User Guide

PFM 1000 Balancing Measuring Device

User Guide for Mobile Devices with iOS

© Danfoss | 2020.03 BC309062448253en-000301 | 1

User Guide PFM 1000

Content

Introduction ........................................................................................................................................ 3

PFM 1000 Instrument Features ......................................................................................................... 3

PFM 1000 Pressure Measuring Unit .................................................................................................. 3

PFM 1000 application installation & Main Display ......................................................................... 4

Application Setup ............................................................................................................................... 4

Pressure Unit Turn-on ........................................................................................................................ 5

Warning! Very important! .................................................................................................................. 5

Measuring ........................................................................................................................................... 5

Measuring Window......................................................................................................................................................... 5

Measuring Context Menu Tabs .................................................................................................................................. 6

Select Valve ....................................................................................................................................................................... 6

Valve Preset ....................................................................................................................................................................... 6

Medium ............................................................................................................................................................................. 6

Kv Direct Setup ................................................................................................................................................................ 6

Set Requested Flow ....................................................................................................................................................... 7

Medium Temperature ................................................................................................................................................... 7

Pressure Measuring Zero, Deaeration of Measuring Hoses ............................................................................ 8

Quick Record .................................................................................................................................................................... 8

Projects ................................................................................................................................................ 9

Project Management ..................................................................................................................................................... 9

Project Window, Project Tab ....................................................................................................................................... 9

Project Context Menu ................................................................................................................................................... 10

New .......................................................................................................................................................................................................10

Open .....................................................................................................................................................................................................10

Save .......................................................................................................................................................................................................10

Save as ..................................................................................................................................................................................................10

Send Project via Mail ......................................................................................................................................................................10

Project renaming .............................................................................................................................................................................10

Project Window, Branches Tab................................................................................................................................... 10

Branch Context Menu ................................................................................................................................................... 11

Add Branch .........................................................................................................................................................................................11

Rename Branch ................................................................................................................................................................................11

Move Branch up ...............................................................................................................................................................................11

Delete Branch ....................................................................................................................................................................................11

Move Branch Down ........................................................................................................................................................................11

Recording ............................................................................................................................................ 12

Record Info Tab ................................................................................................................................................................ 12

Record info Context Menu .......................................................................................................................................... 12

New Record ........................................................................................................................................................................................12

Open Record ......................................................................................................................................................................................13

Read Record .......................................................................................................................................................................................13

Send Record via Mail ......................................................................................................................................................................13

Delete Record ....................................................................................................................................................................................13

Record Items Tab ............................................................................................................................................................. 13

Heating Engineering Calculations ................................................................................................... 14

Preset Calculation ........................................................................................................................................................... 14

Pressure Loss Calculation ............................................................................................................................................. 15

Available Pressure Calculation ................................................................................................................................... 15

Valve Authority Calculation ........................................................................................................................................16

Quick Records Database .................................................................................................................... 16

Maintenance ....................................................................................................................................... 17

Sintered Filters Replacement ..................................................................................................................................... 17

Battery Replacement ..................................................................................................................................................... 17

Troubleshooting ................................................................................................................................. 18

Safety and Device Disposal Instructions ......................................................................................... 18

Batteries ............................................................................................................................................................................. 18

Information for Users on Collection and Disposal of Used Devices and Batteries ................................. 18

Specifications ...................................................................................................................................... 19

2 | BC309062448253en-000301 © Danfoss | 2020.03

User Guide PFM 1000

Introduction

PFM 1000 Instrument

Features

The PFM 1000 instrument is designed for hydraulic balancing of heating and cooling systems. It allows

measuring static pressure, differential pressures and flow in the said systems. Using the differential

pressure measured by the measuring component in the system, PFM 1000 calculates the flow that

runs through the component (balancing valve or measuring orifice). The application corrects the

calculated flow also for anti-freeze mixes in cooling systems. The flow can be measured in all branches

of the whole hydraulic system and the whole system can be balanced.

The core of the instrument consists of the pressure measuring unit that measures pressure in

balancing components of hydronic systems and sends the measured values to the Bluetooth Low

Energy (hereinafter just BLE) technology in a mobile device with the Android or iOS operating

systems. The PFM 1000 measuring unit is very robust with a massive heavy-duty frame that can

withstand a fall from 2 meters. Inside the measuring unit, there is a hydraulic section with a builtin symmetrical differential sensor for accurate digital processing of measured data. The PFM 1000

measuring instrument is very accurate and this accuracy is based on:

• Very accurate measuring of the pressure with a fully differential pressure sensor and 24-bit

processing of data from the pressure sensor

• Possibility of resetting the differential pressure for pressure measuring of very low differential

pressures. The resetting of measuring is done at the hydraulic bypass of pressure inputs.

The PFM 1000 instrument uses advanced digital technologies that compensate inaccuracies usually

occurring in pressure measuring, such as temperature dependencies and measuring non-linearity.

Another feature of the PFM 1000 instrument consists in recording measurements. Data from

measuring can be recorded independently and directly in the pressure measuring unit. The

measuring unit is equipped with a time circuit that allows programming a periodical recording of

measurement independently on the application in the mobile device. Once the recording is complete,

the measuring unit turns off and the record remains stored in the measuring unit until the application

reads it out. Another method of recording consists in recording of current values directly into the

mobile device.

Using the BLE transmission, the PFM 1000 application communicates with the measuring unit; a

user-friendly interface can be handled via the user mobile device. The application processes pressure

values and allows displaying the flows in the measured system based on features of balancing

components stored in the mobile device’s storage. The application stores in the mobile device’s

storage balancing valves of most leading European producers. If, incidentally, a valve in not contained

in the application, you can enter the valve’s Kv and the application will calculate the flow from this

value.

You can handle the software by direct touching required fields, or you can use the menu in the upper

section of the screen.

