Danfoss OP-MPGM034GSP00G, OP-MPHM012SCP00G, OP-MPHM026GSP00G, OP-MPHM010SCP00G, OP-MPHM034GSP00G User Manual

...Page 1

Manual

Optyma PlusTM New Generation

Controller Installation

http://cc.danfoss.com

Page 2

Manual Controller Installation

Contents

English version ................................................................................................................ 7

French version ................................................................................................................ 12

German version ............................................................................................................... 18

Danish version ................................................................................................................ 24

2 FRCC.ES.010.A4.ML

Page 3

Manual Controller Installation

Annex

Optyma Plus™ condensing units are pre-parameterized, depending on the model of compressor

mounted and the type of refrigerant. In the case of a “multi-refrigerant” compressor (e.g. MTZ or MLZ),

the controller parameter “o30” for refrigerant is set to R404A and must be changed for other refrigerants

(see chapter Commissioning - Quick start of the unit / Refrigerant change).

TM

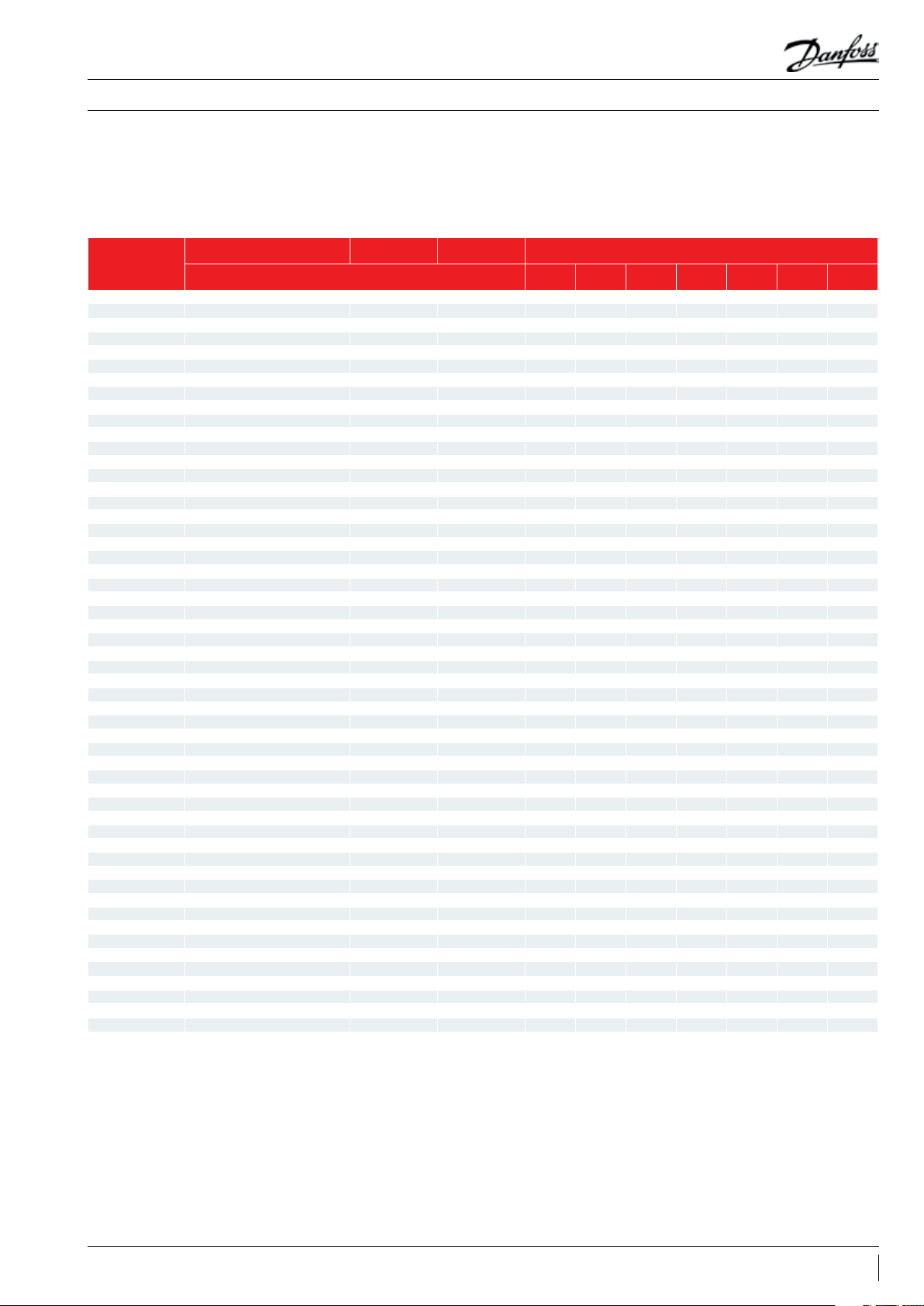

Model* Optyma Plus

Code (controller

parameter o61 )*

1 OP-MPHM007NFP00G 114X4101 NF7MLX X x

2 OP-MPHM010SCP00G 114X4102 SC10MLX X x

3 OP-MPHM012SCP00G 114X4104 SC12MLX X x

4 OP-MPHM015SCP00G 114X4105 SC15MLX X x

5 OP-MPHM018SCP00G 114X4109 SC18MLX X x

6 OP-MPGM034GSP00G 114X4210 GS34MFX x

7 OP-MPHM026GSP00G 114X4214 GS26MLX X x

8 OP-MPHM034GSP00G 114X4229 GS34MLX X x

9 OP-MPZM030MTP00E - MTZ22-4VM X x x x x x

10 OP-MPZM048MTP00G - MTZ28-5VM X x x x x x

11 OP-MPZM048MTP00E - MTZ28-4VM X x x x x x

12 OP-MPZM060MTP00G - MTZ36-5VM X x x x x x

13 OP-MPZM060MTP00E - MTZ36-4VM X x x x x x

14 OP-MPZM086MTP00E - MTZ51-4VM X x x x x x

15 OP-MPZM086MTP00H - MTZ50-6VM X x x x x x

16 OP-MPZM108MTP00E - MTZ65-4VM X x x x x x

17 OP-MPZM108MTP00H - MTZ64-6VM X x x x x x

18 OP-MPZM136MTP00E - MTZ81-4VM X x x x x x

19 OP-MPZM136MTP00H - MTZ80-6VM X x x x x x

20 OP-LPHM018SCP00G 114X3109 SC18CLX.2 X x

21 OP-LPHM026GSP00G 114X3217 GS26CLX X x

22 OP-LPHM048NTP00G 114X3225 NTZ48-5VM X x

23 OP-LPHM048NTP00E 114X3233 NTZ48-4VM X x

24 OP-LPHM068NTP00G 114X3241 NTZ68-5VM X x

25 OP-LPHM068NTP00E 114X3249 NTZ68-4VM X x

26 OP-LPHM096NTP00E 114X3357 NTZ96-4VM X x

27 OP-LPHM136NTP00E 114X3365 NTZ136-4VM X x

28 OP-MPUM034MLP00G 114X4261 MLZ015T5LP9 X x x x x x

29 OP-MPUM034MLP00E 114X4264 MLZ015T4LP9 X x x x x x

30 OP-MPUM046MLP00G 114X4281 MLZ021T5LP9 X x x x x x

31 OP-MPUM046MLP00E 114X4284 MLZ021T4LP9 X x x x x x

32 OP-MPUM068MLP00G 114X4308 MLZ030T5LC9 X x x x x x

33 OP-MPUM068MLP00E 114X4311 MLZ030T4LC9 X x x x x x

34 OP-MPUM080MLP00G 114X4321 MLZ038T5LC9 X x x x x x

35 OP-MPUM080MLP00E 114X4324 MLZ038T4LC9 X x x x x x

36 OP-MPUM108MLP00E 114X4344 MLZ048T4LC9 X x x x x x

37 OP-MPUM125MLP00E 114X4414 MLZ058T4LC9 X x x x x x

38 OP-MPUM162MLP00E 114X4434 MLZ076T4LC9 X x x x x x

39 OP-LPHM215LLP00E 114X3476 LLZ024T4LC9 X x

40 OP-LPHM271LLP00E 114X3482 LLZ033T4LC9 X x

41 OP-MPUM057MTP00G 114X4290 MLZ026T5LP9 X x x x x x

42 OP-MPUM057MTP00E 114X4293 MLZ026T4LP9 X x x x x x

43 OP-LPHM067LLP00E - LLZ013T4LC9 X x

44 OP-LPHM084LLP00E - LLZ015T4LC9 X x

45 OP-LPHM098LLP00E - LLZ018T4LC9 X x

46 OP-MPHM024AJP00G 114X4200 CAJ9513Z X

47 OP-MPHM026AJP00G 114X4212 CAJ4517Z X

48

49 OP-MPHM034AJP00G 114X4226 CAJ4519Z X

50 OP-MPHM034AJP00E 114X4227 TAJ4519Z X

51 OP-LPHM026AJP00G 114X3216 CAJ2446Z X

52 OP-MPGM033AJP00G 114X4220 CAJ4511Y x

53 OP-LPHM074FHP00G 114X3252 FH2511Z X

54 OP-LPHM074FHP00E 114X3253 TFH2511Z X

Generation

OP-MPHM026AJP00E 114X4213 TAJ4517Z X

Code (controller parameter o61 ): Code (contrôleur paramètre o61 / Code (Reglerparameter o61) /

