Page 1

User Manual

PLUS+1® GUIDE Software

Autonomous Control Library Function

Blocks

www.danfoss.com

Page 2

User Manual

PLUS+1® Function Block Library—Autonomous Control Function Blocks

Revision history Table of revisions

Date Changed Rev

January 2020 First edition 0101

October 2021 Added new function blocks to the library 0102

December 2021 Two new function blocks ACL2.1 0103

2 | © Danfoss | January 2020 AQ295075513101en-000101

Page 3

User Manual

PLUS+1® Function Block Library—Autonomous Control Function Blocks

Contents

Library Introduction

Localization.........................................................................................................................................................................................6

Navigation...........................................................................................................................................................................................7

Perception...........................................................................................................................................................................................8

Errata.....................................................................................................................................................................................................9

Change Namespace Value............................................................................................................................................................ 9

ACL Acronyms.................................................................................................................................................................................10

Ackermann Yaw Rate Function Block

Inputs..................................................................................................................................................................................................11

Outputs..............................................................................................................................................................................................12

Angle to Curvature Function Block

Inputs..................................................................................................................................................................................................14

Parameters........................................................................................................................................................................................14

Outputs..............................................................................................................................................................................................14

Curvature to Angle Function Block

Inputs..................................................................................................................................................................................................15

Parameters........................................................................................................................................................................................16

Outputs..............................................................................................................................................................................................16

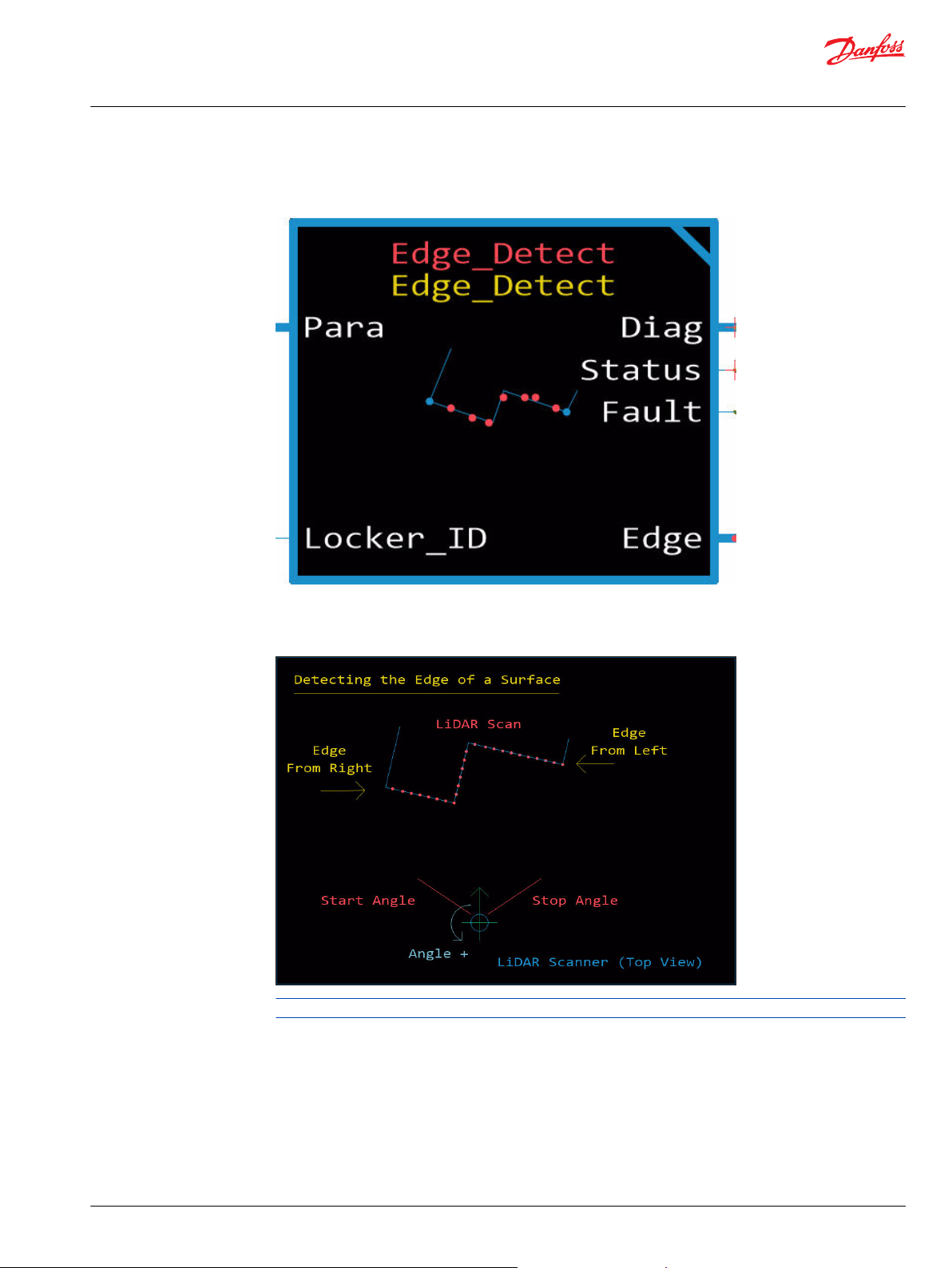

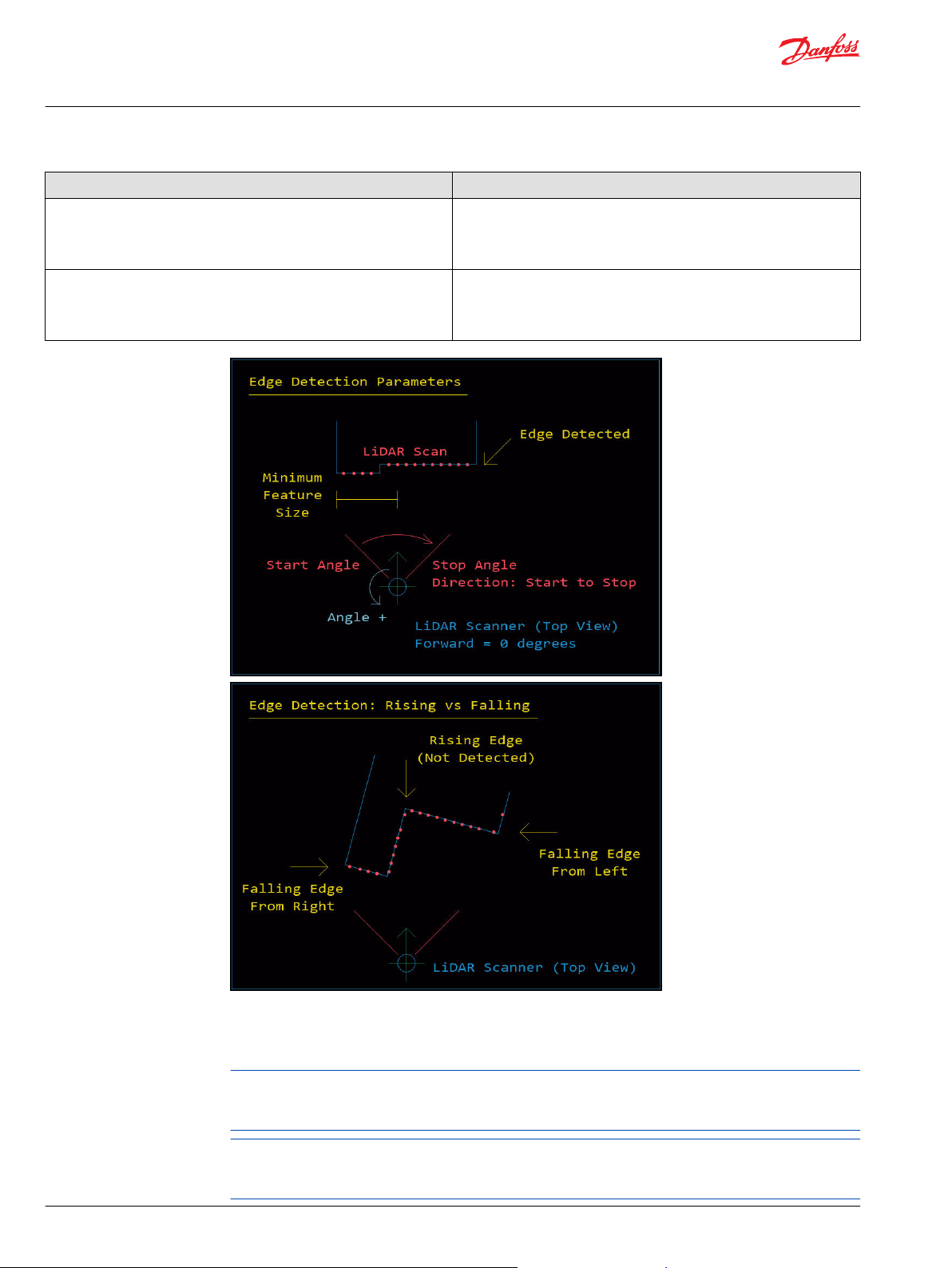

Edge Detection Function Block

Inputs..................................................................................................................................................................................................18

Parameters........................................................................................................................................................................................19

Outputs..............................................................................................................................................................................................20

Extract Ring Function Block

Inputs..................................................................................................................................................................................................21

Parameters........................................................................................................................................................................................21

Outputs..............................................................................................................................................................................................21

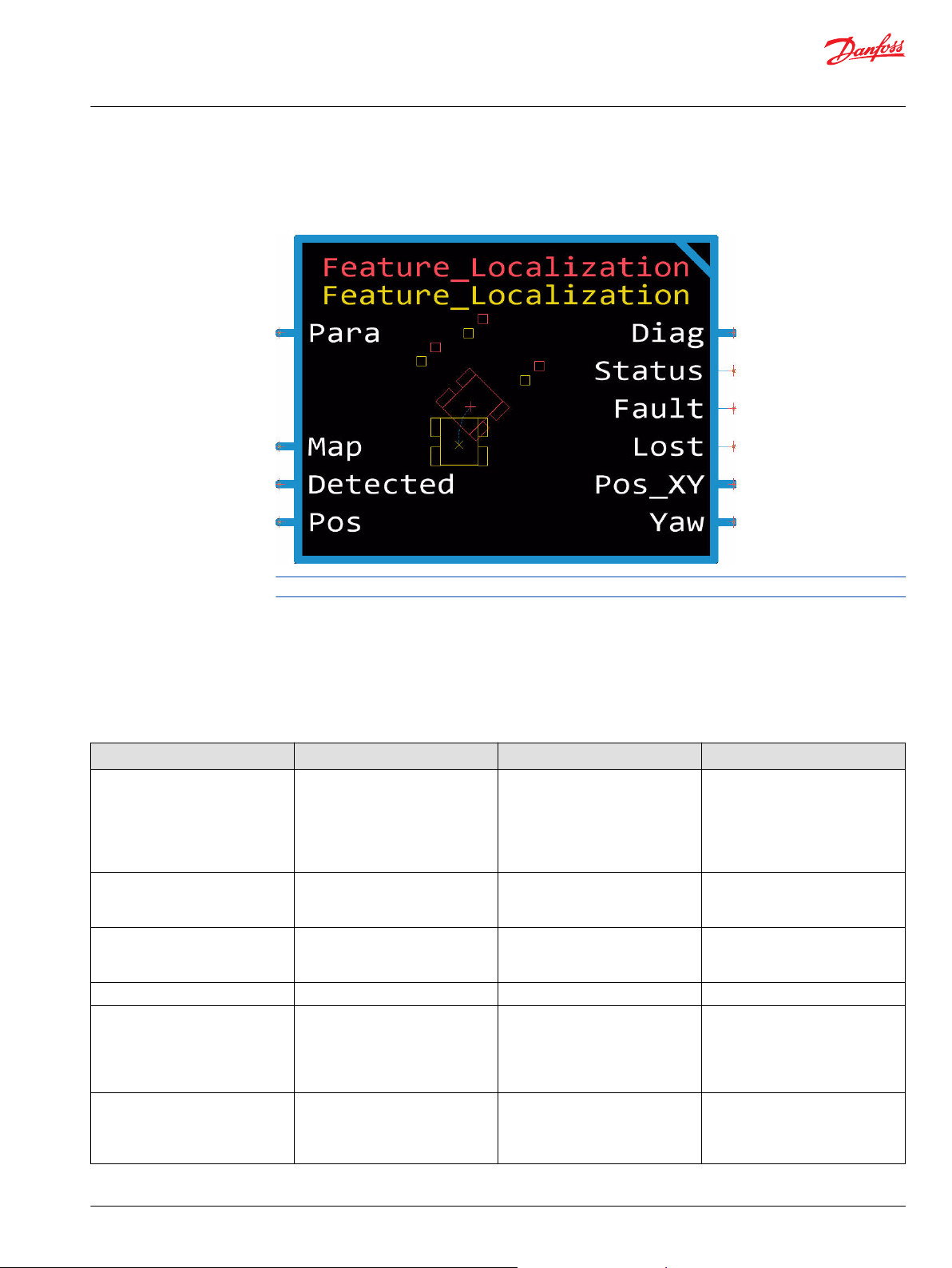

Feature Localization Function Block

Inputs..................................................................................................................................................................................................23

