Page 1

Data sheet

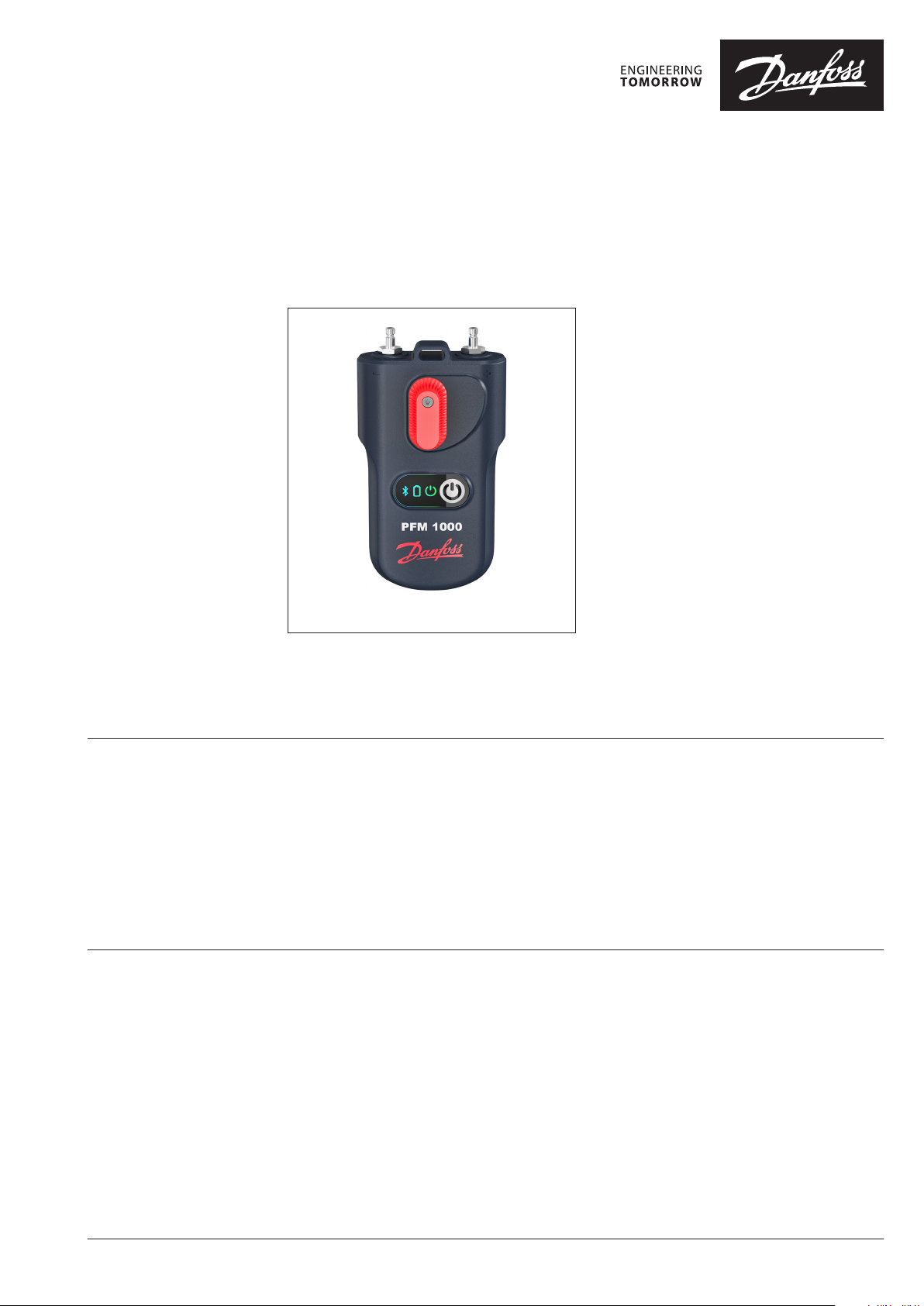

PFM 1000 Measuring Instrument

Description

PFM 1000

Using the differential pressure measured by

the measuring component in the system, PFM

1000 calculates the flow that runs through the

component (balancing valve or measuring orifice).

