Page 1

Technical Information

Module Valve Block

MVB10

www.danfoss.com

Page 2

Technical Information

MVB10 Module Valve Block

Revision history Table of revisions

Date Changed Rev

September 2020 Rebranded to Danfoss 0101

2 | © Danfoss | September 2020 BC353276907439en-000101

Page 3

Technical Information

MVB10 Module Valve Block

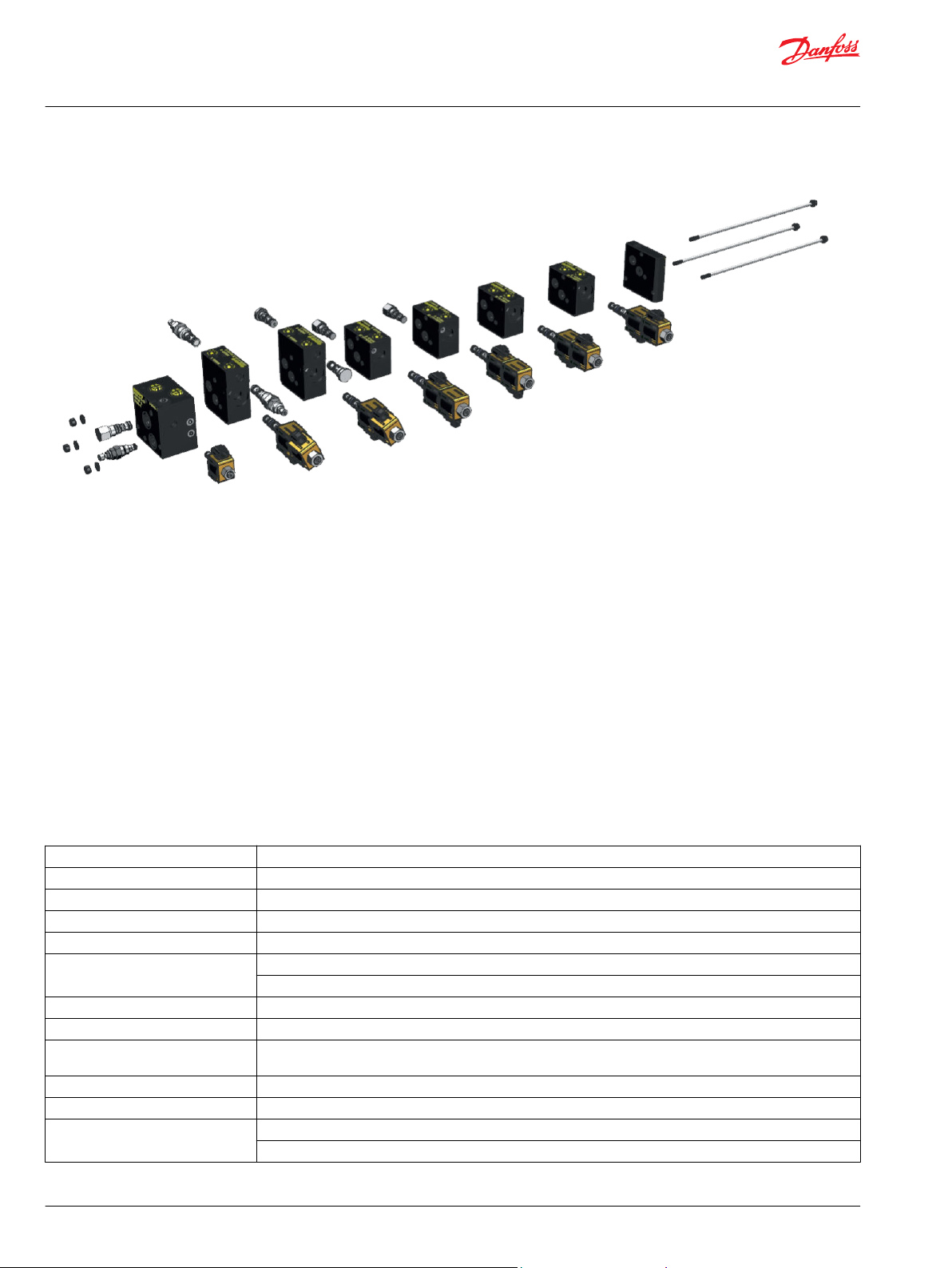

Contents

MVB10 Module HIC System

MVB10 technical data..................................................................................................................................................................... 4