Parameters........................................................................................................................................................................................24

Outputs..............................................................................................................................................................................................25

Obstacle Avoidance Function Block

Inputs..................................................................................................................................................................................................27

Parameters........................................................................................................................................................................................27

Outputs..............................................................................................................................................................................................28

Obstacle Detection Function Block

LiDAR.................................................................................................................................................................................................. 29

Inputs..................................................................................................................................................................................................30

Parameters........................................................................................................................................................................................30

Outputs..............................................................................................................................................................................................31

Origin Function Block

Inputs..................................................................................................................................................................................................33

Parameters .......................................................................................................................................................................................34

Outputs..............................................................................................................................................................................................35

Path Follower Function Block

Inputs..................................................................................................................................................................................................37

Parameters .......................................................................................................................................................................................38

Outputs..............................................................................................................................................................................................39

Restart or Resume Path After ECU Power Loss....................................................................................................................40

Position Filter Function Block

Inputs..................................................................................................................................................................................................41

Outputs..............................................................................................................................................................................................42

Post Detection Function Block

Inputs..................................................................................................................................................................................................45

©

Danfoss | January 2020 AQ295075513101en-000101 | 3

Page 4

User Manual

PLUS+1® Function Block Library—Autonomous Control Function Blocks

Contents

Parameters........................................................................................................................................................................................45

Outputs..............................................................................................................................................................................................45

Projected Path Function Block

Inputs..................................................................................................................................................................................................48

Parameters........................................................................................................................................................................................48

Outputs..............................................................................................................................................................................................49

Reflector Detection Function Block

Inputs..................................................................................................................................................................................................52

Parameters........................................................................................................................................................................................52

Outputs..............................................................................................................................................................................................53

Relative Position Function Block

Inputs..................................................................................................................................................................................................54

Outputs..............................................................................................................................................................................................55

Two Point Planner Function Block

Inputs..................................................................................................................................................................................................56

Parameters........................................................................................................................................................................................57

Outputs..............................................................................................................................................................................................58

UTM Conv Function Block

Inputs..................................................................................................................................................................................................59

Outputs..............................................................................................................................................................................................59

UTM Conv Zone Function Block

Inputs..................................................................................................................................................................................................61

Outputs..............................................................................................................................................................................................62

Wall Detection Function Block

Inputs..................................................................................................................................................................................................63

Parameters........................................................................................................................................................................................64

Outputs..............................................................................................................................................................................................65

Yaw Estimate Function Block

Inputs..................................................................................................................................................................................................67

Parameters........................................................................................................................................................................................67

Outputs..............................................................................................................................................................................................68

Customizable Service Screens

Ackermann Yaw Rate Service Tool Start Screen................................................................................................................. 69

Debug Signals............................................................................................................................................................................70

Angle to Curvature Service Tool Screen................................................................................................................................ 71

Debug Signals ...........................................................................................................................................................................71

Curvature to Angle Service Tool Screen................................................................................................................................ 72

Debug Signals............................................................................................................................................................................73

Edge Detection Service Tool Screen....................................................................................................................................... 74

Debug Signals............................................................................................................................................................................75

Extract Ring Service Tool Screen.............................................................................................................................................. 76

Inputs and Outputs..................................................................................................................................................................77

Scanned Data.............................................................................................................................................................................78

Feature Localization Service Tool Screen..............................................................................................................................79

Inputs............................................................................................................................................................................................ 80

Internals........................................................................................................................................................................................83

Outputs........................................................................................................................................................................................ 84

Obstacle Avoidance Service Tool Screen.............................................................................................................................. 85

Inputs ........................................................................................................................................................................................... 86

Internals........................................................................................................................................................................................87

Outputs........................................................................................................................................................................................ 88

Obstacle Detection Service Tool Screen................................................................................................................................89

Inputs............................................................................................................................................................................................ 89

Internals and Outputs ............................................................................................................................................................ 90

4 | © Danfoss | January 2020 AQ295075513101en-000101

Page 5

User Manual

PLUS+1® Function Block Library—Autonomous Control Function Blocks

Contents

Origin Service Tool Screen..........................................................................................................................................................91

Debug Signals............................................................................................................................................................................92

Path Follower Service Tool Start Screen................................................................................................................................ 94

Debug Signals............................................................................................................................................................................95

Waypoints Info...........................................................................................................................................................................96

Control Points Info................................................................................................................................................................... 97

Position Filter Service Tool Start Screen................................................................................................................................ 98

Debug Signals............................................................................................................................................................................99

Standard Deviation................................................................................................................................................................100

Post Detection Service Tool Start Screen............................................................................................................................101

Debug Signals......................................................................................................................................................................... 102

Projected Path Service Tool Screen...................................................................................................................................... 103

Inputs..........................................................................................................................................................................................103

Internals and Outputs...........................................................................................................................................................104

Coordinates and Score.........................................................................................................................................................105

Reflector Detection Service Tool Screen.............................................................................................................................106

Inputs..........................................................................................................................................................................................106

Outputs......................................................................................................................................................................................107

Features Location...................................................................................................................................................................108

Standard Deviation................................................................................................................................................................108

Relative Position Service Tool Screen...................................................................................................................................109

Debug Signals......................................................................................................................................................................... 110

Two Point Planner Service Tool Screen............................................................................................................................... 111

Inputs .........................................................................................................................................................................................112

Waypoints Info........................................................................................................................................................................ 113

Control Points Info.................................................................................................................................................................114

Internal Signals........................................................................................................................................................................115

Outputs......................................................................................................................................................................................116

UTM Conversion Service Tool Start Screen........................................................................................................................117

Debug Signals......................................................................................................................................................................... 117

UTM Conversion Zone Service Tool Start Screen.............................................................................................................118

Debug Signals......................................................................................................................................................................... 119

Wall Detect Service Tool Start Screen.................................................................................................................................. 120

Debug Signals......................................................................................................................................................................... 121

Yaw Estimate Service Tool Screen.........................................................................................................................................122

Inputs .........................................................................................................................................................................................123

Outputs......................................................................................................................................................................................123

©

Danfoss | January 2020 AQ295075513101en-000101 | 5

Page 6

User Manual

PLUS+1® Function Block Library—Autonomous Control Function Blocks

Library Introduction

The autonomous control function block library offers a quick and easy way to develop PLUS+1® GUIDE

applications that provide the foundation for autonomous machine control systems.

Using the function blocks in this library, developers can create applications that allow machines to

navigate environments without an operator.

Autonomous machine applications are comprised of several core sub-systems built with the autonomous

control function blocks:

•

Localization: One of the core functions of the Autonomous Control Library is to provide accurate

positioning information to Navigation sub-systems. The function blocks listed below aid in

localization.

•

Navigation: The Path_Follower function block helps autonomous machines reach their destination.

•

Perception: Radar systems, laser-based (LiDAR) systems, and ultrasonic sensors can help the

autonomous machine avoid obstacles in its path.

Localization

The physical location of the machine, over time, must be determined so the machine can operate

autonomously.

When processed by a Position Filter, data from a Global Navigation Satellite System (GNSS), Inertial

Measurement Units (IMU), steering angle sensors, and wheel speed sensors can produce a constant and

reliable estimate of a machine's location.

The Autonomous Control function block library uses a Position_Filter to provide a method to combine

GNSS data, IMU data, and odometry data. The Position_Filter function block processes the combined

data to produce an improved estimate of the autonomous machine's position and orientation over time.

To produce location estimates, the Position Filter requires sensor data to be formatted to fit standard

conventions. For example, raw GPS data is conventionally reported in latitude and longitude. The data

must be transformed into the Universal Transverse Mercator (UTM) coordinate system.

The Autonomous Control Library supplies the UTM_Conv, Origin and the Relative_Pos function blocks

to format the data properly for the Position Filter to use.

The UTM Conversion blocks (with and without zone selection) are used to convert from latitude and

longitude to the UTM coordinate frame. The Origin function block captures the starting UTM position of

the machine.

The Relative_Pos is stored as X (East being positive) and Y (North being positive) distance from the

Origin in millimeters. This simplifies operations for downstream blocks, so calculations do not need to be

done on raw latitude and longitude values.

The Ackermann_Yaw_Rate function block uses steering and speed sensor data to form a machinecentric odometry pair. Sensor standard deviation is used in the covariance matrix in the Position Filter.

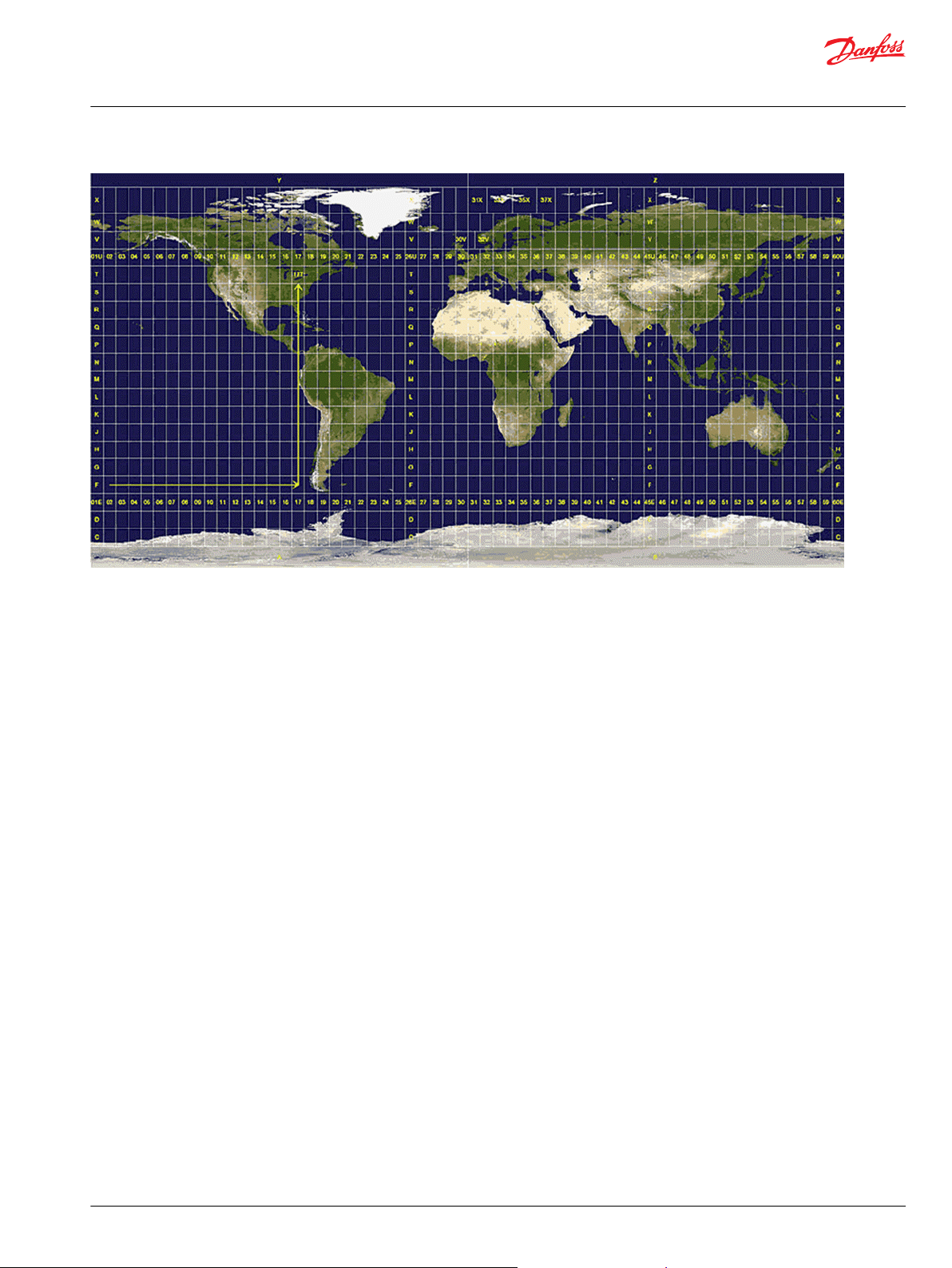

UTM is the coordinate information of the latitude and longitude information of the earth into a plane

coordinate system. The East and West directions are divided into 60 zones, with each zone being 6

degrees. Further, each zone is divided into a band every 8 degrees in the latitude direction, using the

labels C to X. The letters I and O are not used, to avoid their potential confusion with the numbers one (1)

and zero (0). A, B, Y, and Z represent two polar regions.

6 | © Danfoss | January 2020 AQ295075513101en-000101

Page 7

User Manual

PLUS+1® Function Block Library—Autonomous Control Function Blocks

Library Introduction

UTM grid zones on a projected map of the world © Wikimedia Commons

Navigation

The Path_Follower function block compares the current machine position to the desired path and

provides a steering curvature command to bring the machine to the path.

The path is made up of one or more connected Bézier curves. The Bézier curves connect the waypoints to

make the path.

By using Bézier curves, the number of points used to define the path is reduced. This lowers computation

time and needed memory, while retaining the ability to navigate a complex path.

The Path_Follower function block uses a configurable look-ahead distance that determines how the

machine calculates its steering correction commands to reach the intended path. It also allows for

looping and non-looping paths and contains a Search_Path feature to locate the nearest point on the

path when the machine is not on the path.

