Page 1

User Manual

PLUS+1® GUIDE Software

PLUS+1 Function Block Library—Output

Function Blocks

www.danfoss.com

Page 2

User Manual

PLUS+1® Compliant Function Block Library—Output Function Blocks

Revision history Table of revisions

Date Changed Rev

February 2019 Rebranding 0101

May 2016 Updates for new library version. CA

April 2014 Supports Rev 3.00 BB

2 | © Danfoss | February 2019 11062084 | AQ00000275en-000101

Page 3

User Manual

PLUS+1® Compliant Function Block Library—Output Function Blocks

Contents

Risk Reduction

Design, Test, and Secure to Reduce Risks................................................................................................................................4

Design...................................................................................................................................................................................................4

Test.........................................................................................................................................................................................................4

Secure................................................................................................................................................................................................... 5

PVE_Driver Function Block

Inputs....................................................................................................................................................................................................6

Outputs................................................................................................................................................................................................ 7

Function Block Example.................................................................................................................................................................8

Function Block Connections.........................................................................................................................................................9

Status Logic........................................................................................................................................................................................ 9

Fault Logic........................................................................................................................................................................................ 10

Identical Function Blocks Need Different Namespace Values to Successfully Compile...................................... 10

Change Namespace Value.....................................................................................................................................................10

IEC 61508-3 Annex D Supplemental Information.............................................................................................................. 12

PWM_Driver Function Block

Inputs..................................................................................................................................................................................................13

Outputs..............................................................................................................................................................................................13

Function Block Example.............................................................................................................................................................. 14

Function Block Connections...................................................................................................................................................... 16

Status Logic......................................................................................................................................................................................16

Fault Logic........................................................................................................................................................................................ 16

Identical Function Blocks Need Different Namespace Values to Successfully Compile...................................... 16

Change Namespace Value.....................................................................................................................................................17

IEC 61508-3 Annex D Supplemental Information.............................................................................................................. 18

ErrorHistory Function Block

Inputs..................................................................................................................................................................................................19

Outputs..............................................................................................................................................................................................20

Function Block Connections...................................................................................................................................................... 21

Identical Function Blocks Need Different Namespace Values to Successfully Compile...................................... 21

Change Namespace Value.....................................................................................................................................................22

IEC 61508-3 Annex D Supplemental Information.............................................................................................................. 23

©

Danfoss | February 2019 11062084 | AQ00000275en-000101 | 3

Page 4

User Manual

PLUS+1® Compliant Function Block Library—Output Function Blocks

Risk Reduction

Design, test, and secure applications that you develop to reduce risks of personal injury and equipment

damage.

Design, Test, and Secure to Reduce Risks

Applications created with PLUS+1® GUIDE typically control equipment such as tractors, cranes, and

harvesters.

Using heavy, powerful, and mobile off-road equipment always involves the risk of personal injury and

equipment damage, even when this equipment is operating under normal operating conditions.

Abnormal operating conditions greatly increase the risk of personal injury and equipment damage.

The PLUS+1® program has no automatic protections against these risks. The tool has no protection

against the risks that result from bugs in the tool software, errors in the tool manual, or incompatibilities

between software versions of the tool.

You must:

•

Design your application to reduce these risks.

•

Test your application to reduce these risks.

•

Secure your application against unauthorized changes in its operating parameters to reduce these

risks.

Design

Test

As you design your application, you must include the fault checking and the error handling needed to

reduce risks in normal and abnormal operating conditions.

Consider the following when developing fault checking and error handling for your PLUS+1® GUIDE

application:

•

How the machine is normally used.

•

Possible operator errors and their consequences.

•

Industry safety standards and legal requirements.

•

Input and output failures and their consequences. These failures can include:

Joystick, sensor, and other inputs suddenly going to ±100 % or to 0 %.

‒

Joystick, sensor, and other inputs suddenly going to ±100 % or to 0 %.

‒

Outputs that control machinery direction, speed, and force suddenly changing direction or going

‒

to ±100 % or to 0 %.

Decide how likely each failure is. The more likely a failure, the more you need to protect against

the consequences of the failure.

•

The sequence of events and consequences of a fault or error.

•

The sequence of events and consequences of an emergency stop.

After creating an application, you are responsible for testing the application.

Download your application to hardware and test its operation under both normal and abnormal

operating conditions. Make sure:

•

Individual inputs produce expected outputs.

•

Fault handling and error checking work as designed.

You must repeat your tests when you make configuration, calibration, or software changes to the

application.

4 | © Danfoss | February 2019 11062084 | AQ00000275en-000101

Page 5

User Manual

PLUS+1® Compliant Function Block Library—Output Function Blocks

Risk Reduction

Secure

You have the responsibility to secure your application against unauthorized changes.

Always use the PLUS+1® GUIDE program’s Toolkey feature to restrict access to your application’s

operating parameters.

•

Without Toolkey protection, there is an increased risk that unauthorized personnel could use the

PLUS+1® Service Tool program to change your application’s operating parameters.

Changes in your application’s operating parameters might cause unexpected machinery movement

that results in personal injury and equipment damage.

