Page 1

Technical Information

Steering Unit

OSPU

powersolutions.danfoss.com

Page 2

Technical Information

OSPU Steering Unit

Revision history Table of revisions

Date Changed Rev

March 2016 Updated to Engineering Tomorrow design 0202

May 2014 Converted to Danfoss layout - DITA CMS BA

Aug 2013 First edition AA

2 | © Danfoss | March 2016 L1313806 | BC00000222en-US0202

Page 3

Technical Information

OSPU Steering Unit

Contents

A wide range of Steering Components

A wide range of Steering Components....................................................................................................................................4

Conversion factors........................................................................................................................................................................... 5

Technical literature survey

Survey of literature with technical data on Danfoss Steering Components...............................................................6

OSPU general information............................................................................................................................................................ 6

Function

OSPU steering unit...........................................................................................................................................................................7

Function

Function, OSPU LS............................................................................................................................................................................8

Neutral position................................................................................................................................................................................ 8

Steering with normal pump supply...........................................................................................................................................9

Emergency steering: Failing pump supply..............................................................................................................................9

Versions

OSPU LS............................................................................................................................................................................................. 10

Load sensing dynamic............................................................................................................................................................ 10

Non-reaction.............................................................................................................................................................................. 10

Amplification, linear.................................................................................................................................................................10

Amplification, progressive.................................................................................................................................................... 10

Technical data

Displacement, amplification, flow and pressure: OSPU LS ............................................................................................12

A minimum standby pressure..............................................................................................................................................12

Amplification characteristics .....................................................................................................................................................13

Emergency steering: Pressure capability ..............................................................................................................................13

Valve functions in OSPU LS steering units............................................................................................................................14

Pilot pressure relief valve; (P - T, Qp) characteristic...........................................................................................................15

Shock valves.....................................................................................................................................................................................15

Suction valves..................................................................................................................................................................................15

Check valve in P..............................................................................................................................................................................16

Check valve function in LS..........................................................................................................................................................16

Port thread versions for OSPU LS............................................................................................................................................. 17

Dimensions

Dimension.........................................................................................................................................................................................19

Order specifications and weights

Order specifications...................................................................................................................................................................... 20

Weights..............................................................................................................................................................................................20

Code numbers for catalog versions with specifications

Specify your OSPU according to the destinations as in the example underneath the empty scheme:.........21

Code numbers........................................................................................................................................................................... 21

©

Danfoss | March 2016 L1313806 | BC00000222en-US0202 | 3

Page 4

Technical Information

OSPU Steering Unit

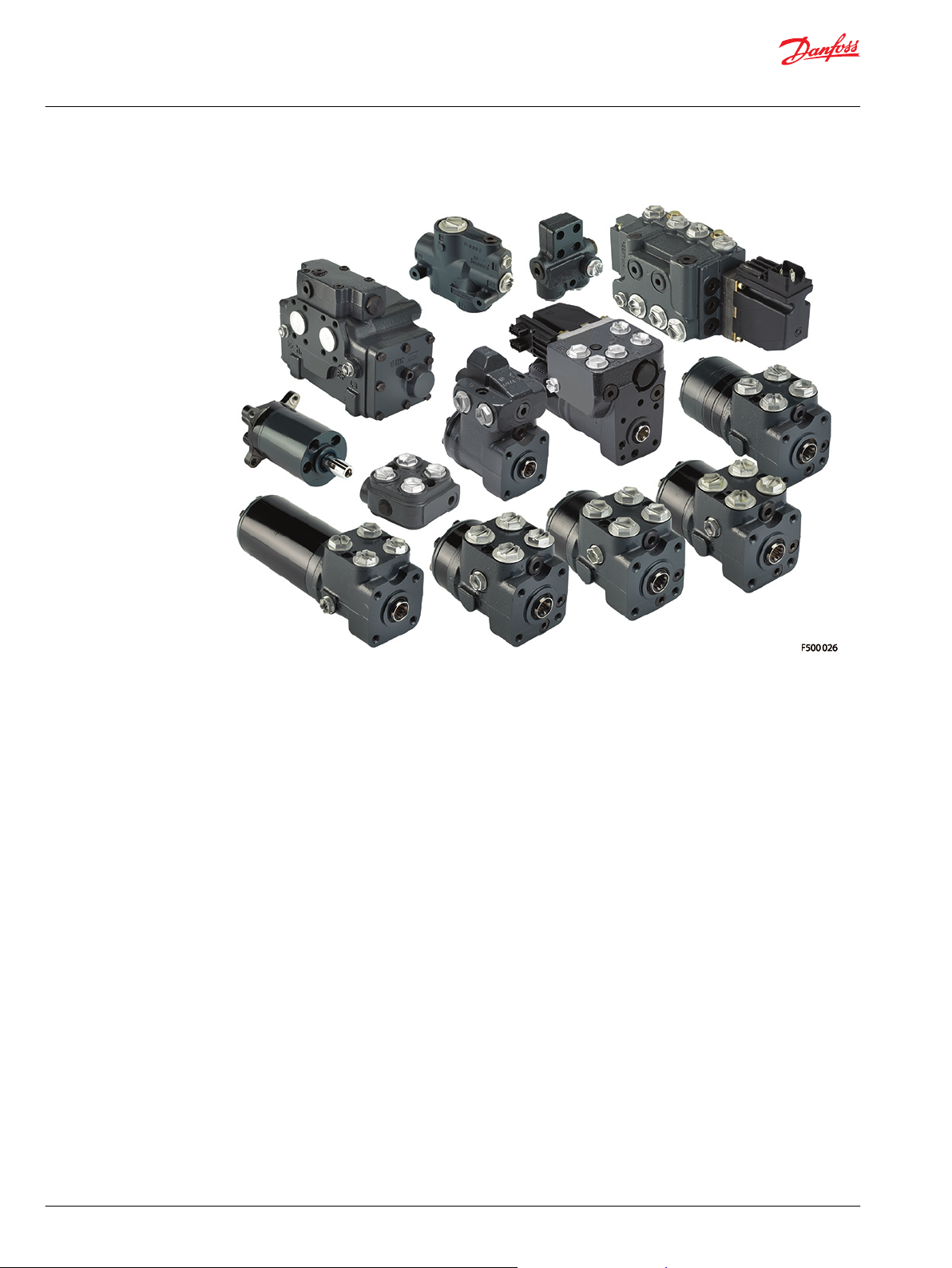

A wide range of Steering Components

A wide range of Steering Components

Danfoss is one of the largest producers in the world of steering components for hydrostatic steering

systems on off-road vehicles. Danfoss offers steering solutions both at component and system levels. Our

product range makes it possible to cover applications of all types - ranging from ordinary 2-wheel

steering (also known as Ackermann steering) to articulated steering, automatic steering (e.g. by sensor)

and remote controlled steering via satellite. We can offer more than 1,800 different steering units and 250

different priority valves categorized in types, variants and sizes.

