Page 1

Instrument for the Balancing of Heating Systems

PFM 3000

User Guide

VUE1V102

Page 2

PFM 3000

Page 3

PFM 3000

Content

Content

Introduction

Invaluable Advantages of PFM 3000

Important User Notice

Putting the Instrument into Operation

Battery Charging

Deaeration of Connecting Tubes

PFM 3000 Zero Measuring Correction

Functions of Keys on the Instrument's

Keyboard

Measuring with PFM 3000

Measuring Flow in the Fittings Not Saved in the

PFM 3000 Memory ..................................

Heating Calculations

............................................

........................................

.................

...............................

...............

....................................

....................

................

...........................................

..........................

...............................

Calculation of the Fitting Presetting for Requested

Flow ...............................................

Calculation of the Pressure Drop for Requested

3

flow ................................................

5

Data Record

6

6

6

6

7

Processing Projects

7

7

Measurements Necessary for the Calculation of

8Language Changing ..................................

Project Balancing ...................................

8Real Time Clock Setting ..............................

9Automatic Shut OFF ..................................

9Display Backlight Time ...............................

10Pressure Units ......................................

Balance Calculation of the Project with a Pressure

10Flow Units ..........................................

Input in the Middle ...................................

10Measuring Filter .....................................

Communication with a Computer

10Valve Selection .....................................

Data Processing and Displaying Program - User

11Valve Presetting Change .............................

software PFM 3000 ..................................

11Measured Medium ..................................

11

11Measuring Without Project ...........................

11System Overpressure Measuring .....................

12Differential Pressure and Flow Measuring .............

Maintenance Instructions

Parts of the Delivery

12

Technical Specifications

13Temperature Measuring .............................

PFM 3000 Menu

13

.......................................

...............................

..................

..........................

...............................

...........................

....................................

13

13

13

13Record Preparing ...................................

14Start of Recording ...................................

15Full Data Memory and Low Battery ....................

15End of Recording ...................................

15

16Creating a New Project ..............................

17Project without a Common Valve .....................

17

18Balance Calculation of the Project ....................

18Results of Project Balancing ..........................

18Project Balancing Check .............................

20

21

21

21Minimum PC Requirements ..........................

21Software Installation .................................

21Operating the Program ..............................

21Measured Data Processing ..........................

23

23

25

27

3

Page 4

PFM 3000

4

Page 5

PFM 3000

Introduction

PFM 3000 has been designed for the servicing and hydraulic

balancing of heating and cooling systems. It is equipped with

a number of added built-in functions that make your work

enjoyable.

The instrument is small. Its hard metal case lets you use it

even under severe outdoor conditions. Even if you spill

water on the case, PFM 3000 stays intact. A delivery

includes standard RS232 interface and user software for the

processing of gathered data.

A basic modulus of the instrument is a differential

manometer with digital pressure processing. It is equipped

with a built-in pressure sensor. The manometer combines

the advantages of digital technology and compensates

temperature dependence and the non-linear character of

measuring. It makes possible the measuring of overpressure

or underpressure in a system and the measuring of

differential pressure. Using pressure difference at a

balancing or measuring component you can measure flow at

particular branches of a system and balance the heating

system. Excellent features of the manometer enable further

accurate measuring.

An external thermometer modulus is a part of the basic

measuring equipment of the instrument. It enables to

measure the temperature of a medium. The thermometer

connects to the RS232 interface connector. One finds it easy

to work with, as its dimensions are compatible with the

dimensions of the measuring needles of balancing valves.

The measuring spike of the thermometer should be plugged

into an output for the measuring of differential flow. Along

with other data temperature is being recorded in the

instrument’s memory.

A built-in flow meter modulus is an indispensable instrument

for the balancing of hydraulic systems. It calculates flow at a

particular branch of a heating system out of pressure

difference at a measuring element. The memory of the

instrument keeps the characteristics of balancing and

measuring elements of established producers. You can

choose a particular type in the instrument’s menu.

There is an automatic flow correction function for flow

measuring in systems with non-freezing additives or cooling

systems.

A valve presetting calculation modulus is an revelsal part of

the flow meter modulus. The output of the valve presetting

calculation function is valve presetting for required flow. The

function calculates valve presetting using valve

characteristics stored in the memory. Therefore you always

receive the right value of presetting.

An integrated recording modulus including a real time circuit

is another positive feature of the instrument. The time circuit

is all time powered from apparatus lithium battery.

The modulus helps keep records from project realisation or

diagnose time actions in a heating system. The memory

stores pressure, flow, temperature, chosen valve, valve

presetting and measurement identification data, which helps

you process and evaluate results on your PC. While

recording measured data with a longer recording period, the

instrument switches automatically to the sleep mode. This is

enabled by a long-term recording function with energy

coming from an internal source.

You can record data at different points of the heating system

and have the current state of the system processed in your

office. You can also choose a periodical recording. The

5

Page 6

PFM 3000

analysis of time actions will help you choose an optimum

system solution.

To download recorded data into your PC you can use

software included in the delivery. The software makes it

possible to display data in a chart or graph. They can also

be printed. Data can be exported in standard PC formats

and processed by a text editor, chart processor or database

programs.

A heating system balancing modulus seems to be the most

important component for the user. The modulus calculates

the balancing of the system with many branches. It makes it

possible to regulate even a complicated heating system

including a common valve. A sophisticated calculation

method optimises hydraulic ratios in the system and

produces a project aiming at minimum energy loss in the

system. The method reduces substantially the time needed

for balancing. The function calculates valve presetting

directly using the characteristics stored in the memory.

Therefore you always receive the right presetting value.

Invaluable Advantages of PFM 3000

y Mechanical design

y Integrated pressure sensor

y Robust metal case

y Water resistant

y Big 4-line display

y Illuminated display

y Well-arranged 16-key foil keyboard

y Chargeable lithium battery

Important User Notice

If you have previously used the instrument to measure liquid

medium, do not expose it to temperature lower than the

point of congelation of measured liquid. The pressure sensor

may be damaged.

Inputs for measuring tubing are equipped with sintered filters

- filtering capacity 50 µm. When measuring in systems with a

lot of dirt, filters get fouled. If the instrument's display

indicates high pressure or one of pressure inputs does not

work after measuring tubing have been disconnected,

replace the filters.