•

Toolkey protection reduces the risk that unauthorized personnel could use the PLUS+1® program to

change your application’s operating parameters.

Refer to How to Use the Toolkey to Restrict Service Tool Access to Application Values in the PLUS+1—How-to

chapter of the PLUS+1 GUIDE User Manual (Danfoss part 10100824).

©

Danfoss | February 2019 11062084 | AQ00000275en-000101 | 5

Page 6

User Manual

PLUS+1® Compliant Function Block Library—Output Function Blocks

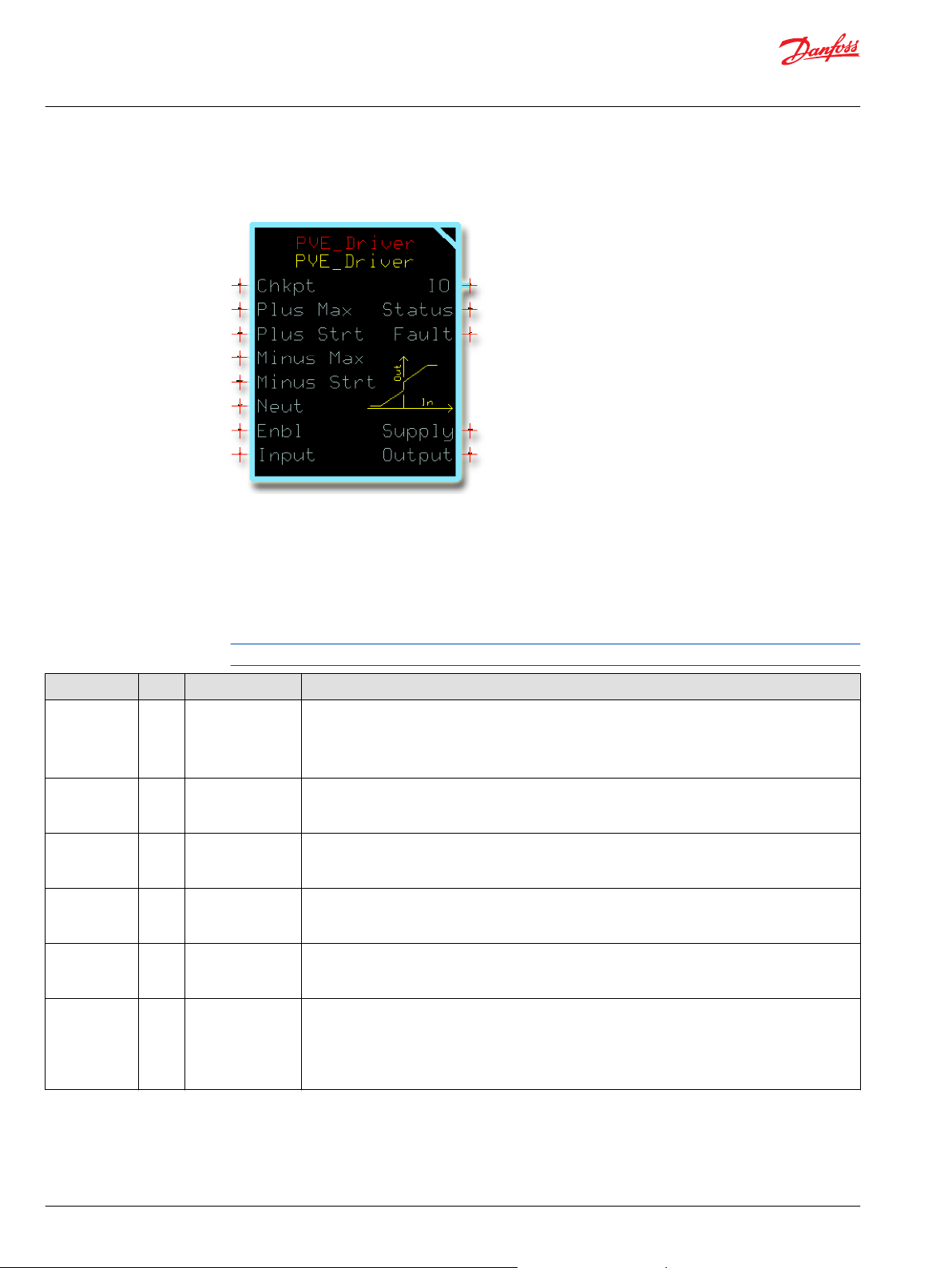

PVE_Driver Function Block

Use the PVE_Driver function block to control a PVE (Proportional Valve Electric) valve through a PWM

(pulse-width modulation) output.

You can use this function block’s Enbl input and Supply output to implement power management in

your application. For more information, see the Technical Information document supplied with your

PVE product.

Inputs

The inputs to the PVE_Driver function block are described.

Use only the data types specified in this table. Other data types cause compiler errors.