Model

: Modèle /

Modell / Model

New

settings are adjustable*

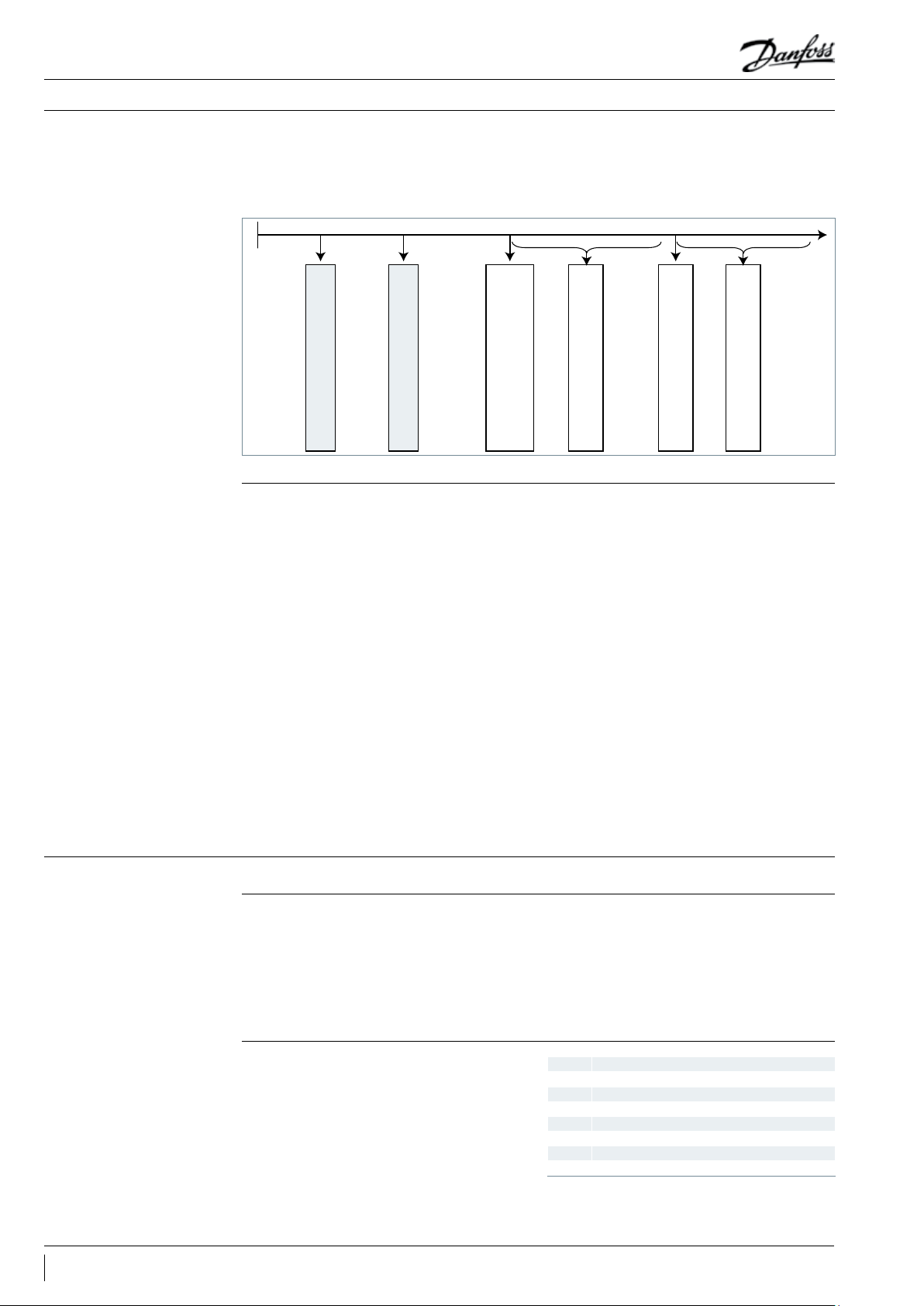

Code-no. Compressor* Refrigerant (controller parameter o30)*

R404A

(19)

R507

(17)

R134a

(3)

R407C

(20)

R22

(2)

Kode (regulatorparameter

R407A**

(21)

o61)

Code-no. : Code n° / Art-Nr. / Bestillingsnr.

Compressor

: Compresseur / Verdichter /

Kompressor

Refrigerant : Réfrigérant (contrôleur paramètre o30) / Kältemittel (Reglerparameter o30) / Kølemiddel (regulatorparameter o30)

*Settings are adjustable : parameters sont réglables / Werte einstellbar / indstillinger er justerbare

**Ongoing qualications for condensing units

R407F**

(37)

3FRCC.ES.010.A4.ML

Page 4

Manual Controller Installation

Annexe

Anhang

Supplement

Les groupes de condensation Optyma Plus™ sont pré-paramétrés, en fonction du modèle de compresseur

et du type de réfrigérant. Dans le cas d’un compresseur «multi-réfrigérants» (p. ex. les modèles MTZ ou

MLZ),

le paramètre du contrôleur «o30» pour le réfrigérant est déni sur R404A et doit être modié en

cas d’utilisation d’un réfrigérant diérent (voir le chapitre Mise en service - Démarrage rapide de l’unité

/ Changement de réfrigérant).

Optyma Plus™ Verüssigungssätze sind vorparametriert für das installierte Verdichtermodell und verwendete

Kältemittel. Im Fall eines Verdichters für mehrere Kältemittel (z.B. MTZ oder MLZ) ist der Reglerparameter

o30 für das Kältemittel auf „R404A“ eingestellt. Der Parameter muss für andere Kältemittel geändert

werden (siehe Kapitel zu Inbetriebnahme – Schnellstart der Einheit/Kältemittelwechsel).

Optyma Plus™-kondenseringsaggregater er parameterafstemt på forhånd afhængigt af den monterede

kompressormodel og kølemiddeltypen. I tilfælde af en kompressor til ere kølemidler (f.eks. MTZ eller

MLZ) er regulatorparameteren ”o30” indstillet til f.eks. R404A og skal ændres ved anvendelse af andre

kølemidler (se kapitlet Idriftsættelse – hurtig start af enheden/kølemiddelskift).

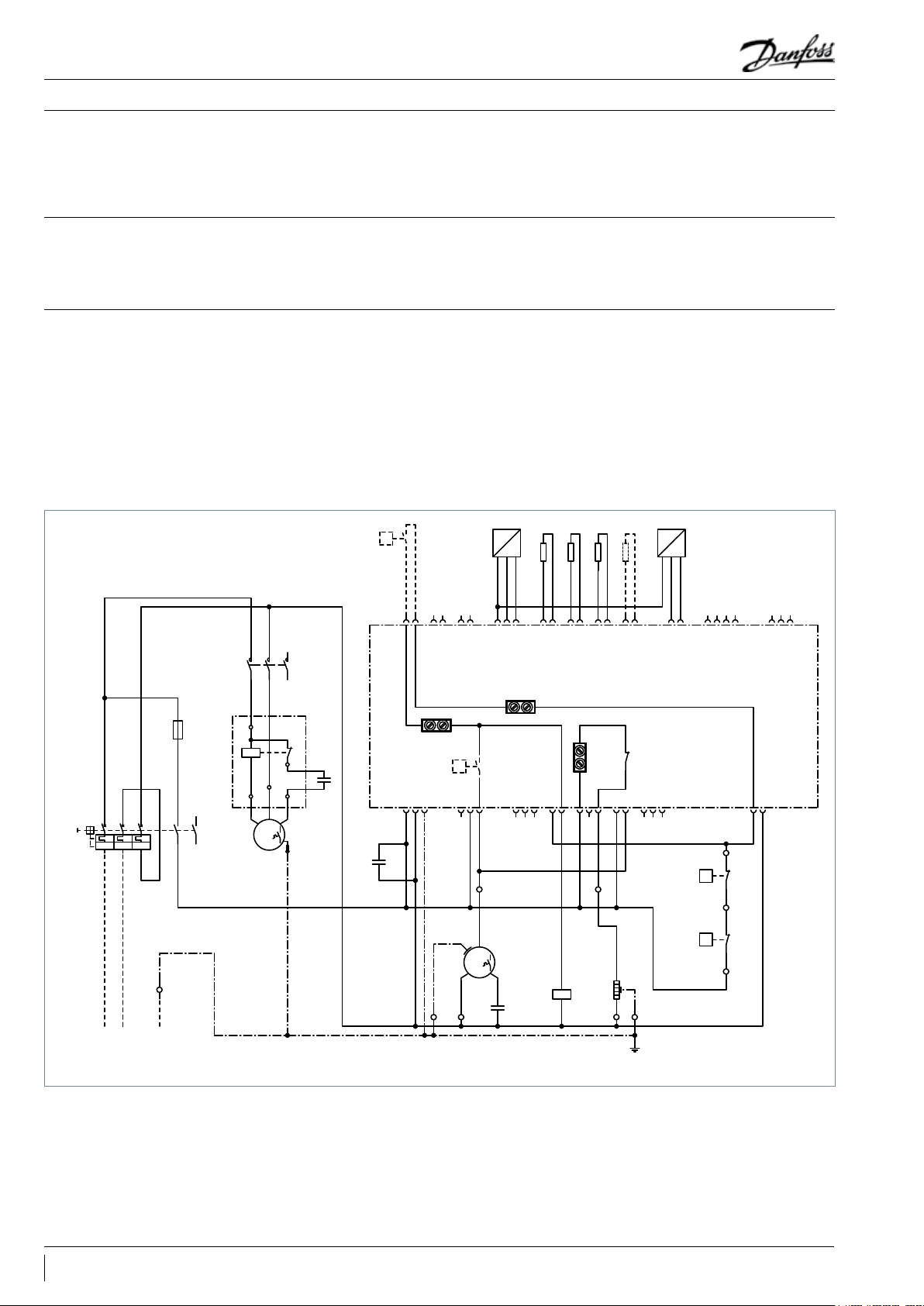

room thermostat

Raumthermostat

thermostat d'ambiance

-B1

-R1 -R2

T>

P

1 2 3

U

-R3 -R4

-B2

P

1 2 3

U

-F1

3,15A

BN

BU

BU

333443

PE

-Q1

1 3 5

I > I > I >

2 4 6

-X1

L N PE

power supply

Zuleitung

alimentation

220-240V1N~/50Hz

BKBKBK

BK

BK

GY

12345

BKBKRD

BK

24

25

BRBRGY

WH

-K2

6

BN

-M1

compresseur

BU

10

11

14

12

13

13

M

1~

compressor

Verdichter

-C1

-C2

-X1 N1

-B5

*Option

123

.

2

5

6

.

6

-X1 14

BK

M

-M2

1~

BL

BR

-C3

.

PE

fan motor

Lüftermotor

ventilateur

1

P>

10111213141516

A1

-K2

A2

crankcase heater

Kurbelwannenheizung

résistance de carter

-K2

.

-R5

21

22

22

23

.

22

-X1

P>

-B3

.

20

-X1

P<

-B4

.

15

-X1

.

.

N2

PE

-K1

44

*Option: A fan pressure switch or fan speed controller can be connected in series to wire n°6

Il est possible de raccorder en série un pressostat ou un contrôleur de vitesse pour le ventilateur au l 6.

An die Ader n°6 kann ein Lüfterdruckschalter oder ein Lüfterdrehzahlregler in Reihe geschaltet werden.

