Page 1

User Guide:

PFM 4000 Measuring Instrument - Multisource Version

Page 2

VUE2B102 © Danfoss 11/2008 HEC

Page 3

Contents

PFM main features ................................................................................................................................................. 5

Introduction ............................................................................................................................................................5

PFM 4000 Multisource components ...................................................................................................................... 6

Switching on and off .............................................................................................................................................. 7

Introduction ............................................................................................................................................................7

Start of measuring................................................................................................................................................... 8

Sensor zero setting................................................................................................................................................ 11

Quick recording.................................................................................................................................................... 12

Data recording......................................................................................................................................................12

Two Sensors Measuring for Balancing by the Proportional Method................................................................... 15

Calculation of valve presetting for a required flow in one branch....................................................................... 16

Calculation of pressure loss on the valve for required flow.................................................................................17

Working with Projects..........................................................................................................................................19

Starting with projects............................................................................................................................................ 20

Creating new project......................................................................................................................................... 21

Preparing for project balancing – measuring.................................................................................................... 23

Balancing of basic project................................................................................................................................25

Project with Central Pressure Input..................................................................................................................26

Balancing calculation of a project with central pressure input - procedure.....................................................27

Measuring actual flow...................................................................................................................................... 29

Replacement of sintered filters.............................................................................................................................30

Using of Routers...................................................................................................................................................31

Scheme of Using Routers................................................................................................................................. 32

Operations after PDA clean reset -.......................................................................................................................33

HEC VUE2B102 © Danfoss 11/2008

Page 4

Radio card installation......................................................................................................................................33

PFM4000 Multisource program installation .................................................................................................... 36

Technical specifications .......................................................................................................................................37

VUE2B102 © Danfoss 11/2008 HEC

Page 5

PFM main features

• Separated main pressure unit and computing unit

based on PDA

Wireless communication in ISM band

• Possible connection up to 10 pressure units

• Accurate pressure measuring with true diff erential

pressure sensor and 24 bit ADC

• Hydraulic by-pass for exact small differential pressure

measuring

• External PT-100 thermometer

• Working with projects

• Programmable autonomous recording mode

• Main unit powered by rechargeable Li-Ion battery

Introduction

PFM 4000 Multisource has been designed for the servicing

and hydraulic balancing of most pressurised heating

and/or cooling systems. It enables measuring of both

under-pressure and over-pressure as well as that of

differential pressure within a given system. Furthermore,

using differences in pressure between the balancing and

measuring elements, the flow through individual branches

of the system can be measured, thus allowing the whole

system to be balanced. PFM 4000 Multisource has a

number of key features that enable easy handling. The

apparatus itself consists of two sepa rate units, main

pressure unit for measuring and computing unit based on

PDA for data analysis. The main pressure is extremely

robust with a sturdy frame and sound cover. It comprises

a differential pressure meter with an integrated true

differential pressure sensor for accurate digital data

processing. Owing to the advantages gained by the use of

digital technology, the PFM 4000 Multisource is able to

compensate for inaccuracies normally associated with

pressure measurements, such as temperature dependency

and non-linearity. In order to increase the accuracy of low

pressure measuring and to enable pressure connection

deaeration, the main pressure unit is designed with incoming

couplers by-pass for hydraulic zero setting. This forms the

basis for the accuracy of subsequent measurements. The

PFM 4000 Multisource can be supplemented with an external

thermometer connected via a coaxial connector. T he

temperature of the working medium can be easily measured

by inserting the thermometer into the differentia l p ressure

outputs due to their size compatibility with the balancing

valve measuring needles. One of the essential PFM 400

Multisource components for balancing hydraulic systems is a

built-in flow meter module. The flow meter works by

calculating the flow through a given branch within the system

using differences in pressure registered by the measuring

element.

