Page 1

MAKING MODERN LIVING POSSIBLE

Handbook

Danfoss Pipes for Hydronic Floor Heating

Page 2

The English language is used for the original instructions.

Other languages are a translation of the original instructions.

(Directive 2006/42/EC)

© 2012 Copyright Danfoss A/S

Page 3

Handbook Danfoss Pipes for Hydronic Floor Heating

Table of Contents

Danfoss FH Pipes

1 Danfoss FH Pipes .......................................... 3

2 FH Composite Pipes ........................................ 3

3 Pressure Loss for FH Composite Pipes ............................ 4

4 FH PE-RT Pipes ............................................ 4

5 Pressure Loss for FH PE-RT Pipes ............................... 5

6 Pipe Bending ............................................. 5

7 Minimum Bending Radius with Bending Springs .................... 5

8 Precautions .............................................. 6

9 Connections ............................................. 6

10 Product Range ............................................ 7

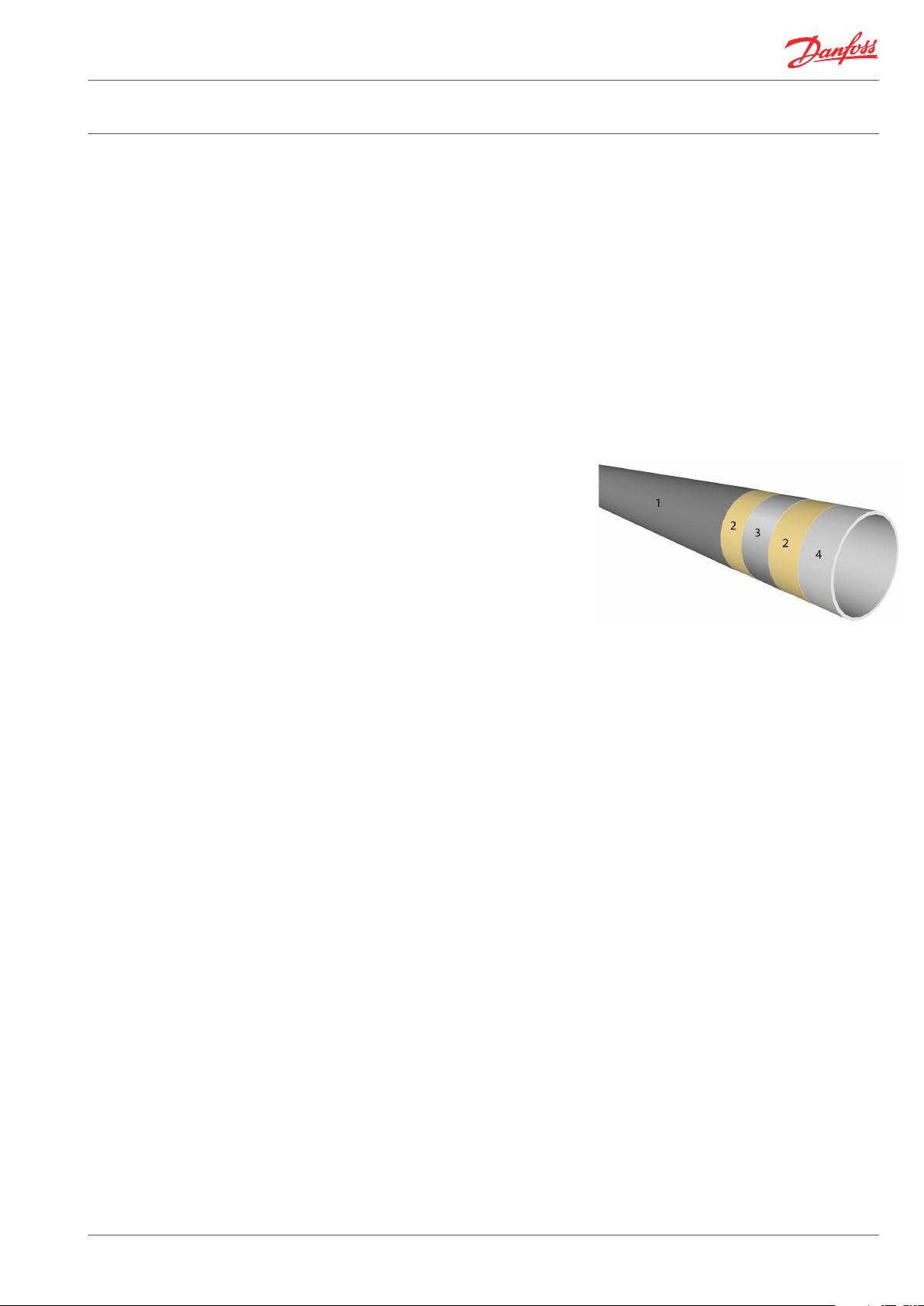

The Danfoss FH pipes are high quality pipes for

under floor heating applications.

All Danfoss FH pipes are manufactured from the

highest quality PE-RT (Polyethylene Raised Temperature resistance) which is a recyclable material

with similar characteristics to those of PE-Xa

pipes.

