only Parameter Files ....................................................................................................................602

How to Create Read-only Parameters File from Scratch.....................................................................................602

How to Create an Additional Read-only Parameter File with Different Values..........................................609

How to Create a New Read-only Parameters File with Changed Parameters............................................ 612

About the CSV Template File Format........................................................................................................................ 617

How to Add a Readme File to an LHX File.....................................................................................................................618

How to Restrict Downloads by Part Number or Serial Number............................................................................ 620

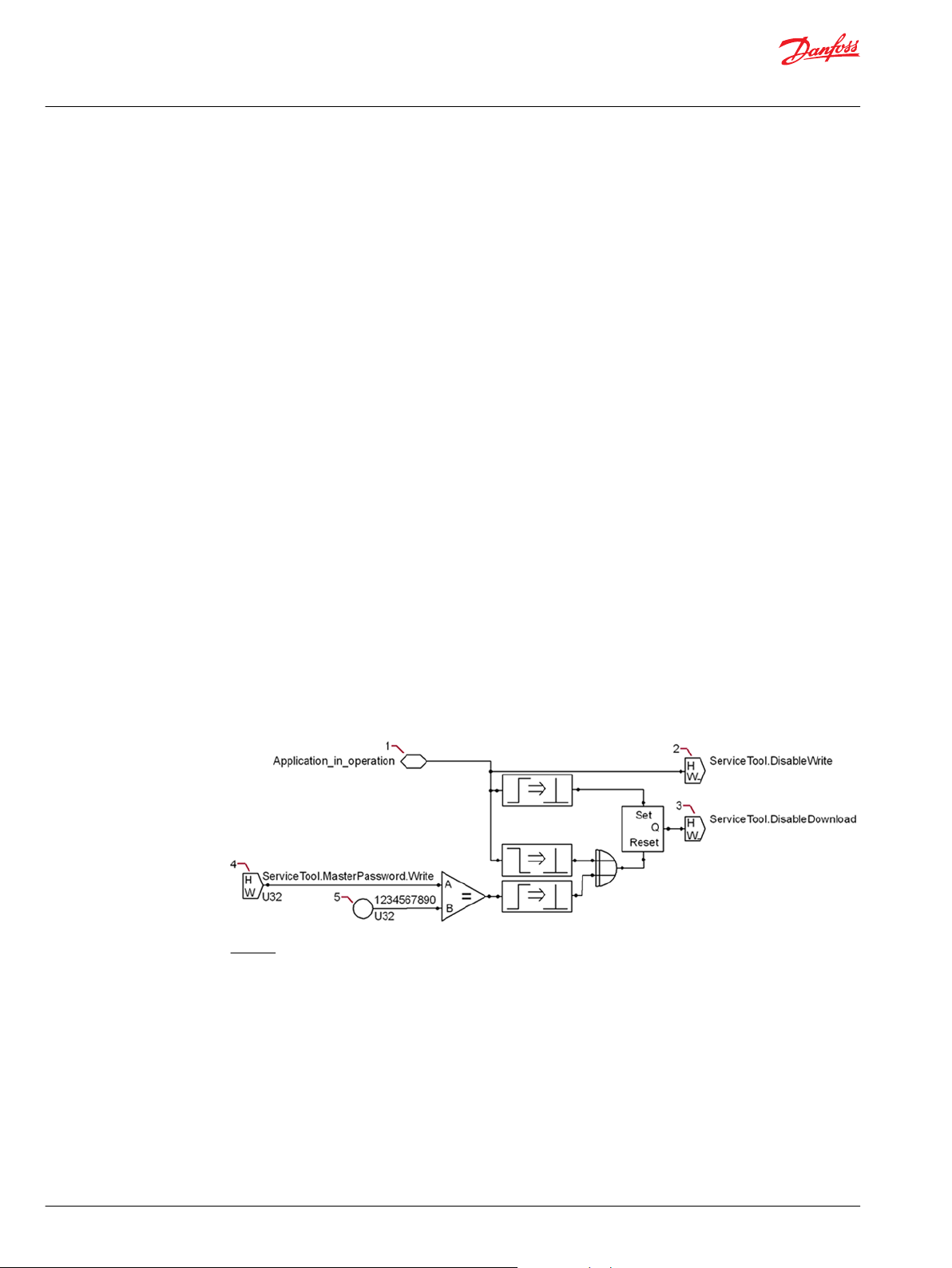

How to Use the Tool Key to Restrict Service Tool Access to Application Values.............................................622

How to Access Values in a Tool Key-Protected Application..............................................................................624

How to Create Linked Pages.............................................................................................................................................. 625

About Linked Pages.........................................................................................................................................................626

About Linked Page Properties..................................................................................................................................... 627

How to Reposition the Link Symbol...........................................................................................................................628

How to Turn a Linked Page into an Object Page........................................................................................................630

About Working with Linked and Object Pages...........................................................................................................631

Do Not Use these Components in Linked Pages...................................................................................................632

Do Not Use these Components in Object Pages...................................................................................................633

How to Make Changes inside a Linked Page..........................................................................................................635

How to Break Links between Pages........................................................................................................................... 636

How to Break Links between Child Pages................................................................................................................637

