Page 1

User Guide

PC tool

Software for addressing, calibration and

parameterization of Basic, Premium and Heavy

Duty gas detection units and gas detection

controller configuration

GDIR.danfoss.com

Page 2

User Guide | Danfoss Gas Detection - PC tool

Contents Page

1. Application possibilities of the software ...........................................................3

2. Scope of delivery .................................................................................3

3. Installation .......................................................................................3

4. Main window with short description ..............................................................3

5. Establish the connection..........................................................................5

5.1 Local bus ...................................................................................5

5.2 Field Bus = Danfoss Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

5.2.1 Display of possible error messages .........................................................8

5.2.2 Context menu in the Central Bus...........................................................9

6. Parameters.....................................................................................10

6.1 Addressing ............................................................................... 10

6.1.1 Addressing of gas detection controller ...................................................10

6.1.2 Addressing of expansion module ........................................................ 10

6.1.3 Addressing of gas detection units........................................................11

6.2 Measuring point MP parameters...........................................................12

6.2.1 MP parameters description .............................................................. 13

6.3 Relay parameters.......................................................................... 14

6.3.1 MP parameters description .............................................................. 15

6.4 System parameters........................................................................ 16

7. Calibration at the local bus...................................................................... 18

7.1 Register tab „Report“ ...................................................................... 18

7.2 Register tab „Zero“ ........................................................................ 19

7.3 Register tab „Gain“ ........................................................................ 20

8. Operating data .................................................................................24

9. History of the data logger....................................................................... 25

10. Notes and general information ................................................................27

2 | DKRCI.PS.S00.C1.02 | 520H12961

© Danfoss | DCS (MWA) | 2018.06

Page 3

User Guide | Danfoss Gas Detection - PC tool

1

Application possibilities of

the software

2

Scope of delivery

3

Installation

4

Main window with short

description

1. Addressing of the Basic, Premium and Heavy

Duty GD Units.

2. Calibration of gain and zero-point of the Basic,

Premium and Heavy Duty GD devices.

3. Configuration of application parameters of the

Basic, Premium and Heavy Duty GD devices.

The PC tool software has to be started from the

USB stick in order to use the available functions.

on the USB stick there are binary data files that

must be opened and/or changed - otherwise; no

functions can be perfomed.

Connect your PC via a USB cable to the adapter

that will automatically start to install the driver

for the USB-RS485 adapter. A virtual COM port

will be generated and this new port number

is required later for configuring the PC tool

Software.

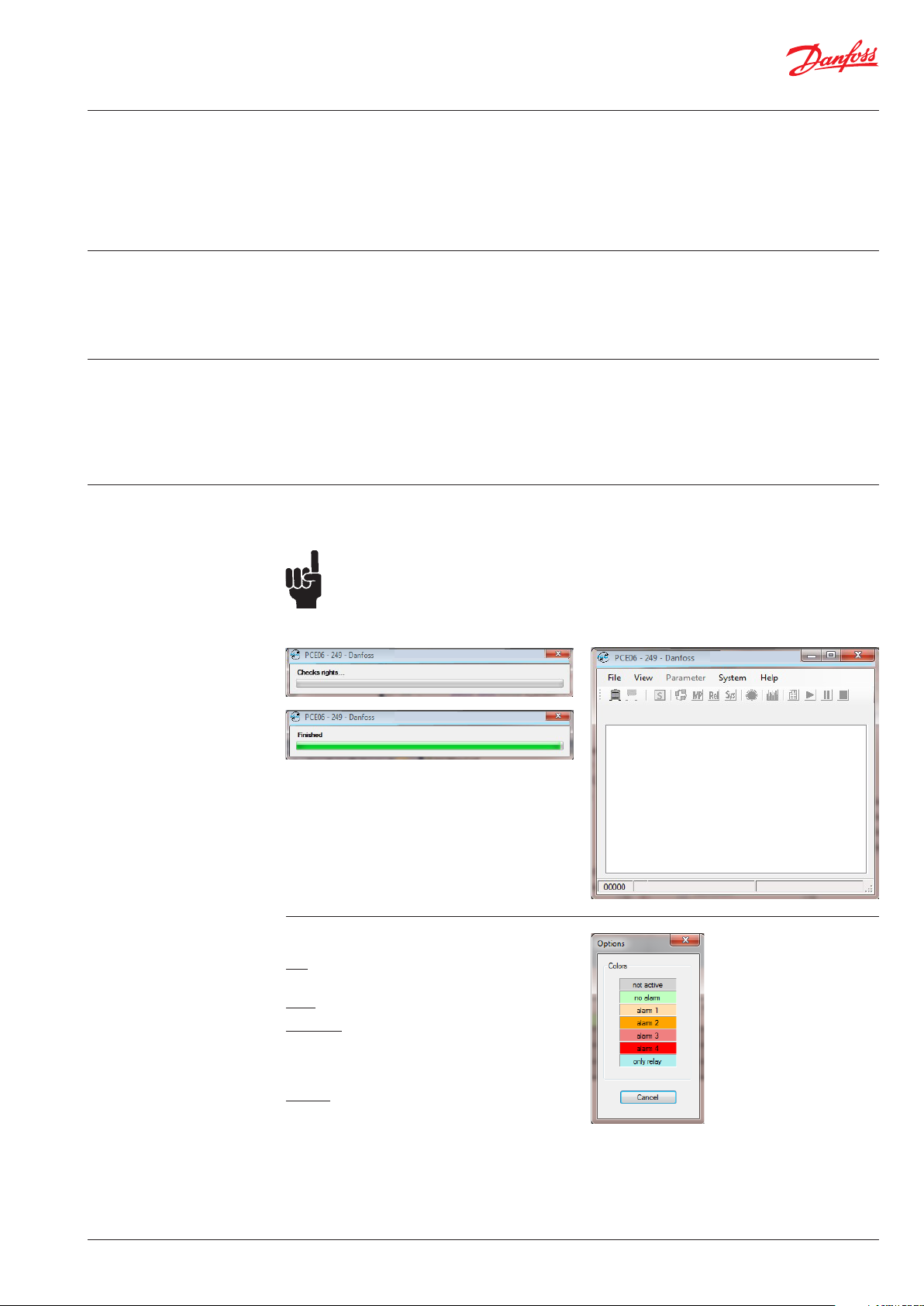

Before the main window starts, the User rights

are checked.

Attention:

If the PC Tool software is not started from

the USB stick or if the rights check fails,

the software will be closed again without

showing the main window.

4. Long-term recording on hard disk in .csv

format.

5. Monitoring of all measured values at a glance,

live.

6. Print of Calibration reports.

7. Gas detector controller configuration

The PC software is an alternative solution to the

Danfoss handheld service tool.

Please use the included USB-RS485 adapter to

physically connect the PC to the sensor.

It is not necessary to install the PC tool Software,

since all parts of the program will be started

during runtime.

The PC tool will run on WINDOWS 7, 8 and 10.

The main window opens only after successful

verification.

The company name and the name of the

software will appear in the window head.

Menu bar:

File has only one submenu ‘Exit’ for quitting the

application.

View has two subitems:

Language

Here you can change the display language.

British English, German and USA English are

currently available.

Options

All possible background colours are listed here

(see image to the right).

© Danfoss | DCS (MWA) | 2018.06

DKRCI.PS.S00.C1.02 | 520H12961 | 3

Page 4

User Guide | Danfoss Gas Detection - PC tool

4

Main window with short

description (continued)

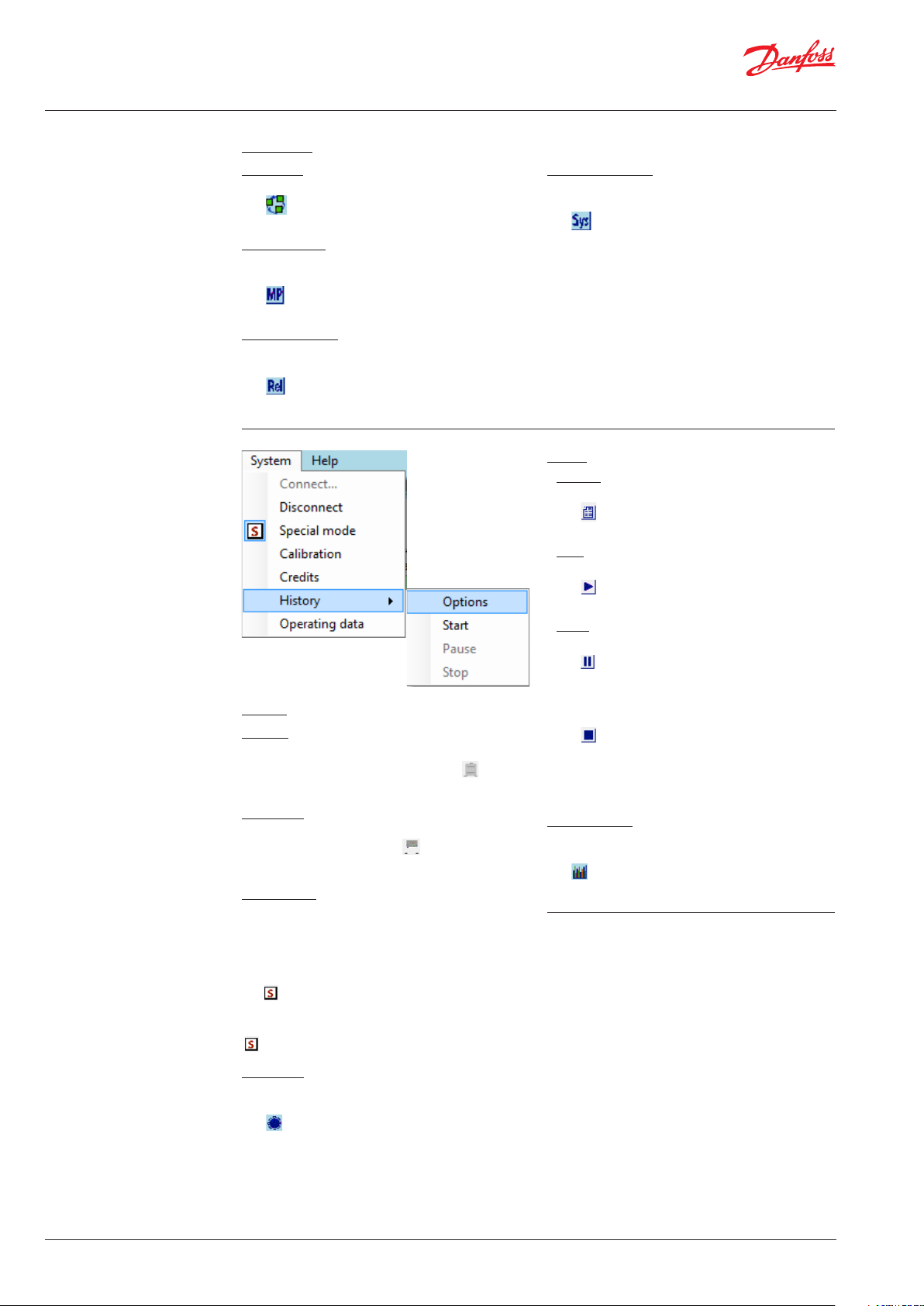

Parameters has four submenus:

Addressing opens the dialog for setting the

address of the connected device.

The icon on the toolbar stands for this menu

item.

MP Parameters opens the dialog where you can

manage the settings for the single measuring

points in the gas detection system.

The icon on the toolbar stands for this menu

item.

Relay Parameters opens the dialog where you can

manage the settings for the single relay outputs

in the gas detection system.

The icon on the toolbar stands for this menu

item.

System has seven submenus:

Connect opens the dialog where you can set the

serial COM port.

You can also access this dialog via the icon on

the toolbar.

Disconnect does not open a new dialog window,

but interrupts the connection to the COM port.

It is also possible to use the icon on the

toolbar to cut the connection.

Special mode does not open a dialog window

either, but sets the connected device into special

mode. If activated again, the special mode

is cancelled and the device will return to the

measurement mode.

The special mode can be switched on or off with

the icon on the toolbar.

If the device is in special mode, the colour of the

menu bar and toolbar changes to blue and the

icon will be displayed in the system menu.

Calibration opens the calibration dialog. The

functions of this window are specified in detail

later.

The icon on the toolbar stands for this menu

item.

System Parameters opens the dialog where you

can manage the system parameters of the gas

detection system.

The icon on the toolbar stands for this menu

item.

The menu items are only active if the connection

to the gas detection controller or gas detection

unit is established. The functions are specified in

the following chapters.

History contains four submenus:

Options starts the history dialog where you can

change all settings for data recording.

The icon on the toolbar stands for this menu

item.

Start - with a click on the start button the

recording is started.

The icon on the toolbar stands for this menu

item.

Pause - with a click on the pause button the

recording is interrupted.

The icon on the toolbar stands for this menu

item.

Stop - with a click on the stop button the

recording is stopped.

The icon on the toolbar stands for this menu

item.

The functions of the history window are

described in detail later.

Operating data opens the operating data dialog.

The functions of this window are described in

detail later.

The icon on the toolbar stands for this menu

item.

Under the toolbar, there is a system tray

displaying error messages concerning the

communication with the connected device.

The middle section of the main window varies

according to the connected device. This is

described in detail later.

At the very bottom of the status bar the following

information is displayed:

Software version of the master

The system tray where currently only the

information on the history is displayed.