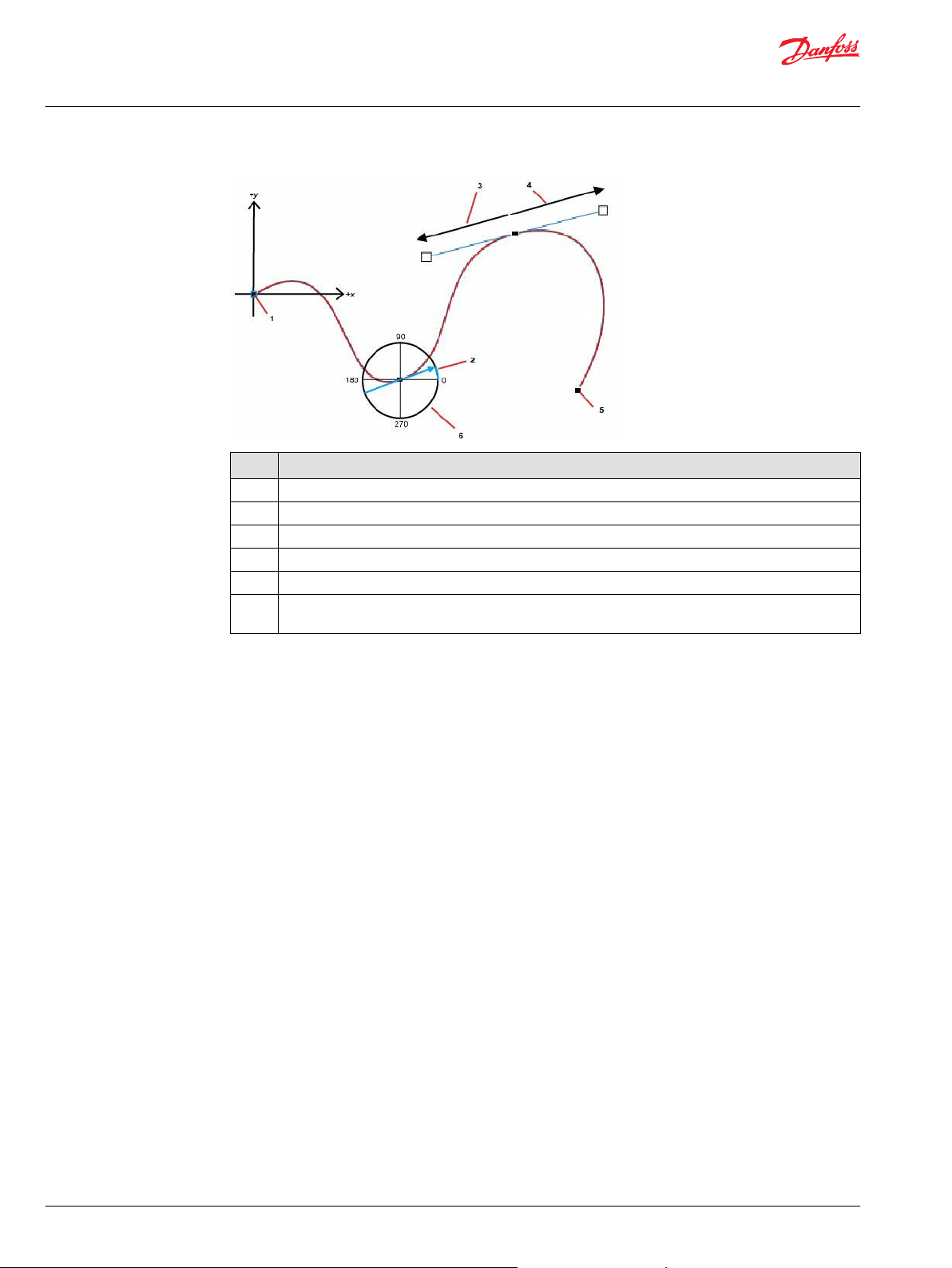

The figure that follows shows a basic path, as well as the components that make up the waypoints on the

path, such as the Relative X Coordinate, Relative Y Coordinate, Bearing, Backward Radius, and Forward

Radius. The Bearing is the angle at which the machine should pass through the waypoint. The curve

between two waypoints is weighted by the length of the Forward Radius of the first point and the

Backward Radius of the second point.

©

Danfoss | January 2020 AQ295075513101en-000101 | 7

Page 8

User Manual

PLUS+1® Function Block Library—Autonomous Control Function Blocks

Library Introduction

Item Description

1 Origin

2 Bearing

3 Backward Radius

4 Forward Radius

5 Waypoint

6 East-North-Up (ENU) Notation.

0 (East), 90 (North), 180 (West), 270 (South)

Perception

An autonomous machine requires sensors to detect and avoid obstacles during navigation.

CAN-based sensors can easily integrate with the Autonomous Control Library. Radar systems are well

suited to detect obstacles for autonomous machines due to their ability to operate in harsh conditions.

LiDAR systems can also provide some obstacle data on CAN, due to their more accurate distance

readings.

Ultrasonic sensors can detect objects that are in close range to the autonomous machine. With their

conical detection zone and an offering of a scalar distance value to the nearest object, these sensors are

useful for emergency braking and in safety curtain scenarios.

8 | © Danfoss | January 2020 AQ295075513101en-000101

Page 9

User Manual

PLUS+1® Function Block Library—Autonomous Control Function Blocks

Library Introduction

Errata

You can successfully compile applications that use the blocks in PLUS+1® GUIDE version 12.2 and later.

Change Namespace Value

To successfully compile your application, change the namespace value for function blocks that are used

more than once in an application.

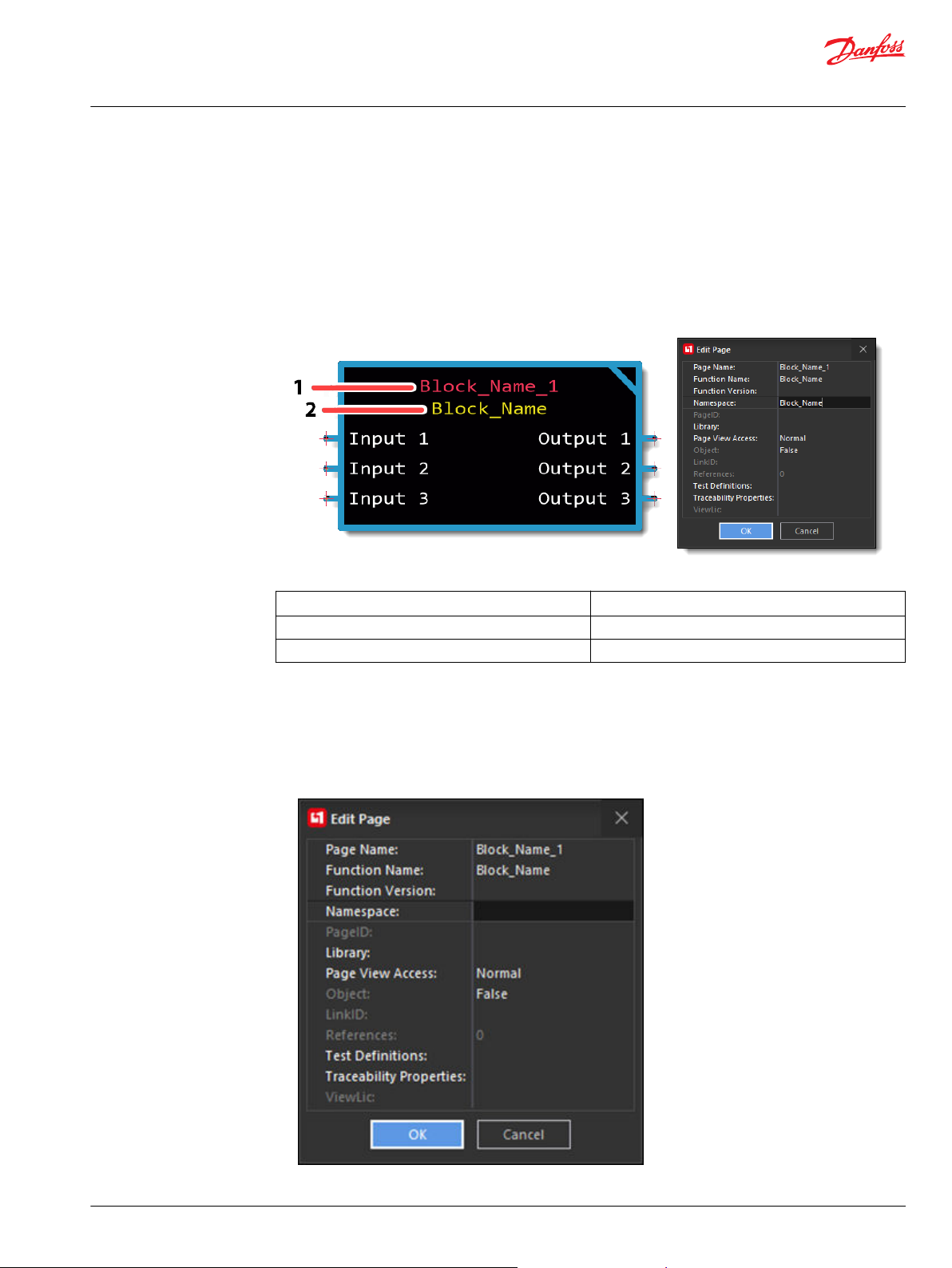

Callout Description

1 Page Name

2 Namespace

1. Enable Query/Change mode.

Select Edit > Query/Change.

•

Or, press Q.

•

2. Click on the function block whose namespace you want to modify.

The Edit Page dialog box opens.

3. In the Namespace field, enter a unique Namespace value.

©

Danfoss | January 2020 AQ295075513101en-000101 | 9

Page 10

User Manual

PLUS+1® Function Block Library—Autonomous Control Function Blocks

Library Introduction

Namespace values are case-sensitive.

•

To save controller memory, use a short namespace value.

•

4. Click OK.

5. Repeat these steps to enter unique namespace values for other identical function blocks.

ACL Acronyms

Acronyms used in the library user manual are described.

Acronym Meaning

ACL Autonomous Control Library

CAN Controller Area Network

ECU Electronic Control Unit

EKF Extended Kalman Filter

ENU East/North/Up

GNSS Global Navigation Satellite System

GPS Global Positioning System

IMU Inertial Measurement Unit

LiDAR Light Detection and Ranging

UTM Universal Transverse Mercator

10 | © Danfoss | January 2020 AQ295075513101en-000101

Page 11

User Manual

PLUS+1® Function Block Library—Autonomous Control Function Blocks

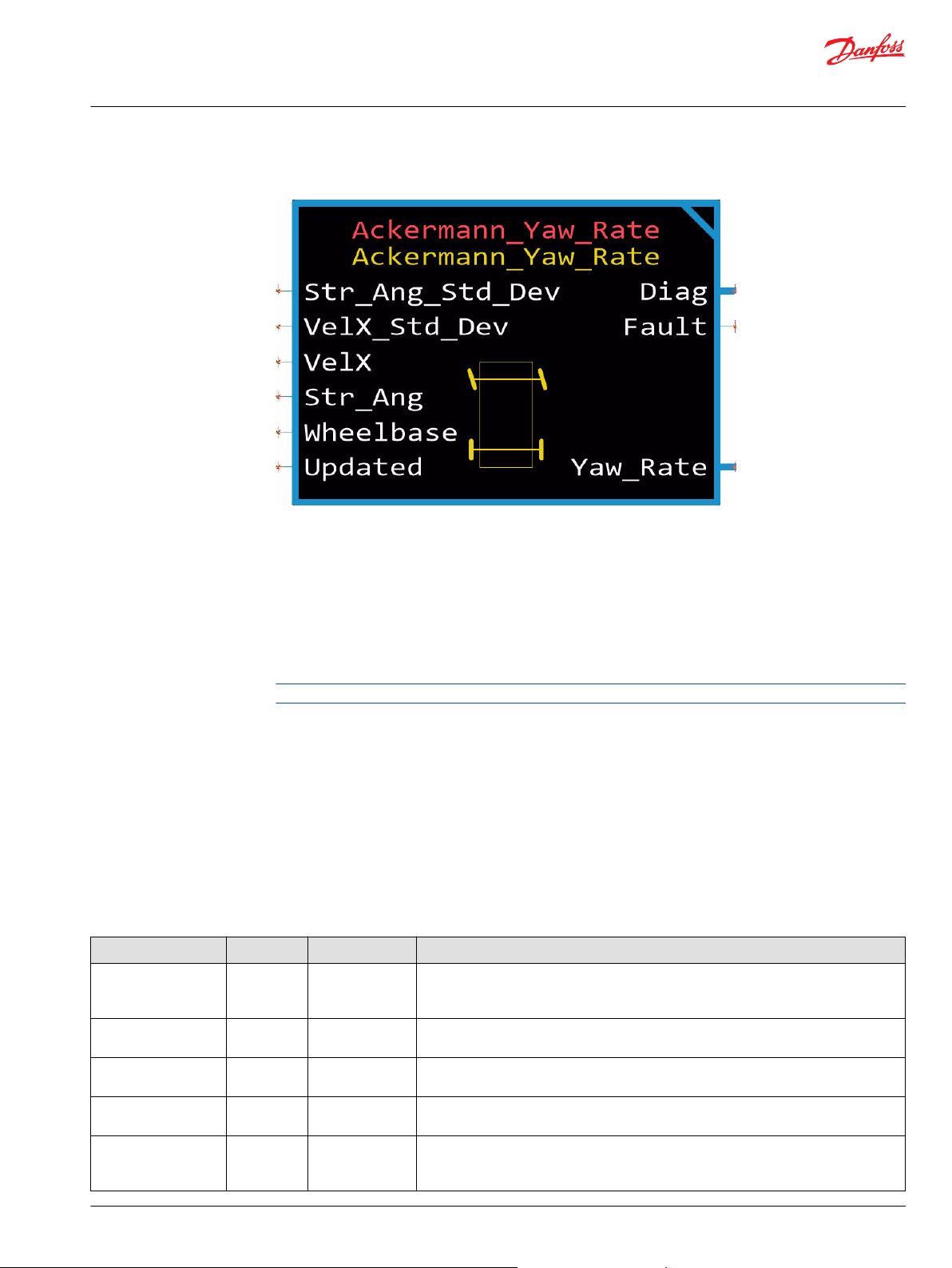

Ackermann Yaw Rate Function Block

The Ackermann Yaw Rate function block provides yaw rate information to the Position Filter.

