Page 1

Operating guide

OPC server for ECL Comfort 310

Table of Contents

1. Introduction to Danfoss ECL OPC Server .......................................................................................................................... 2

2. Configuring databases....................................................................................................................................................... 6

3. Exporting configuration data ............................................................................................................................................ 7

4. Importing data from an XML file ....................................................................................................................................... 8

5. Address Space .................................................................................................................................................................... 9

6. Devices .............................................................................................................................................................................. 11

7. Folders .............................................................................................................................................................................. 14

8. Data Items ......................................................................................................................................................................... 15

9. Conversions ...................................................................................................................................................................... 20

10. Device Parameters ........................................................................................................................................................... 23

11. Simulation Signals ........................................................................................................................................................... 25

12. Alarm Definitions ............................................................................................................................................................. 28

13. How the client connects to and gets data from a server ................................................................................................ 34

_______________________________________________________________________________

© Danfoss | 2016.10 VI.GU.M2.00 | 1

Page 2

Operating guide, OPC server for ECL Comfort 310

1.

The Danfoss ECL OPC Server is an OPC

serves data to OPC clients. The OPC server was implemented

using advanced programming concepts of the current

version of the OPC

generation industrial software applications.

The OPC Server communicates with OPC clients and real time

Danfoss ECL devices. This OPC server is also based on the

popular Modbus protocol and can be connected to real world

Modbus compatible I/O hardware.

Key features of the OPC Server include:

•

•

•

•

•

•

•

•

The OPC Server product contains two parts: a user interface

configuration module and the actual OPC server, the runtime

module.

Configuration module:

The

that holds configurati

name, the ranging, and the alarm settings.

The

actual values of the tags configured. Structures of both

databases are indicated in the following secti

Changes made to the configuration are accepted

restart of the OPC server. However, changes made to the

runtime database are accepted online.

_______________________________________________________________________________________

Introduction to Danfoss ECL OPC Server

-compliant server that

specification for use in developing next

Advanced OPC data quality and data conversion to

client’s request.

Supports multiple multi-drop I/O devices.

Supports multiple groups for easy configuration and

manageability.

Supports popular PLC and RTU data types.

Internally simulated for configuration and testing.

User interface for viewing tags, groups, and real-time

signals.

Supports OPC Data Access (DA) and Alarm and Events

(AE) specifications.

Flexible engineering units and signal ranges

configuration module allows you to create a database

on data of the tags such as the tag

Runtime module:

runtime module uses a runtime database to access the

_______________________________________________________________________________

© Danfoss | 2016.10 VI.GU.M2.00 | 2

ons.

only after a

Page 3

Operating guide, OPC server for ECL Comfort 310

1.1

OLE™ for Process Control (OPC) is a standards-based

approach for connecting data sources (e.g., PLCs, controllers,

I/O devices, databases, etc.) with HMI client applications

(graphics, trending, alarming, etc.).

It enhances the interface between client and server

applications by providing a universally

documented mechanism to communicate data from a data

source to any client application.

Included are not only a detailed guide on how to pass the

data, but also specific information on other attributes to

supplement those data, such as range information, data type,

quality flags, and date and time information.

Figure 1.1 shows the OPC Architecture, which was introduced

by the OPC Foundation. By following the OPC Architecture, a

device needs only one standard driver, which is an OPC

compl

then be connected to that device, either locally or over a

network. Furthermore, connections can be made to more

than one OPC server at the same time.

Figure

Any OPC client application can connect to any OPC server. In

other words, OPC offers true Plug

fields of HMI and industrial automation. OPC server types

include OPC Data Access (DA), OPC Alarm and Events

_______________________________________________________________________________________

What is OLE for process control?

supported and well-

-

iant server. All OPC-compliant client applications can

1-1: General OPC-Based Client-Server Architecture

_______________________________________________________________________________

© Danfoss | 2016.10 VI.GU.M2.00 | 3

-and-Play capability in the

(AE).

