Page 1

Data Sheet

Check valve

Type NRVT

For high pressure CO2 application

NRVT piston type check valves is designed for

installation in discharge line to prevent

refrigerant migration to protect compressor

and enable the pressure equalization of rotary

compressor before startup. In the meanwhile

this valve can be used in other installation

positions of CO2 systems such as hot gas and

suction lines.

Features:

• Stable operation covering full map of

compressor

• Fullls high temperature and pressure

requirements for the discharge lines used in

Transcritical CO2 systems

◦ Rupture proof, optimized TIG welding

◦ Specially-selected sealing material for CO

refrigerant

• Hermetic brass body design

• Compatible to connect both copper/stainless

steel tubes

• In compliance to PED & UL regulations

2

AI405623214680en-000101

Page 2

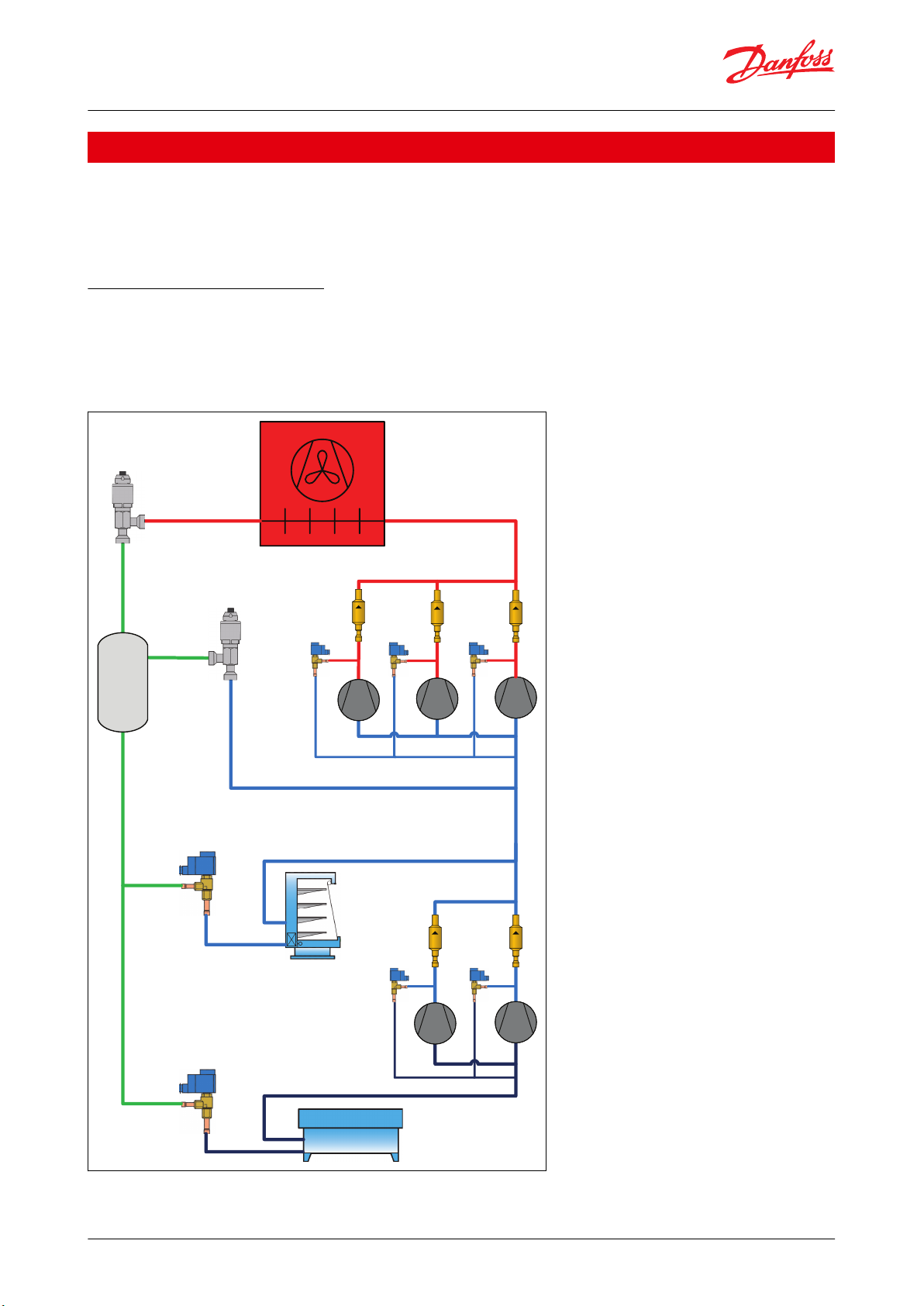

GC

CCMT Light

CCMT Light

AKVP

AKVP

NRVT

NRVT

EVT

EVT

Check valve, type NRVT

Applications

Typical applications for NRVT valves are:

• CO2 MiniPack

• CO2 CDU BLDC

Pressure Equalization/ Relief

• To start rotary BLDC compressors, it is necessary to equilize pressure between discharge and suction line.

