Page 1

Instrument for Balancing of Hydronic Systems

PFM3000 USB

User’s Guide

VU.E1.V2.02

Page 2

PFM3000

Page 3

PFM3000

Contents

3Contents ..................................... .......

5Introduction ................................... .......

6Invaluable Advantages of PFM3000 ............. .......

6Important User Notice ......................... .......

6Getting Started ................................ .......

6Battery Charging .............................. .......

7Flushing of Hoses ............................. .......

7PFM3000 Zero Measuring Correction ........... .......

8Functions of Keys on the Instrument's Keyboard . .......

8PFM3000 Configuration ........................ .......

9Language Setting ............................. .......

9Clock Setting ................................. .......

10Pressure Units ................................ ......

10Flow Units .................................... ......

11Valve Selection ............................... ......

11Measured Medium Selection ................... ......

Selection of Minimum Pressure for Flow

Displaying .................................... ......

Measuring Flow in the Fittings Not Saved in the

PFM3000 Memory ............................ ......

Calculation of Valve Presetting for a Requested

Flow ......................................... ......

12

13Measuring with PFM3000 ...................... ......

13Measuring Without Project ..................... ......

13System Over pressure Measuring ............... ......

13Differential Pressure and Flow Measuring ....... ......

13Automatic in Process Zero Setting .............. ......

14Flow Measuring Limitation ..................... ......

14

15Temperature Measuring ....................... ......

15Heating Calculations .......................... ......

15

Calculation of Valve Pressure Drop for a

Requested flow ............................... ......

Measurements Necessary for the Project

Balancing .................................... ......

Balancing Calculations of Projects with Central

Pressure Input ................................ ......

........ ......

15

16Data Recording ............................... ......

16Recording Settings ........................... ......

16Start of Recording ............................. ......

17Full Data Memory and Low Battery .............. ......

17End of Recording ............................. ......

18Processing Projects ........................... ......

18Creating a New Project ........................ ......

19Project without a Common Valve ............... ......

19

20Project Balancing Calculation .................. ......

20Project Balancing Results ...................... ......

21Project Balancing Check ....................... ......

22

23Communication with a Computer ............... ......

23User Software PFM3000 ....................... ......

23Minimum PC Requirements .................... ......

23Software Installation ........................... ......

23Windows USB Drivers Installation Guide

26Operating the Program ........................ ......

26Data Processing .............................. ......

27Maintenance Instructions ...................... ......

28Parts of the Delivery ........................... ......

29Technical Specifications ....................... ......

3

Page 4

PFM3000

4

Page 5

PFM3000

Introduction

PFM3000 has been designed for the servicing and hydraulic

balancing of most pressurised heating and/or cooling

systems. It enables measuring of both under-pressure and

over-pressure as well as that of differential pressure within a

given system. Furthermore, using the differences in pressure

between the balancing and measuring elements, the flow

through individual branches of the system can be measured,

thus allowing the whole system to be balanced.

PFM3000 has a number of key features that enable easy

handling. The apparatus itself is relatively small and

extremely hard wearing so that it can withstand the harshest

of conditions during operation. After measuring, the acquired

data can be transferred to a PC via a USB interface and

subsequently analysed using a specialised software

provided.

The basic module of the apparatus comprises of a

differential pressure meter with an integrated pressure

sensor that allows digital data processing. Owing to the

advantages gained by the use of digital technology, the

PFM3000 is able to compensate for inaccuracies normally

associated with pressure measurements, such as

temperature dependency and non-linearity. This forms the

basics for the accuracy of subsequent measurements.

One of the essential components for balancing hydraulic

systems is a built-in flow meter module. The flow meter

works by calculating the flow through a given branch within

the system using differences in pressure registered by the

measuring element. Specifications for both the balancing

and measuring elements of well-recognised manufacturers

are pre-programmed in the memory of the PFM3000. These

easily accessed from its main menu. In addition, the flow

meter automatically corrects the flow for different types of

medium within the system being measured, such as systems

with antifreeze additives or cooling systems.

The biggest advantage for the user is conferred by a module

used for heating system balancing calculations. It allows

regulation of complicated multi-branch heating systems

inclusive of any shared valve. The PFM3000 utilises a

sophisticated method for calculating hydraulic resistances

within the system. As a result, the PFM3000 comes up with

a proposal with the lowest energetic loss. This function

dramatically decreases the time required for balancing.

An inverse module to the flow meter module is that used for

the calculation of valve pre-settings, the output of which is a

valve pre-setting value for a required flow. For a given valve,

the pre-setting value is calculated using its respective

parameters stored in the memory of the PFM3000.

The PFM3000 can be supplemented with an external

thermometer connected via the coaxial connector. The

temperature of the working medium can be easily measured

by inserting the thermometer into the differential pressure

outputs due to their size compatibility with the balancing

valve measuring needles. The temperature value is recorded

in the memory of the PFM3000 along with other collected

data.

5

Page 6

PFM3000

Apart from the usual recording and archiving of collected

data, the PFM3000 has an integrated recording module

equipped with a real time circuit. This also enables the

diagnosis of any timed processes taking place in the system,

the analysis of which aids selecting the most optimal system

set up. During recordings with longer measuring periods, the

PFM3000 automatically enters a lower energy consumption

mode. This ensures prolonged recording from the internal

energy source (a lithium battery).

Data can be collected from various points around the

heating system as and when required. In addition, it can also

be collected periodically. The values recorded by the

PFM3000 include pressure, flow (velocity), temperature,

chosen valve and its pre-settings. Each measurement is

given an id, which makes the subsequent data handling

easier. The recorded data can be subsequently transferred

into a PC using the software provided. The software further

enables its analysis in tabulated or graphic formats.

Alternatively, the data can be exported using standard PC

formats and analysed in text editing, table processing or

database programmes. All data can also be printed.

Important User Notice

Do not expose the PFM3000 to temperatures lower than the

freezing point of the previously measured liquid medium as

the pressure sensor may get damaged.

The R20 quick release couplers that are used on the smaller

size measuring tubing contain charcoal filters with filtering

capacity of 50µm, which can get clogged when measuring

systems with abundant particles. These filters should be

changed if an unrealistic pressure value is displayed or if

any of the pressure inputs appear non-functional.

Getting Started

The PFM3000 is supplied with a pre-charged lithium battery

ready for use. After switching on the PFM3000 for the first

time, check alternatively set the real time circuit according to

instructions.

