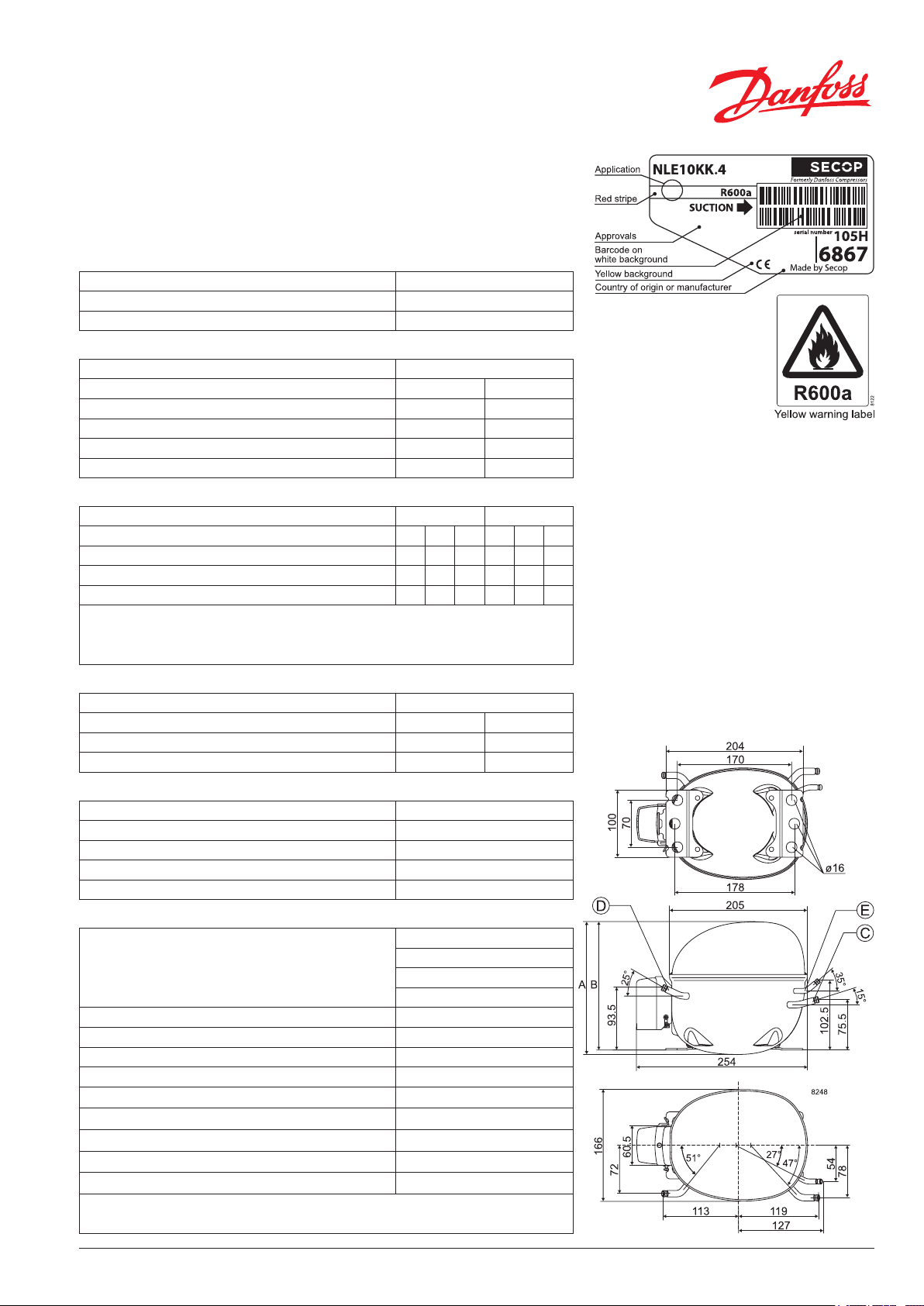

NLE10KK.4

Energy-optimized Compressor

R600a

220-240V 50Hz

General

Code number 105H6867

Approvals EN 60335-2-34 with Annex AA

Compressors on pallet 80

Application

Application LBP

Frequency Hz 50 60

Evaporating temperature °C -35 to -10 –

Voltage range V 198 - 254 –

Max. condensing temperature continuous (short) °C 60 (70) –

Max. winding temperature continuous (short) °C 125 (135) –

Cooling requirements

Frequency Hz 50 60

Application

32°C S – – – – –

38°C S – – – – –

43°C S – – – – –

Remarks on application:

Motor

Motor type RSIR/RSCR

LRA (rated after 4 sec. UL984), HST | LST A – 5.0

Cut in Current, HST | LST A – 9.4

Resistance, main | start winding (25°C) Ω 14.9 17.9

Design

Displacement cm

Oil quantity (type) cm

Maximum refrigerant charge g 150

Free gas volume in compressor cm

Weight without electrical equipment kg 10.7

Dimensions

Height mm A 190

Suction connector location/I.D. mm | angle C 6.2 | 15°

material | comment CU-plated steel | Al caps

Process connector location/I.D. mm | angle D 6.2 | 25°

material | comment CU-plated steel | Al caps

Discharge connector location/I.D. mm | angle E 5.0 | 35°

material | comment CU-plated steel | Al caps

Oil cooler connector location/I.D. mm | angle F –

material | comment –

Connector tolerance I.D. mm ±0.09, on 5.0 +0.12/+0.20

Remarks:

LBP MBP HBP LBP MBP HBP

3

3

3

B 183

B1 –

B2 –

10.09

270 (mineral)

2310

S = Static cooling normally sufcient

O = Oil cooling

F

= Fan cooling 1.5 m/s

1

(compressor compartment temperature

equal to ambient temperature)

F2 = Fan cooling 3.0 m/s necessary

SG = Suction gas cooling normally sufcent

– = not applicable in this area

June 2012 Manufactured by Secop for Danfoss - DEHC.ED.520.B2.02 / 520N1322 1/2

EN 12900 Household (CECOMAF) 220V, 50Hz, 2 W PTC consumption incl., static cooling

Evap. temp in °C -45 -40 -35 -30 -25 -23.3 -20 -15 -10 -6.7 -5 0 5 7.2 10 15 20

Capacity in W 73.9 98.3 128 139 164 207 257

Power cons. in W 81.3 94.3 108 113 123 140 161

Current cons. in A 0.62 0.65 0.70 0.72 0.76 0.83 0.92

COP in W/W 0.91 1.04 1.19 1.23 1.33 1.47 1.60

EN 12900 Household (CECOMAF) 220V, 50Hz, RC 4μF, 2 W PTC consumption incl., static cooling