Connected COM port with baud rate.

4 | DKRCI.PS.S00.C1.02 | 520H12961

© Danfoss | DCS (MWA) | 2018.06

Page 5

User Guide | Danfoss Gas Detection - PC tool

NH3

5

Establish the connection

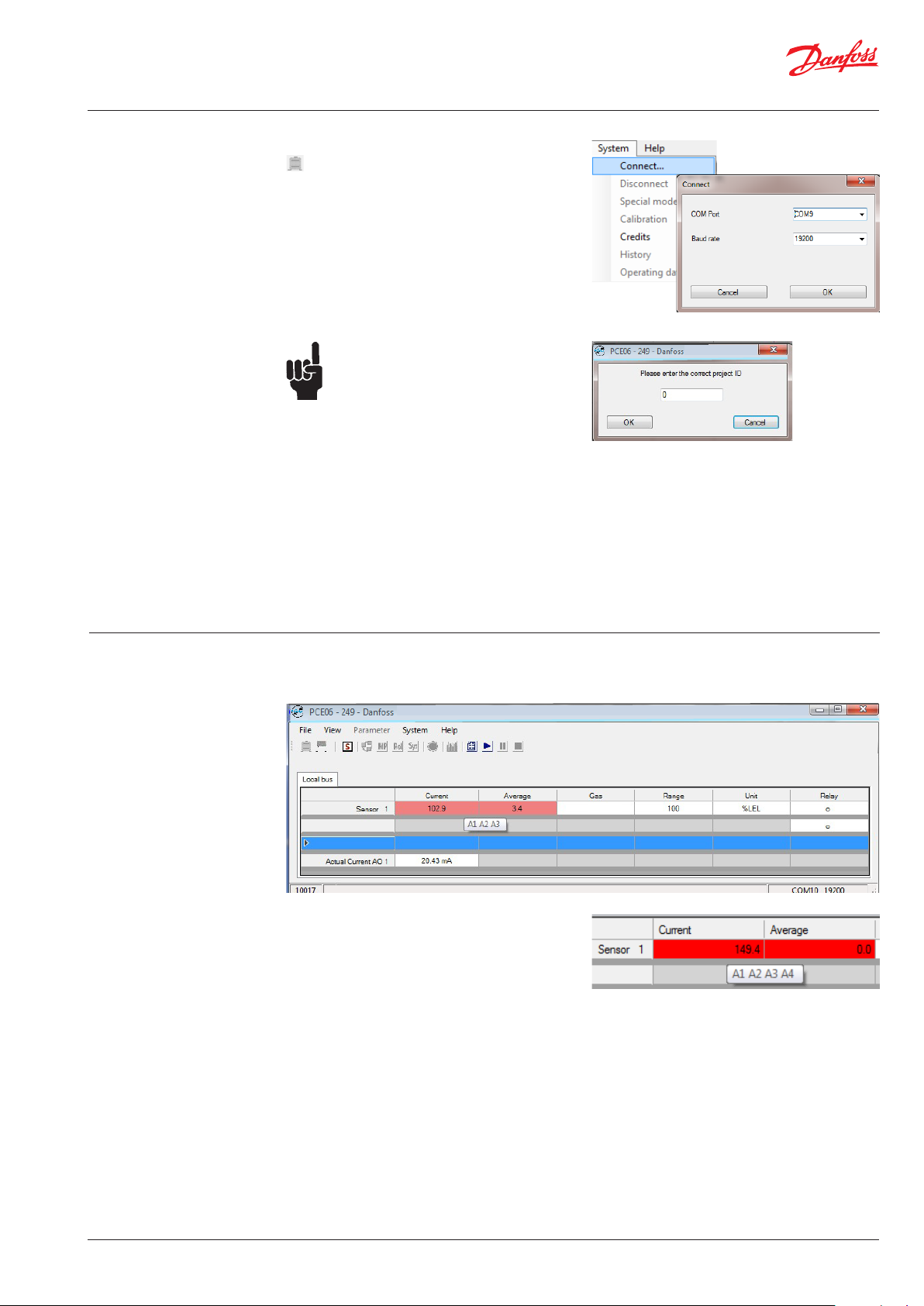

When you click on the Connect button or on the

icon, the application opens the dialog for

setting the serial port.

Only those COM ports that are active on the PC

are displayed. By clicking OK you can establish

the connection to the COM port.

The display in the main window varies

depending on the connected device.

Attention:

If the authorization key (password) of

the PC tool software differs from the

authorization key of the connected

device, a window will appear showing

the input screen for plant ID (password).

Password: 5468

The mask remains open until you

have entered the correct plant ID and

confirmed with OK or cancelled the input

by using the cancel button.

If you click cancel, the application will

close!

If you enter the correct plant ID, the

input screen will release the application

and you can use all functions to the full

extent.

5.1

Local bus

The Danfoss PC tool is connected via the COM

port to the devices of the IO class (Basic, Premium

and Heavy Duty).

A table with four lines appears in the middle of

the main window. The first column of the table

is a header column for each line. If the sensor is

activated, the text “Sensor X” will appear in this

column with X being a number between 1 and 4.

Otherwise the header column remains empty.

The following columns give more information on

the connected digital sensor head or the analog

input.

Current and average value:

The current and average values of the connected

digital sensor head or the analog input are

displayed here. If the alarm thresholds are set to

0, the alarm evaluation will not take place and the

readings will be displayed without alarm (usually

backlighted in green).

If the threshold values are set greater than zero at

the measuring point, a local alarm evaluation is

active and the alarms are marked with different

background colours. In addition, a tool tip

displaying the active alarms will appear, if you

click in the cell.

© Danfoss | DCS (MWA) | 2018.06

DKRCI.PS.S00.C1.02 | 520H12961 | 5

Page 6

User Guide | Danfoss Gas Detection - PC tool

5.1

Local bus (Continued)

Gas:

The gas type of the connected digital Sensor

head or the analog input is displayed here.

Range:

The measuring range of the connected digital

Sensor head or the analog input is displayed

here.

Unit:

The unit of the connected digital Sensor head or

the analog input is displayed here.

Relay:

The last column (Relay) shows the current status

of available relays of the connected device.

means that the relay coil is de-energized

means that the relay is energized.

The indicator reflects the actual energization

state of the relays, regardless of the

parameterization.

For devices with more than 1 input signal

(Premium) the read-back information (current

value) of the analog output signals appears in the

line 4.

It has already been converted to the current

range of 4-20 mA (measuring range 4-20 mA).

6 | DKRCI.PS.S00.C1.02 | 520H12961

© Danfoss | DCS (MWA) | 2018.06

Page 7

User Guide | Danfoss Gas Detection - PC tool

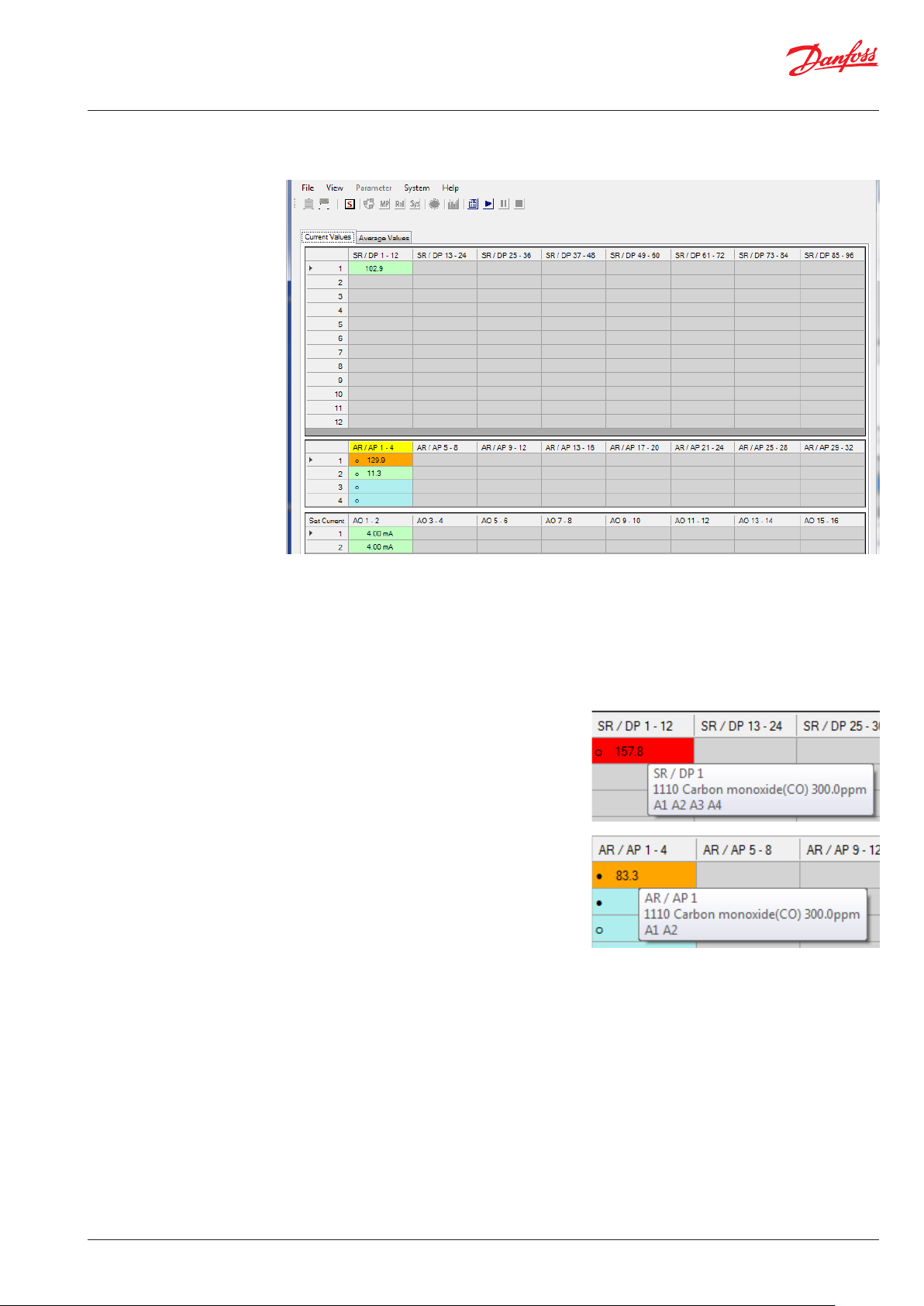

5.2

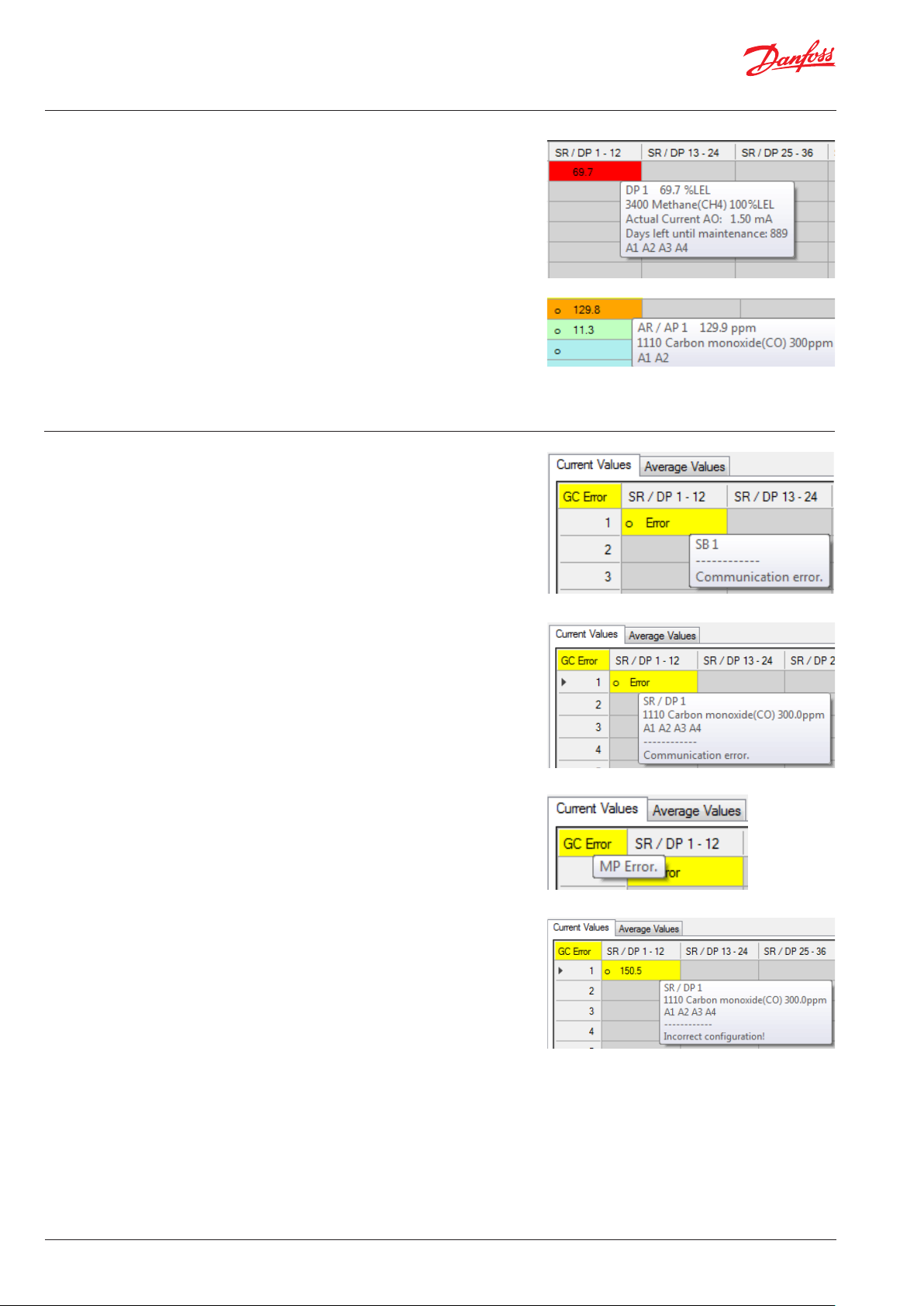

Field Bus = Danfoss Controller

The PC tool is connected via the COM port to the

Danfoss Controller.