Invaluable Advantages of PFM3000

y Mechanical design

y Integrated pressure sensor

y Robust metal case

y Water resistant

y Big 4-line display

y Illuminated display

y Well-arranged 16-key foil keyboard

y Chargeable lithium battery

Battery Charging

The battery status can be checked during measuring by

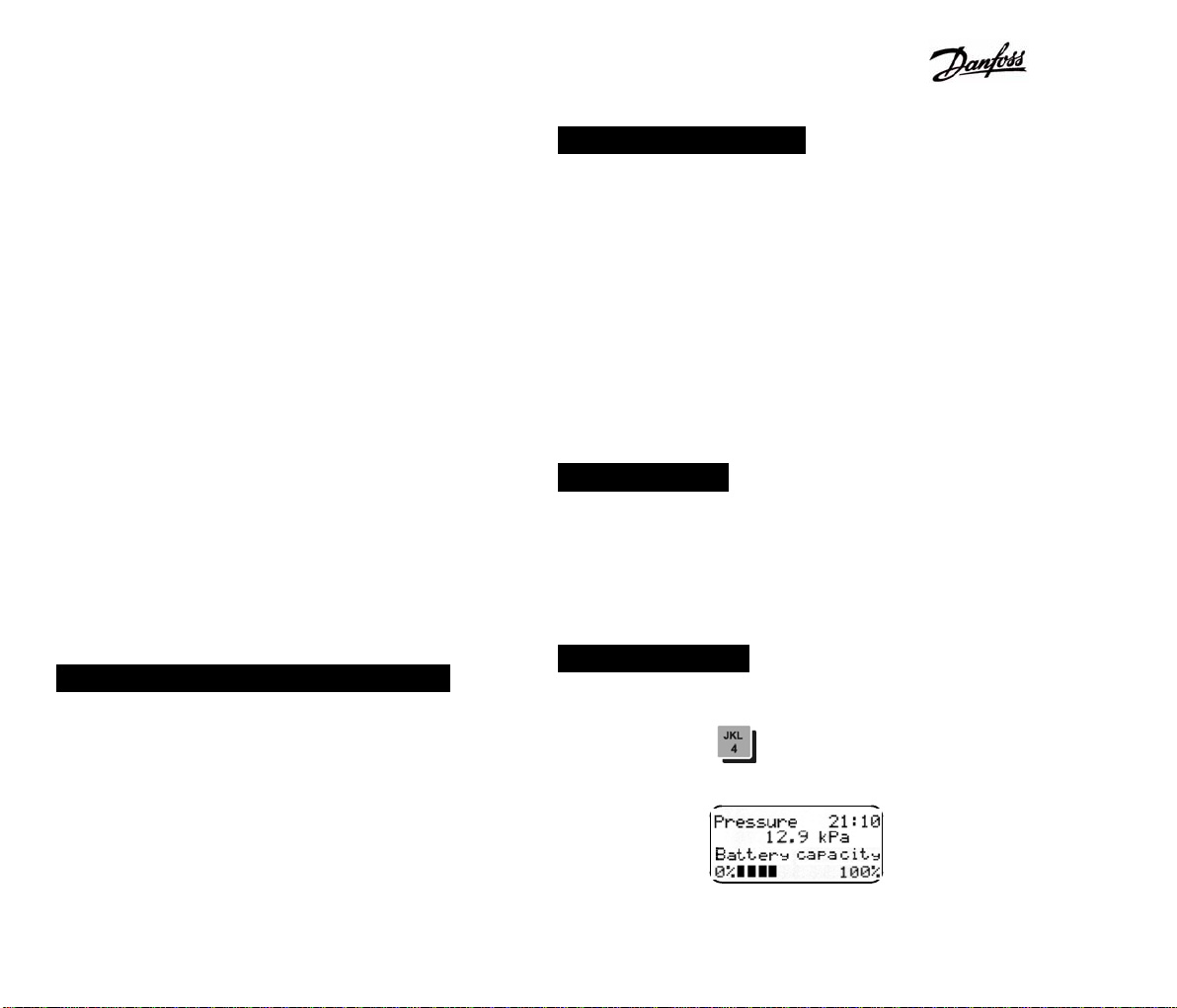

pressing the hot key .Its capacity will be subsequently

displayed in a form of bargraph.

6

Page 7

PFM3000

Message Low Battery! flashes on the display every 15

seconds if the battery capacity reaches less than 5%. It is

possible to run the PFM3000 for a further 6 hours following

the appearance of the above message, after that the

PFM3000 automatically turns itself off. To recharge the

battery, plug charger cable into a port situated at the bottom

of the PFM3000 (see Figure 1), plug power supply unit into a

mains power socket and charge for at least 7 hours.

Flushing of Hoses

The supplied connecting hoses are pre-filled with 50%

ethylene glycol solution.

If you need to flush them immediately after purchase, follow

the instruction outlined below:

y Connect the tubing to a measuring needle fitted with

a ball valve.

y Remove the smaller R20 quick release coupler from the

tubing by pressing the black safety clasp towards it.

y Do not remove attempt to remove the quick release

coupler by pulling using a force, the surface of the

connecting tubes may get damaged

y Plug the measuring needle into the measuring nipple of

the balancing valve.

y Carefully turn the ball valve on.

y Flush the tubing with water until all air bubbles have

disappeared.

y Turn the ball valve off.

y Replace the R20 quick release coupler.

y The tubing will remain filled with watter as both the R20

and R21 quick release couplers have a check-valve.

The tubes should be de-aerated prior to measuring in order

to minimise errors.

PFM3000 Zero Measuring Correction

Should the zero pressure value shift while the PFM3000 is in

use, the ZERO key can be used to correct it. For detailed

Zero Procedure description see chapter Automatic in

Process Zero Setting.

If, however, the zero value error is greater than several kPa,

it is recommended to clean the sintered filters within

measuring tubing. Should the problem persist, please

contact our customer service for assistance. The zero

setting is not registered in the memory of the PFM3000 so

the original pressure and flow values are displayed each

time the PFM3000 is turned on.

7

Page 8

PFM3000

Functions of Keys on the Instrument's

Keyboard

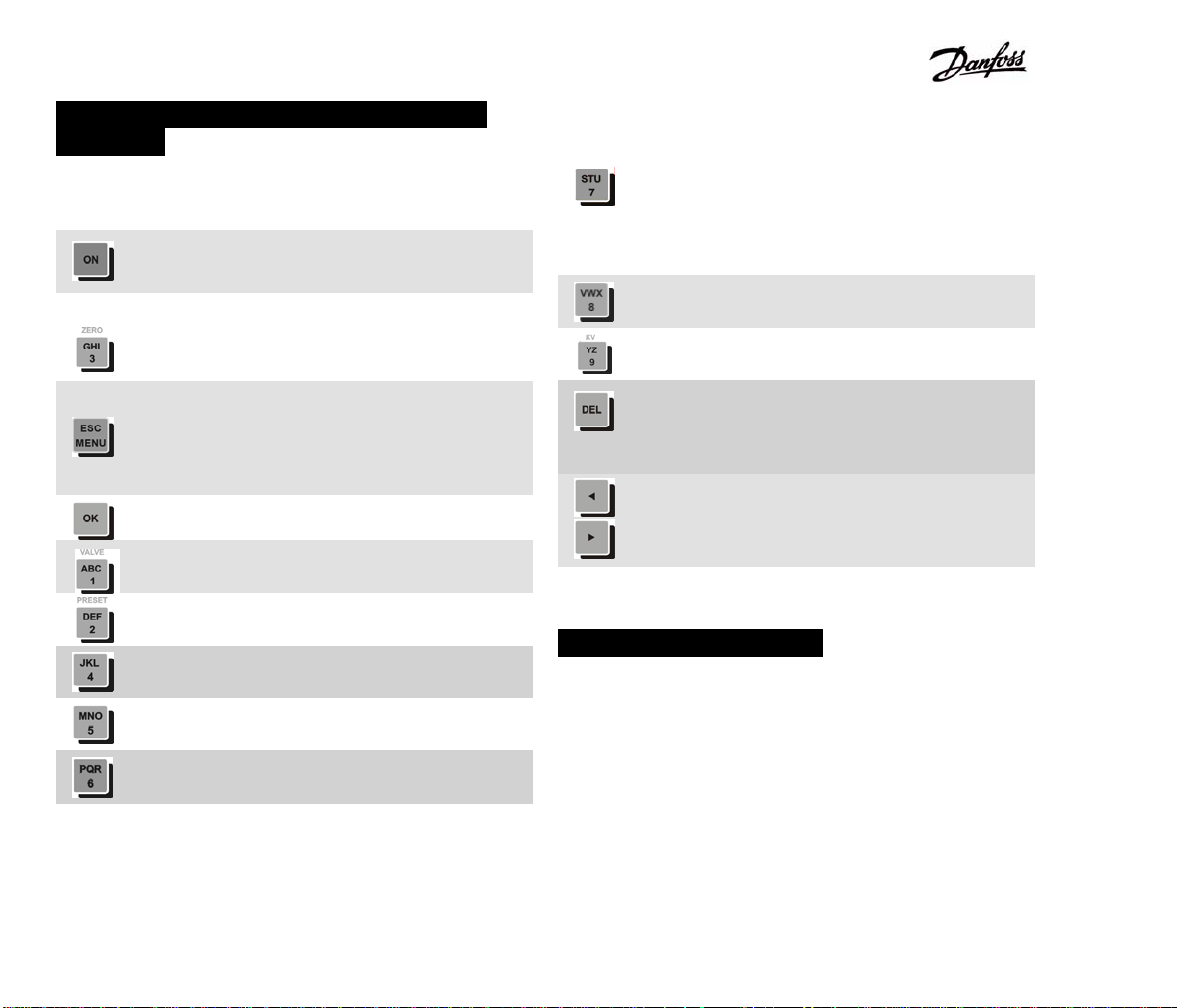

Keys with standard numbers or letters are used to enter data

into computer. Following keys have special functions:

Hold down the key for about a second to turn the

PFM3000 on.

Starts zero procedure used for the correction of

zero setting or differential pressure in face of

static pressure.

Opens main MENU during measuring. Once in

MENU, the key functions to move up a level.

Pressing the ESC/MENU key while entering

data, not the new but the original value is

entered.

Enters values or confirms choices from menu.

Valve hot key. Calls up choice of valves during

measuring.

Presetting hot key. Calls up valve presetting

option

Battery hot key. Calls up battery capacity during

measuring.

Project Change hot key. Lists projects down

while in the Projects Making mode.

Project Change hot key. Lists projects up while

in the Projects Making mode.

Quick record hot key. PFM3000 makes one

record if you press this button while in

measuring mode. Record contains valve type

and preset, actual pressure, flow and

temperature values. You can write 16 chars

description at the end of this function. You can

view quick record as an standard record in

PFM3000 User Software.

KVS hot key. Displays the current KVS of a

valve during measuring.

KV hot key. Displays the current KV of a valve

during measuring.

Pressing the key deletes the last character or

deletes a whole line if held. Of a number being

entered, holding it down deletes the whole

number.

