Page 1

Document category | Product name

Electrical Heating

Pipe Frost Protection

Application manual

Page 2

Page 3

Let Danfoss do the work

Index

Danfoss Group is Denmark's largest industrial group. It is one of the world's

leading companies within heating, cooling and air-conditioning. The Danfoss

Group has more than 23000 employees and serves customers in more than 100

countries.

Danfoss is Europe’s leading brand of electrical cable heating systems and electric

pipe heating systems with over 70 years of experience. The production of

heating cables takes place in France and Poland while the head office is situated

in Denmark.

Pipe Frost Protection

This design guide presents Danfoss’s recommendations for design and

installation of frost protection for pipes. It provides guidance for heating cable

layout, electrical data and system configurations.

Following Danfoss’s recommendations will ensure energy efficient, reliable and

maintenance free solution for constant wattage heating cables with 20 year

warranty, self-limiting heating cables with 5 years of warranty.

1. Application briefing 4

2. System Description 5

3. Products 7

4. System design 11

5. Installation 20

6. Cases 28

Our quality management

system

and compliances

ISO 9001 TS 16949

ISO 14001

Along with full compliance with EU

directives and product approvals

Page 4

1. Application

briefing

During the winter, problems with

freezing in fresh water, waste water,

cooling water, supply water and

sprinkler systems can be avoided by

internal or external pipe heating.

Pipes installed outdoor or inside

unheated premises, even if insulated,

can be subjected to low temperatures

that results in ice generation inside

pipes.

When water turns to ice its volume

expands and in closed pipes ice

becomes strong enough to cause pipe

bursting. This results in damages, water

leakage and costly repairs.

Danfoss heating systems provide

an affordable, easy to install and

adjustable solution in the form of a

thermostat regulated heating cable.

This solution provides a pipeline owner

with a safe, maintenance free and

sustainable system ensuring proper

performance for years.

Benefits

• Avoiding unforeseen repair costs: Frost

protection of pipes eliminates expensive repairs

and replacements after a long cold winter.

• Secures constant flow of water in pipes, even

in the coldest and unpredictable conditions.

• Any installation areas: Can be used on and in

pipes, indoor, outdoor and in ground.

• Approved for use in drinking water supply

systems.

• Reduced cost of installation in rocky and

other ground types, by alowing shallower

installation.

• Possibility for retrofitting of insulated pipes.

Danfoss’s pipe tracing systems

can be used for inside and outside

applications in individual pipes and

pipelines as well as for overhead and

buried pipelines.

4

Application manual · Pipe Frost Protection · VKLUD102 · ©Danfoss

Page 5

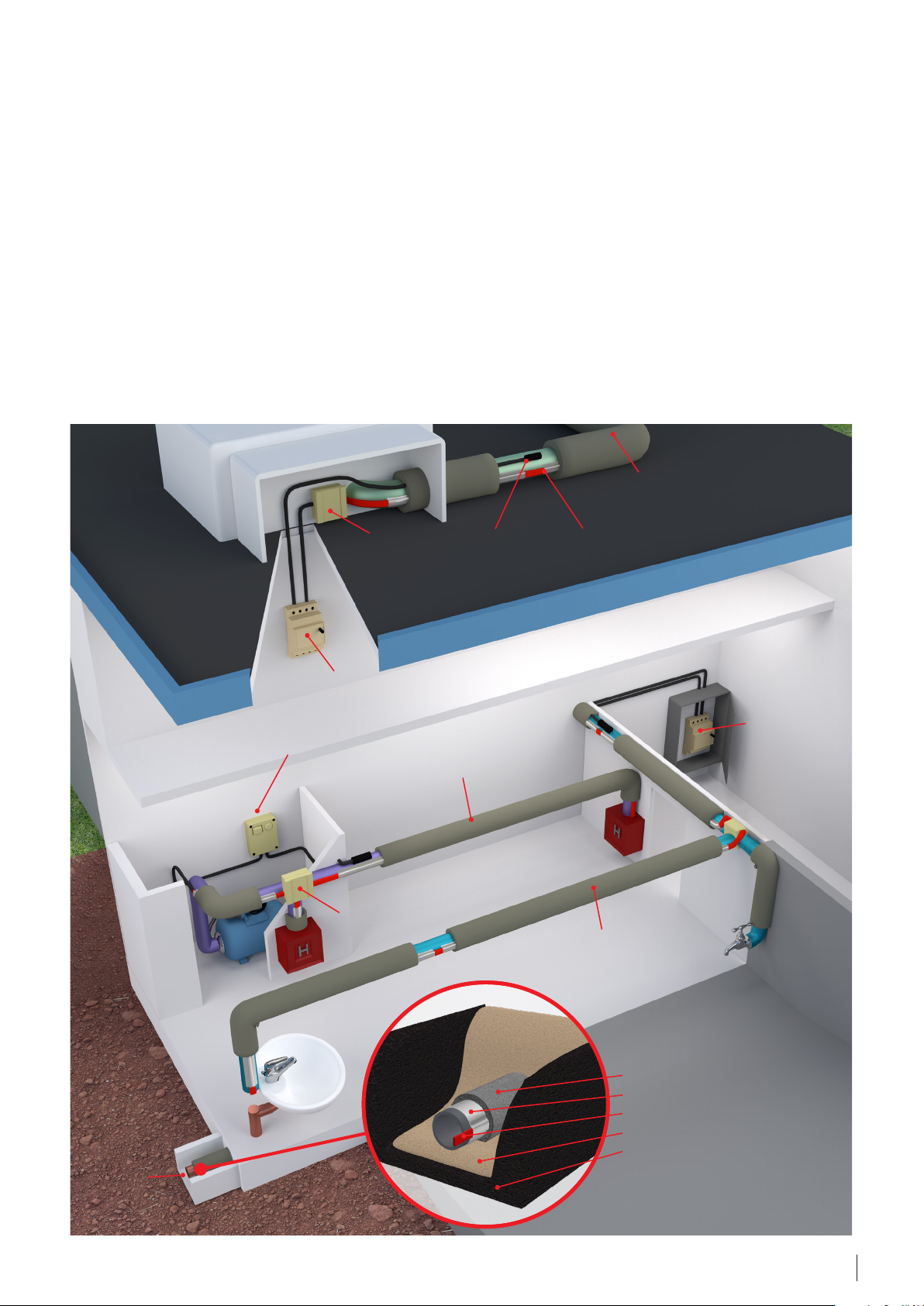

2. System Description

Danfoss heating system provides

a versatile solution for water pipes

protection (including drinking water

pipelines) against freezing.

For on-pipe application:

ECflex constant wattage cables or

self-limiting cables (SLC) such as

ECpipeguard, ECpipeheat 10 V2

provide flexible and on-site cut-tolength solutions.

For in-pipe application:

ECaqua constant wattage cables.

The system is regulated by means

of ECtemp 330 or 610 electronic

thermostats. This is needed for

constant wattage cables and

strongly advised for self-limiting

cables (SLC) to prevent energy

consumption during standby

periods.

To ensure energy efficient solution

the use of an aluminum tape for

cable installation, thermal insulation

of pipes and electronic thermostats

for control are essential.

electrical

connection box

temperature

sensor

heating

Electronic thermostats ECtemp have

a sensor placed directly on pipe to

be protected under its insulation,

and ensure optimal operation with

minimal energy consumption.

-20°C

water pipe

cable

sewer

drain

thermostat

ECtemp 330

thermostat

ECtemp 610

thermostat

ECtemp 330

in electrical

connection box

fire fighting installation

-10°C

electrical

connection box

Cold water installation

insulaiotn

aluminum tape

heating cable

sand

soil / ground

Application manual · Pipe Frost Protection · VKLUD102 · ©Danfoss

5

Page 6

Pipe tracing

Sensor

Heating cable

Insulation

Fitting

Valve

Aluminum tape

In-pipe frost protection

Insulation

Heating Cable

Subsurface pipe tracing

Concrete breeze block (not always installed)

and/or XPS insulation (not always installed)

Danfoss heating cable

Sand bed

Soil

Heating cables can be used with either

metal or plastic pipes (e.g. PVC, PE, PP

etc.). Plastic pipes may have limitations

with regard to the output of a heating

cable installed.

For more information please refer to

the design section of this Application

Manual as well as confirm temperature

limits for plastic pipes with your

supplier.

Installations are divided in two general

application categories:

• Inside buildings

• Outside buildings

The outside application category can

be additionally divided into:

• in air

• in ground installation, as shown on

the pictures above.

Installation inside buildings

Water supply pipes installed inside

buildings, where temperature may

fall below 0 °C, e.g. unheated parking

areas.

For such applications installation of

electrical heating cables to ensure

sustainable water flow and to prevent

icing and subsequent pipe bursting is

strongly advisable and in many cases

required by law.

For further detailes investigate local

buidling norms.

Outside above ground installation

Pipes installed outside buildings are

especially in need of frost protection.

The primary protection is ensured

by insulation but often to protect

pipes in extreme weather conditions

or in course of economic feasibility

it's advantageous to install an

electrical heating system (cables and

thermostat).

Examples of such installations can be

found: on roofs of shopping arcades,

office buildings, hotels or utility

buildings like water stations.

Outside in-ground installation

Water pipes insulated and protected

with electrical heating systems can be

installed in ground at a shallower depth.

In some areas, where the ground is

composed of solid rock, this is the most

economically feasible solution.

Location of electrical heating cables

has to be clearly marked following

local electricity laws. Marking shall

include at least a yellow or red warning

label indicating a supply voltage level.

Additionally, if the cable is not protected

by a concrete block, or similar, a thick

plastic tape should be placed on top

and slightly above the cable for its entire

length. This is to minimize the possibility

of mechanical damage during possible

excavation activities in the future.

6

Application manual · Pipe Frost Protection · VKLUD102 · ©Danfoss

Page 7

3. Products

Heating cables

The following heating cables can be

used for protection of water pipe

heating systems:

Heating cables for on-pipe installation:

• Resistive (constant wattage):

ECflex 10T, ECflex 18T;

ECbasic 20S.