Item Type Range Description

ChkPt BOOL ——

Plus Max U16 0–10000 The Output value produced by a positive Input value of 10000. Duty value for the maximum plus valve

Plus Strt U16 0–10000 The Output value produced by a positive Input value of 1. Duty value for the threshold plus valve

Minus Max U16 0–10000 The Output value produced by a negative Input value of -10000. Duty value for the maximum minus

Minus Strt U16 0–10000 The Output value produced by a negative Input value of -1. Duty value for the threshold minus valve

Neut U16 0–10000 The Output value when either the:

True—include the function block’s built-in Advanced Checkpoint with Namespace in the compiled

•

LHX download file.

False—exclude the function block’s built-in Advanced Checkpoint with Namespace components

•

from the compiled LHX download file.

output.

1000 = 10.00%

output.

1000 = 10.00%

valve output.

1000 = 10.00%

output.

1000 = 10.00%

Input value equals 0.

•

Enable input goes false.

•

Duty value for a neutral valve output.

1000 = 10.00%

6 | © Danfoss | February 2019 11062084 | AQ00000275en-000101

Page 7

User Manual

PLUS+1® Compliant Function Block Library—Output Function Blocks

PVE_Driver Function Block

Item Type Range Description

Enbl BOOL —— Enables valve functionality.

If true:

•

The Output value follows changes in the Input value.

•

The Supply output goes true if the Input value is not 0.

If false:

•

The Output value equals the Neut value.

•

The Supply output goes false.

Input S16 -10000–10000 Input command.

1000 = 10.00%

Outputs

The outputs of the PVE_Driver function block are described.

Item Type Range Description

IO Bus —— Outputs a bus with all of the function block's input and output signals.

This bus provides a convenient way to distribute this function block's signals to your application.

Status U16 —— Reports the status of the function block.

This output follows the standard bitwise scheme described in the Status Logic topic.

Fault U16 —— Reports the faults of the function block.

This output follows the standard bitwise scheme described in the Status Logic topic.

Supply BOOL —— Used to enable/disable the power supply to a PVE. If multiple PVEs are powered with a single digital

output, the “or” of the Supply signals from each function block can be used to enable the PVE power

supply.

True when both:

Enable input is true.

•

Input value is not 0.

•

False if either:

Enable input is false.

•

Input value is 0.

•

Output U16 0–10000 Output command. PWM duty command for controlling a PVE.

