Page 1

Instructions

Optyma™ Slim Pack

OP-HPMP/HPZP/HPUS/LPZP/LPZS

English / English p. 4

Español / Spanish p. 9

Português do Brasil / Brazilian Portuguese p. 14

1 | © Danfoss | DCS (CC)| 2017.03

FRCC.PI.051.A1.ML

Page 2

Instructions

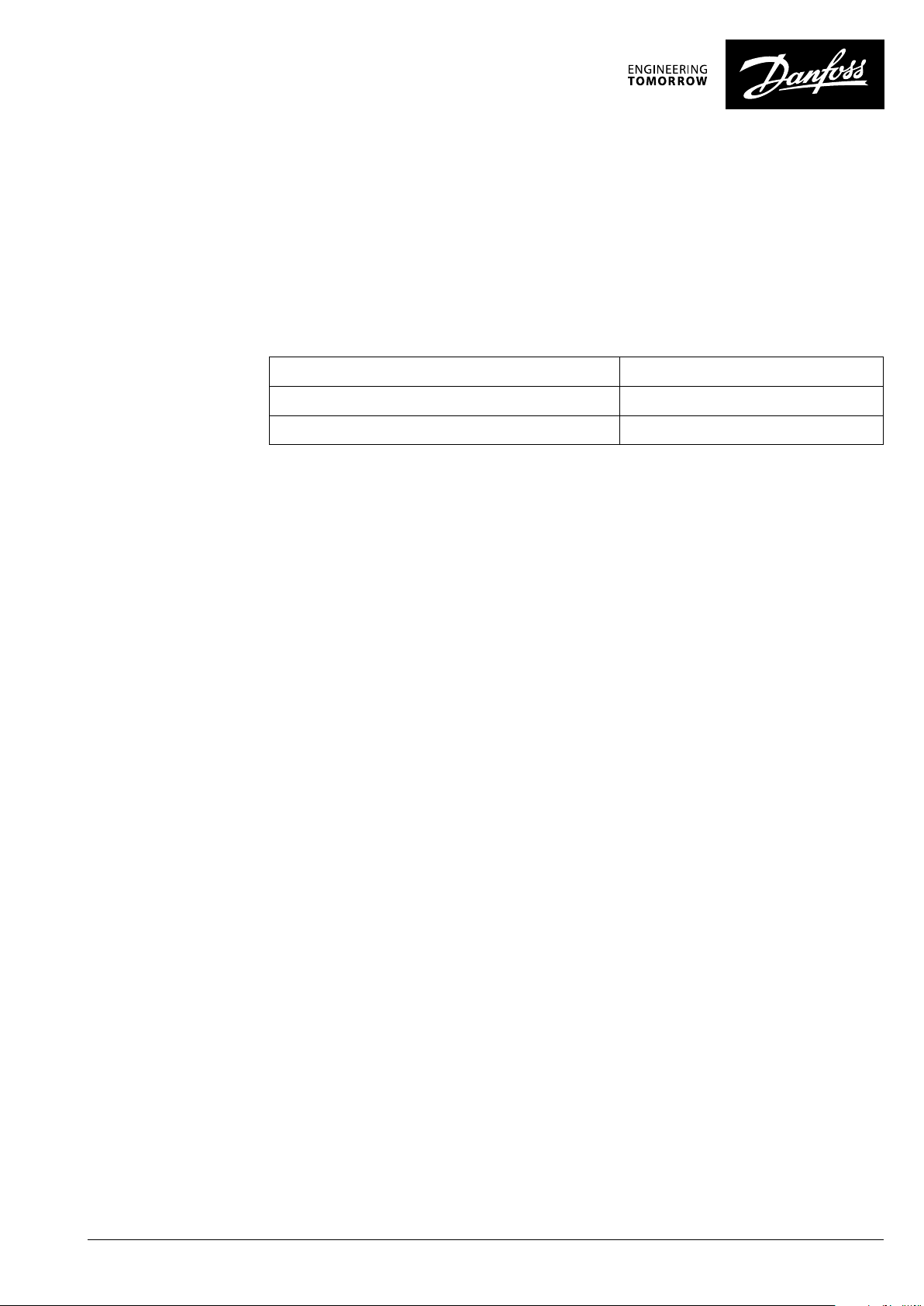

OP-HPMP019-28, OP-HPZP019-28, OP-HPUS015, LPZP048-68

525

327

861

626

OP-HPMP036-40, OP- HPZP036-40, OP-HPUS019-21

Ø8

361

51

30

Ø8

327

880

525

361

861

30

2 | © Danfoss | DCS (CC) | 2017.03

FRCC.PI.051.A1.ML

Page 3

Instructions

OP-HPMP050-064, OP-HPZP050-064, OP-HPUS026-038,LPZP013-018

437

1283

525

Ø8

469

895

30

30

FRCC.PI.051.A1.ML

© Danfoss | DCS (CC) | 2017.03 | 3

Page 4

Instructions

Instructions - Optyma™ Slim Pack

OP-HPMP/HPZP/HPUS/LPZP/LPZS

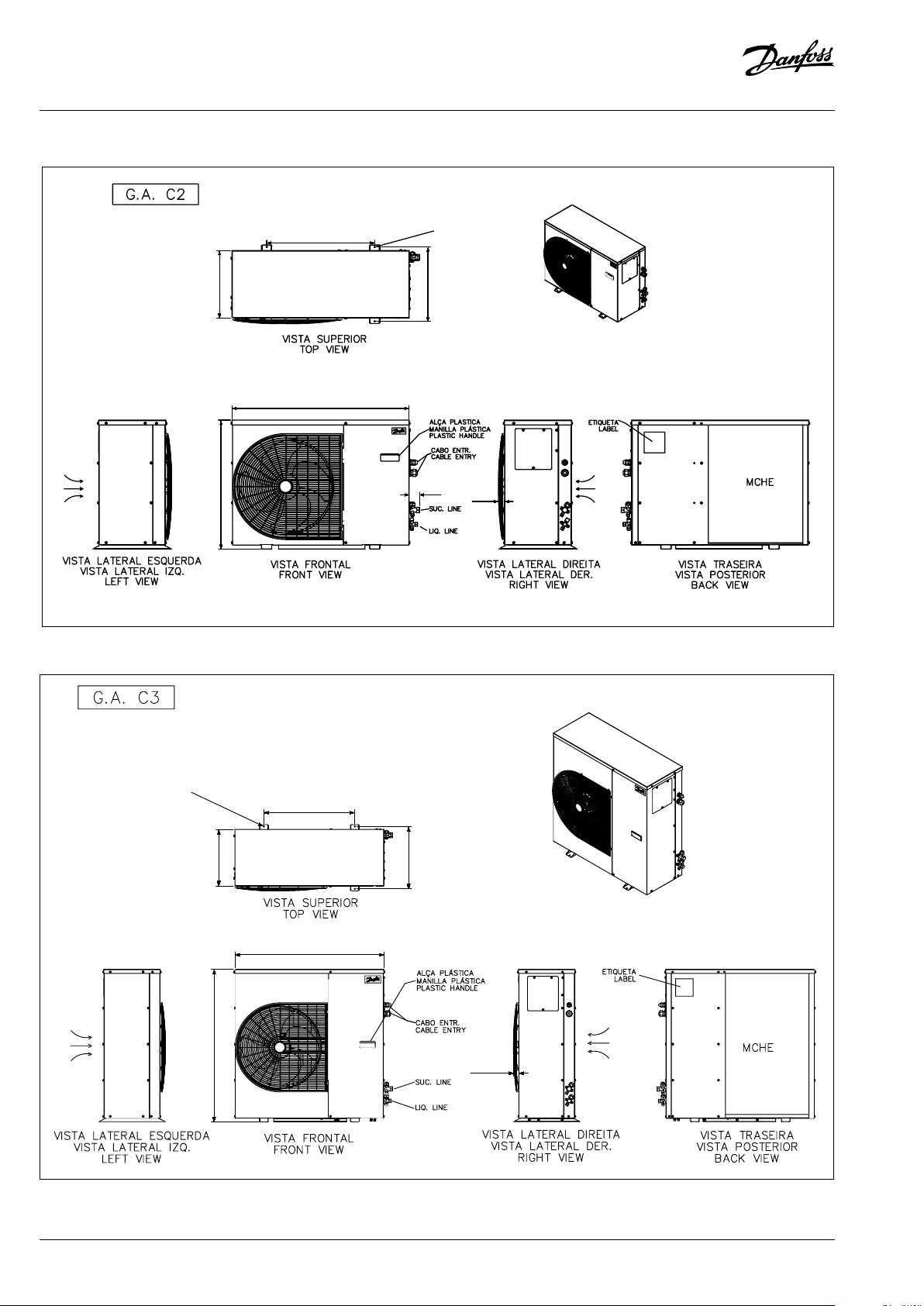

A

B

C

D

A: Model

B: Code number

C: Serial Number and bar code

D: Supply voltage, Locked Rotor Ampere

E: Housing Service Pressure

F: Refrigerant

G: Oil

E

F

G

H

I

J

H: Cable entry ports

I: Suction port

J: Liquid port

K: Microchannel heat exchanger

L

N

M

O

K

Picture 1 : Minimum mounting distances

L

[mm]

250 650 550 550

Installation and servicing of the

condensing units by qualied

personnel only. Follow these

instructions and sound refrigeration

engineering practice relating to installation,

commissioning, maintenance and service.

M

[mm]

N

[mm]

O

[mm]

Picture 2

1 – Introduction

These instructions pertain to Optyma™ Slim Pack

condensing units OP-HPMP, HPZP, HPUS, LPZP,

LPZS (R507A, R404A, R134a, R22) used for refrigeration systems. They provide necessary information regarding safety and proper usage of this

product

The condensing unit includes following:

• Scroll/reciprocating compressor

• Microchannel heat exchanger

• Adjustable low Pressure switch

• Fix high pressures cartridge

• Service valves Suction/ liquid

• Weather proof housing

• Filter drier

• Cranckcase heater for compressor

• Receiver with stop valve

• Sight glass

• Phase sequence relay (scroll compressors)

• Fully pre-wired electrical panel (Contactor)

2 – Handling and storage

• It is recommended not to open the packaging

before the unit is at the nal place for installation.

• Handle the unit with care. The packaging allows for the use of a forklift or pallet jack. Use

appropriate and safe lifting equipment.

• Store and transport the unit in an upright position.