In the middle of the main window two tabs

appear containing two tables and a block each.

The first tab shows the current values and the

second the averages. Both tabs are constructed

identically, so only the tab with current values is

described herein.

The first larger table shows the current values

of the 96 possible digital measuring point

addresses. The second table displays the current

values of a total of 32 possible analog measuring

point addresses.

or information concerning the relay status.

These icons may only appear if the relay is used

at this address. The icons reflect the energization

state of the relay, regardless of the parameter

setting operating/quiescent current or the relay

contacts used.

The alarm status is shown by the coloured

background of the cell.

The cells of inactive measuring points are grey

and empty.

The cells with inactive measuring points, but

with active relays are shown with light blue

background colour and the relay status.

The cells with active measuring points display

the actual value with different background

colours depending on the alarm status of the

measurement point. The definitions of the

colours can be looked up in Options.

In addition to the current value each cell contains

further information about the respective

measuring point: The following icons may be

displayed on the left next to the current value:

# means that this measuring point needs

maintenance. The maintenance for analog

measurement points is monitored and

reported by the EP module, so here the display

is simultaneous for all four possible analog

measuring points.

© Danfoss | DCS (MWA) | 2018.06

DKRCI.PS.S00.C1.02 | 520H12961 | 7

Page 8

User Guide | Danfoss Gas Detection - PC tool

5.2

Field Bus = Danfoss Controller

(Continued)

5.2.1

Display of possible error

messages

When the mouse pointer hovers over the cell, a

tool tip window pops up showing the following

additional information:

- Relay or measuring point address including the

current measuring value

- Nomenclature number with the gas type of the

connected measuring point

- Measuring range and unit of the connected

measuring point

- Active alarms

- Present current of the analog output

- Number of days left until next maintenance

The lower block displays the control information

(set point) of the 16 possible analog outputs.

It has already been converted to the output

current range of 0-22 mA (measuring range 4-20

mA).

A distinction is made between system errors and

measuring point errors.

Messages only concerning the measured value

will appear in the cell instead of the valid current

value. This also includes the communication error

to the sensor board or the digital sensor head.

Messages generated by the gas detection

controller will appear in the upper left corner of

the table. The messages are displayed in the form

of an error code. The detailed breakdown can be

read in the tool tip.

If there is an error at a measuring point, the gas

detection controller, too, will generate an error

message; therefore, the two messages always

occur together.

If the current value is displayed, but highlighted

in yellow, then there is a configuration conflict

between gas detection controller and gas

detection unit.

An automatic measuring point configuration was

deliberately omitted in order to obtain a high

level of security when configuring.

The installer must consciously enter the

configuration of each measuring point

accordingly.

8 | DKRCI.PS.S00.C1.02 | 520H12961

© Danfoss | DCS (MWA) | 2018.06

Page 9

User Guide | Danfoss Gas Detection - PC tool

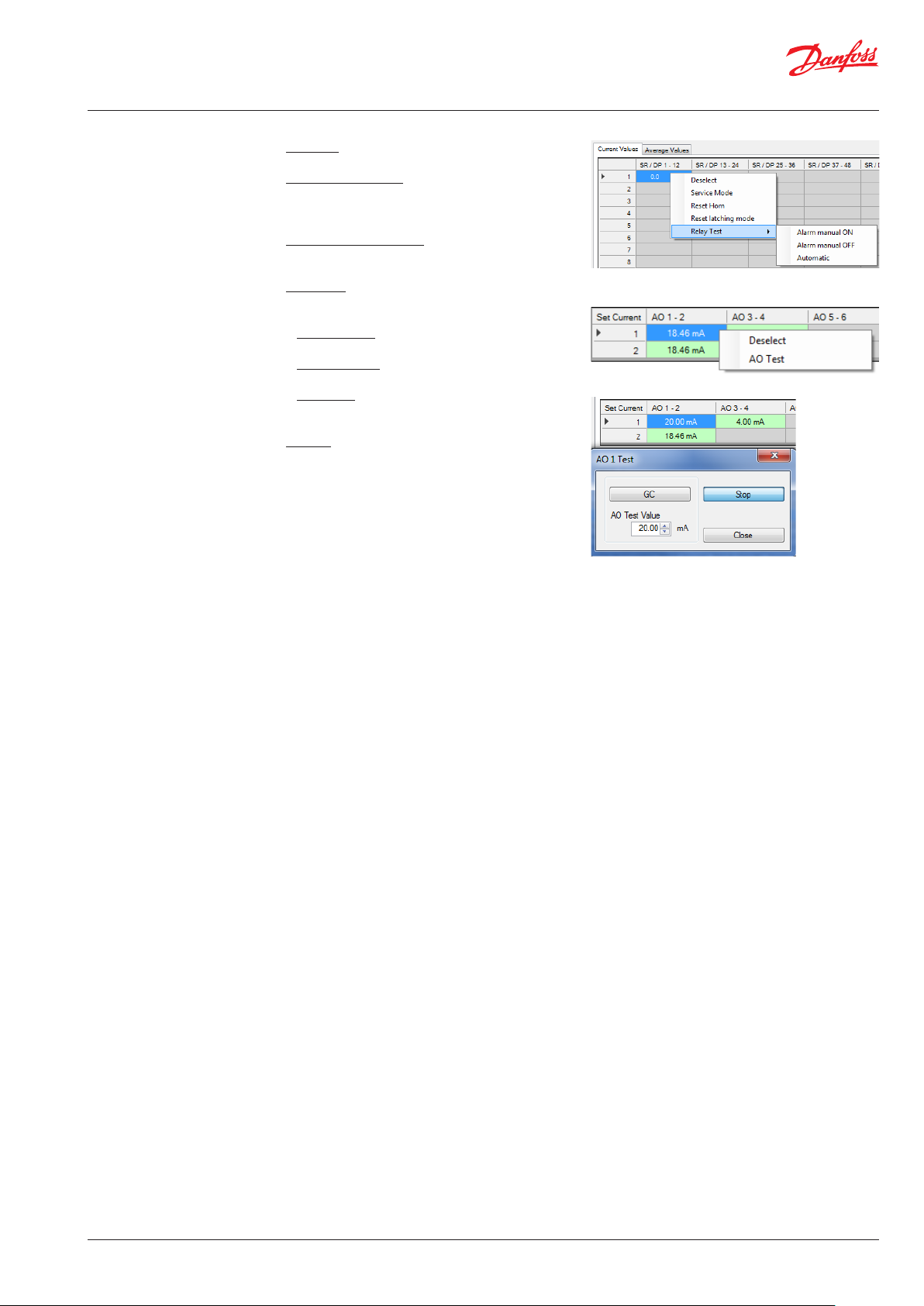

5.2.2

Context menu in the Central Bus

Deselect: The highlighted area is free again.

Acknowledge horn: Allows acknowledgment of

the horn with the address of the selected cell via

the software interface.

Acknowledge latching: Allows acknowledgment

of the latching selected address.

Relay test: Appears only if special mode is

activated and relays are available. It has three

osubmenus:

Alarm Test ON: Turns the relay into the alarm

state.

Alarm Test OFF: Turns the relay into the alarm-

free state.

Automatic: Turns the test function off. The relay

returns to its normal function.

AO test: Appears only if special mode and the

analog output are activated.

Allows testing of the analog output by setting a

fixed value.

- The left button sets the device, where the AO

should be tested; usually the software takes

over the setting automatically.

- The test value for the AO is set in the AO test

value field in the range of 0 - 22 mA.

- The upper right button starts or stops the

transmission of the test value.

- The bottom right button closes the window

for the AO test; if the transfer of the test value

is still active, it will be interrupted.

© Danfoss | DCS (MWA) | 2018.06

DKRCI.PS.S00.C1.02 | 520H12961 | 9

Page 10

User Guide | Danfoss Gas Detection - PC tool

6

Parameters

6.1

Addressing

6.1.1

Addressing of gas detection

controller

6.1.2

Addressing of expansion

module

Attention:

Due to the hard real-time behaviour the

parameter data can only be exchanged if

the device is in special mode.

Therefore, the parameter buttons are

only enabled in special mode.

This dialog opens via Parameters Addressing

or via the quick access toolbar with the icon .

The device to which the PC tool is connected to

The slave address of the gas detection controller

is assigned here.

Here the slave address is assigned to an

expansion module. It is required on the field

bus for communication with the central gas

via COM port will always be addressed. With

the Change button, the new address and any

configuration is taken over.

It is required on the M-Bus for communication

with an alarm master unit.

controller. Addresses from 1 to 7 are allowed,

since there is a maximum of seven expansion

modules.

In addition, the configuration of the expansion

module is set here.

1. column:

Number of analog input with respect to the

connected device. Corresponds to MP number

1 - 4 in MP Parameters.

2. column:

Four analog inputs can be set. They are available

at all times, so the addresses are always reserved

and the buttons AP (X) to AP (X+3) are always

active. The first four analog inputs can only be

set in the controller, so the AP addresses of the

expansion module with address 1 start in line 1

with address AP 5.

3. column:

Since there are only analog inputs, the buttons in

the third column always remain analog.

4. column:

Active: Here you can enable or disable the

analog inputs. Corresponds to the settings in the

MP Parameters menu.

5. column:

Gas type: Here you can select the gas type of the

connected analog sensor. Corresponds to the

settings in the MP Parameters menu.

6. column:

Measuring range: Here you can set the

measuring range of the connected analog sensor.

Corresponds to the settings in the MP Parameters

menu.

10 | DKRCI.PS.S00.C1.02 | 520H12961

© Danfoss | DCS (MWA) | 2018.06

Page 11

User Guide | Danfoss Gas Detection - PC tool

6.1.3

Addressing of gas detection

units

Here the slave address is assigned to a sensor

board. It is required on the field bus for

communication with the GC central device.

Addresses are allowed from 1- 96, because there

1. column:

MP number related to the connected device.

Corresponds to the MP number 1 – 4 in MP

Parameters, with Premium units having a

maximum of two measuring points.

Therefore, the P3 and P4 is always inactive and

greyed out.

can be a maximum of 96 digital measuring

points.

In addition; the desired configuration of the

sensor boards is set here.

2. column:

Up to two DP can be set. With each additional

measuring point the sensor board occupies

an additional address on the field bus. With

two activated measuring points the addresses

X, X + 1 are occupied. These addresses must

not be assigned to any other sensor board! The

superordinate controller can detect address

errors (multiple uses) only via incorrect bus data.

3. column:

Here you can set whether the measured values

should come from the digital sensor head or the

analog input.

4. column:

Active: Since each additional measuring point

occupies one address on the field bus, it is

assumed that this measuring point is physically

present and is therefore automatically activated

when addressed. However, it can be deactivated

manually.

5. column:

Gas type: Here you can select the gas type of the

measuring point. Double gas type configurations

are not allowed, therefore gas types already used

are deactivated in the selection list, displayed

greyed out and can only be used as analog

measurement points several times.

Corresponds to the setting in the MP Parameters.

6. column:

Measuring range: The measuring range of the

measuring point is set here. Corresponds to the

setting in the MP Parameters. It is essential that

it corresponds to the measuring range of the

sensor heads.

© Danfoss | DCS (MWA) | 2018.06

DKRCI.PS.S00.C1.02 | 520H12961 | 11

Page 12

User Guide | Danfoss Gas Detection - PC tool

6.2

Measuring point MP parameters

In the upper part of the dialog are all buttons

and input fields for the activation of a measuring

point:

1. MP address: The address of the measuring

point to be parameterized is entered here.

2. Selection field for the target

device where the parameters

have to be read.

Sb/PX/ MSx = Gas detection units

Ep Module = Expansion Module

GC central unit = Danfoss controller

Note: Parameters can only

be written into a device

directly connected to the PC tool.

3. Button for Digital / Analog:

If digital is set, the addresses 1-96 can be set for

the digital measuring points in MP Address. If

analog is set, the addresses 1-32 can be set for

the analog measuring points in MP Address.

Two buttons are placed in the middle of the

upper half of the dialog:

1. Read MP: Here you load the parameters of

each measuring point from the selected device in

the dialog interface.

2. Write MP: Here you can upload the settings

from the dialog interface into the connected

device. This button is inactive, if you have

selected a device one level down.

If you want to enter the same parameters for a

plurality of measuring points, you do not need to

upload them individually.

In the dialog, there is a button called Duplicate.

In this area there are also two input fields and

a button for specifying a start and end address.

The specified addresses are included when

transferring.

