Page 1

Pilot Operated Check Valves Technical Information

Drain

Quick Reference

Pilot to Open Model No. Cavity Description Flow* Pressure Page

RPC04 NCS04/3 Pilot Operated Check

Valve, Pilot to Open

RPC06 NCS06/3 35 l/min

CP450-1 SDC10-3 30 l/min

RPC12 NCS12/3 90 l/min

Pilot to Open Model No. Cavity Description Flow* Pressure Page

CP458-2 SDC08-3 Pilot Operated Check

Valve, Reverse Pilot to

MC10-RO SDC10-3S 45 l/min

CP451-2 CP12-3S 95 l/min

CP452-2 SDC16-3S 130 l/min

CP453-2 CP20-3S 230 l/min

Open

20.5 l/min

[5.4 US gal/min]

[9.3 US gal/min]

[8 US gal/min]

[23.8 US gal/min]

20 l/min

[5 US gal/min]

[12 US gal/min]

[25 US gal/min]

[34 US gal/min]

[61 US gal/min]

350 bar

[5075 psi]

350 bar

[5075 psi]

240 bar

[3480 psi]

315 bar

[4570 psi]

210 bar

[3000 psi]

250 bar

[3600 psi]

210 bar

[3000 psi]

210 bar

[3000 psi]

210 bar

[3000 psi]

PO - 6

PO - 7

PO - 8

PO - 9

PO - 10

PO - 11

PO - 12

PO - 13

PO - 14

Pilot to Open Model No. Cavity Description Flow* Pressure Page

RPV 06 NCS06/4 Pilot Operated Check

Valve, Pilot-to-open with

drain

* Flow ratings are based on a pressure drop of 7 bar [100 psi] unless otherwise noted. They are for comparison

purposes only.

30 l/min

[8 US gal/min]

315 bar

[4500 psi]

PO - 15

BC332375625108en-000101 • February 2020

PO - 1

Page 2

Pilot Operated Check Valves Technical Information

Quick Reference

Symbol

Pilot to Close Model No. Cavity Description Flow* Pressure Page

Dual Pilot-Operated Checks

Model No. Cavity Description Flow* Pressure

CP453-5 SDC20-2 Pilot Operated Check

Valve, Reverse Pilot-to-

open with vent

CP460-1 SDC10-3 Pilot Operated Check

Valve, Pilot to Close

CP461-1 CP12-3S 115 l/min

CP462-1 SDC16-3S 190 l/min

Model No. Cavity Description Flow* Pressure Page

CP410-1 none Pilot Operated Check

Valve, Catalog HIC

250 l/min

[66 US gal/min]

45 l/min

[12 US gal/min]

[30 US gal/min]

[50 US gal/min]

80 l/min

[21.1 US gal/min]

350 bar

[5075 psi]

210 bar

[3000 psi]

210 bar

[3000 psi]

210 bar

[3000 psi]

210 bar

[3000 psi]

Page

PO - 16

PO - 17

PO - 18

PO - 19

PO - 20

* Flow ratings are based on a pressure drop of 7 bar [100 psi] unless otherwise noted. They are for comparison

purposes only.

BC332375625108en-000101 • February 2020

PO - 2

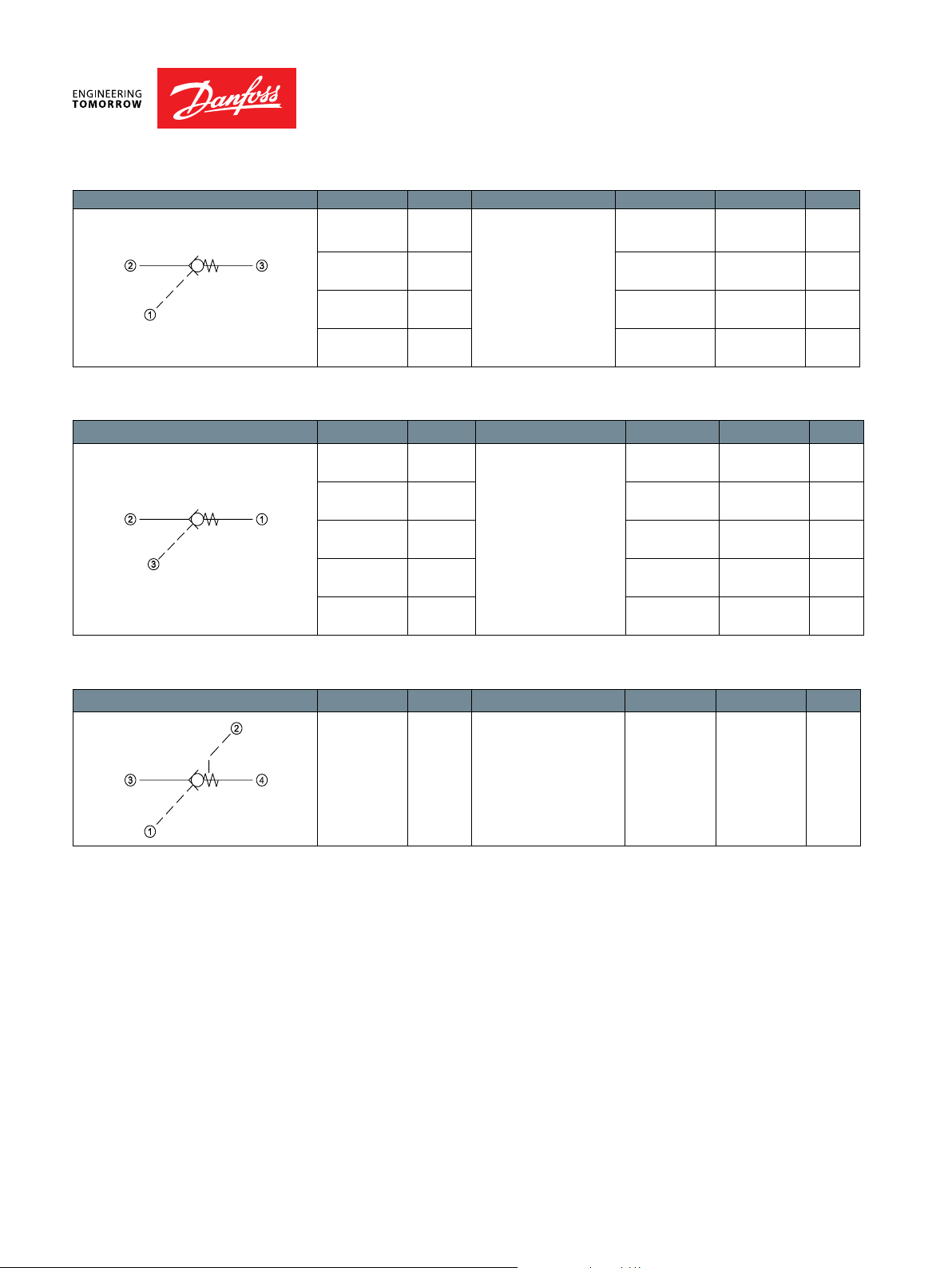

Page 3

Pilot Operated Check Valves Technical Information

Application Notes

MOTION CONTROL

VALVES

Motion control valves, also referred to as load holding valves, are used to control the

motion of a load in the following ways:

· Prevent a load from dropping in case of hose or tube failure.

