Technical Information

Orbital Motors

with Speed Sensor

www.danfoss.com

Technical Information

Orbital Motors with Speed Sensor

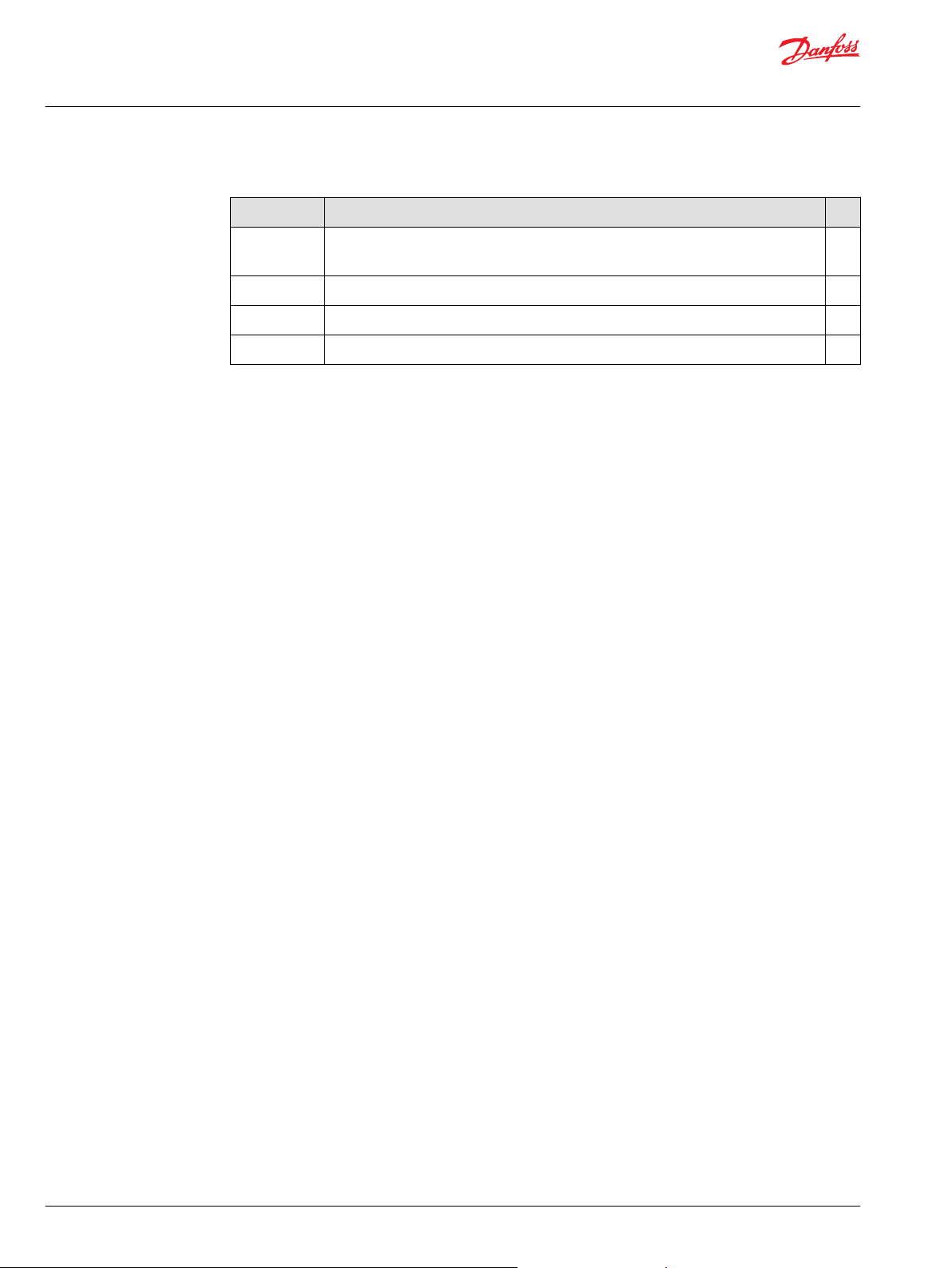

Revision history Table of revisions

Date Changed Rev

June 2021 Changed document number from '520L0830' to 'BC152886483462' and removed obsolete

motors

June 2015 Removed some code numbers 0201

November 2014 Converted to Danfoss layout - DITA CMS CA

November 2012 First edition BF

0401

2 | © Danfoss | June 2021 BC152886483462en-000401

Technical Information

Orbital Motors with Speed Sensor

Contents

A wide range of Orbital Motors

A Wide Range of Hydraulic Motors............................................................................................................................................ 4

Survey of Literature with Technical Data on Danfoss Hydraulic Motors......................................................................4

Data survey

Introduction........................................................................................................................................................................................5

Principle............................................................................................................................................................................................... 5

Advantages.........................................................................................................................................................................................5

Typical Applications........................................................................................................................................................................ 5

Versions OMT EM and OMV EM

Versions................................................................................................................................................................................................6

Features available:...................................................................................................................................................................... 6

Code Numbers OMT EM and OMV EM

Code number.....................................................................................................................................................................................7

Ordering......................................................................................................................................................................................... 7

Technical Data OMT EM

Technical data for OMT EM...........................................................................................................................................................8

Max. Permissible Shaft Seal Pressure.........................................................................................................................................9

OMT EM with check valves and without use of drain connection:........................................................................... 9

