Page 1

Optyma™ Cooler

Air and Electric Defrost Units

Index

1. General Safety Information 1

2. Inspection 1

3. Unloading 2

4. Mounting 2

5. Refrigeration piping 3

6. Expansion Valve 3

7. Drain Line 3

8. Wiring 3

9. Installation 3

10. Vacuum 3

11. Start-up 3

12. Maintenance and service 4

13. Troubleshooting 6

14. Spare Parts 7

15. Reference Data 8

1 - General safety information

All installation and maintenance procedures should be performed by qualified personnel already familiarized with the

equipment.

All field wiring should match the requirements of the equipment, as well as any local or national codes.

Coil edges and other sharp objects should be met with caution, as they can cause serious injury. Fan blades are especially

sharp, and therefore should be handled only while wearing protective gloves.

High temperatures can cause damage to the equipment. The expansion valve must be covered in heat absorbent material and

the suction line sensing bulb removed while brazing the refrigerant connections.

Never use the refrigeration compressor to evacuate the equipment. Never start the refrigeration compressor if it is in a vacuum.

Fan motors are sealed and do not need lubrication

All power sources should be disconnected before any type of service work is performed on the equipment. For cleaning the

equipment, remove and reinstall the drain pan after every cleaning session. Failure to follow these steps can result in damaged

equipment or personal injury.

Inhalation of certain refrigerants can be harmful, or even fatal. Failure to implement proper detection devices, ventilation, and

procedures can result in serious injury or death. Ventilation of all refrigerants should follow all related regulations, as certain

refrigerants are harmful to the environment. For more information, refer to any local or national codes that may apply.

2 - Inspection

Each shipment should be carefully checked against the bill of loading at time of receipt. The shipping receipt should not be signed until

all items listed on the bill of loading have been accounted for. Check carefully for any damage. Any and all shortages or damages should

be reported to the delivery carrier. Damaged equipment during shipment becomes the delivery agent’s responsibility and should not be

returned unless prior approval has been given by Danfoss. The equipment is pressurized with 29 psi (2 Bar) of dry air during manufacturing.

If the unit lost pressure during transportation, contact the warranties department: USwarranty@danfoss.com

For special requirements please contact our factory.

Pssss!

© Danfoss | Climate Solutions | 2021.07

AN378367211987en-US0101 | 1

Page 2

Instructions

3 - Unloading

Special care should be taken while unpacking or uncrating the equipment so that damage and injury can be prevented. Heavy equipment

should be kept on the original pallet until ready for final installation. While using lifting straps, ensure to use a spreader bar and make sure

the straps do not compress the metal construction. When using a forklift, make sure the unit is positioned as shown in the following image.

Pallet

4 - Mounting

The equipment can be mounted using od hangers, lag screws and/or bolts made of stainless steel to prevent galvanic corrosion. Units

should be hung with no degree of inclination so that the condensate drainage works properly. Proper airflow through the unit is essential

for efficient performance and maintenance of design storage temperatures. Never install an evaporator over a doorway.

Mounting reference DACC

1.1xH

Lr/n+1

H

B

Lr

Lr/n+1Lr/n+1

Note: 1.1xH or greater is critical for proper performance

n = number of units to install

Lr = length of room

Unit Dimensions

#

Fans

(in.) (mm) (in.) (mm) (in.) (mm) (in.) (mm) (in.) (mm) (in.) (mm) (in.) (mm) (in.) (mm) (in.) (mm)

1 36 7/8” 937 17 3/8” 442 18” 457 X X X X X X

2 55” 1397 17 3/8” 442 18” 457 87 3/8” 2220 23 3/8” 593 25 1/16” 646 85 11/16” 2177 27 1/2” 698 33 1/2” 851

3 73 1/8” 1857 17 3/8” 442 18” 457 118 7/8” 3020 23 3/8” 593 25 1/16” 646 117 3/16” 2977 27 1/2” 698 33 1/2” 851

4 91 1/4” 2317 17 3/8” 442 18” 457 150 3/8” 3820 23 3/8” 593 25 1/16” 646 148 11/16” 3777 27 1/2” 698 33 1/2” 851

5 109 5/16” 2777 17 3/8” 442 18” 457 X X X X X X

Low Profile Med. Profile High Profile

L B H L B H L B H

Notes

• Do not place the cooler directly over or next to a door.