· Prevent a load from drifting caused by directional control valve spool leakage.

· Provide smooth, modulated motion when the load is in a lowering or run-away

mode.

· Provide smooth, modulated motion when the directional control valve is suddenly

closed.

There are two basic types of motion control valves:

· Pilot-operated, or pilot-to-open check valves will satisfy the rst two of the above

requirements.

· Counterbalance valves will satisfy all four of the above requirements.

Pilot operated check valves

BC332375625108en-000101 • February 2020

PO - 3

Page 4

Pilot Operated Check Valves Technical Information

Application Notes

PILOTOPERATED CHECK

VALVES

Pilot-operated, or pilot-to-open check

valves will positively hold a pressurized

load and will release the load upon

application of a pressure signal to the

pilot port. Pilot-operated check valves

are available as individual cartridges,

standard Cartridge-In-Body (CIB)

packages, or can be created in custom

manifolds by using a standard check

valve such as CV10-NP with a guided

pilot piston. For more information on

pilot pistons, see Accessories.

Cartridge in body

Individual cartridges

A typical circuit application for pilotoperated check valves contains a pump,

directional control valve, and an actuator.

Without a pilot-operated check valve the

load will drift down due to spool leakage

if the directional control valve is centered

with the load raised. Additionally

there is no protection against the load

dropping in the event of hydraulic line

failure. Adding a pilot-operated check

valve helps prevent cylinder drift and

provides protection against hose or

tube failure. In this circuit, moving the

directional control valve to the right

causes the cylinder to extend. When the

directional control valve is centered, the

pilot-operated check valve will prevent

leakage and lock the cylinder in position. Moving the directional control valve to the

right sends pressure/ow to the rod end of the cylinder. This pressure also acts on the

pilot piston to open the check valve and allow the load to be lowered.

Typical circuit application

W W

BC332375625108en-000101 • February 2020

PO - 4

Page 5

Pilot Operated Check Valves Technical Information

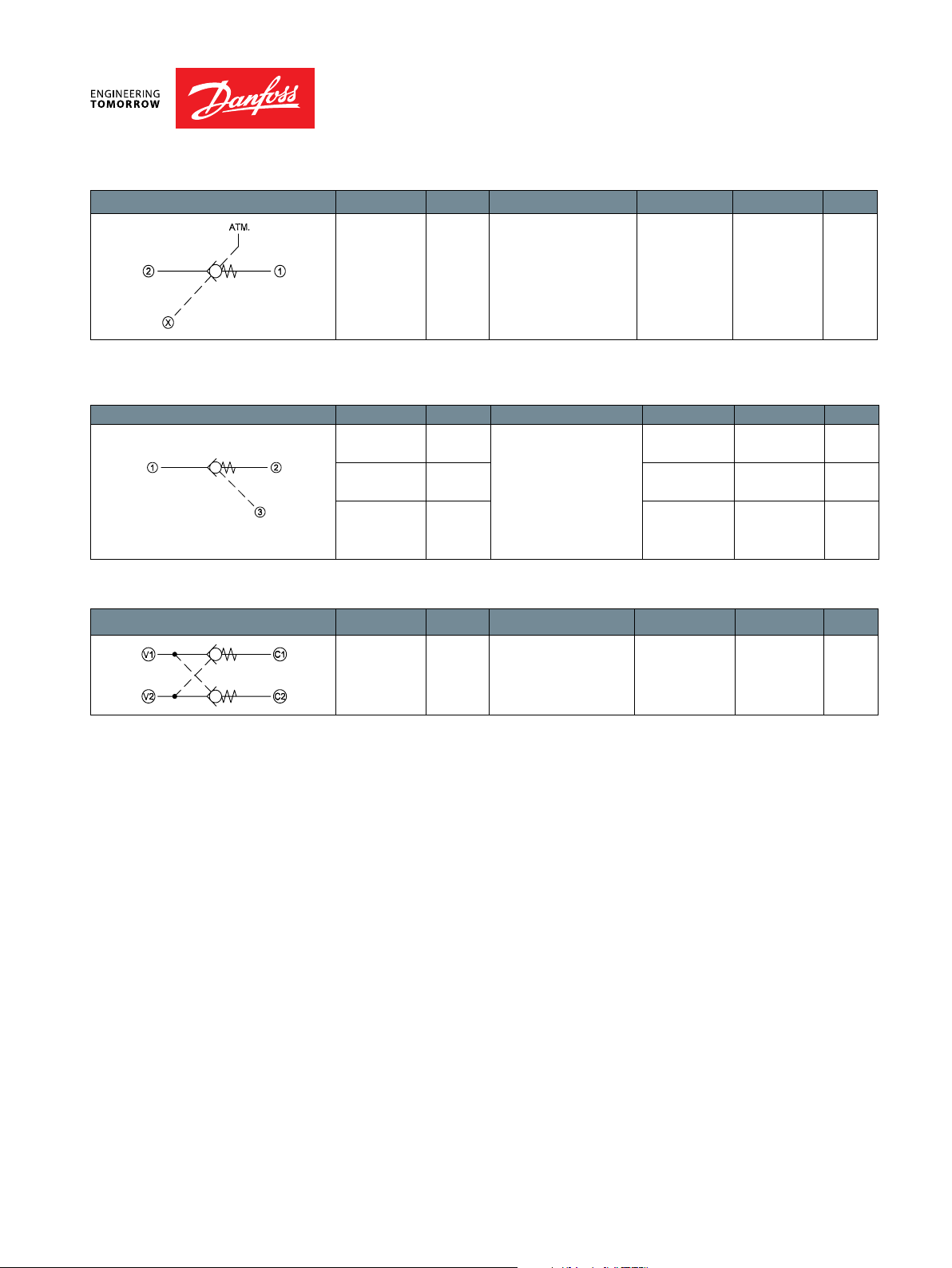

Application Notes

PILOTOPERATED CHECK

VALVES

(continued)

The pressure required to pilot open the check valve can be calculated by:

W + (Pc • Ab)

P =

(Ab • R) - Ar

W + (Pc • Ar)

P =

(Ar • R) - Ab

W = Load

Pc = Check valve crack pressure (typically 0.34-4.5 bar [5-65 psi]; consult catalog sheets

for details)

Ab = Cylinder bore area

Ar = Cylinder rod area

R = Check valve pilot ratio (typically 3:1 or 4:1; consult catalog sheets for details)

Note that these equations are idealized and do not consider any backpressure in the

circuit, which is additive to the pressure required to pilot open the check valve.