OMT EM with check valves and with drain connection:............................................................................................... 9

Pressure drop in motor...................................................................................................................................................................9

Technical Data OMV EM

Technical data for OMV EM........................................................................................................................................................ 11

Max. Permissible Shaft Seal Pressure......................................................................................................................................11

OMV EM with check valves and without use of drain connection:.........................................................................11

OMV EM with check valves and with drain connection:.............................................................................................12

Pressure drop in motor................................................................................................................................................................ 12

Technical Data Speed Sensor

Technical Data Speed Sensor.................................................................................................................................................... 13

Mechanical data:.......................................................................................................................................................................13

Electrical data.............................................................................................................................................................................13

Wiring Diagram...............................................................................................................................................................................14

Speed Sensor with Plug Connection Dimensions..............................................................................................................14

Speed Sensor with Molded in Cable Dimensions.............................................................................................................. 15

Spare Parts........................................................................................................................................................................................15

Speed sensor..............................................................................................................................................................................15

Accessories.......................................................................................................................................................................................15

Cable with plug......................................................................................................................................................................... 15

Wire (shield)................................................................................................................................................................................16

Plug................................................................................................................................................................................................16

Shaft Versions

Shaft Versions..................................................................................................................................................................................17

Port Thread Versions

Port Thread Versions.....................................................................................................................................................................18

Dimensions - US Version

OMT EM............................................................................................................................................................................................. 19

Dimensions - European Version

OMT EM............................................................................................................................................................................................. 21

OMV EM............................................................................................................................................................................................. 22

Weight of Motors

Weight of Motors OMT and OMV.............................................................................................................................................24

©

Danfoss | June 2021 BC152886483462en-000401 | 3

Technical Information

Orbital Motors with Speed Sensor

A wide range of Orbital Motors

A Wide Range of Hydraulic Motors

Danfoss is a world leader within production of low speed hydraulic motors with high torque. We can offer

more than 3000 different hydraulic motors, categorised in types, variants and sizes (incl. different shaft

versions).

The motors vary in size (rated displacement) from 25 cm3 [1.5 in3] to 800 cm3 [48.9 in3] per revolution.

Speeds range up to approx. 1700 min-1 (rpm) for the smallest type and up to approx

600 min-1 (rpm) for the largest type.

Maximum operating torques vary from 13 Nm [115 lbf·in] to 2700 Nm [24.000 lbf·in] (peak) and maximum

outputs are from 12 kW [16.1 hp] to 70 kW [95 hp].

Characteristic features:

Smooth running over the entire speed range

•

Constant operating torque over a wide speed range

•

High starting torque

•

High return pressure without the use of drain line (High pressure shaft seal)

•

High efficiency

•

Long life under extreme operating conditions

•

Robust and compact design

•

High radial and axial bearing capacity

•

For applications in both open and closed loop hydraulic systems

•

Suitable for a wide variety of hydraulics fluids

•

The programme is characterised by technical features appealing to a large number of applications and a

part of the programme is characterised by motors that can be adapted to a given application. Adaptions

comprise the following variants among others:

Motors with corrosion resistant parts

•

Wheel motors with recessed mounting flange

•

Short motors without bearings

•

Ultra short motors

•

Motors with integrated positive holding brake

•

Motors with integrated negative holding brake

•

Motors with integrated flushing valve

•

Motors with speed sensor

•

Motors with tacho connection

•

All motors are available with black finish paint

•

Survey of Literature with Technical Data on Danfoss Hydraulic Motors

Detailed data on all Danfoss motors can be found in our motor catalogue, which is divided into 5

individual subcatalogues:

General information on Danfoss hydraulic motors: function, use, selection of hydraulic motor,

•

hydraulic systems, etc.

Technical data on large motors: OMT and OMV

•

Technical data on large motors: TMK

•

Technical data on large motors: TMT

•

Technical data on large motors: TMVW

•

4 | © Danfoss | June 2021 BC152886483462en-000401

Technical Information

Orbital Motors with Speed Sensor

Data survey

Introduction

Danfoss has developed a speed sensor specially designed for LSHT motors.

The electric output signal is a standard voltage signal that can be used for regulating the speed motor.

Principle

The speed is measured by a sensor in accordance with the Hall principle. Signal processing and

amplification are performed in the sensor housing. A connection is provided in the housing for a Binder

Series 713 plug or a plug with 5 metres of cable (available from Danfoss). The sensor can also be supplied

with 2 metres molded in cable.

Advantages

Robust design

•

CE-marked

•

Fulfils EMC requirements of EN50081 and EN50082

•

Large frequency range, precise regulation

•

No limit on motor performance when compared to corresponding motors without speed sensor

•

IEC 529 degree of protection: IP 67

•

Replacable transducer

•

Standard speed signal

•

Easy installation

•

Electronic signal processing and amplification integrated in the sensor’s housing and requiring no

•

maintenance.

