Page 1

Operating Guide

VACON® NXP Advanced Safety Options

OPTBL, OPTBM, OPTBN

drives.danfoss.com

Page 2

Page 3

VACON® NXP Advanced Safety Options

Operating Guide

Contents

1

Introduction 9

1.1

Purpose of the Manual 9

Additional Resources 9

1.2

Manual and Software Version 10

1.3

1.4

Approvals and Certificates 12

1.5

Product Overview 15

1.6

Terms and Abbreviations 16

Safety 19

2

Safety Symbols 19

2.1

Danger and Warnings 19

2.2

Cautions and Notices 20

2.3

Grounding 22

2.4

Contents

Overview of the System 24

3

Using the Advanced Safety Options 24

3.1

3.2

The Safe State 24

3.3

Integration and Interfaces to Other Systems 25

3.4

Determining the Achieved Safety Level 25

3.5

Advanced Safety Option Variants 27

3.5.1

General Information 27

3.5.2

Input Configuration 27

3.5.3

Output Configuration 28

3.5.4

Option Board OPTBL 30

3.5.5

Option Board OPTBM 31

3.5.6

Option Board OPTBN 32

3.5.7

Closed-loop Control with OPTBM 33

3.5.8

Closed-loop Control with OPTBN 33

3.6

Speed Measurement 33

3.6.1

Safety Speed Sensors 33

3.6.2

Standard Speed Sensors and Combinations 33

3.6.3

Speed Discrepancy with Multiple Speed Sources 35

3.6.4

Encoders 35

3.6.5

Proximity sensors 38

3.6.6

Encoder Signal Verification 39

3.6.7

Usage of Only One Speed Sensor 39

3.6.8

Estimated Speed 40

AQ319736045637en-000101/DPD01798 | 3Danfoss A/S © 2021.06

Page 4

VACON® NXP Advanced Safety Options

Operating Guide

3.6.9

Estimated Speed and Gear Systems 42

3.6.10

Estimated Speed and External Accelerative Forces 43

3.7

Storage of Parameters 43

3.7.1

Storing a Parameter File Backup 44

3.7.2

Restoring a Parameter File from Backup 44

3.8

Advanced Safety Options with the NXP Drive 44

3.8.1

Requirements 44

3.8.2

Compatibility with Drive Applications 45

3.8.3

Option Board Menu on the Control Panel 45

3.8.4

Fault Types 49

4

Installation 51

4.1

Installation Safety 51

4.2

Installing the Option Board 51

Contents

5

VACON Safe Tool 53

5.1

Functions of the VACON Safe Tool 53

5.2

The Parameter File 53

5.3

User Levels and Password Management 53

5.4

Setting the Parameters 54

5.5

Saving a Verified Parameter File to the Option Board 56

5.6

Online Monitoring 56

5.6.1

Viewing the State of the Option Board 56

5.6.2

Activity Log 56

6

Safety Functions 57

6.1

General Information 57

6.1.1

The Different Safety Functions 57

6.1.2

Safety Function States 57

6.1.3

Activation of a Safety Function 58

6.1.4

Violation of a Safety Function 58

6.1.5

Acknowledgment of a Safety Function 59

6.1.5.1

6.1.5.2

6.1.6

Reset of a Safety Function 63

6.1.7

Ramps 64

6.2

Safe Stopping Functions 66

6.2.1

Introduction to the Safe Stopping Functions 66

6.2.2

STO - Safe Torque Off and SBC - Safe Brake Control 67

Acknowledgment of a Safety Function 59

Start-up Acknowledgment 63

AQ319736045637en-000101/DPD017984 | Danfoss A/S © 2021.06

Page 5

VACON® NXP Advanced Safety Options

Operating Guide

6.2.3

6.2.4

Contents

6.2.2.1

6.2.2.2

6.2.2.3

6.2.2.4

SS1 - Safe Stop 1 73

6.2.3.1

6.2.3.2

6.2.3.3

6.2.3.4

6.2.3.5

SS2 - Safe Stop 2 and SOS - Safe Operating Stop 78

6.2.4.1

6.2.4.2

6.2.4.3

Introduction to the STO and SBC Functions 67

The STO Function Used without the SBC Function 68

The STO Function Used with the SBC Function 68

The STO and SBC Signals 69

Introduction to the SS1 Function 73

Time Monitoring 74

Zero Speed Monitoring 74

Ramp Monitoring 75

The SS1 Signals 75

Introduction to the SS2 and SOS Functions 78

Time Monitoring 79

Zero Speed Monitoring 79

6.2.4.4

6.2.4.5

6.2.4.6

6.2.5

SQS - Safe Quick Stop 84

6.2.5.1

6.2.5.2

6.2.5.3

6.3

Safe Monitoring Functions 89

6.3.1

Introduction to the Safe Monitoring Functions 89

6.3.2

SLS - Safe Limited Speed 90

6.3.2.1

6.3.2.2

6.3.2.3

6.3.2.4

6.3.2.5

6.3.3

SMS - Safe Maximum Speed 96

Ramp Monitoring 80

The SOS Safety Function 80

The SS2 and SOS Signals 80

Introduction to the SQS Function 84

The SQS Modes 85

The SQS Signals 85

Introduction to the SLS Function 90

Time Monitoring 90

Ramp Monitoring 91

The Speed Limit Selection of the SLS Function 91

The SLS Signals 92

6.3.3.1

6.3.3.2

6.3.3.3

6.3.4

SSR - Safe Speed Range 99

6.3.4.1

6.3.4.2

6.3.4.3

6.3.4.4

Introduction to the SMS Function 96

The Maximum Speed Monitoring 96

The SMS Signals 97

Introduction to the SSR Function 99

Time Monitoring 99

Ramp Monitoring 100

The SSR Signals 101

AQ319736045637en-000101/DPD01798 | 5Danfoss A/S © 2021.06

Page 6

VACON® NXP Advanced Safety Options

Operating Guide

6.3.5

SSM - Safe Speed Monitor 103

6.3.5.1

6.3.5.2

6.3.5.3

6.3.5.4

6.4

Combinations of Safety Functions 109

7

Safe Fieldbuses 111

7.1

PROFIsafe 111

7.1.1

Introduction to PROFIsafe 111

7.1.2

The Requirements and Restrictions 111

7.1.3

Overview of the PROFIsafe System 112

7.1.4

The PROFIsafe Frame 112

7.1.5

Parameterization for PROFIsafe 113

7.1.5.1

Introduction to the SSM Function 103

Speed Monitoring 104

The SSM Safe Output 104

The SSM Signals 105

General Information on Parameterization 113

Contents

7.1.5.2

7.1.5.3

7.1.6

PROFIdrive on PROFIsafe 115

7.1.6.1

7.1.6.2

7.1.6.3

7.1.6.4

7.1.6.5

7.1.6.6

7.1.6.7

7.1.6.8

7.1.6.9

7.1.6.10

8

Parameter List 125

8.1

General Parameters 125

8.1.1

Parameter File Parameters 125

PROFIsafe Watchdog Time 114

The PROFIsafe Safety Function Response Time (SFRT) 115

General Information on PROFIdrive on PROFIsafe 115

PROFIsafe over PROFIBUS 116

PROFIsafe over PROFINET 117

Data Mapping for PROFIdrive on PROFIsafe 117

Safety Control Word 1 (S_STW1) 117

Safety Status Word 1 (S_ZSW1) 118

Safety Control Word 2 (S_STW2) 119

Safety Status Word 2 (S_ZSW2) 120

VACON Safety Control Word (VS_CW) 122

VACON Safety Status Word (VS_SW) 123

8.1.2

Common Safety Function Parameters 125

8.1.3

Speed Measurement Parameters 125

8.1.4

Ramp Parameters 126

8.1.5

Estimated Speed Parameters 127

8.2

Safe I/O Parameters 127

8.2.1

Digital Input/Output Parameters 127

8.3

Safe Fieldbus Parameters 129

AQ319736045637en-000101/DPD017986 | Danfoss A/S © 2021.06

Page 7

VACON® NXP Advanced Safety Options

Operating Guide

8.3.1

PROFIsafe Parameters 129

8.4

STO and SBC Parameters 129

8.5

SS1 Parameters 130

8.6

SS2 and SOS Parameters 130

8.7

SQS Parameters 131

8.8

SLS Parameters 132

8.9

SMS Parameters 132

8.10

SSR Parameters 133

8.11

SSM Parameters 133

8.12

Validation Parameters 134

9

Commissioning and Validation 135

9.1

Preparing for Commissioning 135

9.1.1

Preparing for Commissioning 135

9.1.2

Procedures Before the First Start-up of the System with the Option 135

Contents

9.2

Doing the First Start-up After the Installation of the Option Board 136

9.3

Validating the Parameter File 137

9.4

Checklist before Taking the System into Use 137

9.5

Bypassing Safety Features 137

10

Operation and Maintenance 139

10.3

Resetting the Password 141

10.4

Factory Reset 141

10.5.1

Updating the Firmware 142

10.6

Replacing the Option Board 143

10.7

Replacement of Other Components of the Safety System 143

10.8

Disposal 144

11

Technical Data 145

11.1

Safety Data 145

11.2

Safe Input/Output Data 145

11.3

Speed Measurement Data 147

11.4

Safe Fieldbus Data 149

11.5

Environmental Data 149

12

Fault Tracing 150

12.1

Presentation of Faults on the Control Board 150

12.2

Fault Codes 151

12.3

OPTAF STO and ATEX Option Board Fault Information 172

AQ319736045637en-000101/DPD01798 | 7Danfoss A/S © 2021.06

Page 8

VACON® NXP Advanced Safety Options

Operating Guide

13

Configuration Examples 173

General Information 173

13.1

13.2

Emergency Stop Using the STO Function 173

SS1 Used with STO(+SBC) 174

13.3

13.4

SS1 Without a Direct Support of the Drive Application 176

13.5

Light Curtain Control of SLS 177

13.6

SLS without a Direct Support of the Drive Application 180

13.7

Using an Output of the Option Board to Control the Access to an Area 182

13.8

PROFIdrive over PROFIsafe Using the PROFIBUS or PROFINET Option Board 185

13.9

A Proximity Sensor for Speed Measurement 187

Contents

AQ319736045637en-000101/DPD017988 | Danfoss A/S © 2021.06

Page 9

NOTE! Download the English and French product guides with applicable safety, warning and caution information from https://

www.danfoss.com/en/service-and-support/.