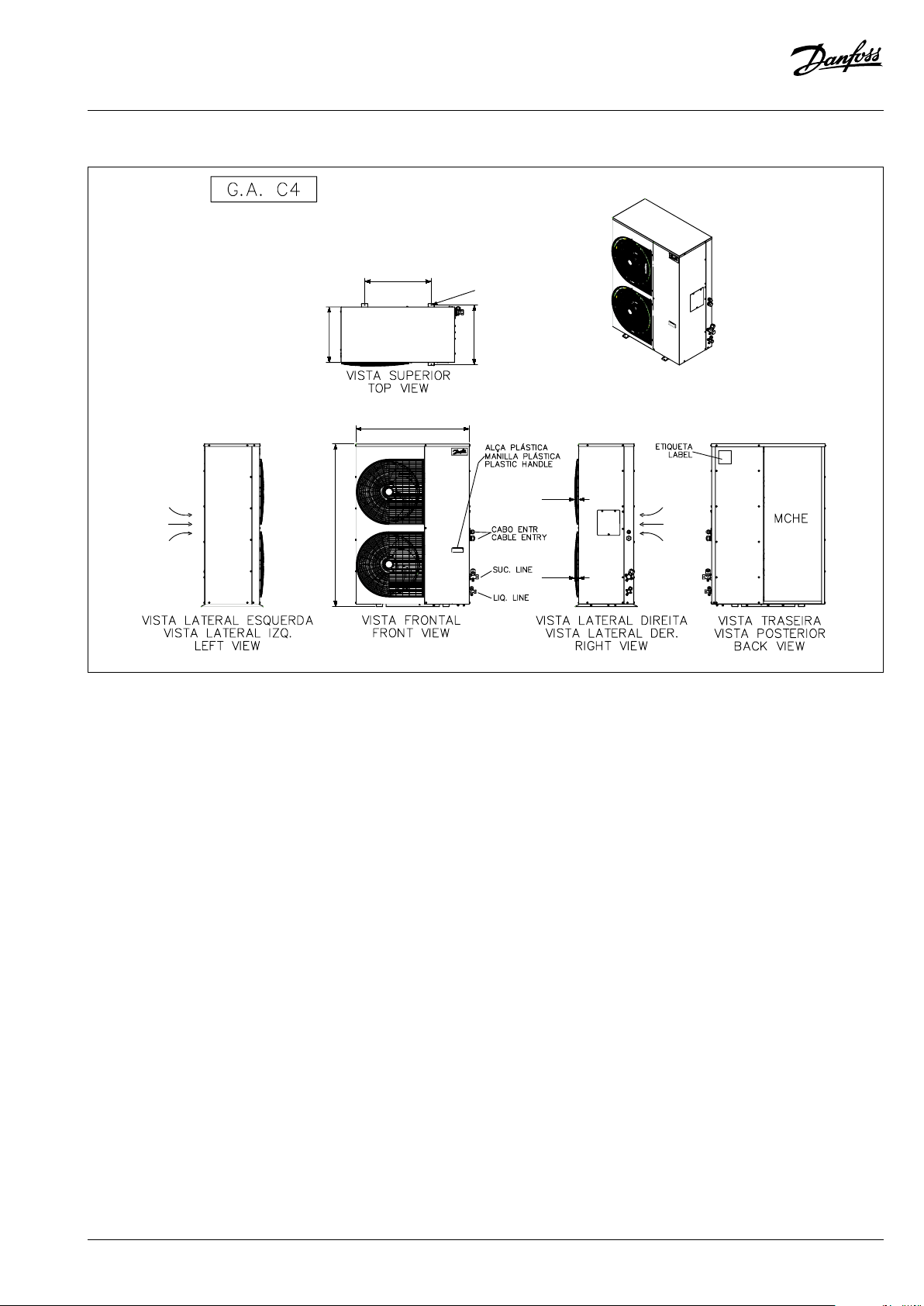

Picture 3

Picture 4

Mounting bolts (not supplied)

• Store the unit between -35°C and 50°C.

• Don’t expose the packaging to rain or corrosive

atmosphere.

• After unpacking, check that the unit is complete and undamaged.

3 – Installation precautions

Do not braze as long the condensing unit is

under pressure.

Never place the unit in a ammable atmosphere

Place the unit in such a way that it is not blocking

or hindering walking areas, doors, windows or similar.

• Ensure adequate space around the unit for air

circulation and to open doors. Refer to picture1

for minimal values of distance to walls.

• Avoid installing the unit in locations which are daily

exposed to direct sunshine for longer periods.

• Avoid installing the unit in aggressive and dusty environments.

• Ensure a foundation with horizontal surface

(less than 3° slope), strong and stable enough

to carry the entire unit weight and to eliminate

vibrations and interference.

• The unit ambient temperature may not exceed

50°C during o-cycle.

• Ensure that the power supply corresponds to

the unit characteristics (see nameplate).

• When installing units for HFC refrigerants, use

The condensing unit must only be used for

its designed purpose(s) and within its scope of

application.

Under all circumstances, the EN378 (or

other applicable local safety regulation)

requirements must be fullled.

The condensing unit is delivered under nitrogen gas pressure (1 bar) and hence it cannot

be connected as it is; refer to the «installation»

section for further details.

The condensing unit must be handled with caution in the vertical position (maximum oset

from the vertical : 15°)

equipment specically reserved for HFC refrigerants which was never used for CFC or HCFC

refrigerants.

• Use clean and dehydrated refrigeration-grade

copper tubes and silver alloy brazing material.

• Use clean and dehydrated system components.

• The suction piping connected to the compressor must be exible in 3 dimensions to dampen

vibrations. Furthermore piping has to be done

in such a way that oil return for the compressor is ensured and the risk of liquid slug over in

compressor is eliminated.

4 – Installation

• The unit must be securely installed on a stable

and rigid support, and xed from the beginning. See picture 2.

• It is recommended to install the unit on rub-

ber grommets or vibration dampers (not supplied).

• Slowly release the nitrogen holding charge

through the schrader port.

• Connect the unit to the system as soon as possible to avoid oil contamination from ambient

moisture.

• Avoid material entering into the system while

cutting tubes. Never drill holes where burrs

cannot be removed.

4 | © Danfoss | DCS (CC) | 2017.03

FRCC.PI.051.A1.02

Page 5

Instructions

• Braze with great care using state-of-the-art technique and vent piping with nitrogen gas ow.

• Connect the required safety and control devices. When the schrader port is used for this,

remove the internal valve.

• It is recommended to insulate the suction pipe

up to the compressor inlet with 19 mm thick

insulation.

5 – Leak detection

Never pressurize the circuit with oxygen or

dry air. This could cause re or explosion.

• Do not use dye for leak detection.

• Perform a leak detection test on the complete

system.

• The maximum test pressure is 32 bar.

• When a leak is discovered, repair the leak and

repeat the leak detection.

6 – Vacuum dehydration

• Never use the compressor to evacuate the system.

• Connect a vacuum pump to both the LP & HP

sides.

• Pull down the system under a vacuum of 500

μm Hg (0.67 mbar) absolute.

• Do not use a megohmmeter nor apply power

to the compressor while it is under vacuum as

this may cause internal damage.

7 – Electrical connections

• Switch o and isolate the main power supply.

• Ensure that power supply can not be switched

on during installation.

• All electrical components must be selected as

per local standards and unit requirements.

• Refer to wiring diagram for electrical connections details.

• Ensure that the power supply corresponds

to the unit characteristics and that the power

supply is stable (nominal voltage ±10% and

nominal frequency ±2,5 Hz).

• Dimension the power supply cables according

to unit data for voltage and current.

• Protect the power supply and ensure correct

earthing.

• Make the power supply according to local standards and legal requirements.

•

The unit is equipped with high and low pressure

switches, which directly cut the power supply to

the compressor in case of activation. Parameters

for high and low pressure cut outs should be

set by installer considering compressor model,

refrigerant and application. Units with Danfoss

MLZ and LLZ compressors are also equipped

with phase sequence relay to protect the unit

against phase loss/sequence/ asymmetry and

under-/over-voltage.

For units with a 3-phase scroll compressor, correct phase sequence for compressor rotation

direction shall be observed.

• Determine the phase sequence by using a

phase meter in order to establish the phase

orders of line phases L1, L2 and L3.

• Connect line phases L1, L2 and L3 to main switch terminals T1, T2 and T3 respectively.

8 – Filling the system

• Wear protective stu like goggles and protective gloves.

• Never start the compressor under vacuum.

Keep the compressor switched o.

• Before charging the refrigerant, verify that the

oil level is between ¼ and ¾ on the compressor

oil sight glass. If additional oil is required please

refer to the compressors label for type of oil.

• Use only the refrigerant for which the unit is

designed for.

• Fill the refrigerant in liquid phase into the

condenser or liquid receiver. Ensure a slow

charging of the system to 4 – 5 bar for R404A /

R507A or R22 and approx. 2 bar for R134a.

• Do not put liquid refrigerant through suction line.

• It is not allowed to mix additives with the oil

and/or refrigerant

• The remaining charge is done until the installation has reached a level of stable nominal

condition during operation.

• Never leave the lling cylinder connected to

the circuit.

9 – Verification before commissioning

Use safety devices such as safety pressure

switch and mechanical relief valve in compliance

with both generally and locally applicable regulations and safety standards. Ensure that they

are operational and properly set.

Check that the settings of high-pressure switches and relief valves don’t exceed the maximum

service pressure of any system component.

• Verify that all electrical connections are properly

fastened and in compliance with local regulations.

• When a crankcase heater is required, it must be

energized at least 12 hours before initial startup and start-up after prolonged shut-down

period.

10 – Start-up

• Never start the unit when no refrigerant is char-

ged.

• All service valves must be in the open position.

See picture 3.

• Check compliance between unit and power

supply.

• Check that the crankcase heater is working.

• Check that the fan can rotate freely.

• Check that the protection sheet has been re-

moved from the backside of condenser.

• Balance the HP/LP pressure.

• Energize the unit. It must start promptly. If

the compressor does not start, check wiring

conformity, voltage on terminals and sequence

phase.

• Eventual reverse rotation of a 3-phase com-

pressor can be detected by following phenomena; unit doesn’t start, the compressor

doesn’t build up pressure, it has abnormally

high sound level and abnormally low power

consumption. In such case, shut down the unit

immediately and connect the phases to their

proper terminals.

• If the rotation direction is correct the low pres-

sure indication on the low pressure gauge shall

show a declining pressure and the high pressure indication on the high pressure gauge

shall show an increasing pressure.

11 – Check with running unit

• Check the fan rotation direction. Air must ow

from the condenser towards the fan.

• Check current draw and voltage.

• Check suction superheat to reduce risk of slug-

ging.

• When a sight glass is provided observe the oil

level at start and during operation to conrm

that the oil level remains visible.

• Respect the operating limits.

• Check all tubes for abnormal vibration. Move-

ments in excess of 1.5 mm require corrective

measures such as tube brackets.

• When needed, additional refrigerant in liquid

phase may be added in the low-pressure side as

far away as possible from the compressor. The

compressor must be operating during this process.

• Do not overcharge the system.

• Never release refrigerant to atmosphere.

• Before leaving the installation site, carry out

a general installation inspection regarding

cleanliness, noise and leak detection.

• Record type and amount of refrigerant charge

as well as operating conditions as a reference

for future inspections.

12 – Maintenance

Always switch o the unit at main switch

before remove fan panel.

Internal pressure and surface temperature

are dangerous and may cause permanent injury.

Maintenance operators and installers require

appropriate skills and tools. Tubing temperature

may exceed 100°C and can cause severe burns.

Ensure that periodic service inspections to

ensure system reliability and as required by local

regulations are performed.

To prevent system related problems, following

Periodic maintenance is recommended:

• Verify that safety devices are operational and

properly set.

• Ensure that the system is leak tight.

• Check the compressor current draw.

• Conrm that the system is operating in a way

consistent with previous maintenance records

and ambient conditions.

• Check that all electrical connections are still

adequately fastened.