1000 = 10.00%

©

Danfoss | February 2019 11062084 | AQ00000275en-000101 | 7

Page 8

User Manual

PLUS+1® Compliant Function Block Library—Output Function Blocks

PVE_Driver Function Block

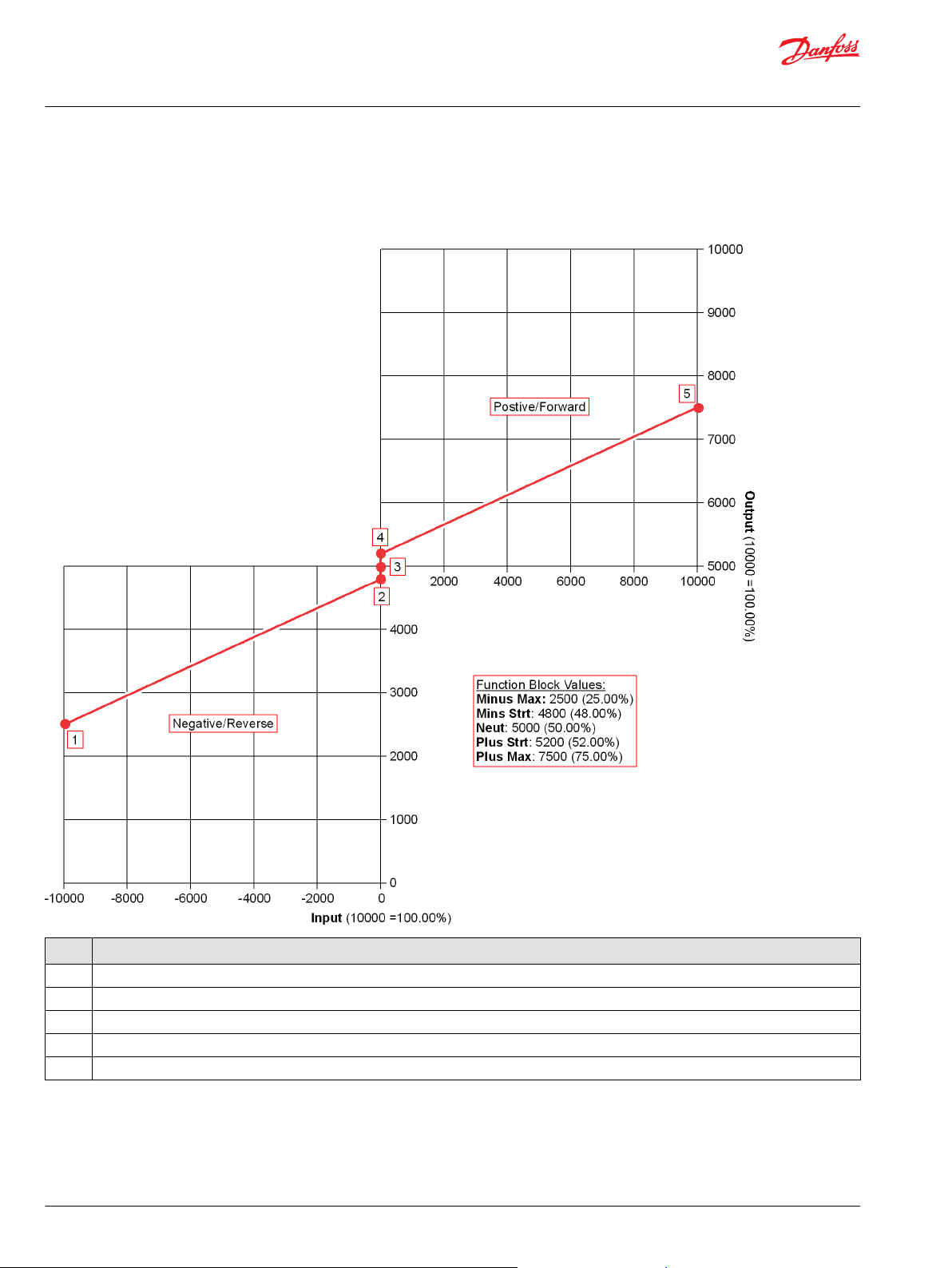

Function Block Example

Use the following example to understand how configuration and operation changes impact the output

of the function block.

Description

Item

1 With a Minus Max value of 2500 (25.00%), a negative Input value of -10000 (-100.00%) produces an Output value of 2500 (25.00%).

With a Minus Strt value of 4800 (48.00%), a negative Input value of -1 (-0.01%) produces an Output value of 4800 (48.00%).

2

3 With a Neut value of 5000 (50.00%), an Input value of 0 (0%) produces an Output value of 5000 (50.00%).

With a Plus Strt value of 5200 (52.00%), a positive Input value of 1 (0.01%) produces an Output value of 5200 (52.00%).

4

With a Plus Max value of 7500 (75.00%), a positive Input value of 10000 (100.00%) produces an Output value of 7500 (75.00%).

5

8 | © Danfoss | February 2019 11062084 | AQ00000275en-000101

Page 9

User Manual

PLUS+1® Compliant Function Block Library—Output Function Blocks

PVE_Driver Function Block

Function Block Connections

Connections you can make with the PVE_Driver function block are described.

Description

Item

1

2 The maximum positive direction Output value produced by a positive Input value of 10000.

3 The threshold positive direction Output value produced by a positive Input value of 1.

4 The maximum negative direction Output value produced by a negative Input value of -10000.

5 The threshold negative direction Output value produced by a negative Input value of -1.

6 The Output value when either the:

7

8 Input command.

9 Outputs a bus with all of the function block's input and output signals.

10 Reports the status of the function block.

11 Reports the faults of the function block.

12 If true, then:

13 Output command.

True—include the function block’s built-in Advanced Checkpoint with Namespace in the compiled LHX download file.

•

False—exclude the function block’s built-in Advanced Checkpoint with Namespace components from the compiled LHX download file.

•

Input value equals 0.

•

Enable input goes false.

•

If true, then:

The Output value follows changes in the Input value.

•

The Supply output goes true if the Input value is not 0.

•

Enable input is true.

•

Input value is not 0.

•

Status Logic

This topic describes how status logic is indicated for the function block.

Condition Hex

Invalid setup. 0x8008 1000

*

Bit 16 set to 1 identifies a standard Danfoss status or fault code.

©

Danfoss | February 2019 11062084 | AQ00000275en-000101 | 9

*

Binary Cause Response Correction

The values of Minus Max,

Minus Strt, Neut, Plus Strt,

and Plus Max do not

successively increase.

Minus Max, Minus Strt,

Neut, Plus Strt, or Plus Max

are out of range.

Output = Neut value.

Supply = false.

Ensure that the Minus Max, Min

Strt, Neut, Plus Strt, and Plus

Max values successively increase.

Return the Minus Max, Minus

Strt, Neut, Plus Strt, and Plus

Max values to within their valid

ranges.

Page 10

User Manual

PLUS+1® Compliant Function Block Library—Output Function Blocks

PVE_Driver Function Block

Fault Logic

This topic describes how fault logic is indicated for the function block.

Condition Hex

Input value is too low. 0x8001 0001 Input value < -10000. Output = Neut value.

Input value is too high. 0x8002 0010 Input value > 10000.

*

Bit 16 set to 1 identifies a standard Danfoss status or fault code.

Identical Function Blocks Need Different Namespace Values to Successfully Compile

*

Binary Cause Response Correction

Supply = false.

If you use the same function block more than once in an application, you must change each function

block’s namespace value to avoid compiler errors.

All function blocks contain Advanced Checkpoint with Namespace components that enable the PLUS+1

Service Tool to read block input and output values.

Some function blocks contain non-volatile memory components that store function block operating

parameters.

Both these components use memory names (“aliases”) to allocate memory. Identical memory names

cause compiler errors.

The namespace value adds a unique prefix to each component name to avoid errors. Keep each

namespace value short to save controller memory.