Page 4

Operating guide, OPC server for ECL Comfort 310

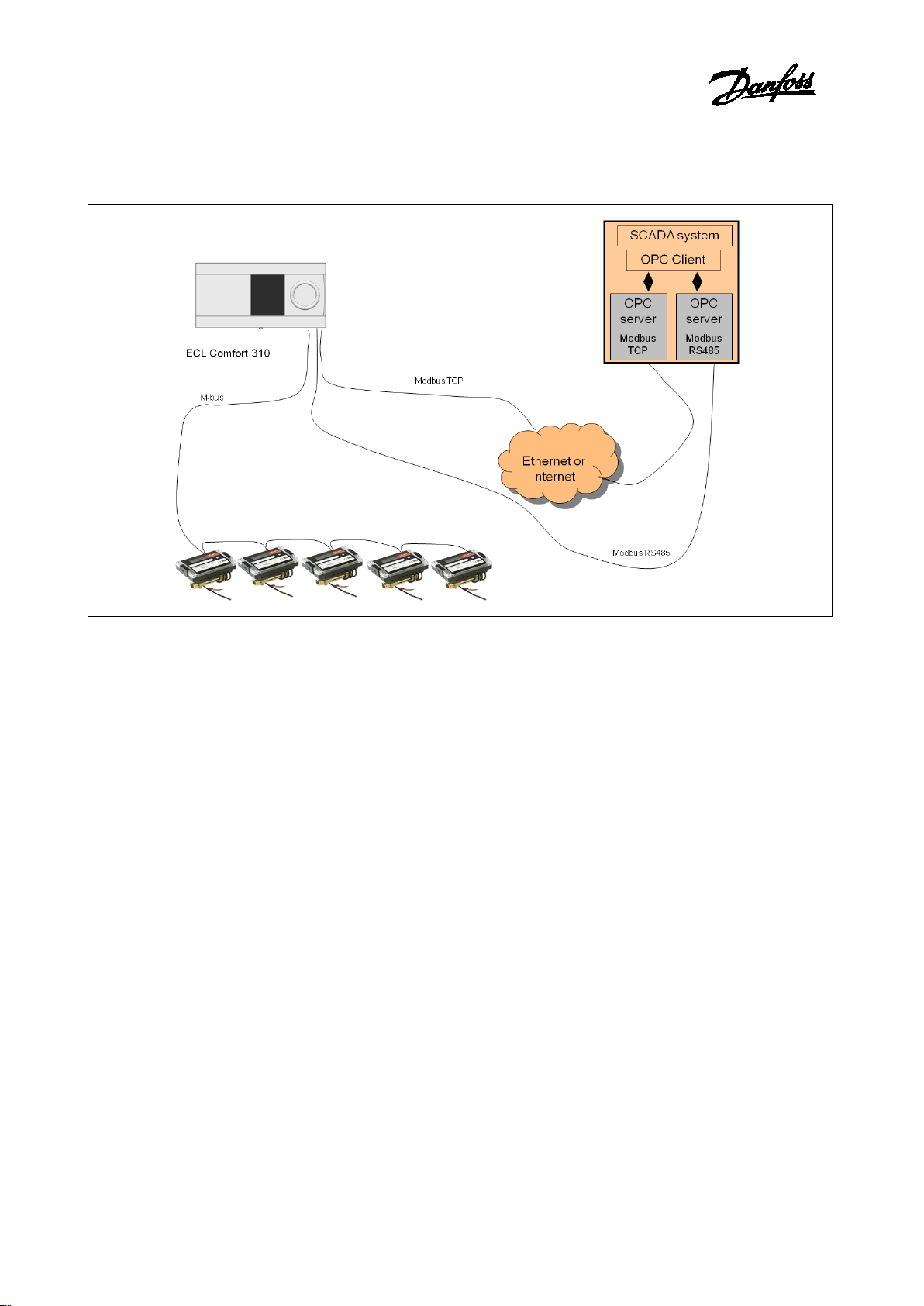

Figure

The OPC Server is based on Standard Modbus protocol for

RS485 and TCP. Heat meter data can be read through the ECL

Comfort controller

_______________________________________________________________________________________

1-2: Danfoss ECL Comfort OPC structure

using the M-bus network.

_______________________________________________________________________________

© Danfoss | 2016.10 VI.GU.M2.00 | 4

Page 5

Operating guide, OPC server for ECL Comfort 310

1.2

OPC Server Configurator can run on the following Microsoft

Windows operating systems:

•

•

•

•

•

•

•

•

•

•

•

†

Supported Editions of Windows Vista are Windows Vista

Business, Ultimate, and Enterprise Edition. Windows Vista Home

and Home Premium Editions are not supported in this release.

††

Windows 2000 is supported for Classic OPC Server installations

only.

The OPC Server Configurator is capable of running on

computer/workstation hardware with the following

specifications:

•

•

•

•

•

•

•

_______________________________________________________________________________________

System requirements

Windows Server 2008 x64 (runs in the 32 bit

compatibility mode)

Windows Server 2008

Windows Vista x64 (runs in the 32 bit compatibility

mode) †

Windows Vista †

Windows Server 2003 x64 (runs in the 32 bit

compatibility mode)

Windows Server 2003 R2

Windows Server 2003 SP2

Windows XP Professional x64 (runs in the 32 bit

compatibility mode)

Windows XP Professional SP3

Windows 2000 Server SP4 ††

Windows 2000 SP4 ††

1 GHz Processor (CPU)

1 GB Physical Memory (RAM)

2 GB Hard Disk space available

DVD drive for installation

SVGA Video Card; 256 or more colors for best results

A mouse or other compatible pointing device (such as a

trackball or touch screen)

Microsoft-compatible keyboard

_______________________________________________________________________________

© Danfoss | 2016.10 VI.GU.M2.00 | 5

Page 6

Operating guide, OPC server for ECL Comfort 310

2.

The OPC Server Configurator provides the ability to create

new

2.1

Database

To create a new Microsoft Access Configuration Database in

the

•

•

•

This configuration database will contain the configuration of

all your devices, and the logical tag naming i

address space.

2.2

Once your configuration is complete, you need to make sure

that your database is “Active”. The database that is

designated as “Active” is the one that the server uses.

To make a database active:

Sel

_______________________________________________________________________________________

Configuring databases

configuration databases.

Creating a Microsoft Access Configuration

Configurator, the following steps have to be completed:

Start the Danfoss ECL OPC Configurator.

Select ‘File’, ‘New’ from the menu and specify a name for

the configuration. For example ‘myProject.mdb’

Select the ‘Save’ button and the configuration file will be

created.

n the OPC

Activating the database

ect ‘File’, ‘Make Active’… and click the ‘Yes’ button.

_______________________________________________________________________________

© Danfoss | 2016.10 VI.GU.M2.00 | 6

Page 7

Operating guide, OPC server for ECL Comfort 310

3.

3.1

The Configurator also allows you to export data from your

configuration database to an XML file. The Configurator also

allo

XML file that specifies the data structure of an XML data file.

The purpose of having the configuration in XML would be

that you have it in another readable format and could

manipulate the content with

the changes again.

To export data, select from the menu ‘File, XML Export’…

This opens the ‘Export XML File’ dialog box. Specify a file a

name and click ‘Save’.

_______________________________________________________________________________________

Exporting configuration data

Exporting data to an XML file

ws you to export the XML schema. A schema is a special

3rd party tools to later import

_______________________________________________________________________________

© Danfoss | 2016.10 VI.GU.M2.00 | 7

Page 8

Operating guide, OPC server for ECL Comfort 310

4.

4.1

The Configurator allows you to import data from your

configuration database to an XML file.

To import data, select from the menu ‘File, XML Import’…

This opens the ‘Import XML File’ dialog box. Select a file and

click ‘Open’.

_______________________________________________________________________________________

Importing data from an XML file

Importing data from an XML file

_______________________________________________________________________________

© Danfoss | 2016.10 VI.GU.M2.00 | 8

Page 9

Operating guide, OPC server for ECL Comfort 310

5.