HEC VUE2B102 © Danfoss 11/2008

5

Page 6

PFM 4000 Multisource components

I

VUE2B102 © Danfoss 11/2008 HEC

6

Page 7

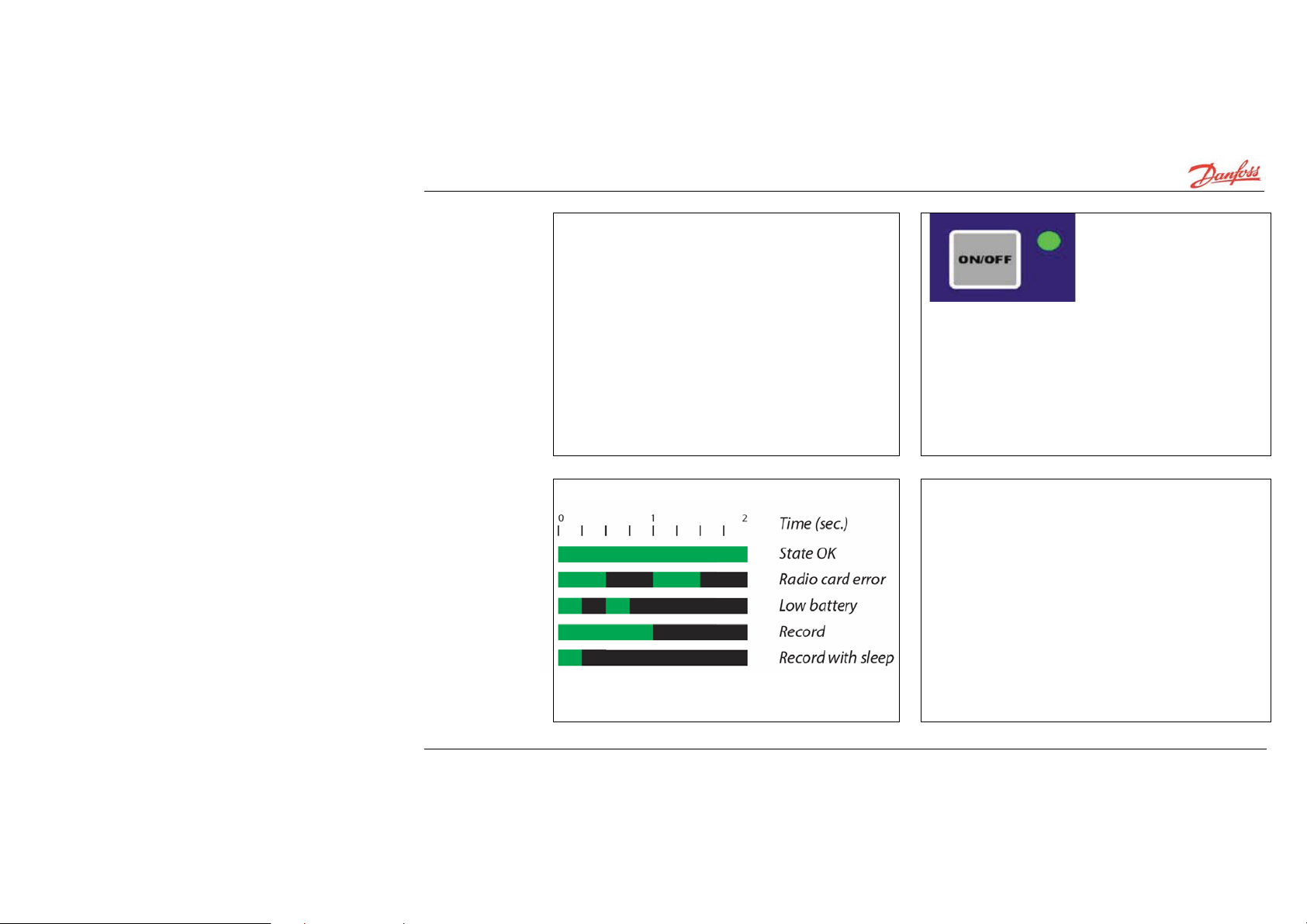

Switching on and off

1. Press ON/OFF button to switch on PFM 4000

Multisource.

The sensor switches off automatically 60 minutes

after the end of communication with PDA.

Introduction

.

HEC VUE2B102 © Danfoss 11/2008

7

Page 8

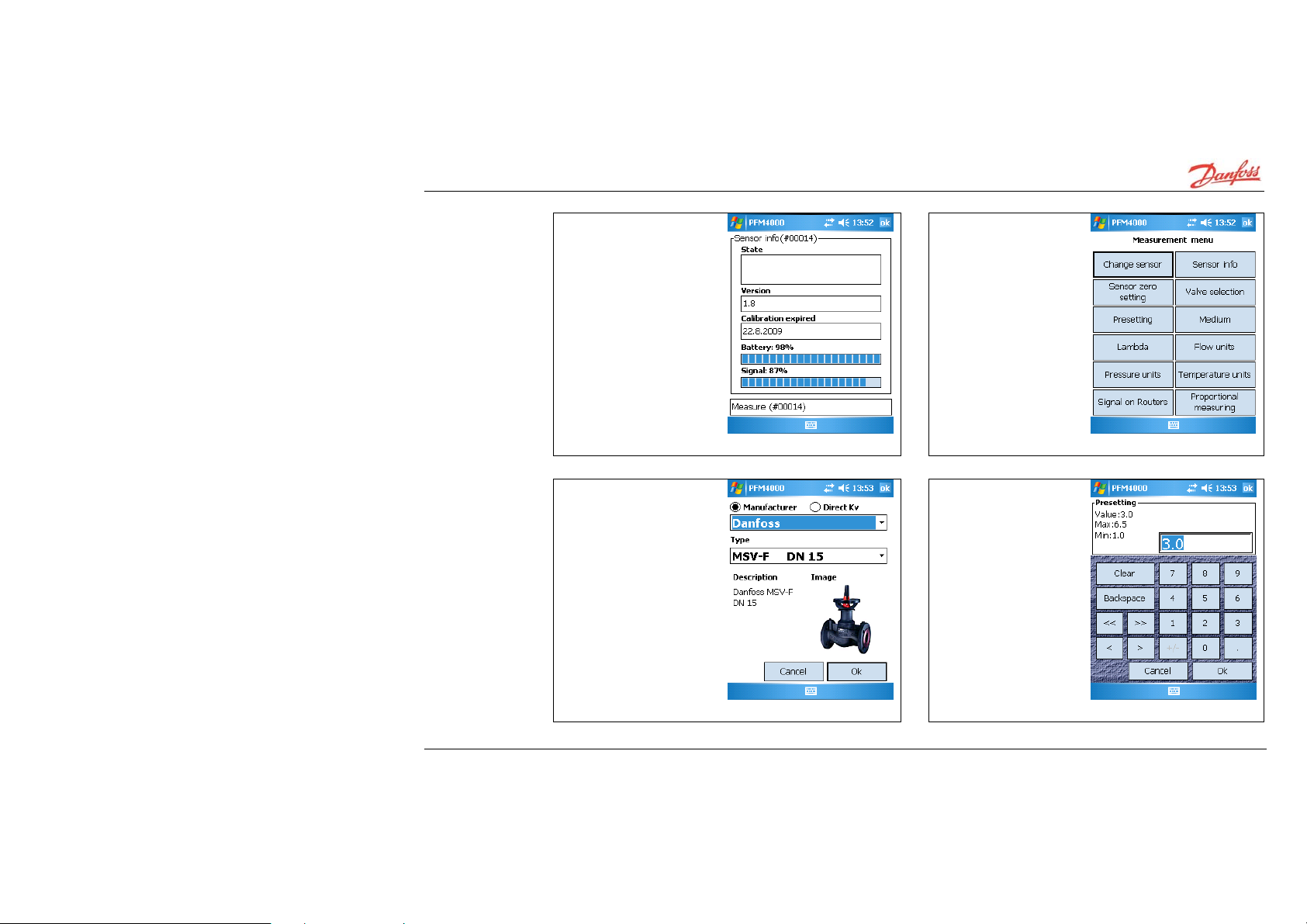

Start of measuring

1. Insert SD card in the

PDA. Run the PFM 4000

Multisource application

from Start Menu.

Select Measure in the main

menu.

2. Tip! Clicking on any

underlined text, e.g.

Valve, will open change

parameter window.

3. Select Menu, Change

sensor to connect

computing unit to the

sensor.

4. Select Search to obtain

a list of available sensors.

Select desired sensor

from the list and confirm

by clicking OK. If you use

router, router #1means

nearest router to PDA.

Searching of pressure

units do not run via

routers. Make sure that

you are close to pressure

unit during searching.

