Danfoss Optyma Trio HU3500D50, Optyma Trio HU4500D50, Optyma Trio HU2900D50, Optyma Trio HU5100D50, Optyma Trio LZ0012D50 Application Manual

...Page 1

Application Guide

Optyma™ Trio

http://RA.danfoss.com.br

Page 2

Page 3

Application Guide

Content

Contents

Introduction.......................................................................................................................... 4

2.1 Application envelope of the Condensing Units for R404A / R507 ............................................................. 5

2.2 Applications ...................................................................................................................................................................5

2.3 Features ........................................................................................................................................................................... 5

2.4 Benets ............................................................................................................................................................................ 5

General Information ............................................................................................................ 5

3.1 Illustrative Image .......................................................................................................................................................... 6

Specications ....................................................................................................................... 6

3.2 Nomenclature ............................................................................................................................................................... 7

3.3 Performance data ........................................................................................................................................................ 9

3.2 General Data ................................................................................................................................................................10

3.5 Electrical Data .............................................................................................................................................................10

3.6 Dimensional Data ..................................................................................................................................................... 11

4.1 Storage and Handling ...............................................................................................................................................12

4.2 Precautions ..................................................................................................................................................................12

Installation and Operation ................................................................................................ 12

4.3 Mechanical Installation ............................................................................................................................................13

4.4 Leak detection ............................................................................................................................................................ 14

4.5 Vacuum dehydration ................................................................................................................................................14

4.6 Electrical Installation ................................................................................................................................................14

4.7 Refrigerant and oil charge ......................................................................................................................................15

4.8 Verication before operating ................................................................................................................................15

4.9 First start-up .................................................................................................................................................................15

4.10 Verication of the unit while operating ..........................................................................................................15

Maintenance ....................................................................................................................... 16

Spare parts .......................................................................................................................... 17

Warranty ............................................................................................................................. 18

Danfoss Guideline .............................................................................................................. 19

3FRCC.PC.053.A1.02

Page 4

Application Guide

Introduction

The content of this material applies only to

“Optyma

TM

TRIO” condensing units. This product

is a Danfoss technology solution with the use of

three in parallel connected scroll compressors

in a robust foil framework with high eciency

micro-channel (MCHE) Danfoss condenser.

Even though a lot of benets for the use of

in parallel compressor systems exist, the

more important benets are the use of less

equipment, exibility on the capacity control,

use of few tubing lines, better control of energy

consumption and reduction of installation

time when compared to the use of dierent

equipment with single compressor systems

toobtain the same capacity.