Return the Input to the valid

range.

®

Change Namespace Value

To successfully compile your application, change the namespace value for function blocks that are used

more than once in an application.

10 | © Danfoss | February 2019 11062084 | AQ00000275en-000101

Page 11

User Manual

PLUS+1® Compliant Function Block Library—Output Function Blocks

PVE_Driver Function Block

1. In the PLUS+1® GUIDE menu bar, click the Query/Change button.

2. Click on the function block whose namespace you want to set to a unique value.

The Edit Page window opens.

3. In the Edit Page window, enter a meaningful Namespace value.

Namespace values are case-sensitive.

•

To save controller memory, use a short namespace value.

•

4. Press Enter.

5. Repeat these steps to enter unique namespace values for other identical function blocks.

©

Danfoss | February 2019 11062084 | AQ00000275en-000101 | 11

Page 12

User Manual

PLUS+1® Compliant Function Block Library—Output Function Blocks

PVE_Driver Function Block

IEC 61508-3 Annex D Supplemental Information

The following table provides IEC 61508-3 Annex D supplemental information.

Item

Function block name

Function block version

Function block development

environment

Compatible hardware

Function block developed in

compliance with

Competence required of

function block integrator

Contacting Danfoss

Description

PVE_Driver.

4.0.

PLUS+1® GUIDE version 8.1 and later.

Verified in the PLUS+1® GUIDE compile process.

When the PLUS+1® GUIDE compiler finds a function block that is incompatible with hardware, it aborts the compile

process and logs an error message. The error message gives the location of the function block and states “Error 80:

component not supported in hwd.”

Danfoss Software Product Development Process (PDP), which includes ISO 9001 and IEC 61508-3 standards.

The knowledge, competence, and training required to:

Understand this manual.

•

Use the PLUS+1® GUIDE program to develop a machine control application.

•

Follow quality software practices to develop a machine control application.

•

https://www.danfoss.com/en/products/software/dps/plus1-software-services-support-and-training/plus1-support-andservices

12 | © Danfoss | February 2019 11062084 | AQ00000275en-000101

Page 13

User Manual

PLUS+1® Compliant Function Block Library—Output Function Blocks

PWM_Driver Function Block

Use the PWM_Driver function block to control an electronic displacement coil (EDC) or other similar

control devices that use pulse-width modulation (PWM) signals to control their displacement.

Depending on how you configure the output of your controller, you can use this generic function block

to:

Control an EDC controlled through current.

•

Control an EDC controlled through duty cycles.

•

Inputs

The inputs to the PWN_Driver function block are described.

Use only the data types specified in this table. Other data types cause compiler errors.

Item Type Range Description

ChkPt BOOL ——

Max U16 0–30000 The maximum Output value produced by an Input value of 10000.

Strt U16 0–30000 The minimum Output value produced by an Input value of 1.

Input U16 0–10000 Input command.

True—include the function block’s built-in Advanced Checkpoint with Namespace in the compiled

•

LHX download file.

False—exclude the function block’s built-in Advanced Checkpoint with Namespace components

•

from the compiled LHX download file.

Coil parameter for the maximum output. This is the end current in a closed-loop control system.

1000 = 100.0 mA (for a controller configured to control an output through current).

10000 = 100.00% (for a controller configured to control an output through duty-cycles).

Coil parameter for the minimum output. This is the threshold current in a closed-loop control system.

1000 = 100.0 mA (for a controller configured to control an output through current).

10000 = 100.00% (for a controller configured to control an output through duty-cycles).

1000 = 10.00%

Outputs

The outputs of the PWM_Driver function block are described.

Item Type Range Description

IO Bus —— Outputs a bus with all of the function block's input and output signals.

This bus provides a convenient way to distribute this function block's signals to your application.

Status U16 —— Reports the status of the function block.

This output follows the standard bitwise scheme described in the Status Logic topic.

Fault U16 —— Reports the faults of the function block.

This output follows the standard bitwise scheme described in the Status Logic topic.

Output U16 0–30000 PWM duty or current command used to drive the control.

1000 = 10.00% (for PWM duty configured controller outputs)

•

1000 = 100 mA (for current configured controller outputs)

•

©

Danfoss | February 2019 11062084 | AQ00000275en-000101 | 13

Page 14

User Manual

PLUS+1® Compliant Function Block Library—Output Function Blocks

PWM_Driver Function Block

Function Block Example

Use the following example to understand how configuration and operation changes impact the output

of the function block.

The figure shows the Output of a PWM_Driver function block driving an EDC controlled through

current.

Description

Item

1 With a Strt value of 150 (15.0 mA), an Input value of 1 (0.01%) produces an Output value of 150 (15.0 mA).

With a Max value of 1200 (120.0 mA), an Input value of 10000 (100.00%) produces an Output value of 1200 (120.0 mA).

2

14 | © Danfoss | February 2019 11062084 | AQ00000275en-000101

Page 15

User Manual

PLUS+1® Compliant Function Block Library—Output Function Blocks

PWM_Driver Function Block

The figure shows the Output of a PWM_Driver function block driving an EDC controlled through duty

cycles.