• In single compressor solution it is possible to manage equalization via high pressure valve and bypass valve

• In system with parallel mounted compressors, It is necessary to install on each compressor check valve in

discharge line and solenoid valve to bypass high pressure to suction line

Figure 1: Pressure Equalization/ Relief

© Danfoss | Climate Solutions | 2022.02 AI405623214680en-000101 | 2

Page 3

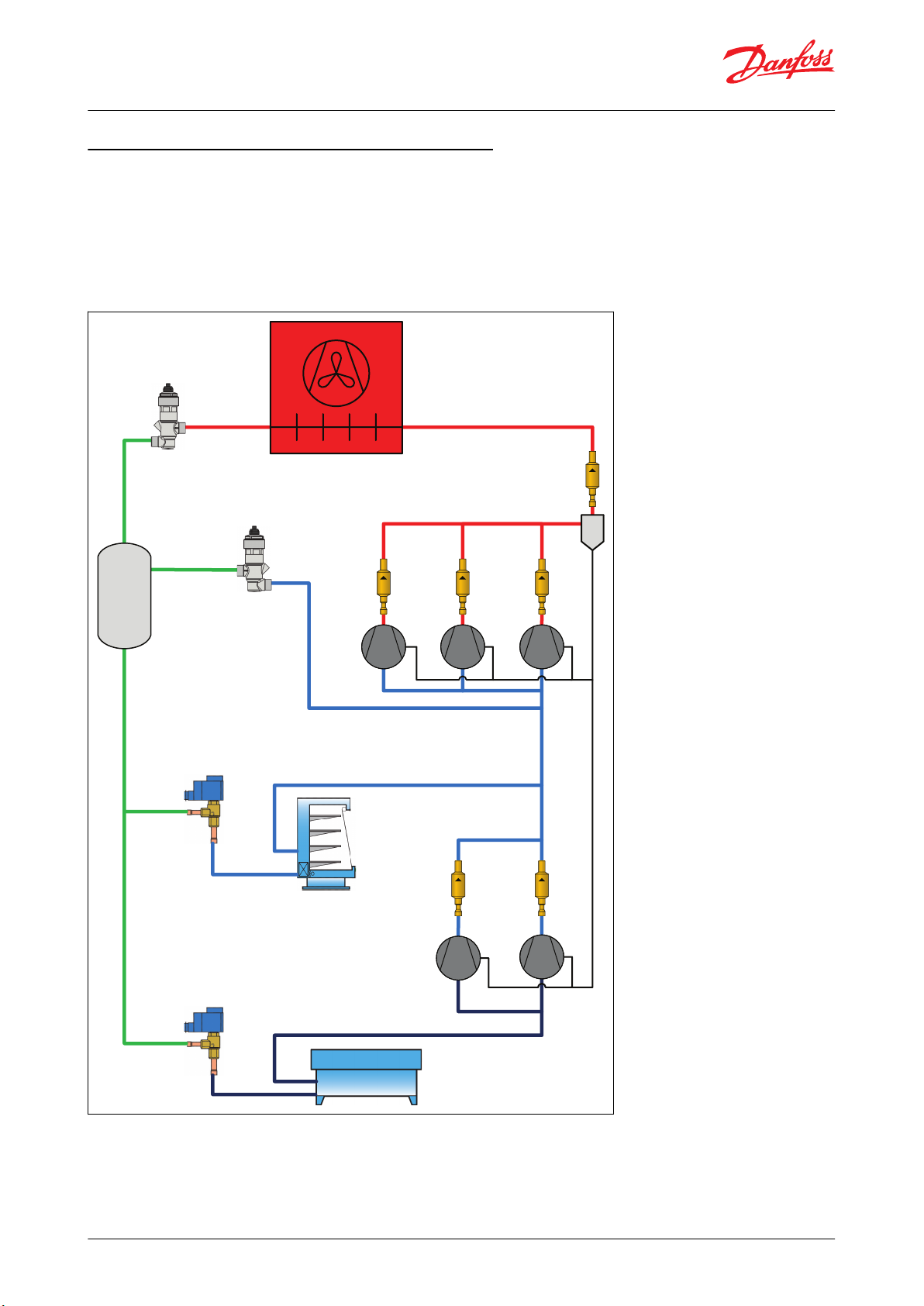

GC

CCMT

CCMT

NRVT

NRVT

NRVT

AKVP

AKVP

Check valve, type NRVT

Discharge line – compressors mounted in parallel

• If using an individual oil separator for each compressor – for protection against back condensation of

refrigerantin the separator with the compressor shut-o.

• If the cylinder heads of the compressors can cool down below the condensing temperature at standstill

• Check valve for a common oil separator (installation position towards the condenser):

– If there is a danger of back condensation from the condenser or liquid receiver