* Valgfrit: En ventilatortrykkontakt eller ventilatorhastighedsregulator kan serieforbindes til ledning nr. 6

4 FRCC.ES.010.A4.ML

Page 5

Manual Controller Installation

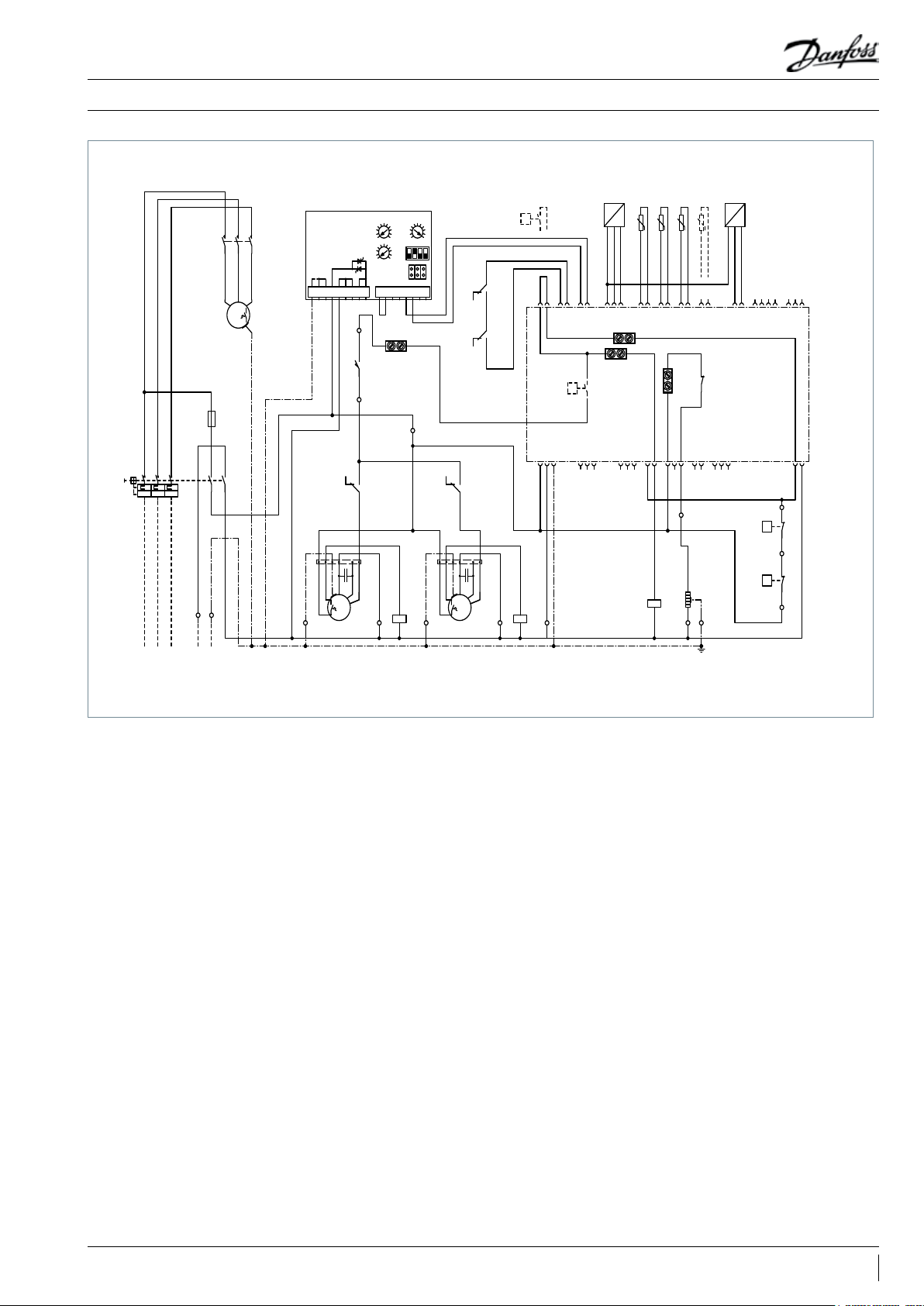

4 8213 7

65

BK

BK

BK

BK

BK

BK

GY

GY

BK

BK

BN

BN

T>

thermostat d'ambiance

Raumthermostat

n-min

set

n-max

E1

ON

OFF

S1

PKE-6

régulation de vitesse 0-10V

Drehzahlsteller 0-10V

speed controller 0-10V

PEPEPE

L1NU1

U1

U2

U2D1GDA1GD

GD

E1

+

GD

-A1

-R1 -R3 -R4-R2

P

U

123

-B1

Option: Room thermostat

limit switch

Endschalter

interrupteur

13

14

-S1

2

.

-X1

1

.

-X1

N1

.

-C1

BU

BU

BN

N2

.

-C2

PE

.

BN

N3

.

PE

.

-X1

BK

BK

3

.

-X1

BNBN

BN

P

U

123

-B2

22

.

-X1

15

.

-X1

20

.

-X1

P<

-B4

14

.

P>

-B3

P>

1

*Option

-B5

2

BNBKGY

I > I > I >

135

246

-Q1

333443

44

3A

-F1

BNBKGY

T1 T2 T3

BU

25

24

123

5

6

10111213141516

22

23

12345

6

-K2

21

22

-K2

A1

A2

-K2

A1

A2

-K3

12(1) 1 4(5)

11(9)

-K3

12(1)

14(5)

11(9)

-K4

A1

A2

-K4

12(4) 14(8)

11(12)

-K3

12(4) 14(8)

11(12)

-K4

M

3~

compressor

Verdichter

compresseur

-M1

BKBUBN

WH

WH

1~

M

GNYE

fan motor 1

Lüftermotor 1

ventilateur 1

-M2

BKBUBN

WH

WH

1~

M

GNYE

fan motor 2

Lüftermotor 2

ventilateur 2

-M3

PE

.

N4

.

crankcase heater

Kurbelwannenheizung

résistance de carter

-R5

power supply

Zuleitung

compresseur

380-400V3N~/50Hz

L1 L2 PEL3 N

PE

N

.

-X1

5FRCC.ES.010.A4.ML

Page 6

Manual Controller Installation

Contents

Commissioning ................................................................................................................. 7

Electrical installations ................................................................................................................................................... 7

Main display (after controller start-up) ...................................................................................................................7

Parameter Menu ............................................................................................................................................................. 7

Quick start of the unit / Refrigerant change.........................................................................................................7

Pump Down - Function ................................................................................................................................................ 8

Day/Night - Function .....................................................................................................................................................8

Service and Maintenance ................................................................................................ 8

Main Display .................................................................................................................................................................... 8

Operating Parameters .................................................................................................................................................. 8

Alarm and Error Messages...........................................................................................................................................9

Repair ................................................................................................................................ 9

Controller failure ............................................................................................................................................................. 9

Factory reset ..................................................................................................................................................................... 9

Controller Replacement of a unit on site .............................................................................................................. 10

Control.............................................................................................................................. 10

Control of condensing pressure...............................................................................................................................10

Control of crankcase heater .......................................................................................................................................10

Control of Fan Speed ....................................................................................................................................................10

Safety Parameter “Low Pressure” for R404A ....................................................................................................... 11

Safety Parameter “High Pressure” for R404A ...................................................................................................... 11

6 FRCC.ES.010.A4.02

Page 7

Manual Controller Installation

Commissioning

Electrical installations

Main display (after controller

start-up)

Parameter Menu

• Arrange electrical connections as mentioned in the table below

• Remove temporarily bridge DI1 (terminals 24 - 25 of the controller) to get access to parameters and

values of the controller without starting the condensing unit

Room Thermostat control without Pump Down

R404A *

function

- Connect Room Thermostat to these terminals

with factory delivered low pressure transmitter

- Connect power supply to main switch acc. wiring diagram, located in front door inner side

R404A *

Pump Down control

- Connect power supply to main switch acc. wiring diagram, located in front door inner side

- Increase the Setting of controller Par. c33 (Pump

Down CUT-OUT value):

e.g. Piston : 0,7bar

e.g. Scroll : 1,7bar

Note: To avoid low pressure alarm, the Setting of

c33 should be higher than c75

*: change for other refrigerants following chapters.

• The controller’s screen displays the Evaporation Temperature in °C

• Press short the lower button of the controller to show the Condensing Temperature in °C

• After a few seconds the display returns to the Evaporation Temperature in °C

• To get access to parameter menu press 5 seconds the upper button of the controller

• The rst Parameter “r05” of the Parameter menu will be shown on the display

• Press short the upper (or lower) button to go to the next Parameter of the Parameter menu. Scroll fast

through the Parameters with a long press on these buttons

• Press short the middle button to show the value of the selected Parameter

• Press afterwards the upper (or lower) button to change the value of the selected parameter. A long

press on these buttons will change the value fast

• The value will be stored after 20 seconds without any action or with a short press on the middle button

• After 20 seconds without pressing any button, the display returns to the main screen, the evaporation

temperature in °C. The parameter menu is closed now, to go back to the parameter menu press again

upper button 5 seconds …

Quick start of the unit /

Refrigerant change

• Optyma Plus™ new generation is preset, depending on the compressor model and refrigerant type.

In the case of a “multi-refrigerant” compressor, the controller of the condensing unit is set for R404A

(see table on page3). If this factory setting ts for the requirement of your application, no controller

parameter must be changed.

• For a refrigerant change go into the parameter menu (press upper button 5 seconds)

• Select parameter “r12” (software main switch) with a short press on lower button

• Activate parameter “r12” with middle button and change the value to 0 (zero)

• Conrm the value with a short press on the middle button (the 3 LED’s start ashing)

• Go to the parameter “o30” (Refrigerant)

• Change the value to 3 (stands for R134a), or 17 (R507), or 20 (R407C), or 19 (R404A)

• Conrm the value with a short press on the middle button

• Select parameter “r12” again

• Change the value to 1 (one)

• Conrm the value with a short press on the middle button (the 3 LED-signs stop ashing and the condensing unit will start if required)

• After 20 seconds the display returns to the evaporation temperature in °C, the new refrigerant and all

relevant parameters are changed

7FRCC.ES.010.A4.02

Page 8

Manual Controller Installation

Pump Down - Function • A “pump-down” limit can be activated with the setting of parameter c33

• To avoid unwanted low pressure alarms, the setting ot this parameter should be higher than the low

pressure cut-out limit parameter c75, … e.g. below

0

meter c75

Day/Night - Function

Scroll: 0,5bar Recip: -0,3bar

Low pressure switch: Cut-Out

Scroll: 1,5bar Recip: 0,5bar

Low pressure switch: Cut-In

Low pressure cut-out limit: Para-

Scroll: 1,4bar Recip: 0,4bar

Scroll and Recip: 0,7bar

Dierential: Parameter c76

Scroll: 1,7bar Recip: 0,7bar

Pump down function: Param. c33

Scroll and Recip: 0,7bar

Dierential: Parameter c76

In some areas it may be necessary to reduce noise level during night time. This is possible with the “Day

/ Night” function of the Optyma Plus™ controller which limits the fan speed. For activation follow the

next steps …

• Activate the parameter menu (press upper button min. 5 sec.)

• Select parameter “r13” Night Oset (temperature oset related to condensing temperature setpoint

for daytime which is parameter “r29”)

• Push middle button and set the desired value, e.g. 005 for 5 Kelvin

• Conrm the value with a short press on the middle button. Do the same with the next parameters

which are required for the “Day / Night” - function …

• Select and set parameter “t17” Day start (hours), e.g. 006 for 06:00 a.m.

• Select and set parameter “t18” Night start (hours), e.g. 022 for 22:00 p.m.

• Select and set parameter “t07” Clock setting (hours), e.g. 011 for 11:xx a.m.

• Select and set parameter “t08” Clock setting (minutes), e.g. 035 for 11:35 a.m.

• Select and set parameter “t45” Clock setting (date), e.g. 010 for 10.xx.xx

• Select and set parameter “t46” Clock setting (month), e.g. 004 for 10.04.xx

• Select and set parameter “t47” Clock setting (year), e.g. 012 for 10.04.12

• All values will be stored with the middle button or after 20s without pressing any button

Service and Maintenance

Main Display

(Evaporating and Condensing

Temperature, Setpoint Temperature Dierence)

Operating Parameters

8 FRCC.ES.010.A4.02

• The controller displays the evaporation temperature in °C (main screen)

• It will show the readout of the condensing temperature in °C after pressing short the lower button

• Pressing short the middle button, the setpoint of the temperature dierence between condensing

and ambient temperature appears which can be directly modied here by pressing the upper or lower

button.