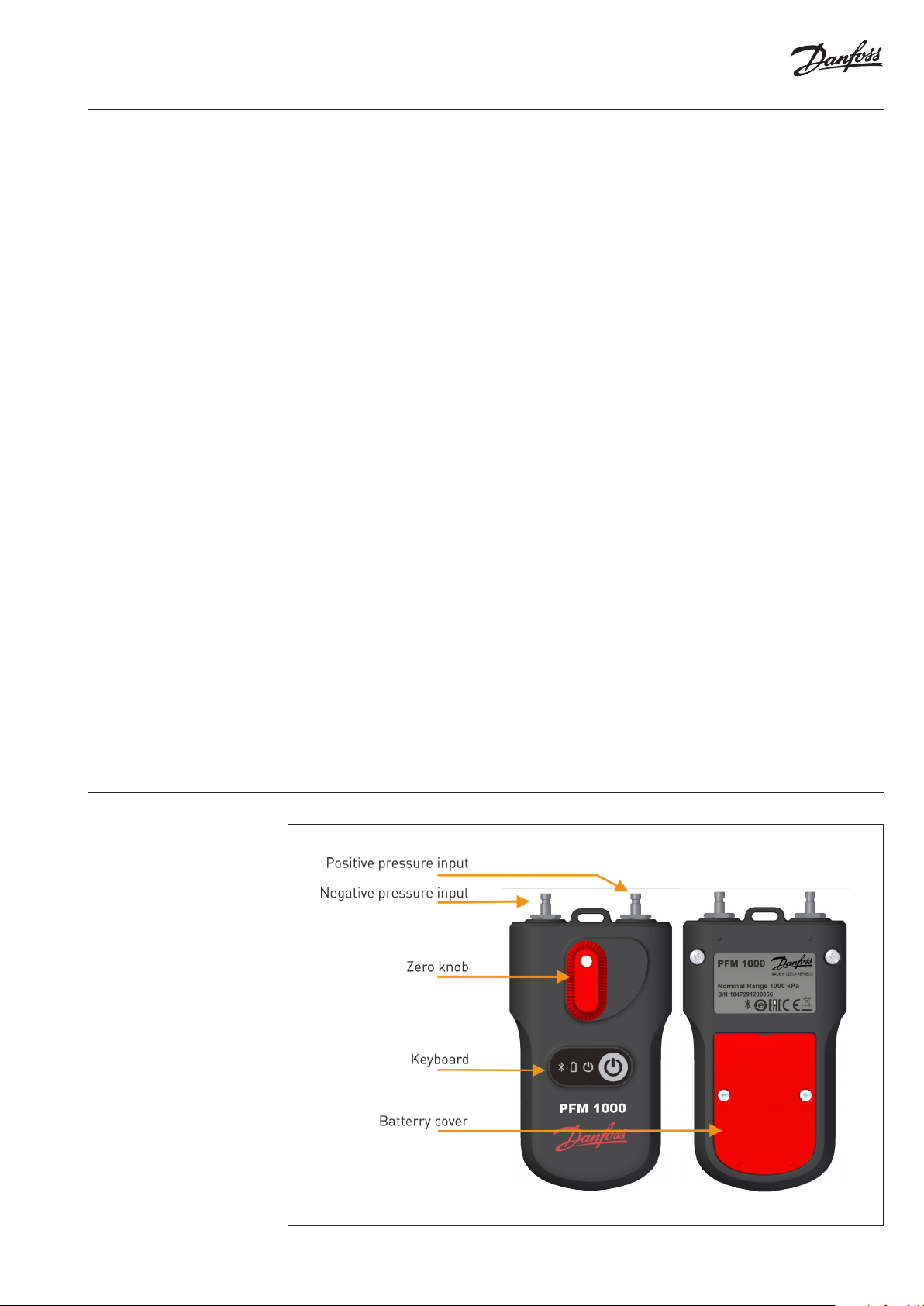

PFM 1000 Pressure

Measuring Unit

BC309062448253en-000301 | 3© Danfoss | 2020.03

User Guide PFM 1000

PFM 1000 application

installation & Main Display

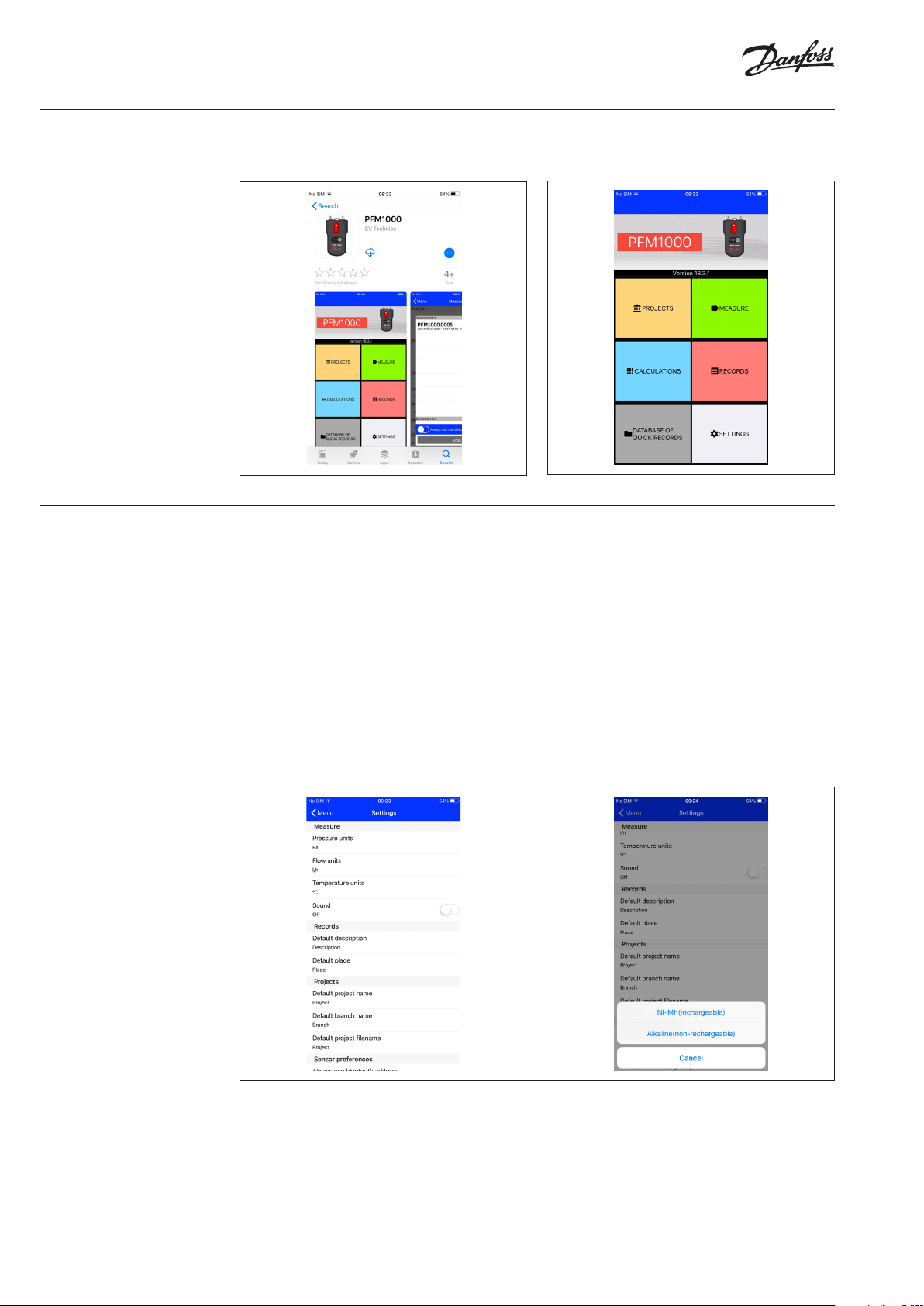

Application Setup Press the Setup button in the introductory window where you can set up the initial features of the

Find in App Store the PFM 1000 application and

install it in your mobile device.

application.

In the Measuring section, these are units for measuring the pressure, flow and temperature. Further,

you can turn on/off here the sound for the whole PFM 1000 application.

Turn on/off the sound in the PFM 1000 application by pressing the Sound button.

In the Records section, you can enter Initial description, Initial record location.

In the Projects section, you can enter Initial project name, Initial branch name, Initial project file name.

In the Sensor preferences, the Bluetooth address of the pressure unit is stored after activating the

Always use the selected device option in Measuring. After the application installation is complete,

this item remains empty. When you will be measuring with the automatic connection of one unit

without searching and you will want to connect another pressure unit, you must delete this field.

Once the Battery type is selected, enter the used AAA battery type in the pressure unit. This setup is

very important for the correct calculation a display of the battery condition indication. You can find

the battery type on the battery. Almost all rechargeable batteries sized AAA are of the NiMH type.

Well-known and of high quality are Eneloop batteries from Panasonic.

Start the PFM 1000 application.

4 | BC309062448253en-000301 © Danfoss | 2020.03

User Guide PFM 1000

Pressure Unit Turn-on

Measuring

When switched on, the instrument initialises itself. This take several seconds and the

green light indicator on the instrument is flashing quickly period 200ms during the

initialisation. Do not establish the Bluetooth connection with the measuring instrument

until this light indicator stops flashing and is on steadily. If the green light indicator fleshes

with 1 second period, there is an error in the BLE module initialisation. Try to switch off the

instrument, wait for several seconds and turn it on again.