Navigates around the main menu or branches

within the Working with Projects mode. Moves

cursor in data entry regime. While in the

measuring mode, it switches displaying modes.

PFM3000 Configuration

Prior to measuring for the first time, the following parameters

can be preset according to your requirements. Once

configured, these settings will automatically be recalled each

time the PFM3000 is switched back on.

Use the following instructions to configure the PFM3000:

8

Page 9

PFM3000

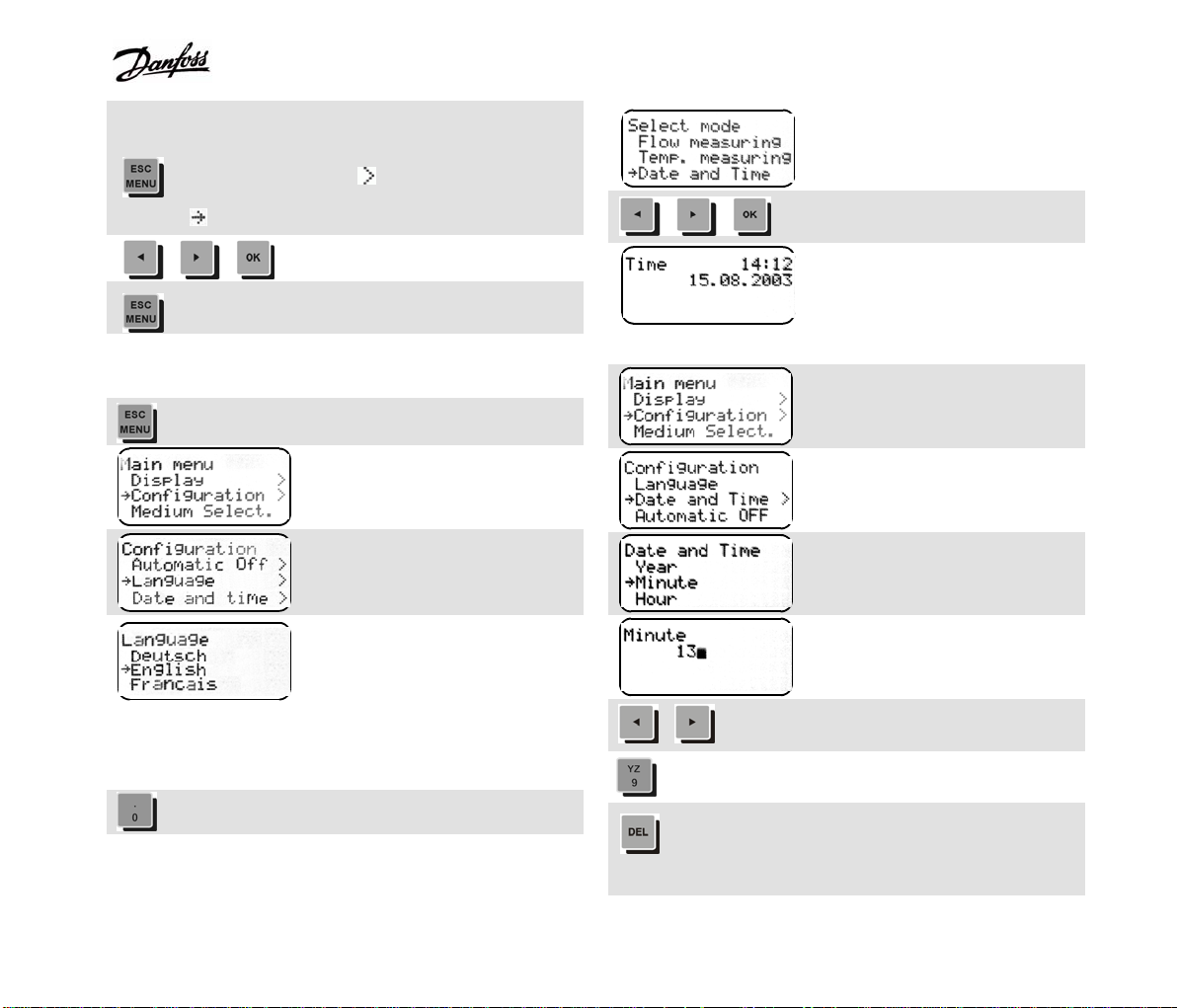

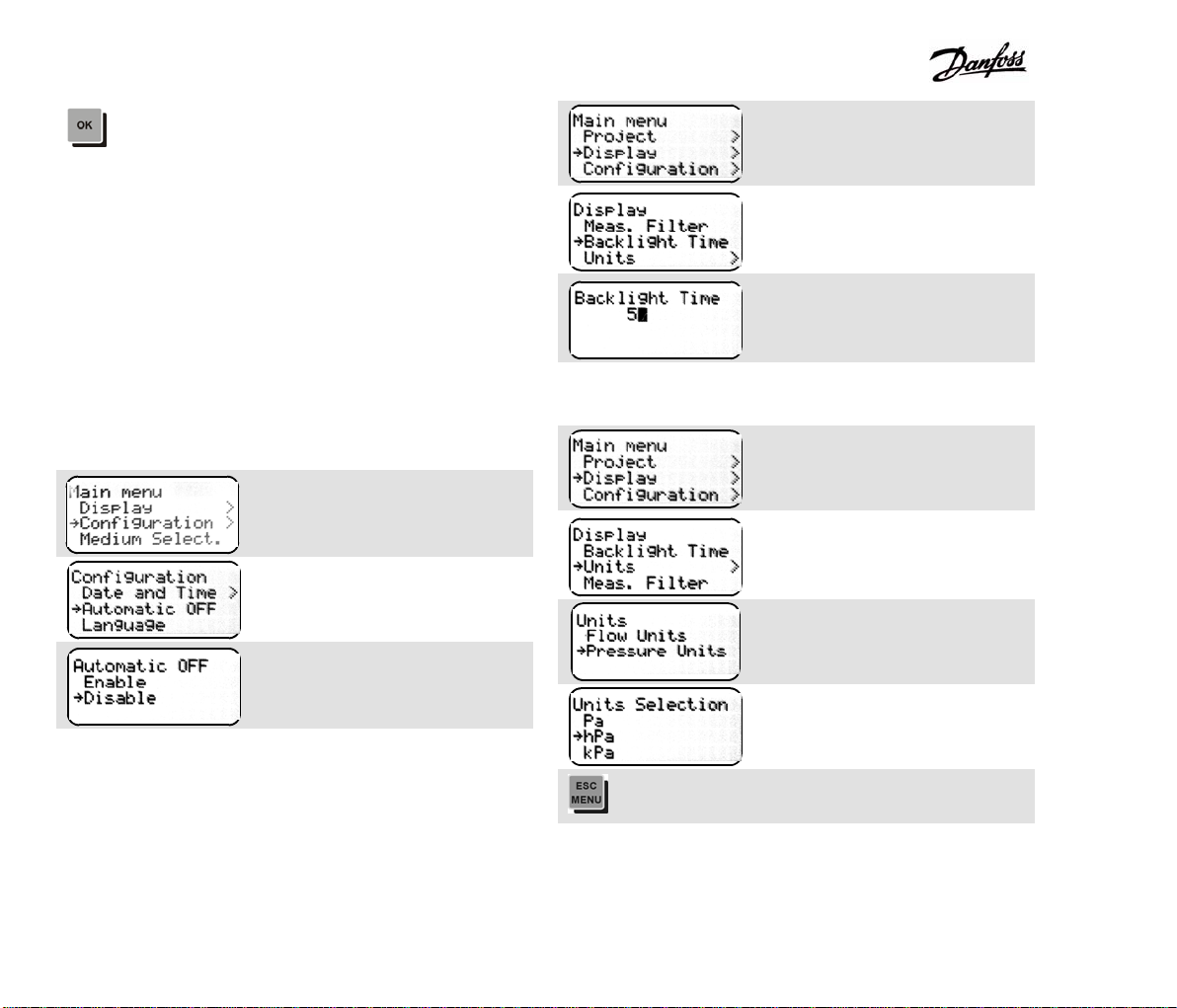

Choose menu by pressing the ESC/MENU key.

The first line in the menu gives the name of an

item followed by a list of subentries. A selected

item is marked by an at the beginning of the

line. If the item selected has further sub entries,

is displayed at the end of the line.

Return to measuring from any level of menu by

holding down the ESC/MENU key for second.

Language Setting

Select and confirm entry.

Open menu

Main Menu

Select Configuration and

confirm.

Menu Configuration. Select

Language and confirm.

Menu Language. Select desired

language and confirm.

Mode menu

Select Date and Time and

confirm.

If incorrect, set date and time as follows:

Open menu. Select

Configuration and confirm.

Configuration menu. Select

Date and Time and confirm.