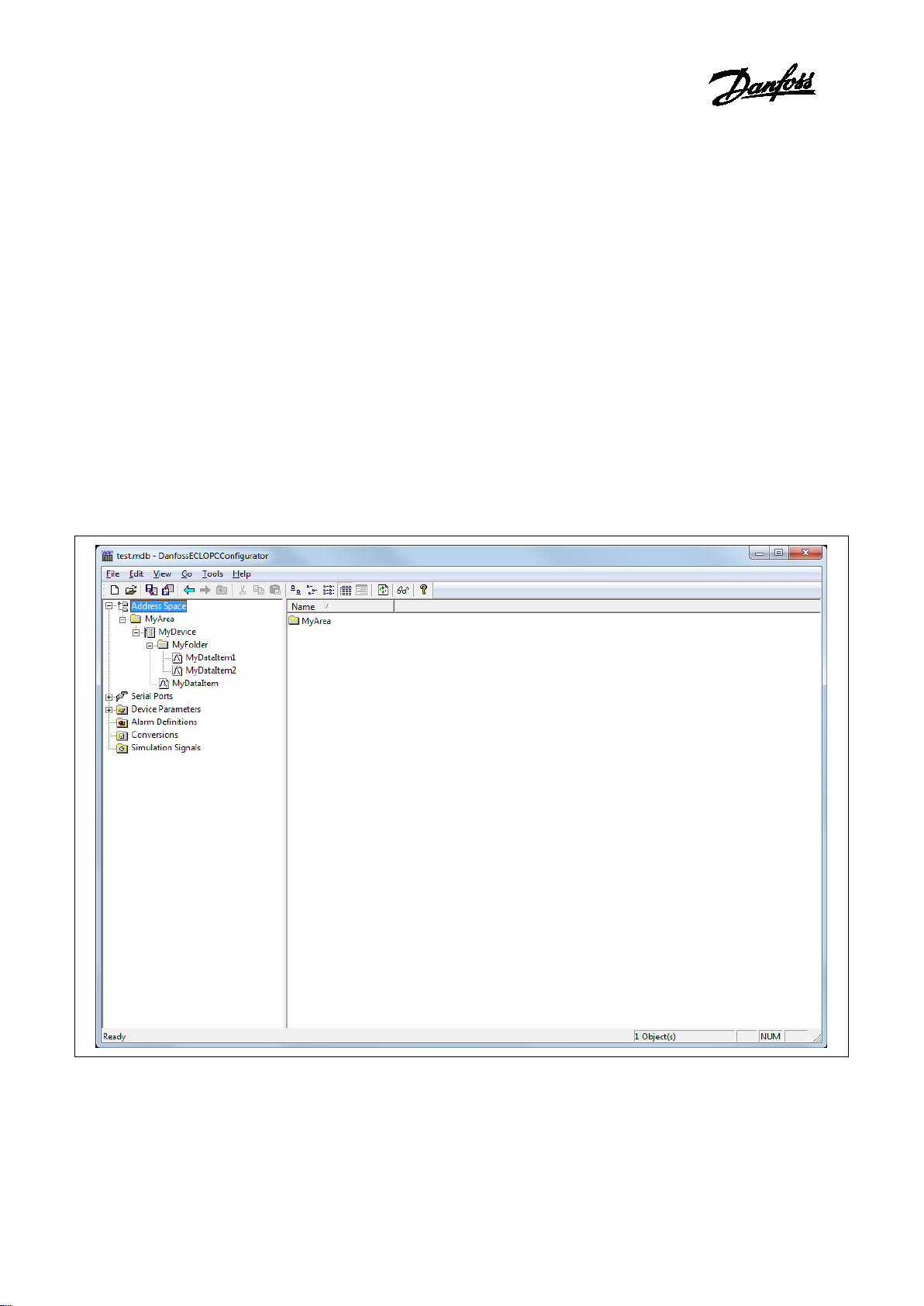

The 'Address Space' branch of the Configurator provides a tree

explorer in Workbench, shown in the figure below, for setting the

properties and connection parameters of the following items:

•

•

•

Data items can be organized hierar

organizing directories and files on your computer's hard disk. The

OPC s

The Configurator module uses the terms

A folder can contain additional folders and also

data items are always the branches in the tree control hierarchy.

The hierarchical structure of the folders and data items helps to

organize the device

Figure

_______________________________________________________________________________________

Address Space

Devices

Folders

Data Items

chically. It is similar to

erver offers several levels of hierarchy.

‘Folder’ and ‘Data Item’.

data items. The

s and tags, as shown in Figure 5.1.