– Systems with long shut-o periods

Figure 2: A diagram of Discharge line – compressors mounted in parallel

© Danfoss | Climate Solutions | 2022.02 AI405623214680en-000101 | 3

Page 4

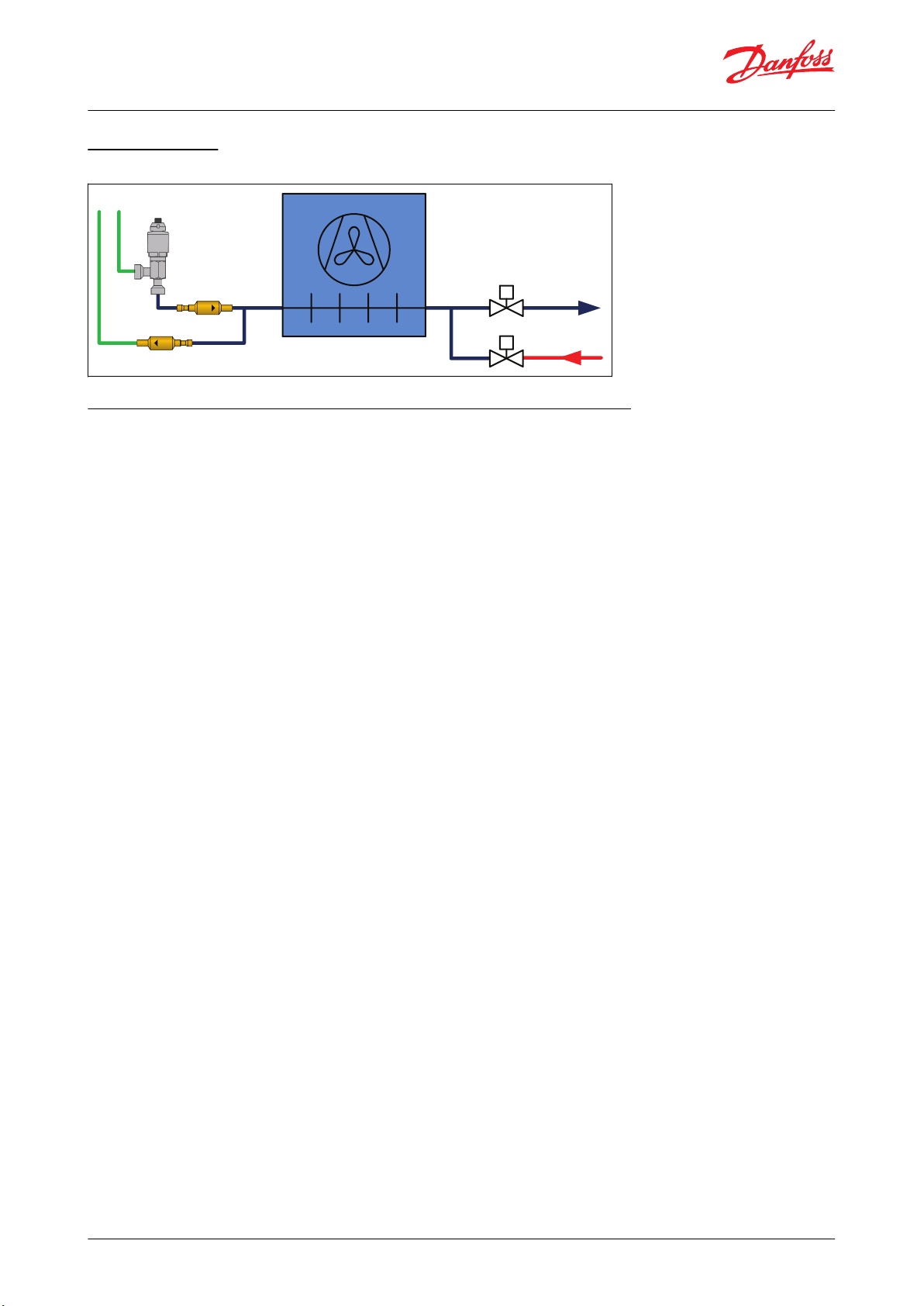

Liquid line

Suction line

Hot Gas line

Defrost drain line

Check valve, type NRVT

Hot Gas Defrost

Figure 3: A diagram of Hot Gas Defrost

Low Pressure lift Multi Ejector / cold & warm ambient temperature

Optimal solution for smaller commercial refrigeration systems

• In colder ambient conditions system operates as a standard booster system

• Ejector is simply controlling the high pressure as a high pressure valve according to the optimal COP Gas Cooler

pressure algorithm

• Pressure in the receiver as pressure dierence between the receiver and Po-MT evaporator suction pressure

• Receiver pressure controlled by rst gas by-pass valve CCMT#1, second gas by-pass valve CCMT#2 is closed

• Check valve on MT evaporator suction line is open

• In warmer ambient conditions temperature out of the gas cooler is high and corresponding optimal pressure in

gas cooler is high too, so ejector can lift all gas mass ow from MT evaporators through the ejector to the

receiver

• Check valve in suction line between compressors and MT evaporators is closed due to pressure dierence

• The pressure in the receiver is result of the ejector performance.

• Both gas by-pass valves CCMT#1 & CCMT#2 are open to minimize pressure loses

• MT compressors are controlled based on Po-MT pressure sensor and Psuc-MT is protection

© Danfoss | Climate Solutions | 2022.02 AI405623214680en-000101 | 4

Page 5

MT

LT

Psuc-MT

Po-MT

GC

CTM 6 LP

NRVT

CCMT#1

CCMT#2

Check valve, type NRVT

Figure 4: Low Pressure lift Multi Ejector / cold & warm ambient temperature

© Danfoss | Climate Solutions | 2022.02 AI405623214680en-000101 | 5

Page 6

Technical data

Values

Refrigerants

R 744 (CO2)

Refrigerant oil

POE, PAG

Max. working pressure

140 bar / 2031 psig