For hydrostatic steering systems Danfoss offers:

•

Mini steering units with displacements from 32 to 100 cm3/rev [1.95 to 6.10 in3/rev], flow up to 20

l/min [5.28 US gal/min], steering pressure up to 140 bar [2030 psi].

•

Steering units with displacements from 40 to 1200 cm3/rev [2.44 to 73.2 in3/rev], flow up to 100 l/min

[26.4 US gaL/min, steering pressure up to 240 bar [3481 psi].

•

Priority valves for rated flows at 40, 80, 120, 160 and 320 l/min [10.6, 21.1, 31.7, 42.3 and 84.5 US gal/

min], pressure up to 350 bar [5076 psi].

•

Pilot operated flow-amplifiers with amplification factors of 4, 5, 8, 10 or 20 for rated oil flows of 240

and 400 l/min [63.4 and 105.7 US gal/min], steering pressure up to 210 bar [3045 psi].

•

Pilot operated steering valve with steering flow up to 100 l/min [26.4 US gal/min], steering pressure

up to 250 bar [3625 psi] and with integrated priority valve for pump flow up to 120 l/min [31.7 US gal/

min].

For electrohydraulic steering systems Danfoss offers:

•

Pilot operated steering valves (pilot operated by hydrostatic steering unit or by electrical signal) with

steering flows up to 100 l/min [26.4 US gal/min], steering pressure up to 250 bar [3625 psi].

•

Steering units with integrated electrical operated steering valve with steering flow up to 50 l/min

[13.2 US gal/min], steering pressure up to 210 bar [3045 psi].

4 | © Danfoss | March 2016 L1313806 | BC00000222en-US0202

Page 5

Technical Information

OSPU Steering Unit

A wide range of Steering Components

Characteristic features for steering units:

•

Low steering torque: From 0.5 N•m to 3 N•m in normal steering situations

•

Low noise level

•

Low pressure drop

•

Many types available: Open center Non-reaction, Open center Reaction, Power Beyond, Closed center

Non-reaction, Load Sensing, Load Sensing Reaction

•

One or more built-in valve functions: relief valve, shock valves, suction valves, non-return valve in Pline and in LS-line

•

Optional port connections (according to ISO, SAE or DIN standards)

Characteristic features for electrohydraulic steering systems with OSPE and EHPS:

•

Possibility of GPS, row sensor, variable steering ratio and joystick steering

•

The possibility of manual steering even on very heavy vehicles

•

EHPS: High steering pressure requiring smaller cylinders and flow

•

EHPS: Low pilot pressure and flow giving extremely low noise in the cabin

•

EHPS: Can be combined with Danfoss PVG 32 proportional valve

Conversion factors

1 N•m = [8.851 lbf•in] 1 l = [0.264 US gal]

1 N = [0.2248 lbf] 1 bar = [14.5 psi]

1 mm = [0.0394 in] °F = [1.8°C + 32]

1 cm3 = [0.061 in3]

©

Danfoss | March 2016 L1313806 | BC00000222en-US0202 | 5

Page 6

Technical Information

OSPU Steering Unit

Technical literature survey

Survey of literature with technical data on Danfoss Steering Components

Detailed data on all Danfoss steering components and accessories can be found in our steering

component catalogues, which is divided in to the following individual sub catalogues:

General information Steering components

Technical data on mini steering units OSPM

Technical data on open center, and closed center steering units OSPB, OSPC, and OSPD

Technical data on load sensing steering units, priority valves and flow

amplifiers

Technical data on hydraulic and electrohydraulic pilot operated steering

valves, electrical actuation modules and appropriate steering units.

Technical data on combined steering unit/electrohydraulic steering valves

and steering wheel sensors

Technical data on load sensing steering unit with amplification OSPU

For technical information on individual variants, please contact the Danfoss Sales Organization.

OSPU general information

OSPU is a flow amplifying, load sensing steering unit, available with amplification factors 2, 3, or 4. OSPU

is a cost-attractive dual displacement steering unit alternative for heavier applications needing reduced

displacement for emergency (manual) steering, such as tractors, backhoe loaders, telehandlers, and

combines.

The OSPU total displacement ranges from 120-500 cc in normal steer mode (amplified). In emergency

steer mode the displacement ranges from 60-125 cc/rev. The standard OSPU has fully linear flow

characteristic (flow versus rpm).

OSPU is also available in a version with continuous progressive amplification factor. This feature will make

a simple “Fast Steer” steering system possible: it enables higher ratio steering flow at higher rpm

meaning less turns lock-lock at higher steering speed. This feature is especially attractive on backhoe

loaders and small wheel loaders.

