Page 1

MAKING MODERN LIVING POSSIBLE

Planning Underfloor Heat

DANFOSS HEATING SOLUTIONS Handbook

Page 2

Handbook Planning Underfloor Heat

Planning criteria

Standards for

underfloor heating

Essential requirements for all calculations:

• Detailed plan of building, construction of outer

walls, and size and type of windows.

These data are essential for calculation of the

heating load in accordance with EN 12831.

• Information on the type of ooring and its

thermal resistance R

dependent on the oor construction, particularly

, since the heat output is

λ,B

that over screed (in accordance with EN 1264 a

thermal resistance of R

living rooms is specied, in bathrooms R

m2 K/W. Other values up to a maximum of 0.15

m2 K/W are to be separately agreed.) R

m2 K/W.

= 0.1 m2 K/W R

λ,B

λ,B

for

λ,B

= 0.0

λ,B

= 0.0

• Building plans, building drawings and all room

data have to be shown. After the calculations,

the pipe layout and data are included in the

building plan.

• Danfoss forms for calculations.

The following standards have to be observed when

planning and installing oor heating:

EN 1991 Action on structures

EN 1264 Underoor Heating, Systems and

Components

Changes in building methods over the last few

decades have brought about lower requirements

for heating homes, so that Danfoss underoor

heating can meet respective heating requirements

for even physiologically acceptable surface temperatures. In some rooms, such as bathrooms,

additional heating may be necessary, as areas

under bath and shower cannot be heated and

a higher temperature is required (24° C instead

of 20° C). In such rooms the underoor heating

maintains the temperature in the oor while other

heat comes from sources such as wall heating,

heated towel rails, etc.

EN 13813 Screed Material and Floor Screeds

Local building regulations.

Professional information on interface

co-ordination when planning heated

underoor constructions (ref: BVF).

Estimated

pre-calculations

DIN 4109 Sound Insulation in the Building

Industry

ISO EN 140-8 Measurement of sound insulation

in buildings and building elements

The output tables of Danfoss SpeedUp and Basic

heating systems show output values for various

room temperatures as well as the temperatures of

the central heating water in relation to dierent

oor nishes. These tables give calculations of the

mean central heating water temperature with

which to run the underoor heating in order to

achieve the desired output.

EN 1264 is crucial for the construction of underoor heating. With the inclusion of EN 13813

‘Screed Material and Floor Screeds’ three Basic

Danfoss constructions are possible.

The required excess heat source temperature

determines the supply temperature which is

described in more detail in the chapter ‘Calculating

the supply Temperature’. The heat ow densities

are distributed evenly over the edge and comfort

zones. The main central heating water temperature is determined by the type of installation (see

output tables).

2

VGCTC202 © Danfoss 06/2009

Page 3

max 29°C

W

Handbook Planning Underfloor Heat

Standard heating load of

an underfloor heated

room

Thermal insulation to

avoid downward heat

loss

When making calculations for Danfoss underoor

heating the standard heat load Q

essential. For underoor heating in multi-storey

of the room is

N,f

buildings the heat gain of the shared oor can be

included into the calculations if there are no

restrictions on the work.

The heat output QH is generally calculated from

the standard heat load of an underoor heated

room Q

accordance with EN 4701 Part 3.

plus an extra calculation allowance in

H,f

QH = (1 + x)* Q

N,f

It is important to consider the thermal resistance

of the insulation below the underoor heating so

that the heat of the underoor heating radiates

mainly upwards.

In accordance with EN 1264, Part 4 there are three

dierent kinds of oor/storey constructions and

various minimum heat resistances.

Thermal Insulation R

A above rooms with similar use 0.75 m2 K / W

B above rooms with dierent

use*, unheated rooms (e.g.

cellar) and on ground oor

C above external air (-15°C) (e.g.

garages, passage ways)

* e.g. rooms above commercially used premises

1.25 m

2.00 m

Ins, min

2

2

K / W

K / W

Q

: Standard heating load of an underoor

N,f

heated room [W]

QH: Heat output calculation

If the heating system, such as an underoor

system, can raise the heat output by raising the

heat source temperature the extra allowance is is

zero. Thus the calculated temperature output

equals the standard heat load of an underoor

heated room.