The PE-RT material gains it’s strength from the

octen side chain molecules which makes additional cross linking redundant. Even without

cross linking the Danfoss FH pipes hava a lifespan

of more than 50 years. All the layers are permanently bonded together with a high quality

bonding adhesive.

1. PE-HD outer layer

2. Adhesive

3. Butt-welded aluminium

4. PE-RT inner pipe

FH Composite Pipes

The Danfoss Composite pipe consists of 5 layers,

the outer layer is made from PE-HD, the core

from aluminium and the inner pipe from PE-RT.

This combination gives the pipe a strong and

protective outer layer making the pipe resistant

for use on building site conditions. The Aluminium core makes installation easier by helping the

pipe stay in the bent shape without springing

back. The PE-RT inner pipe has a smooth surface

which minimizes pressure loss allowing for long

circuit lengths, and at the same time minimize

the murmur in the installation.

No Corrosion

The FH Composite pipe is a 100% oxygen tight

thanks to the continuously butt-welded aluminium core. Oxygen tightness is a must to keep the

installation free from corrosion which ensures a

long life time for the system.

The FH composite pipe exceeds the demand for

oxygen barrier according to DIN 4726

No noise

The aluminium core ensure that the thermal expansion of the pipe is only 1/7 to that of a full

plastic pipe, this helps to prevent noise problems

in the floor construction.

In shape

The Danfoss composite pipe is manufactured in

such a way that the aluminium layer prevents the

pipe from going back to its original form. This

makes it easy to install.

Quality inside

The PE-RT resin is typically available in different

qualities and to ensure that the quality of the

pipe we only use the highest quality of materials.

Danfoss Heating Solutions VGDXA402 © Danfoss 12/2012 3

Page 4

1 2 3 4 5 6 7 8 9101 2 3 4 5 6 7 8 9 102 2 3 4 5 6 7 8 9 10

3

1000

800

600

400

200

100

80

60

40

20

10

Ø 20 / 16 mm

Ø 18 / 14 mm

Ø 17 / 13 mm

Ø 16 / 12 mm

Ø 14 / 10 mm

Ø 11.6 / 8.6 mm

Handbook Danfoss Pipes for Hydronic Floor Heating

Pressure Loss for FH Composite Pipes

Volume flow - water quantity m (kg/h)

Water temperature: 40°C Pressure loss, [Pa/m] (1 mbar = 100 Pa)

Materials PE-RT / Aluminium / PE-HD

Max. working pressure 10 bar

Test pressure 16 bar

Max. flow temperature (short term) 110 °C

Max. working temperature 95 °C (not for continous operation)

Recommended max. working temperature 65 °C

FH PE-RT Pipes

4 VGDXA402 © Danfoss 12/2012 Danfoss Heating Solutions

The Danfoss PE-RT pipe is a multilayer pipe with 5

layers, the outer layer is made from PE-RT which

serves as a protective layer for the EVOH oxygen

barrier. The smooth inner pipe is made from PERT to prevent pressure loss and pipe murmur. Installation is eased by the flexibility that the PE-RT

material provides.

Long life time

The EVOH (Ethylene Vinyl Alcohol) oxygen barrier

in the pipe helps to keep the installation free

from corrosion. The oxygen barrier is accordance

with DIN 4726.

Construction site conditions

The outer layer of the pipe serves as a protection

barrier which keeps the oxygen barrier free from

scratches and makes the pipe well suited for the

conditions on construction sites.

Flexible

The PE-RT material is very flexible which makes it

easy to work with, the flexibility of the material

makes it possible to install the pipe even at low

temperatures.

Page 5

1000

900

800

700

600

500

400

300

200

100

90

80

70

60

50

40

30

20

10

1 2 3 4 5 6 7 8 9 10

1

2 3 4 5 6 7 8 9 10

2

2 3 4 5 6 7 8 9 10

3

100

1000

1.0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

ø

20

/16 mm

ø

20/

15

mm

ø

16 /12 mm

0.1

Handbook Danfoss Pipes for Hydronic Floor Heating

Pressure Loss for FH PE-RT Pipes

Mass flow, kg/h

Flow velocity (m/s) Pressure loss, [Pa/m] (1 mbar = 100 Pa)

Water temperature: 40 °C.

Materials PE-RT / EVOH / PE-RT

Max. working pressure 6 bar

Test pressure 10 bar

Max. flow temperature 95 °C

Max. working temperature 60 °C

Oxygen barrier EVOH

Pipe Bending

The flexible nature of the pipe material makes it

easy and quick for one person to install the Danfoss FH pipes. To achieve a proper bend hold the

small bit showing. It is important not to bend so

hard that the spirals of the bending spring begin

to show on the outside of the PE-sleeve.

pipe at a distance approx. 40 cm and then bend it

to the required radius. To avoid damage to the

Minimum Bending Radius with Bending Springs

pipe kinks should be avoided, this could be made

easier by using a bending spring.

