Page 1

Instructions

Optyma™ Pack

OP-HPMD

L

MADE IN INDIA

A

OP-HPMD031AWW00G

Code no.:

B

Application

C

Refrigerant

D

M.W.P. HP

E

LP (1) 7 bar

Voltage 230V3N~/50Hz

F

LRA 40 12MCC

Serial No.

G

Barcode Serial No:

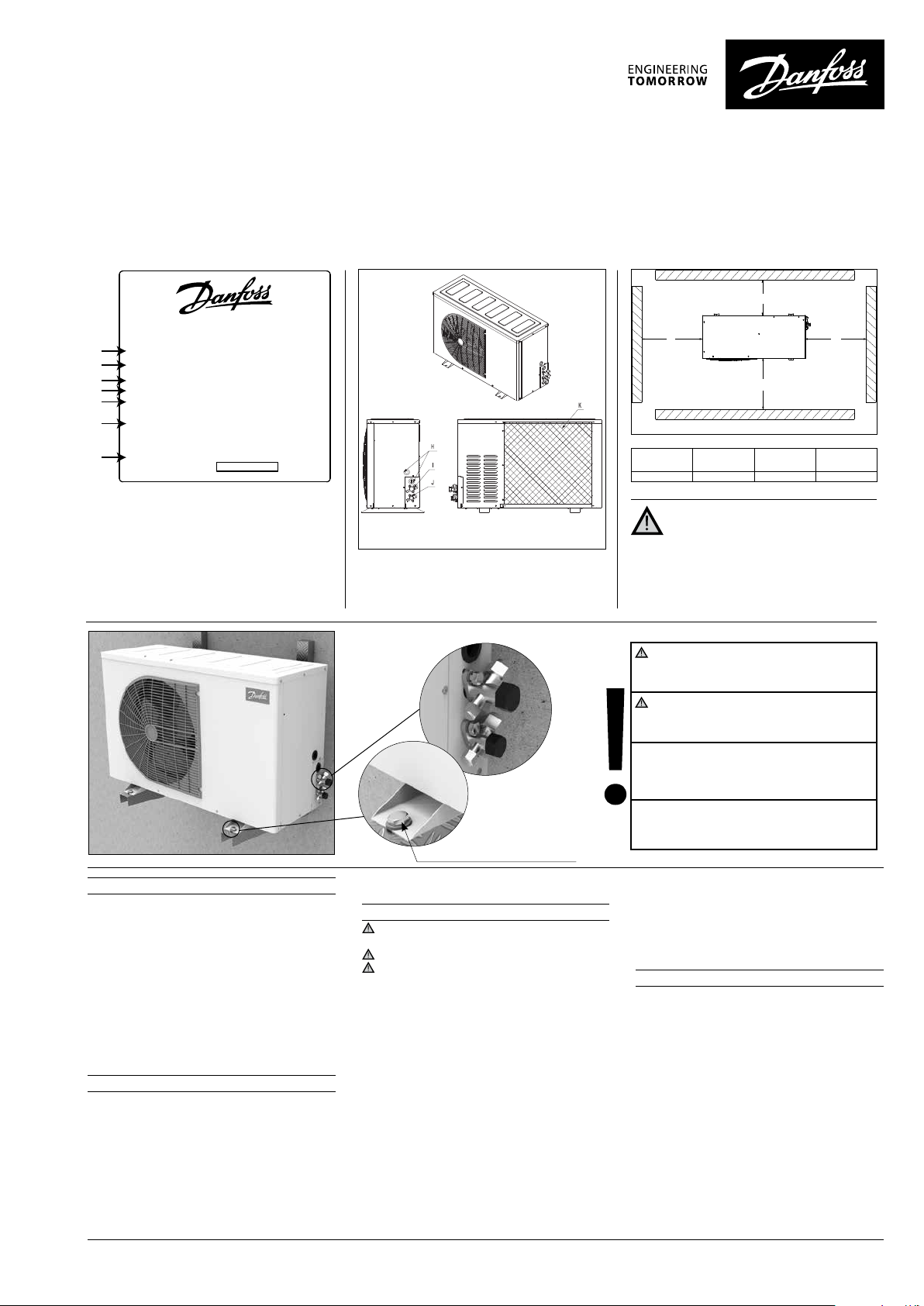

A: Model

B: Code number

C: Application, Protection

D: Refrigerant

E: Housing Service Pressure

F: Supply voltage, Locked Rotor Ampere,

Maximum Current Consumption

G: Serial Number and bar code

Picture 2

114X9101

HBP

(1) R22

(1) 25 bar

123456CG0514

IP54

(2)

(2)

118UXXXX

H: Cable entry ports

I: Suction port

J: Liquid port

K: Coil guard

Mounting bolts

Picture 3

N

M

Picture 1 : Minimum mounting distances

L

[mm]

250 650 550 550

Installation and servicing of the

condensing units by qualified

personnel only. Follow these

instructions and sound refrigeration

engineering practice relating to installation,

commissioning, maintenance and service.

The condensing unit must only be used for

its designed purpose(s) and within its scope of

application.

Under all circumstances, the applicable

local safety regulation) requirements must be

fulfilled.

The condensing unit is delivered under nitrogen gas pressure (1 bar) and hence it cannot

be connected as it is; refer to the «installation»

section for further details.

The condensing unit must be handled with caution in the vertical position (maximum offset

from the vertical : 15°)

M

[mm]

N

[mm]

O

O

[mm]

1 – Introduction

These instructions pertain to Optyma

condensing units OP-HPMD (R22) used for refrigeration systems. They provide necessary information regarding safety and proper usage of

this product.

The condensing unit includes following:

version W00

• Reciprocating compressor

• Fin-Tube heat exchanger

• Cartridge pressure switches

• Discharge gas thermostat (DGT)

• Service valves suction/ liquid

• Weather proof housing

2 – Handling and storage

• It is recommended not to open the packaging before the unit is at the final place for installation.