Menu Date and Time. Select

Minute and confirm.

Enter minutes by pressing

respective number keys.

Clock Setting

Both the time and date are entered this way.

Mode hot key

Moves cursor to the required

position.

Enters number.

...

Press briefly to delete the

number at the position of the

cursor, hold down to delete the

whole number.

9

Page 10

PFM3000

Confirms minute entry.

Hours, days, months and years can be entered accordingly.

There is no need to enter every decade, just those that are

incorrect.

Automatic Switch OFF

The PFM3000 turns itself off automatically after ten minutes

of keyboard inaction. It is therefore recommended to disable

this function prior to prolonged measuring as this can not be

carried out while in the recording mode. Unlike the above

functions, disabling the automatic switch off is not saved in

the starting configuration of the PFM3000 and will be

enabled again each time the PFM3000 is turned back on.

Open menu.

Select Configuration and

confirm.

Menu Configuration.

Select Automatic OFF and

confirm.

Menu Automatic OFF.

Select Disable and confirm.

Display Illumination

Use this function when measuring in poor lighting conditions

or at night. However, due to the high energy consumption,

display illumination decreases the operating time by 50%.

This function can be disabled by setting the illumination time

to zero.

Pressure Units

Flow Units

Open menu. Select Display and

confirm.

Display menu. Select Backlight

Time and confirm.

Menu Backlight Time. Enter

illumination time and confirm.

Main menu. Select Display and

confirm.

Display menu. Select Units and

confirm.

Units menu. Select Pressure

Units and confirm.

Select the unit required and

confirm.

Move up one level.

10

Page 11

PFM3000

Valve Selection

... ...

..

Units menu. Select Flow Units

and confirm.

Select the unit required and

confirm.

Valve hot key

Menu Valve Selection. Select

the required manufacturer and

confirm.

Menu Valve Type Selection.

Select the required valve and

confirm.

Menu Valve Presetting. Enter

valve presetting using the

number pad.

Enter valve presetting.

Decimal point is entered by

holding down the zero key for 1

second. Only one decimal point

is allowed.

Confirm. PFM3000 returns back

into measuring.

However, balancing valves with measuring armatures, such

as Cimbero series for 727 to 748 are selected as follows:

Series 727

comes up with a separate measuring orifice. DN ½” valves

can have up to three possible orifices. The following

combinations are pre-programmed in PFM3000:

727LM = 727L + 721M (valve + measuring orifice)

727LS = 727L + 721S

727 = 727 + 721S

Other dimensions are the same for both the valve as well as

the armature.

Series 737

also comes with a separate measuring orifice. Only

combinations recommended by the manufacturer are

pre-programmed in the PFM3000.

Series 747 and 748

Contains an integrated measuring armature. Both the

regulatory and measuring elements of the valve are

displayed during valve selection. A regulatory element must

always be selected.

Examples of the valve selection:

727 Series

<- Producer

<-Measuring orifice of previous valve

<-Selected combination

<-Measuring orifice of a selected valve

MSV-C Series

<- Producer

<-Measuring orifice of previous valve

<-Selected valve

<-Measuring orifice of selected valve

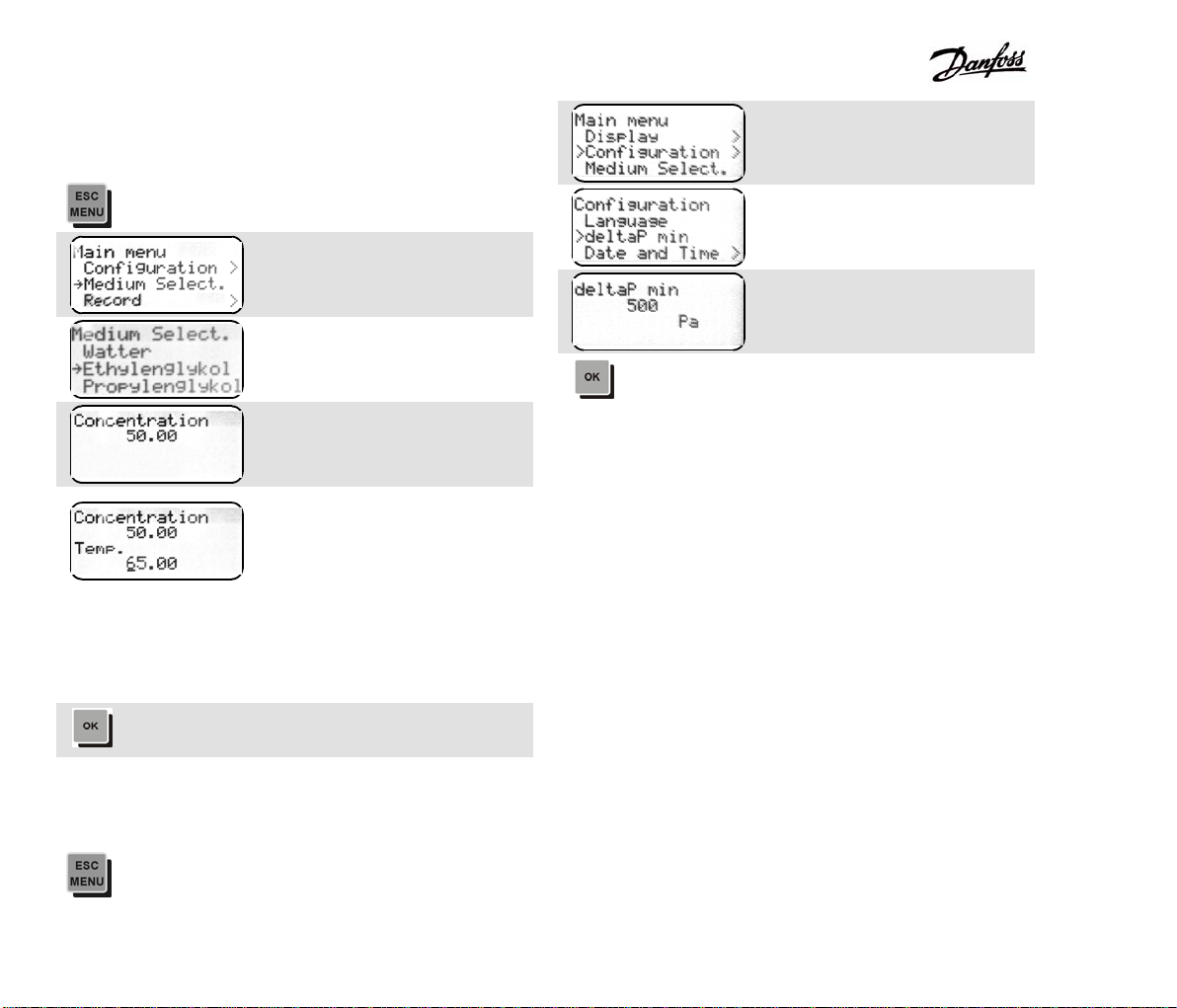

Measured Medium Selection

11

Page 12

PFM3000

When measuring non-freezing media, its necessary to use

measuring correction, which will correct other hydronic

parameters of these mediums.

Open Menu.

Select Medium Select.

Medium Select. menu. Select

medium and confirm.

Enter medium concentration in

% and confirm.

Measured temperature is shown

on the display only if the

temperature probe is connected

to the PFM3000. The probe has

to be in contact with the medium

in order for the temperature to

be measured. In other case do

not connect the thermometer to

PFM3000 and enter

temperature manually.

Confirm.

Select Configuration

Configuration menu. Select

deltaP min.

Enter deltaP min value.

Confirm.

Selection of Minimum Pressure for Flow

Displaying

Open Menu.