OSPB, OSPC, OSPF, OSPD, OSPL,

OSPBX, OSPLX, OVPL, OLS and OSQ

EHPS, EHPS w. OLS 320, PVE for EHPS

and OSPCX

OSPE

SASA

6 | © Danfoss | March 2016 L1313806 | BC00000222en-US0202

Page 7

3 6 9 7 8

P301 477

11 12 13 14 15 16

Technical Information

OSPU Steering Unit

Function

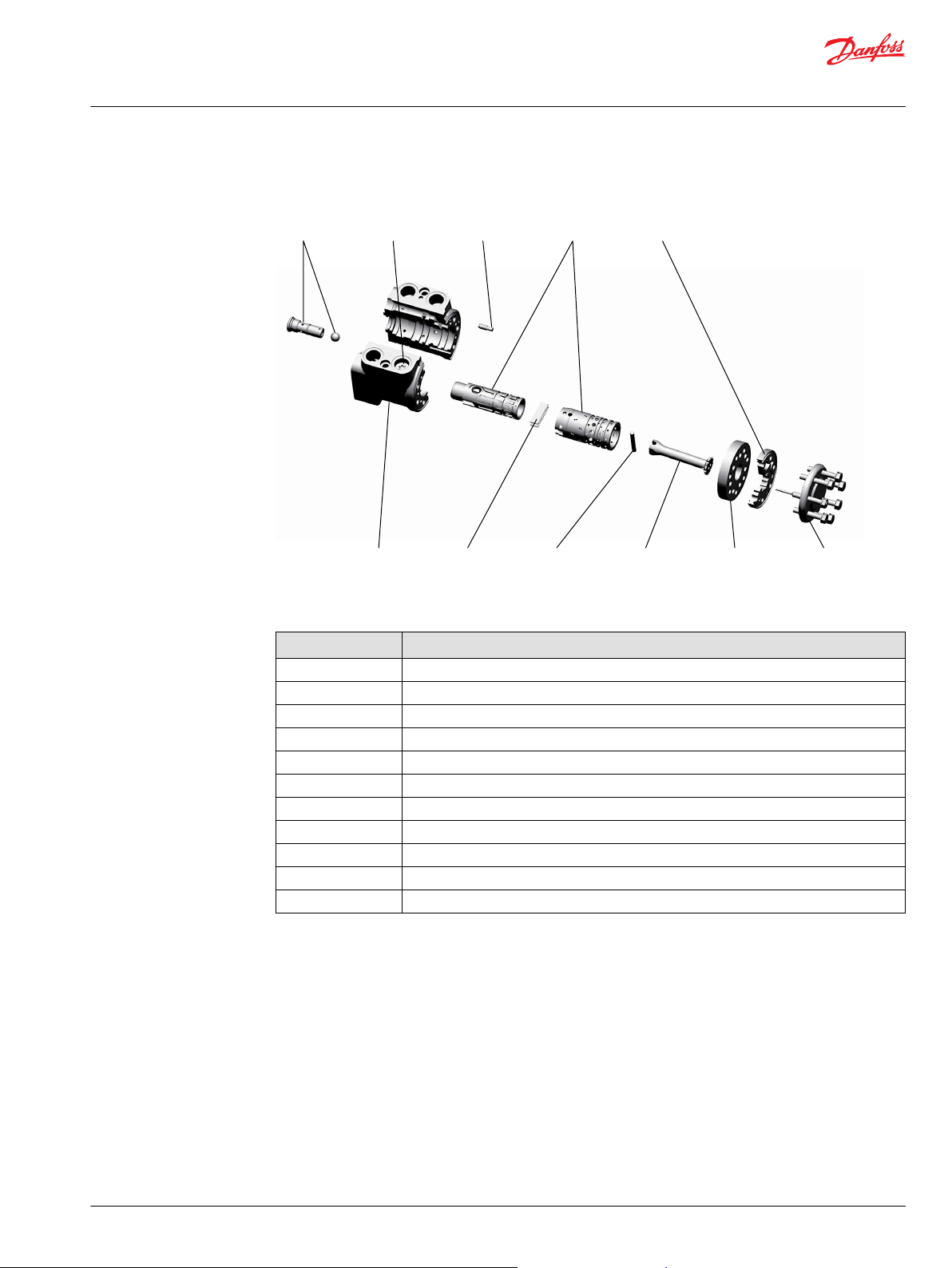

OSPU steering unit

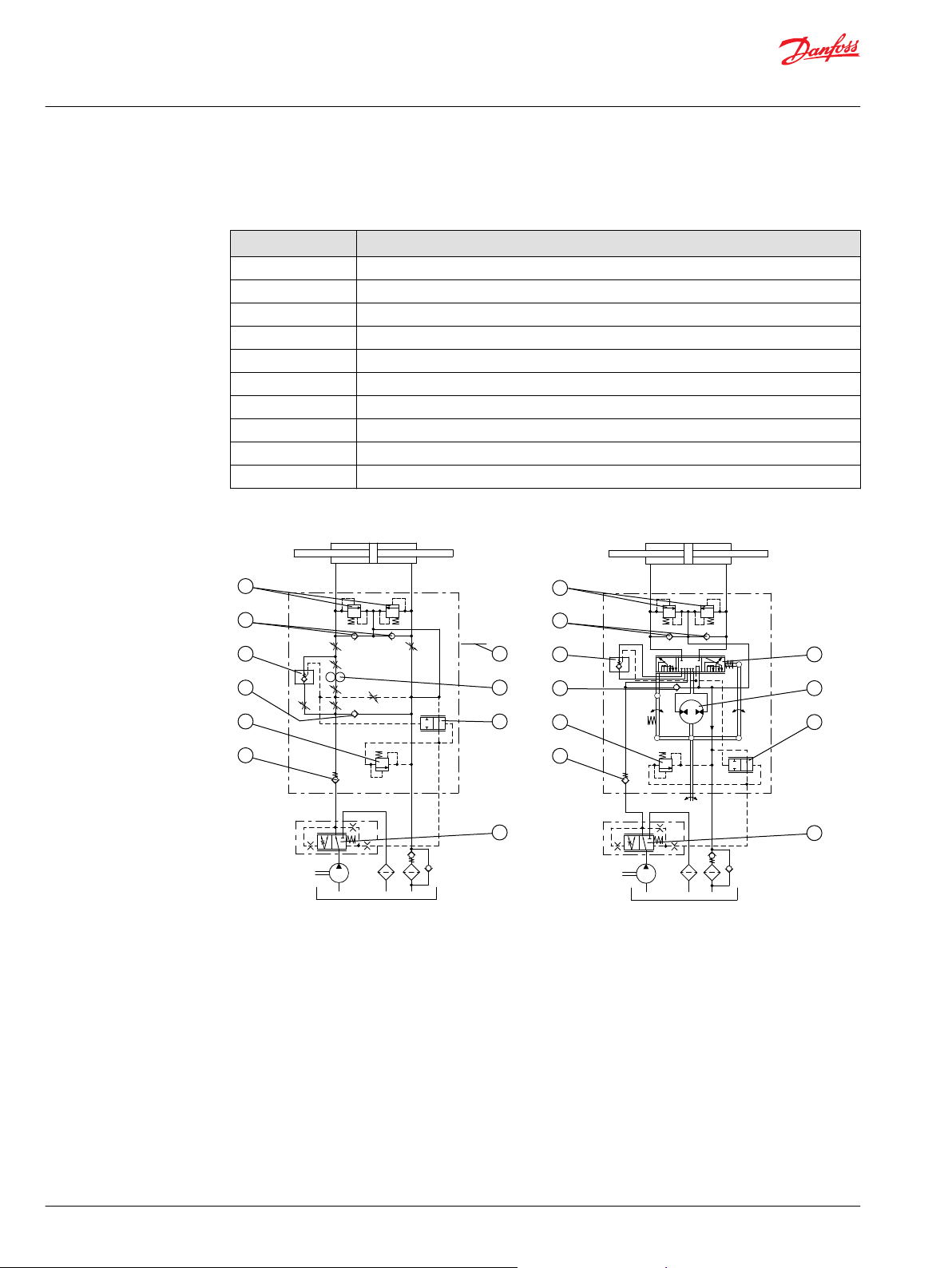

The OSPU includes the following main components:

Designation of OSPU elements

Item Description

3 Torque compensator valve

6 P-check valve

7 Spool/sleeve set

8 Gear set

9 LS copy valve

11 Housing

12 Neutral spring package

13 Cross pin

14 Cardan shaft

15 Distributor plate

16 End cover with screws

©

Danfoss | March 2016 L1313806 | BC00000222en-US0202 | 7

Page 8

A

5

A

4

A

3

A

2

A

1

A

u

A

d

A

1-5,d,u

P

T

LS

L R

P301 479

2

1

3

4

5

6

8

9

7

10

P301 480

T

LS

L R

P

2

1

3

4

5

6

7

8

10

9

Technical Information

OSPU Steering Unit

Function

Function, OSPU LS

Designation of OSPU elements

Item Description

1 Shock valves

2 Suction valves

3 Torque compensator valve

4 Emergency steering check valve

5 Pilot pressure relief valve

6 P-check valve

7 Spool/sleeve set: including bleeds, A1-A5, Au and Ad

8 Gear set

9 LS copy valve

10 Priority valve, dynamic type

OSPU Danfoss symbols

OSPU ISO-symbols

The OSPU is a Load Sensing Dynamic steering unit type with built in amplification function in the spool/

sleeve set (7).