Putting the Instrument into Operation

PFM 3000 is delivered with precharged lithiun battery and is

ready to run immediately. Please check apparatus clock

after first switch on.

Battery Charging

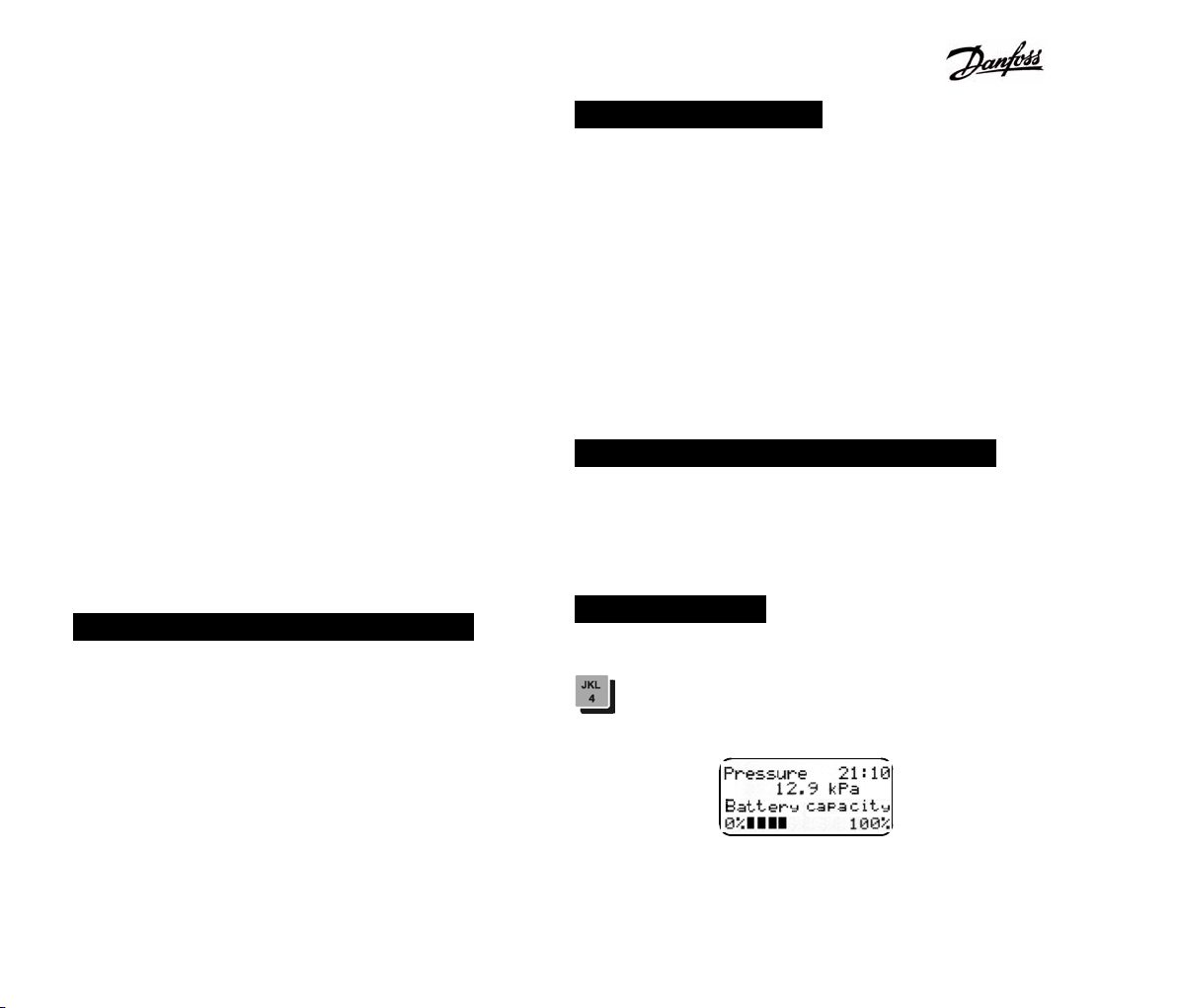

During measuring you can see battery state after hot key

pushing. The battery capacity baragraph appears on

display

6

Page 7

PFM 3000

Message Low Battery! flashes on the display every 15 sec

bellow battery capacity 5%. You can work in this state about

6 hours, after it PFM 3000 automatically switches off.

Connect battery charger into conector under the cover at

PFM 3000 bottom. Charging time is about 7 hours.

Deaeration of Connecting Tubes

To minimize measurement errors, deaerate the connecting

tubing of the instrument. Take a quick coupler R20 off the

tubing by pressing a safety ring (black collar) towards the

quick coupler. Do not disconnect the quick coupler merely by

pulling or force. The surface of the tubing or screw joint

might be damaged. Connect the tubing to the measuring

valve by a quick coupler R21 or to a discharge cock by

means of a measuring adaptor. Flush out the tubing with

water until air bubbles disappear. Put back the quick coupler

R20.

hoses. While it has not requested effect, special

maintenance is needed.

Zero is not stored in PFM 3000 configuration and not

corrected value is measured after new switch on.

