Data Sheet

Oil seperator

Type OUB

Oil seperator type OUB is for use

in all refrigeration plants

Oil separator type OUB is for use in all

refrigeration plants where the compressor

lubricating oil must be returned directly to the

compressor oil sump under all operating

conditions.

In this way lubricating oil from the compressor

is prevented from circulating with the

refrigerant in the refrigeration system itself.

Features

• Ensures oil return to compressor oil sump.

Prevents compressor breakdown caused by

lack of lubrication. Increases compressor

operating life

• High eciency Due to the interaction of

reduced ow velocity, change of ow

direction for oil concentration, collection of

separated oil at high temperatures, and

automatic oil return to the crankcase

• Protects against liquid hammer in the

compressor

• Better utilisation of condenser and

evaporator capacity (no oil-gas collection)

• Pulsation and noise damping on the highpressure side of system

• OUB 1 may be used in the following EX range:

Category 3 (Zone 2)

AI213886423775en-000801

123

781012131517

Float

Oil container

Float needle

Orice

Return oil connection (

1

⁄4 in. / 6 mm are /

solder)

Connection nipple

Inlet connection refrigerant vapour

Outlet connection refrigerant vapour

Oil concentrator

Fixing strap

Oil seperator, Type OUB

Functions

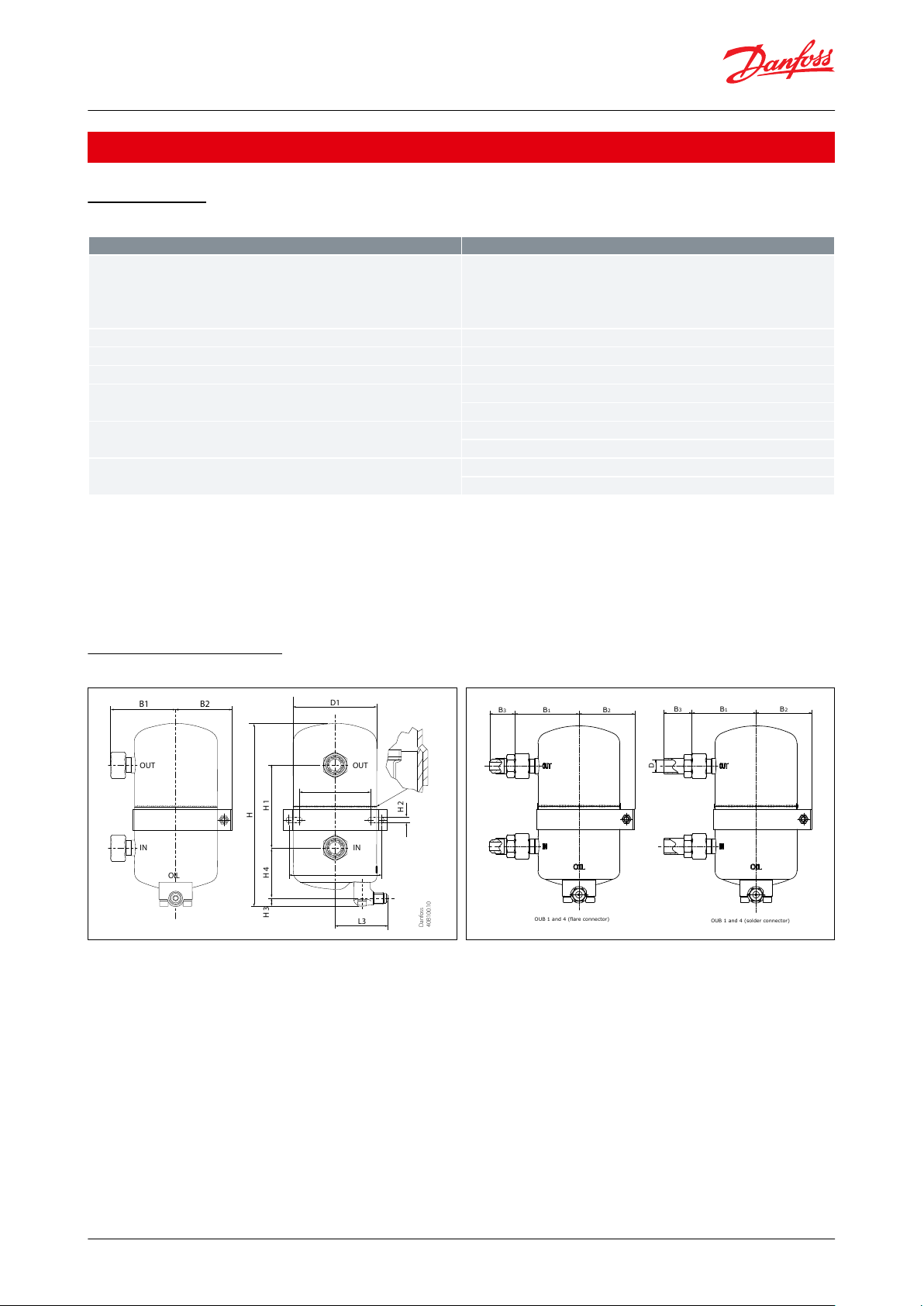

Figure 1: OUB 1/OUB 4

The very eective function of the OUB is due to the interaction of the following:

• velocity and change of ow direction of the incoming mixture of oil and refrigerant

• oil concentration, separation, and ltration

• storage of separated oil at high temperatures, thus preventing absorption of the refrigerant.