The main circuit is identical to other OSP LS steering units like e.g. OSPC: Bleeds of spool/sleeve set (7):

A1-A5 and Ad plus gear set (8).

Additionally the OSPU includes an amplification circuit containing the Au bleed in spool/sleeve/set (7)

and a torque compensator valve (3).

Furthermore the OSPU contains a LS copy valve (9). This valve is needed to be able to use dynamic

priority valve.

Neutral position

The drain bleed Ad of spool/sleeve set (7) is open to tank. All other bleeds, A1-A5 and Au are closed.

When the pump runs, the dynamic flow from the LS line of the priority valve (10) will stream across the LS

copy valve (9) to tank.

8 | © Danfoss | March 2016 L1313806 | BC00000222en-US0202

Page 9

Technical Information

OSPU Steering Unit

Function

Steering with normal pump supply

When turning the steering wheel, the drain bleed Ad will be closed, and all other bleeds, A1-A5 and Au

will open in parallel. Opening area will depend on steering wheel speed. Pressure in LS line will rise

according to steering pressure demand: pressure will be transmitted across the LS copy valve (9) and the

priority valve (10) will supply the requested oil flow and pressure to P port of the steering unit.

The pump oil flow will be split between the parallel connected inlet bleeds: A1 and Au. The oil flow across

A1 is determined by the size of the gear set (8) and the steering wheel speed. The oil flow across Au is

determined by the opening area of Au. The amplification will be constantly independent on steering

speed under normal steering conditions: pump flow and standby pressure must be within demand for

the requested steering speed.

The function of the torque compensator valve (3) is to assure constant amplification: in case pressure

drop may occur across the gear set (8) e.g. due to dirt particles entering the steering unit, the torque

compensator valve (3) will generate the same pressure drop for the amplified oil.

When steering against end stroke, the steering pressure will be limited by the pilot pressure relief valve

(5): pressure in LS line will be limited and so the priority valve will lead the pump flow to EF port of the

priority valve and on to tank.

Emergency steering: Failing pump supply

When pressure in P-port does not match the steering pressure requested, the gear set (8) will act as a

hand pump, when torque is applied to the steering wheel. The displacement for emergency steering is

purely determined by the size of the gear set (8). The check valve function of the torque compensator

valve (3) will prevent back stream of oil across the Au bleed.

When pump flow becomes insufficient, the emergency steering check valve (4) will open and oil will be

led to the gear set (8) from return side of cylinder, additional flow will be sucked from tank as needed.

©

Danfoss | March 2016 L1313806 | BC00000222en-US0202 | 9

Page 10

Technical Information

OSPU Steering Unit

Versions

OSPU LS

Load sensing dynamic

In load sensing steering systems both the steering system and the working hydraulics can be supplied

from just one pump. In addition LS steering systems make energy saving possible by the use of an LS

pump.

Load sensing steering units have a connection for load sensing (LS), so that a load pressure signal can be

directed via the steering unit to a Danfoss priority valve and/or an LS pump. The load sensing signal

controls the oil flow from the priority valve (and/or the LS pump) to the steering unit.

OSPU are all of load sensing dynamic type and require load sensing dynamic priority valves and/or load

sensing variable displacement pumps with “dynamic” control. Load sensing dynamic steering systems

have a constant oil flow in the LS connection direction steering unit also when the steering unit is in

neutral position.

Non-reaction

With non-reaction steering units there is no corresponding movement of the steering wheel when the

driver is not steering the vehicle.

Amplification, linear

The displacement is constant over the entire range of normal steering speed, 0-100 rpm.

Amplification, progressive

The displacement varies over the entire range of normal steering speed, 0-100 rpm.