The Step button defines whether all measuring

points between the start and the end address

should be transmitted or only every second or

every third address.

All input fields must contain numbers.

If you make no or incorrect parameter entries

and you click on an Upload button, the fields

containing errors, are highlighted in yellow, an

info button appears and the device or file

function will not be executed (forcing a correct

and plausible input).

By clicking on the info button, a message

box pops up containing the detailed error

description.

12 | DKRCI.PS.S00.C1.02 | 520H12961

© Danfoss | DCS (MWA) | 2018.06

Page 13

User Guide | Danfoss Gas Detection - PC tool

6.2

Measuring point MP parameters

(Continued)

6.2.1

MP parameters description

On the top right there is the file area with two

buttons:

Export: With this button the parameters of all

measuring points are successively read without

showing them in the dialog interface. At the

start of transmission, the button changes its text

to Cancel, so you can cancel the transfer at any

time by clicking on the same button; but then

the read data will be lost. The remaining buttons

are deactivated until the transmission has been

completed.

When the reading is finalized, you are prompted

to save the file in the .csv format. If you cancel

the storage process, all read data will be lost. For

storing them in a file, they have to be read again!

At the end of the specified filename, the text, MP’

is appended to make sure that the measuring

point parameters are stored here.

Import: After clicking on this button, you are

prompted to select the file you want to load.

Once the correct file is selected, all measuring

point parameters are consecutively uploaded to

the controller. All buttons are disabled during

this process.

If an incorrectly structured file is selected, the

transfer will not be admitted.

© Danfoss | DCS (MWA) | 2018.06

In the middle of the dialog are all input fields for setting the measuring point parameters:

1. Active or Inactive indicates whether the measuring point should be activated (physically present).

2. Unlock or Lock indicates whether the measuring point should be (temporarily) blocked.

3. Gas Type: Here the gas type is assigned to the measuring point.

4. Measuring Range: Here the measuring range is assigned to the measuring point.

5. Threshold 1 - Threshold 4: Values of the alarm thresholds, each with its own function box for

- Alarm release at in- or decreasing concentrations

- Alarm release by current (CV) or average (AV) value.

6. Hysteresis: The measured value has to exceed or to fall below the alarm threshold by the

hysteresis value, so that the alarm will be deleted.

7. CV ON Delay Time (sec): Switch-on delay for the release by the current value in seconds (not

applicable for Heavy duty units, it is always 0)

8. CV OFF Delay Time (sec.): Switch-off delay for the release by the current value in seconds

9. Average Value Overlay / No AV Overlay: Average value overlay is only available for gas type CO.

10. Analog Output: Assignment of MP to one or two analog outputs

11. Alarm / Fault / Latching

- Assignment of relay to alarm (Alarm Relays AR 1 - 32 or Signal Relays SR 1 - 96)

- Setting of alarms in case of an error of the measuring point

- Alarm latching when the gas concentration is again < alarm threshold (requires manual

acknowledgment by the operator)

The information about the current operation is displayed at the very bottom of the status field.

DKRCI.PS.S00.C1.02 | 520H12961 | 13

Page 14

User Guide | Danfoss Gas Detection - PC tool

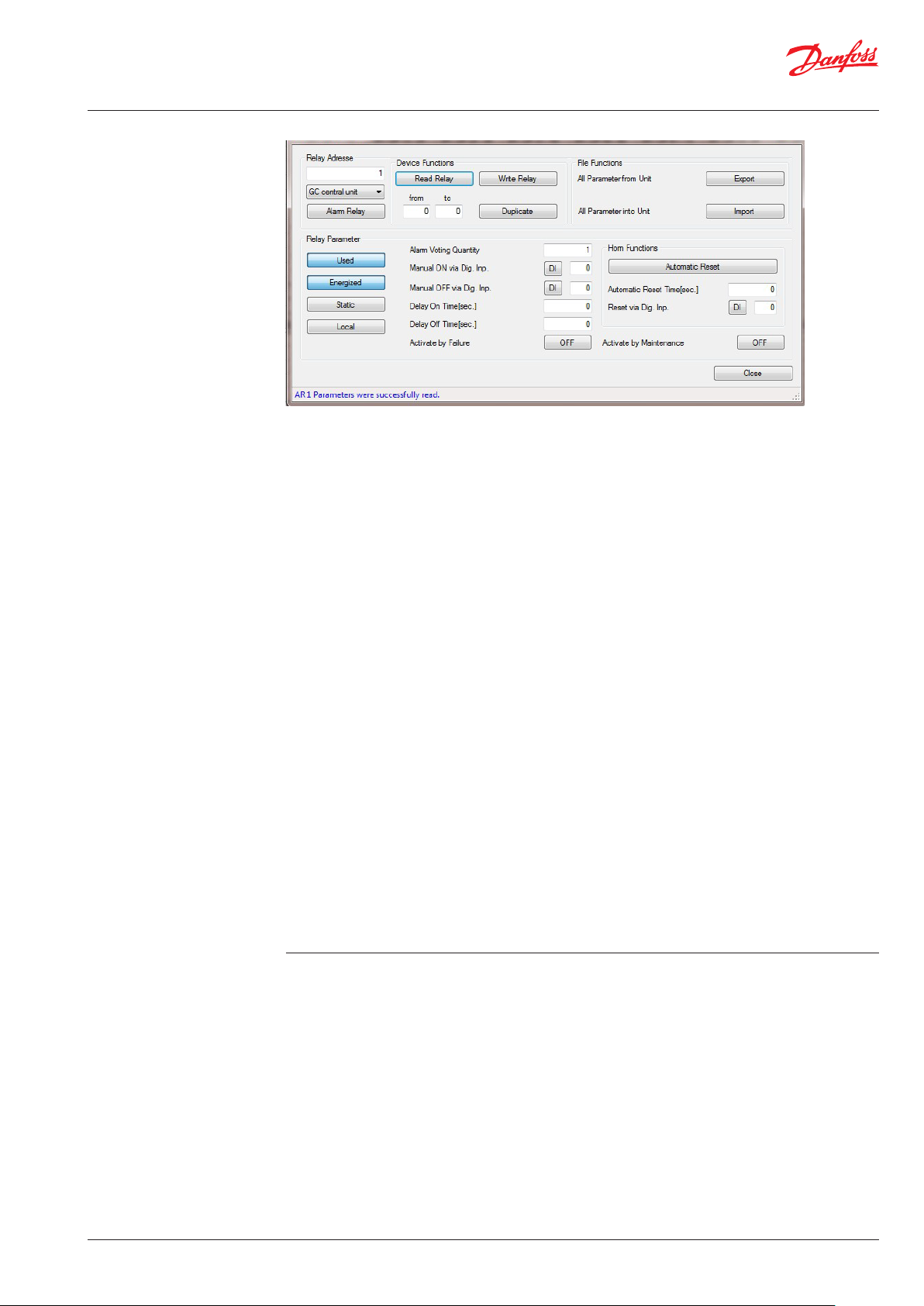

6.3

Relay parameters

Same as for the measuring point parameters, all buttons and input fields for activation of a relay are

located in the upper part of the dialog:

1. Relay Address: Address of the relay to be parameterized.

2. Selection field for the targetdevice from which the

parameters have to be read.

Note: Parameters can only be written in the device directly connected to the PC tool.

3. Button for Alarm Relay / Signal Relay

(only GC central unit):

If Alarm Relay is set, you can set addresses from 1 to 32 for the alarm relays in Relay Address. If

Signal Relay is set, you can set addresses from 1 to 96 for the signal relays in Relay Address.

In the middle of the upper half of the dialog there are two buttons:

1. Read Relay: Here you download the parameters of the corresponding relay from the controller

into the dialog interface.

2. Write Relay: With this button you can write the final settings into the controller, with the

parameters being stored under the specified relay address.

Same as for the measuring point parameters, there is also the Duplicate button and two input fields

for start and end address. Here the relay settings from the start to the end address are transmitted into

the controller.

With the Export button all relay parameters are read by the controller and you are prompted to save

the data in a CSV file. If you cancel the storage, all read data will be lost. The transmission can be

interrupted at any time the same way as for the measuring point parameters.

A previously selected file can be uploaded to the controller by means of the import button.

14 | DKRCI.PS.S00.C1.02 | 520H12961

© Danfoss | DCS (MWA) | 2018.06

Page 15

User Guide | Danfoss Gas Detection - PC tool

6.3.1

MP parameters description

Same as for the MP parameters, all input fields for setting parameters of a relay are located in the

middle of the dialog:

1. Used / Unused:

Indicates whether the relay is physically available.

2. Energized / De-energized: Operating or quiescent current

3. Static / Flashing: Static or flashing mode

4. Local / Remote:

Control mode of the relay:

Own alarm evaluation (local) or override by the GC central unit (remote)

5. Alarm Trigger Quantity: The relay switches only when the number of active alarms has been

reached. Only if all alarms are cleared, the relay switches off again.

6. External relay, manual ON / OFF:

BI(1-96) / DI(1-32) distinguishes between the digital inputs of Gas detection units and expansion

modules.

a.Manual ON via DI: External ON function via digital input

b.Manual OFF via DI: External OFF function via digital input

7. Delay On: Delay time for switching-on in seconds

8. Delay Off: Delay time for switching-off in seconds

9. Horn function:

a. Automatic Reset / Automatic Return: The text of the time specification adapts depending

on the selection.

b. Time for automatic reset / Time for automatic return: is specified in seconds.

c. Reset via DI: The horn is deactivated via the specified digital input DI.

(Distinction: DI = GC and EP modules, all other field modules = BI)

If no time is set (0) and no digital input selected (0), the horn functions are inactive.

10. ON / OFF at Failure: If ON is set, this relay will always switch together with the collective fault

message.

11. ON / OFF at Maintenance: If ON is set, this relay will switch together with the maintenance

message of the devices.

At the very bottom of the status field the information about the current operation is displayed.

© Danfoss | DCS (MWA) | 2018.06

DKRCI.PS.S00.C1.02 | 520H12961 | 15

Page 16

User Guide | Danfoss Gas Detection - PC tool

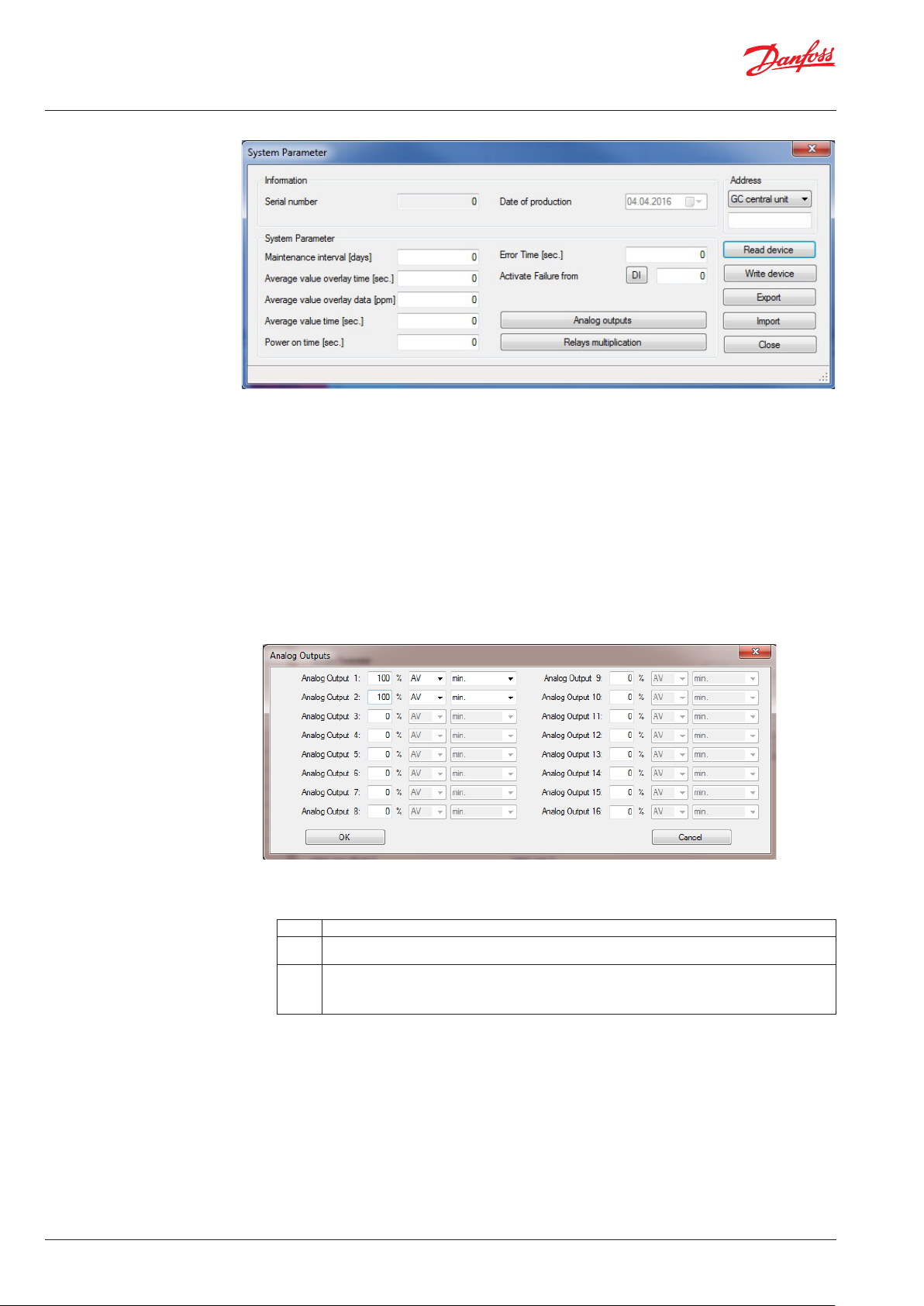

6.4

System parameters

The values on the the upper left of the window can only be read.