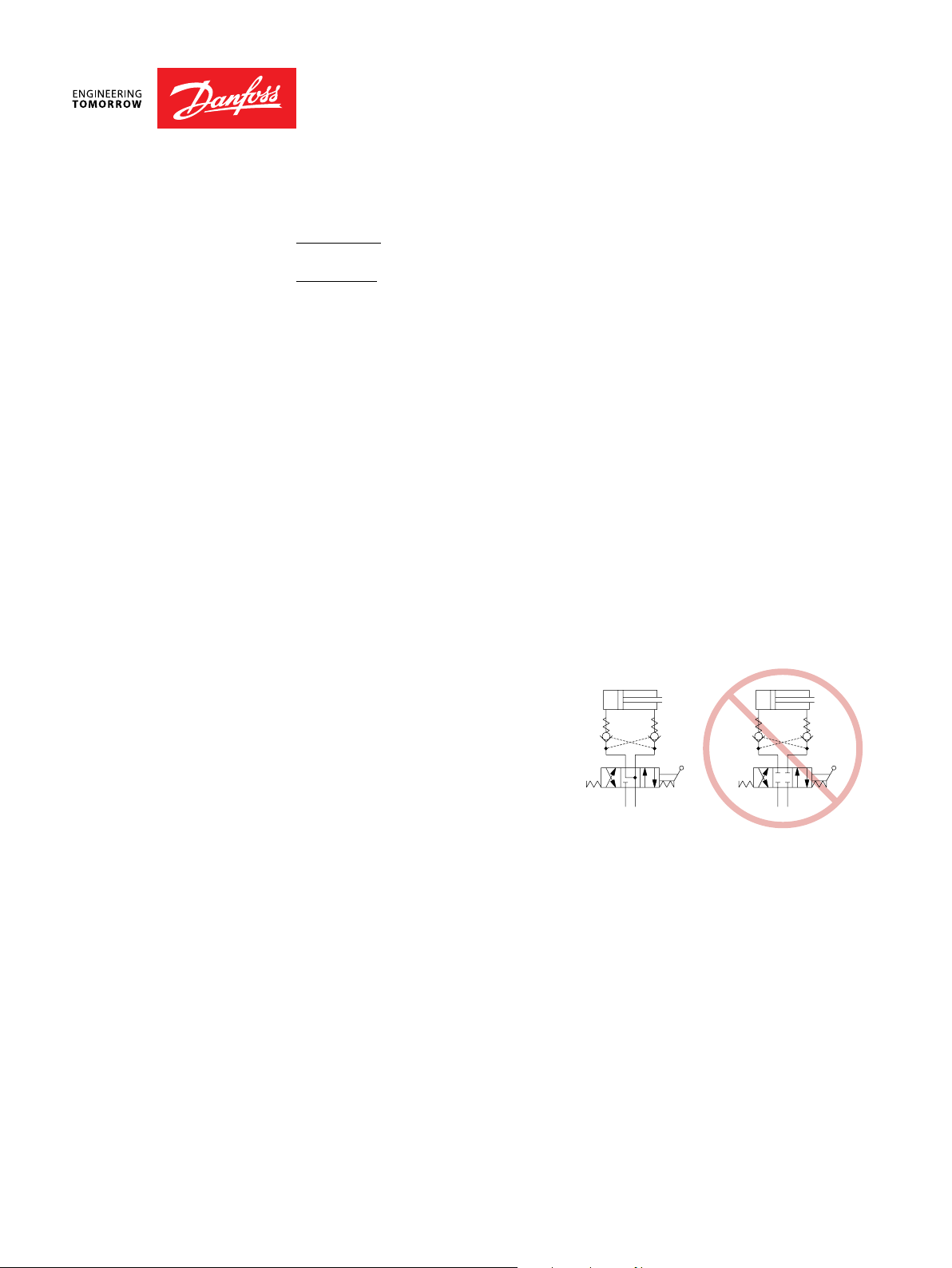

Some additional guidelines for pilot-operated check valve applications:

· Use pilot-operated check valves for load holding, not for motion (speed) control.

Pilot-operated check valves are on-o, non-modulating devices. Trying to

use a pilot-operated check valve to control an overrunning load can result in

severely unstable motion. For motion (speed) control of overrunning loads, use a

counterbalance valve.

· Use caution when applying pilotoperated check valves to the rod

end of a cylinder. Cylinders with

large rod:bore diameter ratios may

intensify rod pressure to a point

where the required pilot pressure

may be dangerously high—

refer to the above equations. If

intensication creates application

concerns, consider using a

counterbalance valve.

cylinder retracts

cylinder extends

Closed center, directional control valves

Do Do not

· Do not use pilot-operated check valves with closed-center, directional control valves.

Pressure trapped between the directional control valve and the pilot-operated check

valve can pilot the check valve open and result in undesired load motion.

· Locate pilot-operated check valves at or near the actuator to provide maximum load

holding protection in the event of hydraulic line failure.

BC332375625108en-000101 • February 2020

PO - 5

Page 6

Pilot Operated Check Valves Technical Information

2

100

0

3-2

2-3

6

4

5

30252015

l/min

10

10

8

Pressure drop

gal/min

86

4

2

psi

bar

0

0

150

50

26 cSt [121 SUS] hyd.oil at 50ƱC [122 ƱF]

Ø 22

[Ø 0.87]

Ø 14

[Ø 0.55]

Ø 15

[Ø 0.59]

6

[0.24]

40.9

[1.61]

42

[1.65]

3

2

1

34-40 Nm

[25-30 lbf*ft]

22 mm

M18 X 1.5

RPC04-2.5-OR-00-V

00 = Cartridge only

Ports & Material

Code

00

15 bar [217.5 psi]15

5

0.5

8

Crack Pressure

8 bar [116 psi]

0.5 bar [7 psi]

2.5 bar [36.25 psi]

Seal Option Seal Kit

Omit = Buna-N

V = Viton

SE1/4 AL, 1/4 BSP

SE4S AL, #4 SAE

SE6S

AL, #6 SAE NCS04/3-SE-6S

NCS04/3-SE-4S

NCS04/3-SE-1/4

Body Nomenclature

No Housing

** Aluminum bodies are to be used for pressures less than 210 bar (3000 psi)

***Other housings available

OR

Omit

Pilot Seal Option

5 bar [72.5 psi]