4 FRCC.PC.053.A1.02

Page 5

Application Guide

General Information

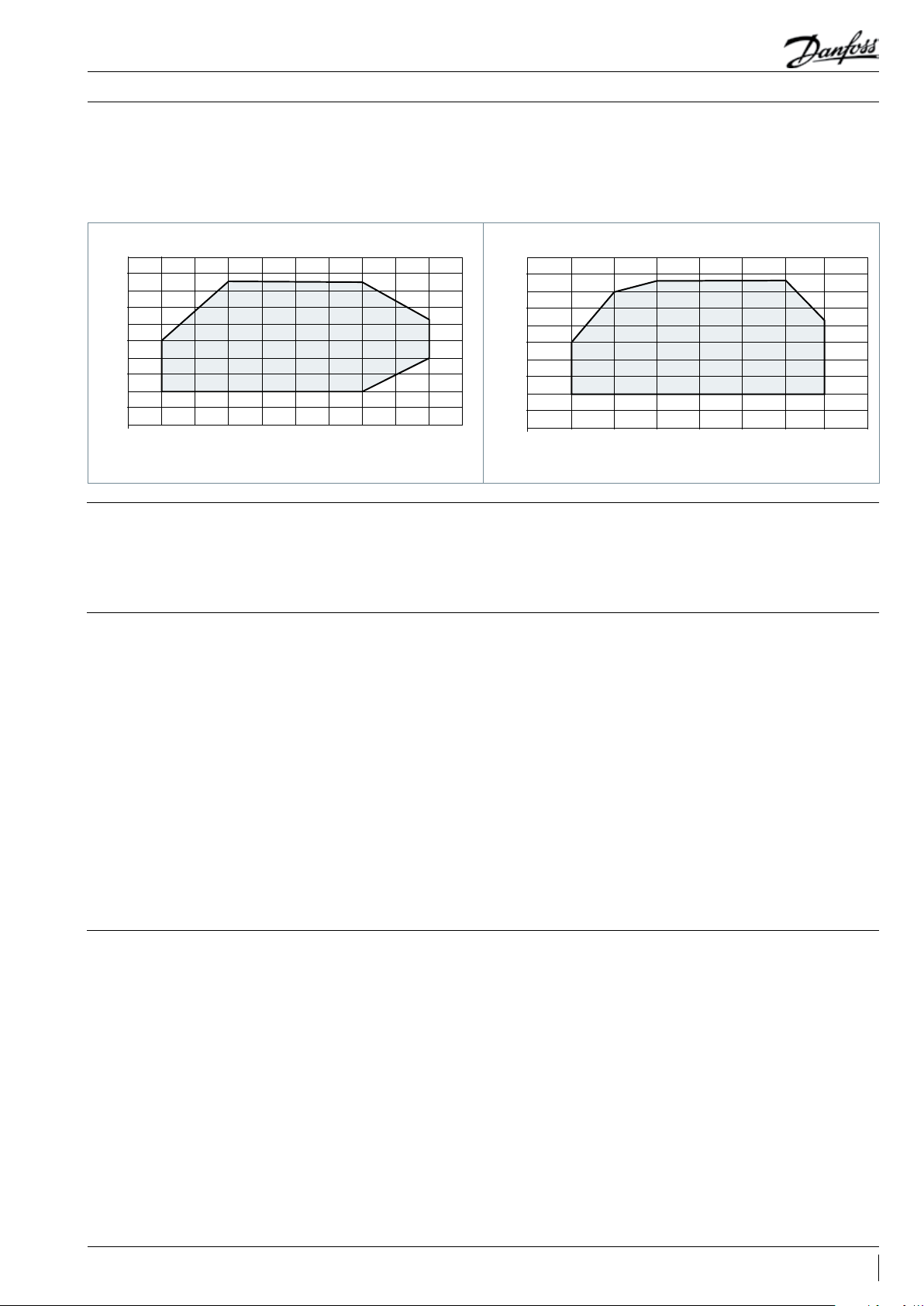

2.1 Application envelope of the

Condensing Units for R404A / R507

Figure 1 Figure 2

50

45

40

35

30

25

20

T amb (°C)

15

10

5

0

-35 -30 -25 -20 -15 -10 -5 0510 15

2.2 Applications

T evap (°C)

This unit is intended for diverse applications,

suchas:

• Medium capability refrigeration systems,

ingeneral;

• Medium and small sized supermarkets;

MBP

2.3 Features

• Scroll Compressors;

• High eciency micro-channel condenser;

• Designed to operate in locations with high

ambient temperature;

• Motorized fans of high performance and low

energy consumption to obtain the maximum

thermal eciency;

• Motorized fans developed specially to

guarantee the perfect operation in humid

environments and great diversity of dirt;

• 6 pole motorized fans selected to assist in low

noise level operations with dynamic balancing;

• Designed for use in outdoor environments;

• Designed for easy installation and maintenance;

• Framework assembled in galvanized steel with

electrostatic painting resistant to corrosion;

50

45

40

35

30

25

20

T amb (°C)

15

10

5

0

-45 -40 -35 -30 -25 -20 -15 -10 -5

T evap (°C)

• Distribution centers for freezing and food

preservation;

• Industrial systems;

• Cold water and liquid cooling units, etc.

• Removable fan guards to facilitate the cleaning

of the serpentine and general maintenance;

• Service valves in the liquid line and suction;

• Liquid receiver with service valves in the inlet

and outlet connections, according to the

NR10norm;

• Combined oil separator and oil reservoir;

• Individual oil control for each compressor

through the electronic level regulators;

• Compressor with thermal shield for motor

protection against high temperatures and

currents;

• Applications for R404A;

• Electric panel according to the NR13 norm;

• There is enough space for the installation of

additional controls, if necessary.

LBP

2.4 Benets

• Compact, light and resistant unit;

• Easy handling;

• Low noise level, 6-pole fan;

• High performance;

• Low energy consumption.