10 | © Danfoss | March 2016 L1313806 | BC00000222en-US0202

Page 11

P301 482

P T

L R

LS

P

T

LS

L R

Technical Information

OSPU Steering Unit

Versions

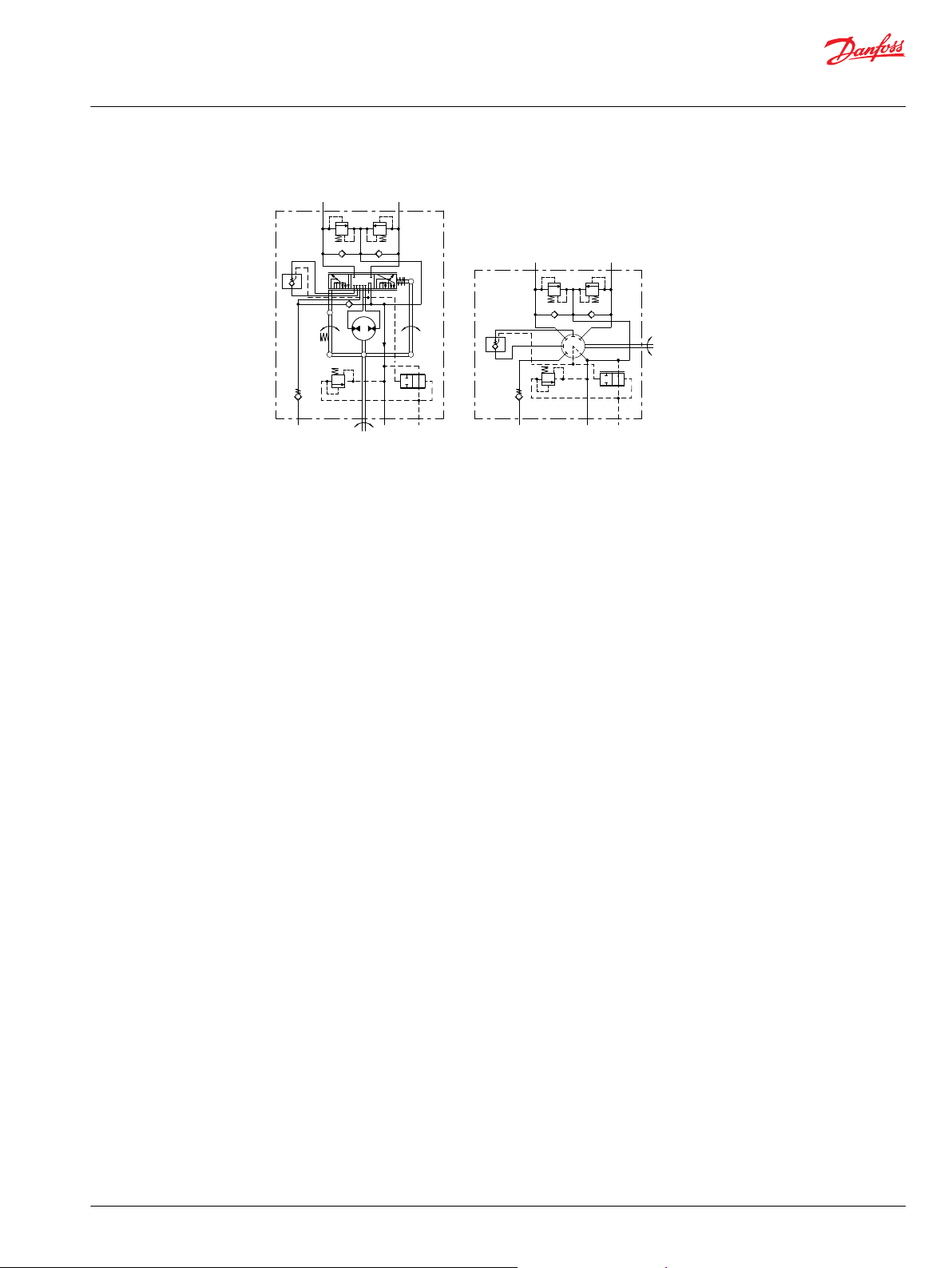

OSPU LS: Steering unit load sensing with integrated valve functions

©

Danfoss | March 2016 L1313806 | BC00000222en-US0202 | 11

Page 12

Technical Information

OSPU Steering Unit

Technical data

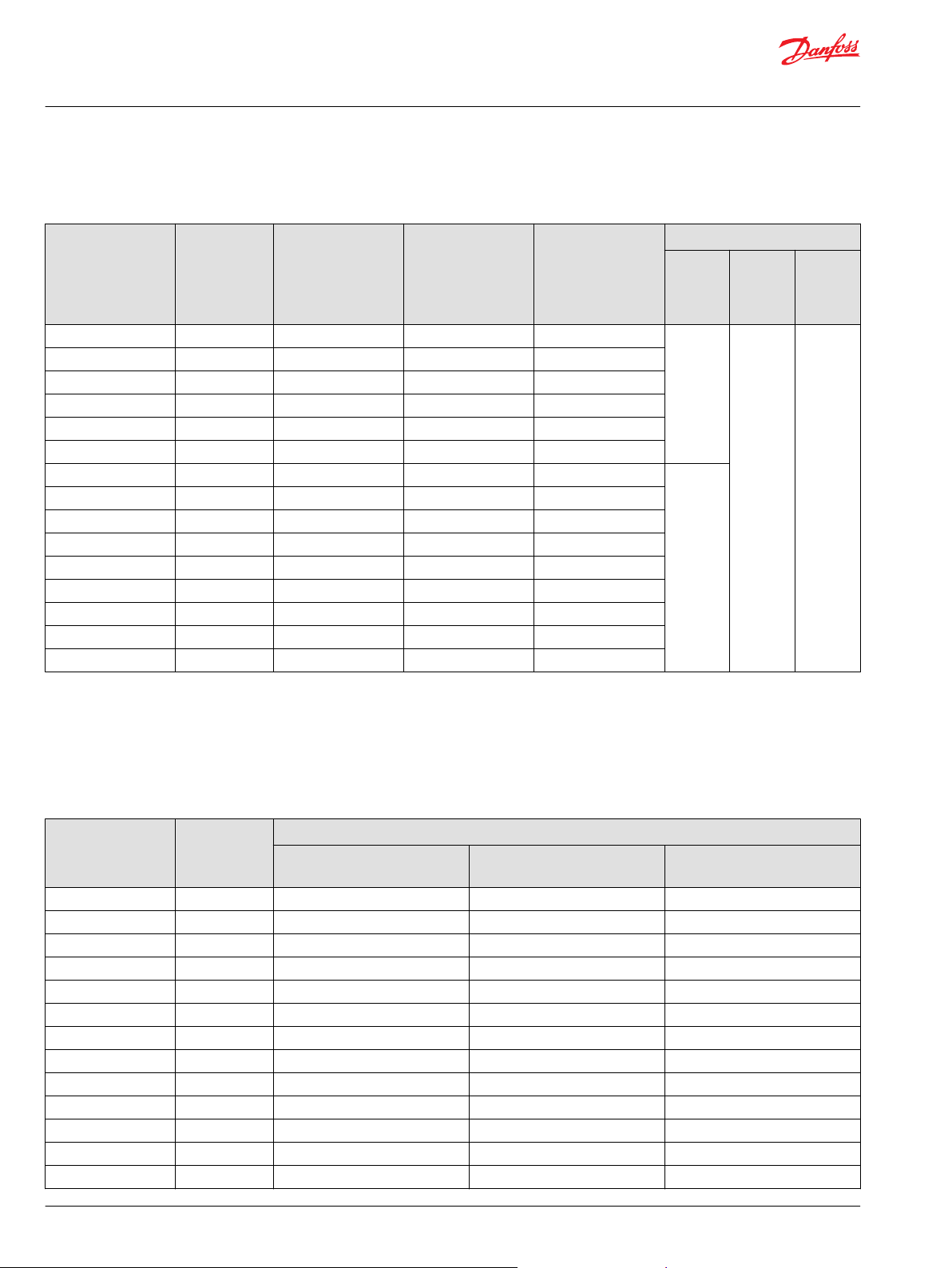

Displacement, amplification, flow and pressure: OSPU LS

For common data: Look in sub catalog: ”General Steering Components”

Steering unit Amplification Displacement

emergency/ manual

steer mode

cm³/rev [in³/rev]

OSPU 60/120 LS 2 60 [3.66] 120 [7.32] 12 [3.17] 175

OSPU 60/180 LS 3 60 [3.66] 180 [10.98] 18 [4.76]

OSPU 60/240 LS 4 60 [3.66] 240 [14.65] 24 [6.34]

OSPU 70/140 LS 2 70 [4.27] 140 [8.54] 14 [3.70]

OSPU 70/210 LS 3 70 [4.27] 210 [12.81] 21 [5.55]

OSPU 70/280 LS 4 70 [4.27] 280 [17.09] 28 [7.40]

OSPU 80/160 LS 2 80 [4.88] 160 [9.76] 16 [4.23] 210

OSPU 80/240 LS 3 80 [4.88] 240 [14.65] 24 [6.34]

OSPU 80/320 LS 4 80 [4.88] 320 [19.53] 32 [8.45]

OSPU 100/200 LS 2 100 [6.10] 200 [12.20] 20 [5.28]

OSPU 100/300 LS 3 100 [6.10] 300 [18.31] 30 [7.93]

OSPU 100/400 LS 4 100 [6.10] 400[24.41] 40 [10.57]

OSPU 125/250 LS 2 125 [7.63] 250 [15.26] 25 [6.60]

OSPU 125/375 LS 3 125 [7.63] 375 [22.88] 38 [10.03]

OSPU 125/500 LS 4 125 [7.63] 500 [30.51] 50 [13.21]

*

Rated flow at 100 rpm steering speed.