5.1: Address Space

_______________________________________________________________________________

© Danfoss | 2016.10 VI.GU.M2.00 | 9

Page 10

Operating guide, OPC server for ECL Comfort 310

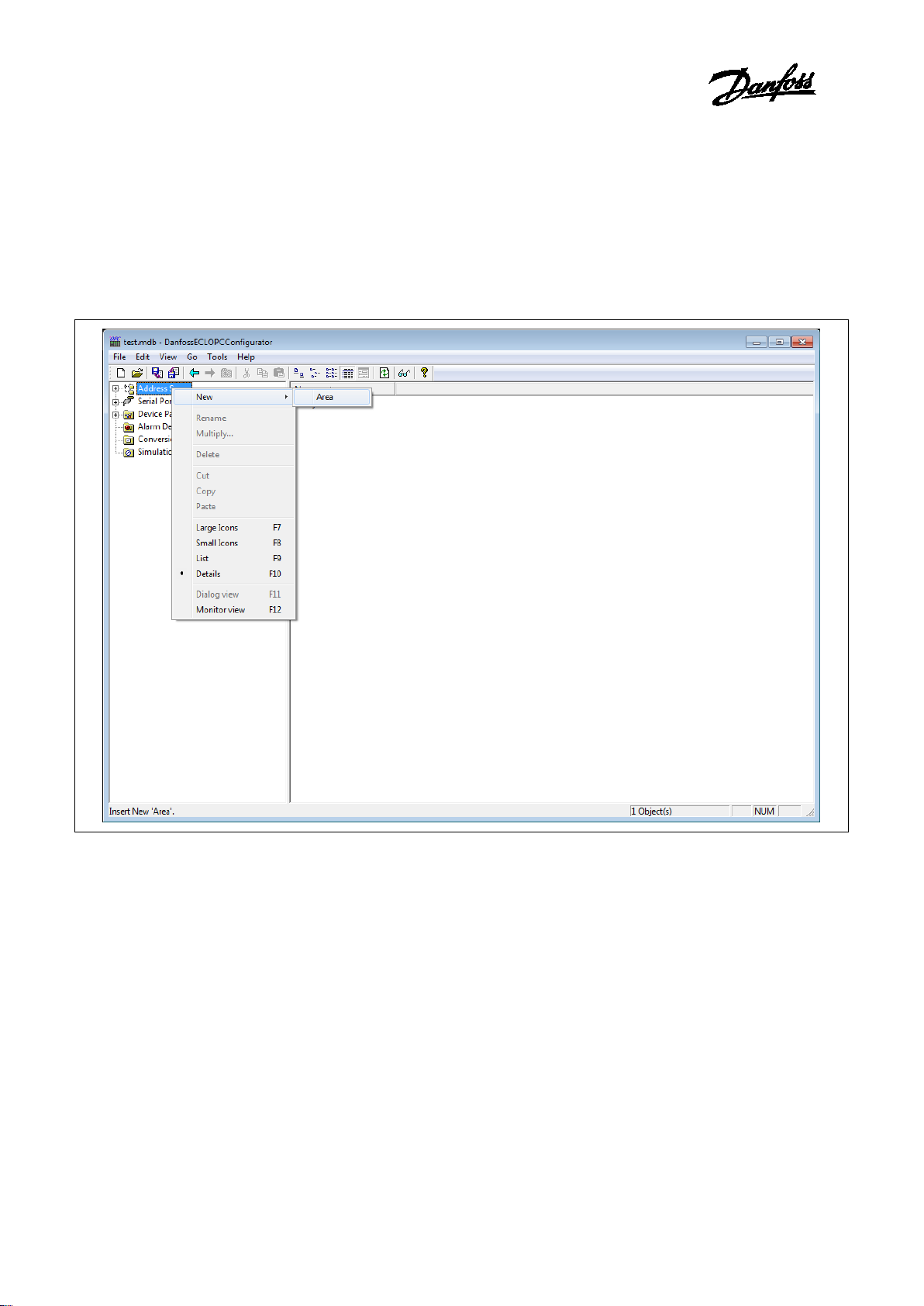

5.1

Area

as many areas as required. At least one area is required.

To add an

Right

branch in the Configurator tree

explorer in Workbench,

Figure

Or

Select the ‘Address Space’ branch in the Configurator tree

explorer in Workbench and

menu item.

_______________________________________________________________________________________

Areas

s can be used to group devices logically. You can configure

new area:

-click on the ‘Address Space’

and click on ‘New Area’.

5-2: Creating a 'New Area' in the Configurator tree explorer in Workbench

use the menu ‘Edit’, ‘New’, ‘Area’

_______________________________________________________________________________

© Danfoss | 2016.10 VI.GU.M2.00 | 10

Page 11

Operating guide, OPC server for ECL Comfort 310

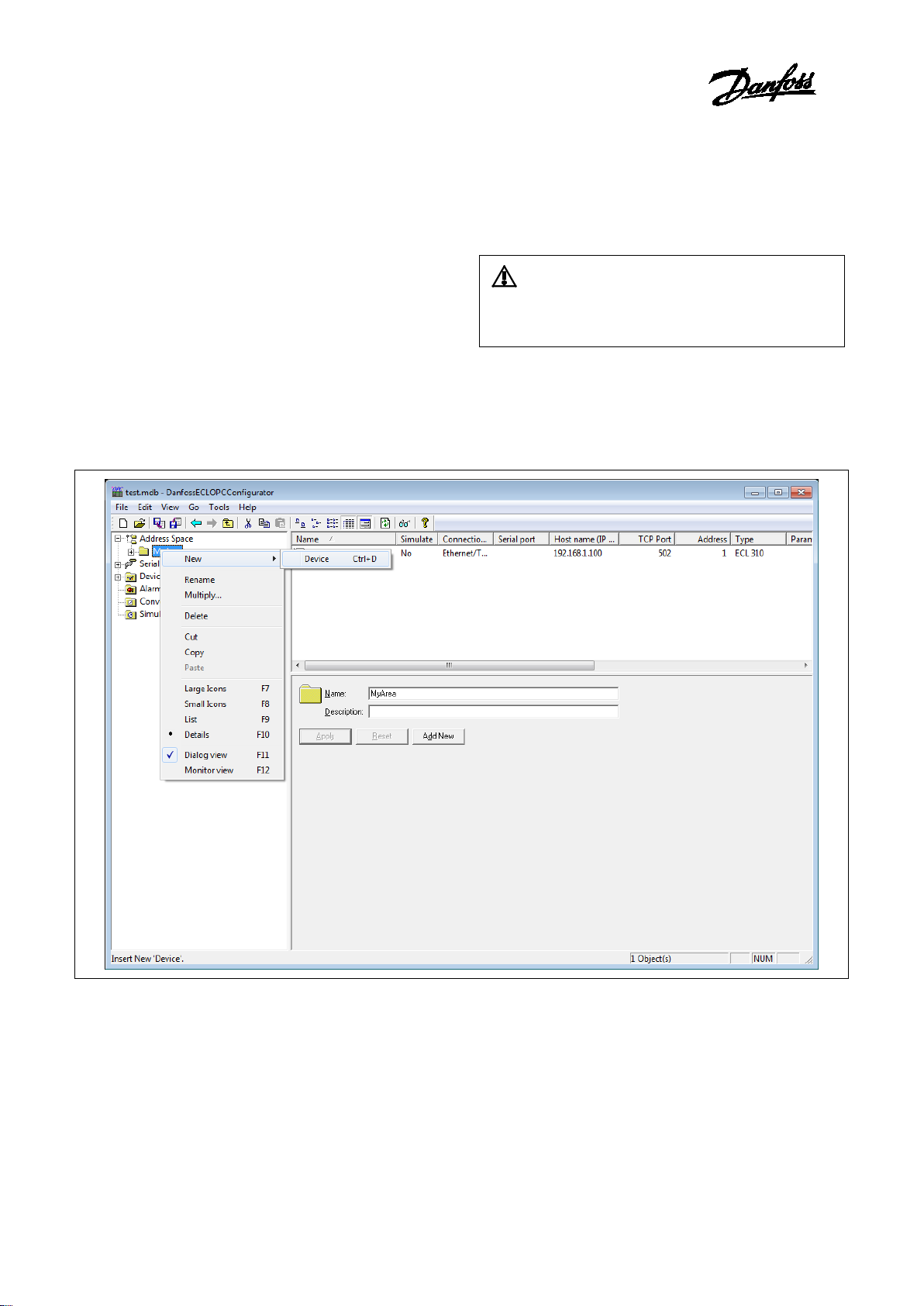

6.

In the Configurato

communicates with the OPC server over TCP/IP.

A device is directly communicating with its socket, so it is

logically under the first level in the

Again, the device is represented by its

address in combination with the unit identifier value uniquely

identifies the device.

Setting up a device requires configuring its IP address, unit

identifier, TCP port, type, timeouts and optimization parameters.

To add a devi

Right

explorer in Workbench,

Figure

Or

Select the ‘Address Space’ branch in the Configurator tree

explorer in Workbench and

menu item.

_______________________________________________________________________________________

Devices

r, a device represents a hardware device that

‘Address Space’ tree.

symbolic name. Also, its IP

ce:

-click the ‘Address Space’ branch of the Configurator tree

and click on ‘New Device’.

It is impossible to have two devices with the same IP

address.