The function block converts machine speed and steering angle into a velocity and yaw rate machinecentric odometry pair.

The pair consists of the linear velocity (meters/second) and the angular velocity (degrees/second). The

values are defined relative to a coordinate frame which has its origin on the center of the rear axle with

the X-axis pointing forward along the machine, Y pointing left along the axle and Z pointing upwards.

•

The X-axis points forward along the machine.

•

The Y-axis points left along the axle.

•

The Z-axis points up.

Input data types must exactly match the indicated type to successfully compile.

The checkpoints page includes advanced checkpoints for each input, output, and internal signal. These

require a unique name space to prevent multiple checkpoints with the same name. See the topic Change

Namespace Value for more information about creating unique namespaces.

Sensor variance—the noise observed in sensor data—can be manually set if it is not provided by the

sensor.

The standard deviation of a sensor characterizes the amount of noise in the sensor. This is obtained from

sensor documentation of manually calculating from a log of steady-state sensor data.

Inputs

Inputs to the Ackermann Yaw Rate function block are described.

Item Type Range Description [Unit]

Chkpt BOOL T/F Enables advanced checkpoints with namespace for each Diag signal.

T: Include checkpoints when compiled.

F: Do not include checkpoints when compiled.

Str_Ang_Std_Dev U32 1-4294967295 The standard deviation of the steering angle.

[0.01 degree]

VelX_Std_Dev U32 1-4294967295 The standard deviation of VelX.

[mm/s]

VelX S32 -25000-25000 The linear velocity of the machine.

[mm/s]

Str_Ang

S16

-7000-7000 The angle between the front of the machine and the steered wheel direction.

Negative values are to the right. Positive values are to the left.

[0.01 degree]

©

Danfoss | January 2020 AQ295075513101en-000101 | 11

Page 12

User Manual

PLUS+1® Function Block Library—Autonomous Control Function Blocks

Ackermann Yaw Rate Function Block

Item Type Range Description [Unit]

Wheelbase

Updated BOOL T/F TRUE when there is new data.

Outputs

Item Type Range Description [Unit]

Diag BUS ——

Fault U16 —— Bitwise code where multiple items can be reported at a time.

Yaw_Rate BUS ——

Yaw_Rate_Std_Dev U32 1-4294967295 The standard deviation of Yaw_Rate.

U16 300-20000 The distance between the centers of the front and rear wheels.

[mm]

T: New data is ready.

F: New data is not ready.

Outputs of the Ackermann Yaw Rate function block are described.

Provides diagnostic values for troubleshooting.

0x0000: No fault.

0x8001: Input value too low.

0x8002: Input value too high.

This bus contains Yaw Rate and its standard deviation data.

Yaw_Rate S32 -1312080-1312080 The angular velocity of the machine relative to the machine's vertical axis.

[0.01 deg/s]

[0.01 deg/s]

Updated BOOL T/F TRUE when new data is available from the conversion.

T: New data is available.

F: New data is not available.

12 | © Danfoss | January 2020 AQ295075513101en-000101

Page 13

User Manual

PLUS+1® Function Block Library—Autonomous Control Function Blocks

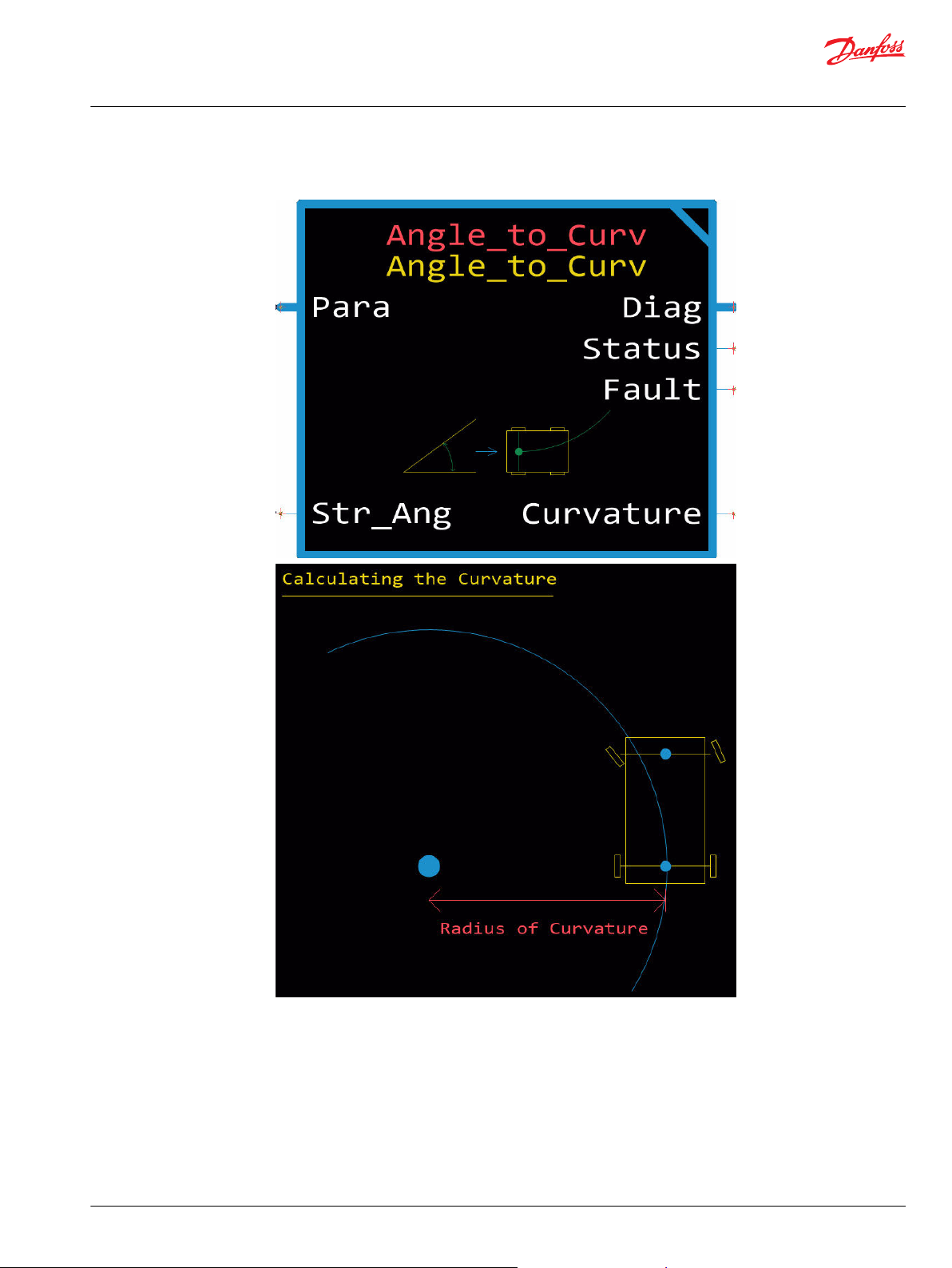

Angle to Curvature Function Block

The Angle to Curvature function block converts a steering angle to curvature.

©

Danfoss | January 2020 AQ295075513101en-000101 | 13

Page 14

User Manual

PLUS+1® Function Block Library—Autonomous Control Function Blocks

Angle to Curvature Function Block

Inputs

The following table describes the inputs of the Angle to Curve function block.

Item Type Range Description [Unit]

Chkpt BOOL T/F Enables advanced checkpoints with

namespace for each Diag signal.

T: Include checkpoints when

compiled.

F: Do not include checkpoints when

compiled.

Str_Ang

Parameters

S16 -9000 to 9000 The angle between the front of the

machine and the steered wheel

direction.

Negative values are to the right.

Positive values are to the left.

[0.01 deg]

The following table describes the parameters of the Angle to Curve function block.

Item Type Range Description [Unit]

Para BUS

Wheelbase

U16 300 to 20000 The distance between the centers of

--

Adjust configuration values here, or

replace them with signals routes

from the application through the

Para BUS.

the front and rear wheels.

[mm]

Default: 5000

Outputs

The following table describes outputs for the function block.

Item Type Range Description [Unit]

Diag BUS —— Bus containing diagnostic values for

troubleshooting. In addition, all

inputs, parameters, and output

signals are contained inside of the

bus.

Status U16 —— Bitwise code where multiple items

can be reported at a time.

0x0000: Status OK.

0x8008: At least one parameter is

out of range.

Fault U16 —— Bitwise code where multiple items

can be reported at a time.

0x0000: No fault.

0x8001: Input value too low.

0x8002: Input value too high.

Curvature

S32

-2,147,483,648 to 2,147,483,647

Curvature calculated based on the

steering angle and wheelbase of the

machine.

Negative values are right curves.

Positive values are left curves

[0.01/km]

14 | © Danfoss | January 2020 AQ295075513101en-000101

Page 15

User Manual

PLUS+1® Function Block Library—Autonomous Control Function Blocks

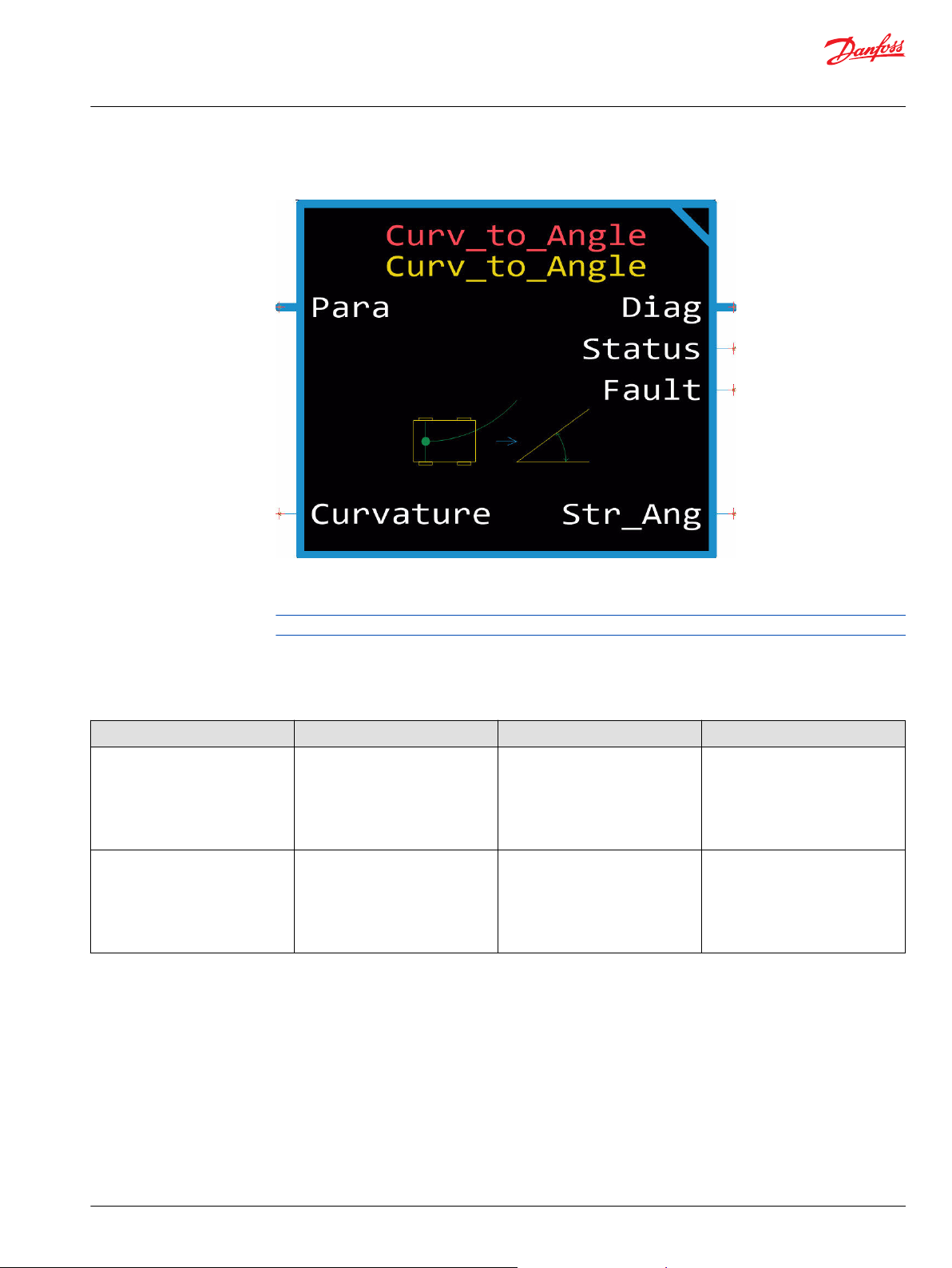

Curvature to Angle Function Block

The Curvature_to_Angle function block converts curvature to steering angle.