• Do not place product directly in front of the cooler.

• The air cooler should have a free air discharge for air throw.

• Do not place coolers in front of each other at a distance less than their air throw indicated in the technical specification sheet.

• In the case of electric defrost units; make sure to leave a free space of at least the length of the unit on the electric connection side

to remove the heaters in case of failure.

• The minimum distance between air defrost units must be 39.4 in.

• If you have reduced space or special room construction, please contact your local sales office to receive the correct advice on unit

mounting.

• This unit cooler should have free air discharge and be located below flat ceilings to achieve rated air throw.

© Danfoss | Climate Solutions | 2021.072 | AN378367211987en-US0101

Page 3

Instructions

5 - Refrigerant piping

Type, sizing and installation of all piping must be in accordance with the recommended and accepted practices for refrigeration

applications. All low temperature piping should also be insulated in accordance with standards ASHRAE. Suction traps should be used

when and if the suction line rises above the unit cooler. On horizontal lines, the good practice installations recommend a minimum slope

according to ASHRAE. It is recommended to have a slope of at least 1/4 inches (0.63 cm) by 10 feet (304.8 cm) in length in order to return

the oil to compressors.

6 - Expansion valve

For direct expansion units, select an expansion valve in accordance with capacity data and as required by expansion valve manufacturer.

Expansion valves with external equalizers should be used. After the temperature has reached design conditions, adjust the expansion

valve to obtain 8 to 10º F superheat at the suction line. Expansion valves are to be installed in accordance with the specific manufacturer’s

recommendations. Units that require an external equalized expansion valve must have that line connected. Proper location of the bulb

is extremely important to the performance of the coil. Good thermal contact to the suction line is also essential. On solder type valves, a

wet cloth wrapped around the valve during installation will protect it from overheating and damage. On multiple evaporator systems, the

piping should be arranged such that the flow from any valve cannot affect the bulb of another.

7 - Drain line

All drain lines subject to freezing temperatures must have drain line heaters and be insulated. Drain line traps must also be heated to

prevent freezing up of the drain line and trap. It is recommended that drain traps be installed outside of the conditioned space. The drain

line must have a slope level and look for the nearest exit to the outside.

8 - Wiring

All wiring must be done in strict accordance with local and national electrical codes. Fan motor(s), local isolators, electrical heater elements

and controllers must be wired in accordance with the electrical wiring diagrams provided. Use copper conductors of appropriate size only.

All electrical installations should only be performed by qualified and authorized personnel.

For thermal motor protection, the installed thermal contacts must be used and wired according to the circuit diagram attached

to the unit.

The unit must be connected to physical ground.

9 - Installation

The installation and maintenance of this equipment should be performed only by qualified professional personnel who are familiar with

this type of equipment. The equipment arrives from factory pressurized with dry air. All equipment must be evacuated before charging

the system with refrigerant. All field wiring should be checked and be in strict conformity with the equipment requirements, as well as all

national and local codes. Use the name plate electrical data for conductor and fuse sizing. Avoid contact with any sharp edges or sharp

coil surfaces. These can be a potential injury hazard. Make sure that all power sources are disconnected before any service work is done

on equipment.

Before starting up unit make sure all accessible electrical parts are secured!

10 - Vacuum

Proper vacuum is essential prior to charging the refrigerant for the system. This avoids many problems that can arise due to lack of detail

within this step. The system should be checked through all cycles to ensure proper operation. ASHRAE best practices for should be

followed when handling vacuum and charging refrigerant.

11 - Start-up

At start-up the following items should be checked:

• Check all threaded connections.

• Check electrical connections of motors, heater elements and any additional components, if applicable.

• Run the fans and check the direction of rotation. Make sure that there is no transport damage.