• The display returns to main screen after a few seconds without any action on the buttons

• Operation conditions of the condensing unit can

be displayed in the parameter menu by selecting parameters “U” … below some examples

u01 Condensing Pressure

u10 Status of DI1 (room thermostat)

u21 Superheat

U22 Condensing Temperature

U23 Evaporation Pressure

U24 Evaporation Temperature

U25 Ambient Temperature

U26 Discharge Temperature

U27 Suction Temperature

Page 9

Manual Controller Installation

Alarm and Error Messages

Repair

Controller failure

(if the controller fails, there is a

possibility to run the condensing

unit in “manual” mode. Proceed as

follows)

• In case of “malfunctions” 3 small LED symbols

will ash on the controller’s screen. Acknowledge with a short press on upper button. Here

some examples below …

A2 Low Suction Pressure Alarm

Safety Input Alarm (DI3: High condensing

A17

/ low suction pressure)

A96 Discharge Gas Temperature High

E20 Condensing Pressure Transmitter Error

E31 Ambient Temperature Sensor Error

E32 Discharge Temperature Sensor Error

E33 Suction Gas Temperature Sensor Error

E39 Evaporating Pressure Transmitter Error

• See wiring diagrams on p. 4-5.

• Disconnect the condensing unit from power supply (turn hardware main switch o)

• Remove wire from controller terminal 22 (safety input DI3) and terminal 25 (room thermostat DI1) and

put them together

• Remove wire from controller terminal 24 (room thermostat DI1) and terminal 11 (compressor supply)

and put them together

• H1, H2, H3 : Remove wire 6* and connect it with terminal bridge for wire 11 and 24.

• H4 : Remove wire U2* from fan speed controller and connect it with wire 11 and 24.

• Remove wire from controller terminal 14 (crankcase heater) and connect it to compressor contactor K2

terminal 22

• Remove wire from controller terminal 12 (supply crankcase heater), extend this wire approximately

40cm and connect it to compressor contactor K2 terminal 21

• Pay attention: Remove the big terminal block from the controller or remove the complete controller

• Connect the condensing unit back to power supply (turn hardware main switch on)

Factory reset

(all factory parameters can be

restored by the following

procedure)

• Turn OFF the main power switch

• While holding simultaneously the up and down button, turn ON the main switch

• Message FAC is displayed, means “FACTORY RESET” restores factory settings

• After a short time message “typ” appears on the screen

• Activate parameter menu and go to parameter o61 (unit type)

• Enter the value 1 to 42 depending on the type of condensing unit (see table 1 on page 3)

• Store the entered value by pressing the middle button of the controller

• After 15 seconds without action the message “ref” appears on the screen

• Activate parameter menu and go to parameter o30 (refrigerant)

• Change the value to 3 (stands for refrigerant R134a), or 17 (R507), or 20 (R407C), or 19 (R404A)

• Store the entered value by pressing the middle button of the controller

• Go to parameter o67 (store values as factory setting)

• Change the value to “on”

• Validate the parameter entered by pressing the middle button of the controller

• After 15 seconds without action the message “OFF” appears on the screen

• Activate parameter menu and go to parameter r12 (main switch)

• Change the value to 1 (condensing unit will start if cooling demand from cold room controller)

• The “Day / Night” function must be reprogrammed too (see chapter Commissioning - Day/Night

- Function)

9FRCC.ES.010.A4.02

Page 10

Manual Controller Installation

Controller Replacement of a

unit on site

Control

Control of condensing pressure

Control of crankcase heater

• Turn OFF the main power switch

• Remove the new controller (remove all plugs, 2 x I-type screws and controller)

• Install the new controller

• Turn ON main power switch again, no factory reset needed

• After a short time message “typ” appears on the screen

• Follow same steps as shown in preceding chapter fth row and following

spare part code controller SINGLE pack: 118U3465

spare part code controller MULTI pack (12pcs.) : 084B8135

• The setpoint of the condensing temperature is calculated from the measured ambient temperature

plus an adjustable Temperature Oset (called Reference) and controlled by the fan speed

• Factory setting of Reference = 8.0K

• The Reference is accessible by pressing short the middle button of the controller

• When Reference is shown, it can be modied with the upper or lower button

• Additionally to this the control of the condensing temperature can be limited by following parameters:

“r82” = minimal condensing temperature (factory set: 10.0°C)

“r83” = maximal condensing temperature (factory set: 40.0°C)

• The controller optimizes the regulation of the crankcase heater itself. The heating power depends on

the ambient temperature and suction pressure and is controlled by Pulse Width modulation

• There is no change of parameters “P45”, “P46” and “P47” necessary on site

Control of Fan Speed

• The fan speed is controlled by PI-control, depends on the actual value and the setpoint of the condensing temperature

• There is no change of parameters “F14” and “F21” to be provided on site

10 FRCC.ES.010.A4.02

Page 11

Manual Controller Installation

Safety Parameter “Low

Pressure” for R404A

0

Suction Pressure

Safety Parameter “High

Pressure” for R404A

Scroll: 0,5bar Recip: -0,3bar

Low pressure switch: Cut-Out

Min. suction pres.: Param. c75

“Mechanical“ Safety - LP

Scroll: 1,4bar Recip: 0,4bar

“Electronic“ Safety - LP

Scroll: 1,5bar Recip: 0,5bar

Low pressure switch: Cut-In

0

Scroll and Recip: 24bar

High pressure switch: Cut-In

Scroll and Recip: 3,0bar

Dierential: Parameter c74

Scroll + "blue" Recip.: 28bar

Max. Pressure: Parameter c73

"black" Recip.: 23bar

Scroll and Recip: 0,7bar

Dierential: Parameter c76

Discharge Pressure

Scroll and Recip: 31bar

High pressure switch: Cut-Out

“Mechanical“ Safety - HP

“Electronic“ Safety - LP

11FRCC.ES.010.A4.02

Page 12

Manuel Mise en service du contrôleur

Sommaire

Mise en service ................................................................................................................ 13

Installations électriques .............................................................................................................................................. 13

Écran principal (après le démarrage du contrôleur) .........................................................................................13

Menu des paramètres .................................................................................................................................................. 13

Démarrage rapide de l’unité/Changement de réfrigérant ............................................................................ 13

Fonction «pump-down» ............................................................................................................................................. 14

Fonction Jour/Nuit .......................................................................................................................................................14

Service et maintenance .................................................................................................. 14

Écran du contrôleur - Achage «permanent» .........................................................................................................14

Visualisation des paramètres de fonctionnement ............................................................................................14

Alarmes et messages d’erreur ...................................................................................................................................15

Dépannage ...................................................................................................................... 15

Défaillance du contrôleur ........................................................................................................................................... 15

Réinitialisation du paramétrage usine...................................................................................................................15

Remplacement du contrôleur d’une unité sur site ........................................................................................... 16

Régulation ....................................................................................................................... 16

Régulation de la condensation ................................................................................................................................ 16

Régulation de la résistance de carter ..................................................................................................................... 16

Régulation de la vitesse de rotation du ventilateur ......................................................................................... 16

Paramétrage de sécurité côté «basse pression» pour le R404A.................................................................17

Paramétrage de sécurité côté «haute pression» pour le R404A ................................................................ 17

12 FRCC.ES.010.A4.04

Page 13

Manuel Mise en service du contrôleur

Mise en service

Installations électriques

Écran principal (après le

démarrage du contrôleur)

Menu des paramètres

• Eectuez les raccordements électriques comme indiqué dans le tableau ci-dessous.

• Retirez temporairement le raccord DI1 (bornes 24 et 25 du contrôleur), an d'accéder aux paramètres

et aux valeurs du contrôleur sans avoir à démarrer le groupe de condensation.

Régulation par thermostat d'ambiance sans

R404A *

fonction

pump down

- Connectez le thermostat d'ambiance à ces

bornes

- Connectez l'alimentation électrique au

sectionneur

principal conformément au schéma

électrique, situé sur la face interne de la porte

avant

avec transmetteur de basse pression livré d'usine

- Connectez l'alimentation électrique au

sectionneur

principal conformément au schéma

électrique, situé sur la face interne de la porte

avant

- Augmentez la valeur du paramètre c33 du

contrôleur

(valeur de COUPURE pump down):

R404A *

Régulation pump down

Exemple piston: 0,7bar

Exemple Scroll: 1,7bar

Remarque: An d'éviter les alarmes de basse

pression, la valeur du paramètre c33 doit être

supérieure à celle du paramètre c75.

*: la procédure à eectuer pour les autres réfrigérants est décrite dans les chapitres qui suivent.

• L'écran du contrôleur ache la température d'évaporation en °C.

• Appuyez brièvement sur le bouton inférieur du contrôleur pour acher la température de

condensation en °C.

• Après quelques secondes, l'écran ache à nouveau la température d'évaporation en °C.

• Pour accéder au menu des paramètres, appuyez 5 secondes sur le bouton supérieur du contrôleur.

• Le premier paramètre du menu, le paramètre «r05» s'ache alors sur l'écran.

• Appuyez brièvement sur le bouton supérieur (ou inférieur) pour accéder au paramètre du menu

suivant. Pour faire déler rapidement les paramètres, appuyez longuement sur ces boutons.

• Appuyez brièvement sur le bouton du milieu pour acher la valeur du paramètre sélectionné.

• Appuyez ensuite sur le bouton supérieur (ou inférieur) pour modier la valeur du paramètre

sélectionné. Appuyez longuement sur l’un de ces boutons pour modier rapidement la valeur.

• La valeur est enregistrée après 20 secondes sans aucune action ou si vous appuyez brièvement sur le

bouton du milieu.

• Si aucun bouton n'est actionné pendant 20 secondes, l'écran principal s'ache à nouveau et indique

la température d'évaporation en °C. Le menu des paramètres est à présent fermé, pour y revenir,

appuyez à nouveau 5 secondes sur le bouton supérieur.

Démarrage rapide de l'unité/

Changement de réfrigérant

• L'Optyma Plus™ nouvelle génération est préparamétré, en fonction du modèle de compresseur et du

type de réfrigérant. Dans le cas d'un compresseur «multiréfrigérant», le contrôleur du groupe de

condensation est conguré pour utiliser du R404A (voir le tableau à la page 3). Si ce réglage d'usine

répond aux besoins de votre application, les paramètres du contrôleur n'ont pas à être modiés.

• Pour changer de réfrigérant, accédez au menu des paramètres (appuyez sur le bouton supérieur

pendant 5 secondes).

• Sélectionnez le paramètre « r12 » (sectionneur principal) en appuyant brièvement sur le bouton

inférieur.

• Activez le paramètre «r12» à l'aide du bouton du milieu et sélectionnez sa valeur sur 0 (zéro).

• Conrmez cette valeur en appuyant brièvement sur le bouton du milieu (les 3 LED se mettent alors à

clignoter).