5FRCC.PC.053.A1.02

Page 6

Application Guide

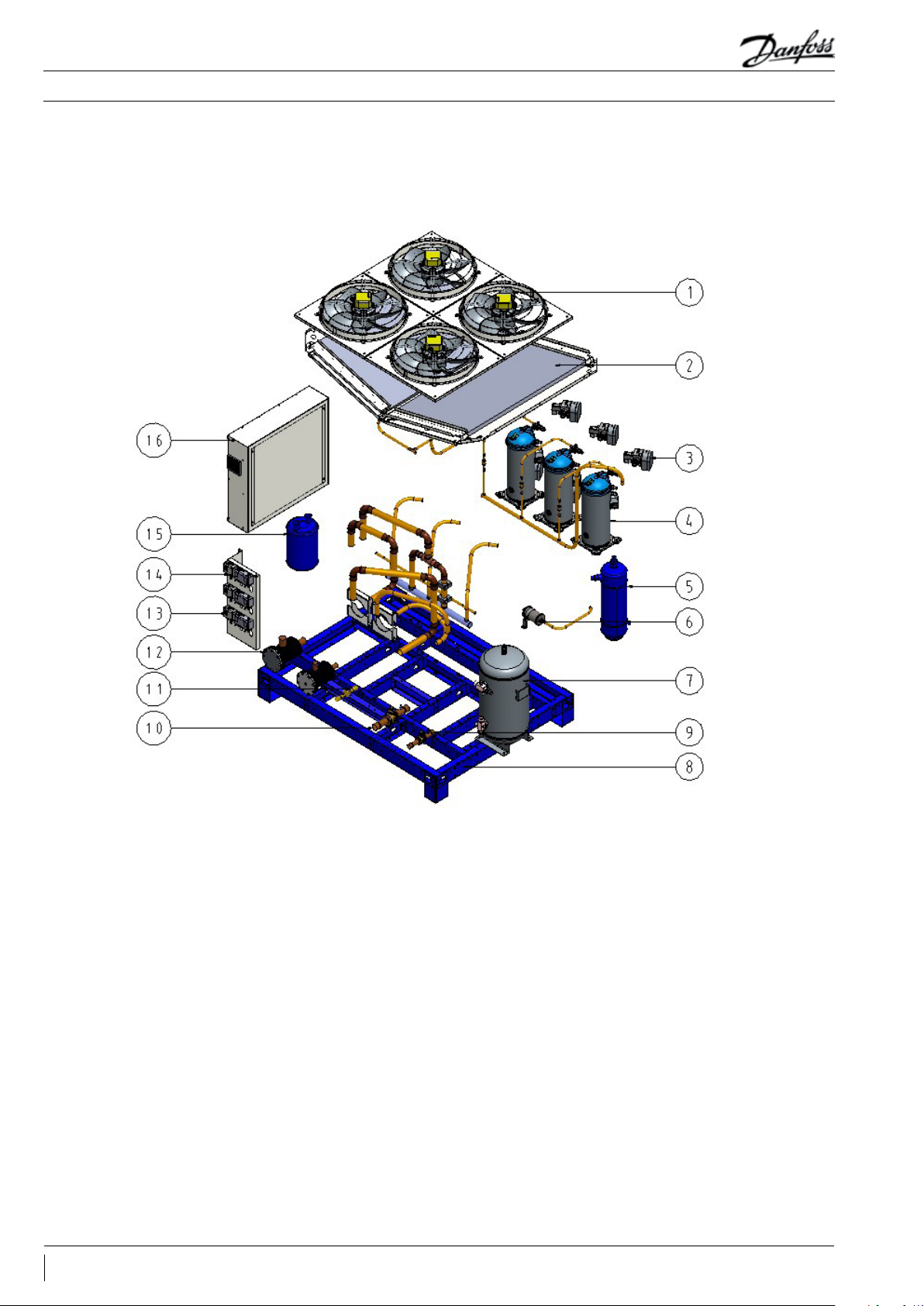

3.1 Illustrative Image

Figure 3

Specications

6 FRCC.PC.053.A1.02

Components

1 - Fan

2 - Micro-channel type condenser

3 - Electronic oil level control valve

4 - Scroll Compressors

5 - Combined separator and oil reservoir

6 - Oil lter

7 - Liquid receiver

8 - Base

9 - Service valve ( GBC) liquid line

10 - Service valve (GBC) suction line

11 - Sight glass

12 - Suction lters and liquid line

13 - High and low security pressure switch

14 - Fan’s control pressure switch

15 - Suction accumulator

16 - Complete electric panel (including

sectionalizers, compressor contactor,

overload relay, fan contactor, circuit breaker,

timers, fault relay/ phase sequence).

Page 7

Application Guide

3.2 Nomenclature

3.2.1 Code and model

Nomenclature for the

Optyma™ Trio line

Specications

H U D Q5100 50

1 2 3 4 5 6

Table 1 Productconguration

1

Application

2

Coolant gas

3

Compressors’

capacity(Kcal/h)

4

Condenser’s

technology

5

Productconguration

6

Electrical Codes

L - Low evaporating temperature

H - High and medium evaporating temperature

U - R404A / R507

Z - R404A / R507

51(00) - 51000 Kcal/h for HBP/MBP

(00)12 - 12000 kcal/h for LBP

D - Micro-channel

Table 1

Q - 220V/3F/60Hz

V - 380V/3F/60Hz

Pressure

switch

Code

Application

50 HBP 3 2 1 1 1 1 1 1 1 1 1 3 4 3 4 3

50 LBP 3 2 1 1 1 1 1 1 1 1 1 3 4 3 4 3

KP5 Fa n

KP15 S afety

Separator

Liquid receiver

andoilreservoir

Filter Drier

Suction

accumulator

Suction

L. Liquid

Service Valve Electric Component

Contactor Circuit breaker

Liquid

Sight Glass

Suction

line

General

Key

Compressor Fan Compressor Fan

Sequence

phase

protector

7FRCC.PC.053.A1.02

Page 8

Application Guide

3.2.2 Label

Figure 4

Model:

Code:

Serial:

Fan (4):

HP Pressure (bar/psi):

LP Pressure (bar/psi):

Specications

A: Model

B: Code

C: Serial number and Bar code

D: Compressors Information

E: Fans Information

F: HP pressure test

G: LP pressure test

Apparent P.

Active P. (kw)

e

H: Apparent power

I: Active power

J: RLA nominal current

K: Maximum current of MCC application

8 FRCC.PC.053.A1.02

Page 9

Application Guide

3.3 Performance data

Specications

HBP R404A/R507 60Hz

Condensing Unit

Model Electrical Code Code C.R. P.C. C.R. P.C. C.R. P.C. C.R. P.C. C.R. P.C. C.R. P.C. C.R. P.C.

32 13910 14.24 172 70 14.51 20990 14.9 4 25090 15. 48 29600 16.0 9 34550 16.72 39960 17. 32

HU2900D50

HU3500D50

HU4500D50

HU510 0D50

Model Electrical Code Code C.R. P.C. C.R. P.C. C.R. P.C. C.R. P.C. C.R. P.C. C.R. P.C. C.R. P.C.

LZ 0012D5 0

LZ0014D50

LZ0018 D50

KEY

C. R. capacity ( Kcal/h )

P.C. Total power including fans (KW)

Q

V

Q

V

Q

V

Q

V

Condensing Unit

Q

V

Q

V

Q

V

115F0555

115F055 6

115F055 7

115F0558

115F055 9

115F056 0

115F056 1

115F056 2

115F056 3

115F056 4

115F0565

115F056 6

115F056 7

115F056 8

35 ---- ---- 16 300 15 .36 198 60 15. 80 23780 16.35 28090 16.9 7 32820 17. 61 38010 18. 23

38 ---- ---- 1529 0 16. 27 1868 0 16.71 22420 17. 27 26530 17. 89 310 40 18. 54 36020 19.18

43 ---- ---- 13 490 17.88 16620 18. 33 20040 18.90 23820 19. 54 2799 0 20.20 ---- ----

32 16 490 17. 04 20180 17.76 24340 18 .46 28970 19.2 0 34060 20.00 39620 2 0.21 45650 21.94

35 ---- ---- 18 990 18.8 6 22940 19.59 27340 20.35 32200 21.17 37510 22.09 43300 2 3.15

38 ---- ---- 17 760 20.06 2150 0 20. 81 25670 21. 58 30290 2 2.42 35360 23.36 40910 24.4 4

43 ---- ---- 15 600 22.27 18980 23.04 22770 23.84 26980 24.70 3165 0 25.67 ---- ----