Description

Item

1 With a Strt value of 3000 (30.00%), an Input value of 1 (0.01%) produces an Output value of 3000 (30.00%).

With a Max value of 1200 (120.0 mA), an Input value of 10000 (100.00%) produces an Output value of 1200 (120.0 mA).

2

©

Danfoss | February 2019 11062084 | AQ00000275en-000101 | 15

Page 16

User Manual

PLUS+1® Compliant Function Block Library—Output Function Blocks

PWM_Driver Function Block

Function Block Connections

Connections you can make with the function block are described.

Description

Item

1

2 The maximum Output value produced by an Input value of 10000.

3 The minimum Output value produced by an Input value of 1.

4 Input command.

5 Outputs a bus with all of the function block's input and output signals.

6 Reports the status of the function block.

7 Reports the faults of the function block.

8 Output command.

True—include the function block’s built-in Advanced Checkpoint with Namespace in the compiled LHX download file.

•

False—exclude the function block’s built-in Advanced Checkpoint with Namespace components from the compiled LHX download file.

•

Status Logic

This topic describes how status logic is indicated for the function block.

Condition Hex

Invalid setup. 0x8008 1000

*

Bit 16 set to 1 identifies a standard Danfoss status or fault code.

*

Binary Cause Response Correction

Strt ≥ Max

Strt or Max value is out of

range.

Output = 0

Fault Logic

This topic describes how fault logic is indicated for the function block.

Condition Hex

Input value is too low. 0x8001 0001 Input value < 0.

Input value is too high. 0x8002 0010 Input value > 10000.

*

Bit 16 set to 1 identifies a standard Danfoss status or fault code.

*

Binary Cause Response Correction

Output = 0

Identical Function Blocks Need Different Namespace Values to Successfully Compile

If you use the same function block more than once in an application, you must change each function

block’s namespace value to avoid compiler errors.

All function blocks contain Advanced Checkpoint with Namespace components that enable the PLUS+1

Service Tool to read block input and output values.

Some function blocks contain non-volatile memory components that store function block operating

parameters.

Ensure that Max > Strt.

Return Strt and Max values to

their allowed range.

Return the Input to the valid

range.

®

16 | © Danfoss | February 2019 11062084 | AQ00000275en-000101

Page 17

User Manual

PLUS+1® Compliant Function Block Library—Output Function Blocks

PWM_Driver Function Block

Both these components use memory names (“aliases”) to allocate memory. Identical memory names

cause compiler errors.

The namespace value adds a unique prefix to each component name to avoid errors. Keep each

namespace value short to save controller memory.

Change Namespace Value

To successfully compile your application, change the namespace value for function blocks that are used

more than once in an application.

1. In the PLUS+1® GUIDE menu bar, click the Query/Change button.

2. Click on the function block whose namespace you want to set to a unique value.

The Edit Page window opens.

3. In the Edit Page window, enter a meaningful Namespace value.

Namespace values are case-sensitive.

•

To save controller memory, use a short namespace value.

•

4. Press Enter.

5. Repeat these steps to enter unique namespace values for other identical function blocks.

©

Danfoss | February 2019 11062084 | AQ00000275en-000101 | 17

Page 18

User Manual

PLUS+1® Compliant Function Block Library—Output Function Blocks

PWM_Driver Function Block

IEC 61508-3 Annex D Supplemental Information

The following table provides IEC 61508-3 Annex D supplemental information.

Item

Function block name

Function block version

Function block development

environment

Compatible hardware

Function block developed in

compliance with

Competence required of

function block integrator

Contacting Danfoss

Description

PWM_Driver.

4.0.

PLUS+1® GUIDE version 8.1 and later.

Verified in the PLUS+1® GUIDE compile process.

When the PLUS+1® GUIDE compiler finds a function block that is incompatible with hardware, it aborts the compile

process and logs an error message. The error message gives the location of the function block and states “Error 80:

component not supported in hwd.”

Danfoss Software Product Development Process (PDP), which includes ISO 9001 and IEC 61508-3 standards.

The knowledge, competence, and training required to:

Understand this manual.

•

Use the PLUS+1® GUIDE program to develop a machine control application.

•

Follow quality software practices to develop a machine control application.

•

https://www.danfoss.com/en/products/software/dps/plus1-software-services-support-and-training/plus1-support-andservices

18 | © Danfoss | February 2019 11062084 | AQ00000275en-000101

Page 19

User Manual

PLUS+1® Compliant Function Block Library—Output Function Blocks

ErrorHistory Function Block

Use the ErrorHistory function block to record application errors.

This function block can maintain up to ten separate error records for an application. Each error record has

a:

Code that indicates the location of the error.

•

Code that indicates the type of the error. (Create separate error records to record different types of

•

errors at the same location.)

Count of the number of times that the error occurred.

•

Time stamps that mark the time of the first error and the time of the most recent error.

•

Two ErrorHistory function blocks can be bussed together to record up to twenty separate application

errors.

The ErrorHistory function block has no Status or Fault outputs.