• Handle the unit with care. The packaging allows for the use of a forklift or pallet jack. Use

appropriate and safe lifting equipment.

• Store and transport the unit in an upright position.

• Store the unit between -35°C and 50°C.

• Don’t expose the packaging to rain or corrosive

atmosphere.

• After unpacking, check that the unit is com-

TM

Pack

© Danfoss | DCS (CC) | 2018.11

plete and undamaged.

3 – Installation precautions

Do not braze as long the condensing unit is

under pressure.

Never place the unit in a flammable atmosphere

Place the unit in such a way that it is not blocking

or hindering walking areas, doors, windows or similar.

• Ensure adequate space around the unit for air

circulation and to open doors. Refer to picture1

for minimal values of distance to walls.

• Avoid installing the unit in locations which are daily

exposed to direct sunshine for longer periods.

• Avoid installing the unit in aggressive and

dusty environments.

• Ensure a foundation with horizontal surface

(less than 3° slope), strong and stable enough

to carry the entire unit weight and to eliminate

vibrations and interference.

• The unit ambient temperature may not exceed

50°C during off-cycle.

• Ensure that the power supply corresponds to

the unit characteristics (see nameplate).

• Use clean and dehydrated refrigeration-grade

copper tubes and silver alloy brazing material.

• Use clean and dehydrated system components.

• The suction piping connected to the compressor must be flexible in 3 dimensions to dampen

vibrations. Furthermore piping has to be done

in such a way that oil return for the compressor is ensured and the risk of liquid slug over in

compressor is eliminated.

4 – Installation

• The installation in which the condensing unit is installed must comply to EEC Pressure directive (PED)

no. 2014/68/EU. The condensing unit itself is not a

”unit” in the scope this directive. Under all circumstances local safety regulations must be fulfilled.

• The unit must be securely installed on a stable

and rigid support, and fixed from the beginning. See picture 2.