Bending with internal bending spring

The pipe is first bevelled to remove inner plastic

edges and make the pipe end nice and circular.

The internal spring is then inserted to leave just a

Pipe dimension[mm]

16 80 (5 x Od) 64 ( 4 x Od) 64 (4 x Od)

Manual pipe bender ra-

20 100 (5 x Od) 80 (4 x Od) 80 (4 x Od)

Od = Outside diameter.

dius [mm]

Bending with external bending spring

The external bending spring is ushed over the

pipe to the bending point. After carrying out

bending the spring is removed.

Internal pipe bending

spring radius [mm]

External bending

spring radius [mm]

Danfoss Heating Solutions VGDXA402 © Danfoss 12/2012 5

Page 6

Handbook Danfoss Pipes for Hydronic Floor Heating

Precautions

Connections

UV-protection

Inside buildings there is no need to take extra

precaution against UV radiation. The grey outer

synthetic layer of the composite pipe is not sensitive to indirect UV radiation inside buildings.

However the Danfoss Composite pipe has to be

protected from direct sunlight and UV radiation.

Completed installations must be covered or protected in another way from UV radiation (e.g. enclosed in a protective pipe).

Frost

The following combinations of Anti-freeze and

anticorrosion with water can be used for the Danfoss FH pipes:

Antifrogen N

▪

Antifrogen L

▪

Tyfocor

▪

Tyfocor L

▪

Tyfocor LS

▪

Danfoss connection fittings are available as compression and press fittings, both variants comes

in the dimension 16 x 2.0mm and 20 x 2.25mm as

the FH pipes.

Compression fitting

The Danfoss compression fitting uses the well

know compression ring technology where the

ring is firmly fixed to the pipe by screwing the

coupling tight. The fitting connection can be disconnected from the manifold but the ring still remains fixed to the pipe.

by Clariant

by Clariant

by Tyforop Chemie GmbH

by Tyforop Chemie GmbH

Tyforop Chemie GmbH

It is important that the proportion of water to

Anti-freeze and anti-corrosion should be a minimum of 25% Vol and a maximum of 80% Vol

since otherwise there is a danger of corrosion in

some metallic areas. Installations that have been

temporarily filled with anti-freeze and anti-corrosion must be emptied and cleaned several times

with water in order to remove any residual product. Any residual product can lead to corrosion.

Anti-freeze and anti-corrosion additives must not

be allowed to attack Polyethylene, EPDM, PPSU,

and brass.

The connection is easily made with help of the

Danfoss hand-press tool which makes installation

possible under all conditions. The pipe is bevelled and simply pressed into the sleeve of the

press fitting. The plastic ring has holes so the

pipe is visible when it is pressed enough into the

sleeve. The ring also serves as guidance as where

to place the press tool before pressing to ensure

a tight connection. After pressing the sleeve the

plastic rings can be removed.

Press fitting

The press fitting is used for fast and economical

connections in the floor. The press fitting technology is a well known and proven technique.

6 VGDXA402 © Danfoss 12/2012 Danfoss Heating Solutions

Page 7

Handbook Danfoss Pipes for Hydronic Floor Heating

Product Range

FH Composite pipes

16 x 2 mm, 200 m,

Code no. 088X0001

16 x 2 mm, 500 m,

Code no. 088X0003

Fittings

Press coupling, 16 x 2 mm, Code no. 088X0020

Press coupling, 20 x 2.25 mm, Code no. 088X0021

Screw coupling, 16 x 2 mm, Code no. 088X0025

Screw coupling, 20 x 2.25 mm, Code no. 088X0026

Compression fitting, ¾” x 16 x 2 mm, Code no.

013G4186

Compression fitting, ¾” x 20 x 2.25 mm, Code no.

013G4093

FH PE-RT pipes

16 x 2 mm, 200 m,

Code no. 088X0004

20 x 2.25 mm, 150 m,

Code no. 088X0005

16 x 2 mm, 500 m,

Code no. 088X0006

Tools

FH dispensing

wheel:

for 200 m

▪

pipes, Code

no. 088X0600

for 500 m

▪

pipes, Code

no. 088X0615

Pipe cutter:

for 16-20 mm

▪

pipes, Code

no. 088X0601

Pipe bevelling tool:

for 16 mm

▪

pipes, Code no.

088X0603

for 20 mm

▪

pipes, Code no.

088X0604

Hand press tool:

Code no. 088X0609

Inserts:

for 16 mm

▪

pipes, Code no.

088X0610

for 20 mm

▪

pipes, Code no.

088X0611

Danfoss Heating Solutions VGDXA402 © Danfoss 12/2012 7

Page 8

Handbook Danfoss Pipes for Hydronic Floor Heating

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without subsequential changes being necessary in specifications already agreed. All trademarks in this material are property of the respective

companies. Danfoss Heating Solutions and the Danfoss Heating Solutions logotype are trademarks of Danfoss A/S. All rights reserved.

8 VGDXA402 © Danfoss 12/2012 Danfoss Heating Solutions

Loading...

Loading...