12

Page 13

PFM3000

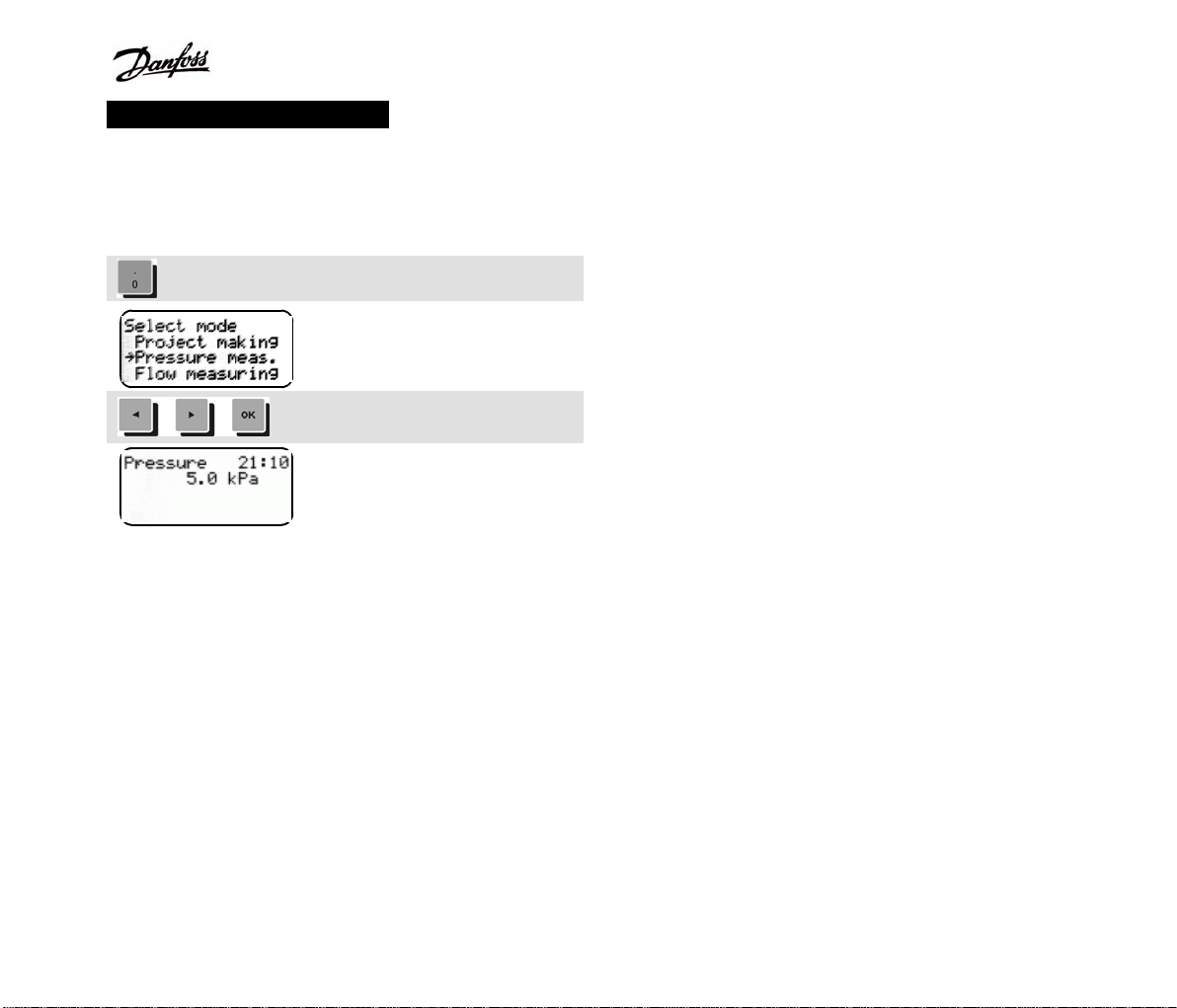

Measuring with PFM3000

Measuring Without Project

System Over pressure Measuring

Mode hot key

Menu Mode.

Select Pressure Meas. and

confirm.

Connect static pressure to the higher pressure input (red).

Do not connect anything to the lower pressure input (blue).

The PFM3000 measures the over-pressure in the system

compared to the atmospheric pressure.

! If you will measure very low differential pressure (up to

5000 Pa) switch on PFM3000 and wait 5 minutes for

pressure module stabilisation.

! The minimum physical measurable differential pressure for

the flow computing is 500 Pa.

Below this value Low P!! message appears on the display.

! Connect first positive pressure inlet (red) and negative

pressure inlet (blue) after that, when you are connecting

measuring device into heating system. This way is identical

with zero procedure if you use Zero function.

! Disconnect first negative pressure inlet and positive

pressure inlet after that, when you are disconnecting device

from the heating system.

! Generally it means, that only positive pressure input is

allowed to be connected into the heating system single.

! Static pressure in heating system interacts the differential

pressure measuring accuracy and flow calculation

subsequently.

Differential Pressure and Flow Measuring

Differential pressure can be measured at any point in the

system. Flow, on the other hand, can only be measured on

regulatory valves, the specifications of which are saved in

the memory of the PFM3000. Connect pressure inputs

- higher pressure to the positive (red) and lower pressure to

the negative (blue) input - to the measuring outputs of the

balancing valve using the tubing provided.

Automatic in Process Zero Setting

PFM3000 has built in automatic correction of static pressure

in the system due to PFM3000 smart zero setting. Make

zero correction every time when you measure small

differential pressure.

Plug in the two water pre-filled measuring hoses in the

measuring nipples of the balancing valve. PFM3000 leave

with open pressure inputs.

13

Page 14

PFM3000

Press ZERO key. Follow the

PFM3000 display, which will

guide you through of the zero

setting process.

PFM3000 makes zero setting at

the atmospheric pressure.

PFM3000 computes flow during

the selected valve.

Neither zero-setting is saved in the instrument's

configuration. Next time you switch the instrument on the

zero is not being corrected.

Connect positive pressure input

(red) and wait until pressure

value display stabilises.

PFM3000 measures static

pressure in system.

After OK key pressing PFM3000

computes zero correction

depends on the static pressure.

Message Connect blue input

appears for the 1.5 s.

You can connect blue input and

measure differential pressure

now. You can choose any

pressure units now.

Measuring mode hot key.

Measuring mode menu

Select Flow Measuring and

confirm.

Flow Measuring Limitation

Minimum physical measurable differential pressure for the

flow computing is 500 Pa. PFM3000 does not calculate flow

under minimum pressure level and this state is indicated by

the message Low Pressure !! on the flow display. Flow

value is blinking when pressure value is under 3x delta Pmin

value.

You can measure flow under this pressure value when you

adjust other minimum pressure limit from menu (delta P

min).

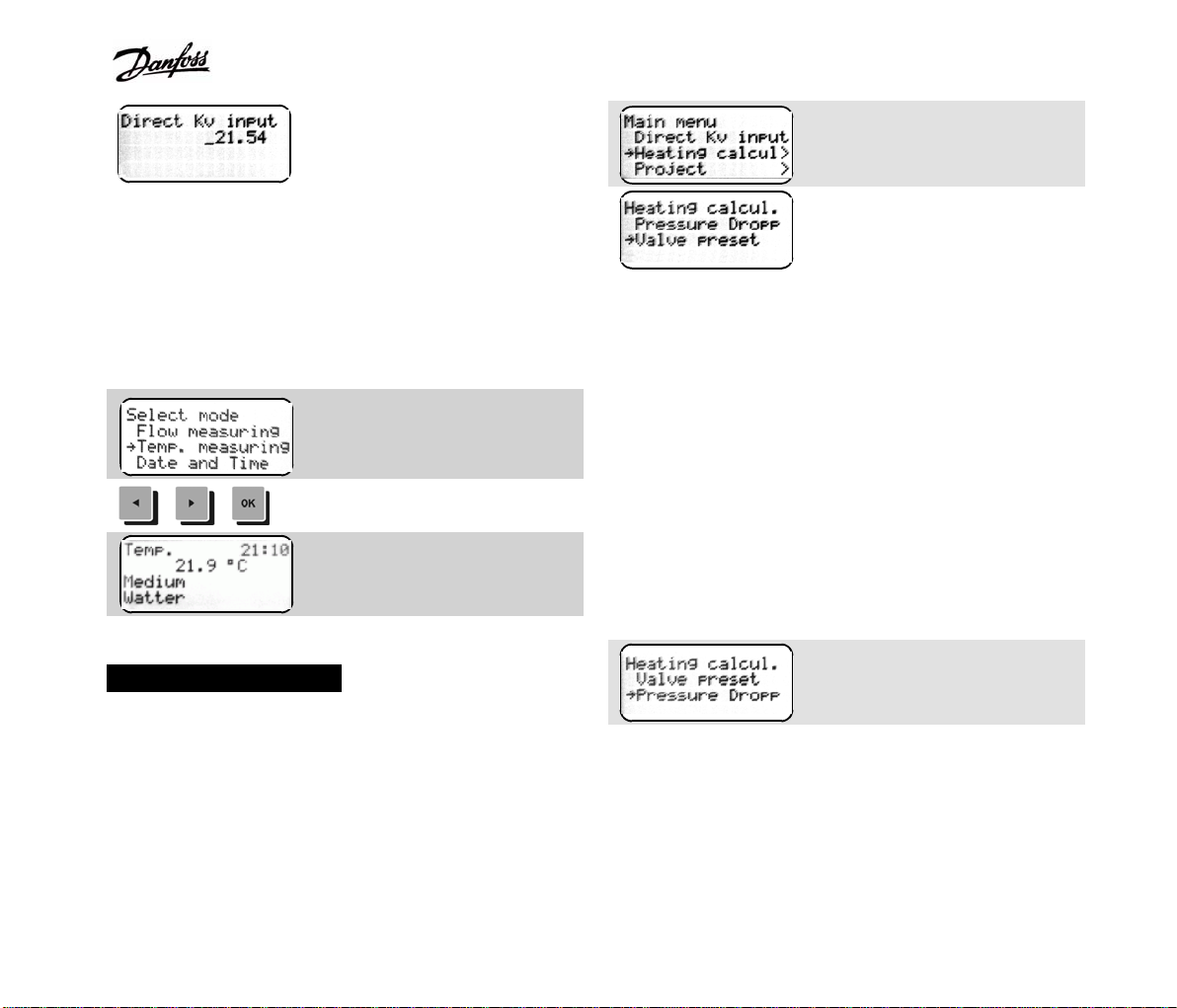

Measuring Flow in the Fittings Not Saved in

the PFM3000 Memory

In order to measure flow, specifications and pre-settings of

the regulatory valve used for measuring have to be entered

into the PFM3000. Specifications for the most commonly

used valves are saved in the memory of the PFM3000. If

not, flow can still be measured if the Kv value of the valve is

known.