†

Any OSPU can withstand 210 bar in max. system pressure. However OSPU w. small gear wheel set and high pressure will have relatively high slippage

Displacement

normal steer mode

cm³/rev [in³/rev]

Rated oil flow

l/min [US gal/min]

values (slippage will be on level with e.g. OSPC with same gear wheel set)

*

Max. pressure, bar [psi]

System

pressure

P-T port

pressure

[2540]40[580]

[3045]

T,

†

absolute

port

pressure

L-T/R-T

port

pressure

280

[4060]

A minimum standby pressure

(P-LS) is needed to achieve the defined amplification characteristic (linear or progressive) up to a certain

maximum steering speed wanted.

Steering unit Amplification Min. standby pressure*, P-LS bar [psi]

For max steering speed

80 rpm

OSPU 60/120 LS 2

OSPU 60/180 LS 3 7 10 12

OSPU 60/240 LS 4

OSPU 70/140 LS 2

OSPU 70/210 LS 3 8 11 13

OSPU 70/280 LS 4

OSPU 80/160 LS 2

OSPU 80/240 LS 3 9 12 13

OSPU 80/320 LS 4

OSPU 100/200 LS 2

OSPU 100/300 LS 3 10 12 15

OSPU 100/400 LS 4

OSPU 125/250 LS 2

6 8 9

9 13 15

7 10 11

10 14 17

8 11 12

13 15 18

9 11 13

15 19 - - 10 12 14

For max steering speed

100 rpm

For max steering speed

120 rpm

12 | © Danfoss | March 2016 L1313806 | BC00000222en-US0202

Page 13

0

5

10

15

20

25

30

35

40

45

0

Rpm

20 40 60 80 100

100 cc GS

Emergency steer

1:2 1:3 1:4 1:2

Progressive

l/min

P301 448

10

7.5

5

2.5

US gal/min

Technical Information

OSPU Steering Unit

Technical data

Steering unit Amplification Min. standby pressure*, P-LS bar [psi]

For max steering speed

80 rpm

OSPU 125/375 LS 3 11 13 - - OSPU 125/500 LS 4

*

Values valid for viscosity range 12-80 mm²/s [66-370 SUS] and temperature range of 30-60°C [86-140°F]

18 - - - - - -

Missing values will be added when available.

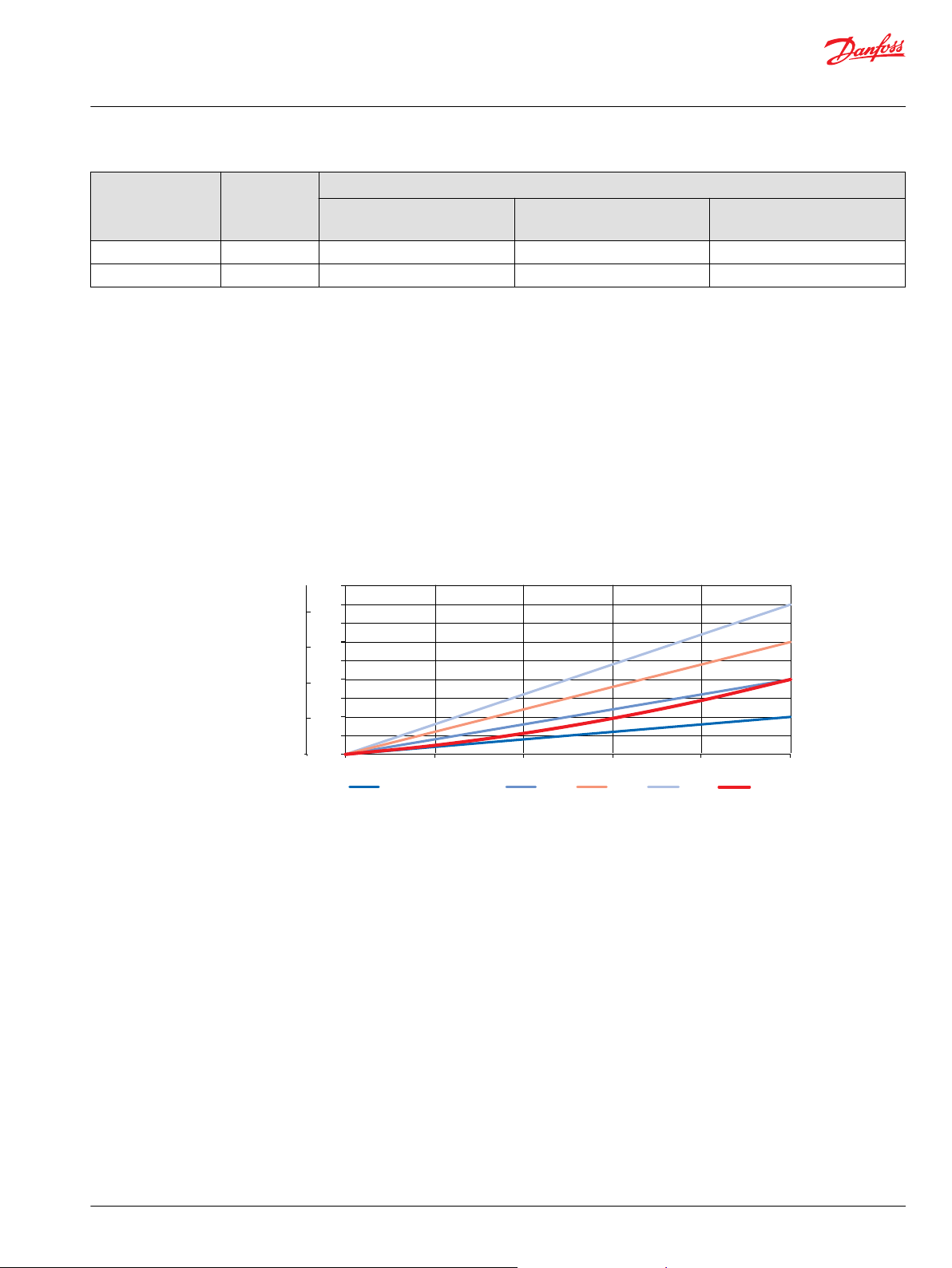

Amplification characteristics

OSPU with linear amplification has constant displacement independent on steering speed inside normal

steering speed range, 0-100 rpm, e.g. OSPU 100/200 LS “Linear” has 200 cm³/rev.

In OSPU with progressive amplification the displacement varies over the entire range of normal steering

speed, 0-100 rpm. OSPU 100/200 LS “Progressive” has the following nominal displacements:

115 cc/rev at >0-~5rpm: 15% amplification

•

150 cc/rev at ~50 rpm: 50% amplification

•

200 cc/rev at ~100 rpm: 100% amplification

•

For max steering speed

100 rpm

For max steering speed

120 rpm

Emergency steering: Pressure capability

©

Danfoss | March 2016 L1313806 | BC00000222en-US0202 | 13

Metered out flow for OSPU 100 shown with amplification factors possible.