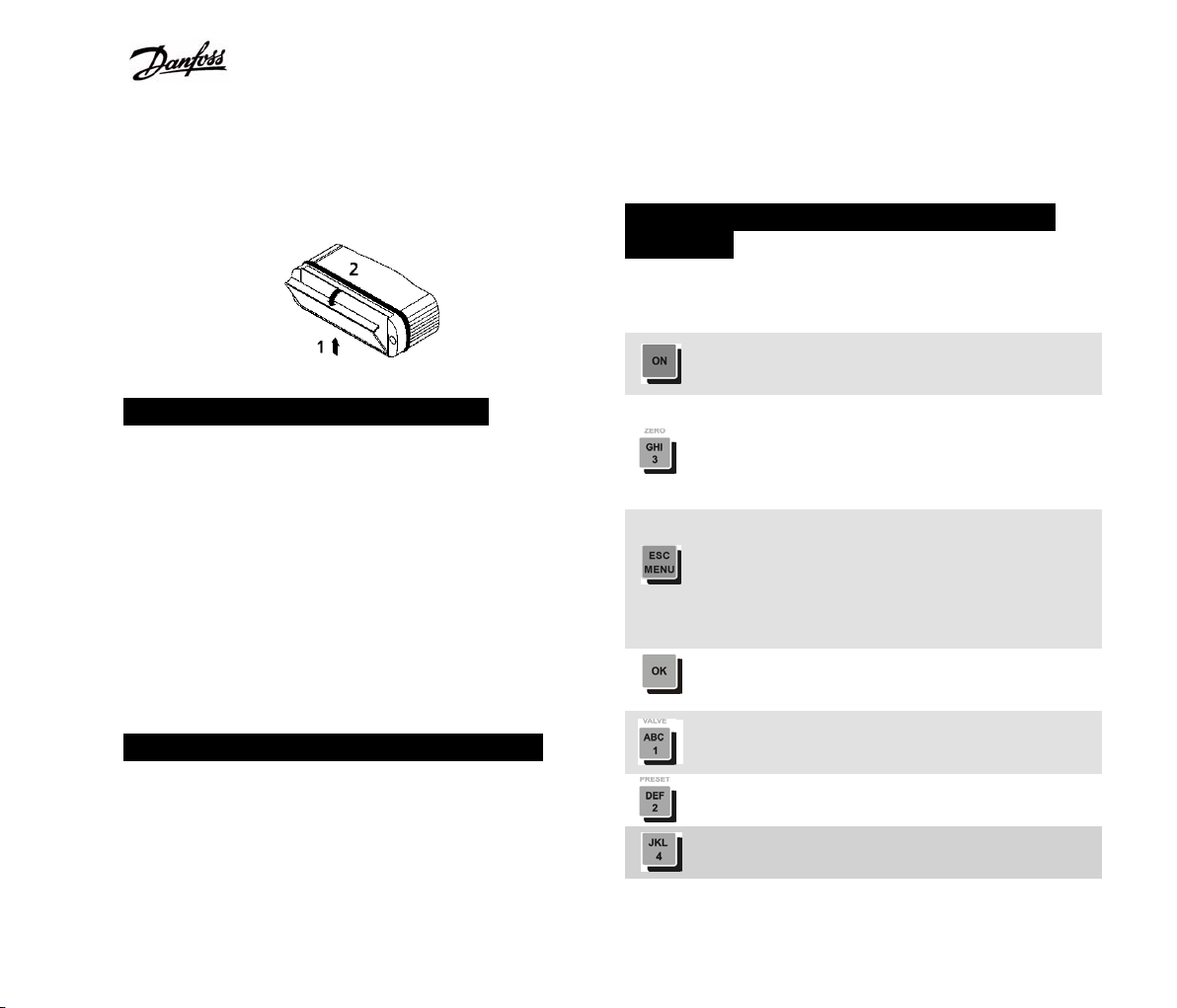

Functions of Keys on the Instrument's

Keyboard

Keys with standard numbers or letters are used to enter data

into computer. Following keys have special functions:

Switches the instrument on and off. To switch on

the instrument, hold the key for one second.

Resets a reading about pressure on the display.

The key also corrects possible zero instability

and the dependence of the differential pressure

on static pressure.

If in the measuring function, it opens the menu.

It is used for the upward movement within the

menu. If you press the key while entering data,

the new value will not be saved. The previous

data will be kept.

Serves to accept a value or a selected

command in menu.

PFM 3000 Zero Measuring Correction

When measuring zero pressure will take an error after a time

of PFM 3000 using, you can correct this effect by ZERO

function. In the instant that zero error is grater some kPa, we

recommend clean or change sintered filters in apparatus

Hot key Valve. While in the measuring mode, it

opens a selection of valves.

Hot key Preset. While in the measuring mode, it

opens a valve presetting.

Hot key Battery. While in the measuring mode,

it opens battery capacity display.

7

Page 8

PFM 3000

Hot key Project Change. While in the Project

making mode, it changes displayed projects.

Deletes a sign from the actual position and

deletes a whole line if held.

Use the keys to move within the menu or the

value entry. While in the measuring mode, it

switches displaying modes. In the Project

making mode, it changes displayed branches.