Main menu. Select Direct Kv

Input and confirm.

14

Page 15

PFM3000

Enter Kv value and confirm.

The Kv value is then used to calculate the flow. Return to the

measuring mode by pressing the Valve or Presetting hot

keys.

Temperature Measuring

Connect thermometer to a turned off PFM3000. Turn on the

PFM3000.

Measuring Mode Menu.

Select Temp. Measuring and

confirm.

Heating Calculations

Enter the required flow. The actual flow is then measured. It

is necessary to close the valve after this point. The

PFM3000 then measures the differential pressure at the

valve. The valve presetting for the required flow is then

calculated from the data above.

Main menu. Select Heating

Calcul. and confirm.

Select Valve Preset and

confirm.

Calculation of Valve Pressure Drop for a

Requested flow

This function calculates the ability of a given valve to

regulate a particular branch of a known dispensable

pressure within the system.

Select the valve type and update its pre-settings as

described above.

Select Pressure Drop from

Heating Calcul. menu.

Calculation of Valve Presetting for a

Requested Flow

This function enables calculation of valve presettings for a

required flow. Select the valve type and update the

presettings saved in the PFM3000.

Enter the required flow and confirm. The pressure drop for

the required flow at the current valve is then displayed. To

terminate the pressure drop calculation press the ESC key.

15

Page 16

PFM3000

Data Recording

Recording Settings

Recording parameters have to be checked and amended if

necessary.

Period/Hours = 0

Period/Minutes = 0

Period/Hours = X

Period/Minutes = Y

Check free record capacity from

Record/Capacity menu.

Check the memory free capacity

displayed in the form of

a bargraph. One bargraph unit is

equal to approximately 250

entries. More free space can be

created by deleting data from

the memory from Record/Erase

menu.

Any recording period can be

from 1 second up to 24 hours in

length.

Data are recorded in the

Period/Seconds format.

Seconds of period are ignored

and PFM3000 records data with

period X:Y. When recording, the

PFM3000 automatically switches

to energy-saving sleep mode,

during which the display is

inactive. It turns itself back on

again just before the end of the

recording period in order to save

the recorded data before

re-entering the sleep mode.

Select menu Record/Place or

Record/Description.

Text comprising of a maximum of 16 characters for each

Place or Description can be entered using A to Z, 0 to 9,

dash and point for later identification.

As every alphanumeric key represents several different

characters, these are entered sequentially at the same

position. Move the cursor using the arrow keys in order to

enter characters one after another using the same key.

Thus each record includes a 32-character identification.

Numbers and letters are entered in the position

of a blinking cursor using the key pad, after

which the cursor moves on position to the right.

Note that previously entered characters will be

overwritten. You can move cursor also by arrow

keys.

Every alphanumeric key has some values. The

key in left, for instance, writes characters A, B,

C, 1 by sequel at the same position. When you

need the same character twice, move the cursor

by arrow after entering the first character and

enter the character again.

Pressing this key deletes the last character

of a number being entered, holding it down

deletes the whole number.

You will confirm the input by the OK key. If you want

leave input without writing, press ESC key.

16

Page 17

Start of Recording

Start the record from

Record/Start menu.

A flashing * appears on the display indicates that

recording is taking place. Recorded parameters include

place or description, valve, valve presetting, time,

pressure, flow and temperature.

Full Data Memory and Low Battery

Should the memory become full

during recording, the PFM3000

switches itself off automatically

within 10 minutes of inactivity.

Low battery state during data record works the same as in

normal measuring. With the battery capacity less then 5 %

message Low Battery! blinks on the display every 15 s.

When zero battery capacity PFM3000 switches off.

End of Recording

By pressing any key, the PFM3000 exits the sleep mode

and the same option of continuing with the recording or

ending it is displayed.

Record continues.

End of record.

17

Page 18

Processing Projects

Creating a New Project

The PFM3000 contains a built-in module for the calculation

of balancing a project with one horizontal and a maximum of

60 vertical branches. The calculation assumes that the

pressure input of the project is constant and that the project

is devoid of negative feedback hydraulic elements (for

instant differential pressure regulators within branches or

thermostatic valves). A ten projects in total can be saved in

the memory of the PFM3000 at any one time. In the case

where the two projects are linked by a centrally located

pressure input it is possible to balance these together.

Project schematic

The presetting value should either be specific for the

given project or such so that the flow through all the

branches is measurable as a pressure drop on each of

the individual branch regulatory valves

Menu Project/New project

Enter Project Name, max. 12

characters.

Common valve selection. Select

No Common Valve For the

project without Common Valve.

Select Common Valve producer.

Select Common Valve type.

Enter Common Valve initial

presetting from Project/Initial

Preset menu.

Menu Branch/New branch.

18

Page 19

PFM3000

Enter name of the branch, max.

12 characters.

Choose balancing valve in

branch.

Enter initial presetting of the

branch balancing valve. Use the

same rules as in the common

valve.

Enter requested flow.

Repeat New branch steps for all

branches in the project.

The order of branches in a project has to be the same as it

is in the real system. To add a branch into the middle of a

project (for instance if a discrepancy is found between the

project documentation and the real layout of the system)

locate the branch immediately before menu

Branch/Selection. Then add the new one after it. All the

subsequent branches will automatically move backwards by

one position

Projects can also be created in a PC using the PFM3000

User Software and downloaded into the PFM3000 as a

whole.

Project without a Common Valve

An example of a schematic view of a project

Occasionally we come across systems without a common

valve on input. PFM3000 makes it possible to balance this

kind of system Creating a project without a common valve is

the same as for project with common valve but select the No

Common Valve option in the Common valve menu and

confirm. When using the computer to create the project,

simply un-tick Common valve.

Measurements Necessary for the Project

Balancing

Set the common valve pre-setting as well as that for

valves in all branches of the system.

Select a respective project from menu Project/Selection

19

Page 20

PFM3000

Connect the PFM3000 at the

entry of the heat-carrying

medium.

Enter menu Project/Input

Pressure

pressure drop value is always equal to zero with

valve closed. To measure the disposable pressure,

different measuring location should be used and the

flow through the above valve should be closed off.

Repeat branch measuring at all project branches.

Project Balancing Calculation

Select Project/Balance calculation/Start to start

Connect the PFM3000 with the

balancing valve within arbitrary

branch. Select a respective

branch from menu

Branch/Selection.

Choose Branch/Measure item.

calculation. The PFM3000 then checks whether all data

necessary for the calculation have been acquired. Should

there be any missing, a message will appear on the display

indicating the branches yet to be measured. The balancing

of the project is then calculated. The outcome of the

calculation are the presettings of all the valves including the

common valve for the desired flow. The actual calculation

takes only several tens of seconds. The progress of the

calculation is shown on the display in the form of a bargraph.

Project Balancing Results

Menu Measure/Initial Preset

The results of the project balancing calculation can be

accessed from Project/Balance calculation/Results menu.

Menu Measure/Valve Closed.

Close the balancing valve.

Return the valve presetting to the original value.

The method described can not be used to measure

the disposable pressure on a balancing valve with

measuring orifice (Cimberio for example). Its valve

Pressure computed from project

compensatory schematic after

the common valve. It is not

possible to execute a project if

the calculated pressure after the

common valve is greater than

20

Page 21

PFM3000

the pressure at the entry of the

project.

Particular branch presetting

including common valve.

If it is not possible to balance a

particular branch for a given

flow, select a greater flow or a

valve with a smaller dimension.

If it is not possible to balance a

particular branch for a given

flow, select a smaller flow or a

valve with a greater dimension.