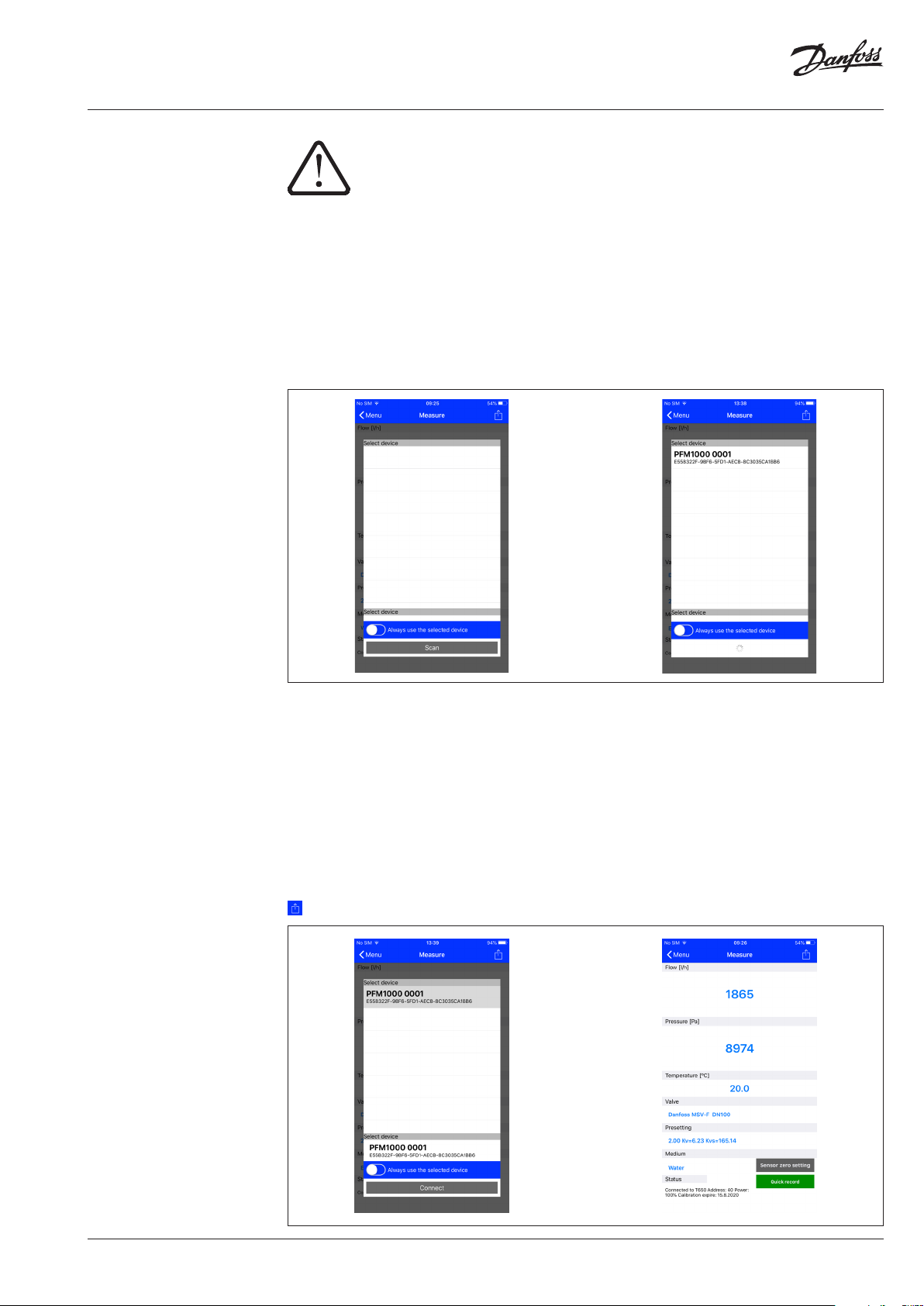

Once the Measuring button is selected, a window is displayed on the introductory screen for

searching and connecting with the measuring unit. After the Scan button is pressed, the PFM 1000

application will search for and display available PFM 1000 devices. Select your PFM 1000 unit from

the displayed list using the last four digits of the serial number and confirm the option by pressing

the Connect button. This function occurs in many other places in the PFM 1000 application. If you

check the Always use the selected device option, the PFM 1000 application will connect with this unit

automatically and will not search for any other. Once the Measuring button is pressed, the Measuring

screen will appear straight away.

You can cancel the Always use the selected device from the Application Setup, the Sensor Preferences /

Always use Bluetooth Address option. Here, delete the Bluetooth address of your pressure unit module.

Measuring Window

Based on the differential pressure measured, type of measured medium, its temperature, valve and

its preset, the application displays the differential pressure in measuring points of the attached fitting

and compute the flow through this fitting.

The status line in the screen’s bottom displays several important pieces of information:

1. The last four digits of the serial number of the pressure unit connected.

2. The percentage status of the battery of the pressure unit connected.

3. The validity of calibration of the pressure unit connected.

4. The firmware version of the pressure unit connected.

You can find settings available in the Measuring window in the context menu after pressing a button.

You can find the button in the upper right corner of the screen.

BC309062448253en-000301 | 5© Danfoss | 2020.03

User Guide PFM 1000

Measuring (continuous)

Measuring Context Menu Tabs

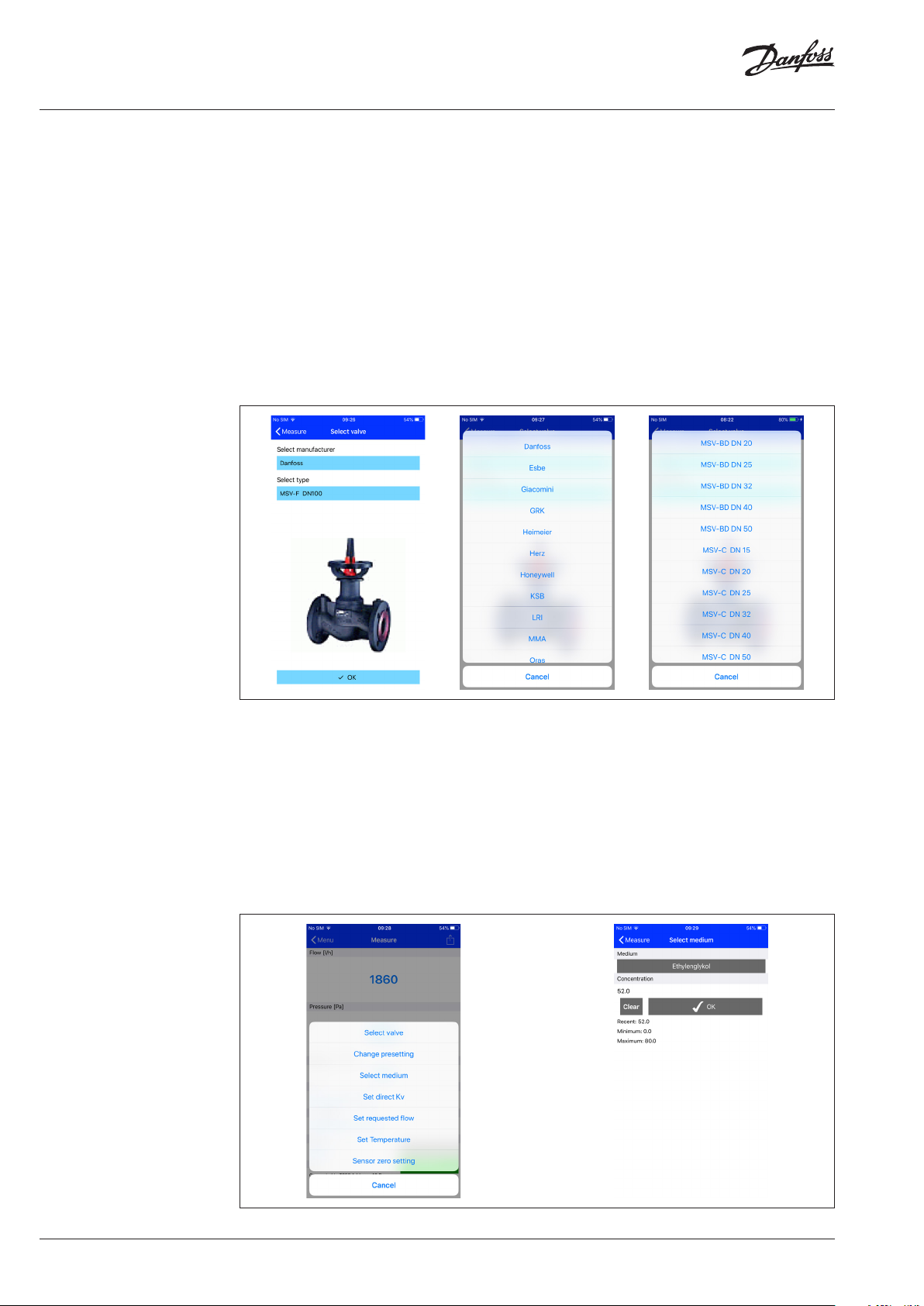

Select Valve

You can select the required valve by pressing the Select valve selection list.