• During the test run observe the equipment and take notice of the following:

- Verify silent operation of the fans (bearings, contacts, balance)

- Check power requirements of electrical motors

- Verify absence of Leaks

- Adjust the expansion valve for proper superheating, if necessary

• After 24 hours of operation, re-check the equipment, especially all rotating parts.

AN378367211987en-US0101 | 3© Danfoss | Climate Solutions | 2021.07

Page 4

Instructions

12 - Maintenance and service

Disconnect all power sources before service!

12.1 Fan motors and heaters

The only electrical components vulnerable to potential malfunction are the fan motors, control voltage regulation circuits (if applicable),

and electrical defrost heaters. In the event of motor or heater failure, the affected part must be removed from the unit and replaced.

12.2 Drain pan

Periodic inspection of the drain pan is recommended. Accumulated dirt and dust should be cleaned out with hot water. If a sign of

improper drainage is apparent then the drain line pitch, drain line heater (if applicable) and drain trap should be checked for proper

operation. Unit can be cleaned using hot water. Special care should be taken when cleaning the unit around the electrical areas including

the fan, wiring and junction boxes. Water could potentially damage the electrical motor.

12.3 Inspection and maintenance

Verify the following points when visually inspecting the equipment:

• Secured threaded connections

• Leaks

• Silent operation of the fans

• General state of the unit such as cleanliness and corrosion

The cleaning of the finned heat exchanger is of the upmost importance to ensure smooth operation and long life of the equipment.

• There is no general rule how often it should be cleaned. Frequency and method of cleaning depend on the customer and must be

determined by the customer´s operating personnel. If necessary, the ice must be defrosted using water at 59°- 77° Fahrenheit. Never

remove ice mechanically with sharp or metallic objects.

• The equipment is always supplied in a clean condition. If, during installation and/or first operation hours, contamination reaches a state

where capacity can be affected, it is necessary that the unit is cleaned before operation.

When cleaning the unit it must be out of operation and all electrical power disconnected.

12.4 Hydraulic heat exchanger cleaning

• When cleaning with pressurized water or compressed air, the fans must be turned off. To avoid damage, never spray the fans directly!

• Clean the coil from top to bottom so that the dirt flows down. Cleaning should continue until all dirt is removed.

• Always clean / spray in the direction of the fins. Never clean at 90 ° of the fins!

• Maximum vapor pressure allowed: 6 bar. Maximum water pressure allowed before the outlet: 80 to 100 bar.