Inputs

The inputs to the ErrorHistory function block are described.

Use only the data types specified in this table. Other data types cause compiler errors.

Item Type Range Description

ChkPt BOOL ——

Clear BOOL —— A positive transition clears all error records from the function block’s memory.

Time U32 0–4,294,967,296 Current time to be recorded when a fault is stored. Used to record the first occurrence of an error and at

Input Bus —— Contains LocList, TypeList, and Assigned signals.

LocList Array[

TypeList Array[

Assigned Array[

n ≤ 20 Array of the location codes for active errors. The error history saves an identifier associated with the

n]U8

n ≤ 20 Array of the type codes for active errors. The error history saves an identifier associated with the error’s

n]U8

n ≤ 20

n]BOO

L

True—include the function block’s built-in Advanced Checkpoint with Namespace in the compiled

•

LHX download file.

False—exclude the function block’s built-in Advanced Checkpoint with Namespace components

•

from the compiled LHX download file.

Sets all the function block’s Location, Type, OC (Occurrence Count), First occurrence, and Last

occurrence values to 0.

the most recent occurrence of the error.

Time units are user-defined.

error’s source location. The location at a given index on this list corresponds to the error type at the

same index of the TypeList.

n ≤ 20

type. The location at a given index on this list corresponds to the error location at the same index of the

LocList.

n ≤ 20

An array where each index indicates whether the corresponding index in the LocList and TypeList has

been stored.

T—the corresponding index in the LocList and TypeList has been stored.

•

F—the corresponding index in the LocList and TypeList has not been stored.

•

©

Danfoss | February 2019 11062084 | AQ00000275en-000101 | 19

Page 20

User Manual

PLUS+1® Compliant Function Block Library—Output Function Blocks

ErrorHistory Function Block

Outputs

The outputs of the ErrorHistory function block are described.

Item Type Range Description

IO Bus —— Outputs a bus with all of the function block's input and output signals.

This bus provides a convenient way to distribute this function block's signals to your application.

Full BOOL —— Indicates that all records are full. New location/type combinations are not stored in the function block’s

internal EEPROM. A second function block can be used to store more records.

T—the function block has no more memory locations available to store error records.

•

F—the function block has at least one memory location available to store an error record.

•

DataOut Bus —— Contains signals to be passed to another ErrorHistory function block. This allows for more location/

type combinations to be stored in EEPROM.

Outputs:

LocList signal.

•

TypeList signal.

•

Assigned signal.

•

Ten sub-buses labeled EE_0, EE_1, EE_2, EE_3, EE_4, EE_5, EE_6, EE_7, EE_8, and EE_9. Signals

•

within these buses provide access to error record values.

LocList Array[

TypeList Array[

Assigned Array[

EE_x Bus —— Each EE_x bus (where x is a value from 0 to 9) connects to a memory location. Memory components in

Loc

Type

OC

Last

First

0–255 Array of location codes for active errors.

20]U8

0–255 Array of error type codes for active errors.

20]U8

—— Array where each index indicates whether the corresponding index in the LocList and TypeList has

20]BO

OL

0–255 Outputs the error location code stored at the memory location connected to Bus_x.

U8

0–255 Outputs the error type code stored at the memory location connected to Bus_x.

U8

0–255 Outputs the total occurrences for the error stored at the memory location connected to Bus_x.

U8

0–4, 294, 967, 295 Outputs the time stamp of the last error stored at the memory location connected to Bus_x. Time units

U32

0–4, 294, 967, 295 Outputs the time stamp of the first error stored at error stored at a memory location connected to

U32

Use as an input to a second ErrorHistory function block.

Use as an input to a second ErrorHistory function block.

been stored.

Can also be used as an input to a second ErrorHistory function block.

T—the corresponding index in the LocList and TypeList has been stored.

•

F—the corresponding index in the LocList and TypeList has not been stored.

•

these memory locations store error records. The function block has ten memory locations to store ten

error records. Signals in each EE_x sub-bus output the error information stored at these memory

locations.

Each EE_x sub-bus has five signals:

Loc signal.

•

Type signal.

•

OC signal.

•

Last signal.

•

First signal.

•

are user-defined.

Bus_x. Time units are user-defined.

20 | © Danfoss | February 2019 11062084 | AQ00000275en-000101

Page 21

User Manual

PLUS+1® Compliant Function Block Library—Output Function Blocks

ErrorHistory Function Block

Function Block Connections

Connections you can make with the function block are described.

Description

Item

1

2 A positive transition clears all the function block’s error records.

3 Bus input for LocList, TypeList, and Assigned signals.

4 Outputs a bus with all of the function block's input and output signals.

5

6 Outputs:

True—include the function block’s built-in Advanced Checkpoint with Namespace in the compiled LHX download file.

•

False—exclude the function block’s built-in Advanced Checkpoint with Namespace components from the compiled LHX download file.

•

T—the function block has no more memory locations available to store error records.

•

F—the function block has at least one memory location available to store an error record.