After clicking on the blue Manufacturer line, the list of valve manufacturers contained in the PFM 1000

instrument database will open from which you select the manufacturer required by you. The database

of valves in the instrument contains valves the world’s leading manufacturers. When selecting the

valve and its preset, the Kv values provided by the manufacturer will be used for the flow calculation.

The Kv values are recalculated by the mathematical function from manufacturers’ tables.

After clicking on the blue Se lect Type line, the list of valves of the given manufacturer will open from

which you can select the required valve type. For simpler orientation and selection, also the photo for

each valve type will be displayed for you.

Valve Preset

You can change the valve preset from the Change presetting selection list.

For every valve, the preset field displays the interval in which you can enter the preset.

Medium

You can select the heat-transfer medium of the measured system by pressing the Select Medium

selection list.

If you select as the medium the Ethylenglycol or Propylenglycol ant-freeze mix, you will have to

enter the given anti-freeze mix concentration in the Concentration field. Then, the application will

recalculate the flow calculation using this value. Also, you can find under the Concentration field data

on the extent in which the concentration can be specified and entered.

Kv Direct Setup

In case the database of valves does not contain the valve you require you can measure the flow using

the Kv direct specification.

You can obtain the table with preset values and Kv values from the documentation of the respective

valve manufacturer.

6 | BC309062448253en-000301 © Danfoss | 2020.03

User Guide PFM 1000

Measuring (continuous)

Set Requested Flow

This function is used for displaying the actual/requested flow ratio at the measured valve (the lambda

quantity in the proportional balancing method). This way you can easily and quickly set up the

requested flow through the valve.

Once the value of requested flow is entered, the flow value in absolute units / the percentage ratio

from the previous paragraph will be displayed in the Flow field in the Measuring screen.

If you set up the requested flow value back to zero,the Flow field in the Measuring window will show

just the flow value in absolute units.

Medium Temperature

Specify the temperature of the medium in the measured system by pressing the Set

Temperatureselection list.

Fill in the temperature data manually in the Temperature field.

For water medium, the effect of the temperature on the flow calculation is negligible. If an anti-freeze is

selected as the medium, the temperature specification is necessary for the flow calculation!!!

BC309062448253en-000301 | 7© Danfoss | 2020.03

User Guide PFM 1000

Measuring (continuous)

Measure

position

Zero setting

position

Pressure Measuring Zero, Deaeration of Measuring Hoses

For measuring low differential pressures (under 500 Pa), it is necessary to reset the pressure measuring

of the measuring unit.

The reset function will be activated from the Sensor zero setting selection list. You will be led

through the reset procedure by gradually emerging pictures. By rotating the pressure reset knob to

the left, the pressure inlets are hydraulically connected and physically there is zero pressure difference

between them. In the pressure measuring unit, the zero pressure value is set. Then, turn the reset

button to its default position.

The connection of the pressure inlets can also be used to bleed the connection hoses of the

measuring unit. For media temperatures above

50 ° C, venting of less than 10 seconds is recommended to avoid unnecessary heating of the pressure

unit measuring circuits.

Quick Record

Selecting the Quick Record button navigates to a new window where additional details of the

recording such as the name or value of the required flow through can be added in the relevant fields.

The initial pressure value on the measured valve prior to recording can also be added. The last field in

the Quick Recording window can be populated with the name of the folder where the recording will

be saved, if left empty the record will be saved in a default location.

8 | BC309062448253en-000301 © Danfoss | 2020.03

User Guide PFM 1000

Projects Project Management

The project management in the PFM 1000 measuring instrument makes the work in the real

technology easier. You can prepare the project you need to measure directly in the PFM 1000

measuring instrument. You can then store two values for each branch of the project - the initial status

of the branch before balancing and its status after balancing. From the data of the whole project you

can then print a report on the project status before balancing and the report on balancing.

For the project measurement you select the respective project and branch. The PFM 1000 measuring

instrument will set the valve and its preset automatically and you are ready for measuring. The

measured data will be again stored automatically in the project’s correct fields.

You can find in the Projects introductory screen two tabs - Projects a Branches.

Project Window, Project Tab

In the Project tab, the input data of the project is entered or measured, such as Project name, File

name for storing projects, Project input pressure. If the Common valve is used in the project, change

the position of the sliding button. Then, you have to specify and enter the Valve type and Initial

preset. Once the system is balanced, you can also specify and enter the Balanced status preset.

BC309062448253en-000301 | 9© Danfoss | 2020.03

User Guide PFM 1000

Projects (continuous) Project Context Menu

After clicking on the button in the Project tab, a

selection list is displayed in which you can work

with projects - New, Open, Save, Mail, Save as,

Delete, Rename Project.

New

Once the New button is selected from the

selection list, a screen is opened in which

you specify and enter the new project name.

Confirm it with the OK button.

After that, the introductory Projects screen is

reopened which already shows the new file

name for storing the new project.

Open

Select from the selection list an already existing

project which you want to open.

Save

The selection list, Save - stores the existing

project with the existing name.

Save as

The Save as selection list, enter the new name

for storing the existing project, confirm with the

OK button.

Send Project via Mail

The Mail selection list. The existing project will

be exported in the .xml format and send via Mail.

In order to have this function available, you have

to have the Email client application set up in

your mobile device. Once this tab is selected, the

Send Mail Email client form is displayed where

the project file is already appended. Fill in the

recipient’s address, the Mail subject, text, and, if

appropriate, the signature. The Mail message will

be sent off after pressing the Send button.

Project renaming

The Rename Project selection list, specify and

enter the new project name for renaming,

confirm with the OK button.