VUE2B102 © Danfoss 11/2008 HEC

8

Page 9

Start of

measuring

(continued)

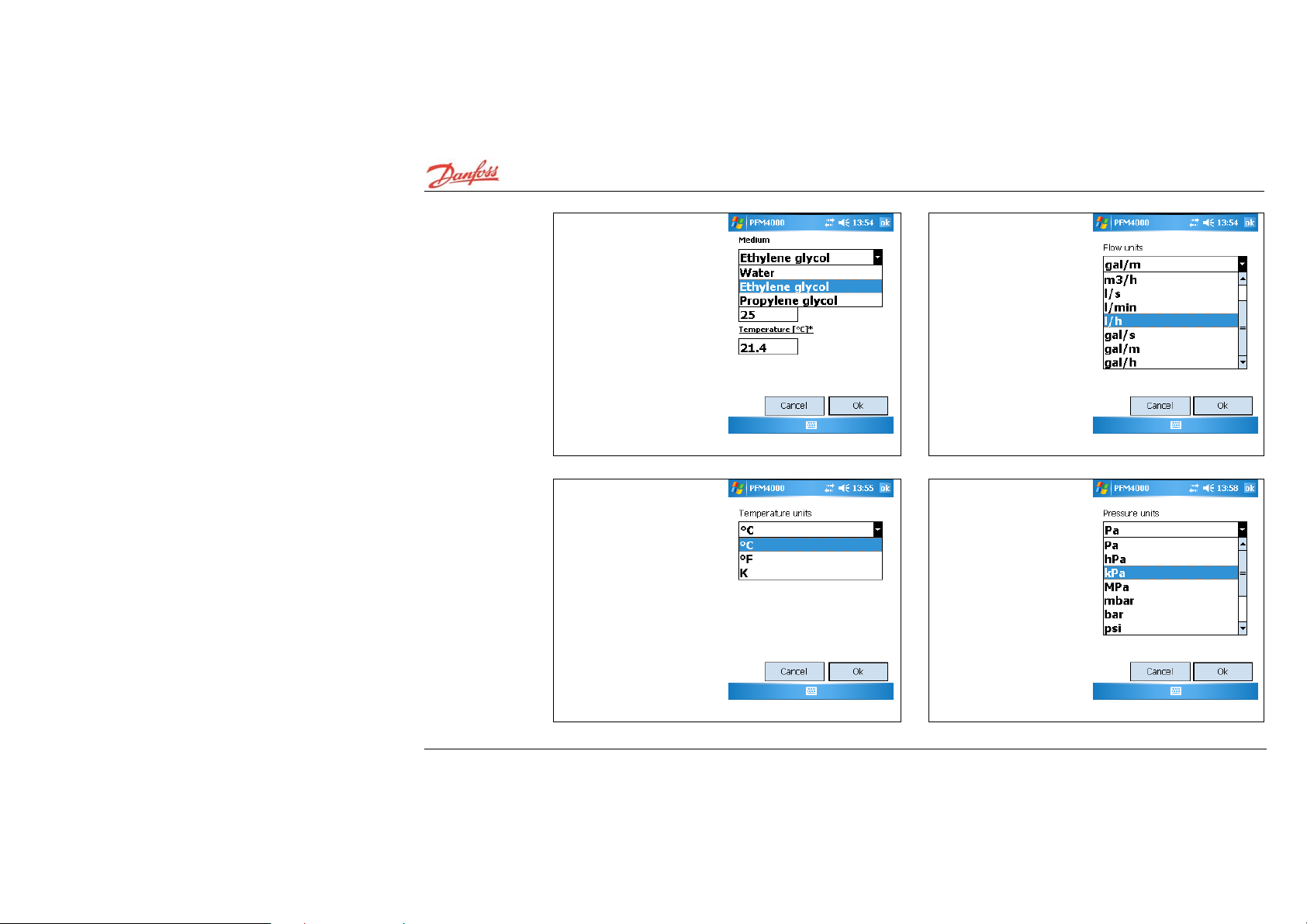

5. Sensor Info button

displays information about

the selected sensor.

6. Click on Valve

selection for changing

valve type or click on

Presetting for changing

presetting value. Change

medium by clicking on

Medium.

7. Select Manufacturer

from list box. Then select

valve type and click Ok.

8. Input valve presetting

and click Ok.

HEC VUE2B102 © Danfoss 11/2008

9

Page 10

Start of

measuring

(continued)

9. Select medium from list

box and fill in value of

concentration.

10. Select flow units from

list box.

11. Select temperature

units from list box.

12. Select pressure units

from list box.

VUE2B102 © Danfoss 11/2008 HEC

10

Page 11

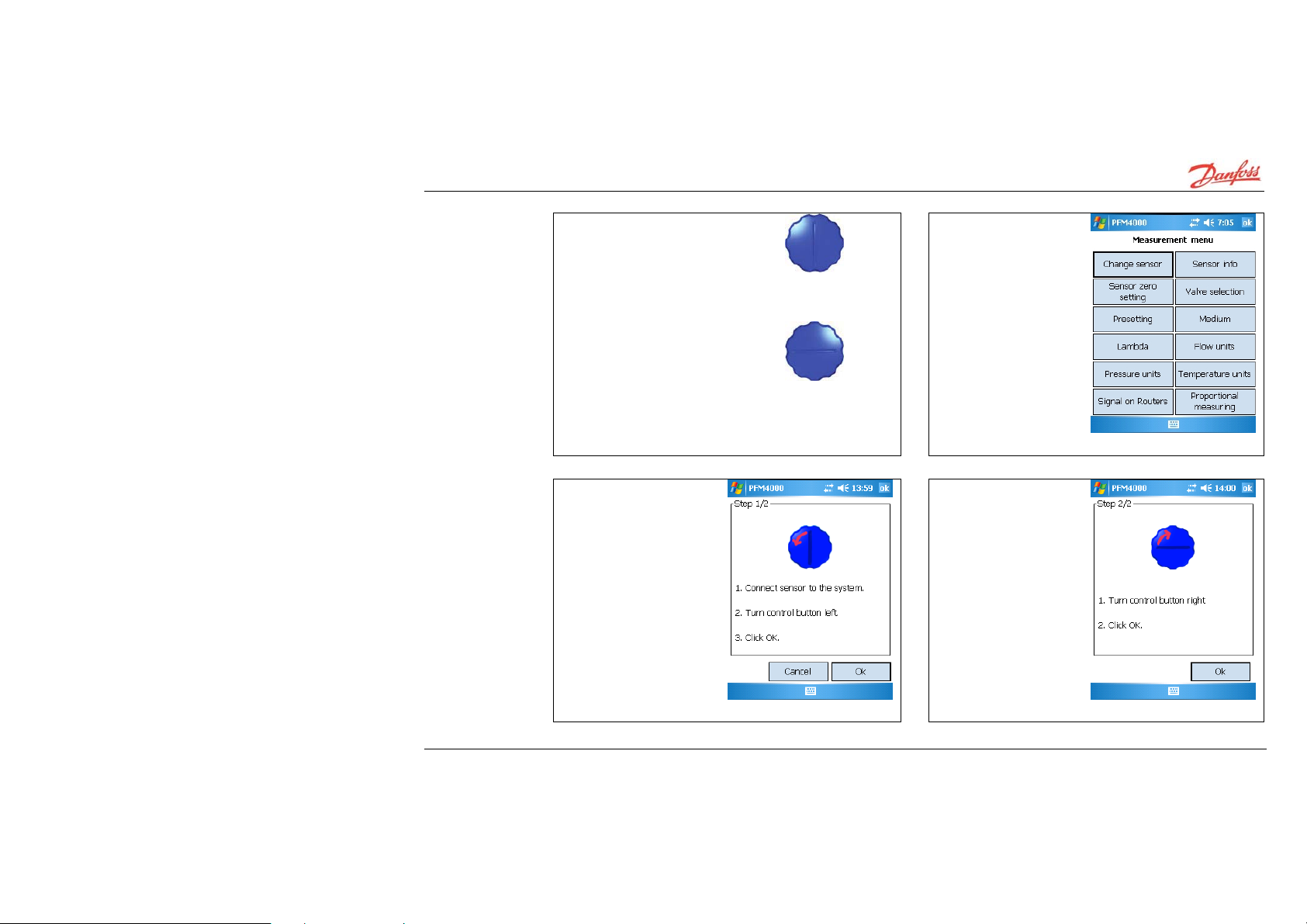

Sensor zero setting

1. Should you want to measure

small differential pressures of

less than 500Pa, the PFM 4000

sensor should be set to zero.

measuring position

zero setting position

2. Zero setting is

achieved by clicking on

Zero button.