To get the steering angle from the Curvature_to_Angle function block you provide a curvature input in

0.01/km and a wheelbase parameter in mm.

Input data types must exactly match the indicated type to successfully compile.

Inputs

The following table describes inputs for the Curve to Angle function block.

Item Type Range Description [Unit]

Curvature

Chkpt BOOL T/F Enables Advanced Checkpoints with

S32

-2,147,483,648 to 2,147,483,647

Curvature calculated based on the

steering angle and wheelbase of the

machine.

Negative values are right curves.

Positive values are left curves

[0.01/km]

Namespace for each Diag signal.

T: Include checkpoints when

compiled.

F: Do not include checkpoints when

compiled.

©

Danfoss | January 2020 AQ295075513101en-000101 | 15

Page 16

User Manual

PLUS+1® Function Block Library—Autonomous Control Function Blocks

Curvature to Angle Function Block

Parameters

The following table describes parameters for the Curve to Angle function block.

Item Type Range Description [Unit]

Para BUS —— Adjust configuration values here, or

replace them with signals routed

from the application through the

Para BUS.

Wheelbase

Outputs

Item Type Range Description [Unit]

Diag BUS —— Bus containing diagnostic data for

Status U16 —— Reports the status of the function

Fault U16 —— Reports the fault status of the

Str_Angle

U16 300 to 20000 The distance between the centers of

the front and rear wheels.

Default: 5000

[mm]

The following table describes outputs for the Curve to Angle function block.

the function block.

block.

0x0000: Status OK.

0x8008: At least one parameter is

out of range.

function block.

0x0000: No fault.

0x8001: Input value too low.

0x8002: Input value too high.

S16 -9000 to 9000 The angle between the front of the

machine and the steered wheel

direction.

Negative values are right curves.

Positive values are left curves

[0.01 deg]

16 | © Danfoss | January 2020 AQ295075513101en-000101

Page 17

User Manual

PLUS+1® Function Block Library—Autonomous Control Function Blocks

Edge Detection Function Block

The Edge Detect function block analyzes the incoming LiDAR scan and parses the data to look for a an

edge between two continuous features.

The edge appears as a discontinuity in the LiDAR scan. This can be used to find any generic edge of a

smooth feature such as a wall or garage door, and it is able to parse the scan from either direction, limit

the range of the scan and the size of the feature to help find more specific features.

Input data types must exactly match the indicated type to successfully compile.

The following table describes the limitations of the function block.

©

Danfoss | January 2020 AQ295075513101en-000101 | 17

Page 18

User Manual

PLUS+1® Function Block Library—Autonomous Control Function Blocks

Edge Detection Function Block

Item Description

Parse Direction The parsing direction is determined by the values chosen for the start and

stop angles. If the start angle is less than the stop angle, the parsing occurs

counter-clockwise. If the start angle is greater than the stop angle, the

parsing occurs clockwise.

Falling Edge The algorithm is designed to find a falling edge within the LiDAR scan

where the distance return values are suddenly much farther away or

disappear. This is not designed to find an interior corner where the returns

appear closer.

Inputs

Inputs to the Edge Detection function block are described.

The Parsing Direction is determined by the values chosen for the Start and Stop angles. If the Start Angle

is less than the Stop Angle the parsing occurs from right to left. If the Start Angle is greater then the Stop

angle the parsing occurs from left to right.

The algorithm is designed to find a Falling Edge within the LiDAR scan where the returns are suddenly

much farther away or disappear. This is not designed to find an interior corner where the returns appear

closer.

18 | © Danfoss | January 2020 AQ295075513101en-000101

Page 19

User Manual

PLUS+1® Function Block Library—Autonomous Control Function Blocks

Edge Detection Function Block

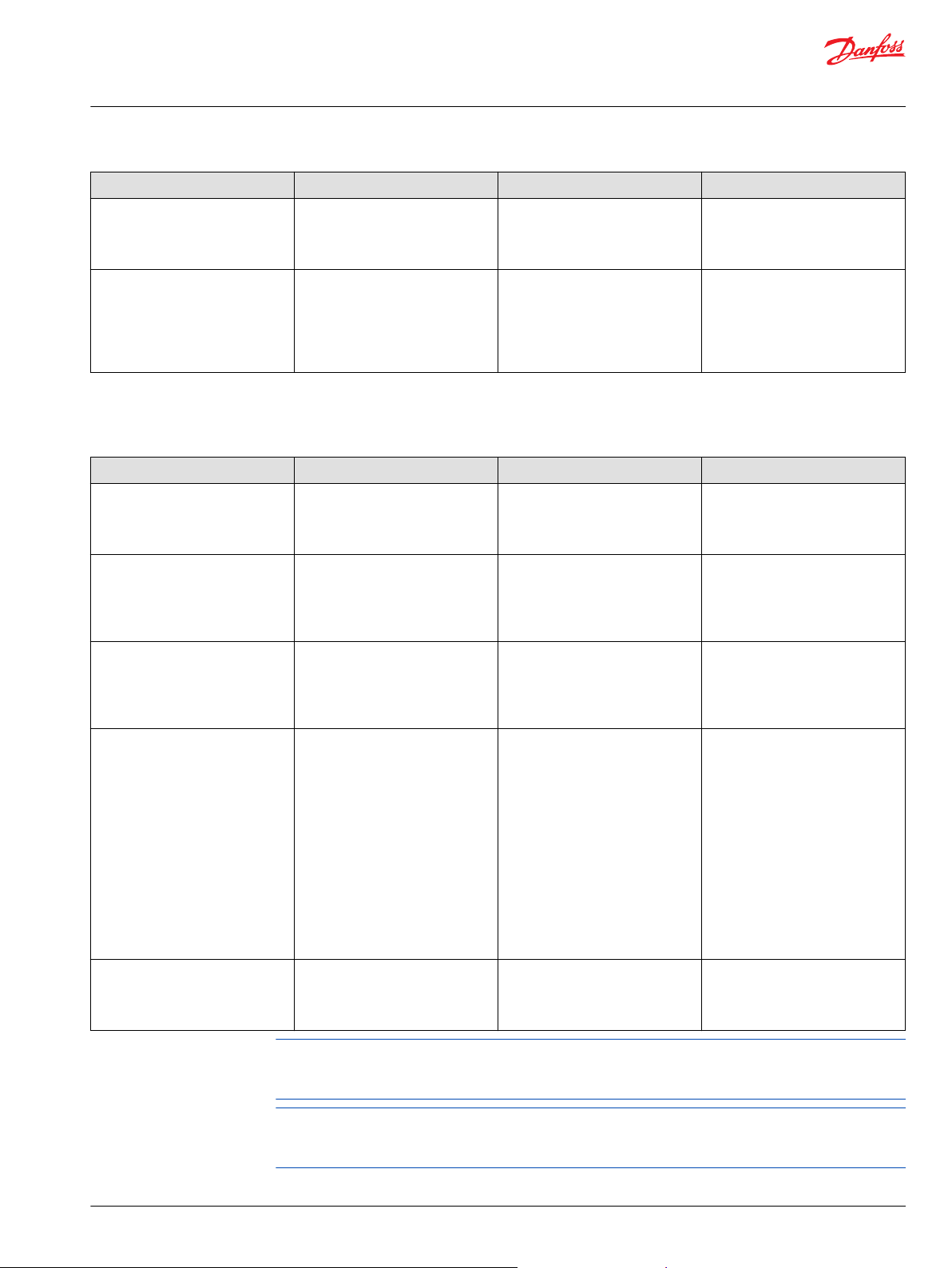

Item Type Range Description

Locker_ID

Chkpt BOOL T/F Enables Advanced Checkpoints with

Parameters

Item Type Range Description [Unit]

Para BUS —— Adjust configuration values here, or

Start_Angle S32 -18000-18000 Specifies which beam of the LiDAR

Stop_Angle S32 -18000-18000 Specifies which beam of the LiDAR

Min_Feature_Size U16 1-60000 Determines how large of an object is

S8 -1-99 Non-negative ID gives location for

point cloud data to be retrieved

from.

-1: Will not process new LiDAR scan.

Namespace for each Diag signal.

T: Include checkpoints when

compiled.

F: Do not include checkpoints when

compiled.

The Edge Detection function block's operating characteristics are set by para bus input signals.

replace them with signals routed

from the application through the

Para Bus.

scan to use to start parsing for an

edge.

Default: 0

[0.01 deg]

scan to use to stop parsing for an

edge.

Default: 18000

[0.01 deg]

required to be identified as a

continuous surface Determines how

large of an object is required to be

identified as a continuous surface

before finding the falling edge. This

can be used to filter out noise from

the sensor or ignore very small

objects.

This can be used to filter out noise

from the sensor or ignore very small

objects.

Default: 1000

[mm]

Ring

U16 0-65535 For 3D LiDAR which ring, or

horizontal row of the scan to use.

For 2D LiDAR set to zero.

Default: 0

Parse Direction: The parsing direction is determined by the values chosen for the Start and Stop Angles. If

the Start Angle is less than the Stop angle the parsing will occur from right to left. If the Start Angle is

greater than the Stop Angle the parsing will occur from left to right.

Edge Detection: The algorithm is designed to find a 'falling edge' within the LiDAR scan where the returns

are suddenly much farther away or disappear. This is not designed to find an interior corner where the

returns would appear closer.

©

Danfoss | January 2020 AQ295075513101en-000101 | 19

Page 20

User Manual

PLUS+1® Function Block Library—Autonomous Control Function Blocks

Edge Detection Function Block

Outputs

Outputs of the Edge Detection function block are described.

Item Type Range Description [Unit]

Diag U16 —— This bus provides diagnostic values

for troubleshooting and information

about the current status of the

sensor.

Status U16 —— Bitwise code where multiple items

can be reported at a time.

0x0000: Status OK.

0x8008: At least one parameter is

out of range.

Fault U16 —— Reports the fault status of the

function block.

Bitwise code where multiple items

can be reported at a time.

0x0000: No fault.

0x8001: Input value too low.

0x8002: Input value too high.

Edge BUS —— The Edge bus contains the updated

information about the location of

the detected edge.

Updated BOOL T/F Indicates that new information is

available from the block.

T: Edge detected.

F: Edge not detected.

Distance U32 1-4294967295 Distance from the edge in radial

coordinates.

[mm]

Angle S16 -18000-18000 Angle to the edge in radial

coordinates.

[0.01 deg]

Edge_X S32 -2147483648-2147483647 X coordinate of the edge relative to

the scanner.

[mm]

Edge_Y S32 -2147483648-2147483647 Y coordinate of the edge relative to

the scanner.