• Keep the unit clean and verify the absence of

rust and oxidation on the unit components,

tubes and electrical connections.

The condenser must be checked at least once

a year for clogging and be cleaned if deemed

necessary. Access to the internal side of the

condenser takes place through the fan panel.

Microchannel coils tend to accumulate dirt on

the surface rather than inside, which makes

them easier to clean than n-&-tube coils.

• Switch o the unit at main switch before re-

move any panel from the condensing unit.

• Remove surface dirt, leaves, bres, etc. with

a vacuum cleaner, equipped with a brush or

other soft attachment. Alternatively, blow compressed air through the coil from the inside out,

and brush with a soft bristle. Do not use a wire

brush. Do not impact or scrape the coil with the

vacuum tube or air nozzle.

If the refrigerant system has been opened, the

system has to be ushed with dry air or nitrogen

to remove moisture and a new lter drier has to

be installed. If evacuation of refrigerant has to be

done, it shall be done in such a way that no refrigerant can escape to the environment.

13 - Warranty

Always transmit the model number and serial num-

ber with any claim led regarding this product.

The product warranty may be void in following

cases:

• Absence of nameplate.

• External modications; in particular, drilling,

welding, broken feet and shock marks.

• Compressor opened or returned unsealed.

• Rust, water or leak detection dye inside the

compressor.

• Use of a refrigerant or lubricant not approved

by Danfoss.

• Any deviation from recommended instructions

pertaining to installation, application or main-

tenance.

• Use in mobile applications.

• Use in explosive atmospheric environment.

• No model number or serial number transmit-

ted with the warranty claim.

14 – Disposal

Danfoss recommends that condensing

units and oil should be recycled by a

suitable company at its site.