Project Balancing Check

y Set the presettings for all the valves including the

common valve and check that the flow matches the

required value.

y Amend small deviations by manually changing the valve

presettings.

y The actual flow can be stored into the project from the

menu Branch/Measure Branch/Actual flow menu

making sure the desired branch has been selected from

Branch/Select branch.

y The balanced project can be downloaded from the

PFM3000 into a PC using the PFM3000 User Software.

Use the Project Mode to check the project after balancing.

Enter PFM3000 mode selection

menu.

Mode selection proposal.

Select Project and confirm.

There are all significant project

data on this display.

Project name at the line 1.

Selected branch at the line 2.

Requested flow at the line 3.

Real flow at the line 4.

hot key lists projects up, key lists projects down.

Use the arrow keys to navigate between branches within

selected project. Changing the selected branch

automatically selects the appropriate valve including its initial

presetting. The calculated presetting value is only selected if

the project has been balanced by the PFM3000.

21

Page 22

PFM3000

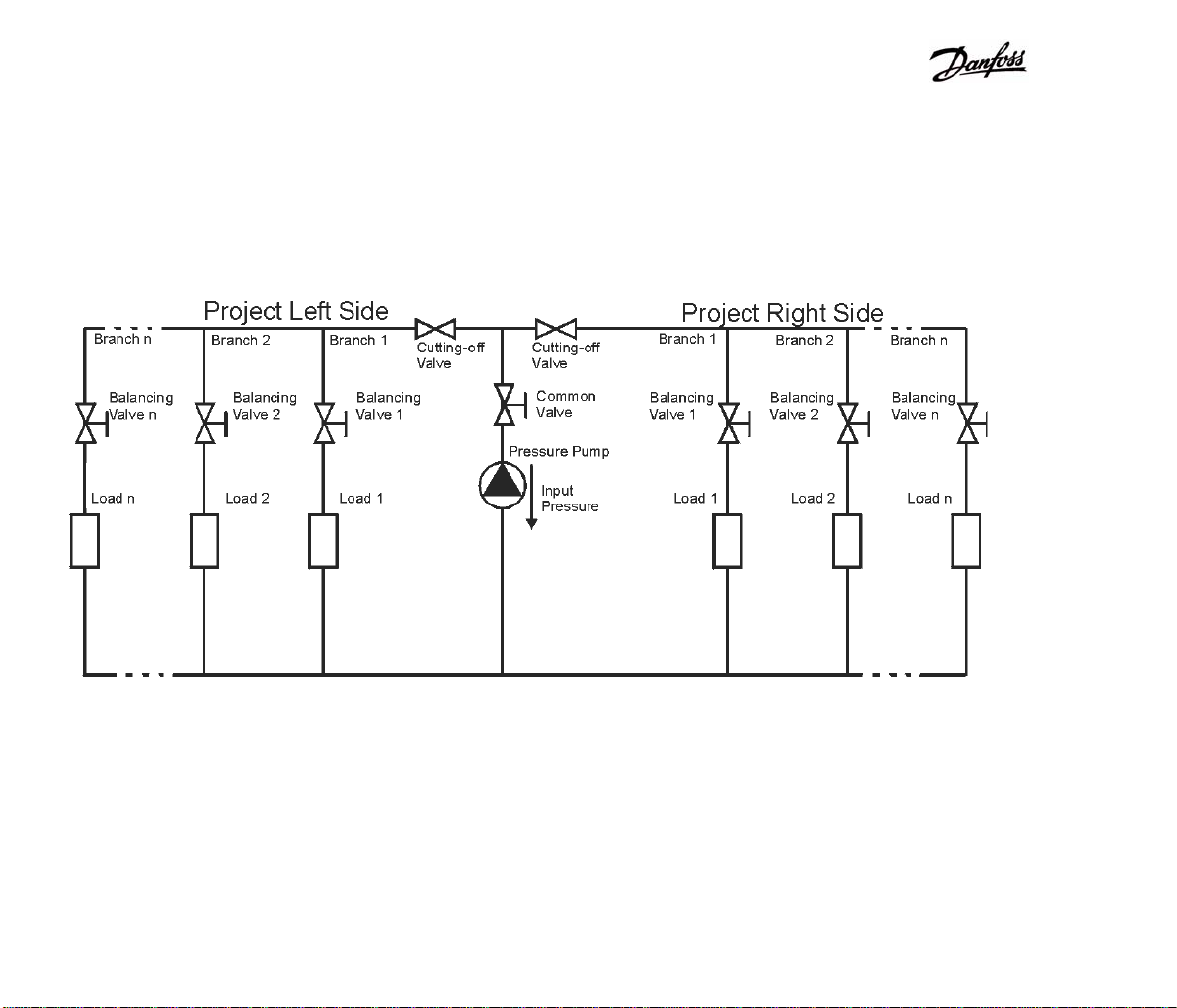

Balancing Calculations of Projects with Central Pressure Input

We often come across systems with one pressure input and distribution of the medium into both sides of the input. It is

possible to balance a project with a central pressure input by dividing it into two separate projects with unidirectional branch

distribution. The two projects are measured and subsequently balanced, both individually and together using the Bind

Projects command as follows.

An example of a schematic view of a project with central pressure input

Balance calculation of the project with a pressure input in the middle - Procedure

y Measure project Right Side.y Create two projects - Left Side and Right Side as

depicted above.

y Close the Right Side of the project by a stop valve.

y Open and measure the Right Side project.

y Start the balance calculation of the Left Side project.

y Start the balance calculation of the Right Side project.y Measure the Left Side project

y Start the balance calculation of the Left Side project.y Close the Left Side project by a stop valve.

y Select Project/Balance calculation/Bind projects to

calculate the balance of the whole system.

22

Page 23

Communication with a Computer

The PFM3000 can be connected to a PC using a USB

interface.

User Software PFM3000

The acquired data can be processed in a PC using the

PFM3000 User Software supplied with the PFM3000. The

data can be presented in the form of a table or a graph,

printed, saved in a *.txt format inherent to the PFM3000 or

exported into another program for further processing. The

data can also be visualised directly while measuring.

Minimum PC Requirements

Pentium II, 128MB RAM, minimum of 10MB free space on

the hard drive, Microsoft Windows 98SE / ME / 2000 or XP.

Software Installation

An installation CD containing software required for PC

communication with the PFM3000 is supplied. It is installed

as follows:

y Insert the installation CD into the disc drive.

y In Windows/Start enter setup.exe. The software will

then be automatically installed.

The driver installation is a two stage process, firstly the USB

section of the driver is loaded followed by the COM Port

driver.

y The CD-ROM provided with the PFM3000 should be

inserted into the CD-ROM drive of the PC prior to

plugging in the device.

y Plug in your device. This should bring up a Found New

Hardware help bubble and launch the Found New

Hardware Wizard. These should describe the Hardware

as PFM3000 Measuring Computer.

Windows USB Drivers Installation Guide

This part describes the installation procedure of the

PFM3000 under Windows OS and information on what to

look for if installation doesn't go as planned.

Make certain that the Install the software automatically

option is checked. Click on Next to continue.

23

Page 24

The default button is STOP Installation - ignore this and

click on the Continue Anyway button. This window does not

appear if you install drivers on older Windows systems.

You may see the above screen during the installation

process as Windows XP copies the files from the CD. No

user intervention is required.

The USB Drivers have now been installed - click the Finish

button finish the USB driver installation and to install the

COM Port drivers. The Found New Hardware wizard will

relaunch for the second part of the driver installation as

shown below.

24

Page 25

After the driver installation is complete, this screen will

appear. Click on Finish to complete the installation. This

time, the Hardware Wizard will display PFM3000 Balancing

Computer as being the software it wants to install.

Make certain that the Install the software automatically

option is checked. Click on Next to continue.

The reason for this message is explained above. The default

button is STOP Installation - ignore this and click on the

Continue Anyway button. This window does not appear if

you install drivers on older Windows systems.

Click the Finish button to complete the second part of the

driver installation. The Help bubble should inform you that

the new hardware is installed and ready to use.

If you have any trable with communication to the device, see

XP Device Manager. PFM3000 has to be mapped to COM

25

Page 26

Port below COM10 for right communication.

Operating the Program

Main toolbar

The main toolbar contains the most commonly used icons

including the Open, Save, Read, Print and Projects

commands.

Unit Selection

Select the units for pressure and flow using Options/Unit

Selection menu, the unit options are as follows:

y mbar, bar, psi, at

y mWs, mmWs, mmHg

Flow

y m3/s, m3/min, m3/hod

y l/s, l/min, l/hod

y gal/s, gal/m, gal/hod

Data Processing

Downloading Data

Connect the PFM3000 to the PC using the communication

cable provided and turn the PFM3000 on. Use the Read icon

to download the data from the PFM3000. If the PFM3000 is

not connected or is turned off, a warning window appears

that it is not connected. These will be displayed in a

tabulated form. A warning window appears if there are no

recorded data.