• Accédez au paramètre «o30» (Réfrigérant).

• Sélectionnez sa valeur sur 3 (pour le R134a), 17 (R507), 20 (R407C) ou 19 (R404A).

• Conrmez cette valeur en appuyant brièvement sur le bouton du milieu.

• Sélectionnez à nouveau le paramètre «r12».

• Sélectionnez sa valeur sur 1 (un).

• Conrmez cette valeur en appuyant brièvement sur le bouton du milieu (les 3 LED s'arrêtent alors de

clignoter et le groupe de condensation démarre si nécessaire).

• Après 20 secondes, l'écran ache à nouveau la température d'évaporation en °C, le réfrigérant et tous

les paramètres liés à ce refrigérant sont modiés.

13FRCC.ES.010.A4.04

Page 14

Manuel Mise en service du contrôleur

Fonction «pump-down»

• Une valeur limite du «pump-down» peut être activée à l’aide du paramètre c33.

• La valeur de ce paramètre devra être supérieure à celle du paramètre c75 (valeur limite de la coupure

sécurité BP), pour éviter une alarme basse pression indésirable.

Pression basse transducteur: Cut-Out

paramètre c75

Scroll: 1,4bar Piston: 0,4bar

c76

Scroll ou Piston: 0,7bar

0

Scroll: 0,5bar Piston: -0,3bar

Pression basse pressostat: Cut-Out

Fonction Jour/Nuit Dans certains endroits, il peut être nécessaire de réduire le niveau sonore durant la nuit. Pour ce faire,

Scroll: 1,5bar Piston: 0,5bar

Pression basse pressostat: Cut-In

Scroll: 1,7bar Piston: 0,7bar

Pump-Down paramètre c33

c76

Scroll ou Piston: 0,7bar

vous pouvez utiliser la fonction « Jour/Nuit » du contrôleur Optyma Plus™, qui limite la vitesse du

ventilateur. Pour activer cette fonction, eectuez les étapes suivantes…

• Activez le menu des paramètres (appuyez sur le bouton supérieur pendant au moins 5 secondes).

• Sélectionnez le paramètre «r13», décalage nocturne (le décalage de température est lié au point de

consigne de la température de condensation en journée, qui est déni par le paramètre «r29»).

• Appuyez sur le bouton du milieu et dénissez la valeur de votre choix, p. ex. 005 pour 5K.

• Conrmez cette valeur en appuyant brièvement sur le bouton du milieu. Répétez cette procédure

pour les autres paramètres à dénir pour la fonction «Jour/Nuit»…

• Sélectionnez et réglez le paramètre «t17» Démarrage jour (heure), p. ex. 006 pour 06h00

• Sélectionnez et réglez le paramètre «t18» Démarrage nuit (heure), p. ex. 022 pour 22h00

• Sélectionnez et réglez le paramètre «t07» Réglage de l'horloge (heure), p. ex. 011 pour 11hxx

• Sélectionnez et réglez le paramètre «t08» Réglage de l'horloge (minutes), p ex. 035 pour 11h35

• Sélectionnez et réglez le paramètre «t45» Réglage de l'horloge (jour), p. ex. 010 pour le 10/xx/xx

• Sélectionnez et réglez le paramètre «t46» Réglage de l'horloge (mois), p. ex. 004 pour le 10/04/xx

• Sélectionnez et réglez le paramètre «t47» Réglage de l'horloge (année), p. ex. 012 pour le 10/04/12

• Pour enregistrer ces valeurs, appuyez sur le bouton du milieu ou n'appuyez sur aucun bouton pendant

20 secondes

Service et maintenance

Écran du contrôleur - Achage

«permanent»

(Températures d'évaporation et

de condensation, diérence de

température de point de consigne)

Visualisation des paramètres de

fonctionnement

14 FRCC.ES.010.A4.04

• Le contrôleur ache la température d’évaporation en °C (écran principal).

• Il indique la température de condensation mesurée en °C lorsque vous appuyez brièvement sur le

bouton inférieur.

• Lorsque vous appuyez brièvement sur le bouton du milieu, le point de consigne de diérence de

température entre les températures de condensation et ambiante s’ache et peut être directement

modié en appuyant sur le bouton supérieur ou inférieur.

• Au bout de quelques secondes, l’acheur revient sur la température d’évaporation en °C.

• Les conditions de fonctionnement du groupe de

condensation peuvent être achées dans le menu

des paramètres en sélectionnant les paramètres

«U»…voir les exemples ci-dessous.

U01 Pression de condensation

U10 État de DI1 (thermostat d'ambiance)

U21 Surchaue

U22 Température de condensation

U23 Pression d'évaporation

U24 Température d'évaporation

U25 Température ambiante

U26 Température de refoulement

U27 Température d'aspiration

Page 15

Manuel Mise en service du contrôleur

Alarmes et messages d’erreur

Dépannage

Défaillance du contrôleur

(En cas de défaillance du contrôleur,

il est possible de faire fonctionner

le groupe de condensation en

mode «manuel», moyennant

quelques adaptations mineures.

Pour ce faire, eectuez la

procédure suivante.)

• En cas de «dysfonctionnement» de l’installation,

3 petites LED, au niveau de l’écran du contrôleur,

se mettent à clignoter. Pour accéder au code

«Erreur», appuyez sur le bouton supérieur. Voici

quelques exemples:

A2 Alarme BP – Pression d’aspiration trop basse

A17

Alarme BP ou HP (Mécanique)

A96

Alarme température de refoulement trop élevée

E20 Incident sur capteur de pression HP

E31

Incident sur la sonde d’ambiance S2

E32

Incident sur la sonde température de refoulement S3

E33 Incident sur la sonde température d’aspiration S4

E39

Incident sur capteur de pression BP

• Voir les schémas de câblage sur p. 4-5.

• Coupez l’alimentation générale au niveau de l’unité de condensation (sélectionneur principal).

• Retirez le l de la borne 22 (entré de sécurité DI3), ainsi que celui de la borne 25 (thermostat de la

chambre froide DI1) et les raccordez entre eux.

• Retirez le l de la borne 24 (thermostat de la chambre froide DI1), ainsi que celui de la borne 11

(alimentation du compresseur) et les raccordez entre eux.

• H1, H2, H3 : Retirez le l 6* et le raccordez avec un « domino » pour les ls 11 et 24.

• H4 : Retirez le l U2* du régulateur de vitesse du ventilateur et le raccordez avec les ls 11 et 24.

• Retirez le l de la borne 14 (résistance de carter) et le raccordez à la borne 22 du contacteur K2 du

compresseur.

• Retirez le l de la borne 12 (alimentation résistance de carter), rallongez ce l d’environ 40 cm et le

raccordez à la borne 21 du contacteur K2 du compresseur.

• Attention : Retirez, du contrôleur, le large bloc de raccordements, ou l’ensemble du contrôleur.

• Remettez sous tension l’unité de condensation (sélectionneur principal).

Réinitialisation du paramétrage

usine

(vous pouvez restaurer tous les

réglages d'usine en eectuant la

procédure suivante)

• Coupez l’alimentation générale au niveau du sectionneur.

• Appuyez simultanément sur les boutons supérieur et inférieur du contrôleur, et réenclenchez le sectionneur

tout en maintenant la pression sur les boutons supérieur et inférieur.

• Le message «FAC» (pour FACTORY RESET ) s’ache, ce qui signie que la réinitialisation des réglages d’usine

est lancée.

• Après quelques instants, le message «typ» s’ache à l’écran.

• Avec le menu déroulant accédez, au paramètre o61 (type de groupe).

• Saisissez une valeur comprise entre 1 et 42 en fonction du type de groupe de condensation (voir le tableau

1 à la page 3).

• Validez le paramètre saisi en appuyant sur le bouton du milieu du contrôleur.

• Après 15 secondes sans aucune action, le message «ref» s’ache à l’écran.

• Avec le menu déroulant, accédez au paramètre o30 (réfrigérant).

• Sélectionnez sa valeur sur 3 (pour le R134a), 17 (R507), 20 (R407C) ou 19 (R404A).

• Validez le paramètre saisi en appuyant sur le bouton du milieu du contrôleur.

• Avec le menu déroulant, accédez au paramètre o67 (enregistrer les valeurs comme réglages d’usine).

• Sélectionnez sa valeur sur «ON» (activer).

• Validez le paramètre saisi en appuyant sur le bouton du milieu du contrôleur.

• Après 15 secondes sans aucune action, le message «OFF» (désactivé) s’ache à l’écran.

• Avec le menu déroulant, accédez au paramètre r12 (sectionneur principal).

• Sélectionnez sa valeur sur 1 (démarrage du groupe de condensation en cas de demande de la part du

contrôleur de chambre froide).

• La fonction « Jour/Nuit» doit également être reprogrammée (voir le chapitre Mise en service - Jour/Nuit

- Fonction).

15FRCC.ES.010.A4.04

Page 16

Manuel Mise en service du contrôleur

Remplacement du contrôleur

d’une unité sur site

Régulation

Régulation de la condensation

• Coupez l’alimentation générale au niveau du séctionneur.

• Retirez l’ancien contrôleur (retirez toutes les prises, les deux vis type I et le contrôleur).

• Câbler électriquement le nouveau contrôleur sur l’unité de condensation

• Mettez l’interrupteur d’alimentation principale sous tension

• Après quelques instants, le message «typ» s’ache à l’écran.

• Suivez les étapes de la section précédente, à partir de la cinquième ligne.

pièce de rechange, code du contrôleur à l’unité: 118U3465

pièce de rechange, code du contrôleur en multi-pack (12 pcs) : 084B8135

• Le point de consigne de régulation de la température de condensation est égal à:

o Température Ambiante Extérieure + Delta T

o avec Delta T = 8.0K (paramétré en usine)

• Ce Delta T est accessible directement en exerçant une pression sur le bouton du milieu du contrôleur

• A ce stade, en appuyant sur le bouton du haut (ou du bas) la valeur « usine » (8.0K) est augmentée (bouton

du haut) ou diminuée (bouton du bas) à chacune des impulsions exercées

• De plus, la possibilité est oerte de limiter cette variation du point de consigne en agissant sur les paramètres

« r82 » et « r83 » du menu déroulant

«r82»=température de condensation minimale (réglage d'usine: 10,0°C)

«r83»=température de condensation maximale (réglage d'usine: 40,0°C)

Régulation de la résistance

de carter

Régulation de la vitesse

de rotation du ventilateur

• Le contrôleur, de par les paramètres rentrés en usine, assure une optimisation de la régulation de la

résistance de carter (temps de fonctionnement et puissance de chaue)

• Aucune modication des paramètres «P45», «P46» et «P47» n’est à prévoir sur site.

• Le contrôleur, de par les paramètres rentrés en usine, assure une optimisation de la régulation de la

vitesse de rotation du ventilateur.

• Aucune modication des paramètres «F14» et «F21» n’est à prévoir sur site.