1. Serial number

2. Date of production

In the left middle area are the input fields for the system parameters:

1. Maintenance interval: The service interval is entered during each maintenance in the field

(current remaining days until maintenance).

2. Average value overlay: Averaging overlay in seconds and ppm

3. Average value time: Time base for averaging in seconds

4. Power On Time: Start delay of alarm evaluation after switching-on in seconds

5. Error time in seconds: Is currently not implemented.

6. Activate failure via DI: Activation of collective fault relays by external DI

7. Analog outputs: Button for opening an additional dialog for the analog outputs.

8. Here, a total of 16 available analog outputs can be configured.

The following values can be set per each analog output:

a. Scaling range:

b. Source for the values to be output: Current or average value.

c. Definition, which signal of all assigned MP will be output:

Min.(= minimum gas signal); average (= average calculation); Max.(= maximum gas signal)

With a click on the OK button the settings for the analog inputs are accepted internally.

The settings are written later together with other system parameters.

16 | DKRCI.PS.S00.C1.02 | 520H12961

0 Analog output not active

1 Analog output active, but is overridden by the GC central unit (Setting is not available in GC controller as it and

only it can control)

10-100 Analog output active

The value indicates the factor how the measuring range is scaled to 4-20 mA, e.g. 100% requires 100% of the

range scaled to 4-20mA

10% only requires 10% of the range scaled to 4-20mA

© Danfoss | DCS (MWA) | 2018.06

Page 17

User Guide | Danfoss Gas Detection - PC tool

6.4

System parameters (Continued)

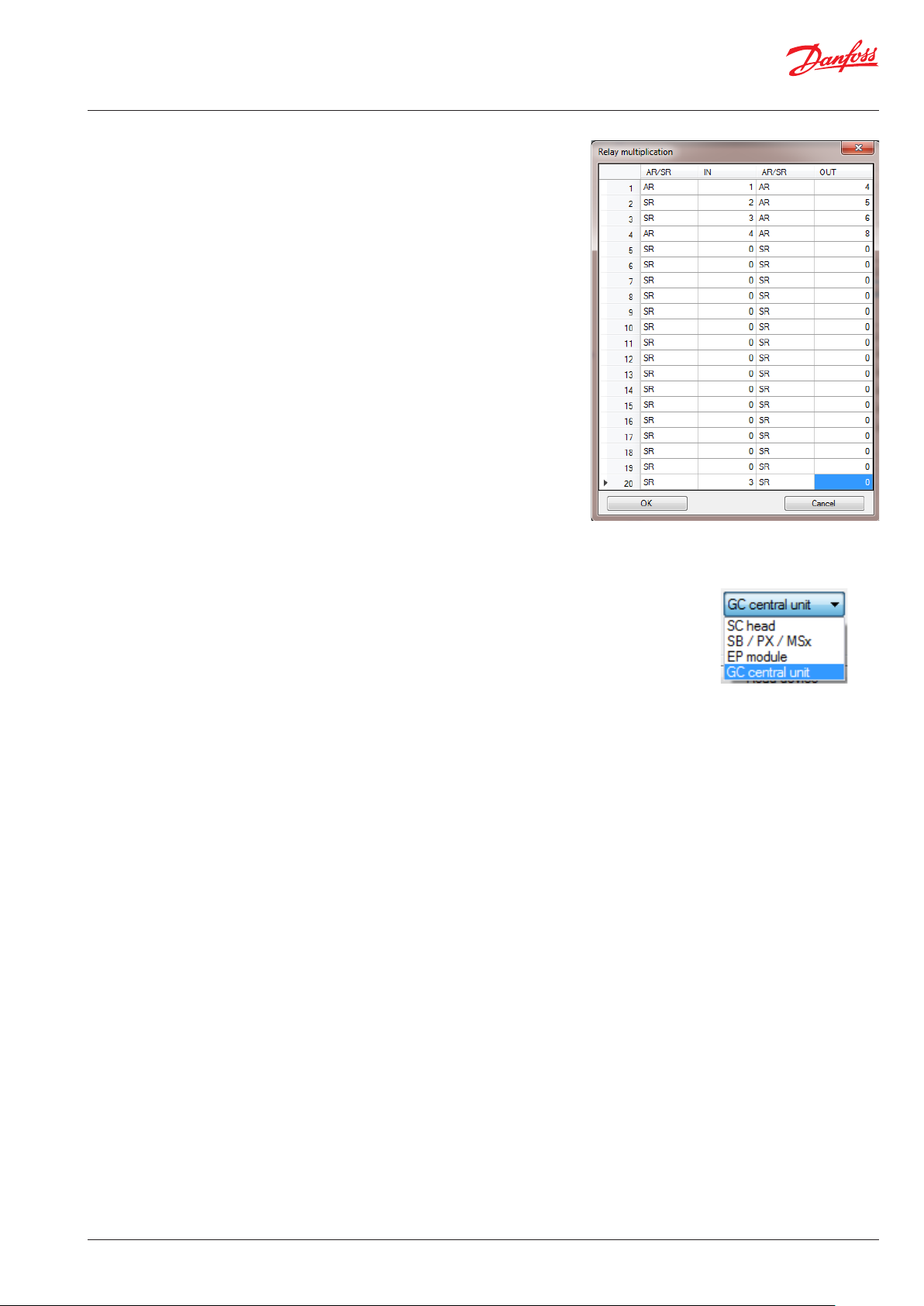

9. Relay Multiplication: is opening an

additional dialog for the relay multiplication.

This feature is available only in the Danfoss

controller.

With the relay multiplication table it is

possible to assign additional relay functions

to an alarm in the system. This corresponds

to one reproduction of the source relay per

entry.

The additional relay then follows the state

of the source relay, but uses its own

relay parameters to allow different needs

of the doubled relay. The source relay can

be configured e.g. as a safety function

relay in de-energized mode whereas the

doubled relay may be defined with flashing

function or as horn function relay.

There is a maximum of 20 entries (Controller)

and three entries (Premium units) for IN and

OUT relays. It is possible on the one hand to

multiply one relay to further relays

or on the other hand to double max. 15

relays (Controller). In the column IN (source),

the relay that has been assigned is set to an

alarm in MP Parameters.

In the column OUT (target) the additionally

required relay is entered.

Next in the dialog System Parameters:

At the right side is the control range with buttons:

1. Address: Just as with the two previous parameter dialogs the system

dialog contains the control range of the addresses with the difference

that system parameters can also be read from a sensor head.

2. Input field for the address the parameters should be read from.

Note: Parameters can only be written in the device directly connected to the PC tool.

Just as with the two previous parameter dialogs, there are two buttons “Read device” and “Write device”.

With these buttons the system parameters are read from the device into the dialog or written back

into the device.

Unlike the other parameter dialogs, there is no Duplicate button, because the system parameters only

exist once.

The System Parameters dialog also has two file buttons to save the settings into a file or to upload

them from a file.

Unlike the other parameter dialogs, the system parameters are saved from the dialog interface into a

CSV file and uploaded from the file into the dialog interface.

© Danfoss | DCS (MWA) | 2018.06

DKRCI.PS.S00.C1.02 | 520H12961 | 17

Page 18

User Guide | Danfoss Gas Detection - PC tool

7

Calibration at the local bus

7.1

Register tab „Report“

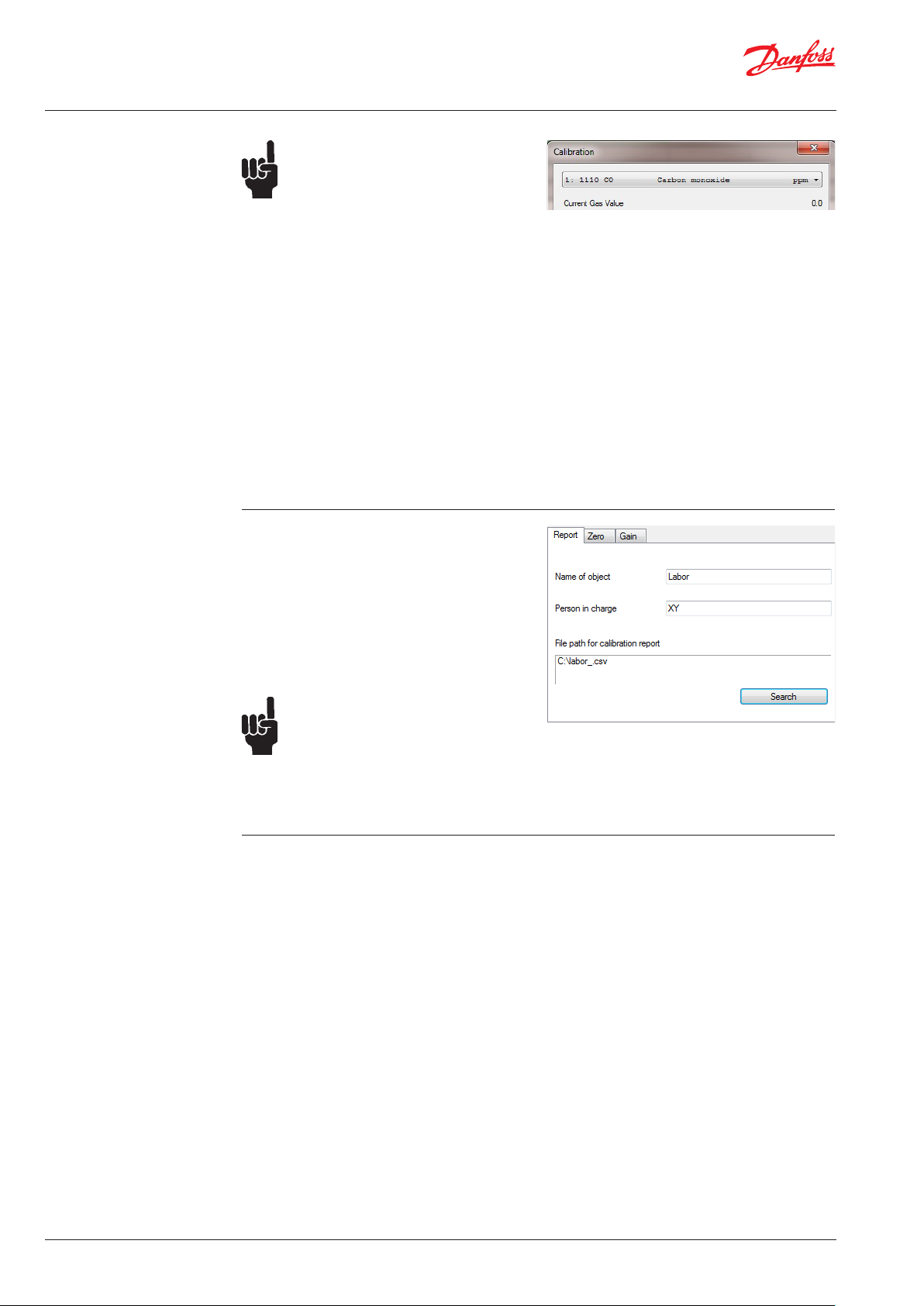

Attention:

The calibration function can only be

used when the device is in special mode.

Therefore, the menu item and the button

for calibration are only active in special

mode.

Using this dialog, the sensor heads can be

recalibrated. The calibration is carried out via the

local bus. Please connect the PC software via the

COM port to the sensor board.

In the upper part of the dialog is a selection box

where you can define the target head. Directly

under it the current value of the set head is

displayed.

In the middle of the dialog there are three

register tabs: Report, Zero and Gain. Directly

below that you can find the system tray with

information on the calibration process. At the

bottom right the close button which quit the

dialog.

The tab Report contains:

- Name of object

Here you can enter the name of the current

object.

- Person in charge

Here you can enter the name of the responsible

person.

- a box with the path to the location of the

calibration report. The file path can be selected

via the Search button.

Attention:

The entries in these fields are important

for the calibration, as this information will

appear in the calibration report.

The software prevents you from

switching to the calibration register tabs

before the object information fields have

not been completed.