REMARQUE Vous pouvez télécharger les versions anglaise et française des guides produit contenant l'ensemble des informations

de sécurité, avertissements et mises en garde applicables sur le site https://www.danfoss.com/en/service-and-support/.

VACON® NXP Advanced Safety Options

Operating Guide

Introduction

1 Introduction

1.1 Purpose of the Manual

This manual describes the VACON® Advanced Safety Options (OPTBL, OPTBM, or OPTBN). The VACON® Advanced Safety Options can

be used with the VACON® NXP AC drive.

The operating guide is intended for use by qualified personnel, who are familiar with the VACON® drives and functional safety.

To use the product safely, read and follow the operating instructions.

1.2 Additional Resources

Resources Available for the Drive and Optional Equipment

VACON® NX OPTAF STO Board Manual

•

VACON® NX All in One Application Guide - information on working with parameters and many application examples

•

VACON® OPTE3/E5 PROFIBUS DP User Guide

•

VACON® NX I/O Boards User Manual

•

VACON® OPTEA/OPTE9 Ethernet Board User Guide

•

VACON® Ethernet Option Boards Installation Guide

•

VACON® RS485 and CAN Bus Option Boards Installation Guide

•

VACON® NXP Advanced Safety Options Quick Guide

•

The Operating Guide of the AC drive provides the necessary information to get the drive up and running.

•

Supplementary publications and manuals are available from

Standards, specifications, and official recommendations

•

EN IEC-62061 – Safety of machinery – Functional safety of safety-related electrical, electronic and programmable electronic control systems, 2005

•

IEC 61784-3 – Industrial communication networks – Profiles – Part 3: Functional safety fieldbuses - General rules and profile definitions, 2010

•

EN ISO 13849-1 – Safety of machinery – Safety-related parts of control systems – Part 1: General principles for design, 2015

•

EN IEC 60204-1 – Safety of machinery – Electrical equipment of machines – Part 1: General requirements, 2006

•

EN IEC 61800-5-2 – Adjustable speed electrical power drive systems – Part 5-2: Safety requirements – Functional, 2007

•

IEC 61508 – Functional safety of electrical/electronic/programmable electronic safety related systems, 2010

•

EN ISO 12100 – Safety of machinery -- General principles for design -- Risk assessment and risk reduction, 2010

•

ISO 14121-1 – Safety of machinery -- Risk assessment -- Part 1: Principles, 2007

•

Amendment – PROFIdrive on PROFIsafe Interface for functional safety; Technical Specification for PROFIBUS and PROFINET related to PROFIdrive – Profile Drive Technology V4.1, Version 3.00.4, April 2011, Order No.: 3.272

•

PROFIsafe – Profile for Safety Technology on PROFIBUS DP and PROFINET IO, Version 2.4, March 2007, Order No: 3.192b

•

Recommendation of Use CNB/M/11.050, rev 05; European co-ordination of Notified Bodies for Machinery, 2013

•

BGIA Report 2/2008e Functional safety of machine controls – Application of EN ISO 13849 –, 2009

Software and Configurations Files

•

The firmware for the Advanced Safety Option, https://www.danfoss.com/en/service-and-support/downloads/dds/fieldbus-firm-

ware/.

•

VACON® Safe, https://www.danfoss.com/en/service-and-support/downloads/dds/vacon-safe/.

The GSD/GSDML file,

•

For US and Canadian markets:

https://www.danfoss.com/en/service-and-support/downloads/dds/fieldbus-configuration-files/.

drives.danfoss.com/knowledge-center/technical-documentation/.

AQ319736045637en-000101 / DPD01798 | 9Danfoss A/S © 2021.06

Page 10

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Manual version

New features

Firmware version

Hardware version

DPD01798B

The first published version of this manual.

DPD01798C

PROFIsafe over PROFINET information added. Chapter Safe fieldbuses

and throughout the manual.

Version history table added.

Table linking option board names to option board codes. Chapter 3.5.1

General Information.

Images edited. Chapters VACON Advanced Safety Option variants and

Configuration examples.

Warning added. Chapter 6.1.4 Violation of a Safety Function.

Fault settings table added. Chapter 3.8.3 Option Board Menu on the

Control Panel.

Safety bypass procedure updated. Chapter 9.5 Bypassing Safety Fea-

tures.

Fault codes edited. Chapter Fault codes.

New configuration example on SLS without drive application support

added. Chapter 13.6 SLS without a Direct Support of the Drive Applica-

tion.

Configuration examples numbered. Chapter Configuration examples.

Other minor updates. Throughout the manual.

DPD01798D

Safety function acknowledgment and reset descriptions updated to

match new behavior. Chapters 6.1.5.1 Acknowledgment of a Safety

Function and 6.1.6 Reset of a Safety Function.

Example of system level calculations updated. Chapter 3.4 Determining

the Achieved Safety Level.

Encoder terminals updated. Chapters 3.5.5 Option Board OPTBM and

3.5.6 Option Board OPTBN.

Option board installation instructions updated. Chapter 4.2 Installing

the Option Board.

Extended slot support and example configuration updated. Chapter 3.1

Using the Advanced Safety Options.

Comment on closed-loop control added. Chapter 3.6.7 Usage of Only

One Speed Sensor.

Old parameters edited and new added. Chapter 3.8.3 Option Board

Menu on the Control Panel.

Watchdog times updated. Chapter 7.1.5.2 PROFIsafe Watchdog Time.

Technical details updated. Chapter 11.1 Safety Data.

Fault codes updated. Chapter Fault codes.

Images edited. Chapters 3.1 Using the Advanced Safety Options, 3.6.8

Estimated Speed, 6.2.3.5 The SS1 Signals, 6.3.4.2 Time Monitoring,

6.3.4.3 Ramp Monitoring, 13.3 SS1 Used with STO(+SBC), 13.5 Light Cur-

FW0281V001

or later

70CVB01938 F

(141X4588) or

later,

70CVB01957 F

(141X4608) or

later,

70CVB01958 E

(141X4610) or

later

VACON® NXP Advanced Safety Options

Operating Guide

Introduction

1.3 Manual and Software Version

This manual is regularly reviewed and updated. All suggestions for improvement are welcome.

The original language of this manual is English.

Always make sure that you use the latest or correct revision of the manual when assessing the behavior of the Advanced safety

option board.

Table 1: Manual and Software Version

AQ319736045637en-000101 / DPD0179810 | Danfoss A/S © 2021.06

Page 11

•

•

•

•

•

•

•

•

Manual version

New features

Firmware version

Hardware version

tain Control of SLS, and 13.6 SLS without a Direct Support of the Drive

Application.

Other minor updates. Throughout the manual.

DPD01798E

New chapter added, 3.6.3 Speed Discrepancy with Multiple Speed Sour-

ces.

Information on internal variables added. Chapter 10.1 Gathering Diag-

nostic Data.

Some fault numbers for fault code 20 Safety system updated. Chapter

Fault codes.

OPTAF option board fault information added. Chapter 12.3 OPTAF STO

and ATEX Option Board Fault Information.

Other minor updates. Throughout the manual.

FW0281V001

or later

70CVB01938 F

(141X4588) or

later,

70CVB01957 F

(141X4608) or

later,

70CVB01958 E

(141X4610) or

later

DPD01798F

PROFINET IO/PROFIsafe Certificate updated. 1.4 Approvals and Certifi-

cates.

Changes in layout and structure.

FW0281V001

or later

70CVB01938 F

(141X4588) or

later,

70CVB01957 F

(141X4608) or

later,

70CVB01958 E

(141X4610) or

later

VACON® NXP Advanced Safety Options

Operating Guide

Introduction

AQ319736045637en-000101 / DPD01798 | 11Danfoss A/S © 2021.06

Page 12

e30bi948.10

VACON® NXP Advanced Safety Options

Operating Guide

1.4 Approvals and Certificates

Introduction

Illustration 1: TÜV Certificate

AQ319736045637en-000101 / DPD0179812 | Danfoss A/S © 2021.06

Page 13

Certificate

PROFIBUS Nutzerorganisation e.V. grants to

Vacon Ltd

Runsorintie 7, 65380 VAASA, FINLAND

the Certificate No: Z20212 for the PROFIsafe Device:

Model Name: Vacon OPTEA, OPTBL, OPTBM, OPTBN Advanced Safety Option

Order-Number: OPTBL, OPTBM, OPTBN

Revision: SW/FW: V4.0.0; HW: 6

Application CRC: Channel A: 0x84C3

Channel B: 0xCB77

This certificate confi rms that the product has successfully passed the certifi cation tests with the

following PROFI

safe scope:

PROFIsafe_V2 functionality on PROFINET IO

Test Report Number:

PS127-2

Authorized Test Laboratory:

SIEMENS AG, Fürth, Germany

The tests were executed in accordance with the following documents:

“

PROFIsafe -

Test Spec

ification

for F-Slaves, F-Devices, and F-Hosts, Version 2.1, March 2007”.