32 22170 22 .35 27880 22.68 34510 23.22 42030 23.93 50390 24 .74 595 40 25.64 69420 26.58

35 ---- ---- 26120 23.95 32430 24. 43 39590 25.09 47560 25.89 56290 26.78 65730 27. 73

38 ---- ---- 24070 25.34 3029 0 25.76 370 90 26.36 44650 27.12 52950 27. 99 61950 28.9 4

43 ---- ---- 20900 28.00 26610 28.26 32760 28 .74 39630 29 .41 47210 30. 23 ---- ----

32 26090 25.90 32180 26.58 39200 27. 45 47170 28.47 56080 29.60 659 00 30.79 76600 31.99

35 ---- ---- 30490 2 7.98 37210 28.83 44830 29.84 53330 30.96 62720 32.14 72990 33.34

38 ---- ---- 28840 28.43 3518 0 30. 31 42430 31.30 50540 32.40 59500 33.57 69320 34.77

43 ---- ---- 25880 31.05 3178 0 31. 81 38320 33.96 4576 0 35.02 54000 36.16 ---- ----

32 ---- ---- 9563 11.13 119 90 12. 08 14 820 13. 11 18 090 14.19 2180 0 15. 30 25960 16.43

35 ---- ---- 910 0 11. 44 11 410 12. 42 14110 13.4 9 17 210 14. 61 20730 15. 78 ---- ----

38 ---- ---- 8 612 12 .03 108 20 12. 78 1337 0 13. 88 16310 15 .06 196 40 16. 28 ---- ----

43 ---- ---- ---- ---- 9777 13 .71 120 90 14 .83 14760 15.85 177 90 17.16 ---- ----

32 ---- ---- 1118 0 12 .96 139 80 14.07 17 210 15. 32 20910 16.66 25080 18. 05 29720 19.4 4

35 ---- ---- 10 630 13.36 132 80 14 .50 1636 0 15.79 198 60 19.19 23810 18. 65 ---- ----

38 ---- ---- 10060 13.6 2 12570 14.96 154 80 16.2 9 18780 17.74 22510 19.27 ---- ----

43 ---- ---- ---- ---- 11360 15.58 139 80 16 .89 169 40 18 .74 20300 20.38 ---- ----

32 ---- ---- 1359 0 15. 60 169 00 17.0 0 20690 18.60 24960 20.34 29700 2 2.19 34910 21.13

35 ---- ---- 1289 0 16.12 1603 0 17. 55 19 620 19.19 23650 21.0 0 2813 0 22.93 ---- ----

38 ---- ---- 12180 16 .50 15130 18 .16 18510 19. 83 22300 21.69 26520 23.70 ---- ----

43 ---- ---- ---- ---- 13 600 18.99 16640 20.66 19990 22.97 23750 25.08 ---- ----

-25 -20 -15 -10 -5 0 5

Ambient

Temperature (°C)

-40 -35 -30 -25 -20 -15 -10

Ambient

Temperature (°C)

OPERATING CONDITIONS:

Overheating: 20 K

Sub-cooling: 0 K

Cooling capacity in (Kcal/h) - Evaporating temperature in (°C)

Cooling capacity in (Kcal/h) - Evaporating temperature in (°C)

9FRCC.PC.053.A1.02

Page 10

Application Guide

3.2 General Data

Specications

60Hz

Condensing Unit Compressor Fan Condenser

(HP)

Chassis

Application

HBP

LBP

15

B

18

23

C

27

15

B

18

24

Model

HU2900D50Q 115F0555 MLZ038T2 121U 859 9

HU2900D50V 115 F055 6 MLZ038T9 121U8591

HU3500D50Q 115F 055 7 MLZ045T2 121U86 01

HU3500D50V 115F0558 MLZ045T9 121U8 593

HU4500D50Q 115F 0559 MLZ058T2 121U 8627

HU4500D50V 115F05 60 MLZ058T9 121U8621

HU510 0D50Q 115F 05 61 MLZ066T2 121U8 623

HU510 0D50V 115F 05 62 MLZ066T9 121U8617

LZ 0012D5 0Q 115F 05 63 LL Z015T 2 121L9515

LZ0012D50V 11 5F0 56 4 LLZ015T9 121L9529

LZ0014D50 Q 115F0565 LL Z018T2 121L9511

LZ0014D50V 115 F0566 LLZ018T9 121L9527

LZ0018 D50Q 115 F05 67 LLZ024T2 121L9507

LZ0018 D50V 115 F0 568 LLZ024T9 121L9525

3.5 Electrical Data

Condensing Unit Compressor Fan

Connection Weight Sound level

Code

Model

Qty

Code

3 17. 0 1.6 500 6 4 13200 N8 1.51 x 2 32 1 5/8 1 1/8 290 300 62 76 84

3 20.7 1.6 500 6 4 1320 0 N8 1.51 x 2 32 1 5/8 1 1/8 290 300 62 76 84

3 26.4 2.7 630 6 4 33600 Q8 2.54 x 2 40 2 1/8 1 1/8 485 500 64 78 86

3 31.2 2.7 630 6 4 33600 Q8 2.54 x 2 40 2 1/8 1 1/8 485 500 64 78 86

3 17. 5 1.62 500 6 4 1320 0 N8 1.51 x 2 32 1 5/8 1 1/8 290 300 62 76 84

3 20.5 1.62 500 6 4 1320 0 N8 1.51 x 2 32 1 5/8 1 1/8 290 300 62 76 84

3 25.3 2. 51 500 6 4 1320 0 N8 1.51 x 2 32 2 1/8 1 1/8 290 300 64 78 86

Diam.

(m3/h)

Qty

(mm)

No. Poles

(m3/h)

Air ow

(L)

Oil

O

(L)

Typ e

Internal Vol.