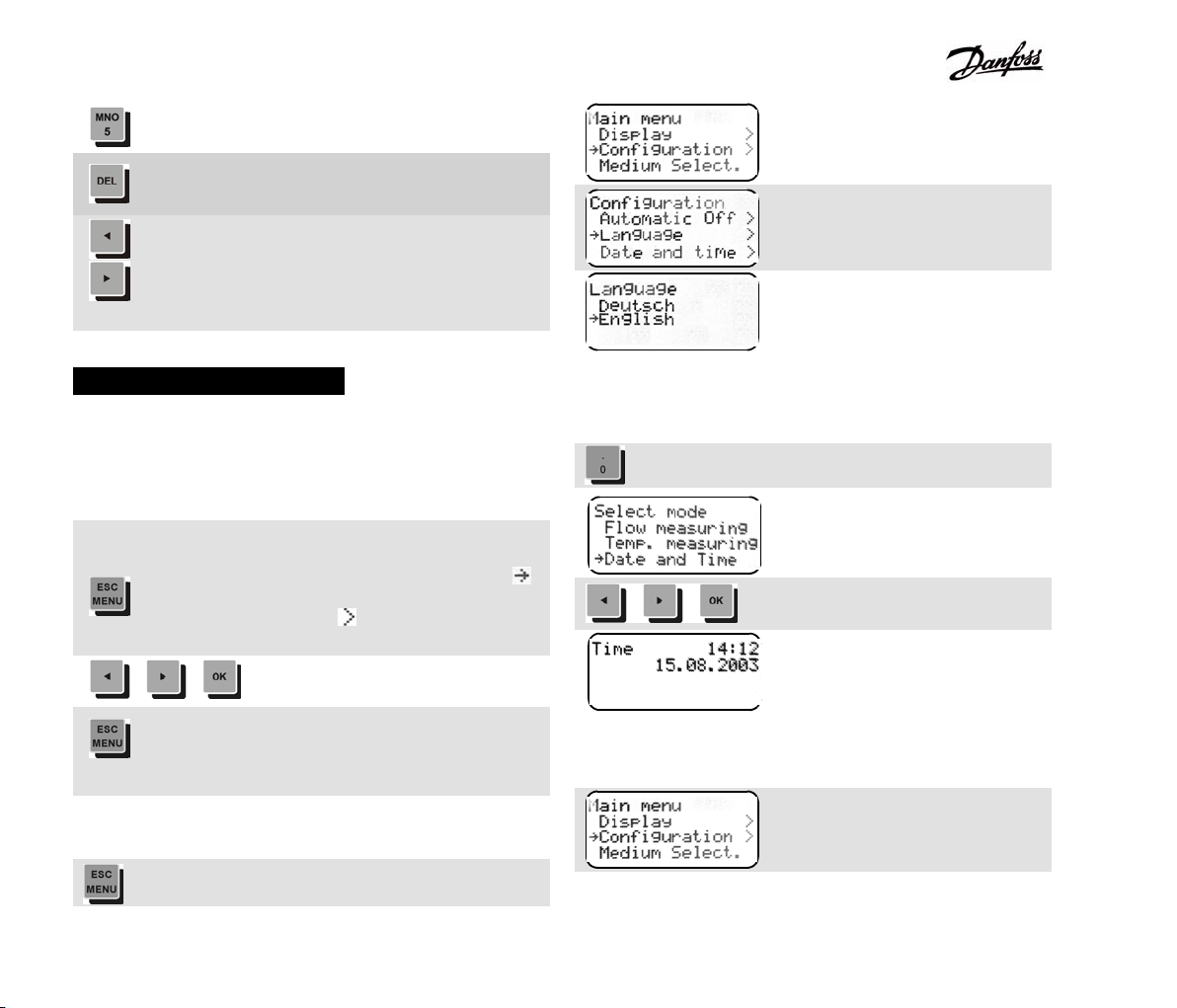

PFM 3000 Configuration

Before measuring, configure the instrument according to a

particular system. The configuration will be saved in the

memory until a next change regardless of shutting down the

instrument.

Press MENU key to open menu. The first line

shows an entry name. The other lines show the

list of sub entries. A selected entry is marked

at the beginning of the line. If the entry has sub

entries, it is marked by at the very end of the

line.

Move in menu and confirm

requested item.

Return one level up, by holding 1 sec you will

return into the measuring from arbitrary menu

level.

Language Changing

Main Menu

Select item Configuration

and confirm it.

Menu Configuration. Select

Language item and confirm it.

Menu Language. Select

requested Language and confirm

it.

Real Time Clock Setting

You can check Date and Time in the Time mode

Mode hot key

Mode offer

Select Date and Time and press

OK.

If PFM 3000 clock setting is incorrect set the appropriate

parameter

Main menu. Select

Configuration item and confirm.

Open menu

8

Page 9

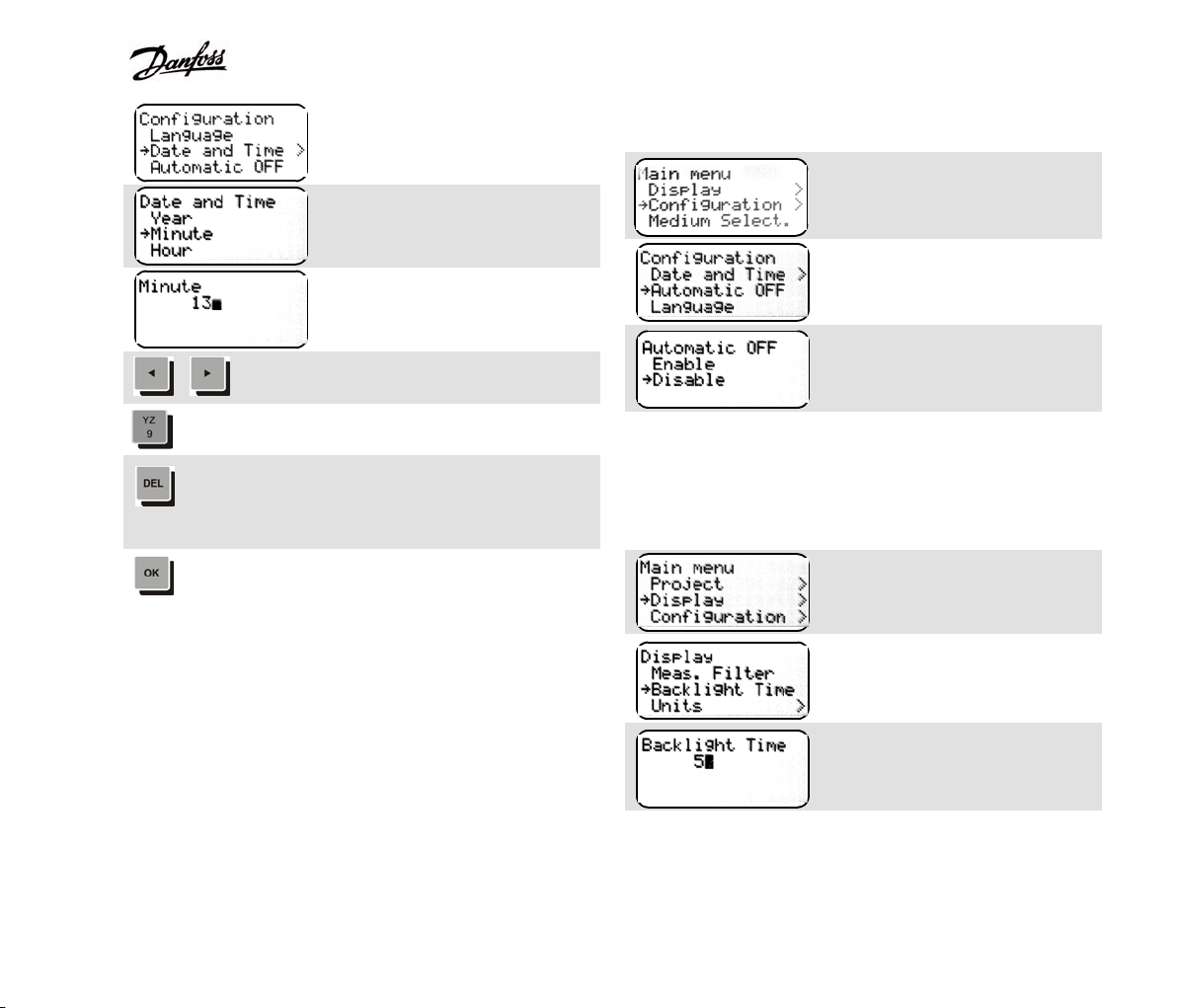

PFM 3000

Configuration menu. Select

Date and Time item and

confirm.