3. Connect sensor to the

system, turn zero valve to

horizontal position and

continue by clicking OK.

4. Turn zero valve back

to vertical position and

confirm by clicking OK.

HEC VUE2B102 © Danfoss 11/2008

11

Page 12

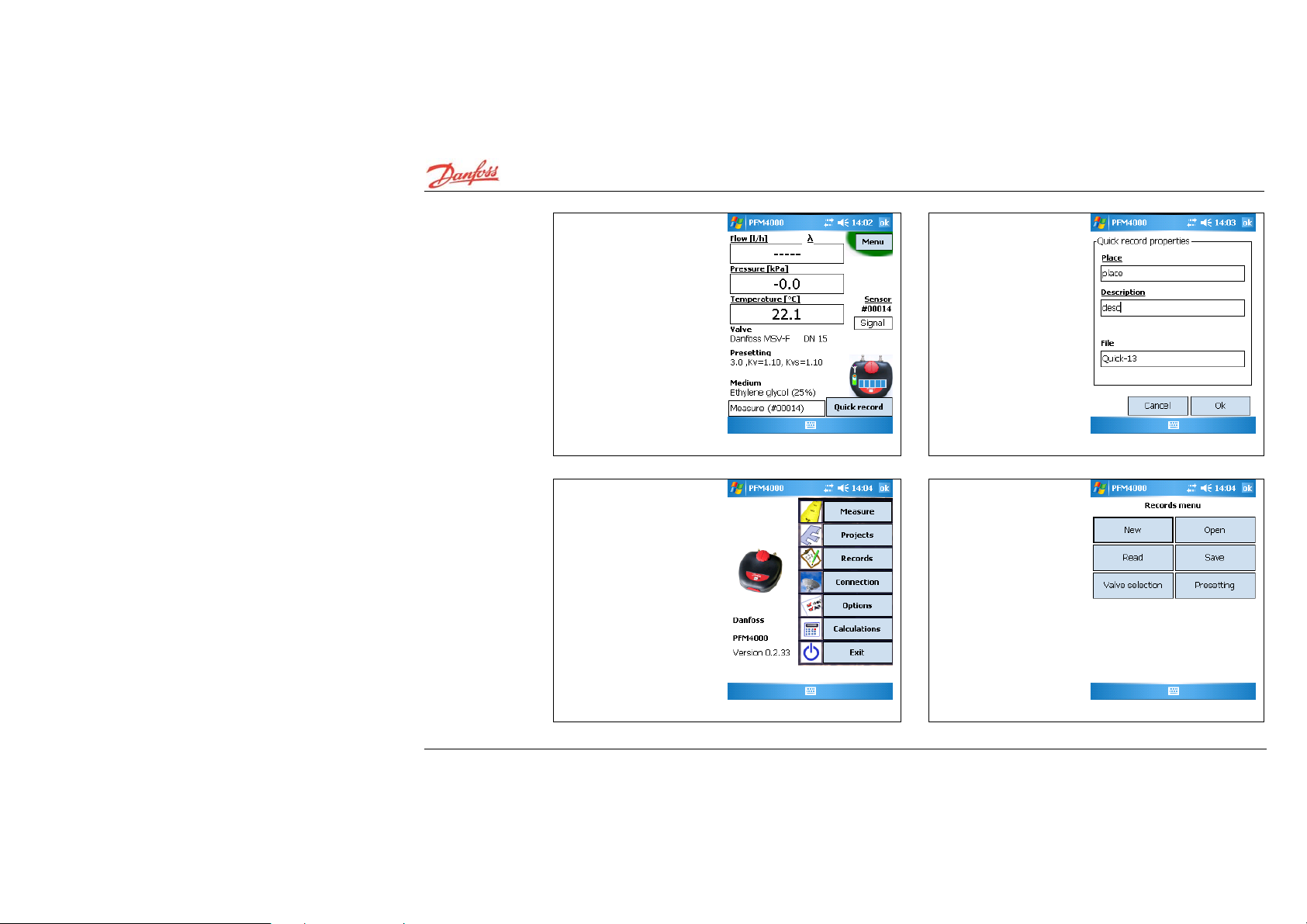

Quick recording

1. Measured value can be

recorded by clicking on

Quick Record button.

2. Input place and name

of entry.

Data recording

1. Select Records in the

main menu.

2. Click on Menu, New

button.

VUE2B102 © Danfoss 11/2008 HEC

12

Page 13

Data recording

(continued)

3. Select recording units.

4. Select place, name,

period and number or

records.