This certificate is granted according to the document:

“Framework for testing and certification of PROFIBUS and PROFINET

products”.

For all products that are placed in circulation by March 19, 2023 the certificate is valid for life.

Karlsruhe, May 14,

2020

_____________________________

(Official in Charge)

Board of PROFIBUS Nutzerorganisation e. V.

_____________________________

(Karsten Schneider)

_____________________________

(Dr. Jörg Hähniche)

e30bi950.10

VACON® NXP Advanced Safety Options

Operating Guide

Introduction

Illustration 2: PROFINET IO/PROFIsafe Certificate

AQ319736045637en-000101 / DPD01798 | 13Danfoss A/S © 2021.06

Page 14

e30bi949.10

VACON® NXP Advanced Safety Options

Operating Guide

Introduction

Illustration 3: EC Declaration of Conformity

AQ319736045637en-000101 / DPD0179814 | Danfoss A/S © 2021.06

Page 15

VACON® NXP Advanced Safety Options

Operating Guide

Introduction

1.5 Product Overview

The Advanced safety option board is intended to be used for implementing safety functions according to application needs. The

option board is intended to be used with the OPTAF STO option board to implement the safety functions and features in VACON

NX drives.

The safety functions available with the Advanced safety option board (according to EN IEC 61800-5-2)

Safe Torque Off (STO)

•

Safe Stop 1 (SS1)

•

Safe Stop 2 (SS2)

•

Safe Operating Stop (SOS)

•

Safe Brake Control (SBC)

•

Safe Limited Speed (SLS)

•

Safe Speed Range (SSR)

•

Safe Speed Monitor (SSM)

•

The manufacturer-specific safety functions

Safe Maximum Speed (SMS)

•

Safe Quick Stop (SQS)

•

For more information on the safety functions, see chapter Safety functions.

The safe fieldbuses supported by the option board

PROFIsafe communication over PROFIBUS

•

PROFIsafe communication over PROFINET

•

Communication over PROFIsafe is implemented according to the PROFIdrive on PROFIsafe amendment.

®

W A R N I N G

DESIGNING OF SAFETY SYSTEMS

Designing a safety-related system incorrectly could result in death or serious injury.

The designing of safety-related systems requires special knowledge and skills.

-

Only qualified persons are permitted to install and set up the product.

-

W A R N I N G

RISK ASSESSMENT OF A SAFETY SYSTEM

The use of safety functions provided by the Advanced Safety Option does not in itself ensure safety.

To make sure that the commissioned system is safe, you must make an overall risk assessment.

-

Safety devices like the Advanced safety option board must be correctly incorporated into the entire system.

-

The entire system must be designed in compliance with all relevant standards within the field of industry. Standards such as

-

EN 12100 Part 1, Part 2, and ISO 14121-1 provide methods for designing safe machinery and for making a risk assessment.

C A U T I O N

PROTECTION AGAINST CONTAMINATION

For the product to work properly, it must be protected against conductive dust and contaminants.

For example, install the Advanced Safety Option board in at least an IP54 enclosure.

-

N O T I C E

This guide provides information on the use of the safety functions that the Advanced Safety Option provides. This information is

in compliance with accepted practice and regulations at the time of writing. However, the product/system designer is responsible for making sure that the system is safe and in compliance with relevant regulations.

AQ319736045637en-000101 / DPD01798 | 15Danfoss A/S © 2021.06

Page 16

Abbreviation

Definition

Admin

The highest user level for accessing the Advanced safety option board functions. Identified via a password.

Acknowledgment

A signal that indicates that a safety function can be deactivated. Valid for safety functions that use manual acknowledgment.

ASM

An asynchronous motor

Continuous mode

Safety function is active as a part of normal operation.

CRC

Cyclic Redundancy Check

CW

Control word

DAT

Device Acknowledgment Time

Diagnostic Coverage

(DC)

The coverage of dangerous failures by run-time diagnostics.

EMC

Electromagnetic compatibility

Encoder interface

board

An option board that has an encoder interface.

F-Device

A communication peer that can perform the PROFIsafe protocol.

F-Host

A data processing unit that can perform the PROFIsafe protocol and service the "black channel".

FMEA

Failure Mode and Effects Analysis

Critical fault

A fault that causes the option board to enter into a fault state and requires a reboot to be reset.

GSD

Generic Station Description (used with PROFIBUS).

GSDML

General Station Description Markup Language (used with PROFINET).

Hardware Fault Tolerance (HFT)

The number of hardware failures that the safety system can tolerate without the loss of the safety function.

HAT

Host Acknowledgment Time.

High demand mode

Safety functions are performed on demand. The frequency of demand is more than once a year.

HTL

High Threshold Logic. A voltage level definition.

I/O

Input/Output

Low demand mode

Safety functions are performed on demand. The frequency of demand is less than once a year.

MTTF

Mean Time To Failure

OPTAF

An option board that handles the activation of the STO function for the AC drive.

OPTBL, OPTBM,

OPTBN

The variants of the Advanced safety option. OPTBL: no encoder interface. OPTBM: with digital pulse type

encoder interface board. OPTBN: with Sin/Cos type encoder interface board.

OPTE3/5

Option board that handles the PROFIBUS DP interface.

OPTEA

Option board that handles the PROFINET IO interface.

VACON® NXP Advanced Safety Options

Operating Guide

1.6 Terms and Abbreviations

Table 2: Symbols and Abbreviations

Introduction

AQ319736045637en-000101 / DPD0179816 | Danfoss A/S © 2021.06

Page 17

Abbreviation

Definition

Parameter file

A configuration file that contains the parameters for an Advanced safety option board.

Unverified parameter file

A parameter file that contains parameters that have not been verified by an Advanced safety option

board.

Verified parameter

file

A parameter file that contains parameters that have been verified and can be used in an Advanced safety

option board.

Validated parameter

file

A verified parameter file that contains parameters that have been tested and approved in the system.

PFH

Probability of failure per hour. Valid for systems that operate in a high demand mode or continuous

mode.

PFHdProbability of dangerous failure per hour.

PFD

Probability of failure on demand. The probability that the safety function does not work when requested.

Valid for systems that operate in a low demand mode.

PL

Performance Level

PLC

Programmable Logic Controller

PMSM

A permanent magnet synchronous motor

PROFIBUS

Standardized fieldbus protocol for RS-485 communication.

PROFIdrive

A specification for implementing AC drive related behavior over PROFIBUS/ PROFINET.

PROFINET

Standardized fieldbus protocol for Ethernet communication.

PROFIsafe

A safe fieldbus layer that operates over PROFIBUS/PROFINET.

Reached

A safety function that is reached has stopped the drive (safe stopping functions), or reached a safe area

for the measured value and monitoring for leaving the area has been activated (safe monitoring functions).

Resettable fault

An error in that can be reset with a reset signal.

Reset (signal)

A signal used to reset the current violations and faults in the drive and/or the Advanced safety option

board and to deactivate the STO function after a violation or fault.

SFF

Safe Failure Fraction

Safe monitoring

function

A safety function that monitors a specific value, usually speed.

Safe stopping function

A safety function intended to stop the motor.

Safe range

A range where the monitored value can be. Exceeding the limits of a safe range will cause a violation of

the safety function.

Safe state

A state of a device or process that should be maintained to avoid dangerous incidents. For the AC drive

system, the safe state is defined as activated STO function.

Service

A user level for accessing the Advanced safety option board functions. Identified via a password. In this

user level, it is not possible to verify a parameter file or change passwords.

SFRT

Safety Function Response Time

SRP/CS

Safety-Related Part of a Control System

VACON® NXP Advanced Safety Options

Operating Guide

Introduction

AQ319736045637en-000101 / DPD01798 | 17Danfoss A/S © 2021.06

Page 18

Abbreviation

Definition

STO

Safe Torque Off. A safety function according to EN IEC 61800-5-2.

SS1

Safe Stop 1. A safety function according to EN IEC 61800-5-2.

SS2

Safe Stop 2. A safety function according to EN IEC 61800-5-2.

SQS

Safe Quick Stop. A manufacturer-specific safety function. Used as a violation response for safe monitoring

functions. Parameterizable to behave as the STO, SS1 or SS2 function.

SQS-STO, SQS-SS1,

SQS-SS2

Used to indicate the STO, SS1 or SS2 function as the selected behavior of the SQS function.

SLS

Safe Limited Speed. A safety function according to EN IEC 61800-5-2.

SSR

Safe Speed Range. A safety function according to EN IEC 61800-5-2.

SSM

Safe Speed Monitor. A safety function according to EN IEC 61800-5-2.

SMS

Safe Maximum Speed. A manufacturer-specific safety function.

SBC

Safe Brake Control. A safety function according to EN IEC 61800-5-2.

SOS

Safe Operating Stop. A safety function according to EN IEC 61800-5-2.

SIL

Safety Integrity Level

SW

Status word

TTL

Transistor-Transistor Logic. A voltage level definition.

Violation

A fault caused by a safety function detecting a violation of the monitored value(s). The value monitored

by a safety function has exceeded the set limit for that value.

Violation response

A reaction to a violation. It is the STO function for the safe stopping functions, and the SQS function for

the safe monitoring functions.

WCDT

Worst Case Delay Time

WDTime

Watchdog Time

VACON® NXP Advanced Safety Options

Operating Guide

Introduction

AQ319736045637en-000101 / DPD0179818 | Danfoss A/S © 2021.06

Page 19

VACON® NXP Advanced Safety Options

Operating Guide

2 Safety

2.1 Safety Symbols

The following symbols are used in this manual:

D A N G E R

Indicates a hazardous situation which, if not avoided, will result in death or serious injury.