2.5

Pilot to Open

230000450

230000160

No seals

Seals

Pilot to Open

RPC04

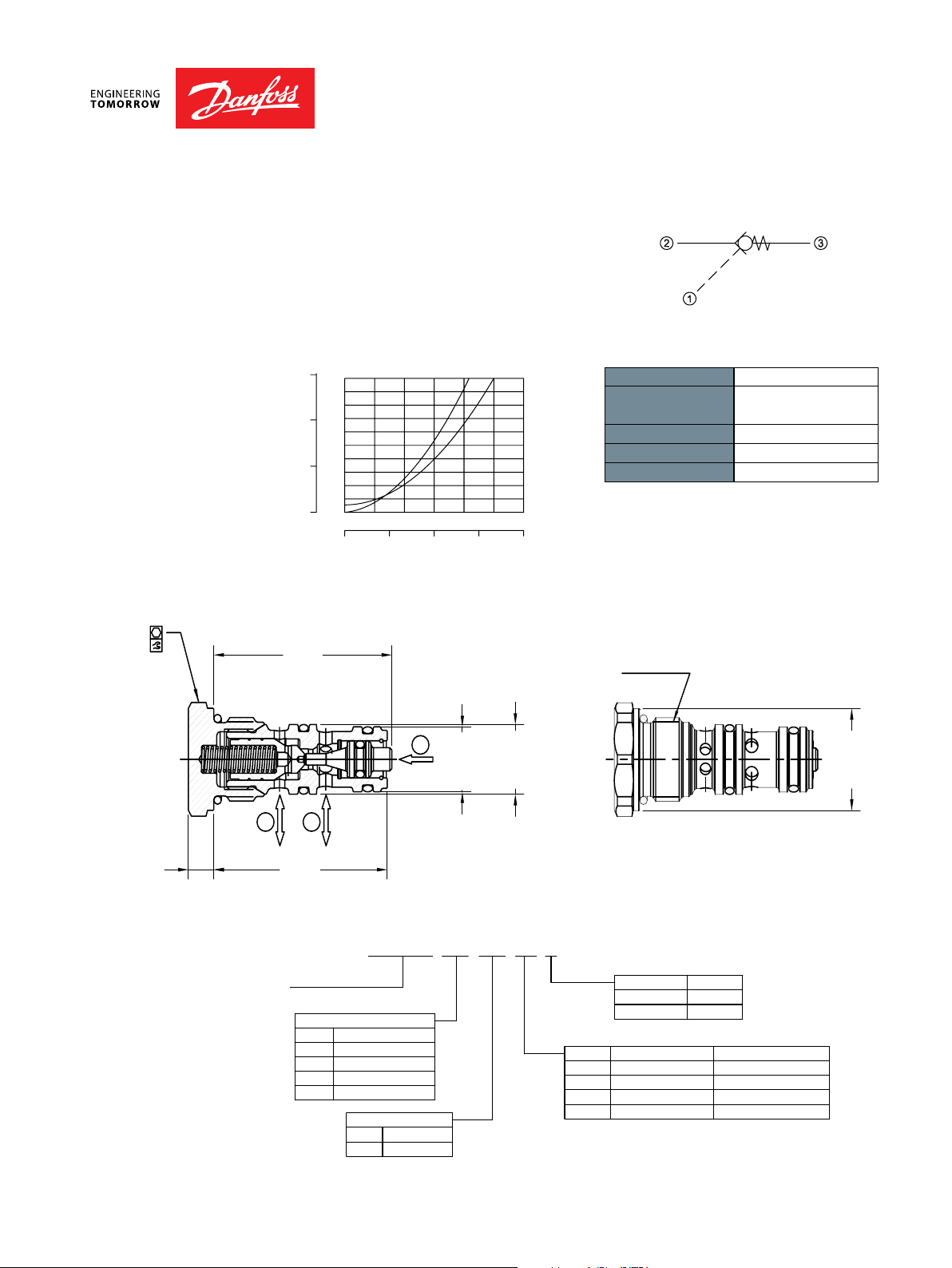

OPERATION

SPECIFICATIONS

DIMENSIONS

mm [in]

This is a pilot-to-open check valve.

Theoretical performance

Cross-sectional view

Schematic

Specications

Rated pressure* 350 bar [5075 psi]

Rated ow at 7 bar

[100 psi]

Weight 0.06 kg [0.13 lb]

Pilot ratio 3.2:1

Cavity NCS04/3

*Rated Pressure based on NFPA fatigue test

standard (at 1 million cycles)

Note: A piston seal requires a 5 bar [72.5 psi] or

greater return spring.

20.5 l/min

[5.4 US gal/min]

ORDERING

INFORMATION

BC332375625108en-000101 • February 2020

PO - 6

Page 7

Pilot Operated Check Valves Technical Information

2-3

26 cSt [121 SUS] hyd.oil at 50ƱC [122 ƱF]

0

bar

36 913

gal/min

Pressure drop

15

0

20

l/min

30 40 5010

5

10

3-2

200

150

50

100

0

psi

49

[1.93]

48.9

[1.93]

2

[0.08]

8.5

[0.33]

Ø 19

[Ø 0.75]

Ø 18

[Ø 0.71]

Ø 26.5

[Ø 1.04]

27 mm

44-50 Nm [32-37 lbf*ft]

M22 X 1.5

1

2

3

SE8S AL, #8 SAE NCS04/3-SE-8S

** Aluminum bodies are to be used for pressures less than 210 bar (3000 psi)

***Other housings available

No Housing

Body Nomenclature

NCS06/3-SE-3/8

NCS06/3-SE-1/2

NCS06/3-SE-6SAL, #6 SAESE6S

AL, 1/2 BSPSE1/2

AL, 3/8 BSPSE3/8

00

Code Ports & Material

00 = Cartridge only

OR

Pilot Seal Option

Omit

RPC06-5-OR-00-V

Pilot to Open

V = Viton

Omit = Buna-N

Seal KitSeal Option

5 bar [72.5 psi]5

10

2

0.5

Crack Pressure

0.5 bar [7 psi]

2 bar [30 psi]

10 bar [145 psi]

Seals

No seals

230000070

230000110

Pilot to Open

RPC06

OPERATION

SPECIFICATIONS

DIMENSIONS

mm [in]

This is a pilot-to-open check valve.

Theoretical performance

Cross-sectional view

Schematic

Specications

Rated pressure* 350 bar [5075 psi]

Rated ow at 7 bar

[100 psi]

Weight 0.10 kg [0.22 lb]

Pilot ratio 3.4:1

Cavity NCS06/3

*Rated pressure based on NFPA fatigue test

standard (at 1 million cycles)

Note: A piston seal requires a 5 bar [72.5 psi] or

greater return spring.

35 l/min

[9.25 US gal/min]

ORDERING

INFORMATION

BC332375625108en-000101 • February 2020

PO - 7

Page 8

Pilot Operated Check Valves Technical Information

6

Pilot to Open

CP450-1

OPERATION

SPECIFICATIONS

DIMENSIONS

mm [in]

This valve is a pilot-to-open check valve.