Typical Applications

Speed indication

•

Setting tightening speed in machine tools

•

Extend/retract positioning of work platforms

•

Granulate metering on injection moulding machines

•

Conveyor speed regulation

•

Metering on salt spreaders

•

©

Danfoss | June 2021 BC152886483462en-000401 | 5

Technical Information

Orbital Motors with Speed Sensor

Versions OMT EM and OMV EM

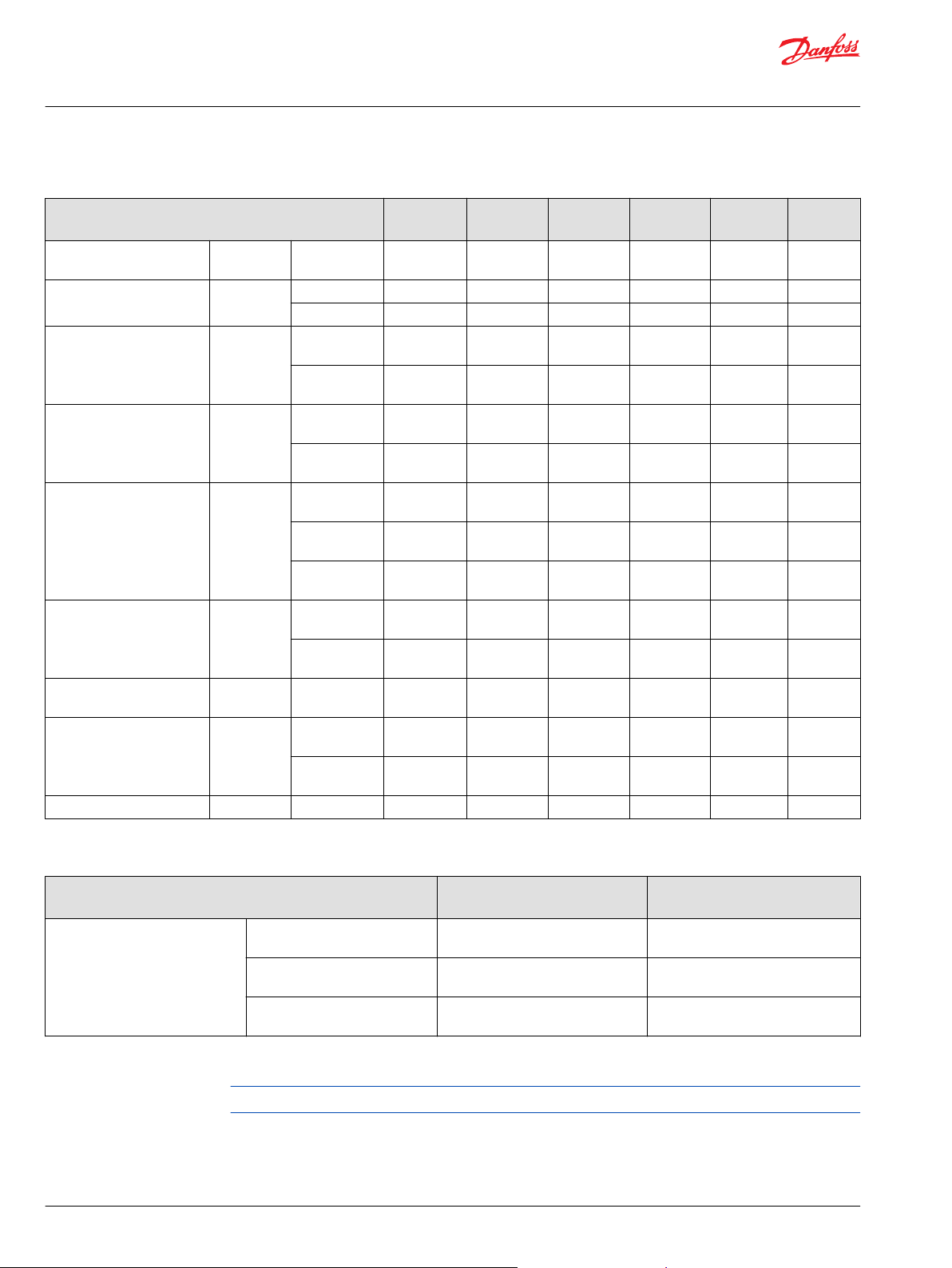

Versions

Mounting

flange

OMT EM Motors

Standard

flange

OMV EM Motors

Standard

flange

Spigot

diameter

Ø125 mm Ø160 mm Cyl. 40 mm G 3/4 X X X Yes Yes OMT EM

Ø5 in Ø6.38 Cyl. 1.5 in 11/16 - 12

Ø160 mm Ø200 mm Cyl. 50 mm G 1 X X X Yes Yes OMV EM

Bolt circle

diameter

(BC)

Shaft Port size European

version delivered

with sensor

for plug

connector

(PNP

version)

UN

US

version delivered

with

sensor

with 2 m

moduled

in cable

(PNP

version)

X X Yes Yes OMT EM

Side

port

vers

ion

Stan

dard

shaf

t

seal

Drai

n

conn

ectio

n

Chec

k

valve

Main type

designation

Features available:

Motors in european version: Speed sensor with 2 metres of molded in cable.

Motors in US versions: Speed sensor for plug connection.

Speed sensor for plug connector in NPN version.