© Danfoss | Climate Solutions | 2021.074 | AN378367211987en-US0101

Page 5

Instructions

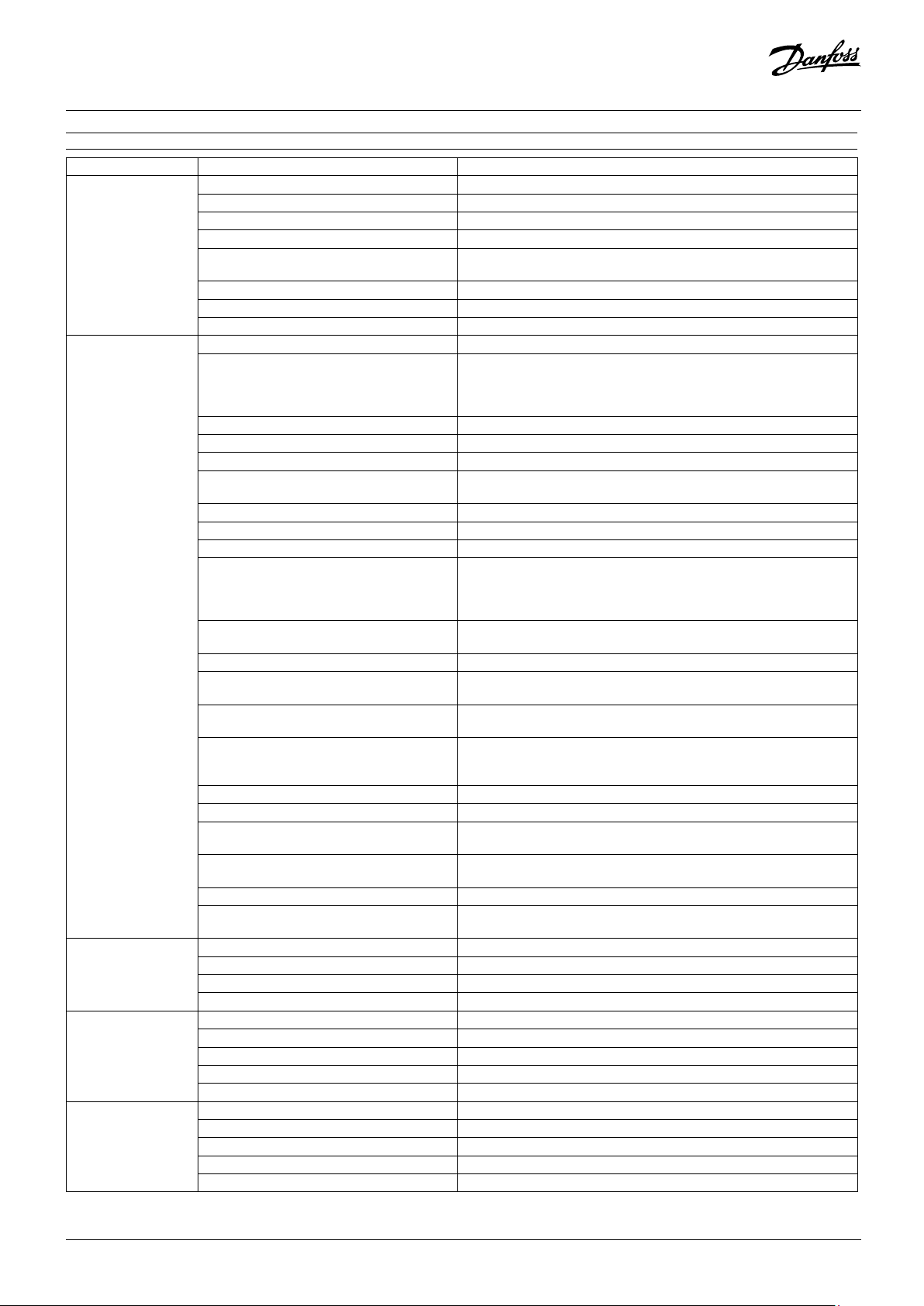

12.5 Preventive maintenance for commercial evaporators

CLEAN using a brush, pressurized water or mild detergent. Make sure the product being used is

appropriate for this particular application. NEVER USE ACID-BASED CLEANER.

CHECK that fans rotate freely and quietly.

REPLACE any motor if it vibrates or makes unusual noise.

INSPECT the unit for unusual vibrations in fans or housing. Identify the fan that is causing vibration.

INSPECT the drain pan to make sure the drain is free from obstructions, including ice buildup.

INSPECT for ice buildup on the coil.

CHECK defrost controller calibration.

CHECK that heaters are working properly during defrost.

VERIFY heater power consumption by comparing it to the data in the electrical diagram

CHECK that the drain line is working properly.

CHECK that all fan screws are tight. Tighten them if necessary.

CHECK that there is no corrosion in fins, pan, housing, soldered joints or copper pipes.

CHECK that there are no grease stains in coil headers, return bends or fins.

VERIFY there are no possible leaks.

CHECK that wiring is in good conditions and protected. Replace protection if necessary.

CHECK that all ground connections are tight.