FRCC.PI.051.A1.03

© Danfoss | DCS (CC) | 2017.02 | 5

Page 6

Instructions

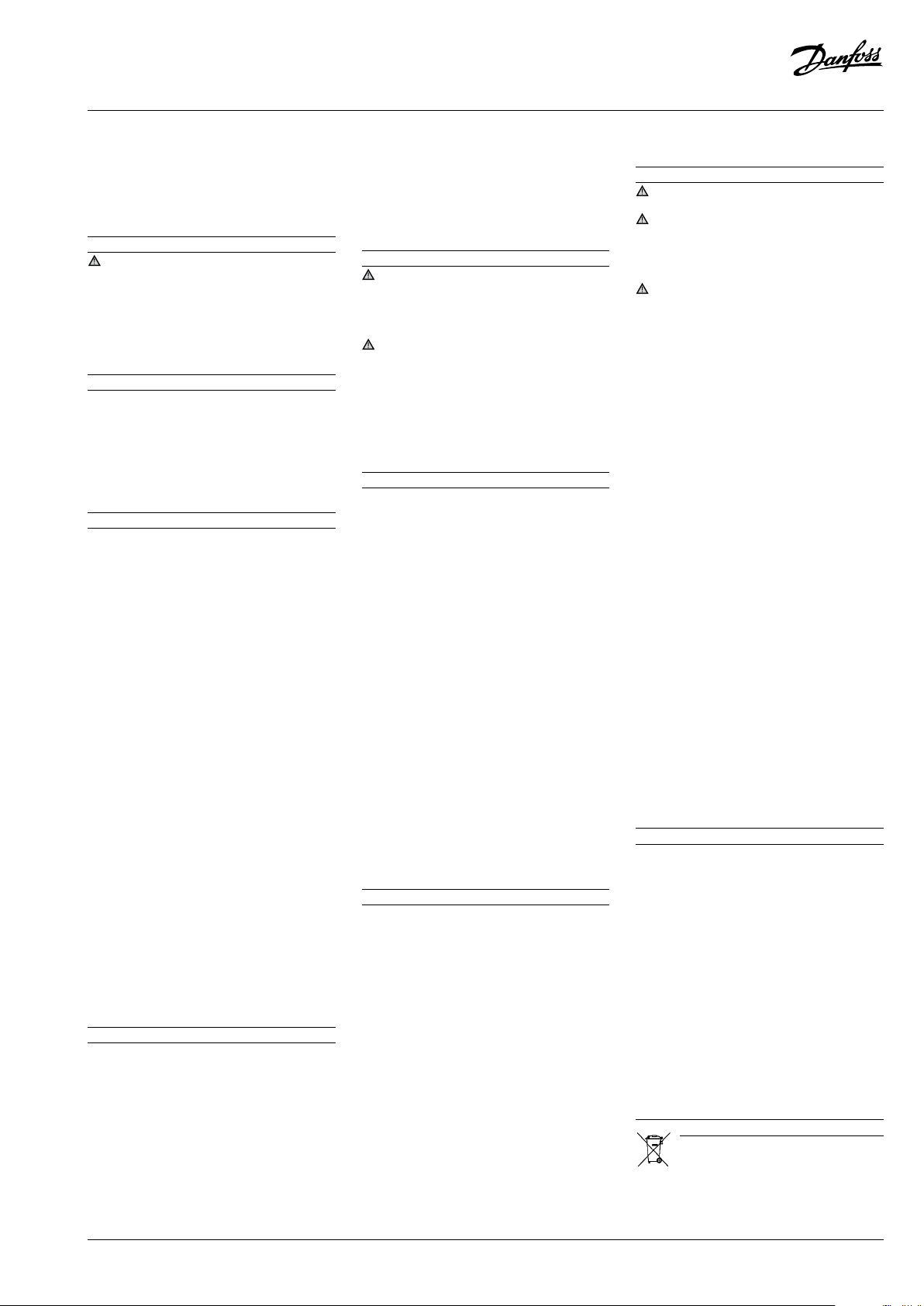

Code N: HPMP, HPZP, LPZP

RC

230V 1~50-60Hz

L1

L2

1

13

5

F1

2 4

6

F2

F3

CR

CS

RL

1

2

5

CV

CV

a1

K

a2

2

PE

CP -COMPRESSOR / COMPRESOR

CR -CAPACITOR MARCHA / RUN

CAPACITOR ARRANQUE / START

CS CV -CAPACITOR VENTILADOR / FAN

F -

FUSÍVEL / FUSIBLE / FUSE

K -CONTATOR / CONTACTOR

PH -

PRESSOSTATO ALTA

PRESOSTATO ALTA

PRESSURE SWITCH - HBP

PL -

PRESSOSTATO BAIXA

PRESOSTATO BAJA

PRESSURE SWITCH - LBP

RC -

RESISTÊNCIA CARTER

CALENTADOR CARTER

CRANKCASE HEATER

RL - RELE / RELAY

V -

VENTILADOR / FAN

R

S

P<

CP

V1

V2

PH

4

1

2

P<

PE

PL

№1

Code N: HPUS

CS

RL

5

PE

RC

CR

13

2 4

230V 1~ 50-60Hz

L1

L2

1

5

F1

6

F2

F3

CV

CV

a1

K

a2

2

PE

COMPRESSOR / COMPRESOR

CP CR -CAPACITOR MARCHA / RUN

CAPACITOR ARRANQUE / START

CS CV -CAPACITOR VENTILADOR / FAN

F -

FUSÍVEL / FUSIBLE / FUSE

K -CONTATOR / CONTACTOR

PH -

PRESSOSTATO ALTA

PRESOSTATO ALTA

PRESSURE SWITCH - HBP

PL -

PRESSOSTATO BAIXA

PRESOSTATO BAJA

PRESSURE SWITCH - LBP

RC -

1

2

RESISTÊNCIA CARTER

CALENTADOR CARTER

CRANKCASE HEATER

RL - RELE / RELAY

V -

VENTILADOR / FAN

C

S

R

CP

V1

V2

PH

4

1

2

P<

P<

PE

PL

6 | © Danfoss | DCS (CC) | 2017.03

№2

FRCC.PI.051.A1.02

Page 7

Instructions

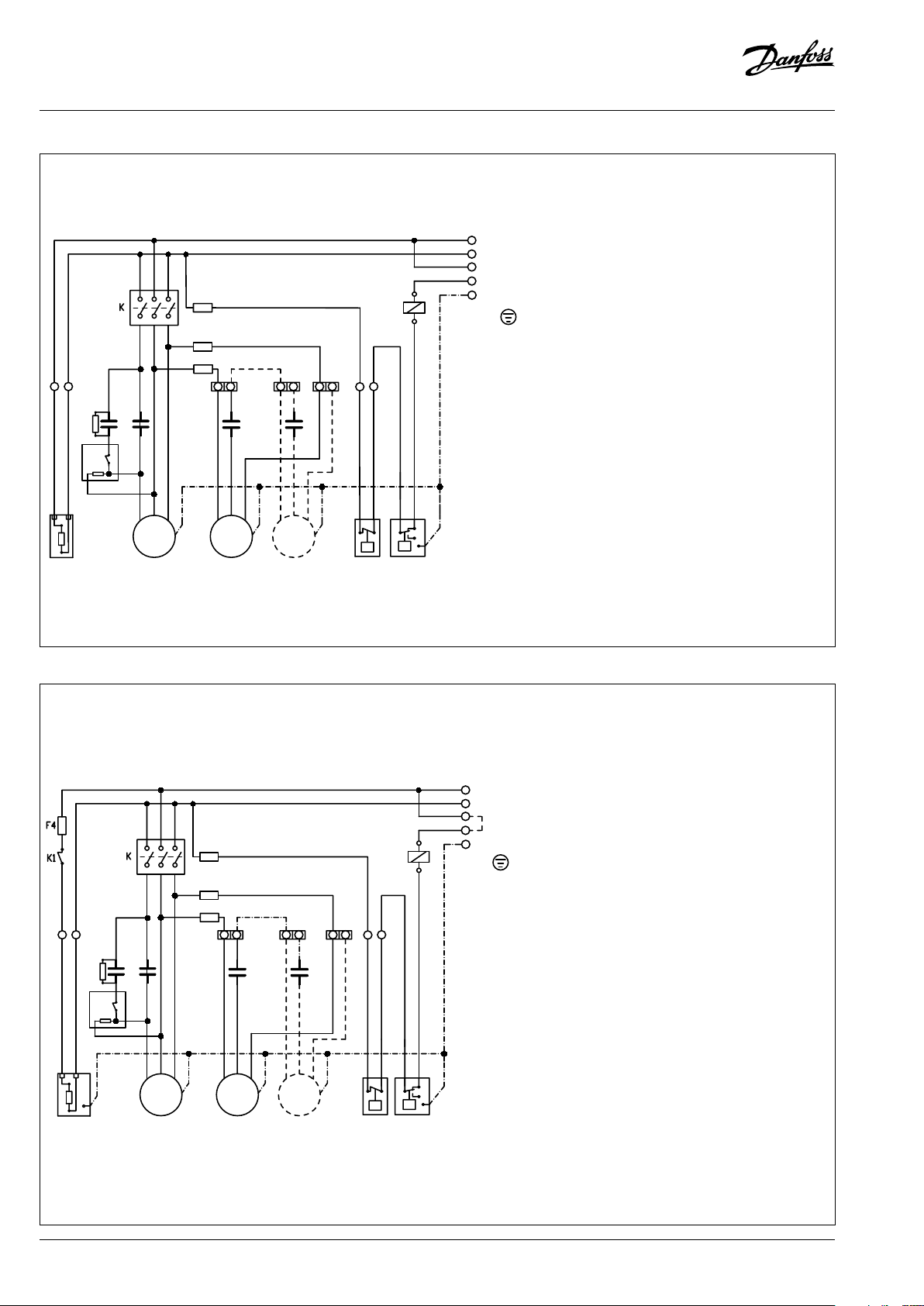

Code Q: HPMP, HPZP, LPZP

13

5

2 4

6

RC

CP

230V 3~50-60Hz

L1

L2

L3

1

F1

F2

F3

CV

CV

a1

K

a2

2

PE

CP -COMPRESSOR / COMPRESOR

CR - CAPACITOR MARCHA / RUN

CAPACITOR ARRANQUE / START

CS CV - CAPACITOR VENTILADOR / FAN

F -

FUSÍVEL / FUSIBLE / FUSE

K -CONTATOR / CONTACTOR

PH -

PRESSOSTATO ALTA

PRESOSTATO ALTA

PRESSURE SWITCH - HBP

PL -

PRESSOSTATO BAIXA

PRESOSTATO BAJA

PRESSURE SWITCH - LBP

RC -

RESISTÊNCIA CARTER

CALENTADOR CARTER

CRANKCASE HEATER

RL -RELE / RELAY

V -

4

1

2

P<

P<

PE

V1

V2

PH

PL

VENTILADOR / FAN

Code Q: HPUS, LPZS

PE

RC

13

2 4

CP

№3

230V 3~ 50-60Hz

F1

M2

S1

SFF

M1

S2

R1 - 1.8KOhm

V2

DEP 101B

CV

PH

5

6

LN

L2 L3

L1

F2

F3

CV

V1

a1

K

a2

4

1

2

P<

P<

PE

PL

L1

L2

L3

1

2

PE

COMPRESSOR / COMPRESOR

CP CR -CAPACITOR MARCHA / RUN

CAPACITOR ARRANQUE / START

CS CV -CAPACITOR VENTILADOR / FAN

F -

FUSÍVEL / FUSIBLE / FUSE

K -CONTATOR / CONTACTOR

PH -

PRESSOSTATO ALTA

PRESOSTATO ALTA

PRESSURE SWITCH - HBP

PL -

PRESSOSTATO BAIXA

PRESOSTATO BAJA

PRESSURE SWITCH - LBP

RC -

RESISTÊNCIA CARTER

CALENTADOR CARTER

CRANKCASE HEATER

RL -RELE / RELAY

V -

VENTILADOR / FAN

FRCC.PI.051.A1.03

№4

© Danfoss | DCS (CC) | 2017.02 | 7

Page 8

Danf

already on order pro

All trademarks in this material are property of the respec

Instructions

Code V: HPMP, HPZP, LPZP

13

5

2 4

6

RC

CP

380V 3~50-60Hz

L1

L2

L3

N

1

F1

a1

K

a2

2

PE

CP -COMPRESSOR / COMPRESOR

CR - CAPACITOR MARCHA / RUN

CAPACITOR ARRANQUE / START

CS CV - CAPACITOR VENTILADOR / FAN

F -

FUSÍVEL / FUSIBLE / FUSE

K -CONTATOR / CONTACTOR

PH -

PRESSOSTATO ALTA

PRESOSTATO ALTA

F2

PRESSURE SWITCH - HBP

PL -

PRESSOSTATO BAIXA

PRESOSTATO BAJA

CV

CV

PRESSURE SWITCH - LBP

RC -

RESISTÊNCIA CARTER

CALENTADOR CARTER

CRANKCASE HEATER

RL -RELE / RELAY

V -

VENTILADOR / FAN

4

1

2

P<

P<

PE

V1

V2

PH

PL

№5

Code V: HPUS, LPZS

PE

RC

13

2 4

CP

380V 3~ 50-60Hz

L1

L2

L3

N

1

F1

M2

SFF

S1

M1

S2

R1 - 1.8KOhm

DEP 101B

LN

5

L2 L3

L1

6

a1

K

a2

2

PE

COMPRESSOR / COMPRESOR

CP CR -CAPACITOR MARCHA / RUN

CAPACITOR ARRANQUE / START

CS CV -CAPACITOR VENTILADOR / FAN

F -

FUSÍVEL / FUSIBLE / FUSE

K -CONTATOR / CONTACTOR

PH -

PRESSOSTATO ALTA

PRESOSTATO ALTA

F2

CV

CV

PRESSURE SWITCH - HBP

PL -

PRESSOSTATO BAIXA

PRESOSTATO BAJA

PRESSURE SWITCH - LBP

RC -

RESISTÊNCIA CARTER

CALENTADOR CARTER

CRANKCASE HEATER

RL -RELE / RELAY

V -

VENTILADOR / FAN

4

1

2

P<

P<

PE

V1

V2

PH

PL

oss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

vided that such alterations can be made without subsequential changes being necessary eady agreed.

8 | © Danfoss | DCS (CC) | 2017.03

№6

tive companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

FRCC.PI.051.A1.02

Page 9

Instrucciones

Instrucciones - Optyma™ Slim Pack

OP-HPMP/HPZP/HPUS/LPZP/LPZS

A

B

C

D

A: Modelo.

B: Código.

C

:

Número de serie y código de barras.

D: Tensión de alimentación, intensidad a rotor

bloqueado (LRA)

E: Presión de servicio de la carcasa

F: Refrigerante

G: Aceite

E

F

G

H

I

J

H: Conexiones de entrada de cables.

I: Conexión de aspiración.

J: Conexión de la línea de líquido.

K: Intercambiador de calor de microcanales.

L

N

M

K

Ilustración 1: Distancias de montaje mínimas

L

[mm]

250 650 550 550

personal cualicado. Siga estas instrucciones

y las prácticas recomendadas en materia

de ingeniería de refrigeración durante las

actividades de instalación, puesta en servicio,

mantenimiento y servicio técnico.

M

[mm]

La instalación y el mantenimiento de

la unidad condensadora deben ser

llevados a cabo exclusivamente por

N

[mm]

O

O

[mm]

Ilustración 2

1 – Introducción

Estas instrucciones pertenecen a las unidades

condensadoras Optyma™ Slim Pack OP-LSHM/

MSUM/MSHM/MSGM (para refrigerantes R507A, R-404A, R-134a y R-22), diseñadas para

sistemas de refrigeración. Incluyen la información necesaria para garantizar la seguridad y el

uso correcto del producto.

Estas unidades condensadoras incluyen los siguientes componentes:

• Compresor scroll/alternativo.

• Intercambiador de calor de microcanales.

• Presostatos dobles.

• Válvulas de servicio (líneas de aspiración y líquido).

• Carcasa hermética.

• Filtro secador.

• Resistencia de cárter para el compresor.

• Recipiente con válvula de cierre.

• Visor de líquido.

• Relé de secuencia de fases (

• Panel eléctrico totalmente precableado (incluye interruptor principal, contactor para compresor y relé de sobrecarga).

2 – Manipulación y almacenamiento

• Se recomienda no abrir el embalaje hasta que

la unidad se encuentre en el lugar en el que se

vaya a proceder a su instalación.

• Manipule la unidad con cuidado. El embalaje

admite el uso de una carretilla elevadora o una

compresor scroll).

Ilustración 3

Ilustración 4

Tornillos de montaje

(no suministrados)

transpaleta para su manipulación. Use siempre

equipos de elevación adecuados y seguros.

• Almacene y transporte la unidad en posición

vertical.

• Almacene la unidad a temperaturas comprendidas entre -35 °C y 50 °C.

• No exponga el embalaje a la lluvia o a atmósferas de carácter corrosivo.

• Tras desembalar la unidad, compruebe que no

falte ningún componente y que no presente

daños.

3 – Medidas a adoptar de cara a la instalación

No realice ningún tipo de soldadura mientras

la unidad condensadora se encuentre presurizada.

No coloque nunca la unidad en una atmósfera de carácter inamable.

Coloque la unidad de forma que no obstruya

u obstaculice vías de paso, puertas, ventanas u

otros elementos similares.

• Aseúrese de que exista espacio suciente alre-

dedor de la unidad para permitir la circulación del

aire y la apertura

tración 1 para co

con respecto a las paredes.

• No instale la unidad en ubicaciones en las que

se vea expuesta a la luz solar directa a diario

durante períodos prolongados.

• No instale la unidad en atmósferas de carácter

de las puertas. Consulte la ilus-

nocer las distancias mínimas

El uso de la unidad condensadora sólo debe

llevarse a cabo para los nes para los que ha sido

diseñada y dentro de su campo de aplicación.

En cualquier circunstancia, han de cumplirse

los requisitos establecidos por la norma EN378

(o cualquier otro reglamento local vigente en

materia de seguridad).

Esta unidad condensadora se suministra con

gas nitrógeno a presión (1 bar) y, por lo tanto, no puede conectarse tal cual; consulte la

sección “Instalación” para obtener más información.

Manipule la unidad condensadora con precaución y en posición vertical (desviación

máxima respecto a la vertical: 15°).

agresivo o polvoriento.

• Disponga una supercie de cimentación horizontal (con una pendiente inferior a 3°), robusta y estable que sirva para soportar el peso del

conjunto de la unidad y eliminar las vibraciones e interferencias.

• La temperatura ambiente de la unidad no debe

superar los 50 °C durante el ciclo de apagado.

• Asegúrese de que la fuente de alimentación

sea compatible con los requisitos de la unidad

(consulte la placa de características).

• La instalación de unidades destinadas al uso

con refrigerantes HFC requiere del empleo de

equipos diseñados especícamente para tales

refrigerantes y que no hayan permanecido en

contacto con refrigerantes CFC o HCFC.

• Use tubos de cobre para refrigeración limpios y

deshidratados y aleaciones de plata como material de soldadura.

• Use componentes de sistema limpios y deshidratados.

• La tubería de aspiración conectada al compresor debe ser exible en las 3 dimensiones para

amortiguar las vibraciones. Además, la tubería

debe disponerse de tal forma que el retorno de

aceite hacia el compresor esté garantizado y

que el riesgo de que se

quido en el compresor se elimine.

4 – Instalación

• La instalación en la que se coloque la unidad

produzcan golpes de lí-

FRCC.PI.051.A1.05

© Danfoss | DCS (CC) | 2017.03 | 9

Page 10

Instrucciones

condensadora debe cumplir los requisitos de la

Directiva 97/23/CE de equipos a presión (DEP).

En sí, la unidad condensadora no tiene la consideración de “unidad” en el campo de aplicación

de dicha directiva.

• La unidad se debe instalar de forma segura en

un soporte estable y rígido al que se deberá jar desde un principio. Consulte la ilustración 2.

• Se recomienda instalar la unidad sobre

arandelas de caucho o elementos que amortigüen las vibraciones (no se incluyen entre

los componentes suministrados).

• Libere paulatinamente la carga de nitrógeno a

través del puerto Schraeder.

• Conecte la unidad al sistema lo antes posible

para evitar que el aceite sufra contaminación

como resultado de la humedad ambiental.

• Evite que penetren materiales extraños en el

sistema durante el corte de los tubos. No practique oricios en lugares en los que no sea posible

eliminar las rebabas.