Evap. temp in °C -45 -40 -35 -30 -25 -23.3 -20 -15 -10 -6.7 -5 0 5 7.2 10 15 20

Capacity in W 73.9 98.3 128 139 164 207 257

Power cons. in W 78.5 91.0 104 109 118 134 152

Current cons. in A 0.41 0.47 0.53 0.55 0.60 0.67 0.76

COP in W/W 0.94 1.08 1.23 1.28 1.39 1.54 1.69

ASHRAE LBP 220V, 50Hz, 2 W PTC consumption incl., static cooling

Evap. temp in °C -45 -40 -35 -30 -25 -23.3 -20 -15 -10 -6.7 -5 0 5 7.2 10 15 20

Capacity in W 90.3 120 156 170 200 252 314

Power cons. in W 81.4 94.3 108 113 123 140 160

Current cons. in A 0.62 0.65 0.70 0.72 0.76 0.83 0.92

COP in W/W 1.11 1.27 1.45 1.51 1.63 1.80 1.96

ASHRAE LBP 220V, 50Hz, RC 4μF, 2 W PTC consumption incl., static cooling

Evap. temp in °C -45 -40 -35 -30 -25 -23.3 -20 -15 -10 -6.7 -5 0 5 7.2 10 15 20

Capacity in W 90.3 120 156 170 200 252 314

Power cons. in W 78.7 91.0 104 108 118 134 152

Current cons. in A 0.41 0.47 0.53 0.55 0.59 0.67 0.76

COP in W/W 1.15 1.32 1.51 1.57 1.70 1.89 2.07

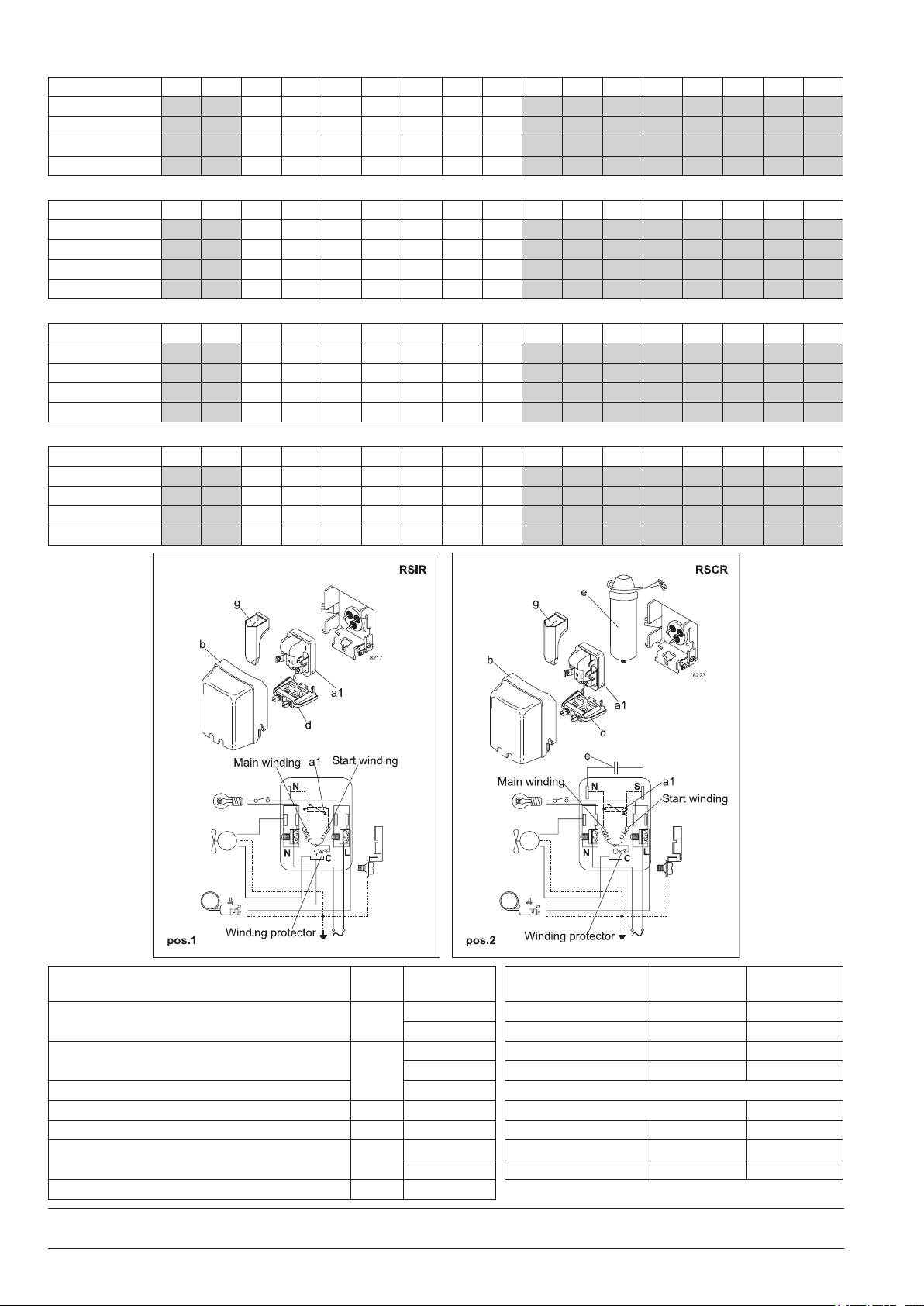

Accessories for NLE10KK.4 Figure Code number Test conditions EN 12900/

ASHRAE

CECOMAF

PTC starting device 6.3 mm spade connectors

4.8 mm spade connectors 103N0018 Ambient temperature 32°C 32°C

PTC starting device 6.3 mm spade connectors

4.8 mm spade connectors 103N0021 Liquid temperature no subcooling 32°C

ePTC starting device 4.8 mm spade connectors 103N0050

a1

(pos.1)

a1

(pos.2)

103N0011 Condensing temperature 55°C 54.4°C

103N0016 Suction gas temperature 32°C 32°C

Cover b 103N2010 Mounting accessories Code number

Cord relief d 103N1010 Bolt joint for one comp. Ø: 16 mm 118-1917

Run capacitor 4 µF 6.3 mm spade connectors

(optional) 4.8 mm spade connectors 117-7119 Snap-on in quantities Ø: 16 mm 118-1919

e

117-7117 Bolt joint in quantities Ø : 16 mm 118-1918

Protection screen for PTC g 103N0476

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to

products already on order provided that such alterations can be made without subsequential changes being necessary in specications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

2/2 Manufactured by Secop for Danfoss - DEHC.ED.520.B2.02 / 520N1322 June 2012

Loading...

Loading...