(in)

(in)

Liq.

Liquid Receiver

L. Liq.

L. Suction

(Kg)

Raw

dB2mdB

5m

(Kg)

Sound Power dBA

60Hz

Model

HU2900D50Q 115F0555 21.37 230V-3F-60Hz 5 6.10 MLZ038T2 121U8 599 3 230V-3F-60Hz 12 3.0 16.7 26.0 500 4 6 380 230V-3F-60Hz 1. 5 0.9

HU2900D50V 115 F055 6 24.03 380V-3F-60Hz 36.52 MLZ038T9 121U8591 3 380V-3F-60Hz 81.0 11 .0 17. 0 500 4 6 380 380V-3F-60Hz 1. 5 0.9

HU3500D50Q 115F 055 7 24.23 230V-3F-60Hz 63.60 ML Z045T2 121U 8601 3 230V-3F- 60Hz 170 .0 19. 2 30.0 500 4 6 380 230V-3F-60Hz 1.5 0.9

HU3500D50V 115F0558 27. 59 380V-3F-60Hz 41.9 2 ML Z045T9 121U 8593 3 380V-3F-60Hz 96.0 12.8 20.0 500 4 6 380 380V-3F-60Hz 1.5 0.9

HU4500D50Q 115F 0559 33.53 230V-3F-60Hz 88.00 ML Z058T2 121U86 27 3 230V-3F-60Hz 190 .0 25.6 40.0 630 4 6 870 230V-3F-60Hz 2.9 1.6 5

HU4500D50V 115F05 60 35.8 0 380V-3F-60Hz 54.40 MLZ058T9 121U8621 3 380V-3F-60Hz 135. 0 16. 0 25.0 630 4 6 870 380V-3F-60Hz 2.9 1. 65

HU510 0D50Q 115F 05 61 37. 99 230V-3F-60Hz 99.70 MLZ066T2 121U 862 3 3 230V-3F-60Hz 235.0 29.5 46.0 630 4 6 870 230V-3F-60Hz 2.9 1. 65

HU510 0D50V 115F 05 62 43.70 380V-3F-60Hz 66.40 MLZ066T9 121U8617 3 380V-3F-60Hz 135 .0 20.0 28.0 630 4 6 870 380V-3F-60Hz 2.9 1. 65

LZ 0012D5 0Q 115F 05 63 23.43 230V-3F-60Hz 61. 50 LL Z015T 2 121L9515 3 230V-3F-60Hz 180.0 18 .5 29.0 500 4 6 380 230V-3F-60Hz 1. 5 0.9

LZ0012D50V 11 5F0 56 4 23.83 380V-3F-60Hz 36.22 LLZ015T9 121L9529 3 380V-3F-60Hz 81.0 10 .9 17. 0 500 4 6 380 380V-3F-60Hz 1.5 0.9

LZ0014D50 Q 115F0565 25.14 230V-3F-60Hz 66.00 LLZ018T 2 121L9511 3 230V-3F-60Hz 18 4.0 20.0 31.0 500 4 6 380 230V-3F-60Hz 1. 5 0.9

LZ0014D50V 115 F0566 27. 59 380V-3F-60Hz 41. 92 LLZ018T9 121L9527 3 380V-3F-60Hz 106.0 12.8 20.0 500 4 6 380 380V-3F-60Hz 1.5 0.9

LZ0018 D50Q 115 F05 67 31. 55 230V-3F- 60Hz 82.80 LLZ024T2 121L9507 3 230V-3F-60Hz 190 .0 25.6 40.0 500 4 6 380 230V-3F- 60Hz 1.5 0.9

LZ0018 D50V 115 F0 568 28.97 380V-3F-60Hz 44.02 LLZ024T9 121L9525 3 380V-3F-60Hz 135. 0 13. 5 21.0 500 4 6 380 380V-3F-60Hz 1.5 0.9

LRA: Rotor amps blocked, RLA: Nominal current, MCC: Maximum direct current, FLA: Full charge current

Code

Tot al po wer

kVA MCC LRA RLA MCC mm W 230V (A) 380V (A)

Frequency

Voltage, Phases,

Amps

Model

Qty

Code

Frequency

Voltage, Phases,

Amps

Diam. Model

Power

Qty

No. Poles

Frequency

Voltage, Phases,

FLA (60Hz)

10 FRCC.PC.053.A1.02

Page 11

Application Guide

Specications

3.6 Dimensional Data

Dimensions (mm) Connections

Condensing Unit

HU2900D50Q 118 4 1530 12 90 128 4 1630 139 0 330 124 146 410

HU2900D50V 1184 1530 12 90 128 4 163 0 139 0 330 124 146 410

HU3500D50Q 11 84 1530 12 90 128 4 163 0 139 0 330 124 146 410

HU3500D50V 1184 153 0 1290 1284 1630 1390 330 124 146 410

HU4500D50Q 1485 2057 13 68 158 5 215 7 1468 250 224 246 348

HU4500D50V 1485 2057 13 68 1585 2157 14 68 250 224 246 348

HU510 0D50Q 1485 2057 13 68 1585 2157 146 8 250 224 246 348

HU510 0D50V 1485 2057 13 68 1585 2157 14 68 250 224 246 348

LZ 0012D5 0Q 118 4 15 30 12 90 128 4 1630 139 0 330 124 146 410

LZ0012D50V 118 4 153 0 1290 12 84 1630 1390 330 124 146 410

LZ0014D50 Q 118 4 153 0 1290 12 84 1630 1390 330 124 146 410

LZ0014D50V 118 4 1530 129 0 1284 16 30 1390 330 124 146 410

LZ0018 D50Q 11 84 15 30 12 90 128 4 1630 139 0 330 124 146 410

LZ0018 D50V 118 4 153 0 1290 12 84 1630 1390 330 124 146 410

Without packaging With packaging Liquid Line Liquid Line

W L H X Y Z A B C D

Figure 5

11FRCC.PC.053.A1.02

Page 12

Application Guide

Installation and Operation

4.1 Storage and Handling

4.2 Precautions

To guarantee an adequate protection,

itis necessary to observe all emphasized

recommendations in this application guide.