16 FRCC.ES.010.A4.04

Page 17

Manuel Mise en service du contrôleur

Paramétrage de sécurité côté

«basse pression» pour le

R404A

Paramétrage de sécurité côté

«haute pression» pour le

R404A

0

c76

Scroll: 0,5bar Piston: -0,3bar

Pression basse pressostat: Cut-Out

Scroll: 1,4bar Piston: 0,4bar

Pression basse transducteur: paramètre c75

Sécurité Electronique BP

Sécurité Mécanique BP

Scroll: 1,5bar Piston: 0,5bar

Pression basse pressostat: Cut-In

0

c74

Scroll ou Piston: 0,7bar

Pression d'aspiration

Pression de condensation

Scroll ou Piston: 24bar

Pression haute pressostat: Cut-In

Scroll et Piston: 3,0bar

Sécurité «mécanique» - HP

Sécurité «électronique» - HP

Piston «noir»: 23bar

Scroll + Piston «bleu»: 28bar

Pression haute paramètre c73

Scroll ou Piston: 31bar

Pression haute pressostat: Cut-Out

17FRCC.ES.010.A4.04

Page 18

Handbuch Reglerinstallation

Inhalt

Inbetriebnahme .............................................................................................................. 19

Elektrische Installation ................................................................................................................................................19

Displayanzeige (nach Reglerstart) .......................................................................................................................... 19

Parametermenü ............................................................................................................................................................. 19

Schnellstart der Einheit/Kältemittelwechsel ......................................................................................................19

Pump-down-Funktion ................................................................................................................................................. 20

Tag-/Nachtfunktion ...................................................................................................................................................... 20

Instandhaltung und Wartung ........................................................................................ 20

Displayanzeige .............................................................................................................................................................. 20

Betriebsparameter ........................................................................................................................................................20

Alarm- und Fehlermeldungen ..................................................................................................................................21

Reparatur ......................................................................................................................... 21

Reglerdefekt .................................................................................................................................................................... 21

Zurücksetzen auf Werkseinstellungen ..................................................................................................................21

Regleraustausch bei einer Einheit vor Ort ........................................................................................................... 22

Regelung .......................................................................................................................... 22

Regelung des Verüssigungsdrucks ...................................................................................................................... 22

Regelung der Kurbelwannenheizung ...................................................................................................................22

Regelung der Lüfterdrehzahl ....................................................................................................................................22

Sicherheitsparameter „Niederdruck“ für R404A ................................................................................................23

Sicherheitsparameter „Hochdruck“ für R404A ..................................................................................................23

18 FRCC.ES.010.A4.03

Page 19

Handbuch Reglerinstallation

Inbetriebnahme

Elektrische Installation

Displayanzeige (nach

Reglerstart)

Parametermenü

• Stellen Sie die elektrischen Verbindungen wie in der Tabelle unten beschrieben her.

• Entfernen Sie vorrübergehend die Verbindungsbrücke DI1 (Klemmen 24 – 25 am Regler), um ohne

Start des Verüssigungssatzes auf die Parameter und Werte zugreifen zu können.

Raumthermostatregelung ohne

R404A *

Pump-down-Funktion

- Raumthermostat an diese Klemmen anschließen.

- Stromversorgung mit Hauptschalter verbinden,

mit Niederdruckmessumformer ab Werk

- Stromversorgung mit Hauptschalter verbinden,

wie im Schaltplan auf der Innenseite der Fronttür

gezeigt.

R404A *

Pump-down-Regelung

wie im Schaltplan auf der Innenseite der Fronttür

gezeigt.

- Einstellung von Reglerparameter c33 (Pumpdown-ABSCHALT-Wert) erhöhen:

z.B. Normalkühlung Hubkolben: 0,7bar, Tiefkühlung Hubkolben: 0,2 bar

z.B. Scroll: 0,7bar

Hinweis: Um Niederdruckalarme zu vermeiden,

sollte die Einstellung von c33 höher sein als c75.

*: Für andere Kältemittel – siehe folgende Kapitel – ändern.

• Das Display des Reglers zeigt die Verdampfungstemperatur in °C an.

• Betätigen Sie kurz die untere Taste, um die Verüssigungstemperatur in °C anzuzeigen.

• Nach wenigen Sekunden kehrt die Anzeige zur Verdampfungstemperatur zurück.

• Zum Aufrufen des Parametermenüs drücken Sie 5Sekunden auf die obere Taste des Reglers.

• Der erste Parameter r05 im Parametermenü wird angezeigt.

• Drücken Sie kurz die obere (oder untere) Taste, um zum nächsten Parameter im Parametermenü zu

wechseln. Für einen schnellen Wechsel durch die Parameter drücken Sie eine der Tasten etwas länger.

• Um den Wert des ausgewählten Parameters anzuzeigen, betätigen Sie kurz die mittlere Taste.

• Drücken Sie anschließend die obere (oder untere) Taste, um den Wert des gewählten Parameters zu

ändern. Durch längeres Betätigen einer der Tasten wird der Wert schnell geändert.

• Der Wert wird durch kurzes Drücken der mittleren Taste oder automatisch nach 20Sekunden ohne

Betätigung einer Taste gespeichert.

• Nach 20 Sekunden ohne Betätigung einer Taste kehrt die Anzeige in die Hauptansicht

(Verdampfungstemperatur in °C) zurück und das Parametermenü wird geschlossen. Um zum

Parametermenü zurückzukehren, drücken Sie erneut die obere Taste für 5Sekunden.

Schnellstart der Einheit/

Kältemittelwechsel

• Optyma Plus™ neue Generation ist entsprechend dem installierten Verdichtermodell und verwendeten

Kältemittel voreingestellt. Im Fall eines Verdichters für mehrere Kältemittel ist der Regler des

Verüssigungssatzes auf „R404A“ eingestellt (siehe Tabelle auf Seite3). Wenn diese Werkseinstellung

zu Ihrer Anwendung passt, muss kein Reglerparameter geändert werden.

• Um die Kältemitteleinstellung zu ändern, rufen Sie das Parametermenü auf (obere Taste für 5Sekunden

drücken).

• Wählen Sie den Parameter r12 (Softwarehauptschalter) durch kurzes Betätigen der unteren Taste.

• Aktivieren Sie Parameter r12 mit der mittleren Taste und ändern Sie den Wert auf „0“.

• Bestätigen Sie den Wert durch kurzes Drücken der mittleren Taste (die drei LEDs blinken).

• Wechseln Sie zum Parameter o30 (Kältemittel).

• Ändern Sie den Wert auf „3“ (steht für R134a), „17“ (R507), „20“ (R407C) oder „19“ (R404A).

• Bestätigen Sie den Wert durch kurzes Drücken der mittleren Taste.

• Wählen Sie erneut den Parameter r12.

• Ändern Sie den Wert auf „1“.

• Bestätigen Sie den Wert durch kurzes Drücken der mittleren Taste (die drei LEDs hören auf zu blinken

und der Verüssigungssatz startet erforderlichenfalls).

• Nach 20Sekunden kehrt die Anzeige in die Hauptansicht (Verdampfungstemperatur in °C) zurück. Die

Kältemitteleinstellung und alle relevanten Parameter wurden geändert.

19FRCC.ES.010.A4.03

Page 20

Handbuch Reglerinstallation

Pump-down-Funktion • Mithilfe des Parameters c33 kann ein Pump-down-Grenzwert aktiviert werden.

• Um ungewollte Niederdruckalarme zu vermeiden, sollte dieser Parameter höher gewählt sein als der

Parameter c75 für die Niederdruckabschaltgrenze, siehe unten.

0

meter c75

Tag-/Nachtfunktion

Niederdruckschalter: Aus

Scroll: 0,5bar Hubkolbenv.: -0,3bar

Niederdruckschalter: Ein

Scroll: 1,5bar Hubkolbenv.: 0,5bar

Scroll: 1,4bar Hubkolbenv.: 0,4bar

Niederdruckabschaltgrenze: Para-

Dierenz: Parameter c76

Scroll und Hubkolbenv.: 0,7bar

Scroll: 1,7bar Hubkolbenv.: 0,7bar

Pump-down-Funktion: Parameter c33

Dierenz: Parameter c76

Scroll und Hubkolbenv.: 0,7bar

In einigen Anwendungsbereichen kann ein reduzierter Geräuschpegel bei Nacht erforderlich sein. Dies

wird durch die Tag-/Nachtfunktion des Optyma Plus™ Reglers ermöglicht. Sie reduziert die Lüfterdrehzahl.

Zur Aktivierung gehen Sie wie folgt vor:

• Rufen Sie das Parametermenü auf (obere Taste min. 5Sekunden drücken).

• Wählen Sie Parameter r13 Nacht-Oset (Temperatur-Oset in Bezug auf den VerüssigungstemperaturSollwert bei Tage; dies ist Parameter r29).

• Drücken Sie die mittlere Taste und stellen Sie den gewünschten Wert ein, z.B. 005 für 5Kelvin.

• Bestätigen Sie den Wert durch kurzes Drücken der mittleren Taste. Verfahren Sie genauso mit den

nächsten Parametern für die Tag-/Nachtfunktion.

• Wählen und setzen Sie Parameter t17 – Beginn Tag (Stunden), z.B. 006 für 6:00Uhr.

• Wählen und setzen Sie Parameter t18 – Beginn Nacht (Stunden), z.B. 022 für 22:00Uhr.

• Wählen und setzen Sie Parameter t07 – Einstellung Uhr (Stunden), z.B. 011 für 11:xxUhr.

• Wählen und setzen Sie Parameter t08 – Einstellung Uhr (Minuten), z.B. 035 für 11:35Uhr.

• Wählen und setzen Sie Parameter t45 – Einstellung Uhr (Tag), z.B. 010 für 10.xx.xx.

• Wählen und setzen Sie Parameter t46 – Einstellung Uhr (Monat), z.B. 004 für 10.04.xx.

• Wählen und setzen Sie Parameter t47 – Einstellung Uhr (Jahr), z.B. 012 für 10.04.12.

Alle Werte werden entweder durch Drücken der mittleren Taste oder automatisch nach 20Sekunden

ohne Betätigung einer Taste gespeichert.

Instandhaltung und Wartung

Displayanzeige

(Verdampfungs- und

Verüssigungstemperatur,

Sollwert Temperaturdierenz)

Betriebsparameter

20 FRCC.ES.010.A4.03

• Das Display des Reglers zeigt die Verdampfungstemperatur in °C an (Hauptansicht).

• Durch kurzes Drücken der unteren Taste wird die Verüssigungstemperatur in °C angezeigt.

• Wenn Sie kurzzeitig die mittlere Taste drücken, wird der Sollwert der Temperaturdierenz zwischen

Verüssigungs- und Umgebungstemperatur angezeigt. Dieser Wert kann direkt durch Drücken der

oberen oder unteren Taste geändert werden.

• Die Anzeige kehrt automatisch nach ein paar Sekunden ohne Betätigung einer Taste in die Hauptansicht

zurück.