• Lleve a cabo las soldaduras con cuidado, empleando técnicas modernas; purgue los conductos haciendo circular gas nitrógeno.

• Conecte los dispositivos de seguridad y control

necesarios. Retire la válvula interna cuando use

el puerto Schraeder a este efecto.

• Se recomienda aislar la tubería de aspiración

hasta la entrada del compresor empleando material aislante con un espesor de 19 mm.

5 – Detección de fugas

No presurice el circuito con oxígeno o aire

seco. Esto podría dar lugar a incendios o explosiones.

• No use tintes para la detección de fugas.

• Lleve a cabo una prueba de detección de fugas

en todo el sistema.

• La presión de prueba máxima es de 32 bar.

• Si detecta una fuga, repárela y lleve a cabo una

nueva prueba de detección de fugas.

6 – Deshidratación por vacío

• No use el compresor para vaciar el sistema.

• Conecte una bomba de vacío a los lados LP y

H P.

• Vacíe el sistema a una presión absoluta de 500

μm Hg (0,67 mbar).

•

No use un ohmímetro ni conecte la alimentación

al compresor mientras este se encuentre sometido a vacío; ello podría causar daños internos.

7 – Conexiones eléctricas

• Apague el sistema y aísle la fuente de alimenta-

ción principal.

• Asegúrese de que la fuente de alimentación no

pueda encenderse durante la instalación.

• La elección de los componentes eléctricos debe

llevarse a cabo de acuerdo con las normas locales

y los requisitos

• Consulte el esquema eléctrico para obtener más

información sobre las conexiones eléctricas.

• Compruebe que la fuente de alimentación sea

compatible con las características de la unidad

y que ofrezca un suministro estable (tensión nominal ±10 % y frecuencia nominal ±2,5 Hz).

• Calcule las dimensiones de los cables de la

fuente de alimentación en función de la tensión y la corriente de la unidad.

• Proteja la fuente de alimentación y asegúrese de

que disponga de una conexión a tierra adecuada.

• Conecte la fuente de alimentación de acuerdo

con las normas locales y los requisitos legales

vigentes.

• La unidad está equipada con presostatos de alta y

baja presión que interrumpen directamente el

suministro eléctrico del compresor al activarse.

Los parámetros de desconexión por alta y baja

presión deben ser ajustados por el instalador considerando el modelo del compresor, el refrigerante y la aplicación. Las unidades con compresores

MLZ y LLZ de Danfoss también están equipadas

con relé de secuencia de fases como medida de

protección contra la pérdida, el error de secuencia y la asimetría de fases, así como frente a efec-

tos de subtensión y sobretensión.

En el caso de las unidades con compresor scroll

trifásico, se deberá respetar la secuencia de fases

correcta a n de que el compresor gire en el sentido apropiado.

• Emplee un medidor de fases para establecer el

orden de las fases de línea (L1, L2 y L3).

• Conecte las fases de línea L1, L2 y L3 a los termi-

nales T1, T2 y T3 del interruptor principal, res-

pectivamente.

8 – Llenado del sistema

• Utilice los equipos de protección oportunos,

como gafas y guantes de seguridad.

•

No ponga en marcha el compresor en condicio-

nes de vacío. Mantenga el compresor apagado.

• Antes de cargar el refrigerante, compruebe que

el nivel de aceite se encuentre entre las marcas

10 | © Danfoss | DCS (CC) | 2017.03

de la unidad.

“¼” y “¾” del visor de aceite del compresor. Si es

necesario añadir aceite, consulte la etiqueta del

compresor para conocer el tipo de aceite que

debe emplearse.

• Utilice exclusivamente el refrigerante para el

que se haya diseñado la unidad.

• Llene el condensador o el recipiente de líquido

con refrigerante líquido. Asegúrese de que la

carga del sistema tenga lugar paulatinamente

hasta alcanzar una presión de 4-5 bar (en el

caso de los refrigerantes R-404A/R-507A y R-22)

o aprox. 2 bar (en el caso del refrigerante R134a).

• No introduzca refrigerante líquido a través de

la línea de aspiración.

• Se prohíbe la mezcla de aditivos con el aceite

y/o el refrigerante.

• L

a carga restante se efectuará hasta que la instalación alcance las condiciones de funcionamiento nominales y estas se mantengan estables.

• No deje la botella de carga conectada al circuito.

9 – Verificación previa a la puesta en servicio

Emplee dispositivos de seguridad (como presostatos de seguridad o válvulas mecánicas de

alivio) que satisfagan los requisitos de las normas de ámbito general y local vigentes, así como

las normas de seguridad aplicables. Asegúrese

de que los dispositivos funcionen y su ajuste sea

correcto.

Compruebe que los niveles de los presostatos de alta presión y las válvulas de alivio no superen la pre

ponentes del sistema.

• Compruebe que todas las conexiones eléctri-

cas se encuentren bien jadas y cumplan las

normas locales.

•

Si es preciso el uso de una resistencia de cárter,

esta deberá energizarse, al menos, 12horas antes

de la puesta en marcha inicial y cualquier puesta

en marcha que ten

longado de inactividad.

10 – Arranque

• No arranque la unidad sin haber cargado antes

el refrigerante.

• Todas las válvulas de servicio deben estar en

posición de apertura. Consulte la ilustración 3.

• Compruebe que la unidad y la fuente de ali-

mentación sean compatibles.

• Compruebe que la resistencia de cárter se en-

cuentre en funcionamiento.

• Compruebe que el ventilador pueda girar libre-

mente.

•

Compruebe que se haya retirado la chapa de protección de la parte posterior del condensador.

• Equilibre las presiones de los lados HP y LP.

• Ponga en marcha la unidad. Debe arrancar de

inmediato. Si el compresor no se pone en marcha, compruebe que los cables sean adecuados, así como la tensión en los terminales y la

secuencia de fases.

• El giro en sentido inverso de un compresor tri-

fásico se puede detectar a través de los siguientes síntomas: la unidad no se pone en marcha,

no se acumula presión en el compresor, el nivel

de ruido es anormalmente alto o el consumo

de potencia es anormalmente bajo. Si detecta

alguno de dichos síntomas, detenga la unidad

de manera inmediata y conecte correctamente

las fases a sus terminales correspondientes.

• Si la dirección de rotación es correcta, el manó-

metro de baja presión deberá indicar una disminución de la presión y el manómetro de alta

presión deberá indicar un aumento de presión.

11 – Comprobaciones con la unidad en funcionamiento

• Compruebe el sentido de giro del ventilador.

Debe circular aire desde el condensador hacia el

ventilador.

• Compruebe el consumo de corriente y la ten-

sión.

• Compruebe el recalentamiento en el lado de

aspiración para reducir el riesgo de generación

de golpes de líquido.

• Si la unidad incorpora un visor de líquido, con-

trole el nivel de aceite durante la puesta en

marcha y el funcionamiento para conrmar

que permanece dentro del rango visible.

• Respete los límites de funcionamiento.

• Compruebe si los tubos sufren alguna vibración

anormal.

exigirán la implantación de medidas correctoras (como la instalación de abrazaderas).

• Si es necesario, se puede agregar refrigerante

líquido a través del lado de baja presión (tan

lejos del compresor como sea posible). El compresor debe permanecer en funcionamiento

durante este proceso.

• No sobrecargue el sistema.

• No libere refrigerante a la atmósfera.

•

Antes de abandonar el lugar de instalación, lleve

sión de servicio máxima de los com-

ga lugar tras un período pro-

Los movimientos superiores a 1,5 mm

a cabo una inspección general de la misma en

cuanto a limpieza, ruido y detección de fugas.

• Anote el tipo y la cantidad de refrigerante cargado, así como las condiciones de funcionamiento, como referencia para la ejecución de

futuras inspecciones.

12 – Mantenimiento

Desconecte siempre la unidad utilizando el

inte

rruptor principal antes de desmontar el panel del

ventilador.

Las presiones internas y las temperaturas superciales de la unidad son peligrosas y pueden

dar lugar a lesiones permanentes.

Los técnicos de mantenimiento y los instaladores deben disponer de la formación y las herramientas apropiadas. La temperatura de los tubos puede superar los 100 °C, como resultado de

lo cual podrían producirse quemaduras de carácter grave.

Asegúrese de que se realicen las inspecciones

de servicio periódicas necesarias para garantizar

la abilidad del sistema, de acuerdo con lo dispuesto en la legislación local vigente.

Para evitar que se produzcan problemas en el

sistema, se recomienda

llevar a cabo periódicamente las siguientes operaciones de mantenimiento:

• Comprobar que los dispositivos de seguridad

funcionen y su ajuste sea correcto.

• Garantizar la ausencia de fugas en el sistema.

• Comprobar el consumo de corriente del com-

presor.

• Conrmar que el sistema funcione de modo

coherente con los registros de mantenimiento

anteriores y las condiciones ambientales.

• Comprobar que todas las conexiones eléctricas

se encuentren correctamente jadas.

• Mantener limpia la unidad y comprobar la au-

sencia de óxido y herrumbre en los componentes, los tubos y las conexiones eléctricas de la

misma.

El condensador se debe revisar al menos una vez

al año para detectar posibles obstrucciones y

proceder a su limpieza, si es necesario. Se puede

acceder a la parte interna del condensador a través del panel del ventilador. La suciedad tiende a

acumularse en la supercie de los serpentines

de los microcanales en lugar de en su interior, lo

que facilita su limpieza en comparación con los

serpentines de tubo y aletas.

• Desconecte la unidad condensadora utilizando

el interruptor principal antes de desmontar

cualquier panel de la misma.

• Elimine la suciedad, las hojas, las bras, etc., de

las supercies empleando una aspiradora a la

que se haya acoplado un cepillo u otro acceso-

rio suave. También puede realizar un soplado

con aire comprimido a través del serpentín

(desde su parte interior hacia su parte exterior)

y cepillarlo con un cepillo de cerdas blandas.

No use cepillos de alambre. No golpee ni raye

el serpentín con el tubo de vacío o la boquilla

de aire.

Si se ha abierto el sistema de refrigerante, este

deberá recorrerse con aire seco o nitrógeno para

eliminar la humedad; asimismo, se deberá instalarun nuevo ltro secador. Si es necesario evacuar el refri

lizar de manera que

pueda escapar a la atmósfera.

13 – Garantía

En cualquier reclamación que presente al respecto de este producto, indique siempre el número de modelo y el número de serie.

La garantía del producto puede quedar anulada

por los siguientes motivos:

• Ausencia de placa de características.

• Modicaciones externas; en particular, perfora-

ciones, soldaduras, patas rotas y marcas de im-

pactos.

• Apertura del compresor o devolución del mis-

mo sin los precintos correspondientes.

• Presencia de óxido, agua o tinte de detección

de fugas en el interior del compresor.

• Uso de un refrigerante o lubricante no homolo-

gado por Danfoss.

• Cualquier divergencia en relación con las ins-

trucciones recomendadas para su instalación,

aplicación o mantenimiento.

• Uso como parte de aplicaciones móviles.

• Uso en atmósferas de carácter explosivo.

• Omisión del número de modelo o el número de

serie en la reclamación bajo garantía.