The standard speed sensor is a PNP version

6 | © Danfoss | June 2021 BC152886483462en-000401

Technical Information

Orbital Motors with Speed Sensor

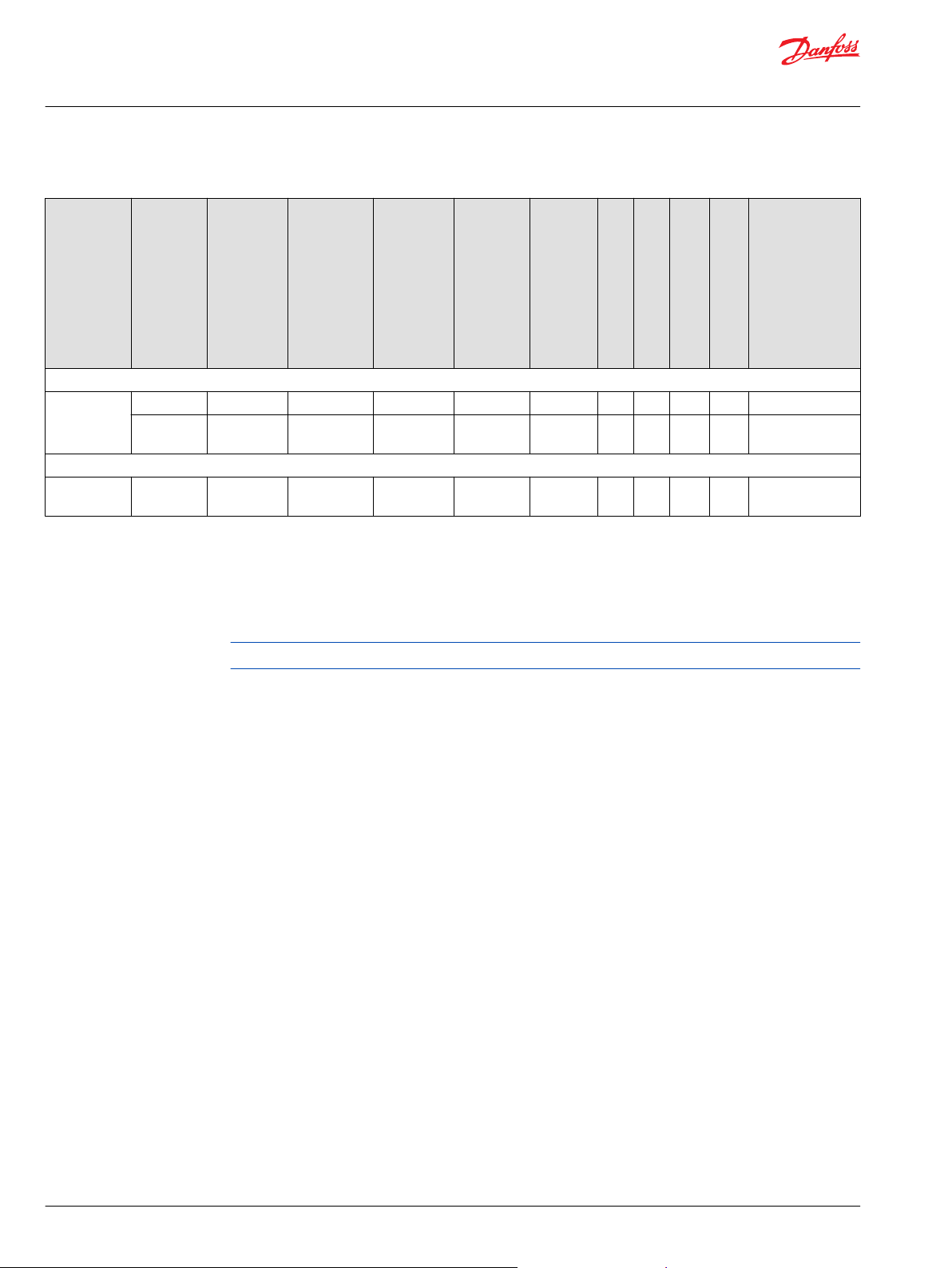

Code Numbers OMT EM and OMV EM

Code number

Code

numbers

OMT EM Motors

151B - - - 3260 3261 3262 3263 3264 3265 - 151B - - - 3700 3701 3702 3703 3704 3705 - -

OMV EM Motors

151B - - - - - - 3266 3267 3268 3269 3270

Displacements

80 100 125 160 200 250 315 400 500 630 800

Ordering

Add the four digit prefix “151-” to the four digit numbers from the chart for complete code number.

Orders will not be accepted without the four digit prefix.

©

Danfoss | June 2021 BC152886483462en-000401 | 7

Technical Information

Orbital Motors with Speed Sensor

Technical Data OMT EM

Technical data for OMT EM

Type

Motor size

Geometric displacements cm

[in3]

Max. speed min

rpm

Max torque Nm

[lbf•in]

Max. output kW

[hp]

Max. pressure drop bar

[psi]

Max. oil flow l/min

[US gal/min]

Max. starting pressure

with unloaded shaft

bar

[psi]

Min starting torque Nm

[lbf•in]

3

-1

cont. 625 625 500 380 305 240

int. 780 750 600 460 365 285

cont. 470

int. 560

cont. 26.5

1)

int.

cont. 200

1)

int.

2)

peak

cont. 100

1)

int.

at max. press.

drop cont.

at max. press.

drop int.