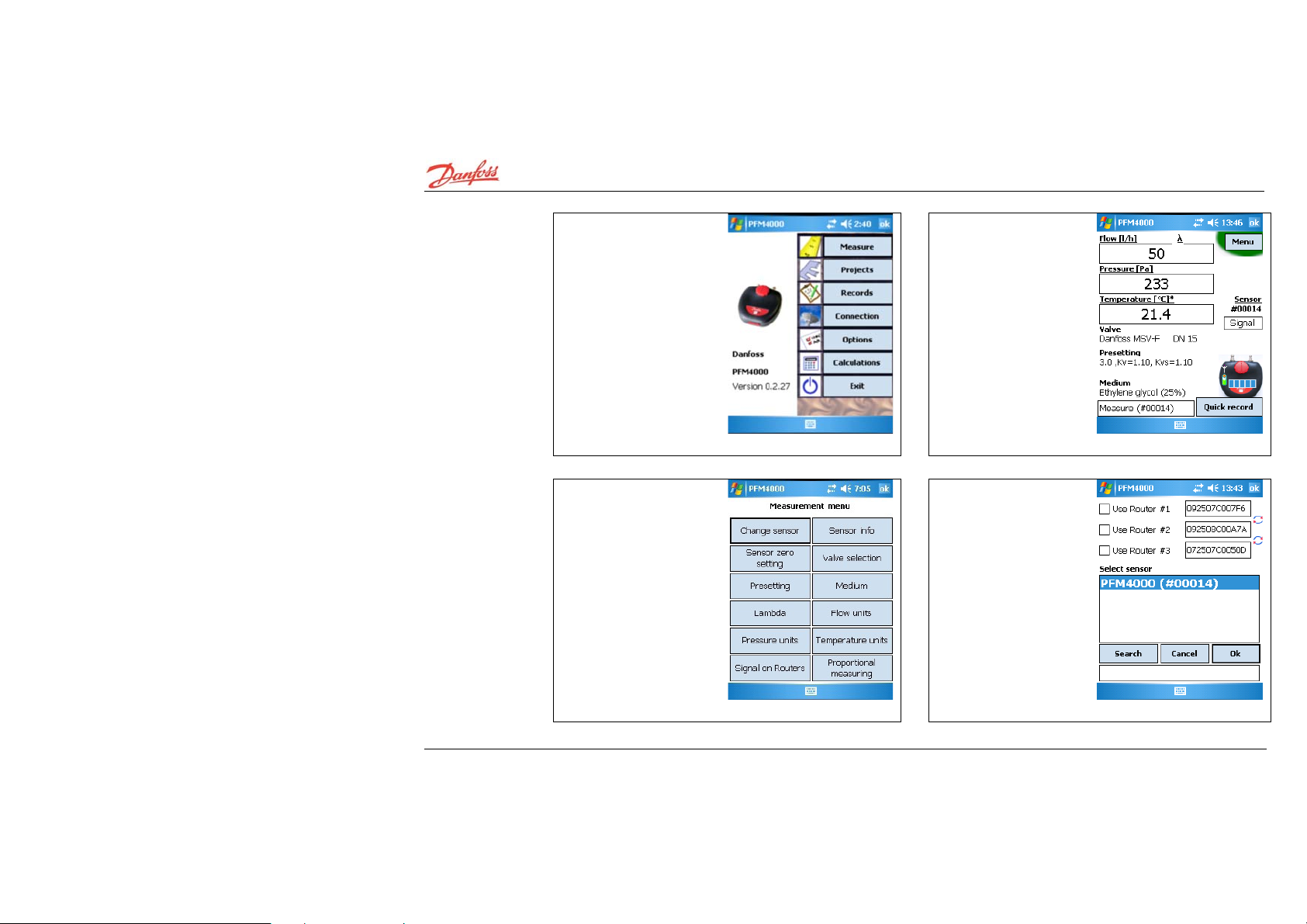

5. Click OK. The setting will be transmitted to the PFM 4000

Multisource sensor and recording will begin. The recording

status will be indicated by PFM 4000 Multisource LED.

6. Clicking on New or

Read button during

recording will pop up a

message. Only answer

this at the end of the

recording period.

HEC VUE2B102 © Danfoss 11/2008

13

Page 14

Data recording

(continued)

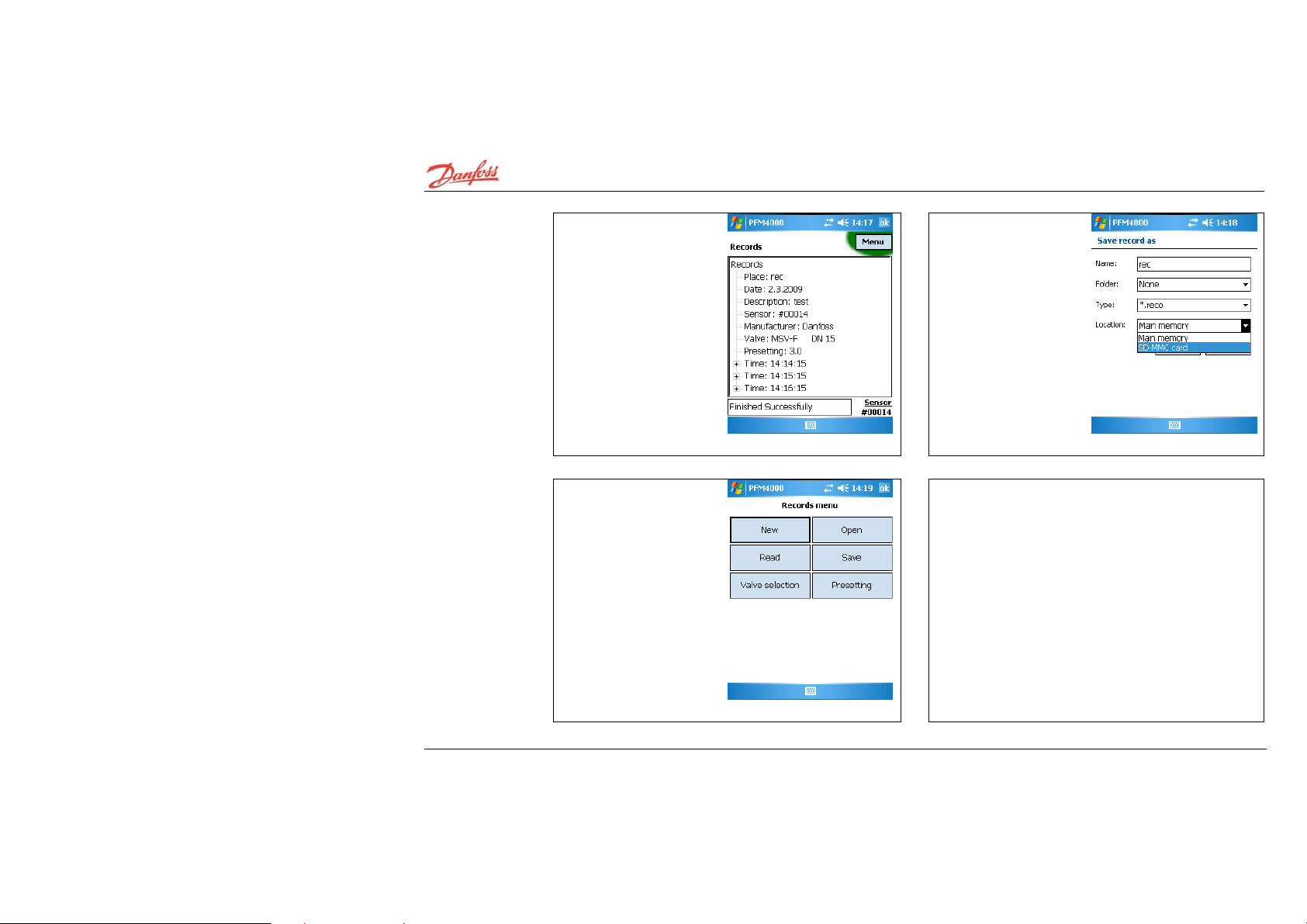

7. Data recorded into the

sensor can be accessed by

clicking on Read button.