W A R N I N G

Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

C A U T I O N

Indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

N O T I C E

Indicates information considered important, but not hazard-related (for example, messages relating to property damage).

Safety

2.2 Danger and Warnings

D A N G E R

SHOCK HAZARD FROM POWER UNIT COMPONENTS

The power unit components are live when the drive is connected to mains. A contact with this voltage can lead to death or serious injury.

Do not touch the components of the power unit when the drive is connected to mains. Before connecting the drive to mains,

-

make sure that the covers of the drive are closed.

D A N G E R

SHOCK HAZARD FROM TERMINALS

The motor terminals U, V, W, the brake resistor terminals, or the DC terminals are live when the drive is connected to mains, also

when the motor does not operate. A contact with this voltage can lead to death or serious injury.

Do not touch the motor terminals U, V, W, the brake resistor terminals, or the DC terminals when the drive is connected to

-

mains. Before connecting the drive to mains, make sure that the covers of the drive are closed.

D A N G E R

SHOCK HAZARD FROM DC LINK OR EXTERNAL SOURCE

The terminal connections and the components of the drive can be live 5 minutes after the drive is disconnected from the mains

and the motor has stopped. Also the load side of the drive can generate voltage. A contact with this voltage can lead to death or

serious injury.

Before doing electrical work on the drive:

-

Disconnect the drive from the mains and make sure that the motor has stopped.

Lock out and tag out the power source to the drive.

Make sure that no external source generates unintended voltage during work.

Wait 5 minutes before opening the cabinet door or the cover of the AC drive.

Use a measuring device to make sure that there is no voltage.

AQ319736045637en-000101 / DPD01798 | 19Danfoss A/S © 2021.06

Page 20

VACON® NXP Advanced Safety Options

Operating Guide

Safety

W A R N I N G

SHOCK HAZARD FROM CONTROL TERMINALS

The control terminals can have a dangerous voltage also when the drive is disconnected from mains. A contact with this voltage

can lead to injury.

Make sure that there is no voltage in the control terminals before touching the control terminals.

-

W A R N I N G

ACCIDENTAL MOTOR START

When there is a power-up, a power break, or a fault reset, the motor starts immediately if the start signal is active, unless the pulse

control for Start/Stop logic is selected. If the parameters, the applications or the software change, the I/O functions (including the

start inputs) can change. If you activate the auto reset function, the motor starts automatically after an automatic fault reset. See

the Application Guide. Failure to ensure that the motor, system, and any attached equipment are ready for start can result in

personal injury or equipment damage.

Disconnect the motor from the drive if an accidental start can be dangerous. Make sure that the equipment is safe to operate

-

under any condition.

W A R N I N G

LEAKAGE CURRENT HAZARD

Leakage currents exceed 3.5 mA. Failure to ground the drive properly can result in death or serious injury.

Ensure the correct grounding of the equipment by a certified electrical installer.

-

W A R N I N G

SHOCK HAZARD FROM PE CONDUCTOR

The drive can cause a DC current in the PE conductor. Failure to use a residual current-operated protective (RCD) device Type B or

a residual current-operated monitoring (RCM) device can lead to the RCD not providing the intended protection and therefore

can result in death or serious injury.

Use a type B RCD or RCM device on the mains side of the drive.

-

2.3 Cautions and Notices

C A U T I O N

DAMAGE TO THE AC DRIVE FROM INCORRECT MEASUREMENTS

Doing measurements on the AC drive when it is connected to mains can damage the drive.

Do not do measurements when the AC drive is connected to mains.

-

C A U T I O N

DAMAGE TO THE AC DRIVE FROM INCORRECT SPARE PARTS

Using spare parts that are not from the manufacturer can damage the drive.

Do not use spare parts that are not from the manufacturer.

-

C A U T I O N

DAMAGE TO THE AC DRIVE FROM INSUFFICIENT GROUNDING

Not using a grounding conductor can damage the drive.

Make sure that the AC drive is always grounded with a grounding conductor that is connected to the grounding terminal

-

that is identified with the PE symbol.

AQ319736045637en-000101 / DPD0179820 | Danfoss A/S © 2021.06

Page 21

VACON® NXP Advanced Safety Options

Operating Guide

C A U T I O N

CUT HAZARD FROM SHARP EDGES

There can be sharp edges in the AC drive that can cause cuts.

Wear protective gloves when mounting, cabling, or doing maintenance operations.

-

C A U T I O N

BURN HAZARD FROM HOT SURFACES

Touching surfaces, which are marked with the 'hot surface' sticker, can result in injury.

Do not touch surfaces which are marked with the 'hot surface' sticker.

-

N O T I C E

DAMAGE TO THE AC DRIVE FROM STATIC VOLTAGE

Some of the electronic components inside the AC drive are sensitive to ESD. Static voltage can damage the components.

Remember to use ESD protection always when working with electronic components of the AC drive. Do not touch the com-

-

ponents on the circuit boards without proper ESD protection.

Safety

N O T I C E

DAMAGE TO THE AC DRIVE FROM MOVEMENT

Movement after installation can damage the drive.

Do not move the AC drive during operation. Use a fixed installation to prevent damage to the drive.

-

N O T I C E

DAMAGE TO THE AC DRIVE FROM INCORRECT EMC LEVEL

The EMC level requirements for the AC drive depend on the installation environment. An incorrect EMC level can damage the

drive.

Before connecting the AC drive to the mains, make sure that the EMC level of the AC drive is correct for the mains.

-

N O T I C E

RADIO INTERFERENCE

In a residential environment, this product can cause radio interference.

Take supplementary mitigation measures.

-

N O T I C E

MAINS DISCONNECTION DEVICE

If the AC drive is used as a part of a machine, the machine manufacturer must supply a mains disconnection device (refer to EN

60204-1).

N O T I C E

MALFUNCTION OF FAULT CURRENT PROTECTIVE SWITCHES

Because there are high capacitive currents in the AC drive, it is possible that the fault current protective switches do not operate

correctly.

AQ319736045637en-000101 / DPD01798 | 21Danfoss A/S © 2021.06

Page 22

Cross-sectional area of the phase conductors (S) [mm2]

The minimum cross-sectional area of the protective earthing conductor in question [mm2]

S ≤ 16

S

16 < S ≤ 35

16

35 < S

S/2

VACON® NXP Advanced Safety Options

Operating Guide

N O T I C E

VOLTAGE WITHSTAND TESTS

Doing voltage withstand tests can damage the drive.

Do not do voltage withstand tests on the AC drive. The manufacturer has already done the tests.

-

2.4 Grounding

Ground the AC drive in accordance with applicable standards and directives.

C A U T I O N

DAMAGE TO THE AC DRIVE FROM INSUFFICIENT GROUNDING

Not using a grounding conductor can damage the drive.

Make sure that the AC drive is always grounded with a grounding conductor that is connected to the grounding terminal

-

that is identified with the PE symbol.

W A R N I N G

LEAKAGE CURRENT HAZARD

Leakage currents exceed 3.5 mA. Failure to ground the drive properly can result in death or serious injury.

Ensure the correct grounding of the equipment by a certified electrical installer.

-

Safety

The standard EN 61800-5-1 tells that 1 or more of these conditions for the protective circuit must be true.

The connection must be fixed.

•

The protective earthing conductor must have a cross-sectional area of minimum 10 mm2 Cu or 16 mm2 Al. OR

•

There must be an automatic disconnection of the mains, if the protective earthing conductor breaks. OR

•

There must be a terminal for a second protective earthing conductor in the same cross-sectional area as the first protective

earthing conductor.

The values of the table are valid only if the protective earthing conductor is made of the same metal as the phase conductors. If this

is not so, the cross-sectional area of the protective earthing conductor must be determined in a manner that produces a conductance equivalent to that which results from the application of this table.

The cross-sectional area of each protective earthing conductor that is not a part of the mains cable or the cable enclosure, must be a

minimum of:

•

2.5 mm2 if there is mechanical protection, and

•

4 mm2 if there is not mechanical protection. With cord-connected equipment, make sure that the protective earthing conductor

in the cord is the last conductor to be interrupted, if the strain-relief mechanism breaks.

Obey the local regulations on the minimum size of the protective earthing conductor.

MALFUNCTION OF FAULT CURRENT PROTECTIVE SWITCHES

Because there are high capacitive currents in the AC drive, it is possible that the fault current protective switches do not operate

correctly.

N O T I C E

AQ319736045637en-000101 / DPD0179822 | Danfoss A/S © 2021.06

Page 23

VACON® NXP Advanced Safety Options

Operating Guide

Safety

N O T I C E

VOLTAGE WITHSTAND TESTS

Doing voltage withstand tests can damage the drive.

Do not do voltage withstand tests on the AC drive. The manufacturer has already done the tests.

-

W A R N I N G

SHOCK HAZARD FROM PE CONDUCTOR

The drive can cause a DC current in the PE conductor. Failure to use a residual current-operated protective (RCD) device Type B or

a residual current-operated monitoring (RCM) device can lead to the RCD not providing the intended protection and therefore

can result in death or serious injury.

Use a type B RCD or RCM device on the mains side of the drive.