Theoretical performance

psi bar

203

174

145

116

87

58

29

154 SUS (33 cSt) hyd. oil @ 100° F (38° C)

14

12

10

8

6

Press ure drop

4

2

0

free flow

8L/min

2.1US gal/min

pilot open

16 24 32 40

Flow

4.26.3 8.5 10.

Cross-sectional view

Schematic

Specications

Rated pressure 240 bar [3480 psi]

Rated ow at 7 bar

[100 psi]

Leakage 6 drops/min @

Weight 0.09 kg [0.20 lb]

Pilot ratio 3.0:1

Cavity SDC10-3

Note: A piston seal requires a 4.5 bar [65 psi] or

greater return spring.

30 l/min

[8 US gal/min]

Rated pressure

ORDERING

INFORMATION

7/8-14 UNF-2A

h 1.00 in

41-47 N.m

1

2

3

47.5

[1.87]

t

[30-35 lbf.ft]

7.9

[0.31]

CP450-1-B-8S-015-0

Seals

Seal kit

B=Buna-N120570

V=Viton 120571

Body and ports

Body P/N

0=Cartridge No body

6S =Aluminum, #6 SAE CP10-3-6S

8S =Aluminum, #8 SAE CP10-3-8S

SE3B =Aluminum, 3/8 BSP SDC10-3-SE-3B

SE4B =Aluminum, 1/2 BSP SDC10-3-SE-4B

Piston seals

0=No seals

S=Seals included

Cracking

Pressure

bar[psi]

065=4.48 [65]

115=7.90 [115]

200=13.8 [200]

315=21.8 [315]

BC332375625108en-000101 • February 2020

PO - 8

Page 9

Pilot Operated Check Valves Technical Information

gal/min

10

15

[0.55]

[Ø 1.50]

RPC12-5-OR-00-V

Pilot to Open

00 = Cartridge only

AL, #8 SAE

AL, #12 SAE

Ports & MaterialCode

00

SE8S

SE12S

V = Viton

Omit = Buna-N

Seal KitSeal Option

**Aluminum bodies are to be used for pressures less than 210 bar (3000 psi)

***Other housings available

0.5 bar [7 psi]0.5

5

10

2.5

Crack Pressure

2.5 bar [36.2psi]

5.0 bar [72.5 psi]

10 bar [145 psi]

Pilot Seal Option

Omit

SE1/2

SE3/4

AL, 1/2 BSP

AL, 3/4 BSP

NCS12/3-SE-3/4

NCS12/3-SE-1/2

Body Nomenclature

NCS12/3-SE-12S

NCS12/3-SE-8S

00 = Cartridge only

OR

230000130

230000360

No Seals

Seals

Pilot to Open

RPC12

OPERATION

SPECIFICATIONS

DIMENSIONS

mm [in]

38 mm

90-100 Nm

[66.4-74 lbf*ft]

This is a pilot-to-open check valve.

Theoretical performance

Pressure drop

psi

0

0

50

0

26 cSt [121 SUS] hyd.oil at 50ƱC [122 ƱF]

bar

10

8

6

4

2

0

0

40

60 80 100 12020

8162432

Cross-sectional view

66

[2.60]

Schematic

Specications

3-2

2-3

l/min

M33 X 2

Rated pressure 315 bar [4570 psi]

Rated ow at 7 bar

[100 psi]

90 l/min

[23.8 US gal/min]

Weight 0.20 kg [0.44 lb]

Pilot ratio 2.8:1

Cavity NCS12/3

Note: A piston seal requires a 5 bar [72.5 psi] or

greater return spring.

32

14

65.5

[2.58]

ORDERING

INFORMATION

BC332375625108en-000101 • February 2020

1

5.5

[0.22]

Ø 26.7

[Ø 1.06]

Ø 27.7

[Ø 1.10]

PO - 9

Ø 37.6

Page 10

Pilot Operated Check Valves Technical Information

6

Seals

r[psi]

Housing and po

SE2B

SE3B

O

Reverse Pilot to Open

CP458-2

OPERATION

SPECIFICATIONS

DIMENSIONS

mm [in]

This valve is a pilot-to-open check valve.

Theoretical performance

psi bar

203

174

145

116

87

58

29

154 SUS (33 cSt) hyd. oil @ 100° F (38° C)

14

12

10

8

free flow

6

2 1

Press ure drop

4

2

0

8L/min

2.1US gal/min

1 2

pilot open

16 24 32 40

Flow

4.26.3 8.5 10.

Cross-sectional view

Schematic

Specications

Rated pressure 210 bar [3000 psi]

Rated ow at 7 bar

[100 psi]

Leakage 6 drops/min @

Weight 0.07 kg [0.15 lb]

Pilot ratio 2.8:1

Cavity SDC08-3

Note: A piston seal requires a 4.5 bar [65 psi] or

greater return spring.

20 l/min

[5 US gal/min]

Rated pressure

1

2

ORDERING

INFORMATION

B=Buna-N 120250

V=Viton 120253

0=No Housing No Housing

=Al, 1/4 BSP SDC08-3-SE-2B

=Al, 3/8 BSP SDC08-3-SE-3B

4S =Al, #4 SAE CP08-3-4S

6S =Al, #6 SAE CP08-3-6S

ther housings available

BC332375625108en-000101 • February 2020

3/4-16 UNF-2A

3

40.6

[1.60]

CP458-2-B-6S-065-0

Seal kit

rtsHousing P/N

ht0.875 in

27-34 N.m

[20-25 lbf.ft]

6.4

[0.25]

Piston seals

0=No seals

S=Seals included

Crack

Pressure

ba

065=4.48 [65]

PO - 10

Page 11

Pilot Operated Check Valves Technical Information

300

100

200

gal/min

10 = 10 bar [145 psi]

Reverse Pilot to Open

MC10-RO

OPERATION

SPECIFICATIONS

DIMENSIONS

mm [in]

45-50 N•m [33-37 lbf•ft]

27mm

This is a pilot-to-open check valve.

Theoretical performance

26 cSt [121 SUS] hyd.oilat 50°C[122°F]

psi

bar

25

20

15

10

5

10 bar

0

36912

5 bar

1 bar

15

Cross-sectional view

3

7/8-14 UNF-2A

605040302010

US

Free

Flow

2 to 1

Pilot

override

1 to 2

l/min

Schematic

Specications

Rated pressure 250 bar [3600 psi]

Rated ow at 7 bar

[100 psi]

Leakage 6 drops/min @

Weight 0.12 kg [0.26 lb]

Pilot ratio 3.0:1

Cavity SDC10-3S

Note: A piston seal requires a 4.5 bar [65 psi] or

greater return spring.