• Self-limiting cables (SLC;

variable wattage):

ECpipeheat 10 V2,

ECpipeguard 10/SLPG-10,

ECpipeguard 25/SLPG-25,

ECpipeguard 33/SLPG-33;

ECiceguard 18/SLIG-18.

Heating cables for in-pipe installation:

• ECaqua 9T.

Mentioned as "in-pipe installation"

is approved for use in contact with

drinking water.

The heating cable is relatively stiff,

which makes the installation easier.

The polyethylene coating prevents

any output or taste alteration of

drinking water.

Self-limiting heating cables are

equipped with a temperature

sensitive resistant element between

two parallel copper conductors.

When conductors are connected to

the mains, the current flows through

the temperature sensitive element

which starts heating. As the element

is heated, the resistance value rises

causing the current decrease and

then the heating is reduced. This

explains the self-limiting output

effect.

Such independent output regulation

takes place on the entire cable based

on the actual ambient temperature.

When the ambient temperature rises,

the cable heating output is reduced.

This self-limiting capability allows

avoiding cable overheating even in

case if two cables cross or touch each

other.

Autonomous power supply of selflimiting heating cables allows their

shortening or extending in any place.

This simplifies cable planning and

installation.

In order to limit power consumption

the heating cable should switch on/

off if it’s length exceeds approx. 3 m,

e.g. by using a ECtemp thermostat.

Resistive cables

ECbasic

ECflex

Self-limiting cables

ECpipeheat 10 V2/ SLPH-10

ECpipeguard 10/SLPG-10

ECpipeguard 25/SLPG-25

ECpipeguard 33/SLPG-33

ECaqua 9T

ECiceguard 18/SLIG-18

Application manual · Pipe Frost Protection · VKLUD102 · ©Danfoss

7

Page 8

Thermostats

To control a pipe heating system

ECtemp 330 (5…45 °C) thermostat

with DIN rail attachment or

wall/pipe mounted ECtemp 610

(IP44) are recommended.

All thermostats are equipped with

wire temperature sensors in set –

NTC 15 kOhm @ 25 °C, 3 m.

Fixing & Connection

Attaching cable to metal or plastic

pipes is recommended by means of

adhesive aluminum tape.

A large choice of connection sets,

shrink tube or system-sets is available

for connection and interconnection

of heating cables (including SLC) to

power supply and to each other. See

also the next page.

A larger variety of connecting

accessories (fixed as well as based

on shrinking-tube) for self-limiting

heating cables is available.

For more information please refer

to the Danfoss product program or

contact your local Danfoss provider.

SLC to box connection set (#19400100)

SLC connection set (#19400126)

ECtemp 330 ECtemp 610

8

Application manual · Pipe Frost Protection · VKLUD102 · ©Danfoss

Glued aluminum tape with warning signs

(#19805076)

Connection box (#19400167)