-

AQ319736045637en-000101 / DPD01798 | 23Danfoss A/S © 2021.06

Page 24

VACON® Loader

SLOT A

Basic I/O

Encoder

Safety PLC or other safety systems

Motor

Power

Unit

STO

option

board

STO

Encoder

signals

Digital

I/O

Safe

fieldbus

Advanced

safety

option

board

Fieldbus

board

SLOT B SLOT C SLOT D SLOT E

NCDrive

VACON® Safe

PC

Drive

Control Board

e30bi367.10

VACON® NXP Advanced Safety Options

Operating Guide

Overview of the System

3 Overview of the System

3.1 Using the Advanced Safety Options

The Advanced safety option board is used to implement safety functions in accordance with the standard EN IEC 61800-5-2. The

option board handles the safe I/O and the monitoring of active safety functions. The option board does not handle the control of

the AC drive. The AC drive can be controlled, for example, with the drive application, or the external process control system can give

the speed reference to the AC drive.

The Advanced safety option board must be used with a subsystem that provides the STO function, it is not possible to use the

Advanced safety option board alone. The STO function is provided, for example, by the OPTAF STO option board. To use the safety

functions that do speed monitoring, an external speed sensor is necessary. The sensor can be a digital or an analog encoder or a

digital proximity sensor. See chapter Speed Measurement.

The Advanced safety option board can be used with the digital I/O and over safe fieldbus. Using a safe fieldbus allows you to control

more safety functions than is possible with the limited number of inputs and outputs that the Advanced safety option board has.

When using a safe fieldbus, install an option board that supports the fieldbus. See 7.1.1 Introduction to PROFIsafe.

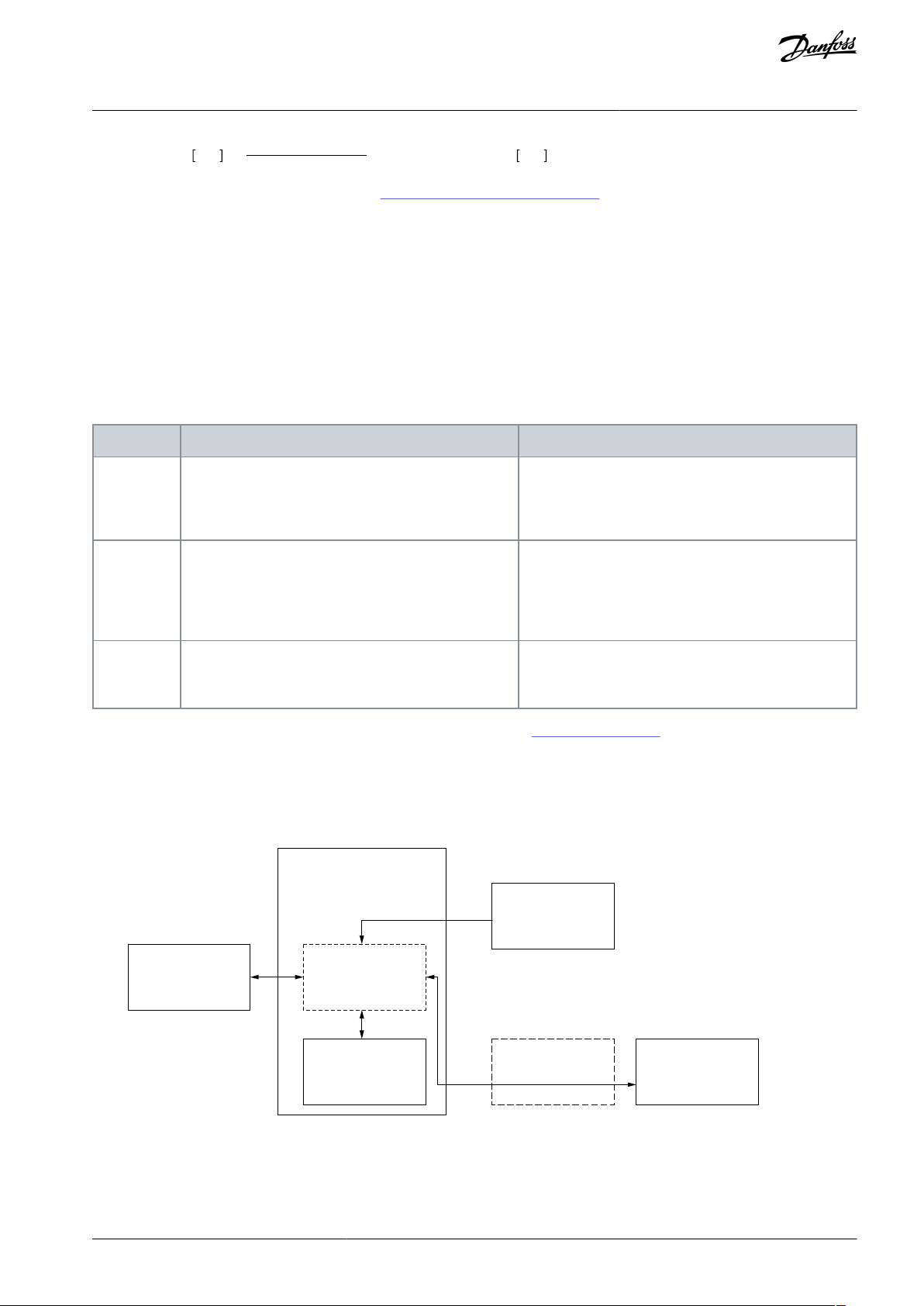

The Illustration 4 shows the configuration of the AC drive with the Advanced safety option board in slot C. The safe fieldbus and the

closed-loop control are optional. The possible configuration and available features can depend on other option boards and their

installation slots. For use cases with other encoder board installed in slot C, see 3.6.4 Encoders.

Illustration 4: An example configuration of the VACON® NXP drive with the Advanced safety option board. The subsystems that handle safety

actions are marked in gray.

The parameterization of the option board is done by selecting and editing the safety functions and features with the VACON® Safe

tool. See

5.4 Setting the Parameters and chapter Parameter List.

3.2 The Safe State

There must be a safe state to which the system can be set when necessary. Usually the safe state is reached when the AC drive does

not generate torque to the motor shaft. In the Advanced safety option board, this is realized by the Safe Torque Off (STO) safety

function.

In some systems, the active STO function in the AC drive does not create a safe state. It means that external forces can generate

torque to the motor shaft and cause it to rotate. To achieve the safe state in these systems, additional means are necessary. For

example, it is possible to use the STO function and a mechanical brake. The brake can be used with the Safe Brake Control (SBC)

safety function of the Advanced option board, or with another safe control system for the brake.

AQ319736045637en-000101 / DPD0179824 | Danfoss A/S © 2021.06

Page 25

VACON® NXP Advanced Safety Options

Operating Guide

The Advanced safety option board forces the AC drive to the safe state, for example, if there is an error detected in the safety system. Other situations when the safe state is enforced are, for example, the parameterization phase and during the start-up of the

drive.

Overview of the System

3.3 Integration and Interfaces to Other Systems

When the Advanced safety option board is integrated to a safety system, the system designer and/or the operator is responsible for

these things:

•

Making an initial system-level risk assessment and reassessing the system any time a change is made.

•

The setup and suitability of parameters, sensors, and actuators used in the system.

•

Validation of the system to the correct safety level.

•

Maintenance and periodic testing.

•

Controlling the access to the system, including password handling.

External systems can collect information from the Advanced safety option board in a few different ways.

The option board related fault and violation information is available in the fault log of the AC drive like other faults. This data must

be interpreted differently to the fault data of the AC drive. See chapter Fault tracing.

The option board has configurable outputs where desired information can be set to be sent to external systems.

The status data can be received over a safe fieldbus.

3.4 Determining the Achieved Safety Level

W A R N I N G

SAFETY AWARENESS IN DESIGN

This chapter is an example and contains simplifications. Using only this data in designing the system can damage the equipment.

Do not use this chapter as a template for designing your system.

-

Perform the design work carefully.

-

The achieved safety level depends on the whole safety chain. The AC drive with integrated safety functions is only one component

in the safety chain.

The things related to the AC drive that affect the achieved safety level:

•

The used speed measurement combination.

•

The implementation of the violation response and of the fault response. In most cases it is realized via the STO option board

(the OPTAF option board for the VACON® NX products).

The components of the safety chain that affect the achieved safety level:

•

The controllers (for example, the safety PLC) that control the safety functions

•

The stop switches

•

The wiring

EXAMPLE

Implementation of the STO safety function, consisting of these subsystems.

•

Emergency stop switch: Pilz PIT es Set/1-family using two N/C contacts. B10d = 104 000 (EN ISO 13849-1) and λd/ λ = 0.20 (EN IEC

62061) for one channel.

•

The OPTAF option board, version VB00328H (141L7786). A two-channel STO option board for the NX family.

•

The Advanced safety option board OPTBL.

N O T I C E

Check the corresponding product guides for the safety values and usage instructions.

AQ319736045637en-000101 / DPD01798 | 25Danfoss A/S © 2021.06

Page 26

Emergency

stop switch

(SIL3,

PLe)

OPTBL

(SIL3, PLe,

Cat 4)

OPTAF &

AC drive

(SIL3, PLe,

Cat 3)

Stop (STO) request

Stop (STO) request

STO

STO

Channel 1

Channel 2

e30bi368.10

Subsystem

SIL, PL

PFHdPFD

avgDCavg

[%]

MTTFd [a]

Emergency stop switch

SIL3, PLe

4.2 x 10

-9

(1)

3.7 x 10

-4

(2)

90

(3)

2849.3

(4)

(4)

OPTBL

SIL3, PLe

6.45 x 10

-11

5.61 x 10

-6

99

373

OPTAF

SIL3, PLe

2.7 x 10

-9

1.3 x 10

-4

60

(5)

1918

Overall safety system (for STO)

SIL3, PLe

6.94 x 10

-9

(6)

5.06 x 10

-4

(7)

74

(8)

281

(9)

VACON® NXP Advanced Safety Options

Operating Guide

Illustration 5: A Logical Presentation of the STO Safety Function

Overview of the System

In this example case, the STO function has one activation per day, and a lifetime of 20 years. For the emergency stop switch, β = 10%

is used as the susceptibility to common cause failure between the channels. No proof test is executed during the lifetime. The example system is limited to Category 3 because the Category 3 element OPTAF option board is used as a single final element.