14 – Eliminación

gerante, esta operación se deberá rea-

Danfoss recomienda que las unidades

condensadoras y el aceite empleado

para su funcionamiento sean reciclados

por una empresa gestora autorizada y

en sus instalaciones.

ninguna fracción de aquel

FRCC.PI.051.A1.05

Page 11

Instrucciones

Code N: HPMP, HPZP, LPZP

RC

230V 1~50-60Hz

L1

L2

1

13

5

F1

2 4

6

F2

F3

CR

CS

RL

1

2

5

CV

CV

a1

K

a2

2

PE

CP -COMPRESSOR / COMPRESOR

CR -CAPACITOR MARCHA / RUN

CAPACITOR ARRANQUE / START

CS CV -CAPACITOR VENTILADOR / FAN

F -

FUSÍVEL / FUSIBLE / FUSE

K -CONTATOR / CONTACTOR

PH -

PRESSOSTATO ALTA

PRESOSTATO ALTA

PRESSURE SWITCH - HBP

PL -

PRESSOSTATO BAIXA

PRESOSTATO BAJA

PRESSURE SWITCH - LBP

RC -

RESISTÊNCIA CARTER

CALENTADOR CARTER

CRANKCASE HEATER

RL - RELE / RELAY

V -

VENTILADOR / FAN

R

S

P<

CP

V1

V2

PH

4

1

2

P<

PE

PL

№1

Code N: HPUS

CS

RL

5

PE

RC

CR

13

2 4

230V 1~ 50-60Hz

L1

L2

1

5

F1

6

F2

F3

CV

CV

a1

K

a2

2

PE

COMPRESSOR / COMPRESOR

CP CR -CAPACITOR MARCHA / RUN

CAPACITOR ARRANQUE / START

CS CV -CAPACITOR VENTILADOR / FAN

F -

FUSÍVEL / FUSIBLE / FUSE

K -CONTATOR / CONTACTOR

PH -

PRESSOSTATO ALTA

PRESOSTATO ALTA

PRESSURE SWITCH - HBP

PL -

PRESSOSTATO BAIXA

PRESOSTATO BAJA

PRESSURE SWITCH - LBP

RC -

1

2

RESISTÊNCIA CARTER

CALENTADOR CARTER

CRANKCASE HEATER

RL - RELE / RELAY

V -

VENTILADOR / FAN

C

S

R

CP

V1

V2

PH

4

1

2

P<

P<

PE

PL

FRCC.PI.051.A1.05

№2

© Danfoss | DCS (CC) | 2017.03 | 11

Page 12

Instrucciones

Code Q: HPMP, HPZP, LPZP

13

5

2 4

6

RC

CP

230V 3~50-60Hz

L1

L2

L3

1

F1

F2

F3

CV

CV

a1

K

a2

2

PE

CP -COMPRESSOR / COMPRESOR

CR - CAPACITOR MARCHA / RUN

CAPACITOR ARRANQUE / START

CS CV - CAPACITOR VENTILADOR / FAN

F -

FUSÍVEL / FUSIBLE / FUSE

K -CONTATOR / CONTACTOR

PH -

PRESSOSTATO ALTA

PRESOSTATO ALTA

PRESSURE SWITCH - HBP

PL -

PRESSOSTATO BAIXA

PRESOSTATO BAJA

PRESSURE SWITCH - LBP

RC -

RESISTÊNCIA CARTER

CALENTADOR CARTER

CRANKCASE HEATER

RL -RELE / RELAY

V -

4

1

2

P<

P<

PE

V1

V2

PH

PL

VENTILADOR / FAN

Code Q: HPUS, LPZS

PE

RC

13

2 4

CP

№3

230V 3~ 50-60Hz

F1

M2

S1

SFF

M1

S2

R1 - 1.8KOhm

V2

DEP 101B

CV

PH

5

6

LN

L2 L3

L1

F2

F3

CV

V1

a1

K

a2

4

1

2

P<

P<

PE

PL

L1

L2

L3

1

2

PE

COMPRESSOR / COMPRESOR

CP CR -CAPACITOR MARCHA / RUN

CAPACITOR ARRANQUE / START

CS CV -CAPACITOR VENTILADOR / FAN

F -

FUSÍVEL / FUSIBLE / FUSE

K -CONTATOR / CONTACTOR

PH -

PRESSOSTATO ALTA

PRESOSTATO ALTA

PRESSURE SWITCH - HBP

PL -

PRESSOSTATO BAIXA

PRESOSTATO BAJA

PRESSURE SWITCH - LBP

RC -

RESISTÊNCIA CARTER

CALENTADOR CARTER

CRANKCASE HEATER

RL -RELE / RELAY

V -

VENTILADOR / FAN

12 | © Danfoss | DCS (CC) | 2017.03

№4

FRCC.PI.051.A1.05

Page 13

Instrucciones

Code V: HPMP, HPZP, LPZP

13

5

2 4

6

RC

CP

380V 3~50-60Hz

L1

L2

L3

N

1

F1

a1

K

a2

2

PE

CP -COMPRESSOR / COMPRESOR

CR - CAPACITOR MARCHA / RUN

CAPACITOR ARRANQUE / START

CS CV - CAPACITOR VENTILADOR / FAN

F -

FUSÍVEL / FUSIBLE / FUSE

K -CONTATOR / CONTACTOR

PH -

PRESSOSTATO ALTA

PRESOSTATO ALTA

F2

PRESSURE SWITCH - HBP

PL -

PRESSOSTATO BAIXA

PRESOSTATO BAJA

CV

CV

PRESSURE SWITCH - LBP

RC -

RESISTÊNCIA CARTER

CALENTADOR CARTER

CRANKCASE HEATER

RL -RELE / RELAY

V -

VENTILADOR / FAN

4

1

2

P<

P<

PE

V1

V2

PH

PL

№5

Code V: HPUS, LPZS

PE

RC

13

2 4

CP

380V 3~ 50-60Hz

L1

L2

L3

N

1

F1

M2

SFF

S1

M1

S2

R1 - 1.8KOhm

DEP 101B

LN

5

L2 L3

L1

6

a1

K

a2

2

PE

COMPRESSOR / COMPRESOR

CP CR -CAPACITOR MARCHA / RUN

CAPACITOR ARRANQUE / START

CS CV -CAPACITOR VENTILADOR / FAN

F -

FUSÍVEL / FUSIBLE / FUSE

K -CONTATOR / CONTACTOR

PH -

PRESSOSTATO ALTA

PRESOSTATO ALTA

F2

CV

CV

PRESSURE SWITCH - HBP

PL -

PRESSOSTATO BAIXA

PRESOSTATO BAJA

PRESSURE SWITCH - LBP

RC -

RESISTÊNCIA CARTER

CALENTADOR CARTER

CRANKCASE HEATER

RL -RELE / RELAY

V -

VENTILADOR / FAN

4

1

2

P<

P<

PE

V1

V2

PH

PL

FRCC.PI.051.A1.05

№6

© Danfoss | DCS (CC) | 2017.03 | 13

Page 14

Instruções

Instruções - Optyma™ Slim Pack

OP-HPMP/HPZP/HPUS/LPZP/LPZS

A

B

C

D

A: Modelo

B: Código

C: Número de série e código de barras

D: Tensão de alimentação, amperagem do rotor

bloqueado, consumo máximo de corrente

E: Condições de teste

F: Refrigerante

G: Óleo lubricante

E

F

G

H

I

J

H: Entradas de cabos

I: Linha de sucção

J: Linha de líquido

K: Trocador de calor microcanal

L

N

M

K

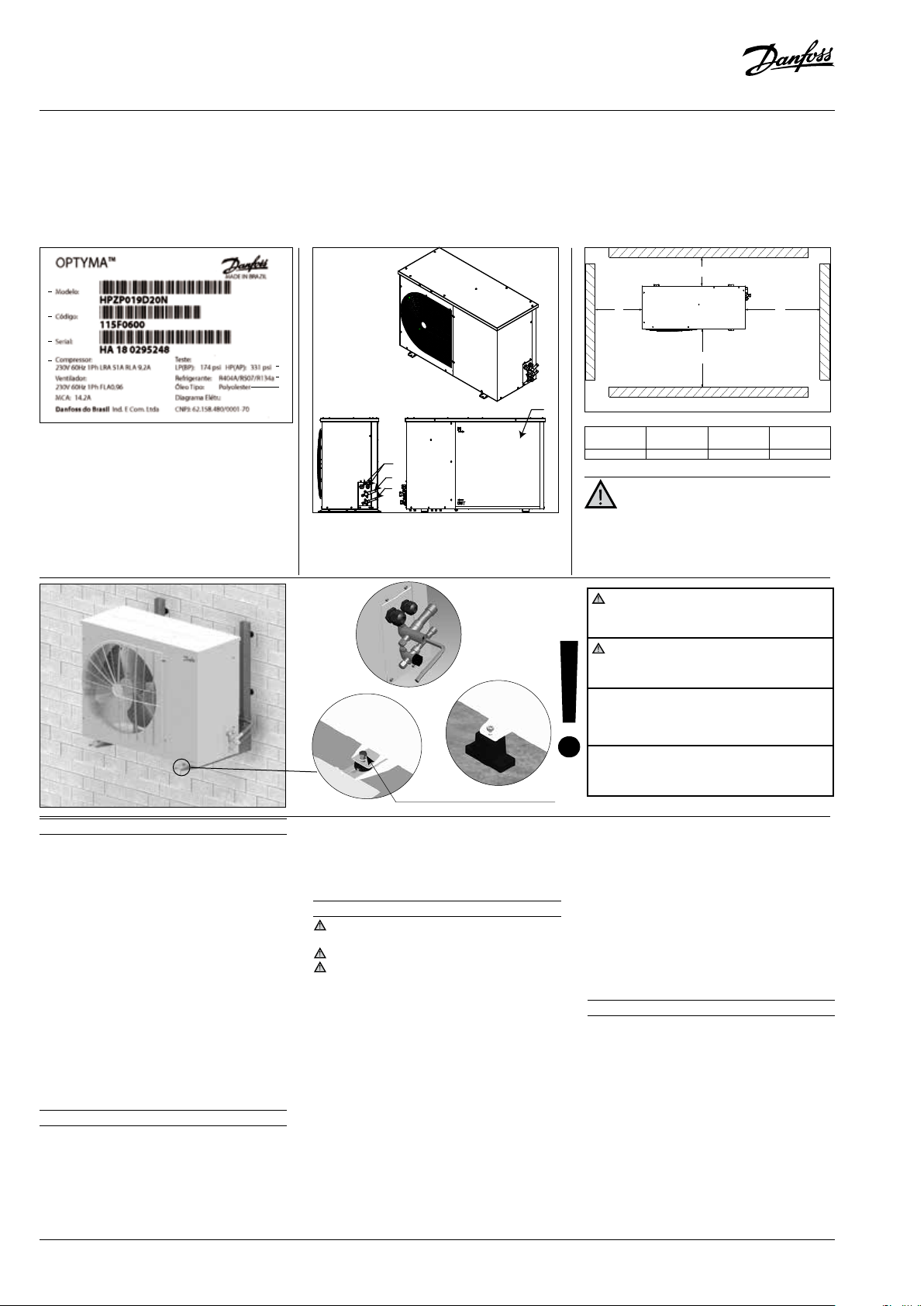

Figura 1 : Distâncias mínimas de montagem

L

[mm]

250 650 550 550

Instalação e manutenção das unidades

condensadoras apenas por pessoal

qualicado. Siga estas instruções e as melhores

práticas da engenharia de refrigeração quanto

à instalação, comissionamento, manutenção e

serviço.