• It is not recommended to open the packaging

before the unit being at the installation site.

• Handle the unit carefully. The framework

allows the use of a forklift or handling cart. Use

appropriate and safe elevation equipment.

• Keep the unit in a vertical position both in

storage and transport.

• Store the unit in an adequate and protected

environment.

• Do not expose the packaging to rain or

corrosive atmosphere.

• After unpacking, verify if the unit is complete

and undamaged.

• The installation and maintenance of this unit

must only be held by a certied installer /

engineer / electrician and in accordance with

the local regulatory guidelines.

• Never place the unit in a ammable atmosphere

• Place the unit in a way that it doesn’t block or

complicate the passage areas, doors, windows,

stairs and other accesses.

• Ensure adequate space around the unit for

theair circulation and door opening. See gure

6to obtain the minimum distance values to

thewalls.

• Avoid installing the unit in aggressive

environments and with dicult access.

• Ensure a base with strong horizontal surface

that is stable enough to support all the

unit’s weight and eliminate the vibrations

bymisalignment.

The next sections will provide necessary

recommendations for the installation and

operation of the Optyma

safety data and appropriate use of the product.

All the equipment must be examined carefully

upon product receipt in order to verify if

no damages were caused by handling and

transportation.

This equipment was carefully inspected in

our factory, in case there is any apparent or

hidden malfunction, notify immediately the

establishment where it was purchased.

• Check if the power supply corresponds

to the technical specications of the unit

(seeproduct’s marking label).

• By installing units for HFC refrigerants, use

specic equipment for that type of refrigerant,

in other words, that have never been used

before for CFC or HCFC.

• The suction tubing must be exible in 3 dimensions

to mue the vibrations. Furthermore, the tubing

must be done in a way so that the return of the

oil to the compressor is ensured and the return of

liquid refrigerant to the compressor is avoided.

The installation at ground level rarely presents

problems, none the less, if it is not installed at

ground level, an additional tubing for drainage

must be considered in the project.

TM

Trio unit, as well as

12 FRCC.PC.053.A1.02

Page 13

Application Guide

Installation and Operation

4.3 Mechanical Installation

Figure 6

• The installation of the unit must comply with

all the current safety local regulations, under all

circumstances.

• The unit must be installed securely on a bracket

or a steady and secure base, with the use of the

vibration shock absorbers with mounting bolts

provided together with the unit. See gure 7.

• Remove the nitrogen load slowly through the

schrader valves located in the suction GBC

service valves and liquid line.

• Connect the unit to the system as quickly as

possible to avoid the oil contamination from

moisture present in the air.

• Avoid the penetration of solid residues derived

from the tubing burr and others.

• Weld the tubing with proper material and always

use nitrogen gas ow to make the environment

inert, avoiding internal carbonation and forming

of residue that may damage the system.

• It is recommended to isolate the suction tubing

with insulation thickness that meets the specic

project conditions for the installation.

• For the initial start-up, the oil level must be

veried and completed with a parcial load, with

the oil provided together with the condensing

unit. If more oil is required, acquire from an

oil distributor the oil of the same brand and

specication provided with the condensing unit.

• After the operation, the sight glass of the oil

compressor must be re-checked and the oil load

completed to adjust to the installation tubing

length, if necessary.

• It is recommended to put the oil through the

service valve of the oil separator/trap through

avacuum pump connected to the high pressure

line.

• The refrigerant charge must be done through the

liquid’s tank service valve or through the schrader

of the GBC service valve of the liquid line.

W

[mm]

Chassis - B 1092 1092 1000 150 0

Chassis - C 1092 10 92 1000 19 00

Note: The specication of the chassis for each model can be found in section “3.6 Dimensional Data” in page 11.

X

[mm]

Y

[mm]

Z

[mm]

13FRCC.PC.053.A1.02

Page 14

Application Guide

4. 3.1 Fi xation

Figure 7

Installation and Operation

Fixation of 4 “vibra-stop” type shock

absorbers included on the Danfoss

supply for the support on the oor

or laying base

4.4 Leak detection

4.5 Vacuum dehydration

4.6 Electrical Installation

• Never pressurize the circuit with oxygen or

dryair. This can cause re or explosion.

• Do not use dye for leak detection.

• The use of nitrogen or the system’s own gas

isrecommended.

• Never use the compressor to empty the system.

• Connect a vacuum pump to the system’s lower

sides LP and HP.

• The vacuum in the system must reach at least a

complete 500 μm Hg (0.67 mbar).

• When the vacuum level is reached, keep it for a

few hours to guarantee the sealing of the system.

• After this stage, isolate the vacuum pump and

place the nitrogen with a pressure of 4 to 5 bar,

keeping the system at this pressure for 4 hours.

• Switch o and isolate the main power supply.

• Make sure that the power supply can’t be

switched on accidentally during installation.

• All the electrical components must be selected

according to the local standards and according

to the unit’s requirements.

• Consult the wiring diagram supplied with the

installation manual for details on electrical

connections.

• Make sure that the power supply matches the

unit characteristics and that the energy source

is stable (nominal voltage ± 10% and nominal

frequency ± 2.5 Hz).

• Dimension the power supply cables according

to the unit data on voltage and current.

• Protect the power supply and ensure that the

grounding of the unit is done according to the

current standards.