Page 9

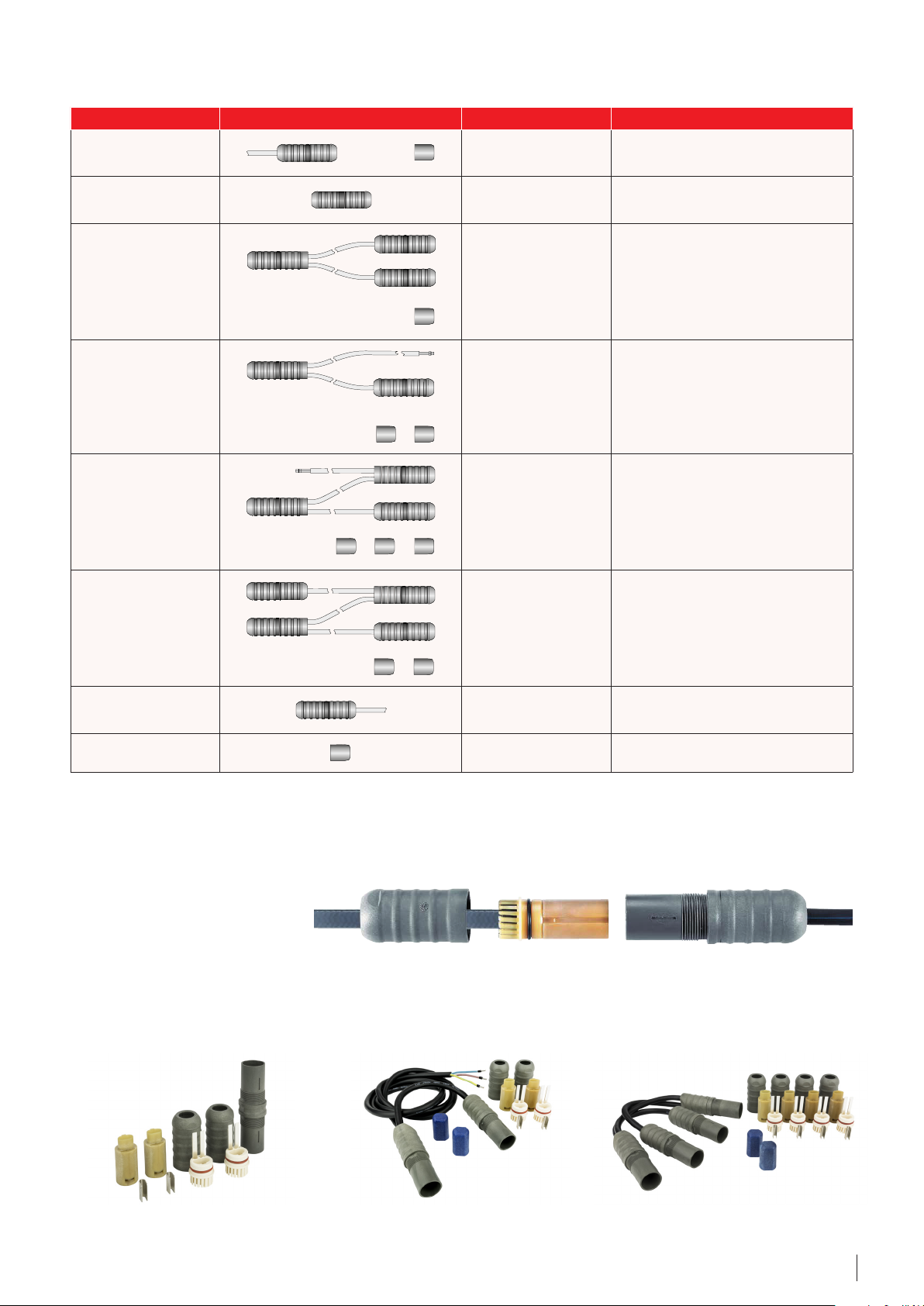

Selection chart: Danfoss Connecto for heating cables with braiding

Article no. Illustration Name Description

088L0416 Connecto B-S

088L0414 Connecto B-C

088L0417 Connecto B-T

088L0418 Connecto B-TE2

088L0419 Connecto B-TE3

Heating cable connection with 1,5 m

power cable and end terminal

Heating cable slice/extension for con-

necting two heating cables

Heating cable T-branch as a T-junction for

three heating cables and 1 end terminal

Heating cable double connection with 1,5

m power cable and 2 end terminals

Heating cable T-branch with 1,5 m power

cable and 3 end terminals

088L0420 Connecto B-X

088L0413 Connecto B-A

088L0415 Connecto B-E Heating cable end terminal

Danfoss Connecto system

installation steps

1. Cut the heating cable straight

2. Push the heating cable in

3. Twist untill closed

Heating cable X-branch for 4 heating

cables incl. 2 end terminals

Heating cable connection with power

cable 1,5 m without end terminal

Connecto B-C Connec to B-TE2 Connecto B-X

Application manual · Pipe Frost Protection · VKLUD102 · ©Danfoss

9

Page 10

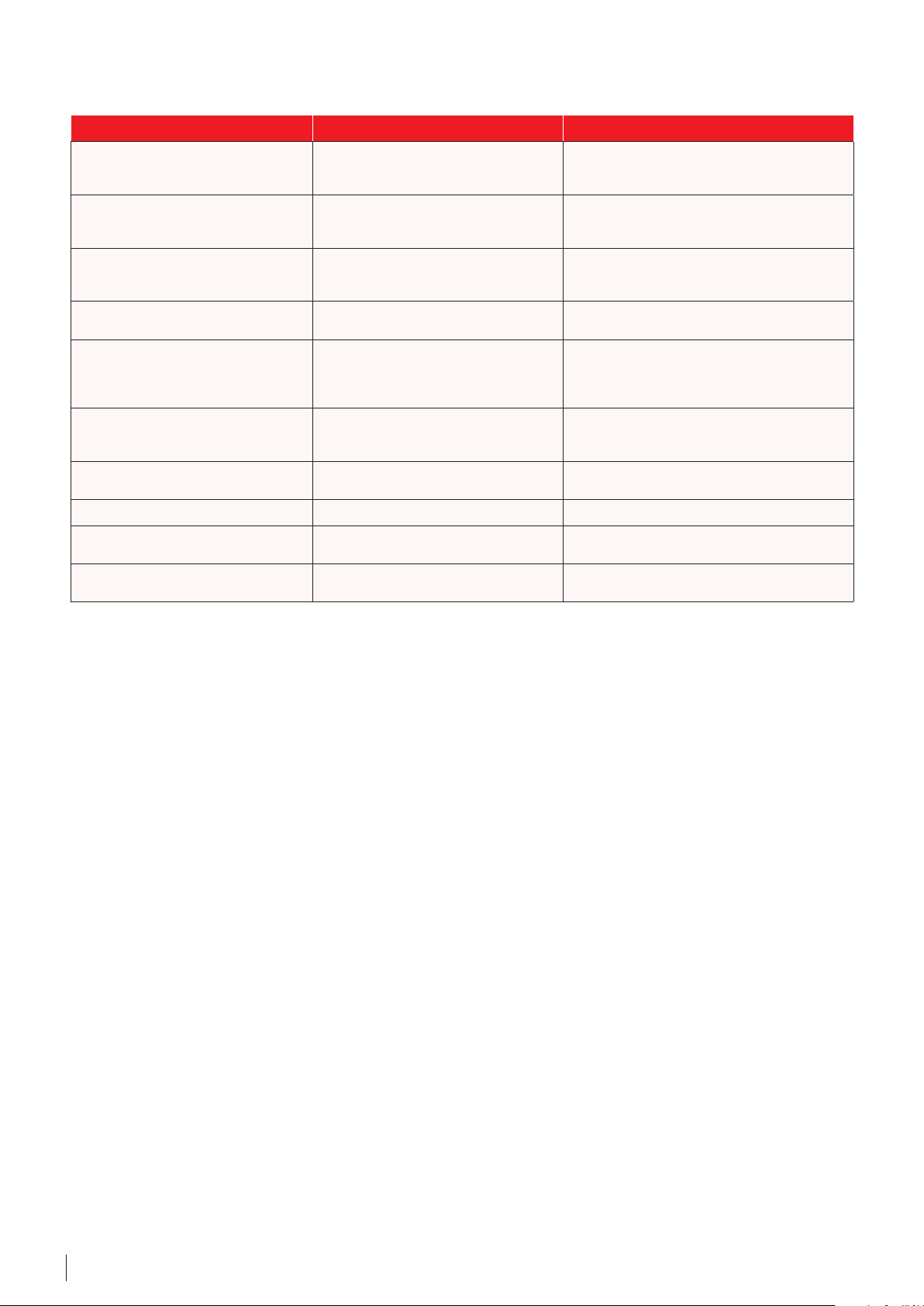

Product overview for the Pipe Frost Protection

Product Options Description

Resistive heating cable

ECflex

Resistive heating cable

ECbasic

Resistive heating cable

ECaqua

Self-limiting heating cable

Danfoss iceguard

Self-limiting heating cable

Danfoss pipeguard

Self-limiting heating cable inside pipe

Danfoss pipeheat 10 V2

Danfoss thermostat ECtemp 330 (5…45 °C)

Danfoss thermostat ECtemp 610 -10…+50 °C, 10 A, IP44, wall/pipe installation

Assembly kit

Fixing Aluminum tape (Alutape)

ECflex 10T, 230 V;

ECflex 18T, 230 V

ECbasic 20, 230 V;

EFSIC 20, 400 V, on drum

ECaqua 9T

with 3/4+1" Pipe fitting

ECiceguard 18 (SLIG-18), on drum

ECpipeguard 10 (SLPG-10), on drum

ECpipeguard 25 (SLPG-25), on drum

ECpipeguard 33 (SLPG-33), on drum

ECpipeheat 10 V2 (SLPH-10) with plug, 2-25 m.

Accessory:

3/4"+1" Pipe fitting (10 bar @ 23 °C)

Connecto

and other assembly kits

Twin conductor, 100% screen.

10 or 18 W/m (230 V); Ø 6,9 mm.

DIN IEC 60800:2009 M2

Single conductor, wire screen.

20 W/m (230 V); Ø 5,5 mm.

DIN IEC 60800:1992

Twin conductor, wire screen,

9 W/m (230 V); Ø 5,7 mm

Approved for use in drinking water.

18 W/m @ 0 °C.

11,8 x 5,8 mm.

10 W/m @ 10 °C.

25 W/m @ 10 °C.

33 W/m @ 10 °C.

11,8 x 5,8 mm

10 W/m @ 10 °C, 100% screen.

7,7 mm × 5,3 mm.

5…45 °C, 16 A, IP20,

DIN rail

For self-limiting cables

Glued aluminum tape 38 mm x 50 m;

0,06 mm; max. 75 °C

For details please refer to the Danfoss Catalogue.

Various specific assembly kits are available.

10

Application manual · Pipe Frost Protection · VKLUD102 · ©Danfoss

Page 11

4. System design

Output of heating cables installed

on pipe should not be less than the

calculated pipe surface heat loss

multiplied by 1,3 safety factor.

In most cases 10 W/m output is enough if:

• the pipe diameter does not exceed

50 mm,

• the temperature of surroundings

does not fall below -30 °C.

• the required temperature inside the

pipe is 5 °C.

In other words, for the above

conditions, the only one 10 W/m cable

line (ECflex 10T, etc.) is required.

• the insulation thickness is at least

the same as the pipe diameter,

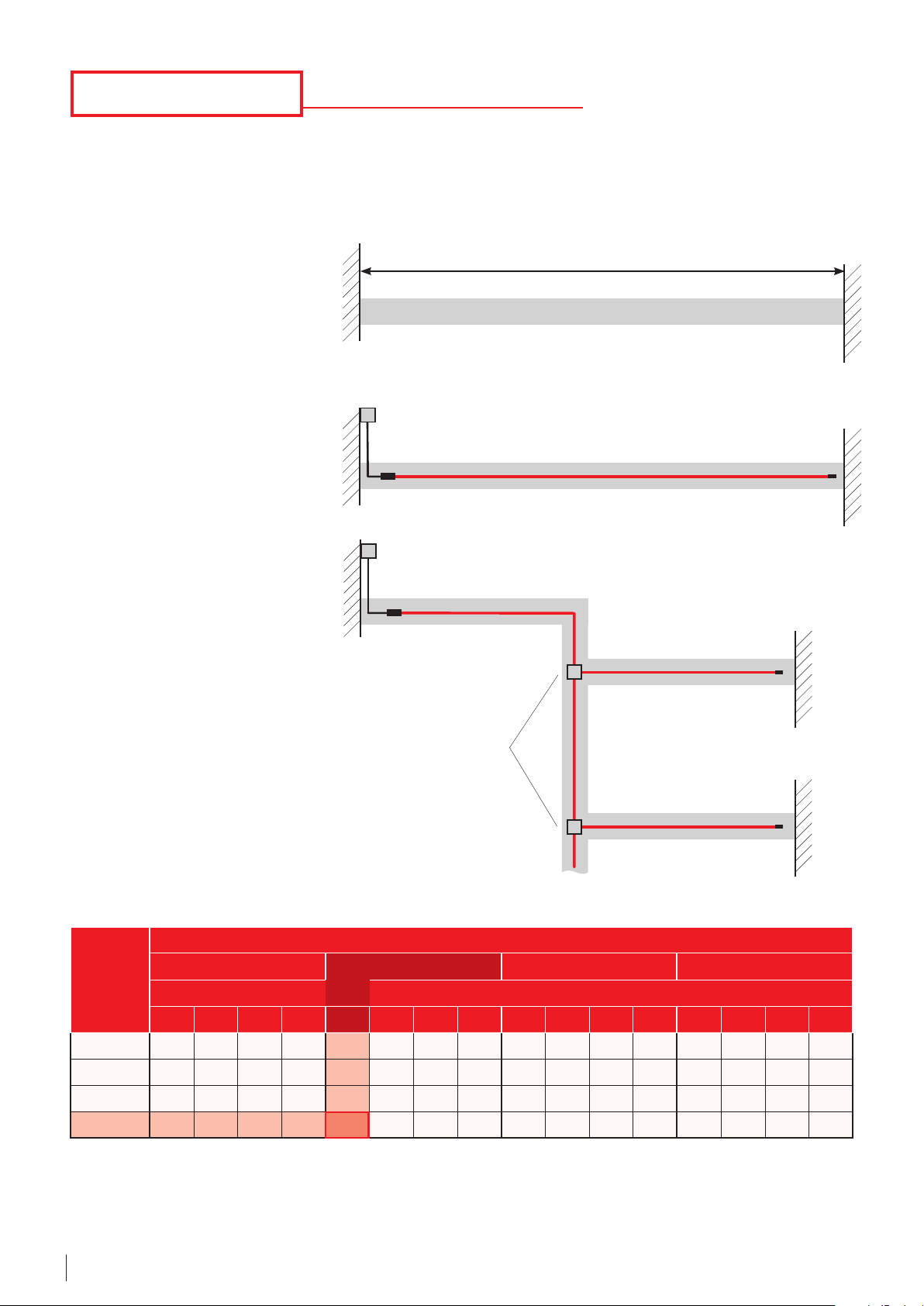

Frost protection of pipe systems [W/m]

To define the heat loss follow the pipe

The table below shows the heat loss

for 1 meter of pipe (q

) for various

pipe

pipe dimensions, insulation thicknesses

and temperatures.

diameter (in [mm] or [inch]) at the top

bar of the table towards the row with

the insulation thickness and using the

appropriate temperature

Required minimal outputs in [W/m], for straight pipelines (without flanges, valves or T-branches).

Inside pipe

diameter

Outside pipe

diameter*

Insulation

thickness

10 mm

20 mm

30 mm

40 mm

50 mm

75 mm

* NPS - Nominal Pipe Size, DN - diamètre nominal/nominal diameter/Durchmesser nach Norm.