6-1: Adding a 'New Device' in the Configurator tree explorer in Workbench

use the menu ‘Edit’, ‘New’, ‘Area’

_______________________________________________________________________________

© Danfoss | 2016.10 VI.GU.M2.00 | 11

Page 12

Operating guide, OPC server for ECL Comfort 310

Configuring devices:

Figure

Connection type:

The OPC server supports two types of data connections: Ethernet

cable and serial cable.

The best performance is achieved by using an Ethernet

connection. In this case the IP address of the device needs to be

specified as well as the TCP

I

computer connected to the device(s) needs to be selected.

Each serial port can be configured by selecting the Serial Ports

branch of the Configurator tree explorer in Workbench and set

the paramet

IP address:

The device

numbers separated by dots that indicate the location of the

device on a TCP/IP network. Each number in the address can

range from 0 to 255.

TC port:

_______________________________________________________________________________________

6-2: Configuring devices

port.

f serial connection is selected, the physical serial port of the

ers for each port.

_______________________________________________________________________________

© Danfoss | 2016.10 VI.GU.M2.00 | 12

‘IP Address’ is a 32-bit value represented as four

Page 13

Operating guide, OPC server for ECL Comfort 310

The TCP Port for Modbus communication via Ethernet is default

502 and should not be changed unless it is specifically required

by the network.

Unit Id (Identifier):

The Unit Id (Identifier) field may be used to communicate via

devices such as bridges and gateways that use a single IP address

to support multiple independent end units.

Type:

The OPC Server supports both the ECL300 and ECL310 devices.

The selected type must match the type of the device connected.

For other devices which support t

communication protocol please select the ‘Custom Type’ option.

The device parameters for ‘Simple devices’ can be configured by

selecting the ‘Device Parameters’ branch of the Configurator tree

explorer in Workbench and set the parameters

devices’.

Timeouts:

Read/Write:

Amount of time (in milliseconds) the OPC server will wait for a

response (read/write) from the device.

Timeouts to Suspend:

The number of consecutive read/write attempts that timeout

before the OPC Ser

device.

Suspend Period:

Amount of time the OPC Server will wait before attempting to

reconnect to the device.

Delay:

Amount of time (in milliseconds) between read attempts.

_______________________________________________________________________________________

he Modbus standard

for ‘Simple

ver will suspend communication with the

_______________________________________________________________________________

© Danfoss | 2016.10 VI.GU.M2.00 | 13

The Suspend Period setting can be decreased to

reconnect faster with a device that has been restarted,

but this will cause the OPC server to generate more

network traffic while a device is down.

Page 14

Operating guide, OPC server for ECL Comfort 310

7.

Folders can be used to group data items logically. You can

configure

subfolders. The OPC server supports up to three folder levels. The

use of folders is not required.

If desirable, the configuration could just contain data items

without any folders. But most likely th

application does not demand too many persistent tags

To add a

Right

Configurator tree explorer in Workbench, then click on

Folder

Figure

Creating a ‘New Folder’ in the Configurator tree explorer in

Workbench

Or

Select the ‘Device Branch’ in the Configurator tree explorer in

Workbench, then use the menu

_______________________________________________________________________________________

Folders

as many folders as required. Each folder can even have

is will only be useful if the

.

new folder:

-click on a ‘Device Branch’ (or another folder) in the

‘New

’.

7-1:

_______________________________________________________________________________

© Danfoss | 2016.10 VI.GU.M2.00 | 14

‘Edit’, ‘New’, ‘Folder’ menu item.

Page 15

Operating guide, OPC server for ECL Comfort 310

8.

A ‘Data Item’ represents a register in the device or a range of

registers. A symbolic name and description is associated with the

data item. An OPC client can obtain the data item description.

The actual OPC item name (tag) is compounded from the

‘

and the name of the data item. Data items can be located in any

folder, even in the root of the address space.

To add a

Right

Workbench

Figure

Creating a

Workbench

Or

Select the ‘Device branch’ in the Configurator tree explorer

in Workbench, then use the menu ‘Edit’, ‘New’, ‘Data

Properties for data items:

Data items have the following properties, as shown in

8

_______________________________________________________________________________________

Data Items

Address Space’ root, the names of the folder and its subfolders,

new data item:

-click a device or folder in the Configurator tree explorer in

and click on ‘New Data Item’.

8-1:

‘New Data Item’ in the Configurator tree explorer in

-2.

_______________________________________________________________________________

© Danfoss | 2016.10 VI.GU.M2.00 | 15

Item’.

Figure

Page 16

Operating guide, OPC server for ECL Comfort 310

Figure

Properties for a

Name:

A logical name for the data item (Setpoint, Param001,

ON_OFF, etc).

Description:

A

Location Type:

Location type is a type of a register in the device. Every device

is identified by its unique address. Its registers are read as

‘Input’ (1 bit long) or ‘Input Register’ (16 bits), or written t

‘Coil’ (1 bit) or ‘Holding Register’ (16 bits). Registers of each

type are addressed by using 16

are divided into ‘Coils’, ‘Inputs’, ‘Input Registers’ and ‘Holding

Registers’. Table 3

Read Only

Read/Write

1 bit

Input

Coil

16 bit

Input Register

Holding Register

Table 3

Name conventions

Modbus Type:

The location type (device data) will be understood as Modbus

type (OPC data type). Modbus data type also depends on the

‘

The ‘Data Length’ (bytes) field tells you how long (in bytes) the

When selecting the Modbus STRING type, you must

_______________________________________________________________________________________

8-2:

‘Data Item’

descriptive comment for the data item.

-bit numbers. Device registers

-1 explains the name conventions used.

Location type’ selected.

_______________________________________________________________________________

© Danfoss | 2016.10 VI.GU.M2.00 | 16

o as

-1:

Example:

‘Coil’ or ‘Input’ (1 bit) device data type can be Modbus

BOOL only.

Page 17

Operating guide, OPC server for ECL Comfort 310

field is for the Modbus type (e.g. ‘REAL’, ‘INT’, ‘UINT’, etc.)

selected. The ‘BOOL’ length is always 1 bit.

specify the data length (how many bytes will the STRING

Simulation:

To test the client functionality, choose a ‘Simulation Signal’

from the ‘Signal’ drop

checkbox. See the ‘Simulation Signals’ section for information

about creating simulation signals.

All levels in the ‘Address Space’ (port, device, folder, data item)

support the process of simulation (Simulate checkbox). The

parent list in the tree is superior; it has a higher priority when

deciding to simulate the data item or not.

In other words, a data item is simulated, if it itself has a

simulation selected, or if any of its parents has the ‘Simulate’

checkbox checked. (

checkbox stays unchecked.)