[mm]

20 | © Danfoss | January 2020 AQ295075513101en-000101

Page 21

User Manual

PLUS+1® Function Block Library—Autonomous Control Function Blocks

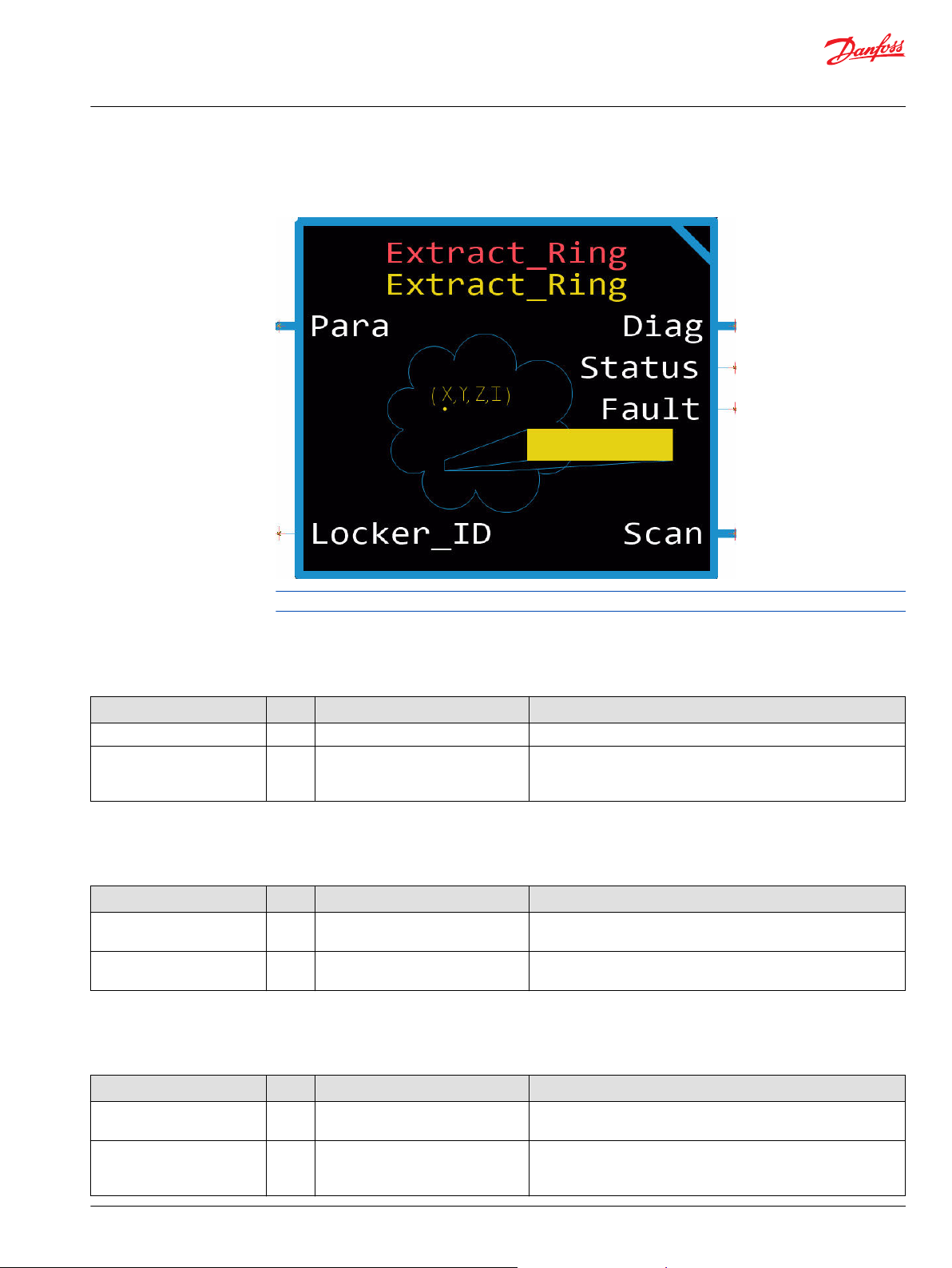

Extract Ring Function Block

The Extract_Ring function block is used to extract a ring of information from the latest LiDAR point cloud

object found inside a data locker.

Input data types must exactly match the indicated type to successfully compile.

Inputs

Inputs to the Extract Ring function block are described.

Item Type Range Description [Unit]

Locker_ID

Chkpt BOOL T/F Enables advanced checkpoints with namespace for each Diag signal.

S8 -1-99 Location where LiDAR scan data is stored.

T: Include checkpoints when compiled.

F: Do not include checkpoints when compiled.

Parameters

Parameters to the Extract Ring function block are described.

Item Type Range Description [Unit]

Para BUS —— Adjust configuration values here, or replace them with signals routed

from the application through the Para bus.

Ring

U16 0 - Number of rings - 1. Ring to extract data from point cloud. For 2D LiDAR set ring to 0

Default: 0

Outputs

Outputs of the Extract Ring are described.

Item Type Range Description [Unit]

Diag BUS —— This bus provides diagnostic values for troubleshooting and

information about the current status of the sensor.

Status

©

Danfoss | January 2020 AQ295075513101en-000101 | 21

U16 —— Bitwise code where multiple items can be reported at a time.

0x0000: Status OK.

0x8008: At least one parameter is out of range.

Page 22

User Manual

PLUS+1® Function Block Library—Autonomous Control Function Blocks

Extract Ring Function Block

Item Type Range Description [Unit]

Fault

Scan

Updated

Num_Points

U16 —— Bitwise code where multiple items can be reported at a time.

0x0000: No fault.

0x8001: Input value too low.

0x8002: Input value too high.

BUS —— The output data of the read from the Data Locker.

BOOL —— True if new data was processed.

U16 0-2048 Number of points in the row.

X (Array[

2048]S

32)

Y (Array[

2048]S

32)

Z (Array[

2048]S

32)

I (Array[

2048]U

16)

-2147483648-2147483647 X coordinate of point in Cartesian coordinates.

[mm]

-2147483648-2147483647 Y coordinate of point in Cartesian coordinates.

[mm]

-2147483648-2147483647 Z coordinate of point in Cartesian coordinates.

[mm]

0-10000

intensity values of points.

22 | © Danfoss | January 2020 AQ295075513101en-000101

Page 23

User Manual

PLUS+1® Function Block Library—Autonomous Control Function Blocks

Feature Localization Function Block

The Feature Localization function block is used to update the location of the machine within a known

environment. This block compares the Map of known features with Detected features and estimates

machine position based on the result of comparison.

Input data types must exactly match the indicated type to successfully compile.

The checkpoints page includes advanced checkpoints for each input, output, and internal signal. These

require a unique name space to prevent multiple checkpoints with the same name. See the topic Change

Namespace Value for more information about creating unique namespaces.

Inputs

Inputs to the Feature Localization function block are described.

Item Type Range Description [Unit]

Map_Features BUS —— These features correspond to

detectable objects in the

environment. They must be in a Map

or global reference frame.

(corresponding to the origin for the

Position).

X (Array[100]S32) -2147483648-2147483647 X components of the center of

detectable features.

[mm]

Y (Array[100]S32) -2147483648-2147483647 Y components of the center of

detectable features.

[mm]

Num_Features U16 0-100 Number of features in the arrays.

Detected_Features BUS —— These are the features detected by

other blocks which should

correspond to Map_Features. They

must be in the machine reference

frame.

Updated

BOOL T/F TRUE when there is new X, Y, and

features to be used for localization.

T: The data is new and valid.

F: The data is not valid, do not use.

©

Danfoss | January 2020 AQ295075513101en-000101 | 23

Page 24

User Manual

PLUS+1® Function Block Library—Autonomous Control Function Blocks

Feature Localization Function Block

Item Type Range Description [Unit]

X

(Array[S32]100) -2147483648-2147483647 X components of center of features

found.

[mm]

Y

(Array[S32]100) -2147483648-2147483647 Y components of center of features

found.

[mm]

Num_Features

Position

Chkpt BOOL T/F Enables advanced checkpoints with

U16 0-100 Number of features in the arrays.

BUS —— This is the position of the machine in

the map or global reference frame.

X S32 -2147483648-2147483647 The Cartesian X component in the

map frame.

[mm]

Y S32 -2147483648-2147483647 The Cartesian Y component in the

map frame.

[mm]

Yaw S32 -72000-72000 The Cartesian Yaw component in

the map frame. The angle used to

describe the machine's heading

using the ENU reference frame.

[0.01 deg]

namespace for each Diag signal.

T: Include checkpoints when

compiled.

F: Do not include checkpoints when

compiled.

Parameters

Parameters to the Feature Localization function block are described.

Item Type Range Description [Unit]

Para BUS —— Adjust configuration values here, or

replace them with signals routed

from the application through the

Para bus.

Distance_Error

Num_Checks

Sensor_Range_Std_Dev

Sensor_Angular_Std_Dev

U16 1-1000 The distance within which to match

the feature. Features will not be

matched if it is farther than this

distance.

Default: 500

[mm]

U16 2-100 Maximum number of matched map

features. Once these many features

are matched, farther features will

not be checked. Lowering this can

improve the processing time.

Default: 100

U16 1-1000 Standard deviation of LiDAR range.

Default: 10

[mm]

U16 1-1000 Angular standard deviation or

angular resolution of LiDAR.

Default: 20

[0.01 deg]

24 | © Danfoss | January 2020 AQ295075513101en-000101

Page 25

User Manual

PLUS+1® Function Block Library—Autonomous Control Function Blocks

Feature Localization Function Block

Outputs

Outputs of the Feature Localization function block are described.

Item Type Range Description [Unit]

Diag U16 —— This bus provides diagnostic values

for troubleshooting and information

about the current status of the

sensor.

Status U16 —— Reports the status of the function

block.

0x0000: Status OK.

0x8008: At least one parameter is

out of range.

Fault U16 —— Bitwise code where multiple items

can be reported at a time.

0x0000: Status OK.

0x8001: Input value too low.

0x8002: Input value too high.

Lost

Pos_XY

X_Std_Dev

Y_Std_Dev

Updated BOOL T/F T: Indicates new and valid data,

Yaw BUS —— This bus provides machine yaw and

Yaw_Std_Dev U32 1-4294967295 The standard deviation of the Yaw

Updated BOOL T/F T: Indicates new and valid data,

BOOL T/F T: No Detected_Features matched

with Map_Features, within

Distance_Error.

F: One or more features matched.

BUS —— This bus provides estimated

machine position in the map and its

standard deviation. If no update, this

bus retains last updated data.

X

S32 -2147483648-2147483647 The estimated X position of the

machine in Map frame.

[mm]

Y

S32 -2147483648-2147483647 The estimated Y position of the

U32 1-4294967295 The standard deviation of the X

U32 1-4294967295 The standard deviation of the Y

Yaw

S32 -72000-72000 The angle used to describe the

machine in Map frame.

[mm]

value.

[mm]

value.

[mm]

without any status/fault errors.

F: Not valid data, no updated

detected features, no matches.

its standard deviation in the map

frame.

machine's heading using the ENU

reference frame.

[0.01 degree]

value.

[0.01 degree]

without any status/fault errors.

F: Not valid data.

©

Danfoss | January 2020 AQ295075513101en-000101 | 25

Page 26

User Manual

PLUS+1® Function Block Library—Autonomous Control Function Blocks

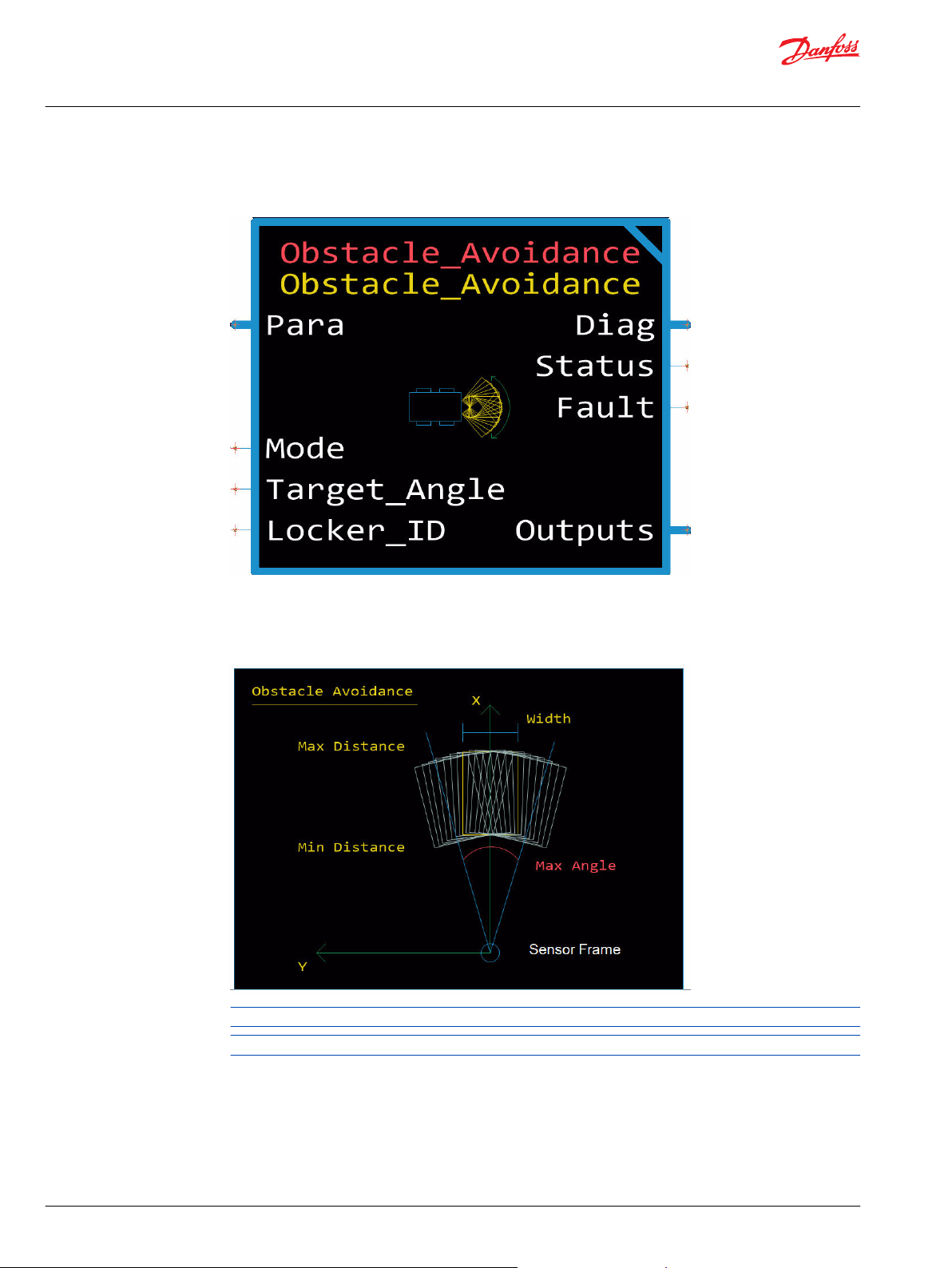

Obstacle Avoidance Function Block

The Obstacle_Avoidance function block simplifies the evaluation of an incoming LiDAR scan and

determines the best option.