• Perform a leak detection test in the entire

system.

• The maximum test pressure is 32 bar.

• When a leak is detected, repair the leak

andrepeat the leak detection.

• If the pressure in the gauge connected to the

suction line and discharge lowers in this period,

locate the leak, perform the repair and restart

the vacuum procedure and check the leak again.

• Do not apply energy to the unit while the

system is under vacuum, as this might cause

internal damage.

• The unit is equipped with high and low pressure

switches, which directly shut o the power

supply to the compressor in case of activation.

The unit is also equipped with a phase sequence

relay to protect the unit against phase/

sequence loss / asymmetry and under voltage /

over voltage.

• Observe the correct phase sequence in the

condensing units which use three-phase

compressors.

• Determine the sequence using a phase gauge

to establish the sequences of the line phases L1,

L2 e L3.

• Connect the line phases L1, L2 e L3

corresponding to the terminals of the

compressor T1, T2 e T3 respectively.

14 FRCC.PC.053.A1.02

Page 15

Application Guide

Installation and Operation

4.7 Refrigerant and oil

charge

4.8 Verication before

operating

4.9 First start-up

• Use individual protection equipment (IPE)

suchas safety glasses and gloves.

• Never start the compressor under vacuum.

Keepthe compressor switched o.

• Before performing the refrigerant charge,

verify if the oil level is between ¼ and ¾ on the

compressor oil display. If necessary, add oil to

the compressors, refer to the compressor’s label

for oil type.

• Only use the coolant for which the unit was

designed for.

• Perform the refrigerant charge in liquid phase

into the condenser and in the liquid receiver.

• Use safety devices according to locally

applicable regulations and security standards.

• Verify if all electrical connections are attached

correctly and in accordance with the local

regulations.

• Never switch on the unit without having

performed a refrigerant charge .

• All service valves must be in the open position.

See gure 5.

• Verify if the power supply is adequately

connected.

• Verify if the crankcase heater is working.

• Verify if the fan can rotate freely.

• Verify if high and low pressure are balanced.

• Energize the unit and verify the conformity of

the wiring, the tension in the terminals and the

phase sequence.

Make sure to perform a slow refrigerant

charge until it reaches 4-5 bar in systems

withR404A/507.

• Never put liquid refrigerant through the

suctionline.

• Never use additive or oil mixtures.

• The remaining charge is carried out until the

installation has reached a stable nominal

condition level during the operation.

• Never leave the lling cylinder connected to

thesystem.

• Keep the crankcase heater switched on for at

least 12 hours before the system start-up, for the

guarantee of proper lubrication and elimination

of the liquid refrigerant from the compressor's

crankcase.

• The potential reverse rotation of a three-phased

compressor can be detected by no pressure

increase, an abnormal sound level of the

compressor and a lower energy consumption

than the one expected. In this case, immediately

switch o the unit and connect the phases to

their appropriate terminals.

• If the direction of rotation is correct, the indication

of low pressure on the low pressure gauge must

display a decreasing pressure and the indication

of high pressure in the high pressure measurer

must display an increasing pressure.

• The electronic buoys must comply with the

indication.

4.10 Verication of the unit

while operating

• Check the rotation direction of the fan. The air

must ow from the condenser to the fan (air

ow from bottom to top).

• Check the high pressure stabilization and the

power supply stability.

• Check the suction overheating to reduce the risk

of the return of liquid to the compressor.

• Observe the compressor oil level in the

beginning and during the operation to conrm

that the oil level remains visible.

• Verify all tubing with respect to unusual

vibration. The movements exceeding 1.5mm

require corrective measures, as the use of

xation supports in the tubing.

• Before leaving the installation site, perform

a general inspection of the installation on

cleanliness, detection of noise and leakage.

• Record type and amount of refrigerant charge,

as well as operation conditions as reference for

future inspections. Use data check sheet

15FRCC.PC.053.A1.02

Page 16

Application Guide

Maintenance

• Always switch o the unit with the main switch

before removing the fan panel, or any other

panel of the condensing unit.

• The internal pressure and the surface

temperature are hazardous and can cause

permanent injuries.

• The installers and/or maintenance operators

must be certied in accordance with the current

standards and with the use of appropriate tools.

• High pressure tubing temperature may exceed

100°C and cause severe burns.

• Make sure that periodical inspection services

are carried out to guarantee the reliability of

the system and to meet the mandatory local

regulations.

• To ensure the good functioning of the unit and

its energy eciency, it is recommended:

• Periodic maintenance;

• Verify if the safety devices are operational

and properly set;

• Make sure the unit retains the xation

steady without fragility;

• Check if the compressor’s current is correct;

• Conrm if the system is operating

consistently with previous maintenance

records in the established conditions;

• Check if all electrical connections still are

properly attached;

• Keep the unit clean and without rust and

oxidation of the unit’s components, tubing

and electrical connections.

• The condenser must be veried at least once

a year regarding the blockage of the ns by

impurities and must be cleaned if considered

necessary. The access to the internal side of

the condenser takes place through the fans

panel (guard). The micro-channel coils tend

to accumulate dirt on the surface and not in

the interior, which makes them easier to clean

comparing to the tube condensers and ns.

• Remove the dirt from the surface, leaves, bers,

etc., with a vacuum, equipped with a brush

or other soft accessory. Alternatively, blow

the compressed air through the condenser

inside out and brush with a soft bristle. Do not

use a wire brush. Do not impact or scrape the

condenser with the vacuum tube or air orice.

• If the refrigeration system is open, the system

must be pressurized with nitrogen processed in

vacuum to remove the moisture and a new lter

drier must be installed.