How to Display a Page Property Value...........................................................................................................................639

Page Property and String Value...................................................................................................................................640

How to Disable (Lock) a Page View..................................................................................................................................641

About Access Properties................................................................................................................................................ 642

How to Change a Page View Access Property........................................................................................................645

How to Customize the Font and Color of Comments...............................................................................................647

How to Limit Downloads to Keyed Hardware............................................................................................................. 650

How to Add a Compiled Code Package.........................................................................................................................652

How to Simplify Opening the Correct P1D File...........................................................................................................654

How to Create and Execute a Test Case.........................................................................................................................656

How to Generate an S-Function....................................................................................................................................... 666

About the S-Function Files............................................................................................................................................668

How to Trace between Implementation and Requirements..................................................................................669

Tracing from Requirements to Implementation................................................................................................... 671

How to Generate an Architecture Document..............................................................................................................673

How to Create and Use a C Code POU............................................................................................................................674

How to Create and Use a C Code File..............................................................................................................................678

How to Import and Use an Existing C Code File..........................................................................................................685

How to Manage Boot Logo.................................................................................................................................................691

How to use the Comment editor......................................................................................................................................692

Classic Screen Editor—How To.............................................................................................................................................. 696

How to Start a Classic Screen Editor Project.................................................................................................................696

How to Update a Project to PLUS+1 GUIDE 5.1.x or Later.......................................................................................700

Define Areas Page—How to Create More Screen Areas..........................................................................................703

Define Areas Page—How to Rename a Screen Area.................................................................................................704

Define Areas Page—How to Delete a Screen Area....................................................................................................705

©

Danfoss | February 2021 AQ152886483724en-002301 | 9

Page 10

User Manual

PLUS+1® GUIDE Software

Contents

Support Tools

Define Areas Page—How to Change Screen Area Properties............................................................................... 706

Define Areas Page—How to Initialize Signal-Enabled Screen Areas...................................................................708

Define Screen Page—How to Assign Additional Screen Areas.............................................................................709

Define Screen Page—How to Remove a Screen Area.............................................................................................. 710

Define Screen Page—How to Create Bar Graphs ......................................................................................................711

Define Screen Page—How to Install Unicode Fonts.................................................................................................712

Define Screen Page—How to Create a Text Group...................................................................................................715

Define Screen Page—How to Set the Font Properties of Text.............................................................................. 718

Define Screen Page—How to Set a Language that a User Cannot Change.....................................................721

Define Screen Page—How to Allow a User to Change Languages..................................................................... 722

Define Screen Page—How to Import Translated Text into an Application......................................................723

How to Export a CSV File with Text that Needs Translation..............................................................................724

How to Add Translated Text to the CSV File........................................................................................................... 726

How to Import a CSV File with the Translated Text..............................................................................................728

About the Language Order...........................................................................................................................................729

Define Screen Page—How to Create Text that Flashes an Alarm........................................................................730

Define Screen Page—How to Display a Data Value.................................................................................................. 734

Define Screen Page—How to Format a Data Value.................................................................................................. 735

Define Screen Page—How to Display an Image List.................................................................................................736

Define Screen Page—How to Display a Text List....................................................................................................... 740

Define Screen Page—How to Display Video................................................................................................................744

Define Screen Page—How to Print a Screen............................................................................................................... 746

Define Screen Page—How to Show the Stacking Order of Items in the Layout Tab....................................749

Define Screen Page—How to Change the Stacking Order of Items in the Layout Tab ...............................750

Change the Order of Items in the Layout Tab........................................................................................................750

Change Stacking Order by Right-clicking................................................................................................................751

Define Screen Page—How to Alphabetically List the Items in the Layout Tab...............................................752

Module Viewer..............................................................................................................................................................................753

Module Viewer Window Menu..........................................................................................................................................754

File Menu in SCS Files......................................................................................................................................................754

Edit Menu in SCS Files..................................................................................................................................................... 755

View Menu in SCS Files................................................................................................................................................... 755

Setup Menu in SCS Files................................................................................................................................................. 756

Add Menu in SCS Files.....................................................................................................................................................756

Module Viewer Window Toolbar......................................................................................................................................757

Module viewer options........................................................................................................................................................ 758

Starting the Module Viewer............................................................................................................................................... 759

Compare SCS Files.......................................................................................................................................................................761

Starting PLUS+1 Compare SCS from the Page Navigator Tab...............................................................................762

Starting PLUS+1 Compare SCS from the Project Manager Tab.............................................................................762

Starting PLUS+1 Compare SCS from the Command Line....................................................................................... 763

How to Add PLUS+1 Compare SCS as a Diff Tool to TortoiseSVN........................................................................764

PLUS+1 Compare SCS...........................................................................................................................................................766

PLUS+1 Compare SCS Toolbar..........................................................................................................................................767

Compare SCS options...........................................................................................................................................................769

About the Order in which Checksum Differences are Identified..........................................................................769

About the Page Tree View.................................................................................................................................................. 770

About the Single, Combined Page Tree View........................................................................................................ 770

About the Separate Page-Tree View..........................................................................................................................771

About the Overlay Pages and the Separate Pages Views........................................................................................771