• It is recommended to install the unit on rub-

ber grommets or vibration dampers . Rubber

pads with mounting bolts are supplied.

• Slowly release the nitrogen holding charge

through the schrader port.

• Connect the unit to the system as soon as possible

to avoid oil contamination from ambient moisture.

• Avoid material entering into the system while

cutting tubes. Never drill holes where burrs

cannot be removed.

AN294425350971en-000101 | 1

Page 2

Instructions

• Braze with great care using state-of-the-art technique and vent piping with nitrogen gas flow.

• Connect the required safety and control devices. When the schrader port is used for this,

remove the internal valve.

• It is recommended to insulate the suction pipe

up to the compressor inlet with 19 mm thick

insulation.

5 – Leak detection

Never pressurize the circuit with oxygen or

dry air. This could cause fire or explosion.

• Do not use dye for leak detection.

• Perform a leak detection test on the complete

system.

• The maximum test pressure is 28 bar.

• When a leak is discovered, repair the leak and

repeat the leak detection.

6 – Vacuum dehydration

• Never use the compressor to evacuate the system.

• Connect a vacuum pump to both the LP & HP

sides.

• Pull down the system under a vacuum of 500

μm Hg (0.67 mbar) absolute.

• Do not use a megohmmeter nor apply power

to the compressor while it is under vacuum as

this may cause internal damage.

7 – Electrical connections

• Switch off and isolate the main power supply.

• Ensure that power supply can not be switched

on during installation.

• All electrical components must be selected as

per local standards and unit requirements.

• Refer to wiring diagram for electrical connections details.

• Ensure that the power supply corresponds

to the unit characteristics and that the power

supply is stable (nominal voltage ±10% and nominal frequency ±2,5 Hz).

• For safe working under compressor specification, unit is equipped with discharge gas thermostat (DGT), which directly cut the power

supply to the compressor in case of activation

(Activates at 130 ±5 °C and deactivates at 105

±10 °C discharge gas temperature. Make sure

that discharge gas thermostat is properly

connected as per wiring diagram (Refer DGT in

WD1 and WD2)

• Dimension the power supply cables according

to unit data for voltage and current.

• Protect the power supply and ensure correct

earthing.

• Make the power supply according to local standards and legal requirements.

•

The unit is equipped with high and low pressure

switches, which directly cut the power supply to

the compressor in case of activation.

• Determine the phase sequence by using a

phase meter in order to establish the phase orders of line phases L1, L2 and L3.

• Connect line phases L1, L2 and L3 to main switch terminals T1, T2 and T3 respectively.

8 – Filling the system

• Wear protective stuff like goggles and protective gloves.

• Never start the compressor under vacuum.

Keep the compressor switched off.

• Before charging the refrigerant, verify that the

oil level is between ¼ and ¾ on the compressor

oil sight glass. If additional oil is required please

refer to the compressors label for type of oil.

• Use only the refrigerant for which the unit is

designed for.

• Fill the refrigerant in liquid phase into the

condenser or liquid receiver.

• Ensure a slow charging of the system to 4 – 5

bar for R22.

• Do not put liquid refrigerant through suction line.

• It is not allowed to mix additives with the oil

and/or refrigerant

• The remaining charge is done until the installation has reached a level of stable nominal

condition during operation.

• Never leave the filling cylinder connected to

the circuit.

9 – Verification before commissioning

Use safety devices in compliance with both

generally and locally applicable regulations and

safety standards.

• Verify that all electrical connections are properly

fastened and in compliance with local regulations.

• When a crankcase heater is required, it must be

energized at least 12 hours before initial startup and start-up after prolonged shut-down period.

10 – Start-up

• Never start the unit when no refrigerant is

charged.

• All service valves must be in the open position.

See picture 3.

• Check compliance between unit and power

supply.

• Check that the crankcase heater is working.

• Check that the fan can rotate freely.

• Check that the protection sheet has been re-

moved from the backside of condenser.

• Balance the High Pressure / Low Pressure.