The LiDAR scanner is typically placed at the front of a machine, but the Sensor_Offset parameters allow

for a variety of sensor placement. The function block places 15 zones radially within the defined

Max_Angle. This primary output is the Best_Angle, which is calculated based on the selected Mode. You

can use the raw zone scores for a more customized interpretation.

Input data types must exactly match the indicated type to successfully compile.

This is a safety block.

The checkpoints page includes advanced checkpoints for each input, output, and internal signal. These

require a unique name space to prevent multiple checkpoints with the same name.

26 | © Danfoss | January 2020 AQ295075513101en-000101

Page 27

User Manual

PLUS+1® Function Block Library—Autonomous Control Function Blocks

Obstacle Avoidance Function Block

Inputs

Inputs to the Obstacle Avoidance function block are described.

Item Type Range Description [Unit]

Mode U8 —— Selection of Best Angle calculation.

0: Raw, no additional processing of zone scores, Best_Angle =

lowest score, a tie goes to the Target_Angle.

1: Weighted, scaling and addition factors are applied to each zone

based on how far away they are from the Target_Angle.

2: Centered, designed for following a corridor and weighted to find

the most open space in the middle.

3: Nearest Acceptable, next closest angle to Target_Angle that

scores below the threshold unless Target_Angle is below the

threshold.

Target_Angle S16 -18000-18000 Desired angle for machine to drive.

[0.01 deg]

Locker_ID U8 -1-99 Location where LiDAR scan data is stored.

Chkpt BOOL T/F Enables Advanced Checkpoints with Namespace for each Diag

signal.

T: Include checkpoints when compiled.

F: Do not include checkpoints when compiled.

Parameters

The following table describes parameters for the Obstacle Avoidance function block.

Item Type Range Description [Unit]

Para BUS —— Adjust configuration values here, or replace them with signals routed

from the application through the Para bus.

Max_Angle U16 0-36000 Magnitude of max left to max right angle.

Default: 3000

[0.01 deg]

Width U16 1-20000 The width of a zone.

Default: 1000

[mm]

Threshold U16 1-10000 Higher limit of points for a zone to be invalid. Used only in mode 3.

Default: 10

[number of points]

Weight_Scale S16 -25000-25000 Scaling factor that is used to multiple the score of the zone. A

negative value steers toward the highest scoring zone.

Default: 1

[0.001]

Weight_Add U16 0-1000 Factor (Integer) that is adding to each zone after scaling factor is

applied.

Default: 0

Min_Distance U16 0-65000 Distance between the steering point of the machine and the start of

the zone.

Default: 0

[mm]

Max_Distance U16 1000-65000 Distance between the steering point of the machine and the end of

the zone.

Default: 1000

[mm]

©

Danfoss | January 2020 AQ295075513101en-000101 | 27

Page 28

User Manual

PLUS+1® Function Block Library—Autonomous Control Function Blocks

Obstacle Avoidance Function Block

Item Type Range Description [Unit]

Min_Height S32 -50000-50000 Minimum height of the zone with respect to the position of the

LiDAR scanner.

Default: 0

[mm]

Max_Height S32 -50000-50000 Maximum height of the zone with respect to the position of the

LiDAR scanner.

Default: 1000

[mm]

Sensor_Offset_[X,Y,Z] S32 —— Offset of the sensor from the desired sensor frame.

Default: 0

[mm]

Sensor_Orientation S16 -18000-18000 Orientation of the LiDAR sensor from the desired sensor frame.

Default: 0

[0.01 deg]

Outputs

Outputs of the Obstacle Avoidance function block are described.

Item Type Range Description [Unit]

Diag BUS —— This bus provides diagnostic values for troubleshooting and

information about the current status of the sensor.

Status U16 —— The status of the function block.

Bitwise code where multiple items can be reported at a time.

0x0000: Status OK.

0x8008: At least one parameter is out of range.

Fault U16 —— Bitwise code where multiple items can be reported at a time.

*Non-Standard

0x0000: No fault.

0x0001: Target_Angle or Mode value too low.

0x0002: Tarteg_Angle or Mode value too high.

0x0004: Locker_ID is invalid.

0x0008: Min_Distance is greater than Max_Distance.

0x0010: Min_Height is greater than Max_Height.

Outputs BUS —— This bus provides zone scores and resulting angle information.

Updated BOOL T/F New information is available from the block namespace for each

Diag signal.

T: New data is available.

F: New data is not available.

Scores

Total_Valid_Points

Zone_Angles

Best_Score

Best_Angle

(Array[

15]U32

)

U32 0-4294967295 Number of valid LiDAR scan points used in the analysis.

(Array[

15]S16)

U32 0-4294967295 Least points count in a single zone out of all the 15 zones.

S16 -32768-32767 Angle of the zone with the best score.

0-4294967295 Reports the number of points in each zone from the LiDar scan data.

[Count]

[Count]

-32768-32767 Array of the calculated orientation of each zone.

[Count]

[Count]

[0.01 deg]

28 | © Danfoss | January 2020 AQ295075513101en-000101

Page 29

User Manual

PLUS+1® Function Block Library—Autonomous Control Function Blocks

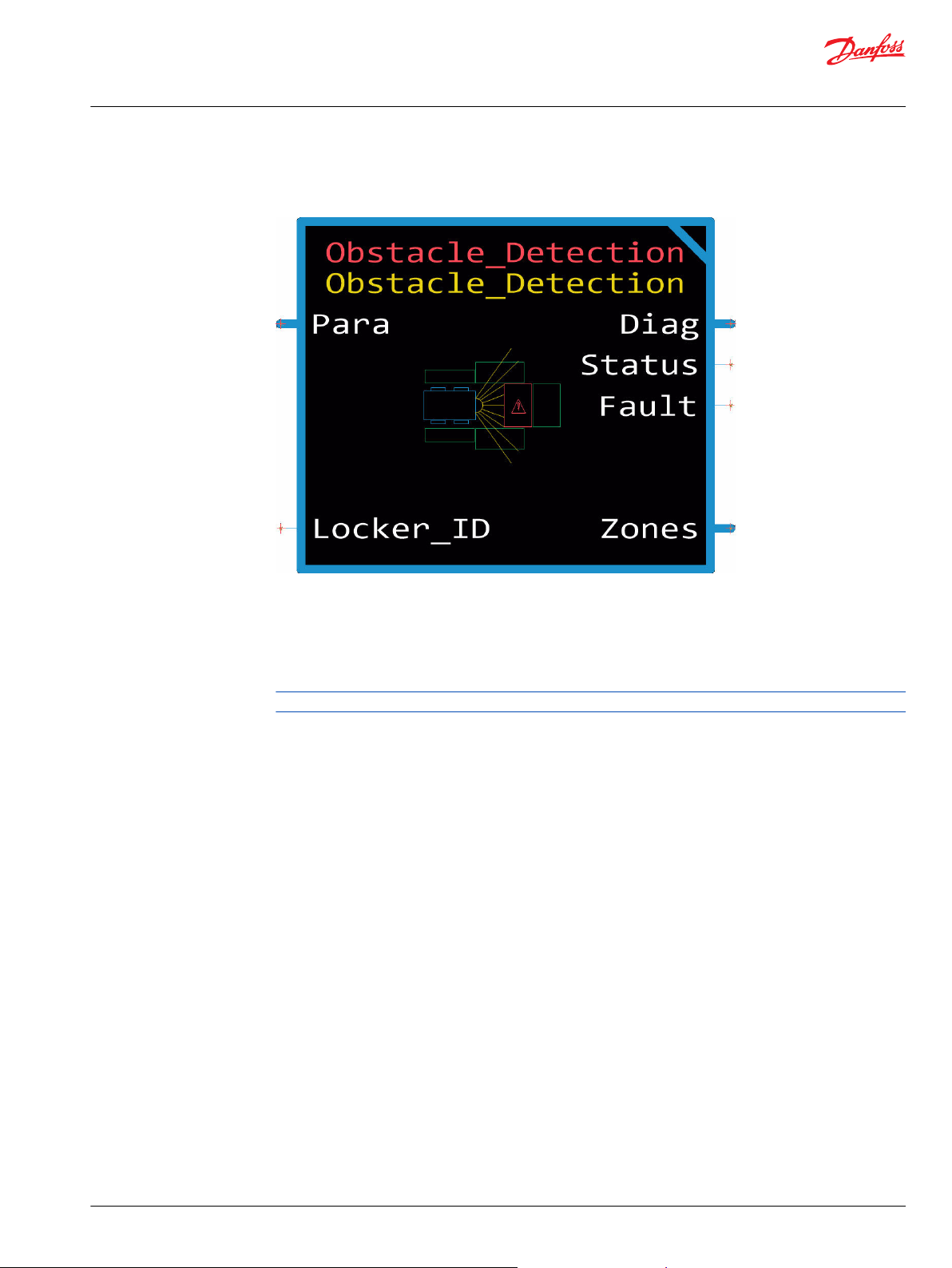

Obstacle Detection Function Block

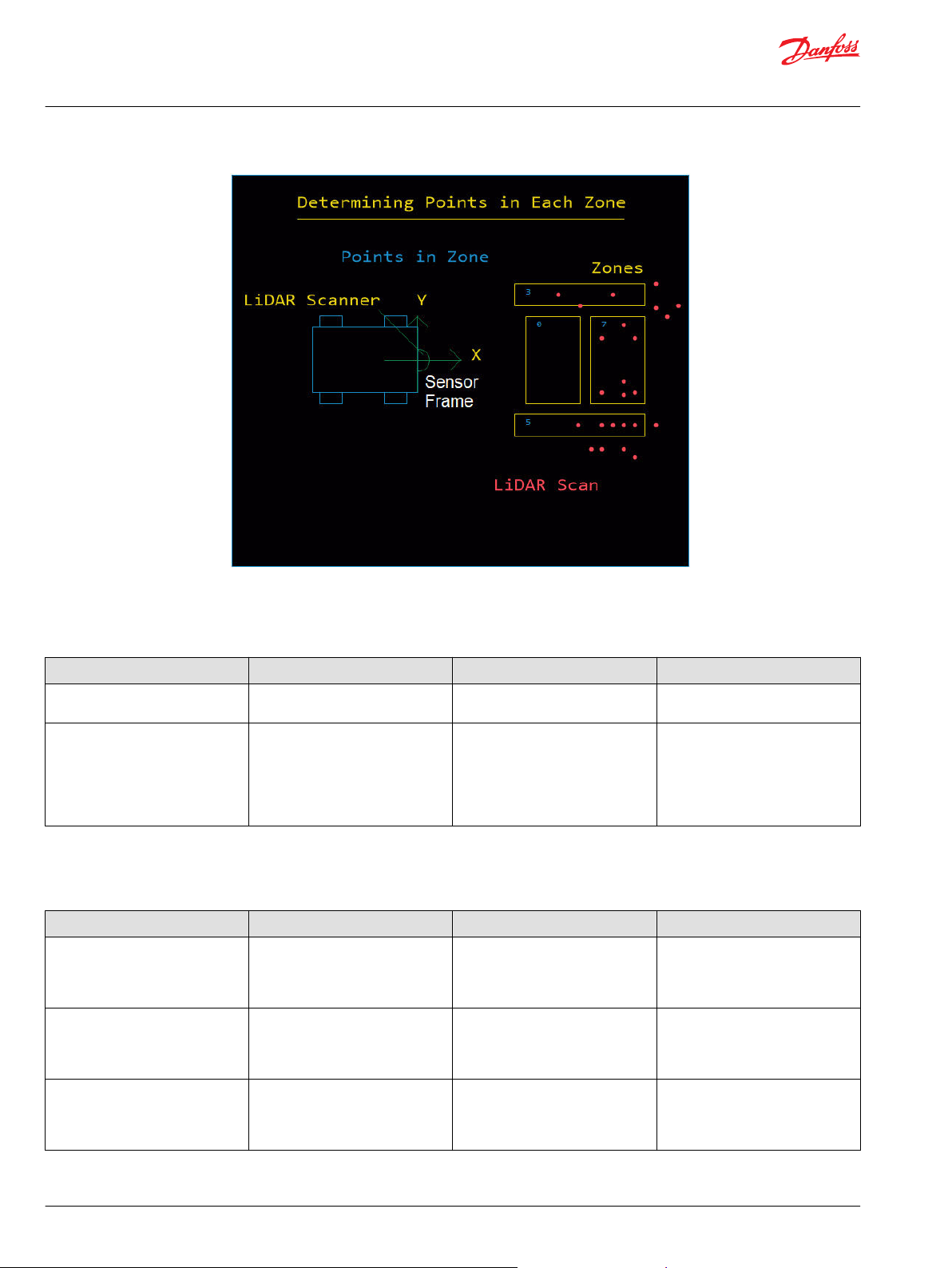

The Obstacle_Detection function block analyzes the incoming LiDAR scan and evaluates each zone

created to determine the number of points that fall inside each zone.

LiDAR

The output is the number of obstacle points falling within the cuboid zone using point cloud data from a

sensor. A point cloud is a set of data points in space where each point is defined by its (X,Y,Z) coordinate.

This function block is extendable into Obstacle Avoidance, Projected Path or Safety Stop function blocks

by processing output data.