M

[mm]

N

[mm]

O

O

[mm]

Figura 2

1 – Introdução

Estas instruções dizem respeito às unidades

Optyma™ Slim Pack OP-HPMP, HPZP, HPUS, LPZP,

LPZS (R507A, R404A, R134a, R22 utilizadas para

sistemas de refrigeração, e fornecem a

informação necessária relativa à segurança e à

utilização correta deste produto.

A unidade condensadora inclui os seguintes

itens:

• Compressor scroll/recíproco

• Trocador de calor microcanal

• Pressostato de baixa ajustável

• Pressostato de alta tipo cartucho

• Válvula de serviço nas linhas de sucção/líquido

• Carenagem para instalação em área externa

• Filtro secador

• Resistência de cárter para compressor

•Tanque de líquido com válvula de bloqueio

• Visor de óleo

• Relé de sequência de fases (

• Painel elétrico totalmente pré-cabeado (contator)

2 – Manuseio e armazenamento

• Recomenda-se não abrir a embalagem até que ela

esteja no local de montagem.

• Manuseie a unidade com cuidado. A embalagem

permite uso de empilhadeira

equipamento de elevação seguro e adequado.

• Armazene e transporte a unidade na posição

vertical.

• Armazene a unidade entre -35 °C e +50 °C.

compressor scroll)

ou paleteira. Utilize

Figura 3

Figura 5: esquema para

instalação em parede

Parafusos de montagem (não fornecidos)

• Não exponha a embalagem à chuva ou a uma

atmosfera corrosiva.

• Após desembalar, certique-se de que a unidade

esteja completa

3 – Medidas de segurança antes da montagem

Não solde a unidade condensadora enquanto

ela estiver pressurizada.

Nunca instale a unidade em atmosferas

inamáveis.

Instale a unidade de modo que esta não bloqueie

nem atrapalhe áreas de passagem, portas, janelas e

ans

.

• Certique-se de que haja espaço suciente ao

redor da unidade para circulação de ar e

abertura de portas. Consulte a Figura 1 para

conhecer os valores mínimos da distância em

relação às paredes.

• Evite instalar a unidade em locais que estejam

diariamente expostos à luz solar durante longos

períodos

• Evite instalar a unidade em ambientes agressivos

ou sujeitos a excesso de poeira

• Certique-se de que a unidade seja instalada em

uma superfície horizontal (com menos de 3º de

inclinação) sucientemente forte e estável para

suportar todo o peso da unidade e para eliminar

vibrações e interferências

• A temperatura ambiente da unidade não deverá

ultrapassar 50ºC nos momentos em que estiver

desligada ou em repouso.

• Certique-se de que a fonte de alimentação

e intacta.

Figura 4 : esquema para

instalação no chão.

.

.

A unidade condensadora apenas deverá

ser utilizada para o(s) m(ns) previsto(s) e

dentro do seu âmbito de aplicação.

Em qualquer circunstância, os requisitos EN378

(ou outros regulamentos locais de segurança

aplicáveis) terão de ser cumpridos.

A unidade condensadora é entregue sob pressão

de gás nitrogênio (1 bar) e como tal não pode ser

ligada tal como está; consulte a seção

“Montagem” para obter mais detalhes.

A unidade condensadora deve ser manuseada

com cuidado na posição vertical (desvio

máximo da posição vertical: 15°)

corresponda às características da unidade

(consulte a placa de identicação).

• Ao instalar unidades para uso com refrigerantes

HFC, utilize equipamentos especialmente

reservados para este m, que nunca tenham sido

utilizados para refrigerantes CFC ou HCFC.

• Utilize tubos de cobre especícos para

refrigeração, limpos e desidratados, e material

de solda em liga de prata.

• Utilize componentes de sistema limpos e

desidratados.

• Os tubos de sucção conectados ao compressor

devem ser exíveis nas 3 dimensões para amortecer

as vibrações. Além disso, elas devem ser dispostas

de modo a garantir o retorno adequado do óleo ao

compressor e eliminar o risco de golpe de líquido

no compressor.

4 – Instalação

• A unidade deve ser instalada rmemente em

um suporte rígido e estável e deve estar xa

desde o início. Ver Figura 2

• Recomenda-se instalar a unidade sobre

calços de borracha ou amortecedores de

vibrações (não fornecidos).

• Libere lentamente o nitrogênio mantendo-se a

carga na respectiva válvula Schrader.

• Conecte a unidade ao sistema o mais rápido

possível, evitando contaminação da carga de

óleo pela umidade ambiente.

• Evite a entrada de material durante o corte de

tubos no sistema. Nunca faça perfurações em

14 | © Danfoss | DCS (CC) | 2017.03

FRCC.PI.051.A1.28

Page 15

Instruções

locais onde as rebarbas não possam ser

removidas.

• Solde com extremo cuidado, usando técnicas

avançadas e circulação com uxo de gás

nitrogênio.

• Conecte os dispositivos de controle e

segurança necessários. Em casos de utilização

da válvula Schrader para estes ns, retire

válvula interna.

• Recomenda-se o isolamento térmico da

tubulação de sucção até a entrada do

compressor com isolamento de 19 mm de

espessura.

5 – Detecção de vazamentos

Nunca pressurize o circuito com oxigénio ou

ar seco. Isto poderá provocar fogo ou explosão.

• Não utilize corantes para detecção de

vazamentos.

• Faça um teste de detecção de vazamentos em

todo o sistema.

• A pressão máxima de teste deve ser de 32 bar

(464 psi).

• Em caso de vazamento, faça o reparo e repita o

teste de detecção de vazamentos em todo o

circuito.

6 – Desidratação de vácuo

• Nunca utilize o compressor para dar vácuo no

sistema.

• Ligue uma bomba de vácuo simultaneamente

nos lados de baixa e de alta pressão.

• Alcance um vácuo estabilizado de 500 μm Hg (0,67

mbar)

.

• Não utilize um megômetro nem acione o

compressor enquanto este se encontrar sob vácuo,

pois isso poderá provocar danos internos.

7 – Conexões elétricas

• Desligue e isole a fonte de energia principal.

• Certique-se de que a fonte de energia não

possa ser ligada acidentalmente durante a

instalação.

• Todos os componentes elétricos devem ser

selecionados segundo os padrões e normas

locais e os requisitos do compressor.

• Consulte o diagrama elétrico para saber detalhes

das conexões elétricas

• Certique-se de que a fonte de alimentação

corresponde às características da unidade e de

que esteja estável (tensão nominal ±10% e

frequência nominal ±2,5 Hz).

• Dimensione os cabos de energia segundo os

dados de corrente e tensão da unidade

• Proteja a alimentação de energia e garanta um

aterramento correto

• Instale o ponto de alimentação de acordo com

os padrões e normas locais.

• A unidade está equipada com pressostatos de alta

e de baixa, que cortam diretamente a energia

fornecida ao compressor caso um destes seja

ativado. Os parâmetros de desarme de pressão alta e

baixa devem ser ajustados pelo instalador

considerando modelo, uido refrigerante e

aplicação. Unidades com compressores Danfoss

MLZ e LLZ também são equipadas com relé de fase

para proteger a unidade contra perda de fase/

sequência/assimetria e sub/sobretensão. Para

unidades com compressor scroll trifásico, deve ser

observada a sequência de fases correta do sentido

de rotação do compressor

• Determine a sequência de fases usando um

medidor de fase para estabelecer as ordens de

fase das fases de linha L1, L2 e L3

• Ligue as fases de linha L1, L2 e L3 aos terminais

principais T1, T2 e T3 respectivamente.

8 – Carga do sistema

• Utilize equipamento de proteção (EPIs) como

óculos e luvas protetoras

• Nunca ligue o compressor sob vácuo.

Mantenha o compressor desligado.

• Antes de carregar o sistema com refrigerante,

verique se o nível do óleo está entre ¼ e ¾ no

visor de óleo do compressor. Se for necessário

mais óleo, consulte a etiqueta do compressor

para saber qual o tipo de óleo correto.

• Utilize apenas o refrigerante para o qual a

unidade foi projetada.

• Carregue com refrigerante no estado líquido

pelo condensador ou no tanque de líquido.

Certique-se de carregar lentamente o sistema

até alcançar 4 a 5 bar para R404A/R507A ou R22

e até aproximadamente 2 bar para R134a.

.

.

.

.

.

.

• Não carregue refrigerante líquido através da

linha de sucção.

• Não é permitido misturar aditivos com o óleo e/

ou com o refrigerante.

• A carga remanescente deve ser dada até a

instalação ter atingido um nível de condições

nominais estáveis durante a operação

• Nunca deixe o cilindro de carga conectado ao

circuito.

9 – Verificação antes do start-up

Utilize dispositivos de segurança, tais como

pressostatos ou válvulas de alívio, em conformidade

com a legislação local e normas de segurança.

Certique-se de que eles estejam adequadamente

regulados e funcionando normalmente

Assegure-se de que as regulagens dos

pressostatos de alta e das válvulas de alívio não

excedam à pressão máxima de funcionamento

de nenhum dos componentes do sistema.

• Certique-se de que todas as conexões

elétricas estejam adequadamente apertadas e

em conformidade com as normas locais.

• Em caso de resistência do cárter, esta deverá

ser ligada pelo menos 12 horas antes da partida

inicial e após um longo período de parada do

equipamento.

10 – Start-up

• Nunca ligue a unidade sem a carga de uido

refrigerante.

• Todas as válvulas de serviço deverão estar na

posição aberta. Ver Figura 3.

• Certique-se de que a tensão e a frequência da

unidade correspondam à da fonte de energia.

• Verique se a resistência do cárter está

funcionando.

• Verique se o ventilador pode rodar livremente.

• Verique se chapa protetora foi removida da

parte traseira do condensador.

• Equalize os lados de alta e de baixa pressão.

• Energize a unidade. Seu funcionamento deve

se iniciar imediatamente. Em caso negativo,

verique as ações, a tensão nos terminais e a

fase de sequência.

• A eventual rotação inversa de um compressor

trifásico pode ser detectada pelos seguintes

fenômenos; a unidade não inicia, o compressor

não gera pressão, apresenta nível de ruído mais

alto e consumo de energia mais baixo do que os

normais. Neste caso, desligue o aparelho

imediatamente e conecte as fases nos respectivos

terminais

.

• Se o sentido de rotação estiver correto, a

indicação de baixa pressão no manômetro

mostrará uma diminuição da pressão e a

indicação de alta pressão mostrará uma pressão

em elevação.

11 – Verificações com a unidade em

funcionamento

• Verique o sentido de rotação do ventilador. O

ar deve uir do condensador para o ventilador.

• Verique a corrente absorvida e a tensão

elétrica.

• Verique o superaquecimento na sucção para

reduzir o risco de golpe de líquido.