45 l/min

[12 US gal/min]

Rated pressure

ORDERING

INFORMATION

8 [0.31]

Crack Pressure

1 = 1 bar [15 psi]

5 = 5 bar [73 psi]

Piston seals

Omit = No seal

OR = Seals included

1.6 [0.06]

37.04 [1.46]

MC10-RO-5-OR-A-B-6S

1

Ø 1.2 [0.83]

2

P103 753

Housing and portsHousing P/N

00 =No Housing No Housing

SE3B =Al, 3/8 BSPSDC10-3S-SE-3B

SE4B =Al, 1/2 BSPSDC10-3S-SE-4B

6S =Al, #6 SAESDC10-3S-6S/6S

8S =Al, #8 SAESDC10-3S-8S/6S

Other housings available

Seals

B = Buna-N

V =Viton

Seal kit

35401419

35401519

BC332375625108en-000101 • February 2020

PO - 11

Page 12

Pilot Operated Check Valves Technical Information

8

Reverse Pilot to Open

CP451-2

OPERATION

SPECIFICATIONS

DIMENSIONS

mm [in]

This valve is a pilot-to-open check valve.

Theoretical performance

psi bar

203

174

145

116

87

58

29

154 SUS (33 cSt) hyd. oil @ 100° F (38° C)

14

12

10

8

free flow

6

Press ure drop

4

2

0

40L/min

21.1 31.7 42.3 52.

10.6US gal/min

pilot open

80 120 160 200

Flow

Cross-sectional view

Schematic

Specications

Rated pressure 210 bar [3000 psi]

Rated ow at 7 bar

[100 psi]

Leakage 6 drops/min @

Weight 0.21 kg [0.46 lb]

Pilot ratio 3:1

Cavity CP12-3S

Note: A piston seal requires a 4.5 bar [65 psi] or

greater return spring.

95 l/min

[25 US gal/min]

Rated pressure

ORDERING

INFORMATION

1-1/16-12 UN-2A

ht1.25 in

1

55.9

[2.20]

3

12.7

[0.50]

2

68-75 N.m

[50-55 lbf.ft]

BC332375625108en-000101 • February 2020

PO - 12

Page 13

Pilot Operated Check Valves Technical Information

11

14

17

20

Other Housings available

Reverse Pilot to Open

CP452-2

OPERATION

SPECIFICATIONS

DIMENSIONS

mm [in]

This valve is a pilot-to-open check valve.

Theoretical performance

psi bar

3

4

5

6

87

58

29

154 SUS (33 cSt) hyd. oil @ 100° F (38° C)

14

12

10

free flow

8

6

Press ure drop

4

2

0

pilot open

40L/min

10.6US gal/min

80 120 160 200

Flow

21.1 31.7 42.3 52.8

Cross-sectional view

Schematic

Specications

Rated pressure 210 bar [3000 psi]

Rated ow at 7 bar

[100 psi]

Leakage 6 drops/min @

Weight 0.29 kg [0.64 lb]

Pilot ratio 3:1

Cavity SDC16-3S

Note: A piston seal requires a 4.5 bar [65 psi] or

greater return spring.

130 l/min

[34 US gal/min]

Rated pressure

1-5/16-12 UN-2A

ht1.50 in

1

2

ORDERING

INFORMATION

Seal Option

Code Seal Material Seal kit

B Buna 120033

V Viton 120034

Housings & Ports

0: Cartridge Only

6B: 3/4 BSP, AL

8B: 1 BSP, AL

12S: #12 SAE, AL

16S: #16 SAE, AL

54.6

[2.15]

3

12.7

[0.50]

CP452-2 - B - 16S

Housing P/N

No Housing

CP16-3S-6B/2B

CP16-3S-8B/2B

CP16-3S-12S/4S

CP16-3S-16S/4S

122-136 N.m

[90-100 lbf.ft]

-

-

065

0

Piston Seals

Code

0

S

Crack Pressure

Code

065

No seals

Seals Included

bar [psi]

4.48 [65]

BC332375625108en-000101 • February 2020

PO - 13

Page 14

Pilot Operated Check Valves Technical Information

11

14

17

20

105.7

Seals

r[

Housing and po

Reverse Pilot to Open

CP453-2

OPERATION

SPECIFICATIONS

DIMENSIONS

mm [in]

This valve is a pilot-to-open check valve.

Theoretical performance

psi bar

3

4

5

6

87

58

29

154 SUS (33 cSt) hyd. oil @ 100° F (38° C)

14

12

10

8

6

Press ure drop

free flow

4

2

0

pilot open

80L/min

160 240 320 400

21.1US gal/min

42.3 63.4 84.5

Flow

Cross-sectional view

Schematic

Specications

Rated pressure 210 bar [3000 psi]

Rated ow at 7 bar

[100 psi]

Leakage 6 drops/min @

Weight 0.66 kg [1.46 lb]

Pilot ratio 3:1

Cavity CP20-3S

Note: A piston seal requires a 4.5 bar [65 psi] or

greater return spring.

230 l/min

[61 US gal/min]

Rated pressure

ORDERING

INFORMATION

1-5/8-12 UN-2A

1

2

3

79.5

[3.13]

Seal kit

B=Buna-N 120380

V=Viton 120381

rtsHousing P/N

0=No Housing No Housing

8B =Al, 1 BSP CP20-3S-8B/2B

10 1-1/4 10B=Al, BSP CP20-3S- B/2B

16S =Al, #16 SAE CP20-3S-16S/4S

20S =Al, #20 SAE CP20-3S-20S/4S

Other housings available

ht1.875 in

217-231 N.m

[160-170 lbf.ft]

16.8

[0.66]

CP453-2-B-20S-065-0

Piston seals

0=No seals

S=Seals included

Crack

Pressure

ba

065=4.48 [65]

psi]

BC332375625108en-000101 • February 2020

PO - 14

Page 15

Pilot Operated Check Valves Technical Information

40

10

15

20

25

Omit = No seals

y

Pilot to Open with Drain

RPV 06

OPERATION

SPECIFICATIONS

DIMENSIONS

mm [in]

27 mm

44-50 Nm•

[32-37 lbfft]•

This is a pilot-to-open check valve with

an internal drain.

Theoretical performance

psi bar

0

0

0

0

50

0

26 mm °C [° F]

20

15

10

5

0

²/sec (cSt) [124 SUS] @ 50 122

0

02468

10 20 30

l/min

US gal/min

3 to

4

4 to

Cross-sectional view

M 22 x 1.5

Schematic

Drain

Specications

3

10

Rated pressure 315 bar [4500 psi]

Rated ow at 7 bar

[100 psi]

30 l/min

[8 US gal/min]

Weight 0.13 kg [0.29 lb]

Pilot ratio 3.4:1

Cavity NCS06/4

Note: A piston seal requires a 4.5 bar [65 psi] or

greater return spring.