Clicking on Save button will

save data.

8. Enter name and place

of file for the read data.

For reasons described

above, It is

recommended to save

onto an SD card.

9. Saved data can be

accessed by clicking on

Open button.

10. When using two sensors, recording can be done on

both sensors simultaneously.

VUE2B102 © Danfoss 11/2008 HEC

14

Page 15

Two Sensors

Measuring for

1. Tap on Proportional

measuring button

2. Balancing by

proportional method

window will open

Balancing by

the

Proportional

Method

3. Select reference sensor, for instance in the upper part of

the window, by clicking on Sensor

4. Select sensor from the branch to be balanced into the

lower part of the window.

5. For both branches, set the correct valve and presetting.

6. Flow in both branches will be displayed in the flow

window in flow units.

link.

7. Input the requested flow for both branches by clicking l

lambda. The display will subsequently change from real to

proportional flow expressed as a % of the requested flow.

HEC VUE2B102 © Danfoss 11/2008

15

Page 16

Calculation of

valve

presetting for

a required

1. Click on Calculations

button in the main menu.

2. Select valve and enter

the current presetting in

the branch. Click on

Calculate presetting

button.

flow in one

branch

3. Enter the required flow

for the branch.

4. Measure the current

flow through the branch.

VUE2B102 © Danfoss 11/2008 HEC

16

Page 17

Calculation of

valve presetting

for a required

flow in one

branch

(continued)

5. Close valve and measure

the available pressure in

the branch.

6. Presetting for the

required flow will appear

in the Results window.

Presetting out of range

message will appear if it

is not possible to achieve

the required flow.

Calculation of

pressure loss

on the valve

for required

1. Click on Calculations

button in the main menu.

2. Select valve and enter

the current presetting in

the branch. Click on

Calculate pressure loss

button.

flow

HEC VUE2B102 © Danfoss 11/2008

17

Page 18

Calculation of

pressure loss on

the valve for

required flow

(continued)

3. Enter the required flow

for the branch.

4. Answer will appear in

the Results window.

VUE2B102 © Danfoss 11/2008 HEC

18

Page 19

Working with Projects

PFM 4000 Multisource includes a built-in module for project

balancing calculations comprised of one horizontal and a

maximum of 100 vertical branches. The calculation assumes

that the pressure input of

the project is constant and that the project is d e void of

negative feedback hydraulic elements (for instance

differential pressure regulators within branches or

thermostatic valves).

Basic Project Schematic

HEC VUE2B102 © Danfoss 11/2008

19

Page 20

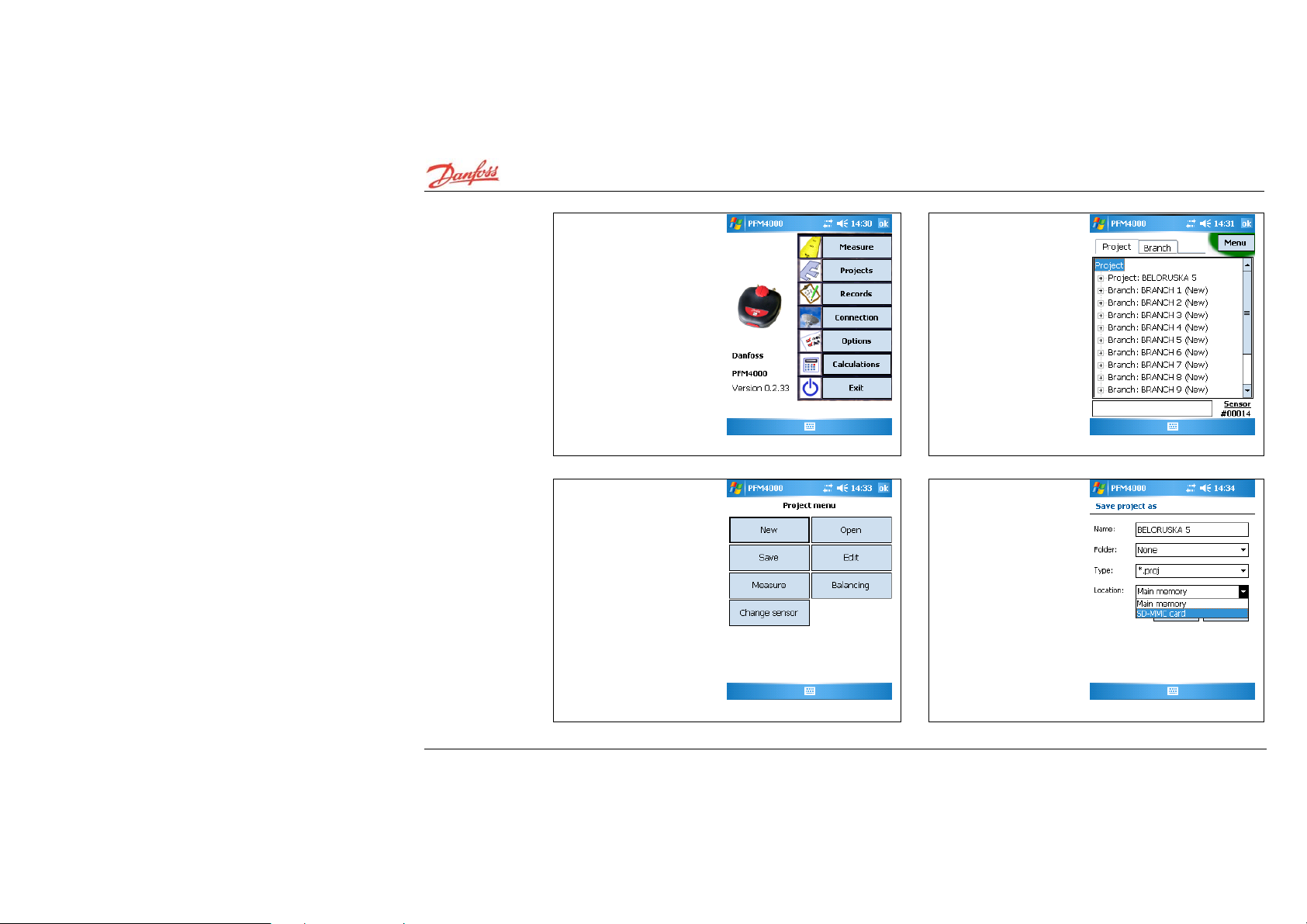

Starting with projects

1. Select Projects in the

main menu.

2. The last project to be

opened in the Project

window.

VUE2B102 © Danfoss 11/2008 HEC

20

3. Press New

4. We recommend you

use the Projects folder

on the SD Card in case

of system failure.