As re-

quired

Once a

month

●

●

●

●

● ●

●

●

●

●

●

●

●

●

Every 3

months

●

●

Every 6

months

Every

year

●

AN378367211987en-US0101 | 5© Danfoss | Climate Solutions | 2021.07

Page 6

Instructions

13 - Troubleshooting

Symptoms Possible causes Possible corrective actions

1.1 Main switch open 1.1.1 Close switch

1.2 Blown fuses 1.2.1 Check for short circuits or overloads. Replace damaged fuse.

1.3 Damaged timer or defrost thermostat 1.3.1 Replace controller.

1.4 Unit in defrost cycle 1.4.1 Wait until cycle completion.

1. Fan is not working

2. Room temperature

too high

3. Ice buildup on ceiling

around evaporator

and/or on fan nozzles,

blades, or grill

4. Coil not clearing frost

after defrost cycle

5. Uneven coil frosting

during refrigeration

cycle

1.5 Coil does not get cold enough to reset

thermostat

1.6 Motor s burnt 1.6.1 Check for voltage surge and replace the motor.

1.7 Ventilator does not turn 1.7.1 Check for any obstruction (ice, debris, etc.) and remove

2.1 Room thermostat set too high 2.1.1 Reduce thermostat setting.

2.2 Superheat too high

2.3 Low refrigerant in system 2.3.1 Check for leaks and charge additional refrigerant in system.

2.4 Coil blocked with ice 2.4.1 Make manual defrost in coil. Check defrost system.

2.5 Unit cooler too close to doors 2.5.1 Relocate unit or add strip/air curtain to door.

2.6 Excessive air infiltration due to open doors

2.7 Product has just been loaded into cold room 2.7.1 Wait until product temperature is lower.

2.8 System is turned off 2.8.1 Turn on refrigeration system.

2.9 Power surge in system fails 2.9.1 Restore power surge.

2.10 Poor air flown in room

2.11 Pressure drop across evaporator too high

2.12 Lack of subcooling in the system 2.12.1 Establish a subcooling in the system.

2.13 Pressure drop across the valve is larger than

the design pressure of the valve

2.14 Expansion valve is blocked with ice due to

moisture in the system

2.15 Expansion valve is blocked with wax or

other impurities

2.16 Expansion valve is too small 2.16.1 Select and replace valve with a higher capacity valve or orifice.

2.17 Expansion valve bulb charge lost 2.17.1 Replace valve

2.18 Incorrect selection of the powerhead of the

expansion valve

2.19 Expansion valve bulb is not making a good

contact with suction line.

2.20 Expansion valve bulb is not insulated 2.20.1 Place insulation over the whole bulb

2.21 Expansion valve bulb is located near large

valves, flanges, headers or rising pipe.

3.1 Defrost cycle is too long. 3.1.1 Decrease defrost cycle.

3.2 Fan delay not working after defrost cycle. 3.2.1 Adjust defrost thermostat correctly or go to 3.3

3.3 Defective defrost thermostat or timer. 3.3.1 Replace component.

3.4 Too many defrost. 3.4.1 Reduce number of defrost per day.

4.1 Heater not working. 4.1.1 Make sure all heaters are working.

4.2 Hot gas supply is not enough. 4.2.1 Make sure there is sufficient hot gas volume to defrost unit.

4.3 Not enough defrost cycles per day. 4.3.1 Increase the number of defrost cycles per day.

4.4 Defrost cycle too short. 4.4.1Increase time on defrost thermostat or timer for longer cycle.

4.5 Defrost thermostat or timer not working. 4.5.1 Replace component.

5.1 Distributor in horizontal position. 5.1.1 Change distributor to vertical position.

5.2 Distributor or capillaries are blocked. 5.2.1 Replace distributor with capillaries.

5.3 After defrost, dripping time is too short. 5.3.1 Increase time for dripping.

5.4 incorrect or missing distributor nozzle. 5.4.1 Add or replace nozzle with appropriate size orifice for conditions.

5.5 Located too close to door opening. 5.5.1 Relocate evaporator

1.5.1 Increase fan delay time after defrost cycle.

1.7.2 Check junction box in fan for any short circuit and repair.

2.2.1 Check if the expansion valve is feeding correctly and clean strainer filter.

2.2.2 Check if bulb is placed in correct position and adjust if necessary.

2.2.3 Adjust the superheat on expansion valve.

2.2.4 Check for low refrigerant charge in system.

2.6.1 Check for doors seals and replace if necessary.

2.6. 2 Keep doors closed as long as possible.

2.10.1 Make sure all fans turn in correct direction

2.10.2 See possible cause 1.7

2.10.3 See symptom 4

2.10.4 Check unit location recommendations

2.11.1 Replace expansion valve with valve having external pressure

equalization, adjust superheat on valve

2.13.1 Select a new valve with the desired pressure drop.

2.14.1 Change drier filter and clean ice off valve.

2.15.1Clean valve port and strainer.