ORDERING

INFORMATION

BC332375625108en-000101 • February 2020

10.0

[0.39]

Piston seals

OR = Seals

4

3

RPV 06 - 5 - OR - 00 -V

67.0

[2.64]

1

2

Seals

V =Viton

Omit = Buna-N

Seal Kit

Consult factor

230000080

Housing and portsHousing P/N

00 =No Housing No Housing

L3/8 =AL, 3/8 BSP NCS06/4-L-3/8

L3/4 =AL,3/4 BSP NCS06/4-L-1/2

L6S=AL,#6 SAE NCS06/4-L-6S

L8S=AL,#8 SAE NCS06/4-L-8S

Other housings available

PO - 15

Page 16

Pilot Operated Check Valves Technical Information

72.6

275

2

X

1

Pilot Port

SAE #4

64.1 [2.52]

57.2 [2.25]

1.875 in

217-231 N·m

[160-170 lbf·ft]

1 5/8-12 UN-2A

Seals

B = Buna-N 120011

V

Housing and po

O

Reverse Pilot to Open with Vent

CP453-5

OPERATION

SPECIFICATIONS

DIMENSIONS

mm [in]

This is a pilot-to-open check valve with

an external pilot connection.

Theoretical performance

33 cSt [154 SUS] hyd.oil @ 38°C [100° F]

psi bar

145 10

8116

87 6

458

29 2

00

l/min

US gal/min

14.5 29.1 43.6

2to1

1to2piloted open

165110550

220

58.1

Cross-sectional view

Schematic

Specications

Rated pressure 350 bar [5075 psi]

Rated ow at 7 bar

[100 psi]

Leakage 6 drops/min @

Weight 1.23 kg [2.71 lb]

Pilot ratio 4:1

Cavity SDC20-2

Note: A piston seal requires a 4.5 bar [65 psi] or

greater return spring.

250 l/min

[66 US gal/min]

Rated pressure

ORDERING

INFORMATION

BC332375625108en-000101 • February 2020

CP453-5-B-16S-4-065

Seal kit

Crack Pressure

bar [psi]

=Viton 120012

rtsHousing P/N

0=No Housing No Housing

065 = 4.3 65

100 = 6.9 100

8B = AL, 1 BSP CP20-2-8B

10B = AL, 1-1/4 BSP CP20-2-10B

16S = AL, #16 SAE CP20-2-16S

20S = AL, #20 SAE CP20-2-20S

Pilot ratio

4 = 4:1

ther housings available

PO - 16

Page 17

Pilot Operated Check Valves Technical Information

116

145

174

203

Seals

Seals included

r[

Housing and po

SE3B

SE4B

O

Pilot to Close

CP460-1

OPERATION

SPECIFICATIONS

DIMENSIONS

mm [in]

This valve is a pilot-to-close check valve.

Theoretical performance

psi bar

87

58

29

154 SUS (33 cSt) hyd. oil @ 100° F (38° C)

14

12

10

8

e drop

6

Press ur

4

2

0

20L/min

5.3US gal/min

2:1

free flow

40 60 80 100

Flow

10.6 15.9 21.1 26.4

Cross-sectional view

7/8-14 UNF-2A

Schematic

Specications

Rated pressure 210 bar [3000 psi]

Rated ow at 7 bar

[100 psi]

Leakage 6 drops/min @

Weight 0.10 kg [0.21 lb]

Pilot ratio 2:1

Cavity SDC10-3

Note: A piston seal requires a 4.5 bar [65 psi] or

greater return spring.

22 l/min

[5.8 US gal/min]

Rated pressure

ORDERING

INFORMATION

BC332375625108en-000101 • February 2020

1

2

46.2

[1.82]

Seal kit

B=Buna-N 120009

V=Viton 120010

rtsHousing P/N

0=No Housing No Housing

=Al, 3/8 BSP SDC10-3-SE-3B

=Al, 1/2 BSP SDC10-3-SE-4B

6S =Al,#6 SAE CP10-3-6S

8S =Al,#8 SAE CP10-3-8S

ther housings available

ht1.00 in

41-47 N.m

[30-35 lbf.ft]

3

7.9

[0.31]

CP460-1-B-8S -2-065-0

Piston seals

0=No seals

S=

Crack

Pressure

psi]

ba

065 =4.48 [65]

Pilot ratio

2=2:1

PO - 17

Page 18

Pilot Operated Check Valves Technical Information

8

Seals

Seals included

r[

]

Housing and po

O

Pilot to Close

CP461-1

OPERATION

SPECIFICATIONS

DIMENSIONS

mm [in]

This valve is a pilot-to-close check valve.

Theoretical performance

psi bar

203

174

145

116

87

58

29

154 SUS (33 cSt) hyd. oil @ 100° F (38° C)

14

12

10

8

6

Press ure drop

4

2

0

40L/min

21.1 31.7 42.3 52.

10.6US gal/min

free flow

80 120 160 200

Flow

Cross-sectional view

Schematic

Specications

Rated pressure 210 bar [3000 psi]

Rated ow at 7 bar

[100 psi]

Leakage 6 drops/min @

Weight 0.21 kg [0.47 lb]

Pilot ratio 2.3:1

Cavity CP12-3S

Note: A piston seal requires a 4.5 bar [65 psi] or

greater return spring.

1-1/16-12 UN-2A

60 l/min

[16 US gal/min]

Rated pressure

ORDERING

INFORMATION

1

2

3

55.9

[2.20]

CP461-1-B-12S -065-0

Seal kit

B=Buna-N 120335

V=Viton 120336

rtsHousing P/N

0=No Housing No Housing

4B =Al,1/2 BSP CP12-3S-4B/2B

6B =Al,3/4 BSP CP12-3S-6B/2B

10S =Al,#10 SAE CP12-3S-10S/4S

12S =Al,#12 SAE CP12-3S-12S/4S

ther housings available

12.7

[0.50]

ht1.25 in

68-75 N.m

[50-55 lbf.ft]

Piston seals

0=No seals

S=

Crack

Pressure

ba

065=4.48 [65]

psi]

BC332375625108en-000101 • February 2020

PO - 18

Page 19

Pilot Operated Check Valves Technical Information

11

14

17

20

105.7

CP462-1 - B - 16S -

065

-

0

Other Housings available

Pilot to Close

CP462-1

OPERATION

SPECIFICATIONS

DIMENSIONS

mm [in]

This valve is a pilot-to-close check valve.

Theoretical performance

psi bar

3

4

5

6

87

58

29

154 SUS (33 cSt) hyd. oil @ 100° F (38° C)

14

12

10

8

6

Press ure drop

4

2

0

80L/min

160 240 320 400

21.1US gal/min

42.3 63.4 84.5

free flow

Flow

Cross-sectional view

1-5/16-12 UN-2A

Schematic

Specications

Rated pressure 210 bar [3000 psi]

Rated ow at 7 bar

[100 psi]

Leakage 6 drops/min @

Weight 0.29 kg [0.64 lb]

Pilot ratio 2.3:1

Cavity SDC16-3S

Note: A piston seal requires a 4.5 bar [65 psi] or

greater return spring.