Menu Date and Time. Select

Minute item and confirm.

Enter minutes.

Move cursor to requested

position.

...

There is no need to enter every decade and/or decimal point

of the number in question, only the desired changes

Rewrite digit at cursor position.

If needed, erase digit at cursor

position by DEL key. Holding

DEL by 1s you will erase whole

number.

Confirm correct number.

Automatic Shut OFF

PFM 3000 shuts down automatically 10 min after pressing

the keyboard for the last time. In case of measuring for a

longer period of time without using the keyboard switch this

function off in the Configuration/Automatic OFF menu.

While in the recording mode, this function is switched off

automatically. It is reactivated after the end of recording. The

automatic shut down command is not saved in the

instrument's configuration. Next time when you switch the

instrument on the function is active again.

Main menu

Select Display item and confirm.

Menu Configuration.

Select Automatic OFF item and

confirm.

Menu Automatic OFF.

Select requested function and

confirm.

Display Backlight Time

This is a function to be appreciated when you measure in

dark. When you set the backlight time to 0, the function is

not active.

Main menu. Select Display item

and confirm.

Display menu. Select Backlight

Time item and confirm.

Enter Backlight Time value and

confirm.

9

Page 10

PFM 3000

Pressure Units

Flow Units

Main menu. Select Display item

and confirm.

Display menu. Select Units item

and confirm.

Units menu. Select Pressure

Units item and confirm.

Pressure units choice. Select

requested unit and confirm.

Back one menu level.

Units menu. Select Flow Units

item and confirm.

Flow units choice. Select

requested unit and confirm.

a change of damping (time constant) of the measured value.

Display reading achieve 99,9% input pressure value after

0,75 s for the Fast filter, 5 s for the Medium Filter and 20 s

for the Slow Filter. There is additional filter for the flow

measuring, which adds 16 s more at arbitrary filtering

choice.

Main menu. Select Display item

and confirm.

Menu Display. Select

Measuring Filter item and

confirm.

Choose requested filter and

confirm.

Valve Selection

Valve choice hot key

Valve manufacturer selection.

Choose requested manufacturer

and confirm.

Valve type selection. Choose

requested valve and confirm.

Measuring Filter

The filtration of measured values makes it possible to

achieve a stabilised display of the value despite the

fluctuation in the measured value. Filtration is manifested as

Valve presetting input.

10

Page 11

PFM 3000

Enter valve presetting.

... ...

..

Decimal point you will enter by 1

s holding. There is only one

decimal point allowed in

PFM 3000.

Confirm. PFM 3000 returns back

into measuring.

Valve Presetting Change

Presetting hot key.

Enter new presetting.

Confirm. PFM 3000 returns back

into measuring.

Measured Medium

PFM 3000 uses a built-in measuring correction function for

heat-carrying mediums. To use measuring correction, we

need to know the temperature of the medium.

Enter Main Menu.

Select Medium Select. item.

Medium Select. menu. Choose

medium and confirm.

Enter medium concentration in

% and confirm.

When the temperature probe is

connected, measured

temperature appears on the

display. You have to connect

temperature probe to the

measured medium in this case.

In other case do not connect the

thermometer to PFM 3000 and

enter temperature manually.

Confirm.

Measuring with PFM 3000

Measuring Without Project

System Overpressure Measuring

Measuring Mode hot key

Measuring Mode choice.

11

Page 12

PFM 3000

Select Pressure Meas. and

confirm.

Connect static pressure to the higher pressure input (red).

Do not connect the lower pressure input (blue). The

instrument measures overpressure in the system compared

with atmospheric pressure.

Differential Pressure and Flow Measuring

PFM 3000 can measure pressure difference at any point in

the system. Flow can be measured only in specified

regulation fittings saved in the memory. Use connection

tubing to connect the measuring outputs of the balancing

valve to pressure inputs. Higher pressure to the positive

(red) input, lower pressure to the negative (blue) input.

To suppress the effect of static pressure in the system, set

PFM 3000 zero.

Completely open the regulation

valve and stop flow of the

medium.

Press ZERO key.

If the zero error exceeds a few

kPa, clean the sintered filters at

the pressure input. Call a

professional if the error persists.

Neither zero-setting is saved in the instrument's

configuration. Next time you switch the instrument on the

zero is not being corrected.

After you turn on the flow, PFM

3000 measures pressure

difference at the regulation

valve.

Measuring mode hot key.

Measuring mode choice

Select Flow Measuring and

confirm.

PFM 3000 computes flow at the

selected valve.

Measuring Flow in the Fittings Not Saved in

the PFM 3000 Memory

To measure flow, enter the respective fitting and its

presetting. You may want to measure flow in the fitting that

is not saved in the PFM 3000 memory.

Main menu. Select Direct Kv

Input and confirm.

Enter Kv value and confirm.

12

Page 13

PFM 3000

PFM 3000 will calculate flow using the given Kv value. Press

the VALVE or the PRESET key and the instrument returns

to standard flow measuring.

Temperature Measuring

Switch Off PFM 3000 and connect the temperature probe.

Switch ON PFM 3000.

Measuring Mode choice.

Select Temp. Measuring and

confirm.

Heating Calculations

Calculation of the Fitting Presetting for

Requested Flow

This function makes it possible to calculate the fitting

presetting for requested flow. Select the type of fitting and

connect PFM 3000 to the measured fitting.

Main menu. Select Heating

Calcul. item and confirm.

Select Valve Preset item and

confirm.

You will be asked to enter requested flow. Measure actual

flow and confirm with key OK. Then close the fitting and

confirm the pressure value under the closed state.

PFM 3000 will calculate presetting for requested flow.

Calculation of the Pressure Drop for

Requested flow

This function will show you, if it is possible to adjust the

branch, when you know available branch pressure. Choose

actual valve type and presetting.