Values in table can be calculated with help of formula on next page (chapter 4.1)

inch (NPS*) ½ ¾ 1 1¼ 1½ 2 2½ 3 3½ 4 4½ 5 6 8 10 12

mm (DN*) 15 20 25 32 40 50 65 80 90 100 115 125 150 200 250 300

mm 21 27 34 42 48 60 73 89 102 114 127 141 168 219 273 324

ΔT, °C Heat loss for 1 meter of pipe, W/m ( λ = 0,04, Safety factor = 1,3)

20 9,8 11,8 14,1 16,8 18,8 22,7 27,0 32 36 40 45 49 58 75 92 109

25 12,2 14,7 17,6 21,0 23,4 28,4 34 40 46 51 56 62 73 93 115 136

30 14,6 17,7 21,2 25,2 28,1 34 40 48 55 61 67 74 87 112 139 164

40 19,5 23,6 28,2 34 38 45 54 64 73 81 89 98 116 149 185 218

60 29,3 35 42 50 56 68 81 97 109 121 134 148 174 224 277 327

80 39,0 47 56 67 75 91 108 129 146 162 179 197 232 299 370 436

100 48,8 59 71 84 94 114 135 161 182 202 223 246 290 374 462 545

20 6,1 7,2 8,4 9,8 10,8 12,8 14,9 17,6 19,7 21,7 23,9 26,2 31 39 48 56

25 7,7 9,0 10,5 12,2 13,5 16,0 18,7 22,0 24,7 27,1 30 33 38 49 60 70

30 9,2 10,8 12,6 14,6 16,2 19,2 22,4 26,4 30 33 36 39 46 58 72 84

40 12,2 14,4 16,8 19,5 21,6 25,6 30 35 39 43 48 52 61 78 96 112

60 18,4 21,6 25,2 29,3 32 38 45 53 59 65 72 78 92 117 143 168

80 24,5 28,7 34 39 43 51 60 70 79 87 95 105 122 156 191 224

100 30,6 36 42 49 54 64 75 88 99 109 119 131 153 195 239 281

20 4,8 5,6 6,4 7,4 8,1 9,4 10,9 12,7 14,1 15,4 16,9 18,4 21,4 27,0 33 38

25 6,0 7,0 8,0 9,2 10,1 11,8 13,6 15,8 17,6 19,3 21,1 23,0 26,7 34 41 48

30 7,3 8,4 9,6 11,0 12,1 14,1 16,3 19,0 21,2 23,2 25,3 27,6 32 40 49 58

40 9,7 11,2 12,8 14,7 16,1 18,8 21,8 25,3 28,2 31 34 37 43 54 66 77

60 14,5 16,7 19,3 22,1 24,2 28,3 33 38 42 46 51 55 64 81 99 115

80 19,4 22,3 25,7 29,4 32 38 44 51 56 62 68 74 86 108 131 154

100 24,2 27,9 32 37 40 47 54 63 71 77 84 92 107 135 164 192

20 4,2 4,7 5,4 6,1 6,7 7,7 8,8 10,2 11,3 12,3 13,4 14,5 16,8 21,0 25,4 29,6

25 5,2 5,9 6,7 7,7 8,3 9,6 11,0 12,7 14,1 15,4 16,7 18,2 21,0 26,2 32 37

30 6,2 7,1 8,1 9,2 10,0 11,6 13,2 15,3 16,9 18,4 20,1 21,8 25,2 31 38 44

40 8,3 9,5 10,8 12,2 13,3 15,4 17,7 20,4 22,6 24,6 26,7 29,1 34 42 51 59

60 12,5 14,2 16,2 18,4 20,0 23,1 26,5 31 34 37 40 44 50 63 76 89

80 16,6 19,0 21,6 24,5 26,6 31 35 41 45 49 53 58 67 84 102 118

100 20,8 23,7 27,0 31 33 39 44 51 56 61 67 73 84 105 127 148

20 3,7 4,2 4,8 5,4 5,8 6,7 7,6 8,7 9,6 10,4 11,2 12,2 14,0 17,4 20,9 24,3

25 4,7 5,3 6,0 6,7 7,3 8,3 9,5 10,8 11,9 13,0 14,1 15,2 17,5 21,7 26,2 30,4

30 5,6 6,3 7,1 8,0 8,7 10,0 11,4 13,0 14,3 15,6 16,9 18,3 21,0 26,0 31 36

40 7,5 8,4 9,5 10,7 11,6 13,3 15,1 17,3 19,1 20,7 22,5 24,4 28,0 35 42 49

60 11,2 12,7 14,3 16,1 17,4 20,0 22,7 26,0 28,7 31 34 37 42 52 63 73

80 14,9 16,9 19,0 21,4 23,2 26,6 30 35 38 41 45 49 56 69 84 97

100 18,6 21,1 23,8 26,8 29,0 33 38 43 48 52 56 61 70 87 105 121

20 3,1 3,5 3,9 4,3 4,6 5,2 5,8 6,6 7,2 7,8 8,4 9,0 10,2 12,5 14,9 17,2

25 3,9 4,3 4,8 5,4 5,8 6,5 7,3 8,3 9,0 9,7 10,5 11,3 12,8 15,6 18,6 21,5

30 4,7 5,2 5,8 6,4 6,9 7,8 8,8 9,9 10,8 11,7 12,6 13,5 15,4 18,8 22,4 25,7

40 6,2 6,9 7,7 8,6 9,2 10,4 11,7 13,2 14,4 15,6 16,8 18,0 20,5 25,0 29,8 34

60 9,3 10,4 11,6 12,9 13,8 15,6 17,5 19,8 21,7 23,3 25,1 27,0 31 38 45 51

80 12,5 13,9 15,5 17,2 18,4 20,9 23,4 26,4 28,9 31 34 36 41 50 60 69

100 15,6 17,4 19,3 21,5 23,0 26,1 29,2 33 36 39 42 45 51 63 75 86

Note. For plastic pipes the linear

output of resistive heating cables

should not exceed 10 W/m. This

restriction does not apply to selflimiting cables (SLC).

Following pages will help step-by-step

to make a right design choice.

difference you will find the heat loss

value at the crossing point.

For this table λ of insulation material

is 0,04 W/m·K (e.g. mineral wool) and

safety factor is 1,3.

Application manual · Pipe Frost Protection · VKLUD102 · ©Danfoss

11

Page 12

4.1. Step-by-step system design

Following pages provide an easy stepby-step design guide for selection of a

Danfoss pipe frost protection system.

The recommendations are provided

relate both constant wattage cables

and self-limiting cables, as well as

thermostats and accessories.

Step 1 2 3 4 5

Step 1 2 3 4 5

Heat loss calculation

Product selection

The detailed example is provided at

the end of this chapter.

Step 1 2 3 4 5

The most important factors to define

the pipe heat losses are the following:

• Pipe diameter

• Insulation thickness

• Difference between inside (desired

maintained temperature) and

outside pipe temperatures (e.g.

outdoor) temperature of the

installation site.

Step 1 2 3 4 5

Step 1 2 3 4 5

Step 1 2 3 4 5

Heat loss calculation

Cable length selection

Regulator selection

Accessories selection

t

a

t

p

The following formula is used for

heat losses calculation for total length

of a pipe to be protected:

Q [W ] =

2 · π · λ · l · (tu - to)

ln(D/d)

1, 3 ,

where:

D - Outside pipe diameter incl. insulation, [m],

d - Pipe diameter without insulation, [m],

l - Total length of pipe, [m],

tp - Desired maintained temperature, [°C],

ta - Outside temperature, [°C],

λ - Thermal conductivity of insulation, [W/m·K],

1,3 - Safety factor.

ln(D/d)

(D/d)

Heat loss values from the table on

λ value for standard insulation material

(like glass wool or styropor), is set to

0,04 W/m·K.

the previous page calculated by the

above formula and divided by total

pipe length. The obtained values are

in [W/m].

12

Application manual · Pipe Frost Protection · VKLUD102 · ©Danfoss

0,0

1,0

0,4

1,5

0,7

2,0

0,9

2,5

1,1

3,0

1,3

3,5

1,4

4,0

d

D

1,5

1,6

1,8

1,9

2,1

2,2

2,3

4,5

5,0

6,0

7,0

8,0

9,0

10,0

15,0

Natural logarithm (ln) values for D/d

ratio: X = D/d.