The heat resistance R

layer is calculated as follows:

R

with a single insulation

λ.ins

S

=

λ,ins

λ

ins

ins

with:

S

: eective insulation thickness [m]

ins

λ

: thermal conductivity [W/m K]

ins

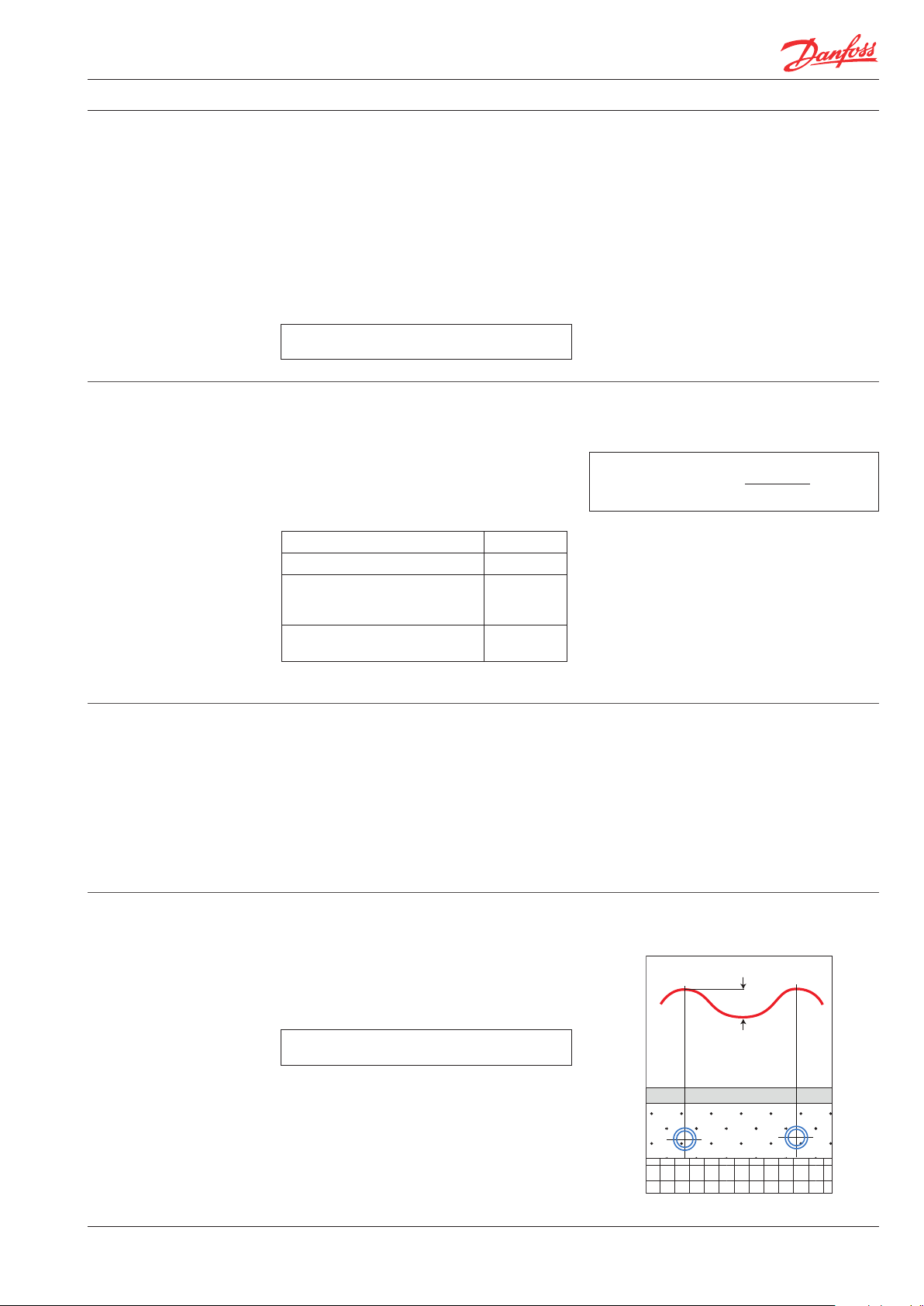

Maximum surface

temperature Θ

Fmax

Fluctuation in

temperature (W)