OMT EM

160

161.1

[9.83]

[4160]

[4960]

[35.5]

32.0

[42.9]

[2900]

240

[3480]

280

[4060]

[26.4]

125

[33.0]

10

[145]

340

[3010]

410

1)

[3630]

OMT EM

200

201.4

[12.29]

590

[5220]

710

[6280]

33.5

[44.9]

40.0

[53.6]

200

[2900]

240

[3480]

280

[4060]

125

[33.0]

150

[39.6]

10

[145]

430

[3810]

520

[4600]

OMT EM

250

251.8

[15.37]

730

[6460]

880

[7790]

33.5

[44.9]

40.0

[53.6]

200

[2900]

240

[3480]

280

[4060]

125

[33.0]

150

[39.6]

10

[145]

530

[4690]

630

[5580]

OMT EM

315

326.3

[19.91]

950

[8410]

1140

[10090]

33.5

[44.9]

40.0

[53.6]

200

[2900]

240

[3480]

280

[4060]

125

[33.0]

150

[39.6]

10

[145]

740

[6550]

890

7880]

OMT EM

400

410.9

[25.07]

1080

[9560]

1260

[11150]

30.0

[40.2]

35.0

[46.9]

180

[2610]

210

[3050]

240

[3480]

125

[33.0]

150

[39.6]

10

[145]

840

[7430]

970

[8590]

Frequency [Hz] max. 1014 975 780 598 475 371

1)

Intermittent operation: the permissible values may occur for max. 10% of every minute.

2)

Peak load: the permissible values may occur for max. 1% of every minute.

OMT EM

500

523.6

[31.95]

1220

[10800]

1370

[12130]

26.5

[35.5]

30.0

[40.2

160

[2320]

180

[2610]

210

[3050]

125

[33.0]

150

[39.6]

10

[145]

950

[8410]

1060

[9380]

Type Max. inlet pressure Max. return pressure with

drain line

OMT EM bar [psi]

cont.

bar [psi]

1)

int.

bar [psi]

2)

peak

1)

Intermittent operation: the permissible values may occur for max. 10% of every minute.

2)

Peak load: the permissible values may occur for max. 1% of every minute.

210

[3050]

250

[3630]

300

[4350]

140

[2030]

175

[2540]

210

[3050]

For further technical specifications please see technical information for OMT and OMV (BC152886483862)

8 | © Danfoss | June 2021 BC152886483462en-000401

151-320.10

151-1674.10

0 100 200 300 400 500 600 700 800 max.

1500

1200

900

600

300

0

100

90

80

70

60

50

40

30

20

10

0

psi bar

P P

min

-1

(rpm)

151-1409.10

0 20 40 60 80 100 120 140 l/min

0 4 8 12 16 20 24 28 32 36 US gal/min

200

150

100

50

0

16

14

12

10

8

6

4

2

0

psi bar

∆ p ∆ p

Q

Q

Technical Information

Orbital Motors with Speed Sensor

Technical Data OMT EM

Max. Permissible Shaft Seal Pressure

OMT EM with check valves and without use of drain connection:

The pressure on the shaft seal never exceeds the pressure in the return line.

OMT EM with check valves and with drain connection:

The shaft seal pressure equals the pressure on the drain line

Max. return pressure without drain line or max. pressure in drain line

--- Intermittent operation: the permissible values may occur for max. 10% of every minute.

___ Continuous operation

Pressure drop in motor

©

Danfoss | June 2021 BC152886483462en-000401 | 9

Technical Information

Orbital Motors with Speed Sensor

Technical Data OMT EM

The curve applies to an unloaded motor shaft and an oil viscosity of 35 mm2/s [165 SUS]

10 | © Danfoss | June 2021 BC152886483462en-000401

Technical Information

Orbital Motors with Speed Sensor

Technical Data OMV EM

Technical data for OMV EM

Type

Motorsize

Geometric displacements cm

[in3]

Max. speed min

rpm

Max torque Nm

[lbf•in]

Max. output kW

[hp]

Max. pressure drop bar

[psi]

Max. oil flow l/min

[US gal/min]

Max. starting pressure

with unloaded shaft

bar

[psi]

Min starting torque Nm

[lbf•in]

3

-1

cont. 510 500 400 315 250

int. 630 600 480 380 300

cont. 920

int. 1110

cont. 42.5

1)

int.

cont. 200

1)

int.

2)

peak

cont. 160

1)

int.

at max. press drop

cont.

at max. press.drop

1)

int.

OMV EM

315

314.5

[19.19]

[8140]

[9820]

[57.0]

51.0

[68.4]

[2900]

240

[3480]

280

[4060]

[42.3]

200

[52.8]

8

[116]

710

[6280]

850

[7520]

OMV EM

400

400.9

[24.46]

1180

[10440]

1410

[12480]

53.5

[71.7]

64.0

85.8]

200

[2900]

240

[3480]

280

[4060]

200

[52.8]

240

[63.4]

8

[116]

910

[8050]

1090

[9650]

OMV EM

500

499.6

[30.49]

1460

[12920]

1760

[15580]

53.5

[71.7]

64.0

[85.8]

200

[2900]

240

[3480]

280

[4060]

200

[52.8]

240

[63.4]

8

[116]

1130

[10000]

1360

[12040]

OMV EM

630

629.1

[38.39]

1660

[14690]

1940

[17170]

48.0

[64.4]

56.0

[75.1]

180

[2610]

210

[3050]

240

[3480]

200

[52.8]

240

[63.4]

8

[116]

1330

[11770]

1550

[13720]

Frequency [Hz] max. 1071 1020 816 646 510

1)

Intermittent operation: the permissible values may occur for max. 10% of every minute.

2)

Peak load: the permissible values may occur for max. 1% of every minute.