Page 21

Creating new project

1. Select the Project tab

and click on Menu, New

followed by Edit buttons.

2. Fill in underlined fields

including Initial

presetting. Uncheck

Common Valve box if it

is not present in the

project

3. Example: Note it is not

necessary to fill in the

Input pressure at this

point. It will be possible to

measure it using the

Project/Measure function,

as described in the next

section. The calculated

Common valve presetting

can be viewed in the

Presetting Window at the

end of project balancing.

4. Select the Branch tab

and click on Menu, Add

button.

HEC VUE2B102 © Danfoss 11/2008

21

Page 22

Creating new

project

(continued)

5. Fill in the Branch name,

Valve Manufacturer and

Type, Requested flow and

the Initial presetting. The

other fields will be filled

automatically during

branch measuring or after

the balancing calculation.

6. Example: Similarly to

the Input pressure, it will

be possible to measure

the Initial flow and Close

pressure using the

Menu/Measure function.

VUE2B102 © Danfoss 11/2008 HEC

22

7. Add the rest of the

branches included in the

project following the above

instructions. Note that the

order of branches in the

project must correspond to

the distance of each branch

from the input pressure

source.

8. The correct order of

branches in the project

can be set by moving

selected up or down in

the project structure.

Page 23

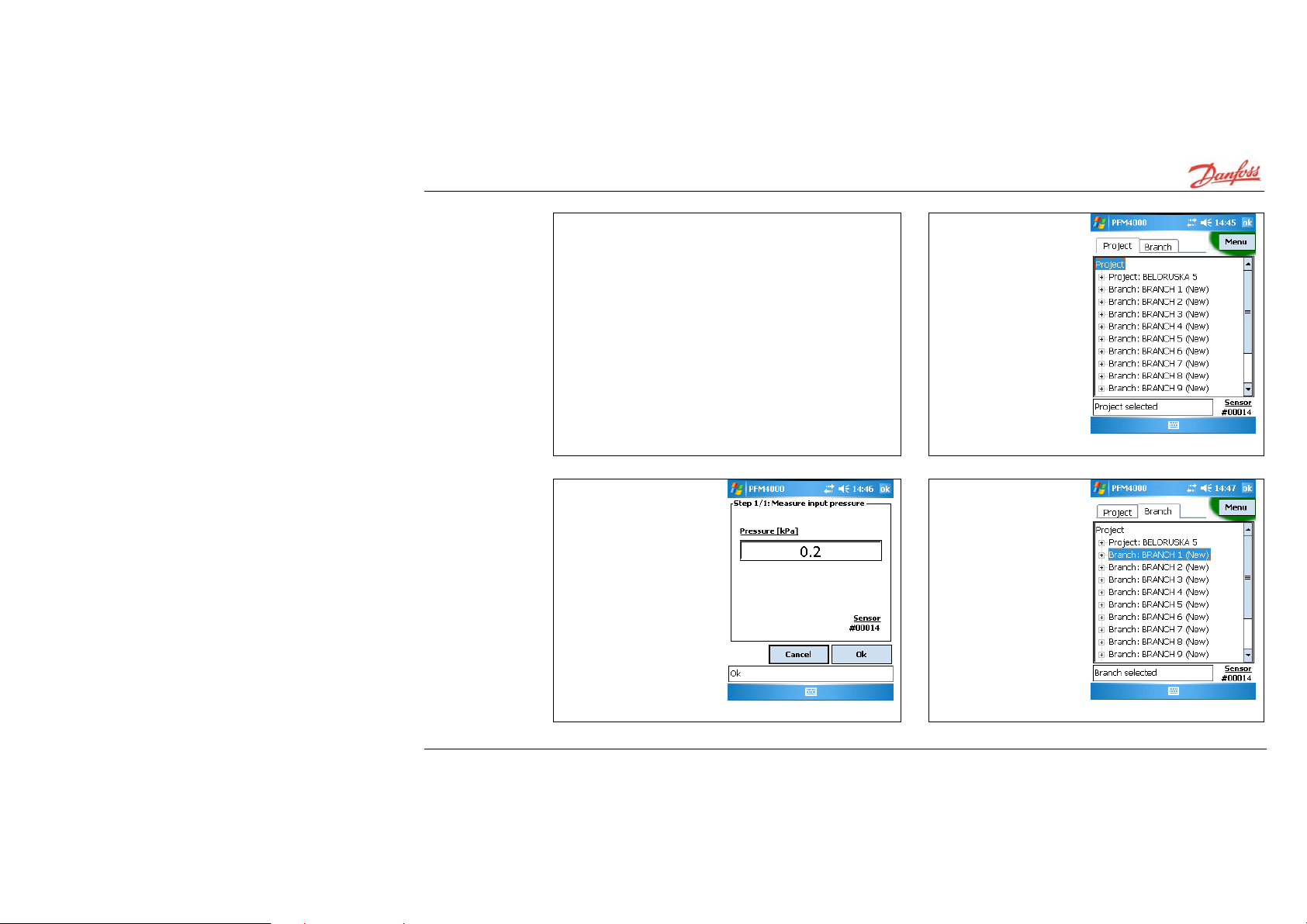

Preparing for project balancing – measuring

1. Prior to measuring, the Initial presetting has to be set on

all balancing valves within the project including the common

valve. When re-balancing an existing or newly designed

project, it is most effective to enter the actual presetting of

balancing valves within.

2. Connect PFM 4000

Multisource sensor to the

input pressure. Select

the Project tab followed

by the Menu/Measure

button.

HEC VUE2B102 © Danfoss 11/2008

3. The value measured will

be automatically filled in

the corresponding field.

4. Connect PFM 4000

Multisource sensor to the

balancing valve at any

branch and select the

appropriate branch in

the Branch tab. It is

necessary to measure

both the Flow through

the valve with Initial

presetting of the

balancing valve and the

Available pressure in the

branch with the

balancing valve being

closed.

23

Page 24

Preparing for

project balancing

– measuring

(continued)

5. Click on the

Menu/Measure button and

select Before project

balancing type of

measuring.

6. PFM 4000 Multisource

will automatically choose

the correct valve and

presetting according to

the branch selected. The

Initial flow measured will

be saved along with the

rest of the branch data.

VUE2B102 © Danfoss 11/2008 HEC

24

7. Close the balancing

valve in the branch prior to

measuring the available

pressure in the branch.

The value measured will

again be saved along with

branch data.

8. The project is ready for balancing after the Initial flow

and Available pressure for each branch of the project has

been measured.

Page 25

Balancing of basic project

1. Return to the Project tab

and click on the

Menu/Balancing button.

2. Select Basic project

balancing. The balancing

progress is depicted by a

bar graph.