2,7

3,0

20,0

3,2

25,0

Page 13

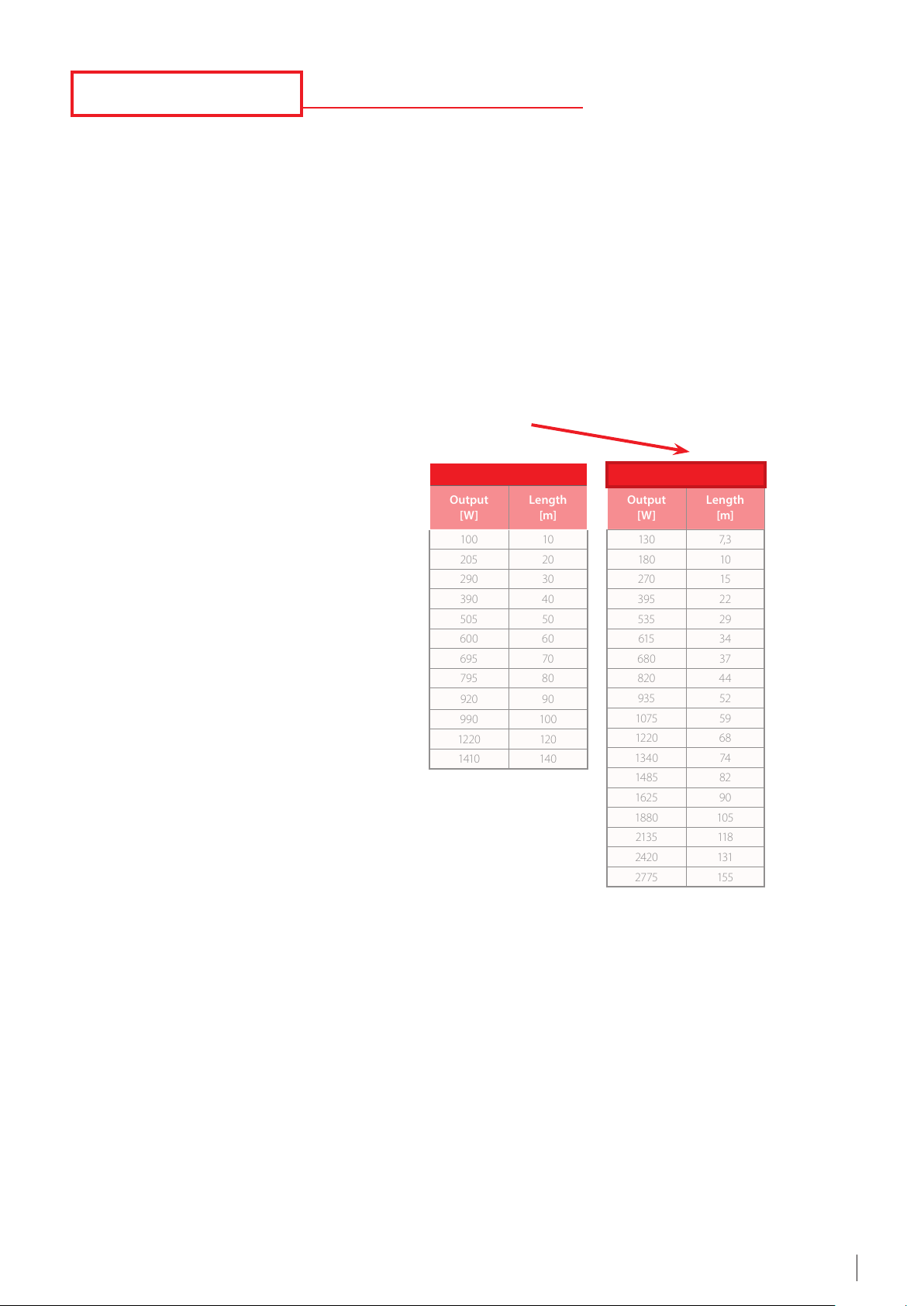

Step 1 2 3 4 5

Product selection

Constant wattage heating cables

Are typically used in case of simple

straight pipe lines installed in a similar

thermal environment.

In such cases selection of the heating

cable directly depends on the pipe

length.

In case of installation of new pipes, or

longer pipe lines, the use of on-pipe

heating cables is preferable.

For shorter or existing pipes installation

of in-pipe heating cables is the only

feasible or available choice.

There are two different cables for

selection with different linear output

(10 W/m or 18 W/m). It's necessary

to choose a heating cable with

output equal or higher than the one

calculated by the formula (including

1,3 safety factor).

Cable outputs are calculated for 230 V.

For 220 V the displayed output value in

[W] shall be multiplied by 0,91 factor.

E.g. ECflex 10T, 60 m with output of

600 W at 230 V, has the output of only

546 W at 220 V.

Example (see also Step 1)

• Pipe diameter d = 65 mm

• Insulation thickness = 20 mm

• Thermal conductivity value for

insulation λ = 0,04

• Desired temperature tu = +10 °C

• Minimum outside temperature

to = -20 °C

Heat loss Q is calculated with help of

formula from Step 1 or from table on

page 11: Q = 16 W/m.

The choice is for cable with linear

output ≥ 16 W/m: ECflex 18T

(18 W/m).

ECf lex 10 T

Output

[W]

100 10

205 20

290 30

390 40

505 50

600 60

695 70

795 80

920 90

990 100

1220 120

1410 140

Length

[m]

ECflex 18T

Output

[W]

130 7,3

180 10

270 15

395 22

535 29

615 34

680 37

820 44

935 52

1075 59

1220 68

134 0 74

1485 82

1625 90

1880 105

2135 118

2420 131

2775 155

Length

[m]

Application manual · Pipe Frost Protection · VKLUD102 · ©Danfoss

13

Page 14

Step 1 2 3 4 5

06

W/m]

Product selection

Self-limiting heating cables (SLC)

SLCs are often used for pipe systems

with many branches, because it's

easier to adjust the cable length to

appropriate pipe length (SLC can

be cut to length provided that the

maximum cable length is observed).

The self-limiting function, that allows

SLC output adjustment based on the

pipe temperature, is a rather useful

feature. However the self-limiting

cable regulation by a thermostat is

recommended due to continuous

use of the SLC, even if heating is not

needed.

When choosing a self-limiting heating

cable it's essential to investigate

whether the heating cable can provide

the required output at the desired

temperature.

How to read the graph

Draw a line from the desired

temperature value (X-axis) and a

calculated heat loss output (Y-axis).

Afterwards find a heating cable with

output values higher (Y-axis) than the

cross point of temperature and output

lines.

Example (see also Step 1)

• Pipe diameter d = 65 mm

• Insulation thickness = 20 mm

• Thermal conductivity value for

insulation λ = 0,04

• Desired temperature tu = +10 °C

• Minimum outside temperature

to = -20 °C

Heat loss Q is calculated by the formula

of Step 1 or from the table on page 11:

Q = 16 W/m.

The choice is for ECiceguard 18 with

linear output of 18 W/m at 10 °C.

40

35

30

Linear output [

25

20

Calculated

heat loss

Q= 16 W/m

15

ECpipeheat 10 V2

ECpipeguard 10

ECpipeguard 25

ECpipeguard 33

ECiceguard 18

14

10

5

0

0102030405

Application manual · Pipe Frost Protection · VKLUD102 · ©Danfoss

Desired temperature

tp= +10 °C

0

Pipe temperature [°C]

Page 15

Step 1 2 3 4 5

ECf lex 10 T

Output

[W]

Length

[m]

100 10

205 20

290 30

390 40

505 50

600 60

695 70

795 80

920 90

990 100

1220 120

1410 140

Cable length selection

Constant wattage heating cables

All ECflex constant wattage heating

cables are manufactured with specific

lengths. A product to be chosen

should be of the same length or longer

than the entire length of the pipe to be

protected.

If the protected pipe is fitted with

some components such as flanges,

valves, supports, T-branches, or

sprinklers some extra cable length

shall be applied. In this case use the

calculation formula in chapter 4.1.

Important:

It's strictly forbidden to cut a constant

wattage cable. In case of surplus cable

length it should be wound around the

pipe, or for metal pipes only it should

be drawn along the pipe at its end.

Length of cable is connected to the

power supply and it's used to its full

availability. A total length of the cable

has to be used. Reducing cable length

by its cutting is strictly forbidden.

Spiral winding of heating cable around

a pipe gives better heat division and

protection, but requires more space

around the pipe during installation and

thus can be unfeasible in some cases.

For further advice concerning the

cable layout please refer to chapter 5.1

(Installation).

Example:

Pipe length L = 50 m,

Q = 16 W/m (as before).

Heating cable of L

cable

= 52 m

and 935 W output is chosen.

L = 50 m

ECflex 18T

Output

[W]

130 7,3

180 10

270 15

395 22

535 29

615 34

680 37

820 44

935 52

1075 59

1220 68

134 0 74

1485 82

1625 90

1880 105

2135 118

2420 131

2775 155

Length

[m]

Connection point

Steel pipe

Connection point

Steel and plastic pipes

L

= 52 m

cable

L

= 52 m

cable

Application manual · Pipe Frost Protection · VKLUD102 · ©Danfoss

15

Page 16

Step 1 2 3 4 5

Connection point

Cable length selection

Self-limiting heating cables

Self-limiting heating cables are

available on drums and ready to be

cut to length. The maximum length of

SLC is defined by: a cable type, start-up

temperature and a fuse size.

The length of a self-limiting heating

cable should be enlarged in case of

presence of valves, flanges and alike, in

the same way as for constant wattage

cables (see chapter 4.1 for further

details).

Maximum length of connected

self-limiting heating cables

The maximum length of the combined

(all parts) self-limiting heating cables

can't exceed the value for this cable

included in the table below.

Example:

Pipe length L = 50 m,

Q = 16 W/m.

L = 50 m

230V

The choice is for ECiceguard 18 with 50 m length.

Connection point

230V

L

< L

total

part 1

max

part 2

Total cable length

L

= part 1 + part 2 + part 3 ≤

total

≤ max. allowed length (L

Example: At start up temperature of

+10 °C, 10 A fuse and ECiceguard 18,

L

= 58 m

max cable

Maximum length values for SLCs at different start-up temperatures and fuse sizes

ECpipeguard 10 EC pipeguard 18 ECpipeguard 25 ECpipeguard 33

Start-up

temperature

10A 16A 25A 32A 10A 16A 20A 25A 10A 16A 25A 32A 10A 16A 25A 32A

–20°C 97 156 226 226 35 56 70 87 46 74 116 146 28 45 71 91

–10°C 110 176 226 226 39 63 79 99 52 84 131 146 32 51 81 103

0°C 119 191 226 226 43 70 88 110 58 93 146 14 6 36 58 91 117

+10 °C 119 191 226 226 58 93 116 145 58 93 146 146 42 67 105 120

Maximum cable lengths are defined for

the case when the cable is switched on

being unheated.

max cable

)

In this case its power consumption

will be in the range of 3-7 times of

its nominal value, when reaching its

T-branch points

part 3

Max. length of heating cable at 230 V [m]

Fuse size of C characteristic

Start-up temperature is the possible

min. ambient temperature at which

the SLC is turned on.

operating temperature.

16

Application manual · Pipe Frost Protection · VKLUD102 · ©Danfoss

Page 17

Step 1 2 3 4 5

Regulator selection

Temperature regulation

Constant wattage as well as selflimiting heating cables require

a thermostat for regulation. The

thermostat ensures maintaining

constant temperature and turning

the heating on while limiting energy

consumption, even for SLCs that are

constantly on and even if it’s not

required.

The thermostat selection depends

on the specific installation. The most

common systems are described

on this page, either with a sensor

placed directly onto the pipe (under

the insulation) or based on the air

temperature sensor.

Systems with a sensor installed

directly on the pipe to be protected is

of the most use.