OMV EM

800

801.8

[48.93]

1880

[16640]

2110

[18680]

42.5]

[57.0]

48.0

[64.4]

160

[2320]

180

[2610]

210

[3050]

200

[52.8]

240

[63.4]

8

[116]

1510

[13360]

1700

[15050]

Type Max. inlet pressure Max. return pressure with drain line

OMV EM bar [psi]

cont.

bar [psi]

1)

int.

bar [psi]

2)

peak

1)

Intermittent operation: the permissible values may occur for max. 10% of every minute.

2)

Peak load: the permissible values may occur for max. 1% of every minute.

210

[3050]

250

[3630]

300

[4350]

140

[2030]

175

[2540]

210

[3050]

For further technical specifications please see technical information for OMT and OMV (BC152886483862)

Max. Permissible Shaft Seal Pressure

OMV EM with check valves and without use of drain connection:

The pressure on the shaft seal never exceeds the pressure in the return line.

©

Danfoss | June 2021 BC152886483462en-000401 | 11

151-320.10

151-1673.10

0 100 200 300 400 500 600 max.

1500

1200

900

600

300

0

100

90

80

70

60

50

40

30

20

10

0

psi bar

P P

min

-1

(rpm)

151-1410.10

0 20 40 60 80 100 120 140 160 180 200 l/min

0 5 10 15 20 25 30 35 40 45 50 US gal/min

200

150

100

50

0

16

14

12

10

8

6

4

2

0

psi bar

∆ p ∆ p

Q

Q

Technical Information

Orbital Motors with Speed Sensor

Technical Data OMV EM

OMV EM with check valves and with drain connection:

The shaft seal pressure equals the pressure on the drain line

Max. return pressure without drain line or max. pressure in drain line

--- Intermittent operation: the permissible values may occur for max. 10% of every minute.

___ Continuous operation

Pressure drop in motor

12 | © Danfoss | June 2021 BC152886483462en-000401

The curve applies to an unloaded motor shaft and an oil viscosity of 35 mm2/s [165 SUS]

Technical Information

Orbital Motors with Speed Sensor

Technical Data Speed Sensor

Technical Data Speed Sensor

Mechanical data:

Temperatur range: -30°C to +90°C

Enclosure acc. to IEC 529: IP 67

Electrical data

Principle: Hall

Supply voltage: 11 - 30V

Load max.: Lhigh = Llow ± 50 mA

No load current, max.: 20 mA

Output signal:

Connection type

Binder Series 713 Molded in cable Connection

Terminal no.: 1 brown UDC (+supply)

2 White No connection

3 Blue UDC (-supply)

4 Black Output signal

Protection: Protected against short circuit and incorrect polarization.

Revolution:

Pulses per revolution (PPR) OMT EM OMV EM

84 102

©

Danfoss | June 2021 BC152886483462en-000401 | 13

Technical Information

Orbital Motors with Speed Sensor

Technical Data Speed Sensor

Calculation of frequency:

Wiring Diagram

Speed Sensor with Plug Connection Dimensions

14 | © Danfoss | June 2021 BC152886483462en-000401

Technical Information

Orbital Motors with Speed Sensor

Technical Data Speed Sensor

Speed Sensor with Molded in Cable Dimensions

Spare Parts

Accessories

Speed sensor

Code numbers

Type Code no.

Sensor with plug (PNP output) 151-5662

Sensor with 2 m [6.56 ft] molded in cable (PNP output) 151-5663

Sensor with 5.5 m [18.04 ft] moulded in cable (PNP output) 151-5667

Sensor with plug (NPN output) 151-5833

Cable with plug

Code numbers

Cable length 5 m [16.4 ft] 984F0101

©

Danfoss | June 2021 BC152886483462en-000401 | 15

Technical Information

Orbital Motors with Speed Sensor

Technical Data Speed Sensor

Wire (shield)

Core: Cu, 4 • 0.34 mm2

Sheath: PUR/PVC, colour: grey

Plug

Type: Binder, Series 713

Cable no: 1 brown

Temperature range: -30 °C to +80 °C

Enclosure acc. to IEC 529: IP 67

2 white

3 blue

4 black

16 | © Danfoss | June 2021 BC152886483462en-000401

Technical Information

Orbital Motors with Speed Sensor

Shaft Versions

Shaft Versions

OMT

A: Cylindrical shaft; 40 mm

C: Parallel key

A12 •8 • 70; DIN 6885

©

Danfoss | June 2021 BC152886483462en-000401 | 17

OMT US Version

B: Cylindrical 1.5 in shaft

D: Parallel key

3/8 × 3/8 × 21/4 in; B.S.46

OMV

A: Cylindrical shaft; 50 mm

C: Parallel key

A14 • 9 • 70; DIN 6885

A

B

C D

G

H

E F

151-1977.11

min. 13 [0.51]

min. 12 [0.47]

min. 18 [0.67]

min. 19 [0.75]

Ø41.5 [1.634]

Ø41.0 [1.614]

Technical Information

Orbital Motors with Speed Sensor

Port Thread Versions

Port Thread Versions

OMT

A: G main ports B: UN main ports

E: ISO 228/1 - G3/4 F: 1 1/16 - 12 UN, O-ring boss port

C: G drain port D: UNF drain port

G: ISO 228/1 - G1/4 H: 9/16 - 20 UNF, O-ring boss port

OMV

A: G Main port B : G drain port

E: ISO 228/1 - G1 G: ISO 228/1 - G1/4

18 | © Danfoss | June 2021 BC152886483462en-000401

Technical Information

Orbital Motors with Speed Sensor

Dimensions - US Version

OMT EM

C: Drain connection 9⁄16 - 18 UNF; 13 mm [0.51 in] deep O-ring boss port

D: 1 1⁄16 - 12 UN; 19 mm [0.75 in] deep O-ring boss port

F : Plug connection: 2 m [6.56 ft] molded in cable

Type Lmax

mm [in]