• Durch Wählen der u-Parameter können Sie die

Betriebsbedingungen anzeigen, z.B.:

u01 Verüssigungsdruck

u10 Status von DI1 (Raumthermostat)

u21 Überhitzung

u22 Verüssigungstemperatur

u23 Verdampfungsdruck

u24 Verdampfungstemperatur

u25 Umgebungstemperatur

u26 Verdichtungsendtemperatur

u27 Saugtemperatur

Page 21

Handbuch Reglerinstallation

Alarm- und Fehlermeldungen

Reparatur

Reglerdefekt

(Für den Fall, dass der Regler

ausfällt, kann der

Verüssigungssatz manuell

betrieben werden. Gehen Sie

dazu wie folgt vor.)

• Bei einer Fehlfunktion blinken die drei kleinen

LED-Symbole in der Regleranzeige. Bestätigen

Sie die Meldung durch Drücken der oberen Taste.

Hier einige Beispiele für Warn-/Fehlermeldungen:

A2 Alarm niedriger Saugdruck

Alarm Sicherheitseingang (DI3: hoher Ver-

A17

üssigungsdruck/niedriger Saugdruck)

A96 Druckgastemperatur hoch

Fehler Verüssigungsdruckmessumformer

E20

E31 Fehler Umgebungstemperaturfühler

E32 Fehler Verdichtungsendtemperaturfühler

E33 Fehler Sauggastemperaturfühler

Fehler Verdampfungsdruckmessumformer

E39

• Bitte beachten sie den Schaltplan auf Seite 4-5

• Trennen Sie den Verüssigungssatz von der Stromversorgung (drehen Sie den Gerätehauptschalter in

die Aus-Position)

• Entfernen Sie die Ader von Reglerklemme 22 (Sicherheitseingang DI3) und Klemme 25 (Raumthermostat

DI1) und verbinden Sie sie miteinander.

• Entfernen Sie die Ader von Reglerklemme 24 (Raumthermostat DI1) und Klemme 11 (Verdichterstromversorgung)

und verbinden Sie sie miteinander.

• H1, H2, H3: Entfernen Sie die Ader 6* und verbinden Sie sie mit der Klemmbrücke für Ader 11 und 24.

• H4: Entfernen Sie die Ader U2* vom Lüfterdrehzahlregler und verbinden Sie sie mit Ader 11 und 24.

• Entfernen Sie die Ader von Reglerklemme 14 (Kurbelwannenheizung) und schließen Sie sie an die

Klemme22 des Verdichterschützes K2 an.

• Entfernen Sie die Ader von Reglerklemme 12 (Stromversorgung Kurbelwannenheizung), verlängern

Sie die Ader um ca. 40cm und schließen Sie sie an die Klemme21 des Verdichterschützes K2 an.

• Achten Sie auf Folgendes: Entfernen Sie den großen Klemmbock vom Regler oder entfernen Sie den

gesamten Regler.

• Schließen Sie den Verüssigungssatz wieder an die Stromversorgung an (drehen Sie den Gerätehauptschalter

in die Ein-Position).

Zurücksetzen auf

Werkseinstellungen

(Alle Werkseinstellungen lassen

sich wie folgt wiederherstellen.)

• Schalten Sie die Einheit über den Gerätehauptschalter aus.

• Während Sie gleichzeitig die obere und untere Taste gedrückt halten, schalten Sie das Gerät am

Hauptschalter wieder ein.

• Die Meldung „FAC“ wird angezeigt. Sie bedeutet, dass das Gerät auf die Werkseinstellungen

zurückgesetzt wird.

• Anschließend wird im Display die Meldung „typ“ angezeigt.

• Rufen Sie das Parametermenü auf und wechseln Sie zum Parameter o61 (Gerätetyp).

• Geben Sie je nach verwendetem Verüssigungssatz einen Wert zwischen „1“ und „42“ ein (siehe

Tabelle1 auf Seite3).

• Speichern Sie den eingegebenen Wert durch Betätigen der mittleren Taste am Regler.

• Nach 15Sekunden ohne Betätigung einer Taste wird im Display die Meldung „ref“ angezeigt.

• Rufen Sie das Parametermenü auf und wechseln Sie zum Parameter o30 (Kältemittel).

• Ändern Sie den Wert auf „3“ (steht für R134a), „17“ (R507), „20“ (R407C) oder „19“ (R404A).

• Speichern Sie den eingegebenen Wert durch Betätigen der mittleren Taste am Regler.

• Wechseln Sie zum Parameter o67 (Werte als Werkseinstellung speichern).

• Ändern Sie den Wert auf „on“.

• Bestätigen Sie den eingegebenen Parameterwert durch Drücken der mittleren Taste am Regler.

• Nach 15Sekunden ohne Betätigung einer Taste wird im Display die Meldung „OFF“ angezeigt.

• Rufen Sie das Parametermenü auf und wechseln Sie zum Parameter r12 (Hauptschalter).

• Ändern Sie den Wert auf „1“ (Verüssigungssatz startet, wenn Kühlstellenregler/Thermostat Kühlung

anfordert).

• Auch die Tag-/Nachtfunktion muss neu programmiert werden (siehe Kapitel zu Inbetriebnahme –

Tag-/Nachtfunktion).

21FRCC.ES.010.A4.03

Page 22

Handbuch Reglerinstallation

Regleraustausch bei einer

Einheit vor Ort

Regelung

Regelung des

Verüssigungsdrucks

Regelung der

Kurbelwannenheizung

• Schalten Sie die Einheit über den Gerätehauptschalter aus.

• Bauen Sie den defekten Regler aus (alle Stecker, 2 x Schrauben TypI und Regler entfernen).

• Installieren Sie den neuen Regler.

• Schalten Sie die Einheit über den Gerätehauptschalter wieder ein. Es ist kein Zurücksetzen auf

Werkseinstellungen erforderlich.

• Anschließend wird im Display die Meldung „typ“ angezeigt.

• Gehen Sie genauso wie im vorherigen Kapitel (Zeile 5 .) vor.

Ersatzteilnummer Regler Einzelpack: 118U3465

Ersatzteilnummer Regler Industriepack (12Stk.): : 084B8135

• Der Sollwert der Verüssigungstemperatur ergibt sich aus der gemessenen Umgebungstemperatur plus

einem einstellbaren Temperatur-Oset (als Referenz bezeichnet) und wird von der Lüfterdrehzahl bestimmt.

• Werkseinstellung der Referenz = 8,0K.

• Um auf die Referenz zuzugreifen, betätigen Sie kurz die mittlere Taste am Regler.

• Wenn die Referenz angezeigt wird, kann sie über die obere oder untere Taste geändert werden.

• Zudem k ann die Regelung der Verüssigungstemperatur mithilfe der folgenden Parameter begrenzt werden:

r82 = min. Verüssigungstemperatur (Werkeinstellung: 10,0 °C)

r83 = max. Verüssigungstemperatur (Werkeinstellung: 40,0 °C)

• Der Regler sorgt selbstständig für eine optimale Regelung der Kurbelwannenheizung. Die Heizleistung

hängt von der Umgebungstemperatur und dem Saugdruck ab und wird durch Pulsbreitenmodulation

bestimmt.

• Eine Änderung der Parameter P45, P46 und P47 vor Ort ist nicht erforderlich.

Regelung der Lüfterdrehzahl

• Die Lüfterdrehzahl wird durch PI-Regelung bestimmt und hängt vom Ist- und Sollwert der

Verüssigungstemperatur ab.

• Eine Änderung der Parameter F14 und F21 vor Ort ist nicht möglich.

22 FRCC.ES.010.A4.03

Page 23

Handbuch Reglerinstallation

Sicherheitsparameter „Niederdruck“ für R404A

0

Saugdruck

Sicherheitsparameter „Hochdruck“ für R404A

Niederdruckschalter: Aus

Scroll: 0,5bar Hubkolbenv.: -0,3bar

Sicherheit Mechanik – Niederdr.

Min. Saugdruck: Parameter c75

Scroll: 1,4bar Hubkolbenv.: 0,4bar

Sicherheit Elektronik – Niederdr.

Niederdruckschalter: Ein

Scroll: 1,5bar Hubkolbenv.: 0,5bar

0

Hochdruckschalter: Ein

Scroll und Hubkolbenv.: 24bar

Dierenz: Parameter c74

Scroll und Hubkolbenv.: 3,0bar

Max. Druck: Parameter c73

Scroll und Hubkolbenv. „blau“: 28bar

Hubkolbenv. „schwarz“: 23bar

Dierenz: Parameter c76

Scroll und Hubkolbenv.: 0,7bar

Verdichtungsenddruck

Hochdruckschalter: Aus

Scroll und Hubkolbenv.: 31bar

Sicherheit Mechanik – Hochdr.

Sicherheit Elektronik – Hochdr.

23FRCC.ES.010.A4.03

Page 24

Manual Regulatorinstallation

Indholdsfortegnelse

Idriftsættelse ................................................................................................................... 25

Elektriske installationer ...............................................................................................................................................25

Regulatorvisning (efter opstart) ..............................................................................................................................25

Parametermenu ............................................................................................................................................................. 25

Hurtigstart af enheden/kølemiddelskift ..............................................................................................................25

Pump down – funktion ............................................................................................................................................... 26

Dag/nat-funktion ...........................................................................................................................................................26

Service og vedligeholdelse ............................................................................................ 26

Hovedvisning .................................................................................................................................................................. 26

Driftsparametre ..............................................................................................................................................................26

Alarm- og fejlmeddelelser ......................................................................................................................................... 27

Reparation ....................................................................................................................... 27

Regulatorfejl .................................................................................................................................................................... 27

Fabriksreset ......................................................................................................................................................................27

Udskiftning af regulator for et aggregat på stedet .......................................................................................... 28

Regulering ....................................................................................................................... 28

Regulering af kondenseringstryk ............................................................................................................................28

Regulering af krumtaphusvarmelegeme .............................................................................................................28

Regulering af ventilatorhastighed .......................................................................................................................... 28

Sikkerhedsparameter “lavtryk” for R404A ........................................................................................................... 29

Sikkerhedsparameter “højtryk” for R404A ........................................................................................................... 29

24 FRCC.ES.010.A4.01

Page 25

Manual Regulatorinstallation

Idriftsættelse

Elektriske installationer

• Arranger elektriske tilslutninger som nævnt i tabellen nedenfor

• Afmonter midlertidigt bro DI1 (regulatorens terminal 24-25) for at få adgang til parametre og værdier

for regulatoren uden at starte kondenseringsaggregatet

Rumtermostat uden pump down-funktion

R404A *

- Tilslut rumtermostat til disse terminaler

- Tilslut strømforsyning til hovedafbryderen i henhold

til el-diagram, der er placeret i sidedørens

inderside

med fabriksmonteret lavtrykstransmitter

- Tilslut strømforsyning til hovedafbryderen

i henhold

til el-diagram, der er placeret på

indersiden af døren foran

- Forøg indstillingen for regulatorpar. c33

R404A *

Pump down-regulering

(udkoblingsværdi for ”pump down”):

f.eks. stempel: 0,7 bar

f.eks. scroll: 1,7 bar

Bemærk: For at undgå lavtryksalarm skal

*: skift til andre kølemidler følgende kapitler.

indstillingen

Regulatorvisning (efter opstart) • Regulatorens display viser kondenseringstemperaturen i °C

for c33 være højere end c75

• Tryk kort på regulatorens nederste knap for at vise kondenseringstemperaturen i °C

• Efter nogle få sekunder vender visningen tilbage til fordampningstemperatur i °C

Parametermenu • Tryk på regulatorens øverste knap i 5 sekunder for at få adgang til parametermenuen

• Parametermenuens første parameter ”r05” vises på displayet

• Tryk kort på den øverste (eller nederste) knap for at gå til det næste parameter på parametermenuen.