18 | DKRCI.PS.S00.C1.02 | 520H12961

© Danfoss | DCS (MWA) | 2018.06

Page 19

User Guide | Danfoss Gas Detection - PC tool

7.2

Register tab „Zero“

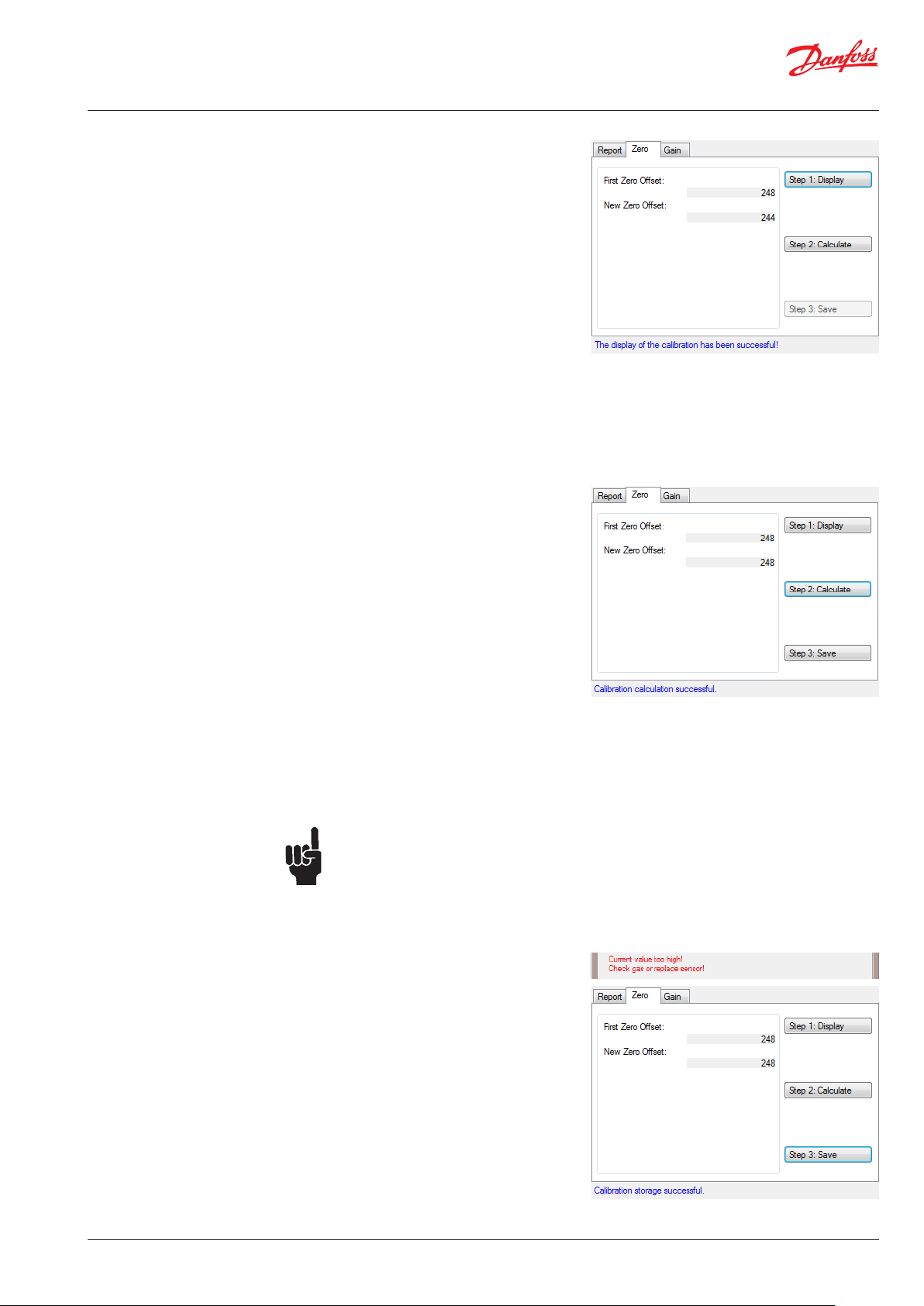

The tab Zero contains:

- First Zero Offset

Here the first zero offset is displayed.

- New Zero Offset

Is displayed as soon as it is successfully

calculated.

- Three buttons:

Step 1: Display

Step 2: Calculate

Step 3: Save

Prior to calibrating the zero point, you have to

display the current values by clicking on the

button Step 1: Display

If the values could be read successfully,

the corresponding message is displayed in the

system tray, and only then the button Step 2:

Calculate is enabled. The current values for the

display are permanently read, and the current

status is always shown in the window. No need

for pressing the button again.

When clicking on the button Step 2: Calculate

the zero calibration switches into the calculation

mode. The calculation of the new zero offset

is permanently executed and displayed in the

associated field. The values are therefore always

updated.

When the calculation has been successfully

completed, the current value in Current gas

value drops to 0 and the button Step 3: Save is

activated.

If you cancel the calibration now by closing the

dialog box or by changing over to another tab, a

message box will be activated asking if you want

to quit this function without saving. With the Yes

button you will definitely cancel the function,

with the No button you will return to the current

dialog.

If you cancel the function definitely or disconnect

the device, the recalculated zero offset value

is lost. After exiting the special mode, the last

stored zero offset is used again.

© Danfoss | DCS (MWA) | 2018.06

Note:

For calibrating the zero point, you need

zero gas or sample gas-free ambient air.

The measured value must not exceed

the 10% mark of the measuring range!

Sensors with higher deviation can no

longer be used.

In this case, the appropriate error message

appears in the system tray and the button “Step

3: Save” is disabled.

Use the button “Step 3: Save” for saving the

new zero offset which will be employed with

immediate effect. This can also be seen with

the display of all measuring points in the main

window. The permanent calculation mode has

finished now.

DKRCI.PS.S00.C1.02 | 520H12961 | 19

Page 20

User Guide | Danfoss Gas Detection - PC tool

7.3

Register tab „Gain“

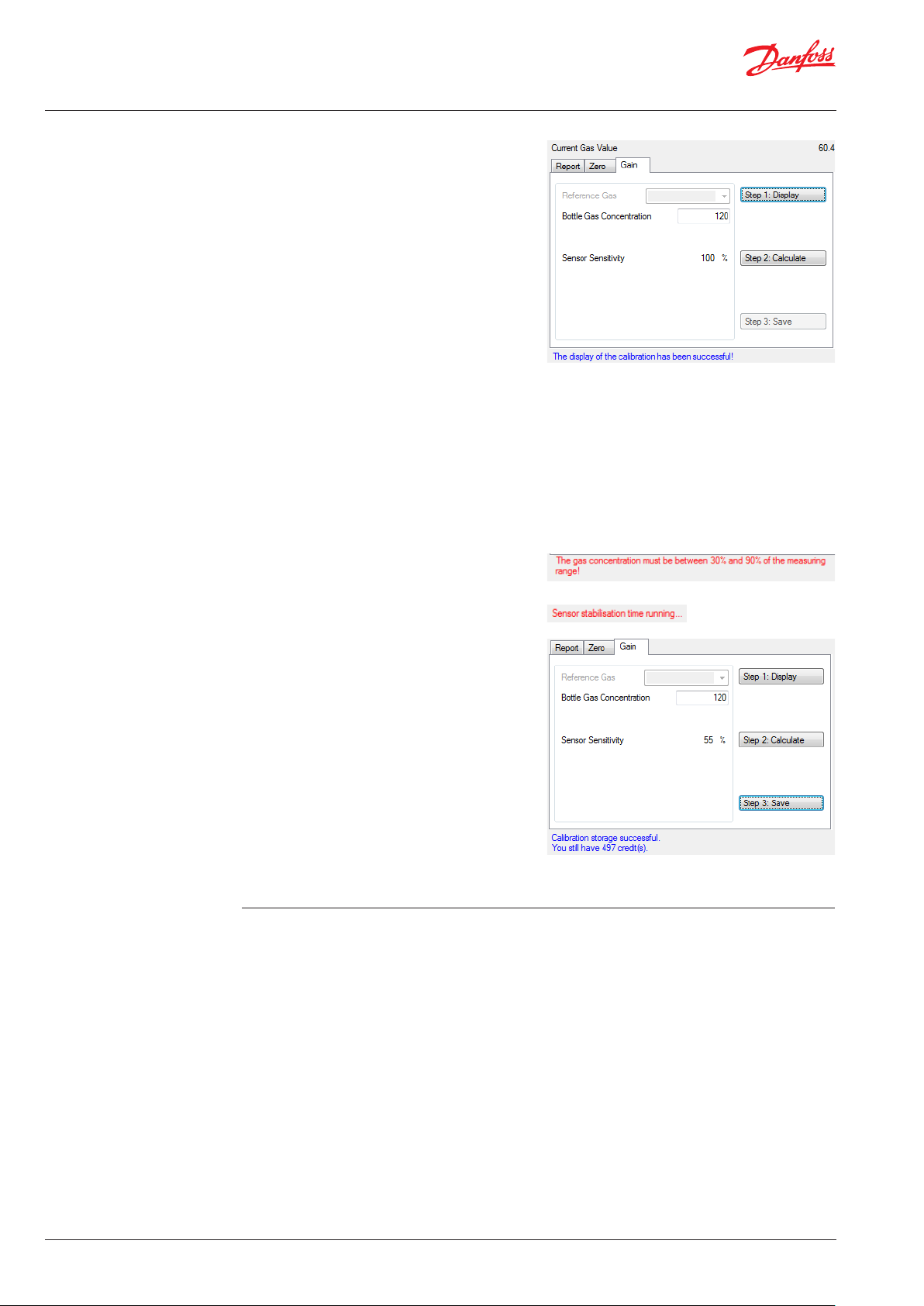

The tab Gain contains:

- Reference gas:

Currently not implemented, intended for the

calibration with reference gas.

- Test Gas Concentration

Enter the concentration of the test gas here.

- Sensor Sensitivity

Is displayed in %.

- Three buttons:

Step 1: Display

Step 2: Calculate

Step 3: Save

Prior to calibrating the gain, you have to display

the current values by clicking on the button

Step 1: Display If the values could be read

successfully, the corresponding message will be

displayed in the system tray, and only then the

button Step 2: Calculate is enabled. The current

values for the display are permanently read, and

the current status is always shown in the window.

No need for pressing the button again.

When clicking on the button Step 2: Calculate

the gain calibration switches to the calculation

mode. The calculation of the new gain is

permanently executed and is based on the test

gas concentration.

If the value of the entered test gas concentration

is too high or too low, an error message will

appear.

The current status for the calculation is displayed

in the system tray beneath the tab.

When the calculation has been successful, the

current sensor sensitivity is displayed, the actual

value in Current gas value accepts the value of the

test gas concentration and the button Step 3:

Save is enabled.

If you cancel the calibration now by closing the

dialog box or by changing over to another tab, a

message box will be activated asking if you want

to quit this function without saving. With the Yes

button you will definitely cancel the function,

with the No button you will return to the current

dialog.

If you cancel the function definitely or disconnect

the device, the recalculated gain factor is lost.

After exiting the special mode, the last stored

gain factor is used again.

20 | DKRCI.PS.S00.C1.02 | 520H12961

© Danfoss | DCS (MWA) | 2018.06

Page 21

User Guide | Danfoss Gas Detection - PC tool

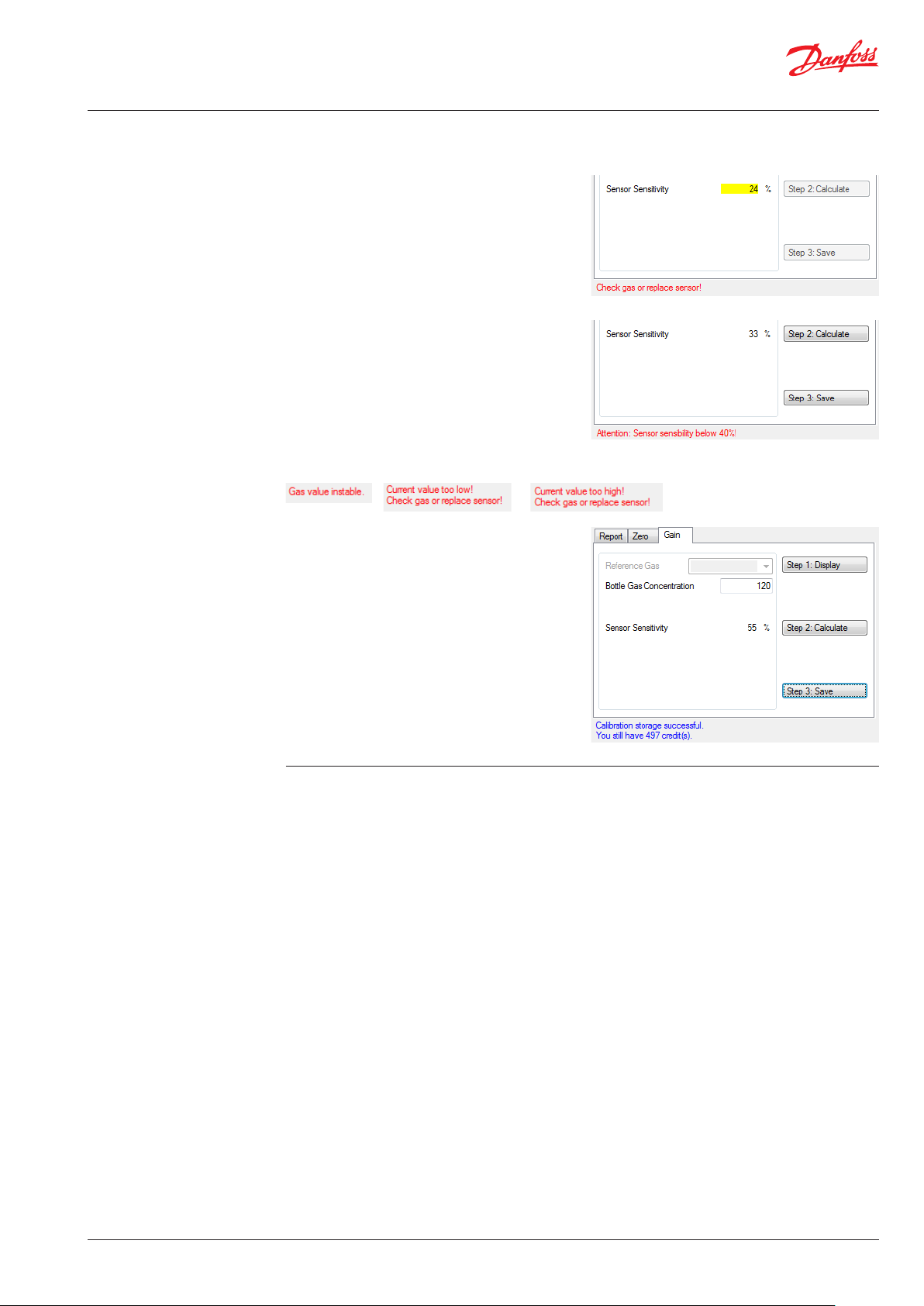

7.3

Register tab „Gain“ (Continued)

If the gain calibration was not successful, there

might be several reasons:

- If the sensor sensitivity is below 30%, the

calibration of the gain is cancelled. The sensor

is either too old and you can no longer calibrate

its gain, or there is no calibration gas present

on the sensor. Storage is not allowed in this

case, therefore, the buttons are disabled.