Temperature regulation using air

sensor

thermostat air temperature sensor

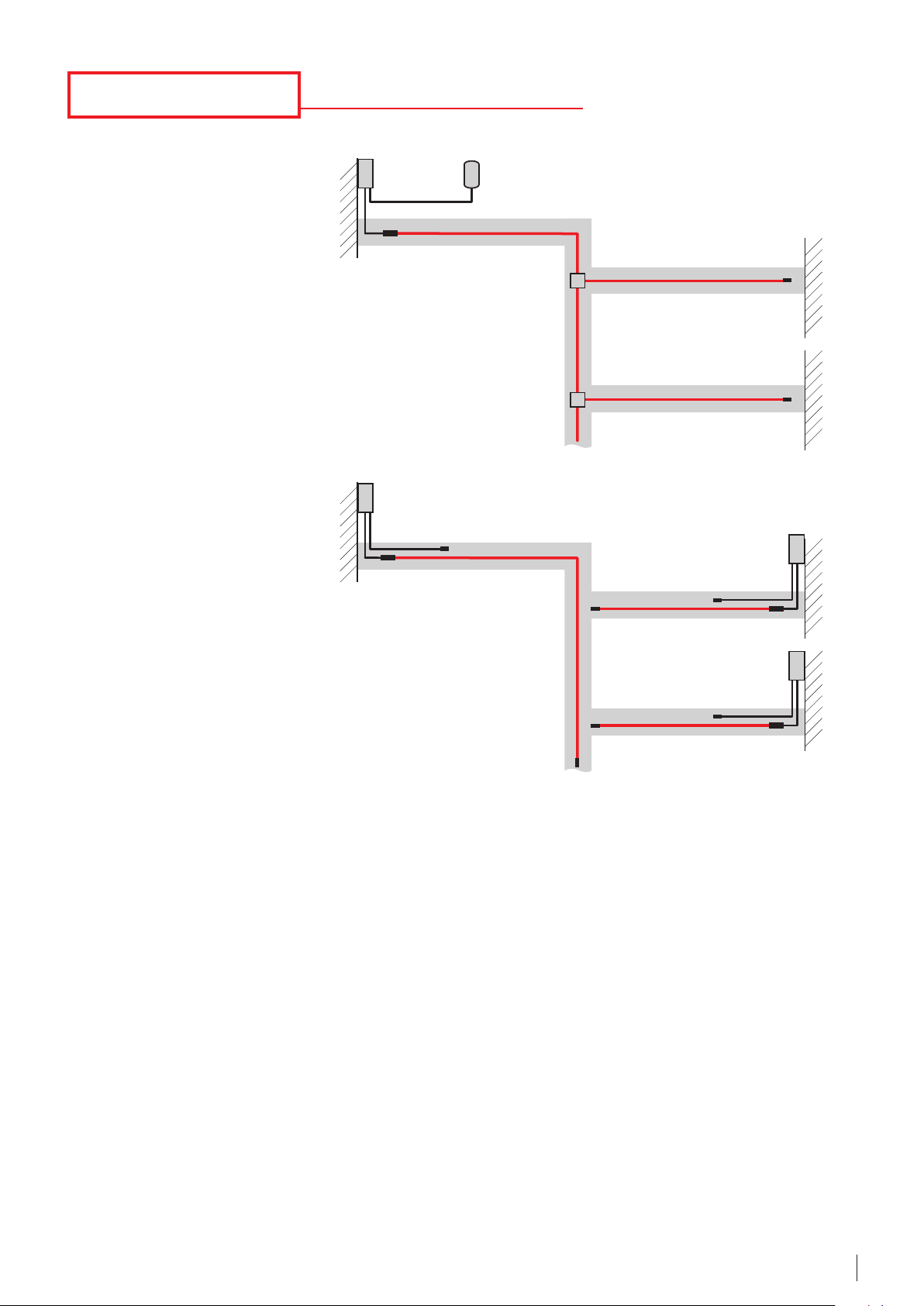

Pipe of different diameters. Installation completed with self-limiting heating cable.

thermostat

on-pipe mounted sensor

thermostat

on-pipe mounted sensor

This system is based on the air sensor

that is installed close to the protected

pipe and that turns on the heating

when the ambient temperature falls

below the set value.

Such set up is primarily used in

cooperation with self-limiting

heating cables.

If the size of the heating elements

exceeds the maximum limit defined

by the thermostat, the connection to

more heating elements needs to be

ensured by means of relays /

contactors. In such installations,

one thermostat can regulate several

heating elements.

Advantage of this system is mostly

visualized in regulating of pipe frostprotection systems, where pipes

have different sizes and insulation

thickness.

thermostat

on-pipe mounted sensor

Pipe of different diameters. Installation completed with constant wattage heating cable.

Temperature regulation using onpipe sensors

It requires, as shown on the picture,

more thermostats, and is necessary

when:

This type of installation, where the

sensor is placed directly on pipe

under insulation, is more precise and

energy efficient way of regulation

than the air sensor.

• pipes have different sizes or

insulation thicknesses;

• changing temperature conditions,

e.g. pipe from building to outside,

and back to the building, or installed

above or underground;

On-pipe sensor regulation is often

used for systems with many pipes and

branches, with different temperature

settings or conditions.

• mixed pipes delivering stagnant and

moving water;

• pipes delivering any fluid sensitive

to rapid temperature changes

This type of regulation, with on-pipe

sensor, is required when installation

is performed with constant wattage

cables, or on plastic pipes (e.g. PVC, PP,

PE, PE-X).

Application manual · Pipe Frost Protection · VKLUD102 · ©Danfoss

17

Page 18

aluminum tapes

(pipe dimension Ø 150 mm)

heating cable

(under the tape)

aluminum tape

aluminum tapes

for cable attachment

to the pipe

metal

pipe

~1 m

app. 1,5 m tape

on 1 m of pipe

(pipe dimension Ø 150 mm)

connection box

power connection

entrance gate

Choice of the thermostat also relates

to its temperature range, expected

place of installation (in DIN-rail

box or outside) and any additional

requirements.

Sensor placing

Sensors for pipe frost-protection

systems should be installed in a place

that is the most representative for

the installation, i.e. in the expected

coldest point of this installation (e.g.

on pipe part facing the entrance to

the unheated parking area).

thermostat

sensor

Example:

Pipe length 50 m, a frost protection

installation with a ECiceguard 18

self-limiting cable with DIN-rail

thermostat.

Maintained temperature = +10 °C.

underground garage

Solution is ECtemp 330 (-10...+10 °C),

but ECtemp 330 (+5...+45 °C) can also

be considered.

For more information please refer to

chapter 3 (Products) or to the Danfoss

Product Catalogue.

Step 1 2 3 4 5

Constant wattage and SLC cables

In case of metal pipes the heating

cable can be attached to the pipe

by means of an aluminum tape

placed at intervals of approx. 1 meter.

Subsequently, the total length of the

heating cable needs to be covered

with aluminum tape, securing cables

to the pipe.

In case of the plastic pipes, before

mounting the cable onto the pipe, the

aluminum tape needs to be applied on

the pipe where the heating cable will

be placed. Other part of the installation

steps resembles that of the installation

on metal pipe.

Selection of connection boxes and

accessories for constant wattage

cables

Constant wattage cables are fitted with

connection cables (power connection),

so no additional connection

accessories are needed.

If electric conneciotn point requires, a

connection box can be used.

Accessories selection

(between layers of aluminum tape)

metal

pipe

plastic

pipe

heating cable

~1 m

heating cable

(under the tape)

(between layers of aluminum tape)

installation through the insulation

pipe insulation

aluminum tape

~1 m

1st layer of tape

heating cable

for cable attachment

to the pipe

app. 1,5 m tape

on 1 m of pipe

2nd layer of tape

app. 2,5 m tape

on 1 m of pipe

(pipe dimension Ø 150 mm)

~1 m~1 m

18

Application manual · Pipe Frost Protection · VKLUD102 · ©Danfoss

(part of a heating cable)

connection muff

constant

wattage cable

end muff

(part of a heating cable)

Page 19

Selection of connection accessories for self-limiting heating cables

Complete set

for 1 branch:

1 x Connection box

3 x Connection to box

1 x Bracket

3 x Through Insulation set

to power supply

230V

connection to box

to power supply

230V

bracket

connection to box

power cable

SLC to SLC connection set

through

insulation set

end element

from connection to box

end element

from connection to box

2. Set of accessories for connection

to power supply (option no. 1):

1 x Connection box

1 x Connection to box

1 x Bracket

1 x Through Insulation set

Connection sets for connection to

box and SLC to SLC contain also end

elements (end muff).

3. Set of accessories for connection

to power supply (option no. 2):

1 x SLC to SLC connection set

1 x Through Insulation set

Connection to power supply

can be done with a heating cable

connected via connection box

(option no. 1), or end up with cold tail

connected with help of option no. 2.

Application manual · Pipe Frost Protection · VKLUD102 · ©Danfoss

Beside shrink tube connection sets,

Danfoss provides a wide range of

easy-fix connection sets for self-limiting

heating cables.

For more details please see

chapter 3 (Products) and the

Danfoss Product Catalogue.

19

Page 20

5. Installation

5.1. General information

Pipe conditions

Before installing heating cables it is

important to check the pipe for any

signs of damage or leakage.

The pipes should be insulated as this

reduces the heat losses considerably.

This applies for all pipes whether they

are below or above the ground.

The cable should be attached to

the pipe gently, so it does not get

damaged. The entire length of the

cable should be attached to the

pipe with aluminum tape and NOT

plastic tape (e.g. PVC), as it contains

plasticizers.

The cable should be laid in such a

manner to avoid sharp edges on the

pipe. Treading on cables should be

avoided and cables should be treated

carefully at all times.

All pipe trenches should be distinctly

marked to indicate that heating cables

have been installed on/ in them. It

should also be marked with a distinct

warning sign, e.g. “WARNING: 230

VOLT HEATING CABLES“.

Insulated pipes must be marked with a

warning sign placed on the outside of

the insulation material.

Heating cable should not be pulled

with more than 25 kg.

Electrical conditions

The screen of the heating cables must

be earthed in accordance with the

local electricity laws.

The resistance and the insulating

resistance of the heating cable

must be checked before and after

installation. The resistance value must

be as indicated on the label of the

connection box.

The sensor cable can be extended to

any reasonable length using a cable of

min 2 x 0,75 mm².