Project Window, Branches Tab

Once the Branches tab is selected, a screen is

displayed where you can set up or measure

parameters of individual branches.

In the first field in this screen, you can specify

and enter the branch name, or, using an arrow

key, you can select the branch you want to be

displayed from the existing branches.

In other fields, you can enter the Valve used in

the given branch and specify and enter the Flow

requested. The other three fields contain the

measured quantities - Disposition pressure, Initial

flow, Actual flow. The other two fields are used

for specifying and entering two values - Initial

preset and Preset. The remaining fields are filled

in automatically.

10 | BC309062448253en-000301 © Danfoss | 2020.03

User Guide PFM 1000

Projects (continuous) Branch Context Menu

After clicking on the button in the Branches

tab, the Branch context menu selection list is

displayed. Here, you can work with branches:

Add branch, Rename branch, Relocate branch

up, Delete branch, Relocate branch down

Add Branch

The Add branch selection list: A screen is opened

in which you specify and enter the new branch

name and confirm with the OK button.

Rename Branch

The Rename branch selection list: A screen

is opened in which you specify and enter the

branch new name and confirm with the OK

button.

Move Branch up

The Move branch up selection list: You can

relocate the existing branch one place up in the

list of branches. You can verify this in the list of

branches by selecting the arrow at the branch

name.

Delete Branch

The Delete branch selection list: You can delete

the branch which is currently being edited.

Move Branch Down

The Move branch down selection list: You can

relocate the existing branch one place down in

the list of branches. You can verify this in the list

of branches by selecting the arrow at the branch

name.

BC309062448253en-000301 | 11© Danfoss | 2020.03

User Guide PFM 1000

Recording The PFM 1000 pressure unit is equipped with the function of independent periodical data recording.

This function may make the project diagnostics easier especially for irregular or long-time processes.

The recorded data contains the record description, date, time, selected valve, valve preset, medium,

temperature of the medium while recording, pressure and flow. Recordings can be read into the

mobile device and further exported and analysed in tables or diagrams. Last but not least, tables

and diagrams can be printed from the data exported like this and reports compiled on the hydraulic

system balancing.

You can find two tabs in the introductory Recordings screen - Record info and Record items.

Record Info Tab

After clicking on the button, the Record Info context menu is displayed where you can work with

records using respective tabs - Add new record, Open record, Save record as, Read record, Send

record via Mail, Delete record.

Record info Context Menu

New Record

From the New selection list, a screen is open where you can select what quantities you want to record.

The pressure recording is always mandatory and cannot be deactivated. Once the quantities to be

stored are selected, you select the medium and its initial temperature in the two subsequent fields.

The last two fields of this screen are designed for specifying and entering the valve on which you

are measuring and its preset. Confirm the entry by the Continue to record options button. Another

screen opens in which you specify and enter the text of the record location and description. The last

two fields are used for entering the interval in which the selected quantities should be measured

and saved, and how many times the record should be repeated. You can activate new recording by

clicking on the Start recording button. During the recording green indicator light is flashing with the

period 2 seconds.

During the data recording you can stop the recording with the following procedure:

1)

In the menu you will choose the option Read out the recorded

2)

After several seconds will appear the window and will ask you for the confirmation, that you want to

stop this

12 | BC309062448253en-000301 © Danfoss | 2020.03

User Guide PFM 1000

Recording (continuous) Open Record

From the Open record selection list, a new screen opens in which the list of records stored by the PFM

1000 application in the mobile device is shown. Once a record is selected in the list, the screen with

data of this record opens, and the data is available for further processing, e.g. to be sent off via Mail.

You can see on the Record Info tab the data from the previous paragraph; the recorded data can be

seen on the Record items tab.

Read Record

From the Read record selection menu, you can read a record from the pressure measuring unit. After

reading, a line opens into which you have to enter the name under which the record will be stored.

The file name extension is added automatically.

Send Record via Mail

In order to have this function available you have to have the Email client application set up in your

mobile device.

Once this tab is selected from the Send record via Mail selection list, the Send Mail Email client form

is displayed where the recordings file is already appended. The recording file format is .xml. Fill in the

recipient’s address, the Mail subject, text, and, if appropriate, the signature. The Mail message will be

sent off after pressing the Send button.

Delete Record

From the Delete selection list, a window is displayed asking whether or not you really want this record

deleted. The record is not deleted before the confirmation.

Record Items Tab

You can read a record from the measuring unit or open a record from the mobile device.

Once the Record items tab is selected, a screen appears where you can see the measured values

along with the time of recording.

BC309062448253en-000301 | 13© Danfoss | 2020.03

User Guide PFM 1000

Heating Engineering

Calculations

Heating engineering calculations allow and make easier solutions of partial tasks and calculations in

balancing hydraulic systems.

There are the following four calculations in the PFM 1000 application:

1. Preset calculation - calculates the valve preset for the flow requested in the current branch.

2. Pressure loss calculation - calculates the pressure loss on the valve for the requested flow and

preset.

3. Available pressure calculation - The “available pressure” is understood to be the minimum pressure

in the branch after the requested flow is attained for the given preset.

4. Valve authority calculation - The valve authority is the ratio between the pressure drop on the

fully opened control valve and the pressure in the whole branch in percent. This quantity helps in

dimensioning the valve and evaluating whether the given valve is suitable for the branch. For the

optimal use of the system regulation, this should be in the range of 50 up to 100%. When this value is

less than 50%, the valve is not dimensioned properly.

Press the Calculations in the application’s main menu. Select the requested valve and its preset in the

respective selection fields of the Calculations introductory screen.

Preset Calculation

It calculates the valve preset in the current branch for the requested flow.

Enter the requested flow in the first Preset calculation screen and confirm the entry with the OK

button. Confirm with the actual flow with Save current measured flow button in the next screen.

Close fully the control valve in the next screen. Confirm the measured pressure value with the Save

current disposal pressure button. Based on the measured values and the requested flow, the PFM

1000 application calculates the needed valve preset and displays the result in the Calculations

window in the Results section of the screen.