OMT 160 EM 190

[7.48]

OMT 200 EM 195

[7.68]

©

Danfoss | June 2021 BC152886483462en-000401 | 19

L1

mm [in]

16.5

[0.650]

21.5

[0.846]

L2

mm [in]

140

[5.51]

145

[5.71]

Technical Information

Orbital Motors with Speed Sensor

Dimensions - US Version

Type Lmax

mm [in]

OMT 250 EM 201

[7.91]

OMT 315 EM 211

[8.31]

OMT 400 EM 221

[8.70]

OMT 500 EM 235

[9.25]

L1

mm [in]

27.8

[1.094]

37.0

[1.457]

47.5

[1.870]

61.5

[2.421]

L2

mm [in]

151

[5.94]

161

[6.34]

171

[6.73]

185

[7.28]

*) The gearwheel set is 3.5 mm [0.138 in] wider across the rollers than the L1 dimensions

20 | © Danfoss | June 2021 BC152886483462en-000401

Technical Information

Orbital Motors with Speed Sensor

Dimensions - European Version

OMT EM

C: Drain connection G 1⁄4 ; 12 mm [0.47 in] deep

D: M10 ; 10 mm [0.39 in] deep

E: G 3⁄4 ; 17 mm [0.67 in] deep

F : Plug connection: Binder Series 713

Type Lmax

mm [in]

OMT 160 EM 190 [7.48] 16.5 [0.650] 140 [5.51]

OMT 200 EM 195 [7.68] 21.5 [0.846] 145 [5.71]

©

Danfoss | June 2021 BC152886483462en-000401 | 21

L1

mm [in]

L2

mm [in]

Technical Information

Orbital Motors with Speed Sensor

Dimensions - European Version

OMV EM

Type Lmax

mm [in]

OMT 250 EM 201 [7.91] 27.8 [1.094] 151 [5.94]

OMT 315 EM 211 [8.31] 37.0 [1.457] 161 [6.34]

OMT 400 EM 221 [8.70] 47.5 [1.870] 171 [6.73]

OMT 500 EM 235 [9.25] 61.5 [2.421] 185 [7.28]

L1

mm [in]

L2

mm [in]

*) The gearwheel set is 3.5 mm [0.138 in] wider across the rollers than the L1 dimensions

C: Drain connection G 1⁄4 ; 12 mm [0.47 in] deep

22 | © Danfoss | June 2021 BC152886483462en-000401

Technical Information

Orbital Motors with Speed Sensor

Dimensions - European Version

D: M12; 12 mm [0.47 in] deep

E: G 1; 18 mm [0.71 in] deep

F : Plug connection: Binder Series 713

Type Lmax

mm [in]

OMV 315 EM 215 [8.46] 22.0 [0.87] 160 [6.30]

OMV 400 EM 222 [8.74] 29.0[1.14] 167 [6.57]

OMV 500 EM 230 [9.05] 37.0 [1.46] 175 [6.89]

OMV 630 EM 240 [9.45] 47.5 [1.87] 186 [7.32]

OMV 800 EM 254 [10.00] 61.5 [2.42] 200 [7.87]

L1

mm [in]

L2

mm [in]

*) The gearwheel set is 3.5 mm [0.138 in] wider across the rollers than the L1 dimensions