In accordance with EN 1264 maximum surface

temperatures for phsysiological reasons are set

as follows:

Comfort zone: 29° C

Edge zone: 35° C

Bathrooms: ti + 9° C = 33° C

Standard room temperatures of 20 or 24° C

in bathrooms result in a dierence in surface

The position of the heating pipe can further

inuence the output. Depending on the position,

varying surface temperatures can occur. Output

is higher above the pipes than in between. The

dierence between the maximum and minimum

surface temperatures is called uctuation (W).

W = θ

F max

- θ

F min

Larger distances between pipes cause larger

uctuation. Lower lying pipes slow down the heating

sy stem but the ‘ long w ay’ to the sur fac e dis tribu tes

the temperature evenly, the uctuation remains

small. Since the maximum oor temperature must

not be exceeded, larger uctuation causes greater

loss in output than a smaller uctuation. In the rst

temperature and room temperature of 9K (in

comfort zones and bathrooms) or 15K (in edge

zones). Limiting the surface temperature has

the eect of limiting the heat output of the

underoor heating. It is an important factor when

deciding whether to choose additional heating.

However, with modern insulation the heat output

in underoor heating is sucient in 99 of 100

cases.

case, average oor temperature is signicantly lower

than the maximum permitted temperature.

VGCTC202 © Danfoss 06/2009

3

Page 4

Handbook Planning Underfloor Heat

1 2 5 20 K

W/m²

200

100

50

30

20

10

Characteristic base line

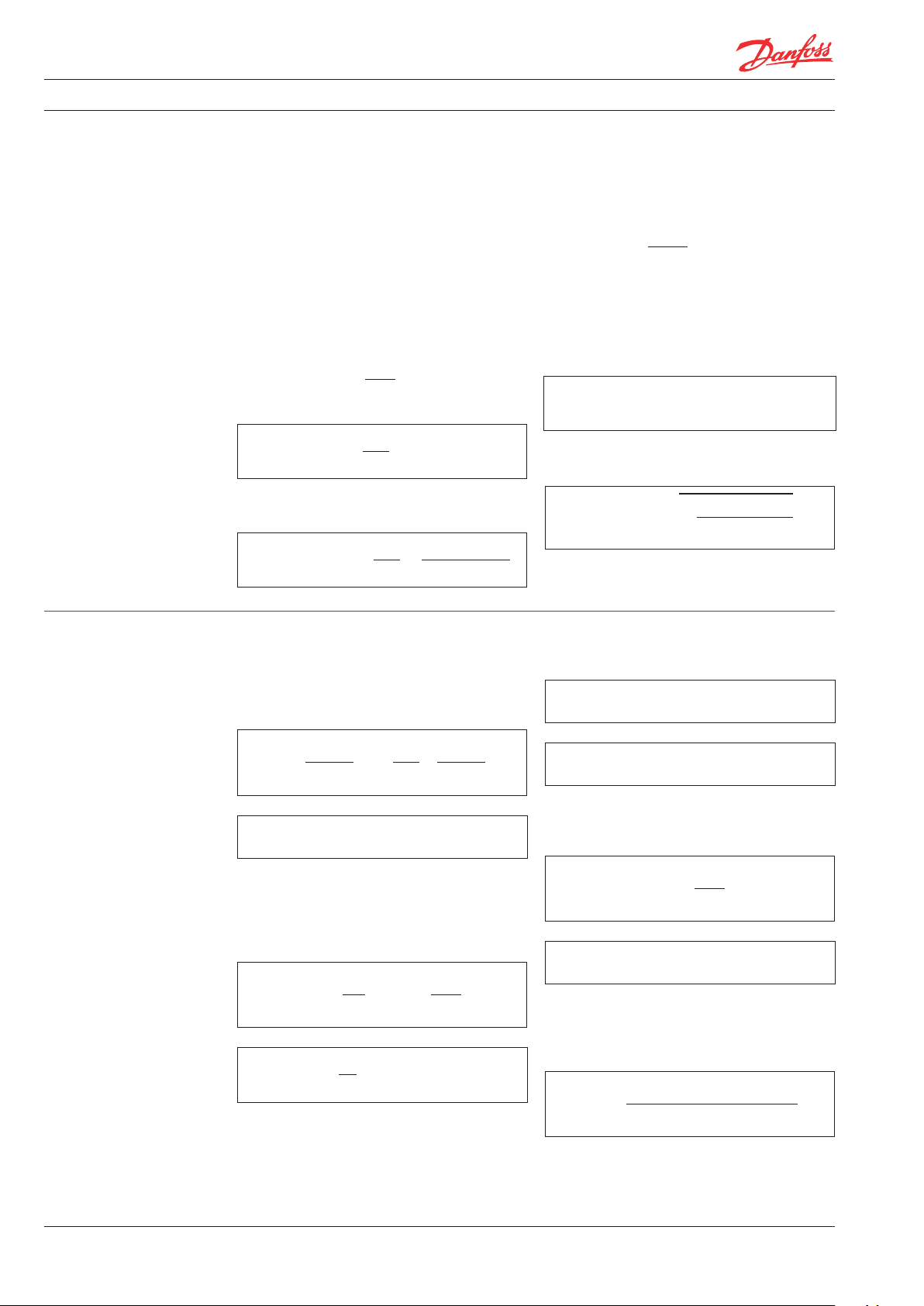

The Characteristic base line shows the relationship between the heat ow density and the

surface temperature (surface temperature minus

room temperature) when the heated area is

evenly heated (uctuation = 0).

Heat output q

Mean surface temperature difference