• Energize the unit. It must start promptly. If

the compressor does not start, check wiring

conformity, voltage on terminals and sequence

phase.

11 – Check with running unit

• Check the fan rotation direction. Air must flow

from the condenser towards the fan.

• Check current draw and voltage.

• Check suction superheat to reduce risk of slug-

ging.

• When a sight glass is provided observe the oil

level at start and during operation to confirm

that the oil level remains visible.

• Respect the operating limits.

• Check all tubes for abnormal vibration. Move-

ments in excess of 1.5 mm require corrective

measures such as tube brackets.

• When needed, additional refrigerant in liquid

phase may be added in the low-pressure side as

far away as possible from the compressor. The

compressor must be operating during this process.

• Do not overcharge the system.

• Never release refrigerant to atmosphere.

• Before leaving the installation site, carry out

a general installation inspection regarding

cleanliness, noise and leak detection.

• Record type and amount of refrigerant charge

as well as operating conditions as a reference

for future inspections.

12 – Maintenance

Always switch off the unit at main switch before remove fan panel.

Internal pressure and surface temperature

are dangerous and may cause permanent injury.

Maintenance operators and installers require

appropriate skills and tools. Tubing temperature

may exceed 100°C and can cause severe burns.

Ensure that periodic service inspections to

ensure system reliability and as required by local

regulations are performed.

To prevent system related problems, following

Periodic maintenance is recommended:

• Verify that safety devices are operational and

properly set.

• Ensure that the system is leak tight.

• Check the compressor current draw.

• Confirm that the system is operating in a way

consistent with previous maintenance records

and ambient conditions.

• Check that all electrical connections are still

adequately fastened.

• Keep the unit clean and verify the absence of

rust and oxidation on the unit components,

tubes and electrical connections.

The condenser must be checked at least once

a year for clogging and be cleaned if deemed

necessary. Access to the internal side of the

condenser takes place through the fan panel.

• Switch off the unit at main switch before remove any panel from the condensing unit.

• Remove surface dirt, leaves, fibres, etc. with

a vacuum cleaner, equipped with a brush or

other soft attachment. Alternatively, blow compressed air through the coil from the inside out,

and brush with a soft bristle. Do not use a wire

brush. Do not impact or scrape the coil with the

vacuum tube or air nozzle.

If the refrigerant system has been opened, the

system has to be flushed with dry air or nitrogen

to remove moisture and a new filter drier has to

be installed. If evacuation of refrigerant has to be

done, it shall be done in such a way that no refrigerant can escape to the environment.

13 - Warranty

Always transmit the model number and serial number with any claim filed regarding this product.

The product warranty may be void in following

cases:

• Absence of nameplate.

• External modifications; in particular, drilling,

welding, broken feet and shock marks.

• Compressor opened or returned unsealed.

• Rust, water or leak detection dye inside the

compressor.

• Use of a refrigerant or lubricant not approved

by Danfoss.

• Any deviation from recommended instructions

pertaining to installation, application or maintenance.

• Use in mobile applications.

• Use in explosive atmospheric environment.

• Working above specified envelope mentioned

(Maximum Ambient temperature 45 °C)

• No model number or serial number transmitted with the warranty claim.

14 – Disposal

Danfoss recommends that condensing units and

oil should be recycled by a suitable company at

its site.

2 | AN294425350971en-000101

© Danfoss | DCS (CC) | 2018.11

Page 3

Instructions

GA drawings

A1 Chassis: OP-HPMD031-043-054

A2 Chassis: OP-HPMD063-068

© Danfoss | DCS (CC) | 2018.11

AN294425350971en-000101 | 3

Page 4

Wiring Diagram

Code G: OP-HPMD031-043-054-063

Code E: OP-HPMD043-054-063-068

WD 1

WD 2

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This

also applies to products already on order provided that such alterations can be made without subsequential changes being necessary in specifications already agreed. All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

4 | AN294425350971en-000101 © Danfoss | DCS (CC) | 2018.11

Loading...

Loading...