The steering unit can be used as a hand pump if oil supply to the steering unit fails.

Below graph can be used as a design guide to choose the needed size of gear set for the OSPU:

•

Determine steering pressure required for the emergency steering maneuver and draw a horizontal

line from this value for Pressure

•

Determine manual input torque allowed on steering wheel and draw a vertical line from this value for

Torque

•

The largest steering unit displacement suitable is the first angled line to the left of intersection. An

example is shown w. 25 bar [362 psi] pressure demand, and 38 Nm [336 lbf•in] allowed manual input

torque: OSPU 80/xxx, OSPU 70/xxx or OSPU 60/xxx are suitable to build up enough pressure for

emergency steering.

Page 14

1100

1000

900

800

700

600

500

400

300

200

100

0

0 100 200 300 400 500 600 700 800 900

Pressure,

[psi]

[lfb•in]

P301 483

0

10

20

30

40

50

60

70

80

0 20 40 60 80 100

60

70

80

100

125

Bar

Torque,

Nm

Gear set size:

P

T

LS

L R

P301 481

2

1

3

4

5

6

7

Technical Information

OSPU Steering Unit

Technical data

OSPU LS emergency steer curves

Valve functions in OSPU LS steering units

Only physical testing on the vehicle in question can verify if the demands for emergency steer capability

will be fulfilled.

All OSPU have the following valves build in as standard:

•

Emergency steering check valve (4)

•

P-check valve (7)

•

Check valve function in LS:

LS copy valve (5)

•

Suction valves (2)

•

Torque compensator valve (3)

OSPU can have built in the following valves (option):

•

Pilot pressure relief valve (6)

•

Shock valves (1)

14 | © Danfoss | March 2016 L1313806 | BC00000222en-US0202

Page 15

A = 170 +5 bar [2465

+73

psi]

-0 -0

B = 140

+5

bar [2030

+73

psi]

-0 -0

3000

2500

2000

1500

1000

0

200

180

160

140

120

100

80

60

0

psi bar

152B79.10

0 10 20 30 40 50 60 70 80 l/min

P-T P-T

Q

p

Q

p

0 2 4 6 8 10 12 14 16 18 20 US gal/min

A

B

OSPC/OSPF/OSPD/OSPU/OSPL LS+OLS 80

Technical Information

OSPU Steering Unit

Technical data

Pilot pressure relief valve; (P - T, Qp) characteristic

The pilot pressure relief valve protects the steering unit against excessive pressure. The pilot pressure

relief valve in the OSPU LS steering unit together with the priority valve limits the maximum steering

pressure P-T. The pilot pressure relief valve is set at an oil flow to the priority valve of 25 l/min [6.60 US

gal/min].

For OSPU Load Sensing dynamic steering units, the setting values are valid at a dynamic flow of 1.1 l/min

[0.29 US gal/min]

Setting tolerance:

</= 170 bar [2645 psi]: rated value +5 bar [72.5 psi].

> 170 bar [2645 psi]: rated value +10 bar [145 psi].

Shock valves

Suction valves

©

Danfoss | March 2016 L1313806 | BC00000222en-US0202 | 15

The shock valves protect the steering unit and reduce external forces on the steering cylinder by limiting

the pressure difference from L to T and from R to T.

The shock valves are set at 3 l/min [0.792 US gal/min]

At higher flow pressure peaks may occur.

The shock valves are of the direct acting type, so they react very quickly.

Setting tolerance: rated value +20 bar [290 psi].

The suction valves allow oil suction to avoid cavitation in the steering cylinder. To provide correct

suction, a back pressure valve must be fitted in the tank line from the steering unit.

Generally Danfoss recommend a back pressure of 2 bar [29 psi], but on vehicles with strong selfstraightening tendencies and on articulated steered vehicles, we recommend 5-10 bar [72.5 - 145 psi]. For

further advice, please contact the Danfoss Sales Organisation.

A connection which incorporates a check valve must be established to allow oil flow to by-pass the back

pressure valve (and filter) from the tank to steering unit. See OSPU LS diagram examples.

Page 16

100

80

60

40

20

0

7

6

5

4

3

2

1

0

psi bar

150-374.10

0 1 2 3 4 5 6 7 8 9 10 11 l/min

T-R

T-L

T-R

T-L

Q

p

Q

p

0 0.25 0.50 0.75 1 1.25 1.50 1.75 2 2.25 2.50 2.75 US gal/min

90

75

60

45

30

15

0

6

5

4

3

2

1

0

psi bar

150-375.11

0 10 20 30 40 50 60 70 80 l/min

Q

p

Q

p

0 3 6 9 12 15 18 21 US gal/min

∆ p ∆ p

Technical Information

OSPU Steering Unit

Technical data

Check valve in P

The check valve in the P connection of the steering unit protects the driver against steering wheel jerks.

The check valve prevents oil from flowing backwards into the pump line when steering against a high

pressure on the cylinder side. The pressure drop across the check valve is indicated on the following

graph, which assumes the use of port adaptors with 11 mm [0.43 in] minimum bore.

Check valve function in LS

16 | © Danfoss | March 2016 L1313806 | BC00000222en-US0202

The LS copy valve of OSPU protects the driver against steering wheel jerks. The LS copy valve prevents oil

from flowing backwards into the LS line to the priority valve when steering against a high pressure on the

cylinder side.

Page 17

min.12[0.47]

min.Ø28[1.10]

B

30°

L

150-603.10-B

150-603.10-D

0.6[0.024]

Ø28.3[1.114]

Ø28.6[1.126]

N

min.15[0.59]

D

150-603.10-E

O

1[0.04]

min.11.5[0.453]

min.Ø22[0.87]

min.Ø26[1.02]

30°

E

150-603.10-F

0.6[0.024]

Ø28.6[1.126]

Ø28.3[1.114]

P

min.15[0.59]

F

Technical Information

OSPU Steering Unit

Technical data

Port thread versions for OSPU LS

B: G port w. spot face (LS)

L: DIN 3852-2 - G ¼

D: G ports w. spot face (P, T, L, R)

N: DIN 3852-2 - G ½

E: Metric port w. spot face and O-ring chamfer (LS)

O: ISO 6149-1 - M12 x 1.5

F: Metric ports w. spot face and O-ring chamfer (P, T, L, R)

P: ISO 6149-1 - M18 x 1.5

©

Danfoss | March 2016 L1313806 | BC00000222en-US0202 | 17

Page 18

150-603.10-H

min.11.5[0.45]

min.Ø21[0.83]

30°

R

H

150-603.10-I

min.15[0.59]

Ø20.8[0.819]

S

I

Technical Information

OSPU Steering Unit

Technical data

H: UNF ports w. O-ring chamfer (LS)

R: ISO 11926-1

7/16-20 UNF O-ring boss port

I: UNF ports w. O-ring chamfer (P, T, L, R)