With a surface temperature of 9K above room

temperature an output of approx. 100W/m2 is

achieved, with an excess temperature of 15K a

heat output of approx. 175 W/m2.

Since the characteristic base line has idealised

physical parameters and is valid independent of

the system, no system, kept at the maximum

permitted surface temperature, can reach an

output of more than 100 W/m2 or 175 W/m2 in

edge zones.

Consequently the specic heat output q of the

oor surface depends on the dierence between

room and surface temperatures as well as the

transferability. The latter is dependent on the

room data, including the needs to air the room

and is described as heat transfer coecient α

here 11.1 W/m2K.

q = α

(θF - θi)

ges

ges

θF = Floor temperature °C

θi = Room temperature °C

Example:

At a room temperature of 20° C and a oor

temperature of 27° C a heat output of

q = 11.1 W/m2 K * 7°K (27° C - 20° C)

= 77.7 W/m2 would be achieved.

Heat source temperature

Installation types

The mean heat source temperature is a rm

component of many calculations. It is calculated

from the mean value of the supply and return

temperatures:

θm = θi + Δθ

H

The heating system Danfoss Basic comprises two

dierent installation types in edge zones and

three in comfort zone areas.

System Possible pipe distance in cm

BasicRail 8.8 (mean)

BasicRail 12 (mean)

BasicRail 20

BasicRail 25

BasicRail 30

BasicGrip and BasicClip 10

BasicGrip and BasicClip 15

BasicGrip and BasicClip 20

BasicGrip and BasicClip 25

BasicGrip and BasicClip 30

SpeedUp and SpeedUp Eco 12.5

SpeedUp and SpeedUp Eco 25

with:

ΔθH: Excess Heat Source Temperature

θi: Standard - Inside Temperature

θm: Heat Source Temperature

The SpeedUp and SpeedUp Eco heating systems

has installation types for the edge and comfort

zones. They dier in pipe distance.