Refrigerant vapour is led through the inlet connection (12). The oil contained in the vapour is separated as a result

of the change in velocity and direction through the oil concentrator (15) which at the same time also acts as an oil

lter.

When the superheated refrigerant vapour ows around the oil container (2) some of the superheat is given o. In

this way the oil container reaches a constant high temperature and the separated oil is stored in a warm state, i.e.

with as low a refrigerant content as possible. Thus, the refrigerant is prevented from owing to the crankcase

where it could cause violent boiling.

The oat (1) opens the needle valve (3) depending on the amount of oil, whereupon the condensing pressure

forces the oil back to the crankcase therefore ensuring automatic oil return.

© Danfoss | Climate Solutions | 2021.02 AI213886423775en-000801 | 2

B2B1

D1

H

H 1

H 2

H 3 H 4

L3

Danfoss

40B100.10

OUT

OIL

IN IN

OUT

OUB 1 and 4 (solder connector)

OUB 1 and 4 (flare connector)

B

1 B

2

B3

D

B1

B

2

B3

Features

Specications

Refrigerants

R22, R134a, R290 **), R404A, R407A, R407C, R407F, R407H, R438A, R448A, R449A,

R449B, R450A, R452A, R454A *), R454C *), R455A *), R507A, R513A, R600 **),

R600a **), R1234ze *), R1270 **)

(1)

- OUB 1 only

(2)

- OUB 1s only

Max. working pressure

PS/MWP = 28 bar

Max. test pressure

Pe = 40 bar

Temperature of medium

-40 – 120 °C

Net volume

OUB 1: 0.52 l

OUB 4: 2.46 l

Oil reservoir

OUB 1: 0.1 l

OUB 4: 0.5 l

Recommended tightening torque of unions

OUB 1: 40 Nm

OUB 4: 90 Nm

Oil seperator, Type OUB

Product specication

Technical data

Table 1: For type OUB

(1)

(1)

OUB 1 is evaluated for R454A, R454C, R455A, R1234ze by ignition source assessment in accordance with standard EN ISO80079-36. Flare

OUB 1 is evaluated for R454A, R454C, R455A, R1234ze by ignition source assessment in accordance with standard EN ISO80079-36. Flare

connections are only approved for A1 and A2L refrigerants.

connections are only approved for A1 and A2L refrigerants.

(2)

(2)

OUB 1s is evaluated for R290, R454A, R454C, R455A, R600, R600a, R1234ze, R1270 by ignition source assessment in accordance with standard

OUB 1s is evaluated for R290, R454A, R454C, R455A, R600, R600a, R1234ze, R1270 by ignition source assessment in accordance with standard

EN ISO80079-36. Flare connections are only approved for A1 and A2L refrigerants

EN ISO80079-36. Flare connections are only approved for A1 and A2L refrigerants

For complete list of approved refrigerants, visit www.products.danfoss.com and search for individual code numbers,

where refrigerants are listed as part of technical data.

Dimensions and weight

Figure 2: OUB 1/OUB 4 - without connection unions

Figure 3: OUB 1/OUB 4 (are & solder connection)

© Danfoss | Climate Solutions | 2021.02 AI213886423775en-000801 | 3

1)2

)

B2B1

D

D1

H

H 1

H 2

H 3 H 4

L3

Danfoss

40B102.10

OUT

OUB 1s ¹)

OIL

IN IN

OUT

OUB 1s

1

⁄4 in. are connection to oil return line.

B2B1

D

D1

H

H 1

H 2

H 3 H 4

L3

Danfoss

40B103.10

OUT

OIL

OUB 1s ²)

IN

OUT

OUB 1s 6 mm ODF solder connection to oil return line.

Type

Flare connection

H

H1H2H3H4L1L2L3B1B2B3øD

1

Net

weight

[in]

[mm]

OUB 1

3

⁄8

10

177805.5949698950605530811.2

1

⁄2

12

177805.5949698950605531811.3

5

⁄8

16

177805.5949698950605538811.4

OUB 4

5

⁄8

16

263

126

8.5967

111

14372948544

131

4.6

3

⁄4

16

263

126

8.5967

111

14372948549

131

4.7125

263

126

8.5967

111

14372948551

131

4.8

Type

Solder

connection

H

H1H2H3H4L1L2L3B1B2B3øD

1

øD

Net

weight

[in]

[mm]

OUB 1

3

⁄8

10

177805.5949698950605529819.6

1.2

1

⁄2

12

177805.59496989506055318112.8

1.2

5

⁄8

16

177805.59496989506055428116.0

1.3

OUB 1s

-10177805.59496989816555-8110.0

1.2-10

177805.59496989506555-8110.0

1.2

Oil seperator, Type OUB

Figure 4: Flare connection to oil return line.