Manual Value:

If the ‘Simulate’ checkbox is checked, the data item will offer a

constant parameter value, because the ‘Manual Value ‘setting

is of the highest priority. The changes in the configuration take

effect only when the server reloads the configuration (on

startup).

Starting Address:

This value specifies the data item address (register number) in

the device data space. With the 'UINT' Modbus type, it is

possible to

Boolean or integer value (this functionality is read

You can specify a group of 'Count' adjacent bits inside a word

starting with 'Bit #'. This way, it is possible to use a register for

several sepa

Use Conversion:

To get the data value converted according to a prescribed

form, choose one of the predefined or user

conversions. See the conversions section for more details.

Generate Alarm:

Check the ‘Generate Ala

generate alarms based on the data item value. The ‘Msg.

prefix’ parameter is the text of the message for this data item.

It will be followed by the text configured for a particular alarm

type. The second part of the alarm me

‘Message Body’ string (see ‘Alarm Definitions’).

The server allows any number of predefined alarm definitions

(templates). You can combine one of them with the specific

tags.

_______________________________________________________________________________________

-down list and check the ‘Simulate’

It may be simulated even if its ‘Simulate’

be represented by).

extract bits from the register and use them as a

rate data items.

-defined

rm’ checkbox to make the server

ssage will contain the

_______________________________________________________________________________

© Danfoss | 2016.10 VI.GU.M2.00 | 17

-only).

Page 18

Operating guide, OPC server for ECL Comfort 310

Additional Properties:

Clicking the ‘Additional

‘Additional Properties’ dialog box, shown in Figure

allows you to set a textual string for an Open/Close label, a

default display, a .bmp file, an HTML file, a sound file, and an

.avi file.

These properties are also

clients. For example, to see the HTML file name being

presented in the OPC client, you should append .HTMLFile to

the OPC Item name.

Figure

‘Additional Properties’ dialog box

Importing XML-file with ‘Data Items’ for ECL device

The OPC Server comes with an XML

configurations and descriptions for all ‘Data Items’ supported

by the ECL device. By importing this XML

are ready for use by the OPC Server or may option

modified to fit specific requirements.

To import XML-file with ‘Data Items’:

Select a Device in the Configurator tree explorer in Workbench

and click on the ‘Import XML’ button.

_______________________________________________________________________________________

Properties’ button opens the

8-3, which

accessible for OPC Data Access

8-3:

-file containing names,

-file all ‘Data Items’

ally be

It is recommended to import the XML-file for the

application used by the ECL Controller to ease the

configuration of its parameters.

_______________________________________________________________________________

© Danfoss | 2016.10 VI.GU.M2.00 | 18

Page 19

Operating guide, OPC server for ECL Comfort 310

Figure

Importing the XML

Select the appropriate ECL device and application key and

click the OK button to import the XM

Figure

Import ECL310 data

_______________________________________________________________________________________

8-4:

-file with ‘Data Items’ in Workbench

L-file:

8-5:

_______________________________________________________________________________

© Danfoss | 2016.10 VI.GU.M2.00 | 19

Page 20

Operating guide, OPC server for ECL Comfort 310

9.

You can tell the server to convert device data value simply by

setting the Conversion properties, as shown in figure

To add a new conversion

Right

explorer in Workbench, then click on ‘New Conversion’.

Figure

Adding a

Workbench

Or

Select the Conversion branch in the Configurator tree explorer

in

This opens the Conversions properties window in the right

pane of Workbench. Configure the following properties as

specified below.

_______________________________________________________________________________________

Conversions

9-1.

-click the Conversions branch of the Configurator tree

9-1:

‘New Conversion’ in the Configurator tree explorer in

Workbench, then use the menu ‘Edit’, ‘New’, ‘Conversion’.

_______________________________________________________________________________

© Danfoss | 2016.10 VI.GU.M2.00 | 20

-

Page 21

Operating guide, OPC server for ECL Comfort 310

Figure

Name:

Specifies the name of the conversion definition. The name can

be up to 12 alphanumeric characters, including underscores

( _ ) and hyphens (

Conversion type:

For each conversion definition, select one of the following

conversion types from the dro

•

•

•

Conversion parameters:

•

•

_______________________________________________________________________________________

9-2: Conversion properties

- ).

p-down list:

None (make float): Converts the data into float data type,

but does not change the value itself. When this option is

selected, the ‘Engineering Units’ and ‘Instrument Range’

fields are disabled.

Linear: Keeps a linear relation between EU and IR.

Square Root: Keeps a square root relation between EU and

IR.

Engineering Units (EU): Client scale; specify low and high

values for the engineering units (if applicable).

Instrument Range (IR): Device scale; specify low and high

values for the instrument range (if applicable).

_______________________________________________________________________________

© Danfoss | 2016.10 VI.GU.M2.00 | 21

Page 22

Operating guide, OPC server for ECL Comfort 310

Clamping:

If clamping is enabled, the data value will be limited to its

‘High Value/EU High Value’ when it exceeds the upper limit,

and similarly to its ‘Low Value/Low EU Value’ parameter when

it exceed

clamping types from the drop

•

•

•

Clamping Parameters:

Specify low and high values for the clamping range.

_______________________________________________________________________________________

s the bottom limit. Select one of the following

-down list:

None: No clamping type is specified.

Clamp on EU: Clamps on the specified low and high

engineering units (EU) values.

As Specified: Clamps on a specified range (set within the

Clamping parameters section of the window) of low and

high values.

_______________________________________________________________________________

© Danfoss | 2016.10 VI.GU.M2.00 | 22

Page 23

Operating guide, OPC server for ECL Comfort 310

10.

To

Right

Con

Parameter’.

Figure

Creating a

e

Or

Select the Device Parameters branch of the Configurator tree

explorer in Wor

‘

This opens the

right-pane of Workbench. Configure the following properties

as specified in Figure

_______________________________________________________________________________________

Device Parameters

add a new device parameter:

-click the ‘Device Parameters’ branch of the

figurator tree explorer, and click on ‘New Device

10-1:

‘New Device Parameter’ in the Configurator tree

xplorer in Workbench

kbench, and use the menu ‘Edit’, ‘New’,

Device Parameter’ menu item.

‘Device Parameters’ properties window in the

10-2.