The cable is attached to the pipe with

strips of aluminum tape placed at

intervals of approx. 1 meter. When the

heating cable has been attached to the

pipe, the entire length of the heating

cable must be covered with lanes

of aluminum tape. This prevents the

heating cable from getting into direct

contact with the insulation material

and ensures a tight fit between the

pipe surface and the heating cable.

Before the heating cable is attached to

the plastic pipe, a full lane of aluminum

tape should be applied to the pipe for

the cable to lie on. This ensures a better

heat distribution to the pipe. Cables

should be attached at the lower part of

the pipe or/and symmetrically around

the pipe.

The connection muff between the

heating cable and the cold tail should

also be fixed with aluminum tape.

The sensor cable is attached to the

pipe in the same way as the heating

cable. The tip at the end of the sensor

should be covered with aluminum

tape and be positioned centrally

between the cable lines and on top of

the pipe, if possible.

The heating cable must not be led

through valves. The heating cable

is relatively stiff that makes the

installation easier.

The cable must be evenly spread and

the crossing of resistive cables must

be strictly avoided.

Pipes are usually insulated with plastic

foam, mineral wool or another kind

of insulation, which can range in

thickness, typically not less than the

pipe diameter.

The insulation should be protected

against damp and moisture that could

damage the insulation and reduce its

efficiency.

Ensure that insulation with bigger

inner diameter is chosen, taking

into account that the pipe diameter

is increased due to heating cable

installation.

Below ground installation

If cables are installed above the

ground in trays, it should be safe

and solid. It should be marked

with a distinct warning sign, e.g.

“WARNING: 230 VOLT HEATING

CABLES“.

When heating cables are installed

below the ground, a plastic tape (red,

yellow etc.) is laid on top of the pipes/

installation to indicate that cables are

placed just below.

For this type of installation it is

necessary to measure the required

pipe run precisely, as the cable cannot

be cut or bent in a loop.

You will need an appropriate assembly

kit to perform cold tail connections

and end muff of heating cables on

drums.

20

Application manual · Pipe Frost Protection · VKLUD102 · ©Danfoss

Page 21

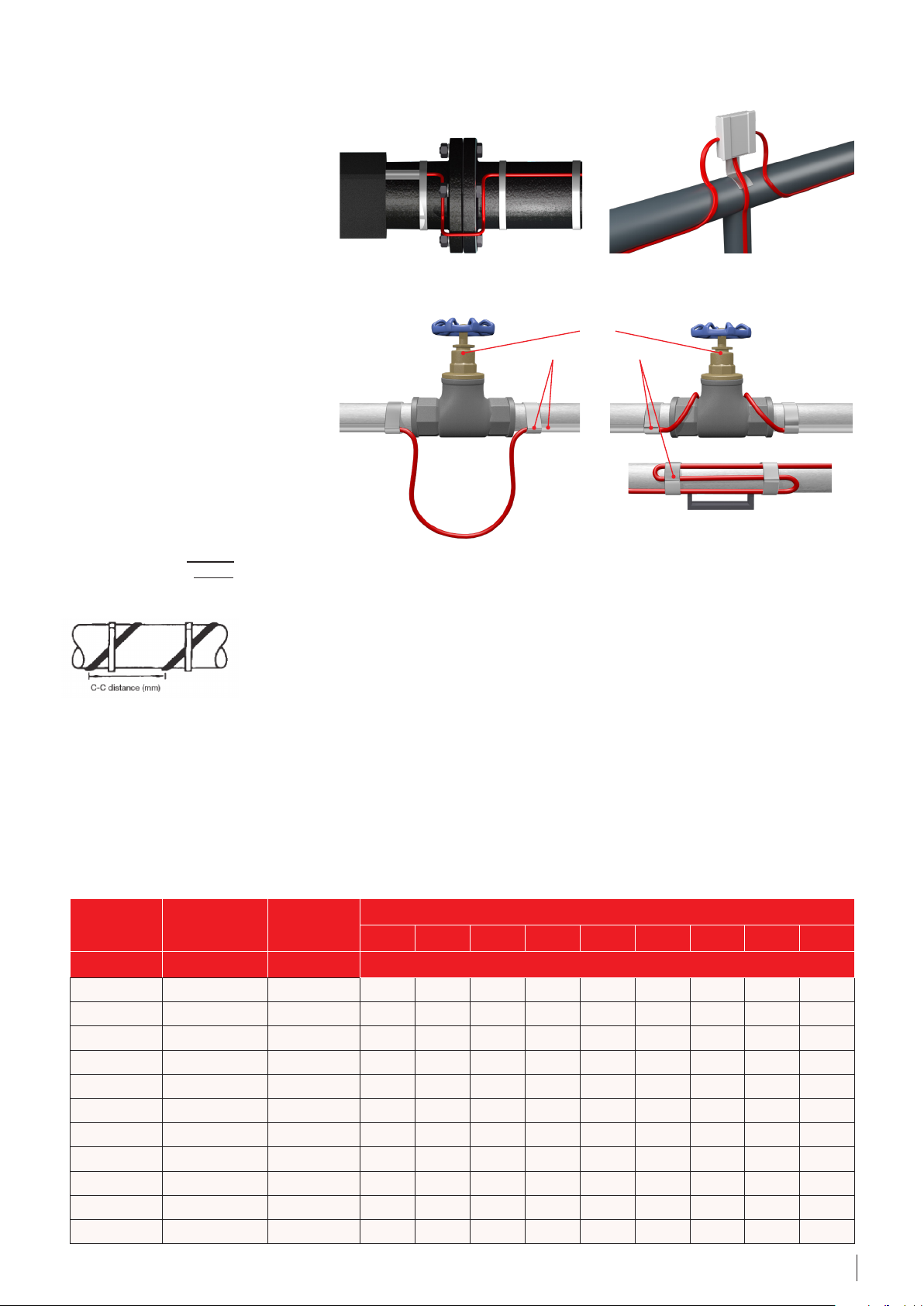

Installation examples

Installation on Special Flanges and

Pumps

Always observe the minimum

tolerable bending diameter of 25 mm

for resistive cables and 64 mm for

self-limitng cable.

Heating cables on specials, valves

etc. should always be positioned

so that they are easily accessible

and replaceable in connection with

inspection and repair and so that it

will not be necessary to cut them!

You can avoid this problem when

there is sufficient cable wrapped in a

spiral around the specials.

Calculation formulas

Centre-centre (C-C) distance for

cables wrapped in a spiral:

C-C = π d

√

1

n2 - 1

Total length of heating cable:

L

[m] = n L

cable

+ 0,5 (C + FV + 2 T)

pipe

Example of cable mounting on a flange.

Heating cables

Mounting example around a valve and a support flange.

where:

d - Outer pipe diameter;

n - Number of cable lines

(min. 2 for DN125-200).

Integer = straight lines (easier

installation).

Decimal = twisted around pipe;

C-C - Centre distance for twisted cable,

[mm];

Example of mouting a self-limiting cable on pipe

with use of connection box and metal bracket.

Valve

Aluminum tape

L

cable

C - Number of cable connections

FV - Number of flanges/valves

T - Number of T-branches

Support bracket

- Total length of heating cable, [m].

Observe max. length for SLC (see

product sheets);

(0,5 m cable each);

(0,5 m cable each);

(1 m cable each).

Some centre-centre fixing distances when more than 1 meter cable is used on a 1 meter pipe.

Outer pipe

diameter

Inner pipe

diameter (DN)

Inner pipe

diameter

1,1 1,2 1,3 1,4 1,5 1,6 1,7 1,8 1,9

Cable length in [m] for each pipe meter

[mm] [mm] [inch] C-C distance [mm]

34 25 1 250 170 140 110 100 86 78 71 66

42 32 1 ¼ 310 210 170 140 130 106 96 88 82

48 40 1 ½ 350 240 190 160 140 121 110 101 93

60 50 2 430 300 240 200 180 151 137 126 117

76 65 2 ½ 520 360 290 240 210 191 174 160 148

89 80 3 630 430 350 290 260 224 203 187 173

102 90 3 ½ 720 490 390 330 290 257 233 214 198

114 100 4 800 560 440 370 330 287 261 239 222

141 125 5 990 680 550 460 400 355 322 296 274

168 150 6 118 0 810 650 550 480 423 384 353 327

219 200 8 1520 1050 840 710 620 551 500 460 426

Application manual · Pipe Frost Protection · VKLUD102 · ©Danfoss

21

Page 22

Quick solution finder

1

2

3

4

1

2

4

3

5

If you don't need to make a heat loss

calculation, the following tables will

help you quickly to find a correct

product for frost protection of pipes.

How to use the table below?

Based on known inner pipe diameter

(DN) e.g. Ø 65 mm, with 30 mm insulation and ∆T of 30K:

Find DN or NPS pipe size in the

According to the table, when looking

up into table on the previous page,

a minimum output to be installed to

protect the pipe from freezing is:

15-25 W/m.

top bar of the table (e.g. DN 65).

Find the temperature difference (∆T),

in the outmost left column (e.g. 30).

Find the insulation thickness in the

Remember to choose preferably the

higher output option, hence

20-25 W/m.

corresponding raw (e.g. 30 mm).

Follow the vertical and horizontal

lines, until they meet.

Table presenting the necessary minimal outputs in [W/m] for straight pipelines (colors and corresponding W/m in table below).

ΔT

[°C]

20

30

40

Specic pipe heat loss q

Insulation

λ = 0,04

[mm]

10

20

30

40

50

10

20

30

40

50

10

20

30

40

50

½”

15

¾”

20

1”

25

Nominal pipe size NPS [inch], DN [mm]

1¼”

32

1½”

40

2”

50

2½”

65

pipe

80

3”

4”

100

5”

125

6”

150

8”

200

Find an appropriate type and number of heating cables to protect the pipe in the following table.