©

Danfoss | June 2021 BC152886483462en-000401 | 23

Technical Information

Orbital Motors with Speed Sensor

Weight of Motors

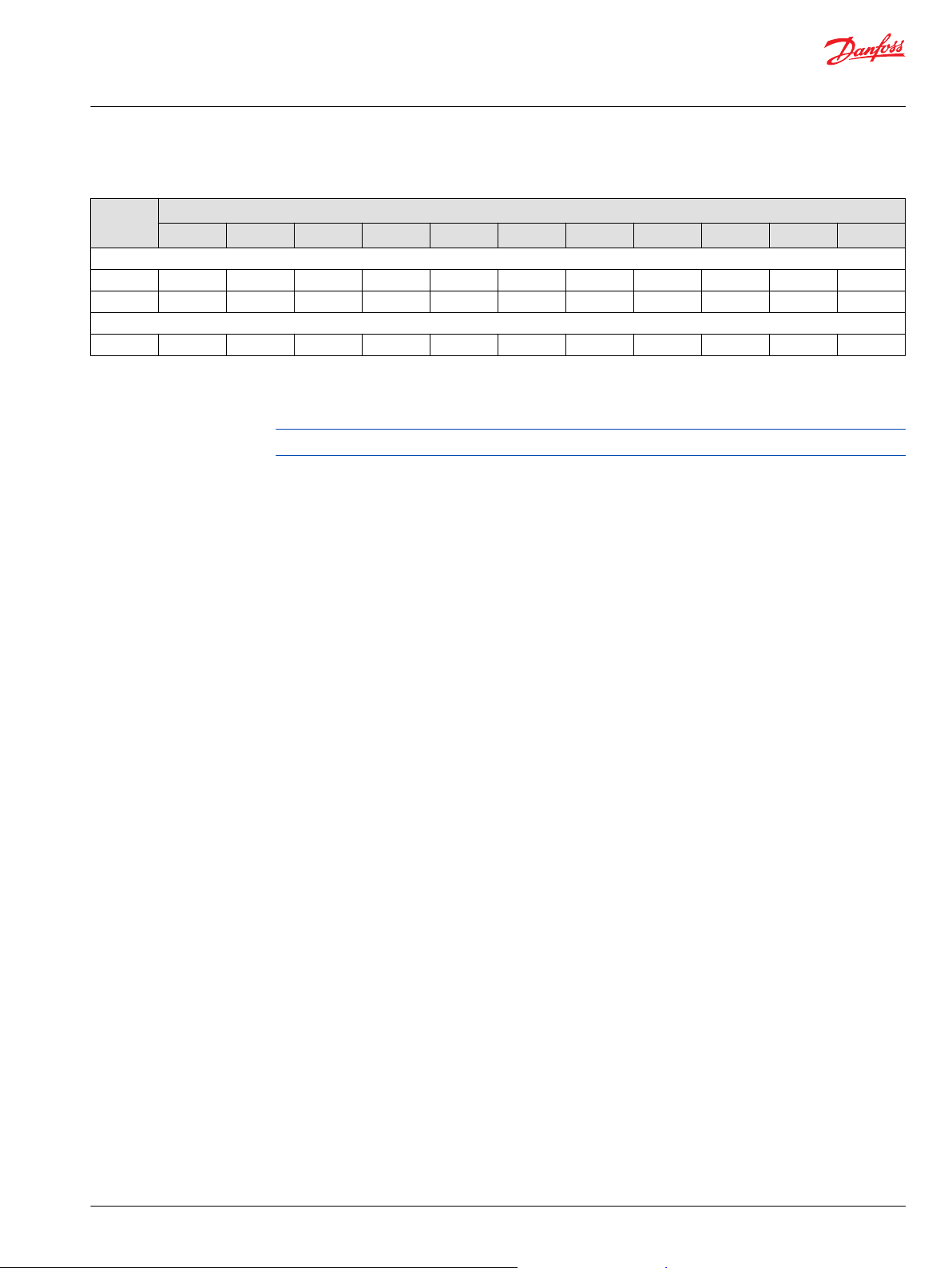

Weight of Motors OMT and OMV

Code no. Weight

151B3260 20.1 [44.31]

151B3262 21.1 [44.31]

151B3263 22.1 [40.72]

151B3264 23.1 [50.93]

151B3265 24.1 [53.13]

151B3266 31.9 [70.33]

151B3260 32.7 [72.09]

151B3261 20.6 [45.42]

151B3268 33.6 [74.07]

151B3269 35.0 [77.16]

151B3270 36.6 [80.69]

151B3700 20.2 [44.53]

151B3701 20.7 [45.64]

151B3702 21.2 [46.74]

151B3703 22.2 [48.94]

151B3704 23.2 [51.15]

151B3705 24.2 [53.35]

kg [lb]

24 | © Danfoss | June 2021 BC152886483462en-000401

Danfoss

Power Solutions GmbH & Co. OHG

Krokamp 35

D-24539 Neumünster, Germany

Phone: +49 4321 871 0

Danfoss

Power Solutions ApS

Nordborgvej 81

DK-6430 Nordborg, Denmark

Phone: +45 7488 2222

Danfoss

Power Solutions (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239 6000

Danfoss

Power Solutions Trading

(Shanghai) Co., Ltd.

Building #22, No. 1000 Jin Hai Rd

Jin Qiao, Pudong New District

Shanghai, China 201206

Phone: +86 21 2080 6201

Products we offer:

Hydro-Gear

www.hydro-gear.com

Daikin-Sauer-Danfoss

www.daikin-sauer-danfoss.com

Cartridge valves

•

DCV directional control

•

valves

Electric converters

•

Electric machines

•

Electric motors

•

Gear motors

•

Gear pumps

•

Hydraulic integrated

•

circuits (HICs)

Hydrostatic motors

•

Hydrostatic pumps

•

Orbital motors

•

PLUS+1® controllers

•

PLUS+1® displays

•

PLUS+1® joysticks and

•

pedals

PLUS+1® operator

•

interfaces

PLUS+1® sensors

•

PLUS+1® software

•

PLUS+1® software services,

•

support and training

Position controls and

•

sensors

PVG proportional valves

•

Steering components and

•

systems

Telematics

•

Danfoss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and

electric components. We specialize in providing state-of-the-art technology and solutions

that excel in the harsh operating conditions of the mobile off-highway market as well as the

marine sector. Building on our extensive applications expertise, we work closely with you to

ensure exceptional performance for a broad range of applications. We help you and other

customers around the world speed up system development, reduce costs and bring vehicles

and vessels to market faster.

Danfoss Power Solutions – your strongest partner in mobile hydraulics and mobile

electrification.

Go to www.danfoss.com for further product information.

We offer you expert worldwide support for ensuring the best possible solutions for

outstanding performance. And with an extensive network of Global Service Partners, we also

provide you with comprehensive global service for all of our components.

Local address:

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without subsequent changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

©

Danfoss | June 2021 BC152886483462en-000401

Loading...

Loading...