Table 3: An Example of System Level Calculations for the STO Safety Function

1

This value is calculated directly from the values provided by the manufacturer. The diagnostic capabilities of OPTBL have not been taken into ac-

count. The calculation formula: PFHd = (1- β)2 x λ

2

The calculation formula: PFD

3

The OPTBL executes "Cross monitoring of inputs without dynamic test", DC: 0%...99%, depending on how often a signal change is done by the

application. A DC of 90% is assumed with the once a day activation.

4

The calculation formula: MTTFd = B10d / (0.1 x cycles per year).

5

OPTAF manual: DC

6

Sum of the individual PFHd values.

7

Sum of the individual PFH

8

The calculation formula:

DC

9

According to EN ISO 13849-1, the MTTFd must be limited to a maximum limit of 100 years per channel. The calculation formula:

MTTF

When designing systems according to IEC-61508, the requirement for the value of the Safe Failure Fraction (SFF) is considered on

subsystem level, not on system level.

avgSTO

dSTO

=

=

= low, using the lower end of the possible range (60%...90%)

avg

DC

Switch

MTTF

dSwitch

1

MTTF

dSwitch

1

MTTF

dSwitch

= (PFHd x TM)/2.

avg

values.

avg

DC

+

MTTF

+

MTTF

+

MTTF

OPTBL

dOPTBL

1

dOPTBL

1

1

dOPTBL

+

+

+

x λ

ch1

DC

MTTF

MTTF

MTTF

x T1 + β x (λ

ch2

OPTAF

dOPTAF

1

dOPTAF

1

dOPTAF

N O T I C E

ch1

+ λ

)/2, where λch = (0.1 x cycles per hour) / B10d).

ch2

AQ319736045637en-000101 / DPD0179826 | Danfoss A/S © 2021.06

Page 27

Option board revision (70CVB01938, 141X4588)

Slot C

Slot D

Slot E

C, E-Yes-F

Yes

Yes

Yes

e30bi413.10

VACON® NXP Advanced Safety Options

Operating Guide

Overview of the System

3.5 Advanced Safety Option Variants

3.5.1 General Information

Newer versions of the Advanced Safety Option have extended slot compatibility. The table Table 4 describes the supported slots for

different revisions of the option board. The compatibility is determined by the revision of the board 70CVB01938 (141X4588). See

Illustration 6 for the location of the revision information.

Table 4: Supported Slots of the Revisions of the Option Board

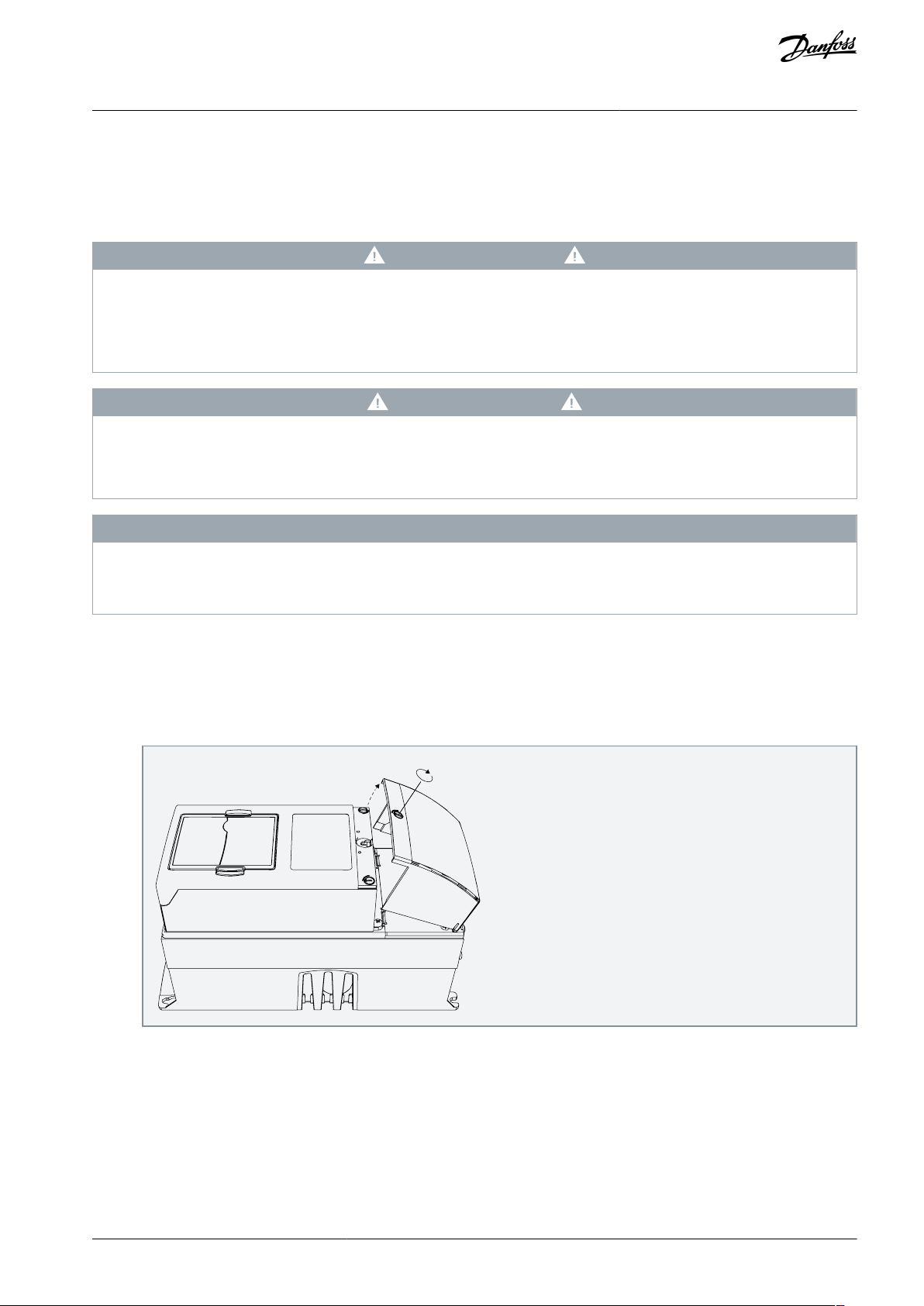

Illustration 6: The Board Identification Sticker on the Advanced Safety Option Board

The Advanced safety option board contains a safe digital I/O for the control and status word signals.

The available connectors of the Advanced safety option board

•

4 two-terminal digital inputs

•

2 two-terminal digital outputs

•

2 STO outputs

•

+24 V supply

•

GND

It is possible to use the digital inputs for selecting ramps and for activating, acknowledging, and resetting safety functions. The twoterminal digital outputs can be used as output signals of the SBC or the SSM function, or configured by combining various signals of

the option board.

If a connected device is powered by an external power supply, make sure that there is common ground between the device and the

Advanced safety option board.

N O T I C E

The digital outputs use internal diagnostic test pulses to make sure that the output logic operates correctly. These test pulses are

visible to external systems. See 11.2 Safe Input/Output Data.

3.5.2 Input Configuration

The 4 two-terminal digital inputs operate in a two-terminal equivalent mode: the state of both terminals must match each other

within a discrepancy time (see 11.2 Safe Input/Output Data).

AQ319736045637en-000101 / DPD01798 | 27Danfoss A/S © 2021.06

Page 28

Input terminal A

Input terminal B

State

Active

Active

The assigned safety function is not requested.

Active

Inactive

The assigned safety state is requested. If longer than 500 ms: the option board detects a

fault.

Inactive

Active

The assigned safety state is requested. If longer than 500 ms: the option board detects a

fault.

Inactive

Inactive

The assigned safety function is requested.

VACON® NXP Advanced Safety Options

Operating Guide

Table 5: The Input States

It is possible to assign these tasks to each of the digital inputs:

•

the request of a safety function

•

the acknowledgment signal

•

the reset signal

•

the proximity sensor

It is possible to assign 1 task per digital input. The exceptions are the acknowledgment signal and the reset signal which can be

assigned to the same input.

Overview of the System

N O T I C E

If proximity sensors are used, it is not possible to assign safety function features to the corresponding inputs. See 3.6.5 Proximity

sensors.

3.5.3 Output Configuration

The 2 two-terminal digital outputs operate in a two-terminal equivalent mode: the state of both terminals must match each other

within a discrepancy time (see

nals are in the same state.

The tasks that can be assigned to each of the digital outputs:

•

the SSM function output

•

the SBC function output

•

simple custom logic

For more information on the SSM and the SBC function outputs, see 6.2.2.3 The STO Function Used with the SBC Function and

6.3.5.3 The SSM Safe Output.

To configure the simple custom logic for an output, select a logical function and desired signals from a configuration group. The

option board uses the selected signals and applies the selected logical function to determine the state of the output.

1. Select the group that contains the desired signal or signals.

2. Select the logical function to combine the selected signals.

3. Select the signal or signals.

If only 1 signal is selected: AND or OR (regardless of which): output = signal. NAND or NOR (regardless of which): output = negative

signal.

See the examples below for signal and output correspondence.

The available logical functions:

•

AND

•

OR

•

NAND

•

NOR

Only 1 logical function per output can be selected.