Figure 5: Solder connection to oil return line.

Table 2: Flare connection

Table 3: Solder connection

© Danfoss | Climate Solutions | 2021.02 AI213886423775en-000801 | 4

Type

Solder

connection

H

H1H2H3H4L1L2L3B1B2B3øD

1

øD

Net

weight

[in]

[mm]

OUB 4

5

⁄8

16

263

126

8.5967

111

14372948540

131

16.0

4.3

3

⁄4

18

263

126

8.5967

111

14372948545

131

19.1

4.3

7

⁄8

22

263

126

8.5967

111

14372948545

131

22.3

4.3125

263

126

8.5967

111

14372948545

131

25.5

4.3

1

1

⁄8

28

263

126

8.5967

111

14372948547

131

28.7

4.3

Oil seperator, Type OUB

© Danfoss | Climate Solutions | 2021.02 AI213886423775en-000801 | 5

Figure

Type

Connection

Rated plant capacity [kW]

Code no. for OUB + unions

(straightway)

[in]

[mm]

Version

R22

R134a

R404A

R507

R407C

OUB 1

3

⁄8

10

Flare

3.1

2.5

3.5

3.5

4.4

040B0010 + 2 × 040B0132

3

⁄8

-

Solder

3.1

2.5

3.5

3.5

4.4

040B0010 + 2 × 040B0140

1

⁄2

12

Flare

3.1

2.5

3.5

3.5

4.4

040B0010 + 2 × 040B0134

1

⁄2

-

Solder

3.1

2.5

3.5

3.5

4.4

040B0010 + 2 × 040B0142

5

⁄8

16

Flare

3.1

2.5

3.5

3.5

4.4

040B0010 + 2 × 040B0136

5

⁄8

16

Solder

3.1

2.5

3.5

3.5

4.4

040B0010 + 2 × 040B0144

Without connection unions

040B0010

OUB 4

5

⁄8

16

Flare

11.6

9.6

12.8

12.8

16.0

040B0040 + 2 × 040B0256

5

⁄8

16

Solder

11.6

9.6

12.8

12.8

16.0

040B0040 + 2 × 040B0266

3

⁄4

-

Solder

11.6

9.6

12.8

12.8

16.0

040B0040 + 2 × 040B0268

7

⁄8

-

Solder

11.6

9.6

12.8

12.8

16.0

040B0040 + 2 × 040B0270

1

1

⁄8

-

Solder

11.6

9.6

12.8

12.8

16.0

040B0040 + 2 × 040B0274

Without connection unions

040B0040

Figure

Type

Connection

Rated plant capacity

[kW]

Code no. for OUB +

unions

(straightway)

[mm]

Version

R22

R134aR404AR507R407C

OUB1s

(1)

10

Solder

3.1

2.53.53.54.4

040B0023

OUB1s

(2)

10

Solder

3.1

2.53.53.54.4

040B0029

Oil seperator, Type OUB

Ordering

Table 4: OUB 1 / OUB 4

Table 5: OUB 1s

(1)

(1)

1

1

⁄4 in. are connection to oil return line

⁄4 in. are connection to oil return line

(2)

(2)

6mm ODF solder connection to oil return line

6mm ODF solder connection to oil return line

© Danfoss | Climate Solutions | 2021.02 AI213886423775en-000801 | 6

Document name

Document type

Document topic

Approval authority

RU Д-DK.БЛ08.B.00828_19

EAC Declaration

Machinery & Equipment

EAC

040B0625.AA

Manufacturers Declaration

PED-UL SA3736

Mechanical - Safety Certicate

-UL034R9541.AA

Manufacturers Declaration

China RoHS

-

034L9630.AA

Manufacturers Declaration

ATEX

-

Oil seperator, Type OUB

Certicates, declarations and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Table 6: Certicates, declarations and approvals

© Danfoss | Climate Solutions | 2021.02 AI213886423775en-000801 | 7

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Coolselector®2 - nd the best components for you HVAC/R system

Coolselector®2 makes it easy for engineers, consultants, and designers to nd and order the best

components for refrigeration and air conditioning systems. Run calculations based on your operating

conditions and then choose the best setup for your system design.

Download Coolselector®2 for free at coolselector.danfoss.com.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its

products without notice. This also applies to products already on order provided that such alterations can be made without subsequential

changes being necessary in specications already agreed. All trademarks in this material are property of the respective companies. Danfoss and

the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.02 AI213886423775en-000801 | 8

Loading...

Loading...