HEC VUE2B102 © Danfoss 11/2008

3. In order to minimise power losses in the project, PFM

4000 Multisource starts balancing with a 3kPa pressure drop

on the balancing valve in the last branch. Next, the nonbalanced branches are optimised. If for any branch a higher

pressure drop is required on the balancing valve, the

computing will be restarted with an increased pressure drop

in the last branch. The balancing stops when the m inimum

number of branches is not balanced.

4. The result of

balancing appears in the

State field in the Start

Balancing window.

25

Page 26

Project with Central Pressure Input

We often come across systems with a central pressure input

with a distribution of the medium to either side of the input.

It is possible to balance such project by virtually dividing it

into two separate projects with

unidirectional branch distribution. The two projects are

measured and balanced individually and subsequently

drawn together using the Bind Projects command as

follows.

VUE2B102 © Danfoss 11/2008 HEC

26

Page 27

Balancing

calculation of

a project

with central

pressure

input procedure

1. Create two projects -

depicted above.

2. Close the Right Side project by a stop valve.

3. Measure the Left Side project.

4. Close the Left Side project by a stop valve.

5. Open and measure the Right Side project.

Left Side

and

Right Side

as

6. Switch to Project tab

and click on the

Menu/Balancing button.

7. Click on Middle power

project balancing button.

8. Open one side of the

middle powered project

– for instance the left

side.

HEC VUE2B102 © Danfoss 11/2008

27

Page 28

Balancing

calculation of a

project with

central pressure

input –

procedure

(continued)

9. Open the second side of

the middle powered project

– right side.

10. PFM 4000

Multisource will balance

the two projects

separately. Next, it will

rebalance the side of the

project that requires

higher pressure after the

common valve. Finally, it

will correct the KV of the

common valve for both

of the projects. The

balancing progress can

be monitored on the PDA

screen.

VUE2B102 © Danfoss 11/2008 HEC

28

Page 29

Measuring actual flow

1. Click on Branch tab and

select branch to measured.

Click on Menu/Measure

button.

2. Select “After project

balancing” and click OK.

HEC VUE2B102 © Danfoss 11/2008

3. The flow value

measured will be entered

under the “Flow”

parameter of the selected

branch.

29

Page 30

Replacement of sintered filters

When PFM 4000 Multisource starts reacting slowly to changes in

pressure or when after powering up the pressure displayed

pressure or when after powering up the pressure displayed

exceeds 5 kPa, it is necessary to change sintered filters as

exceeds 5 kPa, it is necessary to change sintered filters as

shown in the picture below. If there is no improvement, please

shown in the picture below. If there is no improvement, please

return to the manufacturer for servicing.

return to the manufacturer for servicing.

ource starts reacting slowly to changes in

VUE2B102 © Danfoss 11/2008 HEC

30

Page 31

Using of Routers

You can use relay wireless mode for long distance

measuring or measuring in project with heavy radio waves

propagation. Router is designed in PFM4000 casing with

external high performance thin-rod antenna. Router needs

only switching power On and OFF and its state is indicated

by LED diode.

1. Select Menu, Change

sensor to use routers

HEC VUE2B102 © Danfoss 11/2008

2. Check use routers, fill

in radio address if it is

necessary. Radio address

is S/N written on the

bottom side.

Searching of pressure

units do not run via

routers. Make sure that

you are close to pressure

unit during searching.

31

Page 32

Scheme of Using Routers

Using of router for single sensor.

Using of two routers for single sensor.

VUE2B102 © Danfoss 11/2008 HEC

32

Using of two sensors

with routers

(proportional

method).

Page 33

Operations after PDA clean reset -

Radio card installation

When it is possible to

perform clean reset of PDA

it si necessary install radio

card drivers.

Do not insert radio

card to PDA before

installation of

drivers!!!!

Install drivers from PDA

File Explorer folder SD

Card/Drivers in three

steps:

Run 01_elSerial.ARM.CAB.

Tab on Install to continue

installation.

Driver was successfully

installed.

Run 2_netcf.all.wce4.

ARMV4.CA20B.

HEC VUE2B102 © Danfoss 11/2008

33

Page 34

Operations

Tab on Install to continue

installation.

Tab on OK to finish

installation.

after PDA

clean reset -

Radio card

installation

(continued)

Run 03_OpenNETCF.SCF.

ppv3.arvw4.CAB.

Tab on Install to continue

installation.

VUE2B102 © Danfoss 11/2008 HEC

34

Page 35

Operations

after PDA

clean reset -

Radio card

installation

(continued)

After installation of drivers

insert radiocard into PDA.

If New modem detected

Windows is shown, tab on

Dismiss.

Now you can find new

item elComID in Program

group.

elComID software display

COM port used by

radiocard.

Select this COM port in

Connection item from

main menu PFM4000.

HEC VUE2B102 © Danfoss 11/2008

35

Page 36

Operations

after PDA

clean reset -

PFM4000 Multisource program installation

1. Run SD_Card/Setup

/PFM4000.cab from PDA

File Explorer.

2. Tap on PFM4000.cab

icon to install.

3. Choose the “Device”

location for

Danfoss/PFM4000

program.

4. You will use procedure

described in previous

column also for upgrade

of PFM4000 program.

VUE2B102 © Danfoss 11/2008 HEC

36

Page 37

Technical specifications

Main pressure unit

Pressure range................... 0-1000 kPa ~ 0-10 bar

0-2000 kPa ~ 0-20 bar

Max. static pressure....... 10 or 20 bar

Max. over pressure 1200 kPa ~ 12 bar

2200 kPa ~ 22 bar

Reliability, linearity and hysteresis error...... 0.15 % of range

Temperature error....... 0.25 % of range

Static pressure effect.......... ± 200 Pa

Medium temperature - 5 to 90° C (at end of connection tubes)

Ambient temperature...... - 5 to 50° C

Storage temperature................ -10 to 70° C

Temperature probe........ Pt 100 digital

Temperature measuring range.... -20 to 120° C

Temperature measuring error..................... ± 1° C

Power Li lon battery 3.6 V 950 mAh (for Nokia 6230 mobile phone)

Operating time Max. 120 hours

Charging time.................. 7 hours

Interface RF wireless band 868 MHz

Communication speed ..... 9600 bps

RF transmitter power 25 mW

Radio range (open air) Up to 30 m

Wireless routers...... 868 MHz band , 500 mW

Number of routers.... max. 3

Radio range with 3 routers (open air), Multisource....... 300 m

Number of records Max. 3500

Dimensions (w x h x d)............. 77 x 19 x 25 mm

Weight...................................... 620 g

Cover................................ ....... IP 65

Calibration validity............ 12 months

HEC VUE2B102 © Danfoss 11/2008

37

Loading...

Loading...