16 FRCC.PC.053.A1.02

Page 17

Application Guide

Condensing Units

Spare parts

HU2900D50Q

Accumulator 191U0 067 191U0 067 191U0 067 191U 0067 191U00 68 191U00 68 191U0 068

Acoustic Hood - - - - - - -

Compressor 121U 8599 121U8 591 121U86 01 121U8593 121U8 627 121U8621 121U86 23

MCHE Condenser 021Z0139 021Z0 139 021Z0139 0 21Z0139 021Z0140 021Z014 0 021Z0140

Crankcase Resistance - - - - - - -

Motor Fan 191U136 320 191U136320 191U13 6320 191U136 320 191U13598 0 191U135980 191U13 5980

Filter Drier 023U1392 023U1392 023U1392 023U1392 023U1392 023U1392 023U1392

Oil Filter 191U008810 191U008810 191U008810 191U008810 191U008810 191U008810 191U008810

Oil Level Regulator 191U 009 030 191U00 9030 191U 009030 191U 009 030 191U 009030 191U 009 030 191U 009030

Lubricating Oil 120Z 5034 120 Z5034 12 0Z503 4 120Z 5034 120Z5 034 12 0Z503 4 120 Z5034

Oil Separator 191U0 07850 191U0 07850 191U007850 191U0 07850 191U0 07950 191U0079 50 191U 0079 50

KP HP_LP Pressure Switch 06 0-126 466 0 60-126 466 0 60-126 466 06 0-126 46 6 0 60-126 466 0 60-126 466 06 0-126 46 6

KP HP Pressure Switch 0 60 -1171 66 06 0-117 166 0 60 -1171 66 06 0-117 166 0 60 -1171 66 06 0-117 166 0 60 -11716 6

Condensing Units

HU510 0D50V

Accumulator 191U0 068 191U0 067 191U0 067 191U 0067 191U 0067 191U0 068 191U0 068

Acoustic Hood - 120Z5052 120Z5052 120Z5052 120Z5052 120Z5053 120Z5053

Compressor 121U8 617 121L9515 121L9529 121L9511 121L9527 121L9507 121L9525

MCHE Condenser 021Z 0140 021Z 0139 021Z 0139 021Z 0139 021Z 0139 021Z 0139 021Z 0139

Crankcase Resistance - 120Z 504 0 120Z5 040 120Z 504 0 120 Z50 40 12 0Z50 40 120 Z50 40

Motor Fan 191U 13598 0 191U136 320 19 1U13632 0 191U13 6320 191U13 6320 191U136320 191U136320

Filter Drier 023U1392 023U1392 023U1392 023U1392 023U1392 023U1392 023U1392

Oil Filter 191U008810 191U008810 191U008810 191U008810 191U008810 191U008810 191U008810

Oil Level Regulator 191U 009 030 191U00 9030 191U 009030 191U 009 030 191U 009030 191U 009 030 191U 009030

Lubricating Oil 120Z 5034 120 Z5034 12 0Z503 4 120Z 5034 120Z5 034 12 0Z503 4 120 Z5034

Oil Separator 191U0 07950 191U0 07850 191U007850 191U0 07850 191U0 07850 191U0078 50 191U 0078 50

KP HP_LP Pressure Switch 06 0-126 466 0 60-126 466 0 60-126 466 06 0-126 46 6 0 60-126 466 0 60-126 466 06 0-126 46 6

KP HP Pressure Switch 0 60 -1171 66 06 0-117 166 0 60 -1171 66 06 0-117 166 0 60 -1171 66 06 0-117 166 0 60 -11716 6

HU2900D50V

LZ 0012D5 0Q

HU3500D50Q

LZ0012D50V

HU3500D50V

LZ0014D50 Q

HU4500D50Q

LZ0014D50V

HU4500D50V

LZ0018 D50Q

HU510 0D50Q

LZ0018 D50V

17FRCC.PC.053.A1.02

Page 18

Application Guide

Warranty

• Always have the model and serial number of the

condensing unit available for any warranty claim.

• The warranty of the product can be rendered

void in the following cases:

- Absence of nameplate.

- External modications, mainly drilling, welding,

broken feet and shock markings.

- Open compressor or returned without sealing.

- Dye for rust detection, water or leak in the

compressor.

- Use of an o-specication refrigerant or

lubricant.

- Any deviation from the recommended

instructions regarding the installation,

application or maintenance.

- Use of the unit in an environment with an

explosive atmosphere.

- No model number or serial number was

informed in the warranty claim.

18 FRCC.PC.053.A1.02

Page 19

Application Guide

Danfoss Guideline

Danfoss recommends that gases, oils and

other components that can adversely aect

the environment be delivered to dedicated

companies in the recycling or disposal of those

materials for environment protection.

19FRCC.PC.053.A1.02

Page 20

Danfoss Commercial Compressors

Danfoss variable speed scroll compressors

is a worldwide compressor and condensing units manufacturer for refrigeration and HVAC applications. With a wide range of innovative

products of the best quality, we help your company to find the best possible solution in terms of

environment and that reduces the total costs of the product’s life cycle.

We have over 40 years of experience in the development of hermetic compressors which placed us among the global leaders in our business

and positioned us as variable speed technology specialists. Currently we act from the engineering and project up to the production stages in

three continents.

energy efficiency and respect for the

Danfoss Turbocor Compressors

Danfoss scroll compressors

forairconditioning

Danfoss OPTYMA condensing units

Maneurop reciprocating compressors

Compressors for light applications

ofcommercial refrigeration

Our products can be found in diverse applications, such as rooftops, chillers, residential air conditioning,

heat pumps, cold rooms, supermarkets, milk cooling tanks and industrial cooling processes.

www.danfoss.com.br

FRCC.PC.053.A1.02

© Danfoss | DCS (CC) | 2017.11

Loading...

Loading...