_______________________________________________________________________________

© Danfoss | 2016.10 VI.GU.M2.00 | 23

Page 24

Operating guide, OPC server for ECL Comfort 310

Figure

Device Param

Every device is identified by its unique address. Its registers

are read as Input (1 bit long) or Input Register (16 bits), or

written to as Coil (1 bit) or Holding Register (16 bits). Registers

of each type are addressed by using 16

The meaning of numbers in the device parameters dialog,

shown in the figure above, is the maximum amount of data

that can be transferred in one message. Setting the value

equal to 0 (zero) forces the server to use single read/write

messages o

You can also configure the following additional properties for

each device type

Word swap:

Swaps the first word with the second when reading/writing

DINT, UDINT or float values. Word swapping is checked by

default to make it consistent with th

multi

Swap bits:

Reverses the order of bits in word

significant bit becomes the most significant bit).

_______________________________________________________________________________________

10-2:

eter Properties

nly.

-byte variables.

-bit numbers.

e DVT way of storing

-sized values (least

_______________________________________________________________________________

© Danfoss | 2016.10 VI.GU.M2.00 | 24

Page 25

Operating guide, OPC server for ECL Comfort 310

11.

The Configurator offers various OPC data items in the

‘

functionality, choose a simulation signal from the tree

explorer. All levels in the ‘

process of simulation. The parent list in the tree explorer is

superior. It has higher

data item or not.

To add a new simulation signal:

Right

tree explorer, and click on ‘

Figure

Creating a ‘New Simulati

e

Or

Select the Simulation Signals branch of the Configurator tree

explorer in Workbench, then use the menu

‘

This opens the

right

parameters as specified

_______________________________________________________________________________________

Simulation Signals

Simulation Signals’ tree control. To test the client

Address Space’ folder support the

priority when deciding to simulate the

-click the Simulation Signals branch of the Configurator

New Simulation Signal’.

11-1:

on Signal’ in the Configurator tree

xplorer in Workbench

‘Edit’, ‘New’,

Simulation Signal’ menu item.

-pane of Workbench. Configure the following

_______________________________________________________________________________

© Danfoss | 2016.10 VI.GU.M2.00 | 25

‘Simulation Signal Parameters’ window in the

in Figure 11-2.

Page 26

Operating guide, OPC server for ECL Comfort 310

Figure

Each ‘Simulation Signal’ type has specific parameters, as

shown below.

Name:

Sp

name can be up to 12 alphanumeric characters, including

underscores ( _ ) and hyphens (

Type:

For each signal, you can select one of the following signal

types from the

•

•

•

•

specifies the signal frequency

moves the signal origin on

_______________________________________________________________________________________

11-2:

Simulation Signal Parameters

ecifies the name of the selected simulation signal. The

drop-down list:

Read Count is incremented by one every time when the

item is read.

Write Count increments when the item is written.

Random generates random value within the ‘Amplitude’

range starting with ‘Position’.

Ramp’, ‘Sine’, ‘Square’, ‘Triangle’ and ‘Step’ are periodical

signals. Their time behavior is influenced by ‘Period’ and

‘Phase’ parameters. ‘Period’

(in milliseconds), while ‘Phase’

the time axis (in degrees).

- ).

_______________________________________________________________________________

© Danfoss | 2016.10 VI.GU.M2.00 | 26

Page 27

Operating guide, OPC server for ECL Comfort 310

Parameters:

•

•

amplitude will be divided.

_______________________________________________________________________________________

‘Square’ and ‘Triangle’ have one additional parameter:

‘Ratio’. Ratio defines Triangle signal steepness, or Square

signal H/L proportions.

The ‘Number of Steps’ parameter of the ‘Step’ signal

defines the number of steps into which the signal

_______________________________________________________________________________

© Danfoss | 2016.10 VI.GU.M2.00 | 27

Page 28

Operating guide, OPC server for ECL Comfort 310

12.

The OPC Server is an OPC Alarm and Events server that

supports the following alarm types:

•

• Digital Alarms

Alarm parameters are set up in the Configurator under the

‘

which is divided into two alarm template types: ‘

A

‘

only, while

except for the ‘String’

provided in the sample configuration database.

12.1

To add a

Right

tree explorer, then

Figure

Creating a

e

_______________________________________________________________________________________

Alarm Definitions

Limit (High High, High, Low, Low Low)

Alarm Definitions’ tree control, shown in the figure below,

Digital

larm’ definitions and ‘Limit (analog) Alarm’ definitions.

Digital Alarms’ can be defined for a data item of "BOOL" type

‘Limit Alarms’ can be defined for all other types

data type. Default alarm definitions are

Limit Alarms

new limit alarm definition:

-click the ‘Alarm Definitions’ branch of the Configurator

click on ‘New Limit Alarm Definition’.

11-1:

‘New Limit Alarm Definition’ in the Configurator tree

xplorer in Workbench

_______________________________________________________________________________

© Danfoss | 2016.10 VI.GU.M2.00 | 28

Page 29

Operating guide, OPC server for ECL Comfort 310

Or

Select the ‘Alarm Definitions’ branch of the Server

Configurator tree explorer in Workbench,

‘Edit’, ‘New’, ‘Limit Alarm Definition’ menu item.

This opens the ‘Limit Alarm Definition’ properties window in

the right

Figure

Limit Alarm Definition

A limit alarm sets the values for four levels of alarms: ‘LoLo’,

‘Lo, Hi’,

subranges within the data item amplitude. Every subrange

definition includes a ‘

that will be appended to

the alarm message, the ‘

Ack.’

In the ‘

dialog box configure

the following settings:

Name:

In the ‘

_______________________________________________________________________________________

then use the menu

-pane of Workbench.

12-2:

and ‘HiHi’. Limit alarm parameters can have

Message Body’

Severity’ of the alarm, and the ‘Req.

flag for alarm acknowledgement.

Limit Alarm Definition Properties’

Name’ field, type a name for the new limit alarm.

_______________________________________________________________________________

© Danfoss | 2016.10 VI.GU.M2.00 | 29

Page 30

Operating guide, OPC server for ECL Comfort 310

Update Rate:

‘Update Rate’

item value (in milliseconds), and possibly responding by

sending the alarm message.

Deadband:

‘Deadband’

amount of alarm messages and overloading the clients when

the signal oscillates around one of t

deadband value extends the limit zone. It results in sending

only one alarm message even if the signal oscillates.

Deadband indicates the deadband value to apply to the

converted analog values. The deadband value is required and

i

repeated alarm cycles.

Value :

The ‘

fields. For example, a value of 10 for ‘LoLo’ is compared with

the value of the input to determine

state.

Message body:

In the ‘

will appear when the alarm is sent. The message can be any

text string.

Return to Normal.

In the ‘

enter the text that will appear when the alarm is taken care of

(e.g. has been acknowledged). The message can be any text

string.

post a description of LoLo limit.