4

VGCTC202 © Danfoss 06/2009

Page 5

Handbook Planning Underfloor Heat

Heat output curve

Limiting curve

Calculated heat flow

density

The heat output and the uctuation of the surface

temperature are dependent on several factors:

• Floor surface temperature

• Room temperature

• Pipe distances

• Thickness and thermal conductivity of the

load bearing panels

• Lateral heat output

• Thermal resistance of oor nish

• Composition of the layers

In accordance with EN 1264 all factors combine

into the following equation heat ow density q:

q = KH + Δθ

H

with:

q: Heat output [W/m2]

KH: Equivalent heat transfer coecient [W/m2 K]

(ocial DIN check)

ΔθH: Excess heat source temperature

When doing the calculations for underoor

heating, the calculated heat ow density is to be

worked out as follows in accordance with DIN EN

1264, Part 3 :

Q

q

=

des

N,f

A

F

with:

q

Calculated heat ow density [W/m2]

des

Q

Standard-heat load of an underoor heated

N,f

room [W]

AF Floor area to be heated [m2]

The heat output achieved from underoor

heating is

QF = q * A

F

with:

Δθ

H

θ

- θ

=

V

R

- θ

θ

V

θR - θ

i

i

In

with:

θV: Supply temperature

θR: Return temperature

θi: Standard-inside temperature

When keeping to maximum permitted temperatures, the above factors will give, apart from

uctuation, limiting curves (calculated according

to EN 1264, Part 2). The intersections indicate the

heat ow limits and the limits to excess heat

source temperatures.

The data for the heat ow densities of the edge

zones or comfort zones qR and qA can be calculated from the output diagrams where the excess

temperature of the heat source applies.

The approved threshold of the heat ow density

(intersection of curves with limiting curve) must

not be exceeded. The approved density depends

on the thermal resistance of the oor covering

and the construction type.

If one value of the calculated and distributed heat

ow density (qR/qA) is above the threshold heat

ow density, the threshold density rather than the

heat ow density applies. The resulting decrease

in excess heat source temperature also reduces

the heat ow density of the other combination

type of installation.

If the standard heat load of a room heated with

underoor heating is greater than the heat output

of the underoor heating, additional heating for

the shortfall should be considered. Q

N,f

- QF.

with:

q

Calculated heat ow density

des

Q

Standard-heat load of an underoor heated

N,f

room

AF Floor area to be heated

where q is evenly distributed over the edge zone

(maximum 1 m wide) and the comfort zone:

A

R

q =

VGCTC202 © Danfoss 06/2009

A

* qR+

F

A

A

* q

A

A

F

5

Page 6

Handbook Planning Underfloor Heat

Calculation of excess

supply temperature

The calculated supply temperature for a room

with the highest calculated heat ow density is

assigned q

thermal resistance for oor cover of R

K/W. Higher values for R

account. Bathrooms will have R

The dierential temperature σ for the room to be

(except bathrooms) and given a

max

have to be taken into

λ,B

λ,B

= 0.0 m2 K/W.

λ,B

= 0.10 m2

calculated is dened as σ = 5 K. The installation

type is chosen so that q max fully achieves the

threshold heat ow density indicated in the

limiting curve. The maximum permitted excess

ow temperature is

Δθ

V, des

≤ Δθ

when

H, des

+

σ

Δθ

σ

2

≤ 0.5:

H

with Δθ

H, des

≤ Δθ

H, G

otherwise:

Δθ

V, des

= Δθ

H, des

σ

+

+

2 (12 Δθ

2

σ

)

H, des

In all other rooms which are operating on

calculated ow temperatures the dierential

temperature is calculated as follows, as long as

the relation:

σ

j

< 0.5

Δθ

H, j

is:

Δθ

: Excess heat source temperature of each room j

H,j

with:

σ j = 2 * [(Δθ

V, des

) – Δθ

]

H,j

otherwise:

4(Δθ

- Δθ

σ j = 3 * Δθ

*

H, j

[√

1+

V, des

3 * Δθ

)

H, j

-1

H, j

]

Calculation heat source

temperature

For calculating the size of the circulating pump

the mass ow rate is determined as mH (ow rate

of heating water in kg/s). It is independent of the

total output (oor heating output, and heat losses

to other rooms) as well as dierential temperature.