11.2 Safe Input/Output Data). The external system or systems should make sure that the two termi-

AQ319736045637en-000101 / DPD0179828 | Danfoss A/S © 2021.06

Page 29

Group 1 and Group 5

Group 2 and Group 6

Group 3 and Group 7

Group 4 and Group 8

STO Reached

SS1 Reached

SS2 Reached

SQS Reached

SOS Reached

SBC Reached

STO and SBC Reached

SLS 1 Reached

SLS 2 Reached

SLS 3 Reached

SSR Reached

SMS Reached

SSM Reached

SSM Above Max Limit

SSM Below Min Limit

STO Active

SS1 Active

SS2 Active

SQS Active

SLS 1 Active

SLS 2 Active

SLS 3 Active

SSR Active

SMS Active

SSM Active

Warning in any safety function

Limit violation fault in any safety function

State of the signals

Result of the logical function

State of the output

SLS 1 Reached = 0

SSM Below Min Limit = 0

0 OR 0 -> false

Inactive

SLS 1 Reached = 0

SSM Below Min Limit = 1

or

SLS 1 Reached = 1

SSM Below Min Limit = 0

0 OR 1 -> true

Active

SLS 1 Reached = 1

SSM Below Min Limit = 1

1 OR 1 -> true

Active

State of the signals

Result of the logical function

State of the output

SLS 1 Reached = 0

0 NOR 0 -> true

Active

–––

SLS 1 Reached = 1

1 NOR 1 -> false

Inactive

VACON® NXP Advanced Safety Options

Operating Guide

Table 6: The Available Signals in Configuration Groups

Overview of the System

During operation, the option board uses the selected signals and applies the selected logical function to determine the state of the

output. If the result of the logical function on the actual state of the selected signals is "true", the output is active. If the result is

"false", the output is inactive.

EXAMPLE 1 (USING GROUP 2):

Selected signals: SLS 1 Reached, SSM Below Min Limit

Logical function: OR

Table 7: Example 1

EXAMPLE 2 (USING GROUP 2):

Selected signals: SLS 1 Reached

Logical function: NOR

Table 8: Example 2

EXAMPLE 3 (USING GROUP 2):

Selected signals: SLS 1 Reached, SSM Below Min Limit

Logical function: AND

AQ319736045637en-000101 / DPD01798 | 29Danfoss A/S © 2021.06

Page 30

State of the signals

Result of the logical function

State of the output

SLS 1 Reached = 0

SSM Below Min Limit = 0

0 AND 0 -> false

Inactive

SLS 1 Reached = 0

SSM Below Min Limit = 1

or

SLS 1 Reached = 1

SSM Below Min Limit = 0

0 AND 1 -> false

Inactive

SLS 1 Reached = 1

SSM Below Min Limit = 1

1 AND 1 -> true

Active

State of the signals

Result of the logical function

State of the output

SLS 1 Reached = 0

SSM Below Min Limit = 0

0 NAND 0 -> true

Active

SLS 1 Reached = 0

SSM Below Min Limit = 1

or

SLS 1 Reached = 1

SSM Below Min Limit = 0

0 NAND 1 -> true

Active

SLS 1 Reached = 1

SSM Below Min Limit = 1

1 NAND 1 -> false

Inactive

1 3 5 7 9

2 4 6 8

11 13 15 17

12

14 16 1810

Dout1 Dout2 Din1 Din2 Din3 Din4

X4

X3

e30bi410.10

VACON® NXP Advanced Safety Options

Operating Guide

Table 9: Example 3

EXAMPLE 4 (USING GROUP 2):

Selected signals: SLS 1 Reached, SSM Below Min Limit

Logical function: NAND

Table 10: Example 4

Overview of the System

3.5.4 Option Board OPTBL

Use the Advanced safety option board OPTBL when no encoder is used to measure the speed of the motor shaft.

Illustration 7: The Terminals X3 and X4 of the OPTBL Option Board

AQ319736045637en-000101 / DPD0179830 | Danfoss A/S © 2021.06

Page 31

1

STO 1. STO terminal 1 +24 V, to be connected to OPTAF terminal SD1+.

2

STO 2. STO terminal 2 +24 V, to be connected to OPTAF terminal SD2+.

3

GND.4GND.5Dout 1A. Terminal A of digital output 1.

6

Dout 1B. Terminal B of digital output 1.

7

Dout 2A. Terminal A of digital output 2.

8

Dout 2B. Terminal B of digital output 2.

9

+24 V. +24 V supply for external logic.

10

GND.11Din 1A. Terminal A of digital input 1.

12

Din 1B. Terminal B of digital input 1.

13

Din 2A. Terminal A of digital input 2.

14

Din 2B. Terminal B of digital input 2.

15

Din 3A. Terminal A of digital input 3.

16

Din 3B. Terminal B of digital input 3.

17

Din 4A. Terminal A of digital input 4.

18

Din 4B. Terminal B of digital input 4.

1 2 3 4 5 6 9 10 11 12 13 147 8

V GND + - + - + - + - + - + -

X5

X6

X3

X4

e30bi411.10

VACON® NXP Advanced Safety Options

Operating Guide

Overview of the System

3.5.5 Option Board OPTBM

The OPTBM option board is similar to the OPTBL option board, but in addition, the OPTBM option board has a digital pulse TTL/HTL

type encoder interface board attached to it.

The digital pulse type encoder interface board is used to connect encoders with digital signals to the OPTBM option board. The

option board supports encoders with Transistor-Transistor Logic (TTL) and High Threshold Logic (HTL) type signals. Make sure that

the used type is correctly set during parameterization.

The digital pulse type encoder interface board is designed for HTL encoders with a voltage output type of push-pull.

From revision F onwards, the OPTBM (70CVB01957, 141X4608) board enables the use of closed-loop control. To use closed-loop

control, the OPTBM board must be installed in slot C. For further information, see 3.5.7 Closed-loop Control with OPTBM.

Illustration 8: The Terminals X5 and X6 of the Digital Pulse Type Encoder Interface Board

AQ319736045637en-000101 / DPD01798 | 31Danfoss A/S © 2021.06

Page 32

1

Configurable encoder voltage.

2

GND.3A+. Terminal A of digital pulse signal.

4

A-. Terminal A of digital pulse signal.

5

B+. Terminal B of digital pulse signal.

6

B-. Terminal B of digital pulse signal.

7

Z+. Reference signal, optional.

8

Z-. Reference signal, optional.

9

A+. Unmodified encoder signal loopback.

10

A-. Unmodified encoder signal loopback.

11

B+. Unmodified encoder signal loopback.

12

B-. Unmodified encoder signal loopback.

13

Z+. Unmodified encoder signal loopback.

14

Z-. Unmodified encoder signal loopback.

1 2 3 4 5 6 9 10 11 12 13 147 8

V GND + - + - + - + - + - + -

X7

X8

X3

X4

e30bi958.10

1

Encoder voltage. Selectable encoder voltage.

2

GND.3Sin+. Sinus terminal of analog pulse signal.

4

Sin-. Sinus terminal of analog pulse signal.

5

Cos+. Cosine terminal of analog pulse signal.

6

Cos-. Cosine terminal of analog pulse signal.

7

Z+. Reference signal, optional.

8

Z-. Reference signal, optional.

9

Sin+. Unmodified encoder signal loopback.

10

Sin-. Unmodified encoder signal loopback.

11

Cos+. Unmodified encoder signal loopback.

12

Cos-. Unmodified encoder signal loopback.

13

Z+. Unmodified encoder signal loopback.

14

Z-. Unmodified encoder signal loopback.

VACON® NXP Advanced Safety Options

Operating Guide

Overview of the System

3.5.6 Option Board OPTBN

The OPTBN option board is similar to the OPTBL option board, but in addition, the OPTBN option board has a Sin/Cos type encoder

interface board attached to it.

The Sin/Cos type encoder interface board is used to connect an encoder with analog sinus and cosine signal to the OPTBN option

board.

From revision E onwards, the OPTBN (70CVB01958, 141X4610) board enables the use of closed-loop control. To use closed-loop

control, the OPTBN board must be installed in slot C. For further information, see 3.5.8 Closed-loop Control with OPTBN.

Illustration 9: The Terminals X7 and X8 of the Sin/Cos Type Encoder Interface Board

AQ319736045637en-000101 / DPD0179832 | Danfoss A/S © 2021.06

Page 33

VACON® NXP Advanced Safety Options

Operating Guide

Overview of the System

3.5.7 Closed-loop Control with OPTBM

The OPTBM board can be used to realize closed-loop control. To use closed-loop control with OPTBM, check that the OPTBM revision supports closed-loop control, and that the OPTBM board is installed in slot C.

When using closed-loop control with OPTBM, consider the following features or differences compared to the other encoder boards

used for closed-loop control.

•

The value of Pulse/revolution (normally shown as P7.3.1.1) used for closed-loop control is copied from the parameterization of

the Advanced Safety Option. It cannot be edited independently.

•

The parameter Reading Rate (shown as P7.3.1.3.1) can be edited normally.

•

Parameter Invert Direction (normally shown as P7.3.1.2) is not supported or shown. Value "0 = No" is always used.

•

Parameter Encoder Type (normally shown as P7.3.1.4) is not supported or shown. Value "1 = A, B = speed" is always used.

•

The qualifier input ENC1Q is not included in OPTBM.

•

The fast digital input DIC4 is not included in OPTBM.

•

The encoder must use differential signals. Single-ended encoders are not supported.

3.5.8 Closed-loop Control with OPTBN

The OPTBN board can be used to realize closed-loop control. To use closed-loop control with OPTBN, check that the OPTBN revision

supports closed-loop control, and that the OPTBN board is installed in slot C.