190 l/min

[50 US gal/min]

Rated pressure

ht1.50 in

1

2

[2.15]

54.6

3

12.7

[0.50]

122-136 N.m

[90-100 lbf.ft]

ORDERING

INFORMATION

Seal Option

Code Seal Material Seal kit

B Buna 120033

V Viton 120034

Housings & Ports

0: Cartridge Only

6B: 3/4 BSP, AL

8B: 1 BSP, AL

12S: #12 SAE, AL

16S: #16 SAE, AL

Housing P/N

No Housing

CP16-3S-6B/2B

CP16-3S-8B/2B

CP16-3S-12S/4S

CP16-3S-16S/4S

Piston Seals

Code

0

S

Crack Pressure

Code

065

bar [psi]

No seals

Seals Included

4.48 [65]

BC332375625108en-000101 • February 2020

PO - 19

Page 20

Pilot Operated Check Valves Technical Information

62

[1.88]

[0.31]

Seals

Housing and po

Seals included

r[

Catalog HIC

CP410-1

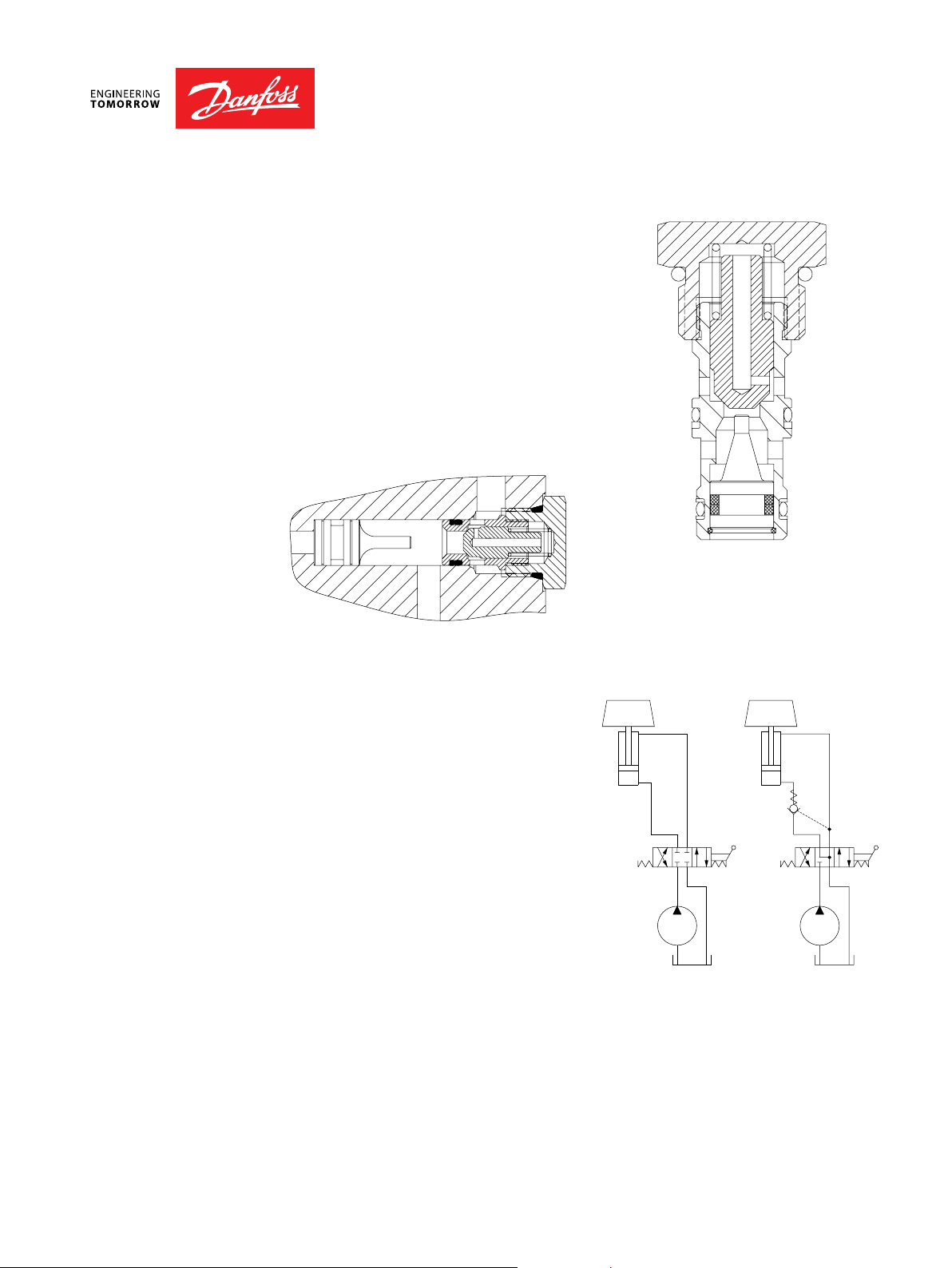

OPERATION

SPECIFICATIONS

DIMENSIONS

mm [in]

This is a dual pilot operated check valve,

which uses two CV10-NP check valves.

Theoretical performance

Pressure drop

psi

150

100

50

0

26 cSt [121 SUS] hyd.oil at 50ƱC [122 ƱF]

bar

10

8

6

4

2

0

15

30

0

4

81

1-2

45 75

60 90

l/min

US gal/min

2012

4

Cross-sectional view

63.5

[2.50]

19.1

[0.75]

31.8

[1.25]

Schematic

Specications

Rated pressure 210 bar [3000 psi]

Rated ow at 7 bar

[100 psi]

Leakage 6 drops/min @

Weight 0.67 kg [1.48 lb]

Pilot ratio 4:1

Cavity none

Note: A piston seal requires a 4.5 bar [65 psi] or

greater return spring.

31.8

15.9

[1.25]

[0.63]

80 l/min

[21.1 US gal/min]

Rated pressure

ORDERING

INFORMATION

C1

95.3

57.2

[2.25]

[3.75]

8.6

[0.34]

C2

7.9

47.8

Seal kitW/ piston seals

B=Buna-N 120072 120176

V=Viton 120161 120177

rts

Housing P/N

6S =Aluminum, #6 SAE 220099

8S =Aluminum, #8 SAE 220100

3B =Al, 3/8 BSP 221794

4B =Al, 1/2 BSP 221652

114.3

[4.50]

38.1

[1.50]

130.5

[5.13]

76.2

[3.00]

CP410-1-B-8S-0-065

V1

V2

Crack

Pressure

ba

065=4.50 [65]

Piston seals

0=No seals

S=

psi]

BC332375625108en-000101 • February 2020

PO - 20

Loading...

Loading...