14 | BC309062448253en-000301 © Danfoss | 2020.03

User Guide PFM 1000

Heating Engineering

Calculations

Pressure Loss Calculation

Enter the requested flow in the first Pressure loss calculation screen and confirm the entry with

the OK button. The application calculates the pressure loss on the valve with the given preset and

requested flow and displays the result in the Calculations / Results section of the screen.

Available Pressure Calculation

Enter the requested flow in the first Available pressure calculation screen and confirm the entry

with the OK button. Confirm saving of the current measured flow with the Save button. Confirm

saving of the measured disposal pressure with the fully closed valve with the Save button in the next

screen. The result will be displayed in the Calculations / Results section of the screen.

BC309062448253en-000301 | 15© Danfoss | 2020.03

User Guide PFM 1000

Heating Engineering

Calculations (continuous)

Quick Records Database Selecting the Quick Record Database button navigates to a new window where previously saved

Valve Authority Calculation

Measure the disposal pressure in the first Valve authority calculation screen with the valve closed,

and confirm with the Save button. Measure the pressure in the next screen with the valve fully open,

and confirm with the Save button. The result will be displayed in the Calculations / Results section

of the screen.

recordings from the Quick Recording window can be browsed. Recordings are saved sequentially into

one file, unless previously specified to be saved elsewhere. The default file is saved in the Internal

Memory/ PFM 1000/Quick Records folder. An empty form is displayed upon opening of the Quick

Record Database. The required file can then be opened from the Quick Record Database menu using

the Open command. The rest of the Quick Record Database menu options are the same as in the

menu for standard recordings, which is described under the Recording section.

16 | BC309062448253en-000301 © Danfoss | 2020.03

User Guide PFM 1000

Maintenance Sintered Filters Replacement

For the correct function of the instrument, replace regularly the sintered filters in the pressure inputs.

Unscrew the pressure input using the 13 mm wrench, replace the clogged filters with a new set, screw

the pressure inputs back and tighten.

Battery Replacement

Unscrew the screws on the battery cover.

Remove the cover and insert new batteries following the technical parameters.

If you insert batteries of a different type, do not forget to change the battery type in the PFM 1000

application.

BC309062448253en-000301 | 17© Danfoss | 2020.03

User Guide PFM 1000

Troubleshooting

Safety and Device Disposal

Instructions

Fault Repair

The instrument cannot be turned on Check batteries, replace batteries

The green light indicator is fleshing with 1 second period

(0.5 of a second is on + 0.5 of a second is of f)

A slow response to the pressure change in inputs, the

measured value when the pressure inputs are free is higher

than 1 kPa

The pressure unit Bluetooth search is not functional, or the

PFM 1000 application is unable to connect with the pressure

unit after pressing Connect, refer to the picture on page 9

The application does not connect with the pressure unit in the

measuring window, the last picture on page 9, or the start or

record reading stops

I have entered the Always use selected device option and

want to measure with a different pressure unit.

The Bluetooth module initialisation is faulty. Turn the

instrument off and on.

The replacement of filters in the pressure inputs. Reset

pressure measuring.

Check the Mobile device setup. If you have the PFM 1000

pressure unit paired with the mobile device, unpair it. BLE

does not pairing of the Bluetooth device as the previous

version required; quite contrary, the pairing impedes the

connection making..

Turn off the pressure unit and on again, repeat the requested

application’s function.

Turn off the Bluetooth in the mobile device, turn it on again,

and repeat the requested application’s function.

In the PFM 1000 application setup go to the Se nsor setup

/ Always use B luetooth address. Here, you will see the BT

module address recorded by your option. Delete the address,

and the application will again search through all pressure

units.

Batteries

• Incorrect handling with batteries may cause spillage of the electrolyte and fire.

• When disposing of batteries, contact local authorities or dealers and get information on the

correct way of disposal.

• Do not expose batteries to heat and fire.

• Do not leave batteries in the car exposed to direct sunshine with windows and doors closed.

• Do not dismantle batteries and short-circuit them.

• Do not use batteries with the packing damaged.

• In case of incorrect replacement of batteries there is the threat of explosion.

• Only use the battery type recommended by the manufacturer for replacement.

Information for Users on Collection and Disposal of Used Devices and Batteries

This symbol on the device, packing or in appended documents means that the used electric and

electronic devices cannot be disposed of in the common communal waste.

For correct disposal, recovery and recycling of used products and batteries, please give them over to

respective collection locations in compliance with the national legislation and directions 2002/96/EC,

2006/66/EC and 2012/19/EC.

By ensuring the correct disposal of the product you can help prevent from occurring potential

dangerous impacts on the environment and human health that would threaten when the product is

not disposed of properly.

Commercial users in European Union may contact their dealers or suppliers.

18 | BC309062448253en-000301 © Danfoss | 2020.03

User Guide PFM 1000

Specifications

Nominal pressure range

1)

1,000kPa or 2,000 kPa Power supply

AAA Alkaline batteries or

NiMH rechargeable batteries

Max. Overpressure 120% of nominal pressure Power Consumption 20mA Bluetooth use

Linearit y and hysteresis error

Error for the pressure range

0 till 5 kPa after pressure zero

setting

Temperature error

Medium temperature

2)

0.15% from nominal pressure

range

± 50 Pa for nominal pressure

range 1 MPa

± 100 Pa for nominal pressure

range 2 MPa

0.25% from nominal pressure

range

Operating time

Zeroing of the pressure

measurement

Max. Aufzeichnung record

quantity

Max. valve and valve producer

quantity in database

-5 to 90°C Water Resistance IP65

According the used battery

type 40h Max.

Mechanical with hydraulic

bypass

2000

Unlimited

Ambient temperature -5 to 50°C Calibration Validity 24 months

Storage temperature -5 to 50°C Dimensions (l x w x d) 140 x75x47 mm

Wireless data transfer Bluetooth Low Energy 5.0 Weight 440 g

1)

Optional

2)

Measured at the e nd of measuring hoses, lengt h 1.5m, Hot wate r flows through PFM 1000 hydraulic pa rts during Pressure zero

procedure. Ma ximum time duration of zero ing when temperature of the m edium exceeds 50°C is 10 seconds.