• Observe o nível do óleo no início e durante a

operação, garantindo que ele se mantenha

visível.

• Respeite os limites operacionais.

• Verique se existem vibrações anormais.

Vibrações superiores a 1,5 mm necessitam de

medidas corretivas, tais como braçadeiras nas

tubulações.

• Quando necessário, pode-se adicionar uma

carga complementar de uido refrigerante no

lado de baixa pressão, o mais longe possível do

compressor, que deve estar em funcionamento

durante o processo.

• Não dê sobrecarga de refrigerante no sistema.

• Nunca libere uido refrigerante para a

atmosfera.

• Antes de deixar o local da instalação, faça uma

inspeção geral da instalação no que diz respeito

à limpeza, ruído e detecção de vazamentos

• Registre o tipo e a quantidade de carga de uido

refrigerante, bem como as condições de

funcionamento para servir de referência para

inspeções futuras

12 – Manutenção

Desligue sempre a unidade no interruptor

principal, antes de manusear o painel do

.

.

.

.

ventilador.

A pressão interna e a temperatura da

superfície são perigosas e podem provocar

lesões permanentes. Os operadores de

manutenção e os instaladores devem ter as

habilidades e ferramentas necessárias. A

temperatura da tubulação pode exceder os

100ºC e provocar queimaduras graves.

Certique-se de que sejam executadas

inspeções de manutenção periódicas de acordo

com as normas locais, para garantir a

conabilidade do sistema.

Para evitar problemas relacionados com o

sistema, são recomendadas as seguintes

manutenções periódicas:

• Verique se os dispositivos de segurança estão

devidamente regulados e funcionando.

• Certique-se de que não haja vazamentos no

sistema.

• Verique a corrente absorvida do compressor.

• Conrme se o sistema está funcionando de uma

forma consistente com os registros de manutenção

e condições ambientais anteriores.

• Verique se todas as conexões elétricas ainda se

encontram devidamente apertadas.

• Mantenha a unidade limpa e verique se há

presença de ferrugem e oxidação em seus

componentes, nas tubulações e nas conexões

elétricas

.

O condensador deve ser vericado pelo menos

uma vez por ano quanto à sujeira e deve ser

limpo sempre que necessário. O acesso ao lado

interno do condensador é feito pelo painel do

ventilador. O condensador microcanal tende a

acumular sujeira na superfície e não em seu

interior, o que o torna mais fácil de limpar em

comparação aos condensadores do tipo tuboaleta.

• Desligue a unidade no disjuntor principal antes

de remover qualquer parte da unidade

condensadora.

• Remova da superfície qualquer resíduo de

sujeira, folhas, bras, etc. com o auxílio de um

aspirador equipado com escova ou outro

acessório do gênero. Alternativamente, pode-se

espirrar ar comprimido de dentro para fora do

condensador e escová-lo com uma escova suave.

Não utilize escova metálica. Não provoque atrito

nem arranhe o condensador com a mangueira e

nem com o bocal do aspirador.

Caso o sistema tenha sido aberto, deve-se injetar

nitrogênio para remover a umidade e um novo

ltro secador deve ser instalado. Caso seja

necessário dar vácuo no sistema, isso deve ser feito

de forma que não escape refrigerante para o

ambiente.

13 - Garantia

Indique sempre o modelo e o número de série do

produto em casos de reclamação de garantia.

A garantia do produto poderá ser anulada nos

seguintes casos:

• Ausência da etiqueta indicativa do número de

série e modelo do produto.

• Modicações externas, tais como perfurações,

soldas, pés partidos e marcas de choques.

• Compressor aberto ou devolvido com o selo

violado.

• Presença de oxidação, água, corante de

detecção de vazamentos no interior do

compressor.

• Utilização de um refrigerante ou óleo

lubricante não aprovado pela Danfoss.

• Não cumprimento de qualquer recomendação

de instalação, manutenção e operação da

unidade.

• Utilização em aplicações móveis.

• Utilização em áreas classicadas (atmosferas

explosivas).

• Ausência de indicação do número de modelo ou

número de série na reclamação de garantia.

14 – Descarte de resíduos

A Danfoss recomenda que as partes e

peças da unidade condensadora, assim

como o óleo do compressor sejam

reciclados por empresas especializadas

em suas instalações.

FRCC.PI.051.A1.28

© Danfoss | DCS (CC) | 2017.03 | 15

Page 16

Instruções

Code N: HPMP, HPZP, LPZP

RC

230V 1~50-60Hz

L1

L2

1

13

5

2 4

CR

CS

RL

1

2

5

F1

6

F2

F3

CV

CV

a1

K

a2

2

PE

CP -COMPRESSOR / COMPRESOR

CR -CAPACITOR MARCHA / RUN

CAPACITOR ARRANQUE / START

CS CV -CAPACITOR VENTILADOR / FAN

F -

FUSÍVEL / FUSIBLE / FUSE

K -CONTATOR / CONTACTOR

PH -

PRESSOSTATO ALTA

PRESOSTATO ALTA

PRESSURE SWITCH - HBP

PL -

PRESSOSTATO BAIXA

PRESOSTATO BAJA

PRESSURE SWITCH - LBP

RC -

RESISTÊNCIA CARTER

CALENTADOR CARTER

CRANKCASE HEATER

RL - RELE / RELAY

V -

VENTILADOR / FAN

R

S

P<

CP

V1

V2

PH

4

1

2

P<

PE

PL

№1

Code N: HPUS

CS

RL

5

PE

RC

CR

13

2 4

230V 1~ 50-60Hz

L1

L2

1

5

F1

6

F2

F3

CV

CV

a1

K

a2

2

PE

COMPRESSOR / COMPRESOR

CP CR -CAPACITOR MARCHA / RUN

CAPACITOR ARRANQUE / START

CS CV -CAPACITOR VENTILADOR / FAN

F -

FUSÍVEL / FUSIBLE / FUSE

K -CONTATOR / CONTACTOR

PH -

PRESSOSTATO ALTA

PRESOSTATO ALTA

PRESSURE SWITCH - HBP

PL -

PRESSOSTATO BAIXA

PRESOSTATO BAJA

PRESSURE SWITCH - LBP

RC -

1

2

RESISTÊNCIA CARTER

CALENTADOR CARTER

CRANKCASE HEATER

RL - RELE / RELAY

V -

VENTILADOR / FAN

C

S

R

CP

V1

V2

PH

4

1

2

P<

P<

PE

PL

16 | © Danfoss | DCS (CC) | 2017.03

№2

FRCC.PI.051.A1.28

Page 17

Instruções

Code Q: HPMP, HPZP, LPZP

13

5

2 4

6

RC

CP

230V 3~50-60Hz

L1

L2

L3

1

F1

F2

F3

CV

CV

a1

K

a2

2

PE

CP -COMPRESSOR / COMPRESOR

CR - CAPACITOR MARCHA / RUN

CAPACITOR ARRANQUE / START

CS CV - CAPACITOR VENTILADOR / FAN

F -

FUSÍVEL / FUSIBLE / FUSE

K -CONTATOR / CONTACTOR

PH -

PRESSOSTATO ALTA

PRESOSTATO ALTA

PRESSURE SWITCH - HBP

PL -

PRESSOSTATO BAIXA

PRESOSTATO BAJA

PRESSURE SWITCH - LBP

RC -

RESISTÊNCIA CARTER

CALENTADOR CARTER

CRANKCASE HEATER

RL -RELE / RELAY

V -

4

1

2

P<

P<

PE

V1

V2

PH

PL

VENTILADOR / FAN

Code Q: HPUS, LPZS

PE

RC

13

2 4

CP

№3

230V 3~ 50-60Hz

F1

M2

S1

SFF

M1

S2

R1 - 1.8KOhm

V2

DEP 101B

CV

P<

PH

5

6

LN

L2 L3

L1

F2

F3

CV

V1

a1

K

a2

4

1

2

P<

PE

PL

L1

L2

L3

1

2

PE

COMPRESSOR / COMPRESOR

CP CR -CAPACITOR MARCHA / RUN

CAPACITOR ARRANQUE / START

CS CV -CAPACITOR VENTILADOR / FAN

F -

FUSÍVEL / FUSIBLE / FUSE

K -CONTATOR / CONTACTOR

PH -

PRESSOSTATO ALTA

PRESOSTATO ALTA

PRESSURE SWITCH - HBP

PL -

PRESSOSTATO BAIXA

PRESOSTATO BAJA

PRESSURE SWITCH - LBP

RC -

RESISTÊNCIA CARTER

CALENTADOR CARTER

CRANKCASE HEATER

RL -RELE / RELAY

V -

VENTILADOR / FAN

FRCC.PI.051.A1.28

№4

© Danfoss | DCS (CC) | 2017.03 | 17

Page 18

Instruções

Code V: HPMP, HPZP, LPZP

13

5

2 4

6

RC

CP

380V 3~50-60Hz

L1

L2

L3

N

1

F1

a1

K

a2

2

PE

CP -COMPRESSOR / COMPRESOR

CR - CAPACITOR MARCHA / RUN

CAPACITOR ARRANQUE / START

CS CV - CAPACITOR VENTILADOR / FAN

F -

FUSÍVEL / FUSIBLE / FUSE

K -CONTATOR / CONTACTOR

PH -

PRESSOSTATO ALTA

PRESOSTATO ALTA

F2

PRESSURE SWITCH - HBP

PL -

PRESSOSTATO BAIXA

PRESOSTATO BAJA

CV

CV

PRESSURE SWITCH - LBP

RC -

RESISTÊNCIA CARTER

CALENTADOR CARTER

CRANKCASE HEATER

RL -RELE / RELAY

V -

VENTILADOR / FAN

4

1

2

P<

P<

PE

V1

V2

PH

PL

№5

Code V: HPUS, LPZS

PE

RC

13

2 4

CP

380V 3~ 50-60Hz

L1

L2

L3

N

1

F1

M2

SFF

S1

M1

S2

R1 - 1.8KOhm

DEP 101B

LN

5

L2 L3

L1

6

a1

K

a2

2

PE

COMPRESSOR / COMPRESOR

CP CR -CAPACITOR MARCHA / RUN

CAPACITOR ARRANQUE / START

CS CV -CAPACITOR VENTILADOR / FAN

F -

FUSÍVEL / FUSIBLE / FUSE

K -CONTATOR / CONTACTOR

PH -

PRESSOSTATO ALTA

PRESOSTATO ALTA

F2

CV

CV

PRESSURE SWITCH - HBP

PL -

PRESSOSTATO BAIXA

PRESOSTATO BAJA

PRESSURE SWITCH - LBP

RC -

RESISTÊNCIA CARTER

CALENTADOR CARTER

CRANKCASE HEATER

RL -RELE / RELAY

V -

VENTILADOR / FAN

4

1

2

P<

P<

PE

V1

V2

PH

PL

18 | © Danfoss | DCS (CC) | 2017.03

№6

FRCC.PI.051.A1.28

Page 19

Danfoss A/S

6430 Nordborg

Denmark

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This

also applies to products already on order provided that such alterations can be made without subsequential changes being necessary in specications already agreed. All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

19 | © Danfoss | DCS (CC) | 2017.03

FRCC.PI.051.A1.ML

Loading...

Loading...