Select Pressure Drop item from

Heating Calcul. menu.

Enter requested flow. PFM 3000 will compute pressure drop

across actual valve with actual presetting. When the

computed result is greater then the available pressure, you

simply know, that this requested flow is not genuine.

Leave off the pressure drop computing by ESC key.

Data Record

Record Preparing

You have to check respectively set up record parameters

from the Record menu.

13

Page 14

PFM 3000

Period/Hours = 0

Period/Minutes = 0

Period/Hours = X

Period/Minutes = Y

Check free record capacity from

Record/Capacity menu.

The display indicates filled

memory space in the form of a

baragraph. One baragraph unit

equals appr. 100 records. If

there is not enough vacant

memory space, delete the

memory in Record/Erase menu.

Record period may be from 1 s

up to 24 hours.

PFM 3000 records data with

period from Period/Seconds

input.

Seconds of period are ignored

and PFM 3000 records data with

period X:Y. While waiting for the

record the instrument switches

into the energy-saving sleep

mode. The display is not active

at that time. After

pre-programmed period elapses,

PFM 3000 wakes up and

measures time necessary for

parameters fixation. After that

record shoots and apparatus go

to the sleep mode again.

Select menu item Record/Place

or Record/Description.

Enter the identification chains of the record made of

letters from A to Z, numbers from 0 to 9, space, dash and

point (max. 16 characters). Thus each record includes a

32-character identification.

The characters are written in blink cursor

position. You can move cursor by arrow keys.

Alphanumeric key pressing overwrite the

character at cursor position. Every alphanumeric

key has some values. The key in left, for

instance, writes characters A, B, C, 1 by sequel

at the same position. After you press another

key, the cursor moves right one position. When

you need the same character twice, move the

cursor by arrow after entering the first character

and enter the character again.

This key deletes character in cursor position and

whole text right from the cursor moves one

character left. Holding the key by 1 sec erases

complete line.

You will confirm the input by the OK key. If you want

leave input without writing, press ESC key.

Start of Recording

Start the record from

Record/Start menu.

At the beginning of each recording the memory saves a

location and description (entered in the previous

paragraph), selected valve and presetting, time, pressure,

14

Page 15

PFM 3000

flow and temperature. During the data record flashes

before the time reading.

*

Full Data Memory and Low Battery

When the data memory fills up

during record, following display

will appear.

The record will stop and PFM 3000 switches off after 10

minutes.

Low battery state during data record works the same as in

normal measuring. With the battery capacity less then 5 %

message Low Battery! blinks on the display every 15 s.

When zero battery capacity PFM 3000 switches off.

End of Recording

Record continues.

Processing Projects

PFM 3000 has a built-in modulus for the calculation of

project balancing with one horizontal distribution and a

maximum of 32 vertical branches. The calculation method

presumes there is constant pressure at the input of the

project and the project includes no hydraulic elements with a

feedback (regulators of differential pressure at branches,

thermostatic valves).

You can store two this projects into the instrument memory.

Also it is able calculation of project balancing powered in the

middle by binding two simple projects.

Project schematic

End of record.

During record with Sleep apparatus wakes up by any key

pressing and apparatus ask you for the end of record as

the previous case.

Note: The Zero function (the correction of the zero shift of

measuring) is not active in the sleep mode.