•

Ten sub-buses labeled EE_0, EE_1, EE_2, EE_3, EE_4, EE_5, EE_6, EE_7, EE_8, and EE_9. Signals within these buses provide access to error

•

record values.

LocList signal. Use as an input to a second ErrorHistory function block.

•

TypeList signal. Use as an input to a second ErrorHistory function block.

•

Assigned signal. Use as an input to a second ErrorHistory function block.

•

Identical Function Blocks Need Different Namespace Values to Successfully Compile

If you use the same function block more than once in an application, you must change each function

block’s namespace value to avoid compiler errors.

All function blocks contain Advanced Checkpoint with Namespace components that enable the PLUS+1

Service Tool to read block input and output values.

Some function blocks contain non-volatile memory components that store function block operating

parameters.

Both these components use memory names (“aliases”) to allocate memory. Identical memory names

cause compiler errors.

The namespace value adds a unique prefix to each component name to avoid errors. Keep each

namespace value short to save controller memory.

©

Danfoss | February 2019 11062084 | AQ00000275en-000101 | 21

®

Page 22

User Manual

PLUS+1® Compliant Function Block Library—Output Function Blocks

ErrorHistory Function Block

Change Namespace Value

To successfully compile your application, change the namespace value for function blocks that are used

more than once in an application.

1. In the PLUS+1® GUIDE menu bar, click the Query/Change button.

2. Click on the function block whose namespace you want to set to a unique value.

The Edit Page window opens.

3. In the Edit Page window, enter a meaningful Namespace value.

Namespace values are case-sensitive.

•

To save controller memory, use a short namespace value.

•

4. Press Enter.

5. Repeat these steps to enter unique namespace values for other identical function blocks.

22 | © Danfoss | February 2019 11062084 | AQ00000275en-000101

Page 23

User Manual

PLUS+1® Compliant Function Block Library—Output Function Blocks

ErrorHistory Function Block

IEC 61508-3 Annex D Supplemental Information

The following table provides IEC 61508-3 Annex D supplemental information.

Item

Function block name

Function block version

Function block development

environment

Compatible hardware

Function block developed in

compliance with

Competence required of

function block integrator

Contacting Danfoss

Description

ErrorHistory.

4.0.

PLUS+1® GUIDE version 8.1 and later.

Verified in the PLUS+1® GUIDE compile process.

When the PLUS+1® GUIDE compiler finds a function block that is incompatible with hardware, it aborts the compile

process and logs an error message. The error message gives the location of the function block and states “Error 80:

component not supported in hwd.”

Danfoss Software Product Development Process (PDP), which includes ISO 9001 and IEC 61508-3 standards.

The knowledge, competence, and training required to:

Understand this manual.

•

Use the PLUS+1® GUIDE program to develop a machine control application.

•

Follow quality software practices to develop a machine control application.

•

https://www.danfoss.com/en/products/software/dps/plus1-software-services-support-and-training/plus1-support-andservices

©

Danfoss | February 2019 11062084 | AQ00000275en-000101 | 23

Page 24

Danfoss

Power Solutions GmbH & Co. OHG

Krokamp 35

D-24539 Neumünster, Germany

Phone: +49 4321 871 0

Danfoss

Power Solutions ApS

Nordborgvej 81

DK-6430 Nordborg, Denmark

Phone: +45 7488 2222

Danfoss

Power Solutions (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239 6000

Danfoss

Power Solutions Trading

(Shanghai) Co., Ltd.

Building #22, No. 1000 Jin Hai Rd

Jin Qiao, Pudong New District

Shanghai, China 201206

Phone: +86 21 3418 5200

Products we offer:

Comatrol

www.comatrol.com

Turolla

www.turollaocg.com

Hydro-Gear

www.hydro-gear.com

Daikin-Sauer-Danfoss

www.daikin-sauer-danfoss.com

DCV directional control

•

valves

Electric converters

•

Electric machines

•

Electric motors

•

Hydrostatic motors

•

Hydrostatic pumps

•

Orbital motors

•

PLUS+1® controllers

•

PLUS+1® displays

•

PLUS+1® joysticks and

•

pedals

PLUS+1® operator

•

interfaces

PLUS+1® sensors

•

PLUS+1® software

•

PLUS+1® software services,

•

support and training

Position controls and

•

sensors

PVG proportional valves

•

Steering components and

•

systems

Telematics

•

Danfoss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and

electric components. We specialize in providing state-of-the-art technology and solutions

that excel in the harsh operating conditions of the mobile off-highway market as well as the

marine sector. Building on our extensive applications expertise, we work closely with you to

ensure exceptional performance for a broad range of applications. We help you and other

customers around the world speed up system development, reduce costs and bring vehicles

and vessels to market faster.

Danfoss Power Solutions – your strongest partner in mobile hydraulics and mobile

electrification.

Go to www.danfoss.com for further product information.

We offer you expert worldwide support for ensuring the best possible solutions for

outstanding performance. And with an extensive network of Global Service Partners, we also

provide you with comprehensive global service for all of our components.

Local address:

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without subsequent changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

©

Danfoss | February 2019 11062084 | AQ00000275en-000101

Loading...

Loading...