2.15.2 Clean solenoid valve and its filter.

2.15.3 Replace the oil in the refrigeration system.

2.18.1 Select a powerhead according to the application.

2.19.1 Fasten bulb to suction line appropriately.

2.21.1 Replace expansion valve with valve with external pressure equalization,

adjust valve overheating.

© Danfoss | Climate Solutions | 2021.076 | AN378367211987en-US0101

Page 7

Instructions

Symptoms Possible causes Possible corrective actions

6.1.1 Check hater power supply.

6.1.2 Change drain line heater.

6.2.1 Check heater power supply

6.2.2 Change drain line heater

6.4.1 Clean drain line.

6.4.2 Insulate drain line properly (if blocked with ice)

6.8.1 Make sure drain pan is close to heaters or hot gas coil.

7.2.1 Make sure drain pan is leveled towards the back

6. Ice accumulation on

drain pan

7. Water accumulation

on drain pan or water

spreading outside unit

14 - Spare parts

6.1 Drain line heater not working.

6.2 Tray heater not working.

6.3 Unit tilted unproperly. 6.3.1 Level unit to horizontal position.

6.4 Drain line plugged.

6.6 Thermostat not working. 6.6.1 Replace defective component.

6.7 Drain line without water tramp 6.7.1 Install water tramp in drain line outside cold room

6.8 Drain pan not placed properly in unit after

maintenance.

7.1 Drain line plugged. 7.1.1 Clean drain line.

7.2 Drain pan not placed properly in unit after

maintenance.

7.3 Unit tilted unproperly. 7.3.1 Level unit to horizontal position.

# Fans

1 119-8938 119-8938 119-8957 119-8957 X X

2 119-8940 119-8940 119-8958 119-8969 119-8980 119-8969

3 119-8942 119-8942 119-8960 119-8971 119-8981 119-8971

4 119-8944 119-8944 119-8962 119-8962 119-8982 119-8962

5 119-8946 119-8946 X X X X

Profile Fan

Low Profile 119-8937

Med. Profile 119-8956

High Profile 3~460V 119-8979

Evaporator protection 4501.1 119-8993

Evaporator protection 4503.1 119-8992

Coil Heater Tray Heater Coil Heater Tray Heater Coil Heater Tray Heater

Low Profile Med. Profile High Profile

AN378367211987en-US0101 | 7© Danfoss | Climate Solutions | 2021.07

Page 8

15 - Reference data

Service record Danfoss Unit Cooler

One data sheet must be completed for each installation and each cooler, with a copy for the owner, a copy for the installer and the original

for Danfoss. If another company is to provide the service and maintenance, additional copies should be prepared as necessary

Danfoss Unit Cooler

System reference data

The refrigeration installation contractor must complete and sign the information bellow:

Date of installation of system_________________________________________________________________________________________

Installer name and address ___________________________________________________________________________________________

_________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________

Evaporator(s)

Evaporator Model No._______________________________________________________________________________________________

Evaporator Serial Number____________________________________________________________________________________________

Electrical System _____________________________ Volts _____________________________ Phases_____________________________

Expansion valve brand and model _____________________________________________________________________________________

Ambient at startup ______________________________________ °F

Box design temperature __________________________________ °F

Box operating temperature _______________________________ °F

Thermostat setting ______________________________________ °F

Defrost setting ___________ / day__________________minutes fail proof ___________ / day ____________________ minutes fail proof.

Evaporator suction line temperature _______________________ °F

Superheat at evaporator _________________________________ °F

Discharge __________ No. of times ____________ Final Microns ___________ No. of times _____________ Final Microns ______________

Evaporator drain line with trap external to box Yes � No �

Please do not forget to register your product!

To register your product Simply scan the Below QR code and follow the prompts, it’s easy and secure.

8 | AN378367211987en-US0101

© Danfoss | Climate Solutions | 2021.07

Loading...

Loading...