- If the sensor sensitivity is higher than 30%, but

lower than 40%, the gain is calibrated, but it is

noted that the sensor is defective; furthermore,

you should check if calibration gas is present on

the sensor.

- The calibration of gain is not possible with the

following error messages either.

Use the button Step 3: Save for saving the

new gain factor which will be employed with

immediate effect. This can also be seen with

the display of all measuring points in the main

window. The permanent calculation mode has

finished now.

© Danfoss | DCS (MWA) | 2018.06

DKRCI.PS.S00.C1.02 | 520H12961 | 21

Page 22

User Guide | Danfoss Gas Detection - PC tool

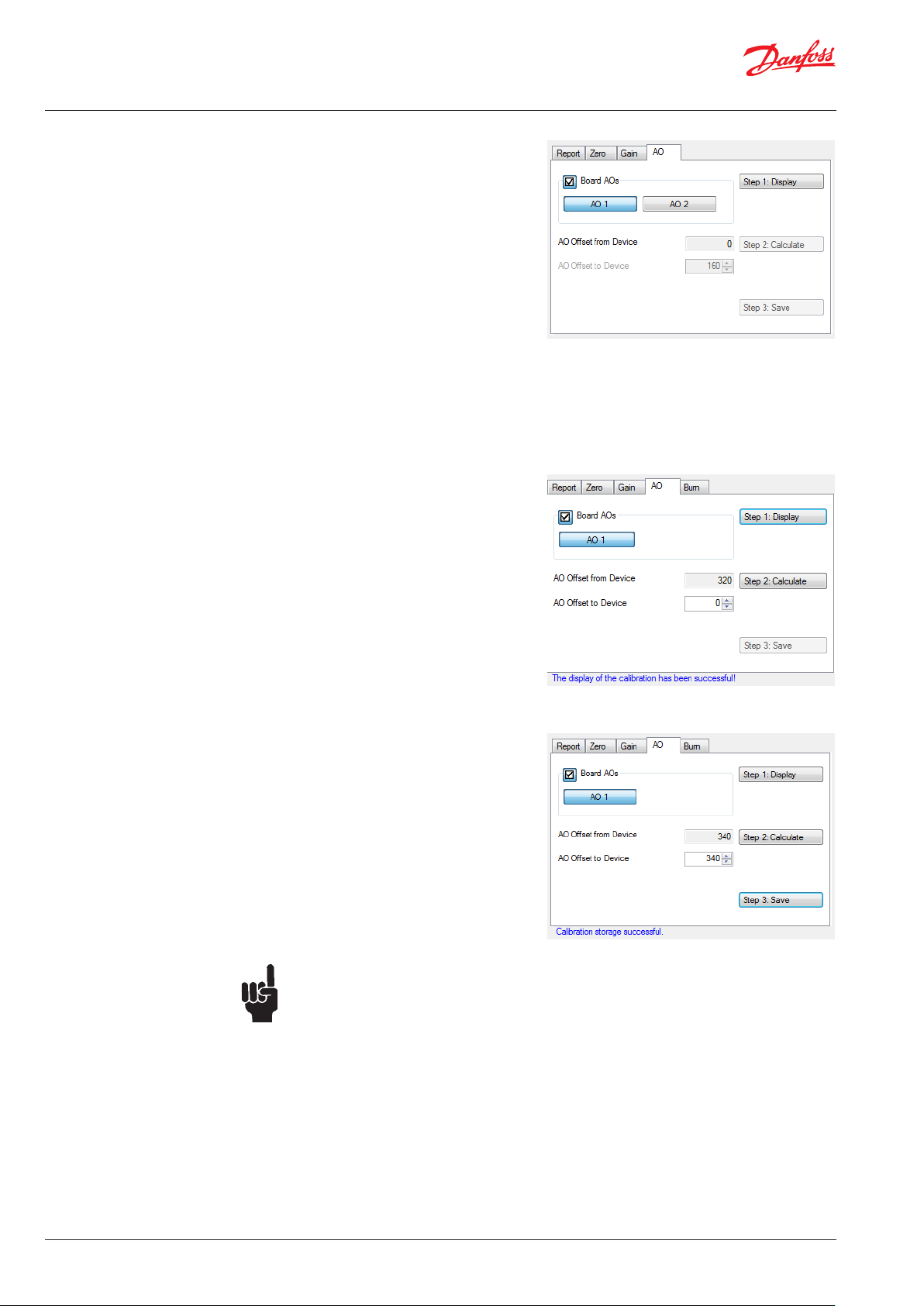

7.4

Zero-point calibration of the

analog output

The tab AO contains:

- Board AOs

Here you can set whether the analog output of

the connected device should be calibrated. If

the box is not ticked, the device, in which

the AO should be calibrated, will be set via the

selection field of the measurement points.

- AO1 and AO2:

Depending on the connected device type

there is either only the AO1 or additionally the

AO2.

- AO Offset from device

Here the current offset of the analog output is

displayed.

- AO Offset to device

Here the new offset is set in the range of 160 to

700 (AD converter value)

- Three buttons:

Step 1: Display

Step 2: Calculate

Step 3: Save

Prior to calibrating the AO zero-point, you must

display the current values by clicking on the

button Step 1: Display. If the values could be

read successfully, the corresponding message

will be displayed in the system tray, and only then

the button Step 2: Calculate will be enabled. The

current values for the display are permanently

read, and the current status is always shown in

the window. No need for pressing the button

again.

When clicking on the button Step 2: Calculate

the AO zero-point calibration switches to the

calculation mode. The calculation of the new

signal zero offset is permanently executed and

displayed in the corresponding box. The values

are therefore always updated.

When the calculation has been successful, the

actual value is not added to it and the button

Step 3: Save is enabled.

If you cancel the calibration now by closing the

dialog box or by changing over to another tab, a

message box will be activated asking if you want

to quit this function without saving. With the Yes

button you will definitely cancel the function,

with the No button you will return to the current

dialog.

If you cancel the function definitely or disconnect

the device, the recalculated zero offset is lost.

After exiting the special mode, the last stored

zero offset is used again.

Note:

To calibrate the analog output zero, you

need an amperimeter to change it until

the value corresponds to the desired

zero.

If the calculation was not successful, the

corresponding error message appears in the

system tray and the button Step 3: Save is

disabled.

With the Step 3: Save button the new zero offset

is stored and will be used immediately.

22 | DKRCI.PS.S00.C1.02 | 520H12961

© Danfoss | DCS (MWA) | 2018.06

Page 23

User Guide | Danfoss Gas Detection - PC tool

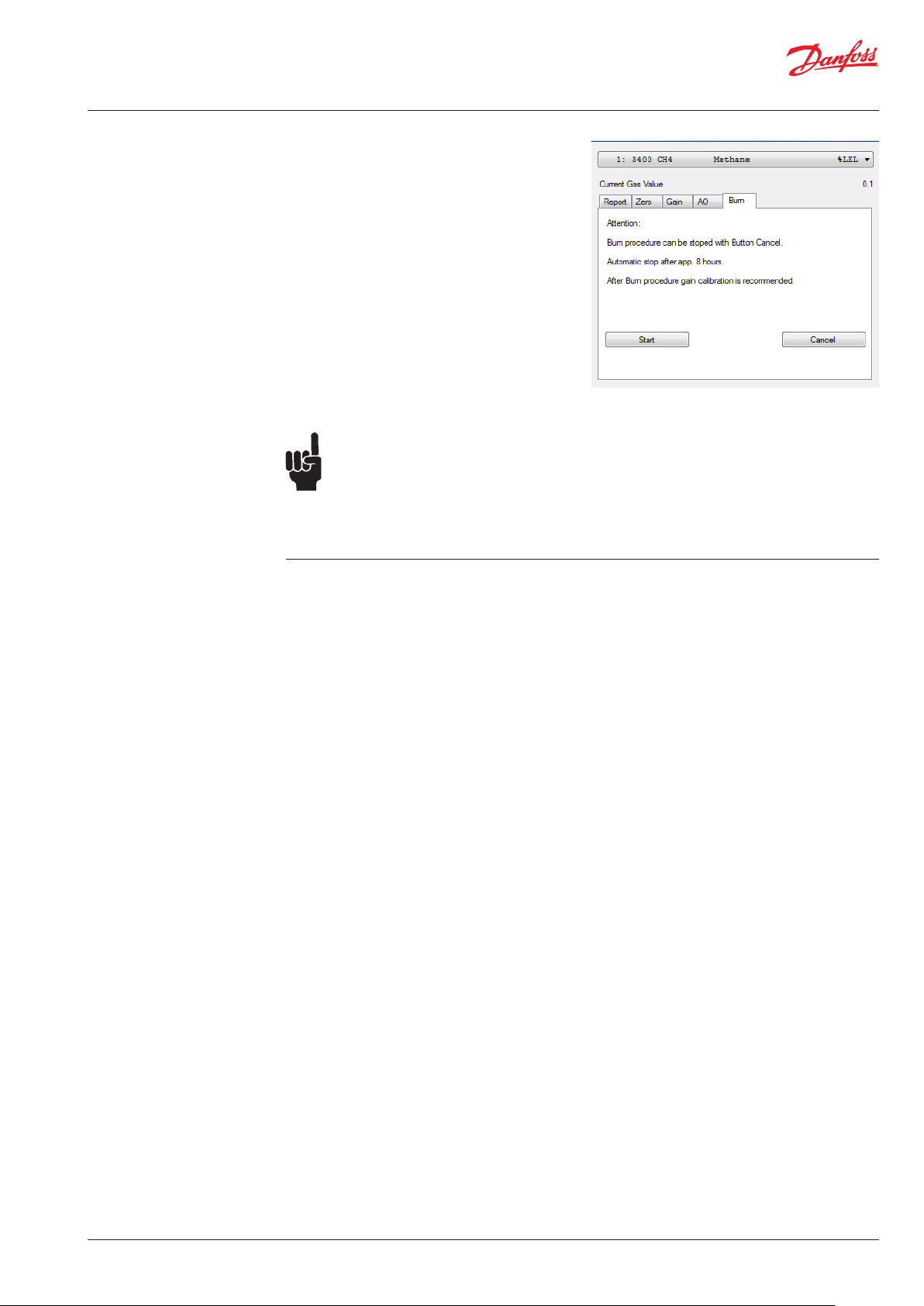

7.5

Register tab “Burn” (selfcleaning by burning)

This tab Burn is for starting the process of heating

a pellistor sensor up for self-cleaning.

- The Start button sets the command for

burning free.

- The Cancel button interrupts the burning

process.

The buttons are only enabled for Pellistor sensors.

The function is for heating catalytic bead sensors

(pellistors) up to a higher temperature for a

certain time in order to remove any residues on

the heating wire.

It is used if the sensors show too low sensitivity

on some or all combustible gases due to dirt on

the filament.

Before starting the burn-off, a combustible test

gas - the best would be hydrogen - has to be

applied to the pellistor with a calibration cap in

order to intensify the combustion.

Note:

The burning cannot improve or undo the

natural aging!

The operation can be stopped with Cancel at any

time.