Organisation of Data

Data is organised according to its place of acquisition

entered during measuring. Selecting from a list of places, the

measured data including pressure, flow and temperature are

displayed, either in the numerical or a graph form. Graphs

can be moved around by right clicking and holding while

dragging the object. Left clicking and holding while moving a

mouse enlarges the selected area of the graph.

Working with Graphs

Pressure

y Pa, hPa, kPa, Mpa

The graph toolbar contains icons for displaying data in the

26

Page 27

initial magnification, zooming in or out and for the

amendment of the graph title.

Working with Data

The measured data can either be stored on a hard drive in

the PFM3000 format using File/Save As or exported into

another program using File/Export from the main toolbar.

The File/Open command enables access to previously

saved data.

Printing

The PFM3000 User Software enables printing raw data in

tabulated form or graphs showing the change of pressure,

flow and temperature in a given time. Select data to be

printed form the list of measured locations. Print tables using

the Print/Print Data Table command. When printing graphs,

use Printer/Printer Set Up and set the page orientation to

landscape. Print graphs using the Print/Print Pressure

Graph or Print Flow Graph.

without a common valve, the Common valve item must be

un-ticked. Use the Add icon to insert a project or a branch

into a tree of projects and branches. Select the project of

interest by right clicking on it with a mouse, enter the branch

details including its name, valve, presetting and requested

flow.

Working with projects

The Open and Save icons on the main toolbar are used to

download projects/data to and from a hard drive. Similarly,

the Read and Save icons are used fro downloading to and

from the PFM3000. However, take care not to overwrite

projects or data, as it is possible to modify the data using

both the computer and PFM3000. To minimise this, a

window appears on the screen before reading projects.

Clicking on the Print icon will print the selected project.

9 Please use only Latin characters in Project and

Branch Name, not Russian in the meantime.

Project and Saving Projects

Up to 10 projects for balancing hydraulic systems with a

maximum of 60 branches each can be created and saved at

any one time.

Project Tool Bar

Creating a project

Each project contains data about the type of common valve,

its presetting and about the input pressure. For projects

Maintenance Instructions

The PFM3000 should be calibrated every 12 months.

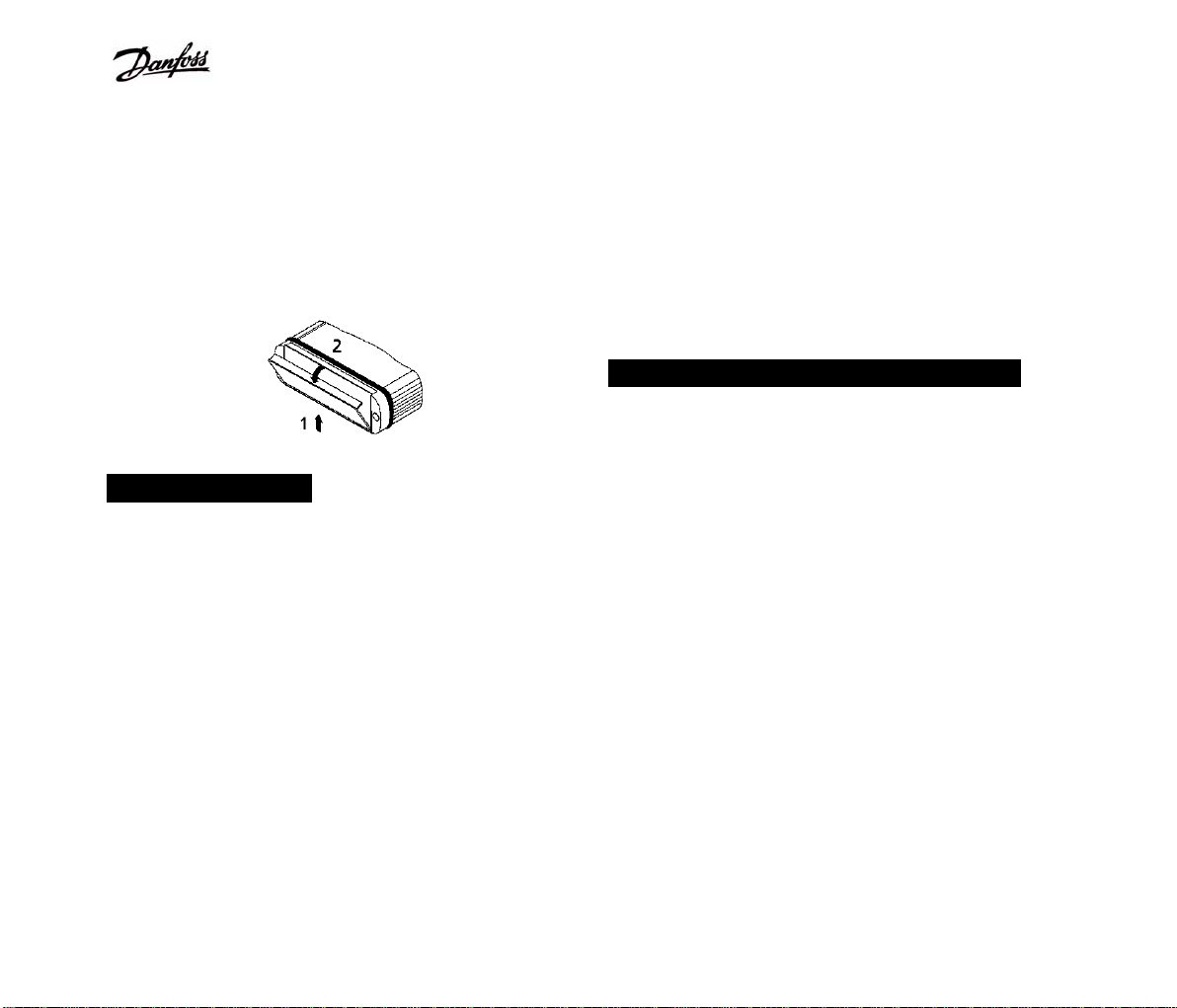

The sintered filters within the R20 quick release valves

should be replaced every 12 months. See the figure bellow

for instructions:

27

Page 28

Parts of the Delivery

PFM3000 measuring computer 1 pcs

battery charger 1 pcs

thermometer PT100 digital 1 pcs

connecting tubing 1 pair

quick coupling R21 1 pair

quick coupling R20 1 pair

Adapter 7 mm 1 pair

measuring adapter G3/4" 1 pair

reduction G3/4-G1/2 1 pair

measuring nozzle 1 pair

User Software CD 1 pcs

USB communication cable 1 pcs

User’s guide, warranty certificate 1 pcs

plastic case 1 pcs

28

Page 29

Technical Specifications

PFM3000

CommentUnitValueItem

kPa1 000Pressure range

kPa1 500Maximum overpressure

% of range0,15Linearity, repeability and hysteresis error

% of range0,25Temperature error

corrected by smart zero settingsStatic pressure effect

°C-5 to 90Medium temperature

°C-5 to 50Ambient temperature

°C-10 to 70Storage temperature

PT 100 digitalTemperature probe

°C-20 up to 120Range of Temperature probe

°C+/- 1Temperature error

Li-Ion batteryPower

1 sec up to 24 hoursPeriod of record

7,2 V

1250 mAh

hours7Charging time

USBInterface

mm77x192x25Dimensions w x h x d

g390Weight

IP65Cover

months12Calibration validity

at the end of a

connecting tubes 1.5 m

Maximumhours120Operating time

Maximum1 800No of records

Maximumvalves400No of pre-programmed valves

Maximum10No of projects

Maximum60No of branches in each project

29

Page 30

PFM3000

30

Page 31

PFM 3000 MenuPFM 3000 Menu

PFM 3000

Project

Selection

Balanc. Solve

Start

Bind Projects

Results

Source Pressure

Common Valve

New Project

Rename Project

Branch

Selection

Measure

New Branch

Edit Branch

Valve Closed

Initial Preset.

Real Flow

Display

Units

Pressure Units

Flow Units

Backlight Time

Pa

hPa

kPa

MPa

mbar

bar

psi

at

mWs

mmWs

mmHg

m3/s

m3/min

m3/hod

l/s

l/min

l/hod

gal/s

gal/m

gal/hod

Configuration

Date and Time

Automatic OFF

Language

DeltaP min

Minute

Hour

Day

Month

Year

Medium Select. Record

Watter

Ethylenglykol

Propylenglykol

Capacity used

Description

Start

Erase

Period

Place

Hours

Minutes

Seconds

Direct KV Input

Heating Calcul.

Valve Preset

Pressure Drop

Delete Project

Initial Preset.

Delete Branch

31

Page 32

PFM 3000A

32

Page 33

33

www.danfoss.com

Loading...

Loading...