Severity:

‘

defined value for alarm Priority. The valid

OPC severity range is 0 (lowest) to 1000 (highest).

Requires Ack:

The ‘Requires Ack’ field is used for OPC condition alarms to

determine whether the alarm needs a user

acknowledgement. If the ‘Requires Ack’ field is checked, then

the alarm requires a user acknowledgement. If the value is

not checked,

acknowledged

any values specified in configuration mode.

_______________________________________________________________________________________

defines the frequency of checking the data

prevents the server from generating a huge

he limits specified. The

s calculated on borderline alarming limit values to prevent

Value’ field is used to calculate the state of the input

if the alarm is in ‘LoLo’

Message Body’ field, enter the warning message that

Return to Normal’ field, check the check box and then

Severity’ is the OPC-

then the alarm is posted as already

.

_______________________________________________________________________________

© Danfoss | 2016.10 VI.GU.M2.00 | 30

It is not necessary to enter a message text or a base text.

The Server will default to the OPC subcondition name and

the OPC condition name. For example, a LoLo alarm will

Changes to the alarm property fields (HiHi, LoLo, Hi, Lo,

Message Text, etc.) in runtime through an OPC tag update

will be automatically saved to the database, over-writing

Page 31

Operating guide, OPC server for ECL Comfort 310

12.2

To add a

Right

Configurator tree explorer, then click on

Alarm Definition

Figure

Creating a

tree explorer in Workbench

Or

Select the 'Alarm Definitions' branch of the Configurator tree

explorer in Workbench, then use the menu ‘Edit’, ‘New’, ‘Digital

Alarm Definition’ menu item.

_______________________________________________________________________________________

Digital alarms

new digital alarm definition:

-click the 'Alarm Definitions' branch of the

‘New Digital

’.

12-3:

‘New Digital Alarm Definition’ in the Configurator

_______________________________________________________________________________

© Danfoss | 2016.10 VI.GU.M2.00 | 31

Page 32

Operating guide, OPC server for ECL Comfort 310

This opens the ‘Digital Alarm Definition’ properties window in the

right

Figure

Digital Alarm Definition

Specify a ‘Value’ for the digital alarm (‘True’ or ‘False’).

Message Body:

In the ‘Message Body’ field, enter the warning mes

appear when the alarm is sent. The message can be any text

string.

Return to Normal:

In the ‘Return to Normal’ field, check the check box and then enter

the text that will appear when the alarm is taken care of (e.g. has

been acknowl

Severity:

‘Severity’ is the OPC

y. The valid OPC

severity range is 0 (lowest) to 1000 (highest).

_______________________________________________________________________________________

-pane of Workbench.

12-4:

edged). The message can be any text string.

-defined value for alarm Priorit

_______________________________________________________________________________

© Danfoss | 2016.10 VI.GU.M2.00 | 32

sage that will

It is not necessary to enter a message text or a base text.

The server will default to the OPC subcondition name

and the OPC condition name.

Page 33

Operating guide, OPC server for ECL Comfort 310

Requires Ack:

The ‘Requires Ack’ field is used for OPC condition alarms to

determine whether the alarm needs a user acknowledgement.

Apply:

‘Apply’: Saves all changes specified in the pro

The alarm definition appears in the tree control.

_______________________________________________________________________________________

perties dialog box.

_______________________________________________________________________________

© Danfoss | 2016.10 VI.GU.M2.00 | 33

Page 34

Operating guide, OPC server for ECL Comfort 310

13.

a server

When OPC servers are installed on the system, they are registered

so that clients can find them and users can view th

make a client/server connection, the user must first choose a

server. The server name selected is used to get a class ID which, in

turn, is used to create a COM object. If the user selects a server

that is not currently running, the system starts the server and then

creates the object in that server on behalf of the client.

Once the COM object is created, the client application has an

IOPCServer interface, as defined in the OPC specification. This is

the main interface to an OPC server, and

this as the Server interface. (The other interface is Group.) An OPC

client always creates a group in the server and registers an advice

interface with it to get asynchronous data notification.

When an item is added, the dialog dis

flat list of names, depending on the server. The names are queried

from the Server object using the filter string and requested data

type. When the user either types or selects a name, an item by that

name is added to the Grou

immediately to get an initial value.

Items in a group are scanned by the server; when their values

change, the advise interface in the client is notified. A data

structure containing the data for each item whose value or qu

has changed (and only those items) is passed to the client’s advice

interface. The client unpacks and uses the data.

13.1

The server status dialog periodically queries the server object for

status and displ

The ‘Group Parameters’ dialog box queries the group state and

displays the results. The ‘OK’ button and ‘Apply’ button in the

‘Group Parameters’ dialog box write the parameters from the

dialog to the Group object and read the parameters b

primarily controls the scanning and updating of data. When a

group is inactive, it does not send data notifications to the client

and, typically there is no reason to scan the items when the group

is inactive.

The ‘Update Rate’ in the ‘Group Par

the rate at which data notifications should be sent back to the

client, assuming that data have changed. This is also the rate at

which items are scanned on behalf of this client.

_______________________________________________________________________________________

How the client connects to and gets data from

em in a list. To

this document refers to

plays either a hierarchy or a

p object. This item is also read

Server status and group parameters

ays the results.

_______________________________________________________________________________

© Danfoss | 2016.10 VI.GU.M2.00 | 34

ameters’ dialog box specifies

ality

ack. This

Page 35

Operating guide, OPC server for ECL Comfort 310

13.2

The OPC server is the actual runtime module. The OPC server is

responsible for accessing the data on the OPC clients' requests.

The OPC server has no user interface. It will be started

automatically when the OPC client connects to the server.

The runtime module

and write operations are performed directly with no intermediate

cache level. It has the effect that every client works with accurate

data. In normal situations, the data in the database will be

accessed (read/write) by OPC clients. However, the data are stored

in a standard database, and other software applications can

manipulate its data as well through programming techniques

such as Microsoft's ADO (ActiveX Data Objects) or OLE DB. The

OPC Server refreshes (with

to inform the OPC clients of changes through some external

application.

One of the basic concepts of the OPC server is that monitored data

are relatively stable in time. The runtime module resides in the

Danfoss/Danf

_______________________________________________________________________________________

Danfoss ECL Runtime Module

operates directly with the database. Read

a configurable delay) its tags in order

oss ECL OPC server directory.

_______________________________________________________________________________

© Danfoss | 2016.10 VI.GU.M2.00 | 35

Loading...

Loading...