Media temperature range

-40 °C – 150 °C / -40 °F – 302 °F

Flow direction

Single-ow

Valve direction

Sraightway

Serviceable

non-serviceable

Product engraving

Packaging label

M

a

d

e

i

n

U

S

A

020-6411

M

R

3

0

0

7

2

1

/

S

NRVT

TS/COT-40C TO 150C

PS 140BARDP/MAP2031PSIG

Information

Explanation

Danfoss

Danfoss Logo

NRVT

Product type

020-6411

Code number for ordering

PS 140 BAR DP/MAP 2031 PSIG

Max. working pressure

TS/COT -40°C TO +150°C

Media temperature range

MR

Place of manufacture

300721/S

Production date: DDMMYY/S (S: shift)

MADE IN USA

Country of origin

UL and EAC logos

Approval

Information

Explanation

Check valve

Product Description

NRVT

Product type

020-6411

Code number

R744

Refrigerant

Straightway

Direction

DN 3/8 in ODF

Connection

PS 140bar/MWP 2031psig

Max Working Pressure

Check valve, type NRVT

Product specication

Technical data

Table 1: Technical data

Identication

Relevant product data is available on the product and box label. An example of a box label and product label are

shown, including an explanation of the content.

Table 2: Box label & product label (example)

Table 3: Product engraving

Table 4: Packaging label

© Danfoss | Climate Solutions | 2022.02 AI405623214680en-000101 | 6

Page 7

Information

Explanation

TS -40/+150°C -40/302°F

Media temperature range

MR

Place of manufacture

110122

Production date: DDMMYY

MADE IN USA

County of origin

Data Matrix

Content of traceability data matrix code (IDKey)

EAN code

Barcode for individual code no. identication according to EAN standard

Danfoss A/S, 6430 Nordborg, Denmark

Address

1

5

4

6

2

3

Position

Description

Material

1

Valve body

Brass2Piston

Brass3Spring

Stainless steel

4

Piston guide

Brass5Stop face

Brass6Tailpiece

Brass

Check valve, type NRVT

Design and materials

The pressure of the uid passing through a refrigeration system opens the valve, while any reverse ow closes the

valve.