© Danfoss | DCS (MWA) | 2018.06

DKRCI.PS.S00.C1.02 | 520H12961 | 23

Page 24

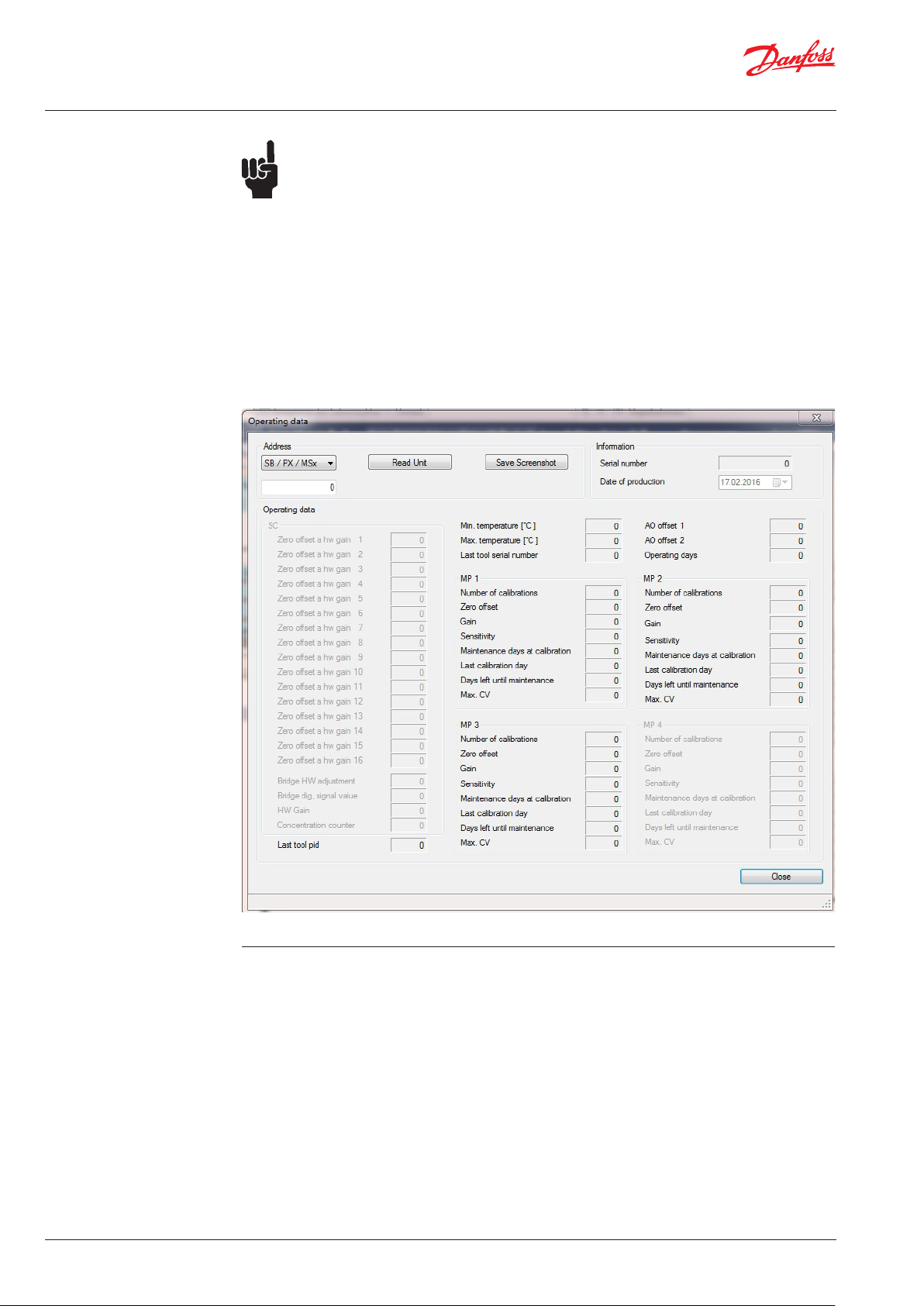

User Guide | Danfoss Gas Detection - PC tool

8

Operating data

Note:

The operating data can only be

exchanged with the device if the device

is in the special mode. Therefore, the

operating data buttons are only enabled

in the special mode.

At the top left of the dialog there is the address

activation area. It contains the following entry

options:

- Selection box Device Type: Device type the

operating data are read from.

- Selection box Address: Address the operating

data are read from.

Just as for the Parameters you can read out the

operating data across hierarchical levels.

- Read Unit and Write file. The function for

storing the file is not yet implemented.

The information area concerning the device is

located to the right of the address field.

- Serial number

- Date of production

Grey fields are not valid for the read-out device.

The large operating data area is divided into

several sections.

SC area

Here only the operating data of a head are

displayed.

• Concentration counter

MP x

Here the operating data are displayed based on

a measuring point.

• Number of calibrations

• Zero offset: current zero offset.

• Gain: current gain

• Sensitivity: compared to new condition

• Maintenance days at calibration

• Last calibration day: operating day at the last

calibration.

24 | DKRCI.PS.S00.C1.02 | 520H12961

• Days left until maintenance: Number of days

remaining until the next maintenance

• Max CV: Maximum current value

All other fields are displayed along with each

device:

• Last Tool PID: Marking of the tool the last

calibration was performed with.

• Min. temperature

• Max. temperature

• Last tool serial number

• AO offset x

• Operating days

The Close button closes the window.

© Danfoss | DCS (MWA) | 2018.06

Page 25

User Guide | Danfoss Gas Detection - PC tool

9

History of the data logger

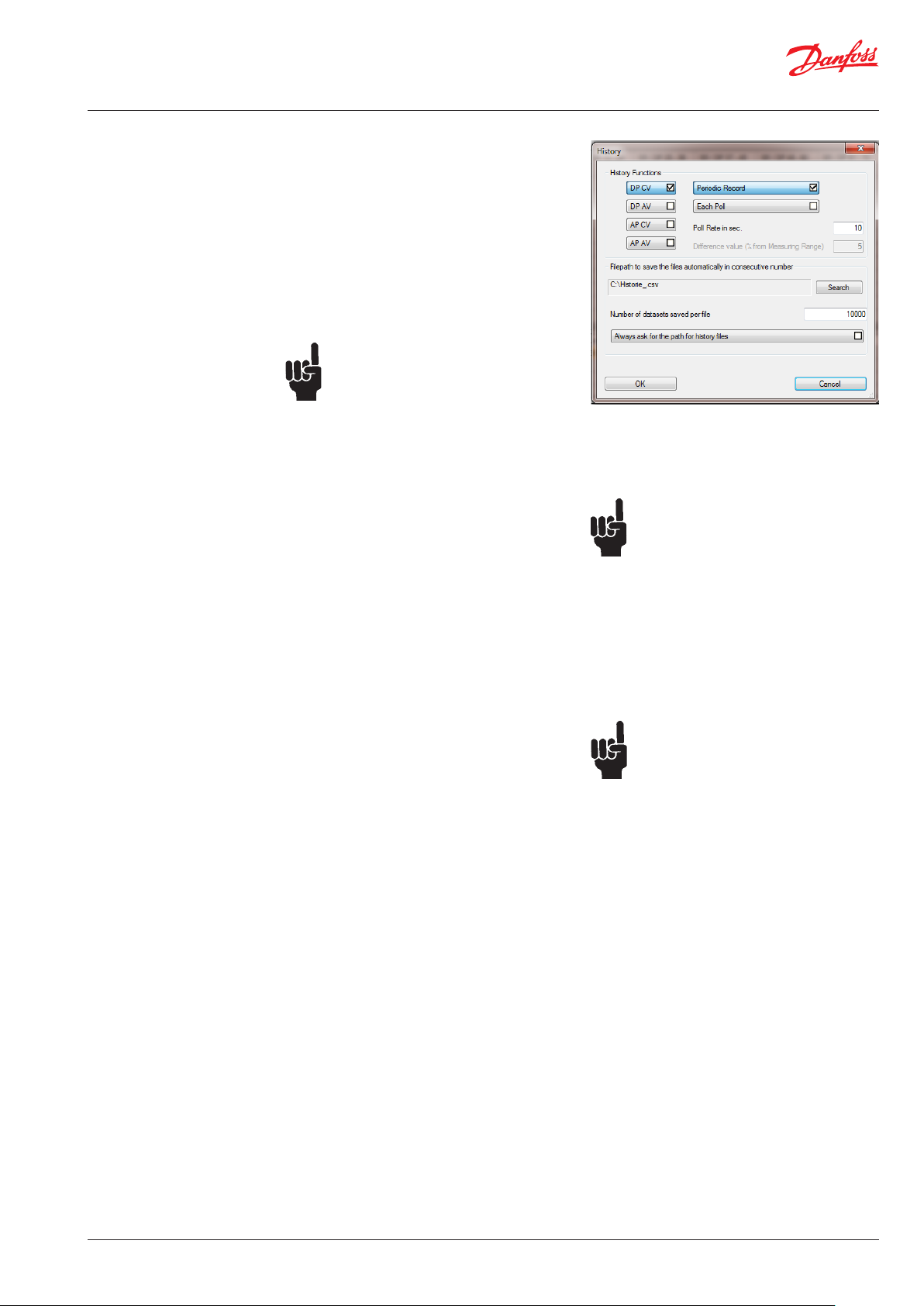

Options:

In the upper half, you can manage all settings

for the measured value control of all measuring

points:

- If only the current value or the average value, or

both are monitored.

- If Periodic Record is active, monitoring is

continuously performed at certain time

intervals.

- If Each Poll is active, storage is performed with

each measurement cycle.

Note:

This setting is not recommended for

extended periods of time, since the data

transfer between the devices is very fast

and the PC cannot keep up the speed.

- Poll rate in sec. represents the time interval in

which the data are written. As the PC timer

is not synchronized with the timer of the

device, there may be minimal time delays when

recording.

- If Periodic Record is not active, the values are

written by the data logger only if the measured

value changes by the Difference value.

In the bottom half, the path is indicated where

the audit records are stored automatically.

Separate files for digital measurement points (DP)

and analog measurement points (AP) are started.

The corresponding files are marked by the

abbreviation DP or AP in the filename.

A consecutive number is automatically added

to the specified name of the file, so that the file

is not overwritten. If there are already files with

the same name in the specified directory, the

numbers will continue.

E.g.

- If the files 1, 2 and 3 are in the directory, the

PC tool software will start saving the

file with number 4.

- If the files 1, 3, and 6 are in the directory, the

file 2 will be written first, then 4, then 5, 7, 8,

9, etc., so that the gaps are filled! This has the

disadvantage that it will not be represented in

chronological order (e.g. with Excel Diagram).

Each automatically saved file contains as many

records as indicated in the field Number of

datasets saved per file.

If Always ask for the path of history files is

active, a file storing dialog will appear when

starting the history, in order to control the path

right from the start.

Note:

Each dataset is directly written into

the file. Therefore, the file must not be

opened during the ongoing operation of

history!

The user must have access rights for the

specified path, otherwise the file will not

be written.

The imported data are stored with the OK button.

This function of the PC tool allows you to

record and monitor the measured values of all

connected digital and analog measurement

points.

Note:

Missing or incorrect settings will have

a serious impact on the monitoring!

© Danfoss | DCS (MWA) | 2018.06

DKRCI.PS.S00.C1.02 | 520H12961 | 25

Page 26

User Guide | Danfoss Gas Detection - PC tool

9

History of the data logger

(Continued)

Start:

This menu item or button starts the history.

The following information appears at the very

bottom of the main window in the status bar.

- A green LED changing to red from time to time.

The green LED indicates that history is enabled.

If the LED changes to red, a record is just being

written into the file.

- Two numbers separated by a minus.

The first number represents the number of

records in the current file with digital measuring

points (DP).

The second number represents the number

of records in the current file with analog

measuring points (AP).

- The specified path where the files are stored.

Pause:

This menu item or button interrupts the

recording. It is useful if you want to view the file

in between. If you resume the recording with the

start button, the current file will continue to be

written.

Stop:

This menu item or button stops the recording.

A new file is started after restarting.

Attention:

If the LED flashes green-red, but the

numbers remain at 0, the software

tries to write the history files, but fails.

In this case, please check access rights

to the path or run the PC tool as an

administrator.

Attention:

If the file was opened, please pay

attention to closing the file before

restarting.

Structure of Files:

Regardless of whether only digital or only analog

measuring points or both are recorded, the files

are of an identical structure.

- The first column contains the date and time

with hours, minutes and seconds.

- The second column indicates the measurement

values as current and / or average values.

- From the third column on, the measured values

are displayed. 96 entries for digital measuring

points and 32 entries for the analog measured

values.

The measured values are displayed according

to the measuring range. If the system contains

mixed measurement points, the scaling of the

measured values may be different according to

the measuring range.

A minus instead of the measured value means

that the measurement points are not activated.

If there is an error at a measuring point, it is

shown in form of a hexadecimal error code.

E.g.: 0x8100 Underrange

26 | DKRCI.PS.S00.C1.02 | 520H12961

© Danfoss | DCS (MWA) | 2018.06

Page 27

User Guide | Danfoss Gas Detection - PC tool

10

Notes and general

information

It is important to read this user manual

thoroughly and clearly in order to understand

the information and instructions. The Danfoss

Gas Detection units must be used within product

specification capabilities. The appropriate

operating and maintenance instructions and

recommendations must be followed.

Due to on-going product development, Danfoss

reserves the right to change specifications

without notice. The information contained herein

is based upon data considered to be accurate.

However, no guarantee is expressed or implied

regarding the accuracy of this data.

Installers’ Responsibilities

It is the installer’s responsibility to ensure that

all Danfoss Gas Detection units are installed in

compliance with all national and local codes

and OSHA requirements. Installation should

be implemented only by technicians familiar

with proper installation techniques and with

codes, standards and proper safety procedures

for control installations and the latest edition of

the National Electrical Code (ANSI/NFPA70). It is

also essential to follow strictly all instructions as

provided in the installation guides.

Maintenance

It is recommended to check the Danfoss Gas

Detection units regularly. Due to regular

maintenance any performance deviations may

easily be corrected. Re-calibration and part

replacement in the field may be implemented by

a qualified technician and with the appropriate

tools.

© Danfoss | DCS (MWA) | 2018.06

DKRCI.PS.S00.C1.02 | 520H12961 | 27

Page 28

28 | DKRCI.PS.S00.C1.02 | 520H12961

© Danfoss | DCS (MWA) | 2018.06

Loading...

Loading...