Use cases for this include all machines, indoor and outdoor navigation, and safety stop blocks.

Input data types must exactly match the indicated type to successfully compile.

The primary input to the Obstacle Detection block is the LiDAR scanner interface.

The internal algorithm takes into consideration the user-specified parameters and creates a cuboid zone.

Parameters include, X, Y, Z, Yaw, Length, Width, Min-Height, Max-Height. Then all the points in the point

cloud are checked if they are within the cuboid or not.

©

Danfoss | January 2020 AQ295075513101en-000101 | 29

Page 30

User Manual

PLUS+1® Function Block Library—Autonomous Control Function Blocks

Obstacle Detection Function Block

Inputs

Inputs to the Obstacle Detection function block are described.

Item Type Range Description [Unit]

Locker_ID

Chkpt BOOL T/F Enables Advanced Checkpoints with

S8 -1-99 Location where LiDAR scan data is

stored.

Namespace for each Diag signal.

T: Include checkpoints when

compiled.

F: Do not include checkpoints when

compiled.

Parameters

The following table describes parameters for the Obstacle Detection function block.

Item Type Range Description [Unit]

Para BUS —— Adjust configuration values here, or

replace them with signals routed

from the application through the

Para bus.

X (ARRAY[100]S32) -2147483648-2147483647 X component of Cartesian location

of the center of the zone.

Default: zeros (100)

[mm]

Y (ARRAY[100]S32) -2147483648-2147483647 Y component of Cartesian location

of the center of the zone.

Default: zeros (100)

[mm]

30 | © Danfoss | January 2020 AQ295075513101en-000101

Page 31

User Manual

PLUS+1® Function Block Library—Autonomous Control Function Blocks

Obstacle Detection Function Block

Item Type Range Description [Unit]

Z (ARRAY[100]S32) -2147483648-2147483647 Z component of Cartesian location

of the center of the zone.

Default: zeros (100)

[mm]

Yaw (ARRAY[100]S16) -18000-18000 Orientation of the zone.

Default: zeros (100)

[0.01 deg]

Width (ARRAY[100]U16) 1-20000 Width of the zone.

Default: 1000 * ones (100)

Length (ARRAY[100]U16) 0-65000 Length of the zone.

Default: 1000 * ones (100)

[mm]

Num_Zones U8 0-100 Number of zones.

Default: 1

Min_Height (ARRAY[100]S32) -50000-50000 Minimum height of the zone with

respect to the position of the LiDAR

scanner.

Default: zeros (100)

[mm]

Max_Height (ARRAY[100]S32) -50000-50000 Maximum height of the zone with

respect to the position of the LiDAR

scanner.

Default: 1000 * ones (100)

[mm]

Outputs

Outputs of the Obstacle Detection function block are described.

Item Type Range Description [Unit]

Diag BUS —— This bus provides diagnostic values

for troubleshooting and information

about the current status of the

sensor.

Status U16 —— Reports the status of the function

block.

0x0000: Status OK.

0x8001: Input value too low.

0x8008: At least one parameter is

out of range.

Fault U16 —— Bitwise code where multiple items

can be reported at a time.

0x0000: No fault.

0x8001: Input value too low.

0x8002: Input value too high.

Zones

Updated BOOL T/F New information is available from

BUS —— Contains the updated information

for the zones.

the block.

T: New data is available.

F: New data is not available.

©

Danfoss | January 2020 AQ295075513101en-000101 | 31

Page 32

User Manual

PLUS+1® Function Block Library—Autonomous Control Function Blocks

Obstacle Detection Function Block

Item Type Range Description [Unit]

Scores

(Array[100]S32) —— Reports how many points from the

LiDAR scan were counted within

each given zone.

[Count]

Total_Valid_Points

U32 —— Number of valid LiDAR scan points

that were used in the analysis. This

can be used to determine a ration or

to identify an unusually low number

of points from the scanner.

[Count]

32 | © Danfoss | January 2020 AQ295075513101en-000101

Page 33

User Manual

PLUS+1® Function Block Library—Autonomous Control Function Blocks

Origin Function Block

The Origin function block stores UTM coordinates of the machine's starting point, and uses this data to

calculate the relative position of the autonomous machine as it operates.

The origin can be set on startup. It can also be updated during application runtime, which can be useful

for repetitive algorithms, such as path coverage.

It is recommended to delay setting the origin location until valid position data (GNSS location) has

resolved to an accurate position.

Inputs

Inputs to the Origin function block are described.

Item Type Range Description [Unit]

SetOrigin BOOL T/F When true, the function block stores the current origin in the Para or UTM bus depending on the

CustomOrigin.

T: Update the origin being stored.

F: Origin being stored stays the same.

UTM BUS —— GNSS data using the UTM coordinate system.

UtmX U32 0-10⁹ The UtmX value given from the conversion using the WGS84 ellipsoid model.

[mm]

UtmY U64 0-10¹⁰ A custom UtmY value using the WGS84 ellipsoid model.

[mm]

UtmY_Upper U32 —— The 32 most significant bits of UtmY as stored in a U64 value.

UtmY_Lower U32 —— The 32 least significant bits of UtmY as stored in a U64 value.

Band U8 0, 67-72, 74-78,

80-88

Zone U8 1-60 The zone that the UtmX and UtmY values are in.

The band that the UtmX and UtmY values are in.

ASCII values represent the letter of the band.

©

Danfoss | January 2020 AQ295075513101en-000101 | 33

Page 34

User Manual

PLUS+1® Function Block Library—Autonomous Control Function Blocks

Origin Function Block

Item Type Range Description [Unit]

Updated BOOL T/F TRUE when there is new data.

The stored values are updated only if no data has been stored yet.

CustomOrigin

is FALSE and

Updated

turns TRUE.

T: New data is ready.

F: New data is not ready.

Chkpt BOOL T/F Enables advanced checkpoints with namespace for each Diag signal.

T: Include checkpoints when compiled.

F: Do not include checkpoints when compiled.

Parameters

The Origin function block's operating characteristics are set by para bus input signals.

Item Type Range Description [Unit]

Para BUS —— Adjust configuration values here, or replace them with signals routed from the application through the

Para bus.

80-88

9

A custom UtmX value using the WGS84 ellipsoid model.

Default: 0x20EBC948

[mm]

[mm]

Default: 0x00000001

Default: 0x6B7EAF74

The latitude band where the UtmX and UtmY values are. Values are represented in ASCII, not letters.

Default: 85

Unit: NA

Default: 32

Unit: NA

T: Uses values in Para BUS.

F: Use values from the UTM BUS.

Default: True

The stored values are updated only if no data has been stored yet.

CustomOrigin

is TRUE and

Updated

turns TRUE.

T: New data is ready.

F: New data is not ready.

Default: True

UtmX U32 0-10

UtmY U64 0-10¹⁰ A custom UtmY value using the WGS84 ellipsoid model.

UtmY_Upper U32 —— The 32 most significant bits of UtmY as stored in a U64 value.

UtmY_Lower U32 —— The 32 least significant bits of UtmY as stored in a U64 value.

Band U8 67-72, 74-78,

Zone U8 1-60 The UTM zone where the UtmX and UtmY values are.

CustomOrigin BOOL T/F Uses the custom origin values specified here in the Para bus when TRUE.

Updated BOOL T/F TRUE when there is new data.

34 | © Danfoss | January 2020 AQ295075513101en-000101

Page 35

User Manual

PLUS+1® Function Block Library—Autonomous Control Function Blocks

Origin Function Block

Outputs

Outputs of the Origin function block are described.

Item Type Range Description [Unit]

Diag BUS ——

Status U16 —— Bitwise code where multiple items can be reported at a time.

Fault U16 —— Bitwise code where multiple items can be reported at a time.

Origin BUS —— Stores the UTM values for the origin.

UtmX U32 0-10⁹ The UtmX value used as the origin.

0-10¹⁰

OriginZone

UtmY U64

UtmY_Upper U32 —— The 32 most significant bits of UtmY as stored in a U64 value.

UtmY_Lower U32 —— The 32 least significant bits of UtmY as stored in a U64 value.

Band U8 67-72, 74-78, 80-88 The band that the UtmX and UtmY values are in.

Zone U8 1-60 The UTM zone where the UtmX and UtmY values are.

Updated BOOL T/F TRUE when new data is being stored for the origin.

U8 1-60 The zone that the origin UTM is in.

Provides diagnostic values for troubleshooting.

0x0000: Status OK.

0x8008: At least one parameter is out of range.

0x0000: No fault.

0x8001: Input value too low.

0x8002: Input value too high.

0x8010: Input value is out of range.

[mm]

The UtmY value used as the origin.

[mm]

ASCII values represent the letter of the band.

T: New data is stored.

F: The origin has not changed.

This is the same value as the zone in the Origin BUS.

©

Danfoss | January 2020 AQ295075513101en-000101 | 35

Page 36

User Manual

PLUS+1® Function Block Library—Autonomous Control Function Blocks

Path Follower Function Block

The Path_Follower function block allows a machine to follow a path made up of a series of Bézier curves.

Paths can be loaded as a fixed path when the machine starts or can be added dynamically. The function

block outputs tracking errors relative to the path as well as a curvature, which brings the machine onto

the path within the look-ahead distance.

Input data types must exactly match the indicated type to successfully compile.

The current path is lost if the ECU loses power unexpectedly or is power cycled while following a path. To

recover from an ECU power loss, see the topic Restart or Resume Path After ECU Power Loss.

Item Description

1 Origin

2 Bearing

3 Backward Radius

4 Forward Radius

5 Waypoint

6 East-North-Up (ENU) Notation.

0 (East), 90 (North), 180 (West), 270 (South)

36 | © Danfoss | January 2020 AQ295075513101en-000101

Page 37

User Manual

PLUS+1® Function Block Library—Autonomous Control Function Blocks

Path Follower Function Block

Inputs

Inputs to the Path Follower function block are described.

The following figure helps describe waypoints.

Item Type Range Description [Unit]

Pos

Path BUS —— A bus that contains options for the path and a way to define

Waypoint_X (ARRAY[50]S32) -2147483648-2147483647 The X position of the waypoint.

Waypoint_Y (ARRAY[50]S32) -2147483648-2147483647 The Y position of the waypoint.

Bearing (ARRAY[50]S32) -72000-72000 Angle at which the machine goes through the waypoint.

Forward_Radius (ARRAY[50]U32) 0-4294967295 Distance from the waypoint to the forward control point.

Backward_Radius (ARRAY[50]U32) 0-4294967295 Distance from the waypoint to the backward control point.

StartingWaypoint U8 0-49 The index in the array that has the first waypoint to be added

BUS —— A bus that contains position and orientation data for the

machine.

X

S32 -2147483648-2147483647 The X position of the machine.

[mm]

Y

S32 -2147483648-2147483647 The Y position of the machine.

[mm]

Yaw S32 -72000-72000 The yaw of the machine.

This uses the ENU convention and the right hand rule.

[0.01 degree]

the path for the machine to follow.

[mm]

[mm]

This uses the ENU convention and the right-hand rule.

[0.01 degree]

Smaller radii yield sharper turns.

[mm]

Smaller radii yield sharper turns.

[mm]

to this loop.

If Starting Waypoint + NumOfWaypoints

is greater than 50, then the index of waypoints wraps back to 0.

Intended for use with ring buffers, normally set to 0.

NumOfWaypoints U8 0-50 The number of waypoints to add to this loop.

Confirm with output signal NumOfWaypointsAdded.

©

Danfoss | January 2020 AQ295075513101en-000101 | 37

Page 38

User Manual

PLUS+1® Function Block Library—Autonomous Control Function Blocks

Path Follower Function Block

Item Type Range Description [Unit]

Reverse BOOL T/F Specifies the order that waypoints are added to the path.

T: The waypoints are added to the path in reverse order. 180

degrees are added to the bearing. Backward and forward radii

are swapped.

F: The waypoints are added based on their current order in the

array.

Search_Path BOOL T/F Specifies if the path is searched.

T: Searches the entire path to find the nearest point to the

machine to navigate toward. If Tracking_Error is less than

Lookahead_Dist, search is not performed.

F: Does not search path. Follows the path from the beginning

to the end.

Loop_Path

Target_Spacing U16

Chkpt BOOL —— Enables advanced checkpoints with namespace for each Diag

BOOL T/F Set TRUE to loop the path. This is only updated during the first

loop or when Reset is TRUE.

Cannot have more than 50 waypoints.

T: The path keeps looping.

F: The path is only done once.

1-65535

Reset BOOL T/F Clears the current path and stores the settings for the new

Accuracy of the interpolation of the path segments.

Smaller values increase the accuracy but also increase the

processing time.

This is only updated during the first loop or when Reset is

TRUE.

Segments are split into at least 4 steps, and at most 1000 steps,

even if the value of Target_Spacing specifies otherwise.

[mm]

path.

T: Clears the path and stores the value for Loop_Path and

Target_Spacing for the next path.

F: Does not clear the path.

signal.

T: Include checkpoints when compiled.

F: Do not include checkpoints when compiled.

Parameters

The Path Follower function block's look-ahead distance is set by para bus input signal.

Item Type Range Description [Unit]

Para BUS —— Input for external parameter values.

Adjust configuration values here, or replace them with signals routed from the application through

the Para bus.