Rul hurtigt gennem parametrene med et langt tryk på disse knapper

• Tryk kort på den midterste knap for at få vist værdien for det valgte parameter

• Tryk derefter på den øverste (eller nederste) knap for at indstille værdien af det valgte parameter.

Et langt tryk på disse knapper skifter hurtigt værdien

• Værdien lagres med et kort tryk på den midterste knap(kvittering for accept af den nye værdi)

• Efter 20 sekunder uden tryk på nogen knap vender visningen tilbage til ”hovedbilledet” på displayet,

fordampningstemperatur i ° C. Parametermenuen er lukket nu. Tryk igen på den øverste knap i 5

sekunder for at gå tilbage til parametermenuen

Hurtigstart af enheden/

kølemiddelskift

• Optyma Plus™ New Generation er forudindstillet, afhængig af kompressormodel og kølemiddeltype.

I tilfælde af en kompressor til ere kølemidler er kondenseringsaggregatets regulator indstillet til

R404A (se tabel på side 3). Hvis denne fabriksindstilling passer til dine anvendelsesbehov, skal ingen

regulatorparametre ændres.

• Gå ind i parametermenuen for kølemiddelskift (tryk på øverste knap i 5 sekunder)

• Vælg parameter ”r12” med et kort tryk på nederste knap

• Aktiver parameter ”r12” med midterste knap, og indstil værdien til 0 (nul)

• Bekræft værdien med et kort tryk på den midterste knap (de 3 LED’er begynder at blinke)

• Gå til parametret ”o30” (kølemiddel)

• Indstil værdien til f.eks. 3 (står for R134a), 17 (R507), 20 (R407C) eller 19 (R404A)

• Bekræft værdien med et kort tryk på den midterste knap

• Vælg igen parameter ”r12”

• Indstil værdien til 1 (et)

• Bekræft værdien med et kort tryk på den midterste knap (de 3 LED-skilte stopper med at blinke,

og kondenseringsaggregatet starter om nødvendigt)

• Efter 20 sekunder vender visningen tilbage til fordampningstemperaturen i ° C. Det nye kølemiddel og

alle relevante parametre er ændret

• r12 er regulator hovedafbryder

25FRCC.ES.010.A4.01

Page 26

Manual Regulatorinstallation

Pump down – funktion

Dag/nat-funktion

• En grænse for ”pump down” kan aktiveres ved indstilling af parameter c33

• For at undgå uønskede lavtryksalarmer skal indstillingen for dette parameter være højere end parameter

c75 for lavtryksudkobling, f.eks. som herunder

0

Parameter c75

Lavtryksafbryder: Udkobling

Scroll: 0,5 bar stempel: -0,3 bar

Lavtryksafbryder: Indkobling

Scroll: 1,5 bar stempel: 0,5 bar

Scroll: 1,4 bar stempel: 0,4 bar

Udkoblingsgrænse for lavtryk:

Dierens: Parameter c76

Scroll og stempel: 0,7 bar

Scroll: 1,7 bar stempel: 0,7 bar

Pump down-funktion: Param. c33

Dierens: Parameter c76

Scroll og stempel: 0,7 bar

I nogle områder kan det være nødvendigt at reducere støjniveauet om natten. Dette er muligt med

Optyma Plus™-regulatorens dag/nat-funktion, som begrænser ventilatorhastigheden. Følg nedenstående

trin ved aktivering.

• Aktiver parametermenuen (tryk på øverste knap i min. 5 sek.)

• Vælg parameter ”r13” natforskydning (temperaturforskydning relateret til kondenseringstemperaturens

indstillingspunkt for dag, hvilket er parameter ”r29”

• Tryk på den midterste knap, og indstil den ønskede værdi, f.eks. 005 for 5 Kelvin

• Bekræft værdien med et kort tryk på den midterste knap. Gør det samme med de næste parametre,

der er påkrævet for ”dag/nat”-funktionen.

• Vælg og indstil parameter ”t17” dagstart (timer), f.eks. 006 for kl. 6.00

• Vælg og indstil parameter ”t18” natstart (timer), f.eks. 022 for kl. 22.00

• Vælg og indstil parameter ”t07” indstilling af ur (timer), f.eks. 011 for kl. 11.xx

• Vælg og indstil parameter ”t08” indstilling af ur (minutter), f.eks. 035 for kl. 11.35

• Vælg og indstil parameter ”t45” indstilling af ur (dato), f.eks. 010 for 10.xx.xx

• Vælg og indstil parameter ”t46” indstilling af ur (måned), f.eks. 004 for 10.04.xx

• Vælg og indstil parameter ”t47” indstilling af ur (år), f.eks. 012 for 10.04.12

• Alle værdier gemmes ved at trykke på den midterste knap

Service og vedligeholdelse

Hovedvisning

(Fordampnings- og

kondenseringstemperatur,

indstillingspunkt for

temperaturforskel)

Driftsparametre

26 FRCC.ES.010.A4.01

• Regulatoren viser fordampningstemperaturen i ° C (”hovedbilledet” på displayet)

• Den viser udlæsningen for kondenseringstemperaturen i °C efter kort tryk på den nederste knap

• Ved kort tr yk på den midterste knap ses indstillingspunktet for temperaturforskellen mellem kondenseringsog omgivelsestemperatur, som direkte kan modiceres her ved tryk på øverste eller nederste knap.

• Visningen vender tilbage til ”hovedbilledet” på displayet efter få sekunder uden betjening af knapperne

• Driftsforhold for kondenseringsaggregatet kan

vises i parametermenuen ved valg af parametrene

”U”. Se eksempler her:

u01 Kondenseringstryk

u10 Status for DI1 (rumtermostat)

u21 Overhedning

U22 Kondenseringstemperatur

U23 Fordampningstryk

U24 Fordampningstemperatur

U25 Omgivelsestemperatur

U26 Afgangstemperatur

U27 Sugetemperatur

Page 27

Manual Regulatorinstallation

Alarm- og fejlmeddelelser

Reparation

Regulatorfejl

(hvis regulatoren har

fejlfunktion, er det muligt at

køre kondenseringsaggregatet i

"manuel" tilstand. Gå frem som

følger)

• I tilfælde af ”fejlfunktion” blinker 3 små LED-symboler

på regulatorens display. Godkend med et kort tryk

på øverste knap. Se nogle eksempler her.

A2 Alarm for lavt sugetryk

Sikkerhedsindgangsalarm (DI3: Højt kon-

A17

denseringstryk/lavt sugetryk)

A96 Afgangsgastemperatur høj

E20 Fejl i kondenseringstryktransmitter

E31 Fejl i omgivelsestemperaturføler

E32 Fejl i afgangstemperaturføler

E33 Fejl i sugegastemperaturføler

E39 Fejl i fordampningstryktransmitter

• Se ledningsdiagrammer på side 4-5

• Afbryd kondenseringsaggregatet fra strømforsyningen (slå hovedafbryder fra)

• Fjern ledning fra regulatorterminal 22 (sikkerhedsindgang DI3) og terminal 25 (rumtermostat DI1),

og sæt dem sammen

• Fjern ledning fra regulatorterminal 24 (rumtermostat DI1) og terminal 11 (kompressorforsyning DI1),

og sæt dem sammen

• H1, H2, H3: Fjern ledning 6*, og forbind den med terminalbroen for ledning 11 og 24.

• H4: Fjern ledning U2* fra ventilatorhastighedsregulatoren, og forbind den med ledning 11 og 24.

• Fjern ledningen fra regulatorterminal 14 (varmelegeme til krumtaphus), og tilslut den til kompressorkontaktor

K2 terminal 22

• Fjern ledningen fra regulatorterminal 12 (forsyning, krumtaphusvarmelegeme), forlæng denne ledning

ca. 40 cm, og tilslut den til kompressorkontaktor K2 terminal 21

• Vær omhyggelig: Afmonter den store terminalblok fra regulatoren, eller afmonter hele regulatoren

• Tilslut kondenseringsaggregatet til strømforsyningen igen (slå hovedafbryder for hardware til)

Fabriksreset

(alle fabriksparametre kan

gendannes ved følgende

procedure)

• Slå hovedafbryderen FRA

• Hold op- og nedknappen nede samtidig og slå hovedafbryderen TIL

• Beskeden FAC vises, hvilket betyder ”fabriksreset”, gendanner fabriksindstillinger

• Efter kort tid vises beskeden ”typ” på displayet

• Aktiver parametermenu, og gå til parameter o61 (enhedstype)

• Indtast værdien 1 til 42, afhængigt af typen af kondenseringsaggregat (se tabel 1 på side 3)

• Gem den indtastede værdi ved at trykke på regulatorens midterste knap

• Efter 15 sekunder uden betjening ses beskeden ”ref” på displayet

• Aktiver parametermenuen, og gå til parameter o30 (kølemiddel)

• Indstil værdien til f.eks. 3 (står for kølemiddel R134a), 17 (R507), 20 (R407C) eller 19 (R404A)

• Gem den indtastede værdi ved at trykke på regulatorens midterste knap

• Gå til parameter o67 (gem værdier som fabriksindstilling)

• Indstil værdien til ”on”

• Bekræft det indtastede parameter ved at trykke på regulatorens midterste knap

• Efter 15 sekunder uden betjening ses beskeden ”OFF” på displayet

• Aktiver parametermenu, og gå til parameter r12 (hovedafbryder)

• Indstil værdien til 1 (kondenseringsenhed starter ved kølebehov fra kølerumsregulator)

• Dag/nat-funktionen skal også genprogrammeres (se kapitlet Idriftsættelse – Dag/nat-funktion)

27FRCC.ES.010.A4.01

Page 28

Manual Regulatorinstallation

Udskiftning af regulator for et

aggregat på stedet

Regulering

Regulering af kondenseringstryk

Regulering af

krumtaphusvarmelegeme

• Slå hovedafbryderen FRA

• Afmonter den ”gamle” regulator (afmonter alle propper, 2 skruer af I-type og regulator)

• Montér den nye regulator

• Slå hovedafbryderen TIL igen, fabriksreset ikke nødvendigt

• Efter kort tid vises beskeden ”typ” på displayet

• Følg samme trin som vist i foregående kapitel fra femte række og frem

reservedelskode regulator, ENKELTpakke: 118U3465

reservedelskode, regulator, MULTIpakke (12 stk.) : 084B8135

• Indstillingspunktet for kondenseringstemperaturen beregnes ud fra den målte omgivelsestemperatur