Cable type

Constant wattage

Cable

ECaqua 9T (in-pipe/on pipe)

ECflex 10T

ECflex 18T

ECpipeheat 10 V2

Self-limiting Cable

ECpipeguard 10

ECpipeguard 15

ECpipeguard 25

Example

Quick solution nder

A 12 meter DN50 ( outer Ø 60 mm)

drain pipe with 20 mm insulation

(λ = 0,04 W/m·K) and a drain valve

needs frost protection down to -25 °C

(∆t = +5 °C - (-25 °C) = 30 °C).

The specific pipe heat loss q

pipe

depends on the pipe diameter,

insulation thickness and temperature

difference. The specific pipe heat loss

q

from the calculation table above -

pipe

15-25 W/m (yellow, marked 5).

0 - 6 6 - 10 10 - 15 15 - 25 25 - 50 >50

1

1

1

1

1

Calculation by formula on p. 12.

Exact pipe heat loss:

2π λ ∆t

q

=

pipe

D

In

d 60

1,3 =

2π 0,04 30

60 + 20 + 20

In

Solution:

1 line ECpipeguard 25 W/m with

1 cable connection is chosen.

Specic pipe heat loss q

1

1

1

2

1

1

1 2

1

1

Cable length:

L

= n L

cable

= 1 12 + 0,5 (1 0,5 + 1 + 2 0) = 13 m.

1,3 = 19,2

W

As ECtemp 610 controller with a

m

wire sensor is chosen to be attached

between pipe and insulation.

Optionally: 2 parallel lines of ECflex 10T,

with a nearest length of 30 m can be

chosen. Cable should be wrapped

a little, because length is more than

calculated: 2 · 13 m = 26 m.

[W/m]

pipe

2-3

2

Max. 4

Max. 3

2

1 2

+ 0,5 (C + FV + 2 T) =

pipe

More

insulation

required

22

Application manual · Pipe Frost Protection · VKLUD102 · ©Danfoss

Page 23

5.2 Installation specifics

There are several ways of the cable

attachment to the pipe:

1. One or more cables are led in a

straight line along the side of the

pipe, see fig. 7 and fig. 8.

2. The cable is attached to the pipe in

waves or a spiral, see fig. 9.

3. The cable is installed inside the pipe,

see fig 10. The Special Pipe fitting

(3/4"+1", 10 bar @ 23 °C;

included in ECaqua 9T is required

for heating cable connection to the

pipe, see fig. 11.

The heating cable is mounted

directly on the pipe and secured with

aluminum tape, ensuring optimal

contact (heat transfer) between the

cable and the pipe. The same applies

for wire sensors.

Before the heating cable is attached to

the plastic pipe, a full lane of aluminum

tape should be applied to the pipe for

the cable to lie on.

Fig. 12 shows the recommended ways

to mount the cable lines, depending

on the amount of heating cables to

place on the pipe.

The temperature sensor should be

mounted at 90 degrees from the

heating cable, counting around the

perimeter of the pipe, or at least 5 cm

away from it.

But preferably at the opposite side of

the pipe, compared to placement of

the heating cable.

Insulation

Sensor

Aluminum tape

Heating cable

Fig. 7

Insulation Insulation Pipe

Heating cable

Fig. 9

Sensor

Heating cable

Fig. 8

Insulation

Mounting of heating cables on

pipes with large diameter

(> Ø 100 mm)

In case of larger pipe diameters it's

strongly advised to use more, evenly

divided, lengths of heating cable, with

lower linear output.

Example:

Pipe diameter size = 150 mm, with a

calculated heat loss of Q = 30 W/m, it's

advisable to use 2 lengths of cable with

linear output of 18 W/m, than 1 cable

with output of 33 W/m.

Fig. 10

Pipe diameter

20 – 100 1

125 – 200 2

250 – 400 3

450 – 600 4

Number of parallel running

lines of heating cable

Aluminum tape

Fig. 12. Recommended ways to mount the cable lines.

Fig . 11

Application manual · Pipe Frost Protection · VKLUD102 · ©Danfoss

23

Page 24

230 V power supply

Example of a solution with use of

self-limiting heating cables

If the maximum length of self- limiting

heating cable exceeds the length

displayed on page 16 (under: choice

of cable length), it needs to be divided

into smaller portions.

Example:

With choice of ECpipeguard 10

(SLPG-10), where the total length of

the pipe is 256 m.

Expected start-up temperature is

-20 °C, desired pipe temperature is

t = +5 °C, and a maximum available

fuse size is: 16 A. From a table on page

16 or proper Data sheet, the maximal

cable length for this SLC is only: 156 m.

It will be necessary to divide the pipe

in 2 independent circuits, with separate

power supply points, as shown on the

picture.

Example of division:

Circuit 1: part 1 + part 2 = 156 m;

Circuit 2: part 3 + part 4 = 100 m.

230 V power supply

(circuit no. 1)

part 1

circuit no. 1

Division in circuits – self-limiting heating cables

part 1 part 3

part 2

230 V power supply

(circuit no. 2)

part 3

part 1

part 4

circuit no. 2

Example of a solution with use of

constant wattage heating cables

In case of the constant wattage

heating cables, the maximal length of

the circuit is limited by the maximum

produced length of the heating cable.

Because the constant heating cables

are not allowed to be cut, at each

T-branch, new cable(s) should be

connected. Each pipe needs to have a

heating cable chosen to accommodate

it's length.

Example:

For frost protection of a metal pipe

shown on the picture, following

solution was chosen.

• Heating cable no. 1:

ECflex 10T, 140 m.

• Heating cable no. 2:

ECflex 10T, 40 m.

• Heating cable no. 3:

ECflex 10T, 40 m.

• Heating cable no. 4:

ECflex 10T, 30 m.

(circuit no. 1)

power supply

(circuit no. 2)

cable no. 2

heating cable no.1

230 V

heating

Division in circuits – constant wattage heating cables

pipe length36 m

heating

cable no. 3

pipe length36 m

pipe length 138 m

230 V

power supply

(circuit no. 3)

power supply

230 V

(circuit no. 4)

heating

cable no. 4

pipe length 28 m

24

Application manual · Pipe Frost Protection · VKLUD102 · ©Danfoss

Page 25

5.3 Installation Summary

20mm –25

DN25

o

C

+5

o

C

1. Check the pipe system to be heated

and make sure that the pipes are

dry, smooth and tight. Check and

prepare the switch board.

12

9 3

6

4. Twisted lines are attached as shown

for every approx. 1 m pipe with

aluminum tape.

Straight lines must be fitted as

shown at 5 or 7 o’clock.

In-pipe cables are fitted directly into

the pipe and tightened.

2. Draw a plan positioning cable(s),

sensors and thermostat, cable connections, cold tail, connection box,

cable paths and switch board.

5. Apply aluminum tape below (mandatory for plastic pipes) and on top on

the whole length of the cable. Make

sure that the cables do not cross

sharp edges without relief and that

any constant wattage cables do not

cross back on itself.

Attach the cable securely to the

pipe with use of tape and taking

care of preventing appearance of air

pockets.

3. Check the insulation resistance and

Ohm rating of the heating cables.

Compare the Ohm rating with the

nominal written on the cable label.

6. Attach and cover the sensor and the

tip on top of the pipe with aluminum tape. Extend cold tails / terminate cables and place conne- ctions

dry. Mount connection box on the

pipe or close to the pipe and install

the thermostat next to the pipe.

Commissioning

9. Re-check and compare the insulation

resistance and also Ohm rating for

constant wattage cables and earth

resistance.

7. Re-check the insulation resistance

and also Ohm rating for constant

wattage cables. Connect cables to

connection boxes and to the switch

board.

8. After insulation, place safety marking

tape on the insulation jacket or pipe

trenches for every 5 m. In subsurface

installations, a cover ribbon with a

warning sign must be laid 10 cm

above the cables.

Application manual · Pipe Frost Protection · VKLUD102 · ©Danfoss

10. Danfoss thermostat must be

commissioned as prescribed in the

thermostat manual. Recommended

pipe temperature setting is

+3 to +6 °C.

11. Train the end user or daily supervisor

in the operation and maintenance of

the frost protection system.

12. Before every heating season,

check for faults in the switchboard,

thermostat and sensors. Re-check

and compare the insulation

resistance and also Ohm rating for

constant wattage cables and earth

resistance.

25

Page 26

5.4 Important

Temperature distribution

Aluminum tape and insulation

are important when it comes to

performance and very important in

relation to plastic pipes. A DN50 plastic

pipe (e.g. PP) with 10 W/m at reference

temperature -10°C is shown under 3

different installations.

No alutape overheats constant

wattage cables.

SLC will limit itself and heat insufficiently.

Self-Limiting Cables and standby

savings with thermostat

Always install a thermostat for selflimiting cables >3 m as it

• prolongs the cable lifetime;

• saves the standby energy

consumption;

• leaves e.g. drinking water cold and

fresh, when no heat is needed.

Alutape above and below the cable gives better

performance.

50 mm insulation maintains ∆t = 50 K.

20 mm insulation maintains ∆t = 30 K.

Constant wattage cables with alutape

do not overheat.

26

Application manual · Pipe Frost Protection · VKLUD102 · ©Danfoss

Page 27

Notes

Application manual · Pipe Frost Protection · VKLUD102 · ©Danfoss

27

Page 28

6. Cases

THE GAS TURBINE PLANT,

Tereshkovo, Russia

Pipe tracing.

Project size:

ECpipeguard 33 - 170 m;

ECpipeguard 25 - 635 m;

ECtemp 316 (10…+50 °С) - 17 pcs.;

Outdoor sensor IP-44 - 17 pcs.;

Connection kit for SL cables - 160 pcs.;

ECfast (25m) - 36 pcs.;

Alutape 38 mm х 50 m - 1400 m.

SPAR ZENTRALE SALZBURG,

Salzburg, Austria

Frost protection system on water pipes.

Project size:

ECpipeguard 10 - 700 m;

Centrally placed regulators - 25 pcs.

VGHWC102 © Copyright Danfoss | Feb 16, 2021

Loading...

Loading...