BC309062448253en-000301 | 19© Danfoss | 2020.03

Danfos

produc

Al

Danfoss A/S

Heating Segment • heating

User Guide PFM 1000

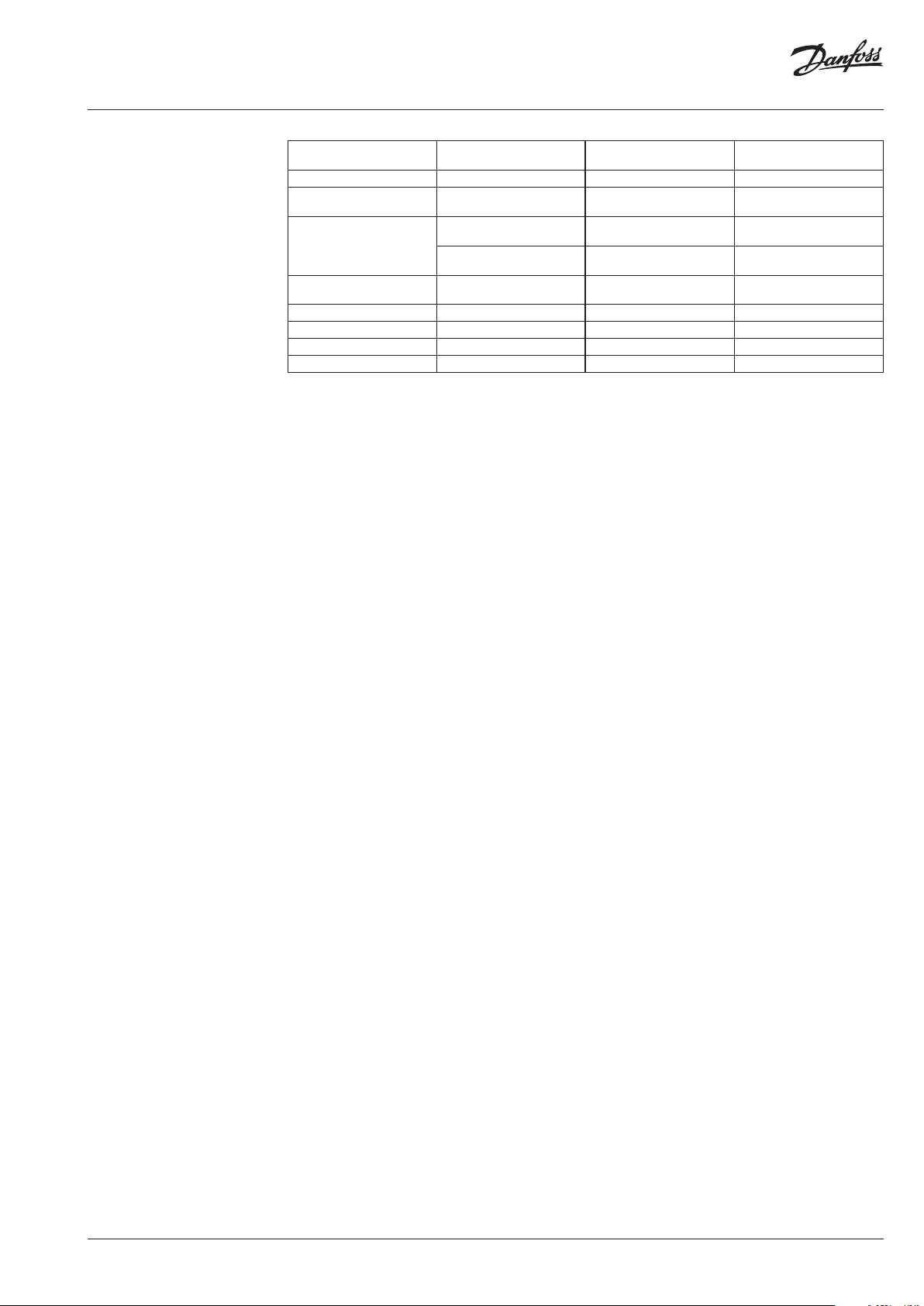

Part Name

部件名称

Pressure un it case

测量仪器套 装

Hydrauli c part of the press ure unit

测量仪器的液压件

Electr onic component s of the pressure uni t

测量仪器的电子元器件

Batteries

电池

Measuring needles

测量探针

Hoses

软管

Quick coup lings for the hose s

测量接头

Ada ptor R 21

转换器R21

Suitcase

套装盒

O: Indica tes that this hazar dous substance con tained in all of the h omogeneous ma terial for this par t is below the limi t requirement in GB /T 26572;

O: 表示该有害物质在该部件所有均质材料中的含量均在GB/T 26572规定的限量要求以下。

X: Indica tes that this hazar dous substance co ntained in at least o ne of the homogen eous material fo r this part is above th e limit requirem entw in GB/T 26572;

X: 表示该有害物质至少在该部件的某一均质材料中的含量超出GB/ T 26572规定的限量要求。

Pb/铅 Hg/汞 Cd/镉

O O O O O O

X O O O O O

O O O O O O

O O O O O O

X O O O O O

O O O O O O

X O O O O O

X O O O O O

O O O O O O

Hazardous Substances Table/有害物质含量表

Cr(VI)/

六价铬

PBB/

多溴联苯

PBDE/

多溴二苯醚

s can accept no responsibility for possible errors in catalogues, brochures and o ther printed material. Danfoss reserves the right to alter its products w ithout notice. This also applies to

ts already on order provided that such alterations can be m ade without subsequential changes being necessary in specications already agreed.

l trademarks in this material are p roperty of the respective companies. Danfoss an d all Danfoss logotypes are trademarks of Danfoss A/S. All rights r eserved.

.danfoss.com • +45 7488 2222 • E-Mail: heating@danfoss.com

© Danfoss | DHS-SRMT/SI | 2020.0320 | BC309062448253en-000301

Loading...

Loading...