In NRVT check valve a sealing disc is activated by the spring to close or open the valve, and the force of the spring

determines the Min. opening pressure. When the refrigerant ows through the valve and the dierential pressure of

the ow is higher than the Min. opening pressure, the piston will move towards the stop face and compress the

spring, then the valve will open.

Figure 5: Design and materials

Dimensions and Weights

You will nd downloadable dimension drawings for individual code numbers on Danfoss store as part of the Visuals

tab for individual code numbers.

© Danfoss | Climate Solutions | 2022.02 AI405623214680en-000101 | 7

Page 8

D

L

L1

L1

Danfoss

64G8052

Type

Connection Size

Connection tol‐

erance

LL1øD

Net weight

Code no.

[in.]

[mm]

[mm]

[mm]

[mm]

[mm]

[kg]

NRVT 10s

3/8

-

-0.76/+0.76

110.5

8.6

26.4

0.2

020-6401

NRVT 10sH

0.35

020-6411

NRVT 12s

1/2-110.5

10.4

26.4

0.2

020-6402

NRVT 12sH

0.35

020-6412

NRVT 16s

5/8-132.1

12.7

34.9

0.35

020-6403

*

NRVT 16sH

0.35

020-6413

*

Check valve, type NRVT

Figure 6: Dimensions and Weights

NOTE:

(*) 5/8 in. will be available in July, 2022

© Danfoss | Climate Solutions | 2022.02 AI405623214680en-000101 | 8

Page 9

Valve type

Multi pack

Code no.

Solder ODF × ODF

Kv

Cv

Min. OPD Δp

Max.

working

pres‐

sure:

PS/MWP

Media temperature

range

PED cat‐

egory

Start open

Fully open

[in.]

[mm]

[m3/h]

[gal/min]

[bar]

[psi]

[bar]

[psi]

NRVT 10s

020-6401

3/8 1.20

1.39

0.01

0.15

0.05

0.73

140 bar /

2031 psig

-40 °C – 150 °C / -40

°F –302 °F

Art. 4.3

NRVT 12s

020-6402

1/2 2.10

2.44

NRVT 16s

020-6403*

5/8 4.80

5.57

NRVT 10sH

020-6411

3/8 1.20

1.39

0.25

3.63

0.9

13.05

NRVT 12sH

020-6412

1/2 2.10

2.44

NRVT 16sH

020-6413*

5/8 3.50

4.06

Check valve, type NRVT

Ordering

Table 5: Ordering

NOTE:

(*) 5/8 in. will be available in July, 2022

© Danfoss | Climate Solutions | 2022.02 AI405623214680en-000101 | 9

Page 10

File name

Document type

Document topic

Approval authority

EAC Declaration

EAC

EAC RU

033F4003

Manufacturers Declaration

PED

Danfoss

033F4006

Manufacturers Declaration

China RoHS

Danfoss

033F4010

Manufacturers Declaration

RoHS

Danfoss

Mechanical - Safety Certicate

UL

UL

Check valve, type NRVT

Certicates, declarations, and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Certicates, declarations, and approvals

Table 6: Certicates, declarations, and approvals

© Danfoss | Climate Solutions | 2022.02 AI405623214680en-000101 | 10

Page 11

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Coolselector®2 - nd the best components for you HVAC/R system

Coolselector®2 makes it easy for engineers, consultants, and designers to nd and order the best

components for refrigeration and air conditioning systems. Run calculations based on your operating

conditions and then choose the best setup for your system design.

Download Coolselector®2 for free at coolselector.danfoss.com.

Any information, including, but not limited to information on selection of product, its application or use, product design, weight, dimensions, capacity or any other

technical data in product manuals, catalogues descriptions, advertisements, etc. and whether made available in writing, orally, electronically, online or via download,

shall be considered informative, and is only binding if and to the extent, explicit reference is made in a quotation or order conrmation. Danfoss cannot accept any

responsibility for possible errors in catalogues, brochures, videos and other material. Danfoss reserves the right to alter its products without notice. This also applies to

products ordered but not delivered provided that such alterations can be made without changes to form, t or function of the product. All trademarks in this material

are property of Danfoss A/S or Danfoss group companies. Danfoss and the Danfoss logo are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2022.02 AI405623214680en-000101 | 11

Loading...

Loading...