15

Page 16

PFM 3000

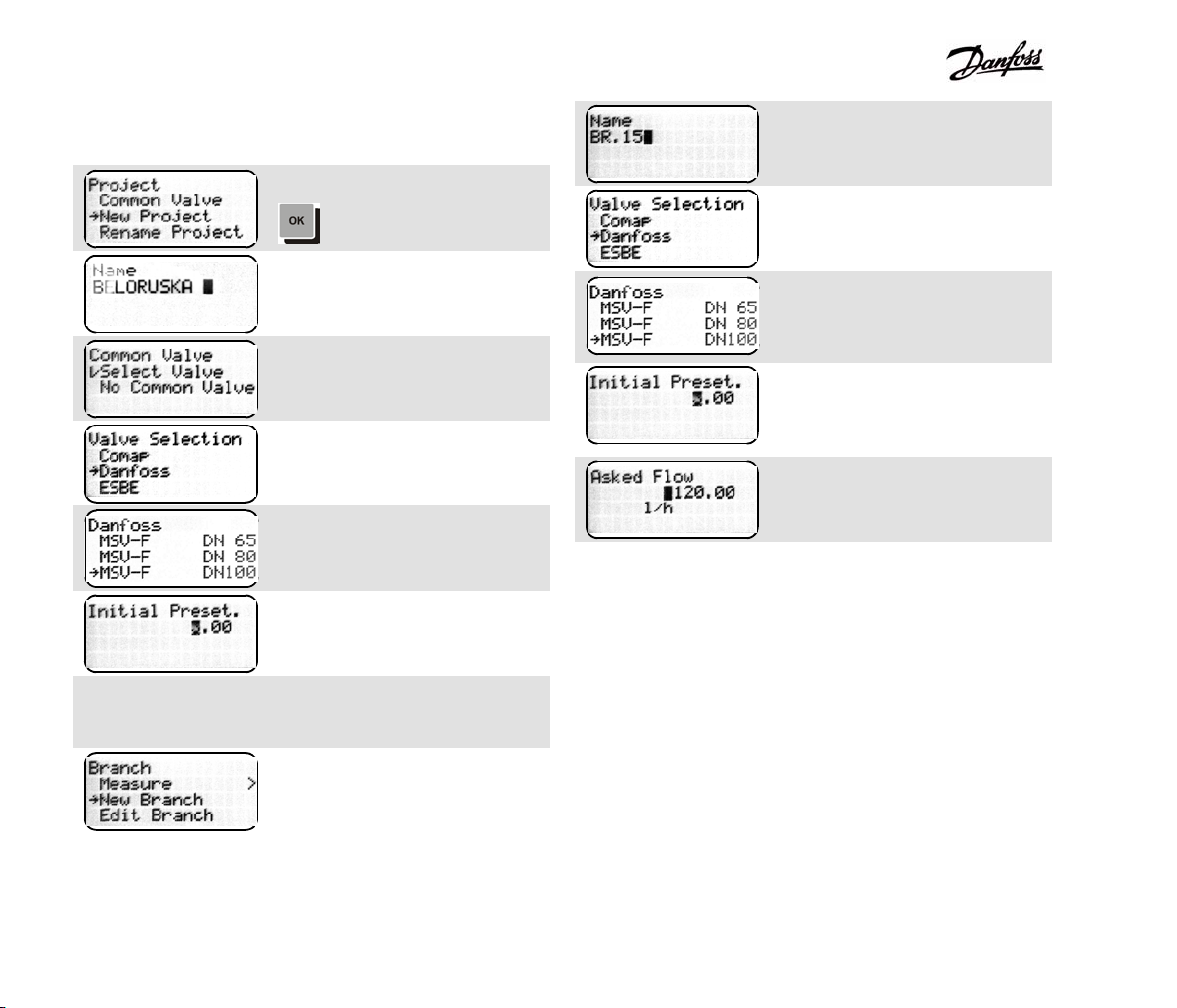

Creating a New Project

For new heating system may be projected value. For old

systems this presetting value, which will allow measurable

pressure drop at all branch balancing valves.

Menu Project/New project

Enter Project Name, max. 12

characters.

Common valve choice. For the

project without Common Valve

select No Common Valve.

Select Common Valve producer.

Select Common Valve type.

Enter Common Valve initial

presetting from Project/Initial

Preset menu.

Menu Branch/New branch.

Enter name of the branch, max.

12 characters.

Choose balancing valve in

branch.

Enter initial presetting of the

branch balancing valve. Use the

same rules as in the common

valve.

Enter requested flow.

Repeat New branch steps for all

branches in the project.

The branches has to be added in the order of distance from

heating medium input, so they are in the real project

topology. When you create new project in PFM 3000 at one

blow, each additional branch adds behind previous branch.

When you need add a branch somewhere in the middle of

the system, you need to select branch before the new

branch from menu Branch/Selection.

16

Page 17

PFM 3000

Project without a Common Valve

System without a common valve schematic

Occasionally we come across systems without a common

valve on input. PFM 3000 makes it possible to balance this

kind of system by selecting Project/Common valve/

Without common valve. If you create the project on

personal computer then cancel marking Common valve.

Connect PFM 3000 to the input

(into the measured system) of

the heat-carrying medium.

Menu Project/Input Pressure

Go to the first project branch and

connect PFM 3000 to the

balancing valve. Select a

respective branch.

Choose Branch/Measure item.

Menu Measure/Initial Preset

Measurements Necessary for the Calculation

of Project Balancing

Set all fittings in the project including common valve to

initial presetting.

Select a respective project from menu

Project/Selection.

Menu Measure/Valve Closed.

Close the balancing valve.

Set back initial presetting.

Repeat branch measuring at all project branches.

You can also create project in PC and download it into the

17

Page 18

PFM 3000

PFM 3000. Make use the User software PFM 3000.

Balance Calculation of the Project

Select Project/Balance calculation/Start to start

calculation. PFM 3000 checks whether all values needed for

calculation have been measured. In case some values are

missing, the instrument will indicate branches that still have

to be measured. The result of calculation is the presetting all

valves including the common valve for requested flow.

During the balance calculation the display indicates progress

the procedure in the baragraph.

Results of Project Balancing

When calculation is over, display the results under

Project/Balance calculation/Results menu.

Pressure behind common valve

computed from project

compensatory scheme.

Particular branch presetting

including common valve.

It is not possible to balance the

branch. It must be higher

requested flow value for

particular valve or smaller

dimension of the valve.

It is not possible to balance the

branch. It must be smaller

requested flow value for

particular valve or bigger

dimension of the valve.

Project Balancing Check

y Set the calculated presetting at all project branches

including the common valve. Actual flow should

correspond to requested flow.

y If necessary, correct small flow deflections from

requested values by changing fitting presetting.

y Store actual flow into the project in the

Branch/Measure Branch/Actual flow menu. Do not

forget to select a respective branch under

Branch/Select branch.

For balancing check is very expedient Projects Mode, so

that you can easily change branches with branch parameters

for displaying.

PFM 3000 mode selection hot

key.

Mode selection proposal.

18

Page 19

Select Project and confirm.

There are all significant project

data on this display.

Project name at the line 1.

Selected branch at the line 2.

Requested flow at the line 3.

Real flow at the line 4.

Hot key switches two PFM 3000 projects, you can list

between branches by arrow keys. When you change the

branch, PFM 3000 automatically chooses appropriate valve

and presetting for real flow calculation. When the project is

balanced in PFM 3000, apparatus chooses balanced

presetting, in other case initial presetting.

PFM 3000

19

Page 20

PFM 3000

Balance Calculation of the Project with a Pressure Input in the Middle

We often come across systems with one pressure input and distribution into both sides of the input. PFM 3000 makes it

possible to measure this kind of system by dividing it into two projects with simple distribution. You measure and balance the

projects separately. Then using the command Bind projects you balance the whole system with the input in the middle.

Scheme of the System with a Pressure Input in the Middle

Balance calculation of the project with a pressure input in the middle - Procedure

y Measure project Right Side.y Create two projects - marked as the Left Side and

Right Side in the picture.

y Start the balance calculation of the Left Side project.y Close the Right Side by the right stop valve.

y Pre-adjust all valves in the left side to initial presetting.

y Close the Left Side. Open the Right Side.

y Start the balance calculation of the Right Side project.

y Start the balance calculation of the Left Side project.y Measure project Left Side.

y Select Project/Balance calculation/Bind projects to

calculate the balance of the whole system.

20

Page 21

PFM 3000

Communication with a Computer

PFM 3000 can be easily connected to the computer by a

serial RS232 line.

Data Processing and Displaying Program User software PFM 3000

User software provide easily work with data recorded in

instrument and easily prepare projects in PC.

Recorded data can be processed by the PC program that is

a part of the apparatus delivery. Data can be displayed in a

chart and graph. They can be printed and also exported for

further processing by chart editors e.g. Data may be saved

in PC in the internal format of PFM 3000 (*.txt) for further

processing.

For the balancing of hydraulic systems the program makes it

possible to prepare two projects with a maximum of 32

branches of each.

During measuring data can viewed directly on the computer

monitor.