The application corrects the calculated flow also

for anti-freeze mixes in cooling systems.

The flow can be measured in all branches of the

whole hydraulic system and the whole system

can be balanced.

The PFM 1000 has been designed to create

hydraulic balance in heating, cooling and

domestic hot water systems. It enables measuring

of static pressure, differential pressure and flow.

PFM1000 components

• Main measuring unit

• Measuring needles & hoses

• Smartphone for displaying results and

analysis (not included)

The main pressure sensor is extremely robust

with a sturdy frame. Inside the pressure sensor is

a differential pressure gauge with an integrated

true differential pressure sensor for accurate

digital data processing.

Conectivity between measuring unit and

smartphone is wireless via Bluetooth.

PFM1000 can be connected to ANDROID and iOS

devices using app downloaded from PLAY STORE

(Android) or APPLE STORE (iOS)

Features

Usage

• Acurate pressure measuring with true

pressure sensor with 24 bit pressure

procesing.

• Digital compenstion of temperature effects

and the pressure sensor nonlinearity.

• Correction of flow calculation based on

antifreeze liquid characteristics.

• Compatible with Android (7,0+) and iOS

devices.

The PFM 1000 must be connected on the high

side as well as on the low side of the valve using

the appropriate needles, connectors and hoses.

If you are to measure under high static pressure

it is recommended to connect the red hose first

in order to protect the membrane inside the

pressure sensor. If you connect the blue hose first

the pressure sensor may be damaged.

You can read flow and pressure on the Android

/ iOS smartphone which is separate from the

pressure sensor.

• Wireless data transferfrom measuring unit to

mobile Bluetooth Low Energy technology.

• User-friendly interface.

• Easy balancing valve selection from a

photographic menu.

• A record of the measured values with the

capacity of up to 2,000 recordings.

• Can be used as data logger

• Very robust construction, can withstand fall

from hight of 2m.

How to measure:

1. Select manufacturer

2. Select the type of valve

3. Select the dimension of the valve

4. Select pre-setting

5. Connect the valve to the pressure sensor

6. Zero adjust

7. Measure the flow

© Danfoss | 2022.02 AI309060680246en-000203 | 1

Page 2

Data sheet PFM 1000 Measuring Instrument

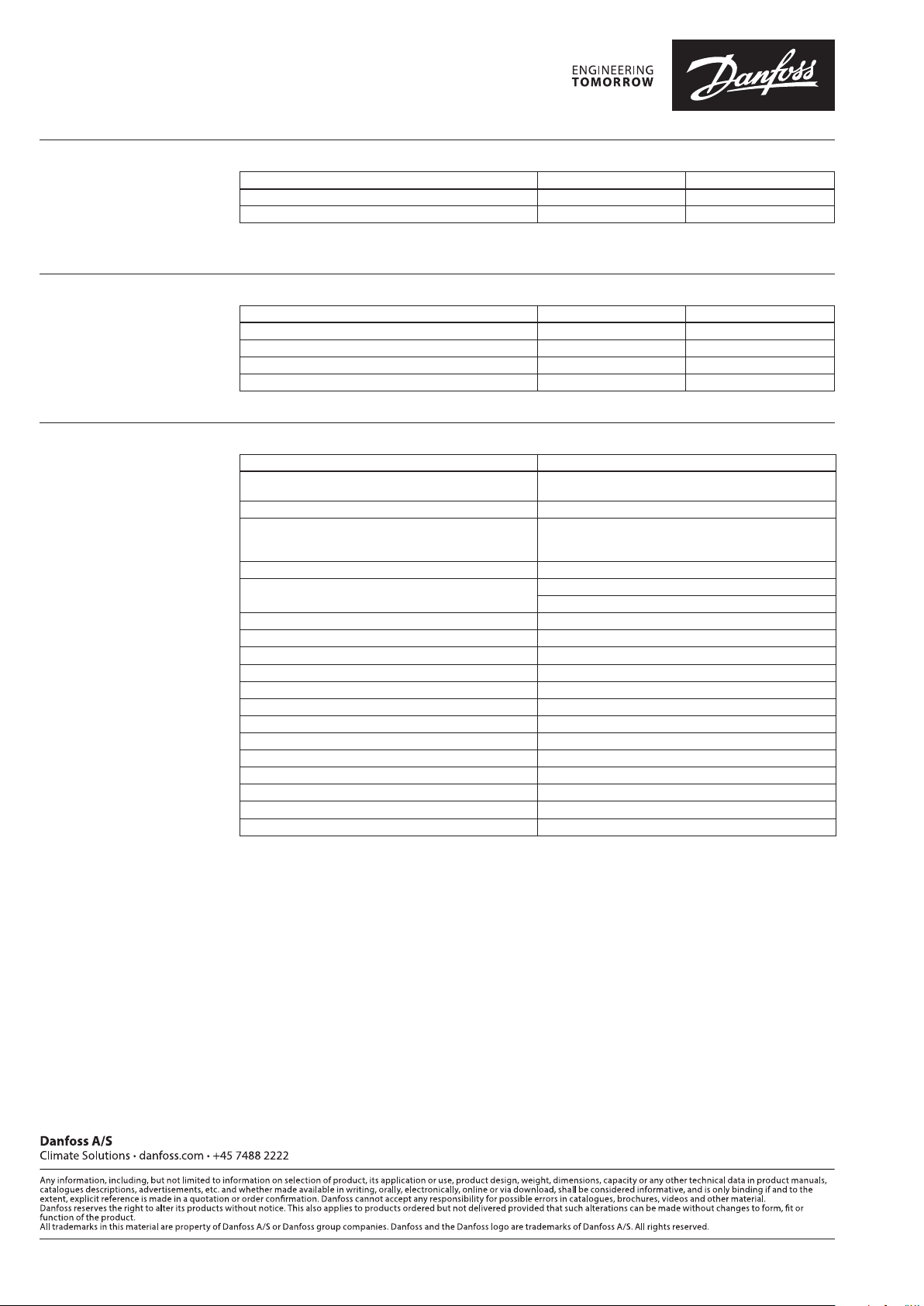

Ordering

Accessories

Technical data

Typ e Pressure Code No.

PFM 1000 measuring instrument 10 ba r 003Z8260

PFM 1000 measuring instrument 20 bar 0 03Z8 261

All versions are upgradable with additional pressure sensors and routers.

Typ e Set / pcs. Code No.

Set of the hoses PFM1000 - 2x1,5m 1 set 003Z8262

Set of the filters PFM1000 2 pcs 003Z8263

Set of the needls PFM1000 2 pcs 003Z8264

Adapter R21 2 pcs 003Z8267

Typ e Specification

Pressure range

Nominal pressure 10 or 20 bar

Max. over pressure

Reliability, linearity and hysteresis error 0.15 % of range

Error for the pressure range 0 till 5 kPa af ter pressure zero

setting

Temperature error 0.25 % of range

Medium temperature

Ambient temperature - 5 to 50 °C

Storage temperature + 5 to 50 °C

Ambient humidity 95% r.h., non-condensing

Power supply AAA Alkaline batteries or NiMH rechargeable batteries

Operating time Max. 45 hours

Power consuption 20mA

Wireless data tetansfer Bluetooth Low Energy 5.0

Dimensions w x h x d 180 x 80 x 52 mm

Weight 440 g

IP rated enclosure IP 65

Calibration validity 24 months

1)

measured at the e nd of measuring hoses, length 1.5m, H ot water flows thru PFM1000 hydraulic part s during Pressure zero procedure .

Maximum tim e duration of zeroing when tem perature of the medium exce eds 50°C is 10 seconds.

1)

± 100 Pa for nominal pressure range 2 MPa

0-1000 kPa ~ 0-10 bar

0-2000 kPa ~ 0-20 bar

120% of nominal pressure:

120 0kp a ~12 b ar

2400kpa ~ 24 bar

± 50 Pa for nominal pressure range 1 MPa

- 5 to 90 °C

© Danfoss | DCS-SGDPT/SI | 2022.022 | AI309060680246en-000203

Loading...

Loading...