mH =

* q

A

F

σ * C

R

1 +

(

W

R

- θ

θ

o

i

q * R

u

)

u

+

u

with CW = 4190 J/kgK

The partial heat transfer resistance of the oor

construction Ro (upwards) encompasses both the

thermal conductivity and thermal resistance

upwards:

1

Ro =

with1= 0.093 m2 K/W

+ R

α λ

α

S

u

+

λ ,B

u

The sum of the downwards thermal conductivity

and downwards thermal resistances is:

Ru = R

λ, ins

with R

+ R

λ, oor

= 0.17 m2 K/W

α, oor

+ R

λ, render

+ R

α, oor

The mass ow rate mH can also be expressed

when converted as the ow rate VH:

m

VH =

with ρ = 0.998 kg/dm

H

ρ

3

To determine the ow rate of a heating circuit the

ow rate of the room VH must be divided by the

number of heating circuits:

V

VHK =

Number of heating circuits

H

6

VGCTC202 © Danfoss 06/2009

Page 7

Handbook Planning Underfloor Heat

Pressure loss

For the calculations and size of the circulating

pump it is important to calculate pressure loss. In

order to calculate pressure loss the total length of

the pipes IHK and supply and returns have to be

determined. Here it is important that the length

of the supply and return pipes FEED is double the

distance of room to manifold (supply and return).

Depending on the laying type the following

values are relevant:

lH = Pipe length of edge zone layout plan * AR

+ Pipe length of comfort zone layout plan * A

The mean length of the heating circuit IHK is

calculated thus:

I

IHK = FEED +

Here it must be mentioned that the area layout

and the number of heating circuits are determined

by the type of screed, i.e. the heating circuits must

be compatible with the screed sections.

Number of heating circuits

(

H

A

)

The pressure loss diagram (cf. pressure loss

diagram for Danfoss composite pipe) shows, via

ow rate per heating circuit V

resistance as pressure loss Δp per m. To calculate

the total loss of a heating circuit, this value has to

be multiplied by the length of the heating circuit.

ΔpHK = Δp * l

Individual heating circuits have dierent lengths

and dierential temperatures and show dierent

loss of pressure. Pressure compensation ensures

that all heating circuits are supplied with

sucient water. The ow adjustment is made on

the return valve by determining the ow per

minute (i.e. the volume ow [l/h] of the individual

heating circuits is divided by 60 [min.]).

The total water volume within an underoor heating system is calculated by the length of all

heating circuits IHK multiplied by a factor of 0.113

(l/m).

, the pipe friction

HK

HK

Correlation between flow

rate, pressure loss and

differential temperature:

Threshold values

The smaller the dierential temperature:

• the higher the volume ow

• the higher the ow speed of the medium and

• the higher the pressure loss

• The maximum supply temperature must not

exceed 55° C for wet cement and calcium

sulphate (CAF) screed

• Heating circuits should not be longer than

100 m, 110 m maximum.

• The optimum length is 120 m.

• Pressure loss of 250 mbar must not be

exceeded since the circulating pump, apart

from maintaining the pressure head, has to

cope with pressure losses in the heating

circuits and in the whole system (in manifold,

its valves, supply and return pipes, mixing

valves, etc.).

• The maximum supply must not exceed 50° C

for gypsum plaster.

Raising the dierential temperature causes a

reduction in ow rate.

VGCTC202 © Danfoss 06/2009

7

Page 8

Handbook Planning Underfloor Heat

Floor Heating

Quick Planner

Quick and easy dimensioning of the floor heating system

The proper dimensions for oor heating systems

can be calculated in a matter of minutes by using

the Internet-based Danfoss Floor Heating

Dimensioning Programme.

With a few, basic inputs, this easy-to-use software

will provide all the necessary information regarding

system design, product selection, and commissioning. This makes the Danfoss Floor Heating

Dimensioning Programme a very valuable tool in

both the bidding and the implementation phases.

8

VGCTC202 © Danfoss 06/2009

Loading...

Loading...