S: ISO 11926-1 ¾-16UNF O-ring boss port

18 | © Danfoss | March 2016 L1313806 | BC00000222en-US0202

Page 19

44

[1.73]

Ø 25.4

[1.00]

29

[1.14]

7.0

[0.27]

Ø82 ±0.3

[3.23 ±0.01]

45˚

57 [2.24]

L R

T

P

B

Ø 44.4 ±0.05

[1.75 ±0.01]

max 87 [3.43]

Ø91 [3.58]

47 [1.85]

44 [1.73]

A

2.8

[0.11]

LS

51

[2.01]

35

[1.38]

38 [1.50]

85 [3.35]

102 [4.02]

min.7.1

[0.28]

L2

L1

max.5.3 [0.21]

LS

P301 478

Technical Information

OSPU Steering Unit

Dimensions

Dimension

OSPU LS

European version: US version:

A: G ½ w. spot face (G, DIN 3852-2) 15 mm [0.59 in] deep

or

A: 3/4 - 16 UNF O-ring boss ISO 11926-1 15 mm [0.59 in]

deep

M18 x 1.5 ISO 6149-1,15 mm [0.59 in] deep

B: M10 x 1.5, 16 mm [0.63 in] deep B: M 10 × 1.5, 16 mm [0.63 in] deep,

LS: G 1/4 w. spot face (G, DIN 3852-2) 12 mm [0.47 in]

deep or

M12 x 1.5 ISO 6149-1, 11.5 mm [0.45 in] deep

Type L1,

mm [in]

60/xxx 137 [5.39] 7.8 [0.31]

70/xxx 138 [5.43] 9.1 [0.36]

80/xxx 139 [5.47] 10.4 [0.41]

100/xxx 142 [5.59] 13.0 [0.51]

LS: 7/16 - 20 UNF o-ring boss ISO 11926-1, 11.5 mm [0.45

in] deep

L2,

mm [in]

125/xxx 145 [5.71] 16.2 [0.64]

©

Danfoss | March 2016 L1313806 | BC00000222en-US0202 | 19

Page 20

Technical Information

OSPU Steering Unit

Order specifications and weights

Order specifications

Variants, OSPU

Gear set,

displacement

Amplified

displacement

Spool/sleeve

set

Amplification

Housing

Relief valve

Shock valves

*

Amplification factors available, linear: 2, 3 or 4

†

Housing, threads:

cm³/rev 60 70 80 100 125

cm³/rev 120, 180, 240 140, 210, 280 160, 240, 320 200, 300, 400 250, 375, 500

*

Type LS: Load Sensing dynamic, non-reaction

Characteristic L: Linear P: Progressive (only available w.

amplification factor “2”)

†

Thread M: Metric G U: UNF

Bar 100 – 210 (N for no relief valve wanted)

Bar 160 – 260 (N for no shock valves wanted)

Weights

P, T. L & R LS

Metric, ISO 6149-1 M 18 x 1.5 – O* +

G, DIN 3852-2 G ½ UNF O-ring boss ISO 11926-1 ¾ - 16 UNF –

O*

O-ring chamfer on port connection

S**

Spot face around port connection

S**

S**

O*

All OSPU’s have the following valves included:

Manual Steering Check Valve

•

Inlet Check Valve in P-port

•

Check Valve function in LS

•

Suction Valves in cylinder ports

•

Torque Compensator Valve

•

Type OSPU Weight kg [lb]

60/xxx 5.3 [11.47]

70/xxx 5.4 [11.90]

80/xxx 5.5 [12.13]

100/xxx 5.6 [12.35]

125/xxx 5.8 [12.79]

M 12 x 1.5 – O* +

S**

G ¼ 7/16 - 20 UNF –

S**

O*

20 | © Danfoss | March 2016 L1313806 | BC00000222en-US0202

Page 21

Your wish: OSPU

Example: OSPU 70 210 LS L M 170 230 PB

Gear set, displacement

Amplified displacement

Spool/sleeve set

Amplification Characteristic

Housing, thread

Relief valve setting

Shock valves setting

Unit painted black

Technical Information

OSPU Steering Unit

Code numbers for catalog versions with specifications

Specify your OSPU according to the destinations as in the example underneath the empty scheme:

Code numbers

Code numbers Specifications according to above description format

11131317 OSPU 70 210 LS L M 170 230 PB

©

Danfoss | March 2016 L1313806 | BC00000222en-US0202 | 21

Page 22

Technical Information

OSPU Steering Unit

22 | © Danfoss | March 2016 L1313806 | BC00000222en-US0202

Page 23

Technical Information

OSPU Steering Unit

©

Danfoss | March 2016 L1313806 | BC00000222en-US0202 | 23

Page 24

Danfoss

Power Solutions GmbH & Co. OHG

Krokamp 35

D-24539 Neumünster, Germany

Phone: +49 4321 871 0

Danfoss

Power Solutions ApS

Nordborgvej 81

DK-6430 Nordborg, Denmark

Phone: +45 7488 2222

Danfoss

Power Solutions (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239 6000

Danfoss

Power Solutions Trading

(Shanghai) Co., Ltd.

Building #22, No. 1000 Jin Hai Rd

Jin Qiao, Pudong New District

Shanghai, China 201206

Phone: +86 21 3418 5200

Products we offer:

Comatrol

www.comatrol.com

Schwarzmüller-Inverter

www.schwarzmuellerinverter.com

Turolla

www.turollaocg.com

Hydro-Gear

www.hydro-gear.com

Daikin-Sauer-Danfoss

www.daikin-sauer-danfoss.com

Bent Axis Motors

•

Closed Circuit Axial Piston

•

Pumps and Motors

Displays

•

Electrohydraulic Power

•

Steering

Electrohydraulics

•

Hydraulic Power Steering

•

Integrated Systems

•

Joysticks and Control

•

Handles

Microcontrollers and

•

Software

Open Circuit Axial Piston

•

Pumps

Orbital Motors

•

PLUS+1® GUIDE

•

Proportional Valves

•

Sensors

•

Steering

•

Transit Mixer Drives

•

Danfoss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and

electronic components. We specialize in providing state-of-the-art technology and solutions

that excel in the harsh operating conditions of the mobile off-highway market. Building on

our extensive applications expertise, we work closely with our customers to ensure

exceptional performance for a broad range of off-highway vehicles.

We help OEMs around the world speed up system development, reduce costs and bring

vehicles to market faster.

Danfoss – Your Strongest Partner in Mobile Hydraulics.

Go to www.powersolutions.danfoss.com for further product information.

Wherever off-highway vehicles are at work, so is Danfoss. We offer expert worldwide support

for our customers, ensuring the best possible solutions for outstanding performance. And

with an extensive network of Global Service Partners, we also provide comprehensive global

service for all of our components.

Please contact the Danfoss Power Solution representative nearest you.

Local address:

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

©

Danfoss | March 2016 L1313806 | BC00000222en-US0202

Loading...

Loading...