When using closed-loop control with OPTBN, consider the following features or differences compared to the other encoder boards

used for closed-loop control.

•

The value of Pulse/revolution (normally shown as P7.3.1.1) used for closed-loop control is copied from the parameterization of

the Advanced Safety Option. It cannot be edited independently.

•

The parameter Reading Rate (shown as P7.3.1.3.1) can be edited normally.

•

Parameter Invert Direction (normally shown as P7.3.1.2) is not supported or shown. Value "0 = No" is always used.

•

The parameter Interpolation (normally shown as P7.3.1.4) is not supported. Value "0 = No" is always used.

3.6 Speed Measurement

3.6.1 Safety Speed Sensors

The speed measurement methods supported by the Advanced safety option board:

•

Sin/Cos encoder

•

Digital pulse encoder (TTL or HTL)

•

Proximity sensor

For parametric information, see 8.1.3 Speed Measurement Parameters.

When certified speed sensors are used, the sensors can be used to implement safety functions up to the safety level stated in the

certificate. To use these speed sensors, make sure that the sensor monitoring executed by the option board fulfills the requirements

that the sensor has for the speed monitoring device. For the monitoring executed by the Advanced safety option board, see 3.6.6

Encoder Signal Verification.

3.6.2 Standard Speed Sensors and Combinations

The speed measurement methods supported by the Advanced safety option board:

•

Sin/Cos encoder

•

Digital pulse encoder (TTL or HTL)

•

Proximity sensor

For parametric information, see 8.1.3 Speed Measurement Parameters.

The option board can be used with standard speed sensors. The table below shows the maximum achievable safety levels for com-

binations of different speed sensors without certificate.

In addition to speed sensors, it is possible use estimated speed from the control board of the AC drive as a second channel for speed

measurement diagnostics.

Calculate and take into account the relevant safety values for the encoder when assessing the fulfillment of the requirements for the

targeted safety level(s). The relevant safety values include these values:

AQ319736045637en-000101 / DPD01798 | 33Danfoss A/S © 2021.06

Page 34

Safety

function

Sin/Cos

Digital Pulse +

estimated

speed

2 x Proximity

sensor

Proximity sensor + estimated speed

Sin/Cos + proximity sensor

Digital Pulse +

proximity

sensor

Any other

combination

STO

(+SBC)

SIL 3, PLe,

Cat4

SIL 3, PLe, Cat4

SIL 3, PLe,

Cat4

SIL 3, PLe, Cat4

SIL 3, PLe, Cat4

SIL 3, PLe, Cat4

SIL 3, PLe,

Cat4

SS1

SIL 3, PLe,

Cat4

SIL 3, PLe, Cat4

SIL 3, PLe,

Cat4

SIL 3, PLe, Cat4

SIL 3, PLe, Cat4

SIL 3, PLe, Cat4

SIL 3, PLe,

Cat4

SS2, SOS

SIL 2, PLd,

Cat3

---

SIL 2, PLd, Cat3

--SQS-STO

SIL 3, PLe,

Cat4

SIL 3, PLe, Cat4

SIL 3, PLe,

Cat4

SIL 3, PLe, Cat4

SIL 3, PLe, Cat4

SIL 3, PLe, Cat4

SIL 3, PLe,

Cat4

SQS-SS1

SIL 3, PLe,

Cat4

SIL 3, PLe, Cat4

SIL 3, PLe,

Cat4

SIL 3, PLe, Cat4

SIL 3, PLe, Cat4

SIL 3, PLe, Cat4

SIL 3, PLe,

Cat4

SQS-SS2

SIL 2, PLd,

Cat3

---

SIL 2, PLd, Cat3

--SLS

SIL 2, PLd,

Cat3

SIL 2, PLd, Cat2

SIL 3, PLe,

Cat4

SIL 2, PLd, Cat2

SIL 3, PLe, Cat4

SIL 3, PLe, Cat4

-

SMS

SIL 2, PLd,

Cat3

SIL 2, PLd,

Cat2

(1)

SIL 3, PLe,

Cat4

(2)

SIL 2, PLd,

Cat2

(1)

SIL 3, PLe,

Cat4

(2)

SIL 3, PLe,

Cat4

(2)

-

SSM

SIL 2, PLd,

Cat3

SIL 2, PLd, Cat2

SIL 3, PLe,

Cat4

SIL 2, PLd, Cat2

SIL 3, PLe, Cat4

SIL 3, PLe, Cat4

-

SSR

SIL 2, PLd,

Cat3

SIL 2, PLd, Cat2

SIL 3, PLe,

Cat4

SIL 2, PLd, Cat2

SIL 3, PLe, Cat4

SIL 3, PLe, Cat4

-

VACON® NXP Advanced Safety Options

Operating Guide

•

PFH

•

Category

•

Performance level

For the diagnostic coverage for the encoder, see 3.6.6 Encoder Signal Verification.

Table 11: Achievable Safety Levels when Using Speed Sensors without Certificate

Overview of the System

1

Only if the monitored limits to both directions are set to the same value or both values are greater than the value of Allowed Deviation of Speed

Sources.

2

Only if the monitored limits to both directions are set to the same value.

Table

urement can be the limiting factor on system level. For example, either SIL 2 or SIL 3 can be achieved with the OPTAF STO option

board as a single final element. See the VACON® NX OPTAF STO Board Manual for further information.

For non-safe Sin/Cos encoders, it is required in the table Table 11 that the encoder is implemented in analog design. The fault

model "Exchange of Sin and Cos signal inside the encoder" must be excluded.

Combinations that are not listed in the table Table 11 are not tested or supported, and offer no increase to the claimed safety levels.

It can still be possible to use unlisted combinations. Regardless of the used speed measurement combination, it is the responsibility

of the system designer to make sure that the used combination is adequate and sufficient.

When multiple speed sources are used, the monitored limit of a safety function must not be set below the value of Allowed Deviation of Speed Sources.

Table 11 gives the maximum SIL, PL, and Cat levels that can be achieved with a combination. Other factors than speed meas-

N O T I C E

N O T I C E

AQ319736045637en-000101 / DPD0179834 | Danfoss A/S © 2021.06

Page 35

VACON® NXP Advanced Safety Options

Operating Guide

Overview of the System

3.6.3 Speed Discrepancy with Multiple Speed Sources

When you use multiple speed sources, for example, a Sin/Cos encoder and a proximity sensor, or estimated speed and a speed

sensor, the speed values measured by these sensors must be within the allowed deviation of each other.

There is new behavior in the software version FW0281 V004: the reaction to exceeding the deviation depends on the request for

safety functions. If a safety function is requested, the reaction is a fault and STO will be activated. If no safety function is requested,

the reaction is a warning and STO will not be activated. This enables continuing the process and stopping at an acceptable and safe

position. It is also possible to start a single drive in already running process where there is a difference in estimated speed and encoder speed before the drive enters run mode, that is, a "flying start" situation.

C A U T I O N

INSUFFICIENT SPEED MEASUREMENT CAPACITY

When the warning for speed difference is active, the safety system cannot guarantee that the speed measuring capability is sufficient.

Running in this mode should be kept to minimal, for example to only start the motor in "flying start" situation or to continue

-

to a safe position.

If running the motor in this situation cannot be accepted, a possible solution is to use the Safe Speed Monitor (SSM) safety function.

It can be set to "Always active" mode. So, the safety function is always requested and the reaction to speed discrepancy is always

fault and STO. This is the same as the behavior in the previous software version (FW0281 V003 and older).

The value for the allowed deviation between the speeds can be set during parameterization. A formula for a recommended value

with a speed sensor and estimated speed can be found in chapter Estimated speed.

3.6.4 Encoders

The encoder interface boards of the Advanced safety option board have two connector sets. The cables from an encoder are connected to one connector set. The other connector set provides the encoder signals as output that can be connected to other devices that use the encoder data. Such device can be, for example the standard encoder board that is used to realize the closed-loop

control. The Advanced safety option board transmits the signals from the encoder to the other connector set without any modification.

N O T I C E

When you use speed sensors for the safety functions, it is possible that the AC drive operates in open loop or closed-loop control.

When closed-loop control is used, a closed-loop enabling option board must be used in slot C. This can be either a separate encoder board or the Advanced Safety Option.

N O T I C E

When you use speed sensors without SIL claims, estimated speed from the AC drive can be used as a second independent channel to fulfill the requirements of safety standards. See chapter Standard Speed Sensors and Combinations.

N O T I C E

The encoder signals consist of two separate channels (for example, sinus and cosine). Do not change the order or modify the

channels before connecting them to the Advanced safety option.

When the Advanced Safety Option is used for closed-loop control, it must be installed in slot C. Connect the encoder cables to the

board normally.

When closed-loop control is used with a separate encoder board, connect the SinCos/Digital pulse signal cables of the encoder to

the encoder interface board of the Advanced safety option board. Connect also the encoder interface board to the encoder board in

slot C. The encoder board implements the closed-loop control by using the encoder interface board to receive feedback. See the

figure below.

AQ319736045637en-000101 / DPD01798 | 35Danfoss A/S © 2021.06

Page 36

SinCos / Digital pulse

Encoder

Board

Advanced

safety

option

board

SLOT C SLOT D

Drive

Control Board

Encoder

SinCos / Digital pulse signals

e30bi369.10

Absolute

Encoder

SinCos / Digital pulse

SinCos / Digital pulse signals

Absolute

Encoder

Board

Absolute

Data

Advanced

safety

option

board

SLOT C SLOT D

Drive

Control Board

e30bi370.10