Minimum PC Requirements

PC 486, 16 MB RAM, min. 2 MB space left on HDD,

Windows 95 or higher

y Insert the installation disc into the disc drive.

y In Windows click setup.exe under Start/Run. The

program installs the software automatically.

Operating the Program

Main toolbar

The toolbar includes the icons of the most frequent

operations.

From the left: open file, save file, download data from the

instrument, print and work with projects.

Selecting units

The program allows various units of pressure and flow to be

entered and displayed. Choose Options/Units Selection to

select the units of pressure and flow.

You can select from the following units:

Pressure

y Pa, hPa, kPa, Mpa

y mbar, bar, psi, at

y mWs, mmWs, mmHg

Flow

y m3/hod, m3/min, m3/s

y l/hod, l/min, l/s

Software Installation

An installation CD-ROM is a part of the instrument

accessory. It contents software needed for communication

with PC.

Installation procedure:

Measured Data Processing

Downloading data from the instrument

Use a communication cable to connect the instrument.

Switch PFM 3000 on. Click Read to download data from

21

Page 22

PFM 3000

apparatus. Unless PFM 3000 is connected or switched on,

the message PFM 3000 not connected will be displayed. If

there are no recorded data, the message No recorded data

will be displayed.

If data have been recorded, they will be displayed in the user

software.

Data classification

Data are classified into records from particular places. Select

a requested place to receive measured pressure, flow and

temperature.

Measured data can be viewed also in graphs.

Graph view toolbar

The toolbar includes buttons for the scale adjustment and

the graph heading adjustment.

The functions of the icons (from the

left): original scale, scale up, scale

down, heading adjustment.

To move along the graph, use the right mouse-button. To

blow up an area, create a rectangle by clicking the left

mouse-button in the left top corner of the area and move to

the right bottom corner.

Using data

You can save data to the disc in the PFM 3000 format from

menu File/Save as choose export from File/Export menu to

export them in the database format. Exported data you can

again open in a spreadsheet programs, for instance Excel.

To browse previously saved data, click File/Open.

Printing

You can print recorded data and graphs indicating pressure,

flow and temperature change within a time period with an

adjustable recording period. Select a printer type under

Print/Printer set-up…. You can print either table and

graphs of stored values. To print a graph, use a landscape

page orientation. Select requested data from measured

points.

Project preparation and project saving

For the balancing of hydraulic systems the program makes it

possible to prepare two projects with a maximum of 32

branches of each.

Project tool bar

Creating a project

Each project includes information about the common valve,

input pressure and the common valve set-up. In the Project

section fill in the name, the common valve type from the

valve list and input pressure. For project without common

valve deselect Shared Valve box. Hit Add button to attach

the project to the tree of projects and branches in the left

part of the window. To enter branches, select a respective

project (click the mouse button at the respective project). In

the Branch section fill in the name, requested flow and the

valve from the valve list. To attach a branch to the tree of

project and branches, select Add in the Branch section.

After entering all branches, save the projects to the disc.

22

Page 23

PFM 3000

Working with projects

Click Open and Save at the tool bar to download project

files from/to the disc. The file can consist of max. of two

projects.

Click Read from the instrument and Write to download

projects. Projects and their branches may get modified also

in the PFM 3000. Save data in the instrument carefully to

avoid overwriting previously saved projects or measured

data. Therefore before downloading a project from PFM

3000 you have to confirm a requested operation in a

displayed dialogue box.

Click Print to print the project on a selected printer.

Maintenance Instructions

Calibrate the instrument every 12 months.

Replace sintered filters at pressure inputs every 12 months.

Sintered filter is located in the R20 quick coupling (smaller

one). You can replace sintered filter by the following

drawing:

Parts of the Delivery

PFM 3000 measuring computer 1 pcs

battery charger 1 pcs

thermometer PT100 digital 1 pcs

connecting tubing 1 pair

quick coupling R21 1 pair

quick coupling R20 1 pair

hoses Din 7 mm connection 1 pair

measuring adapter G3/4" 1 pair

reducer G3/4-G1/2 1 pair

measuring nozzle 1 pair

CD with the user software 1 pcs

RS232 communication cable 1 pcs

detailed manual, warranty certificate 1 pcs

plastic case 1 PCs

23

Page 24

PFM 3000

24

Page 25

Technical Specifications

PFM 3000

CommentUnitValueItem

kPa1 000Pressure range

kPa1 500Maximum overpressure

% of range0,15Linearity, repeability and hysteresis error

% of range0,25Temperature error

% of range0,06Static pressure effect

°C-5 až 90Medium temperature

°C-5 až 50Ambient temperature

°C-10 až 70Storage temperature

PT 100 digitalTemperature probe

°C-20 up to 120Range of Temperature probe

°C+/- 1Temperature error

Li-Ion batteryPower

1 sec up to 24 hoursPeriod of record

RS 232Interface

7,2 V

1250 mAh

hours7Charging time

mm77x192x25Dimensions w x h x d

g390Weight

IP65Cover

months12Calibration validity

at the end of a

connecting tubes 1.5 m

max.hours120Operating time

max.1 800No of records

max.valves400No of pre-programmed valves

max.2No of projects

max.32No of branches in each project

25

Page 26

PFM 3000

26

Page 27

PFM 3000 MenuPFM 3000 Menu

PFM 3000

Project

Selection

Balanc. Solve

Start

Bind Projects

Results

Source Pressure

Common Valve

New Project

Branch

Selection

Measure

New Branch

Valve Closed

Initial Preset.

Real Flow

Display

Units

Pressure Units

Flow Units

Meas. Filter

Backlight Time

Pa

hPa

kPa

MPa

mbar

bar

psi

at

mWs

mmWs

mmHg

m3/s

m3/min

m3/hod

l/s

l/min

l/hod

Configuration

Date and Time

Automatic OFF

Language

Minute

Hour

Day

Month

Year

Medium Select. Record

Watter

Ethylenglykol

Propylenglykol

Capacity used

Start

Erase

Period

Place

Hours

Minutes

Seconds

Direct KV Input

Heating Calcul.

Valve Preset

Pressure Drop

Rename Project

Delete Project

Initial Preset.

Edit Branch

Delete Branch

Description

27

Page 28

29

www.danfoss.com

Loading...

Loading...