System configuration guidelines................................................................................................................................................5

Inlet module

MVB10-I-LS..........................................................................................................................................................................................7

MVB10-I................................................................................................................................................................................................9

Inlet module component selection.........................................................................................................................................11

Interface module

MVB10-IF........................................................................................................................................................................................... 13

Working module

MVB10-W...........................................................................................................................................................................................15

MVB10-W-C...................................................................................................................................................................................... 17

MVB10-W-LH with counterbalance valves............................................................................................................................19

MVB10-W-LH with pilot check valves..................................................................................................................................... 21

MVB10-W-C-LH with counterbalance valves....................................................................................................................... 24

MVB10-W-C-LH with pilot check valves.................................................................................................................................27

MVB10-W-F.......................................................................................................................................................................................29

MVB10-W-F-LH with counterbalance valves........................................................................................................................31

MVB10-W-F-LH with pilot check valves................................................................................................................................. 34

Working module component selection.................................................................................................................................37

End module

MVB10-E............................................................................................................................................................................................ 40

Tie rod kits (seals included)

©

Danfoss | September 2020 BC353276907439en-000101 | 3

Page 4

Technical Information

MVB10 Module Valve Block

MVB10 Module HIC System

Danfoss has a range of modular HICs developed to match 40 years of experience in HIC and cartridge

design with today's market request of compact and flexible solutions. The Danfoss MVB10 system is

designed for the electro-hydraulic control of mobile machines for performance up to 80 l/min inlet flow

and 210 bar working pressure, rated to 1 million cycles according to the NFPA T2.6.1 endurance test.

The modularity concept enables machine developers to create flexible hydraulic control solutions with

standard components, ensuring the best speed to market is achieved with a high quality product.

Moreover, MVB10 is completely configurable, allowing end customers to apply standard, cost effective

solutions in applications.

The MVB10 also offers the flexibility to easily expand with optional features, thus reducing stock value

while increasing technical and logistic flexibility. MVB10 offers a unique synergy with Danfoss PVG 16 and

PVG 32 through an available interface module that allows the two products to be used in combination

while using common hardware. This capability unlocks a whole new and exciting potential for tailormade solutions that can match exactly the increasingly demanding the hydraulic controls market.

MVB10 technical data

General technical data

Ambient temperature -25° C to + 50° C

Input flow max 80 l/min [21.1 US gal/min]

Working section rated flow 22 l/min [5 US gal/min]

Load operating max pressure

Tank peak pressure

Oil temperature NBR seals: -40° C to 100° C [-40° F to 212° F]

Oil absolute viscosity limits 12-400 cSt [66-1854 SUS]

Oil recommended viscosity 12-54 cSt [66-250 SUS]

Permissible oil types See Danfoss documents Hydraulic Fluids and Lubricants (BC152886484524) and Biodegradable Hydraulic Fluids

Oil cleanliness ISO 4406: 18/17/13 or better

Maximum number of sections 10 (for more, consult your Danfoss representative)

Surface treatment Manifolds: black anodized

*

Rated pressure based on NFPA fatigue test standards (at 1 Million Cycles)

*

*

210 bar [3045 psi]

210 bar [3045 psi]

VITON seals: -26° C to 204° C [-15° F to 400° F]

Applications (520L0465)

Cartridges: zinc plated

4 | © Danfoss | September 2020 BC353276907439en-000101

Page 5

LE

MVB 10-I -LS

SV0

RV1

SH2

SH1

SV1

MVB 10- W

LE1

MVB 10-W- C

SH4

SH3

PSV 2

B1 A1 B2 A2

LS

P

T

SH6

SH5

CB1 CB2

PSV 3

MVB 10-W-C -LH- VCB0 6

LE2

MVB 10-E

Orifice

Provision

B3 A3

Tan k

Pum p

Technical Information

MVB10 Module Valve Block

MVB10 Module HIC System

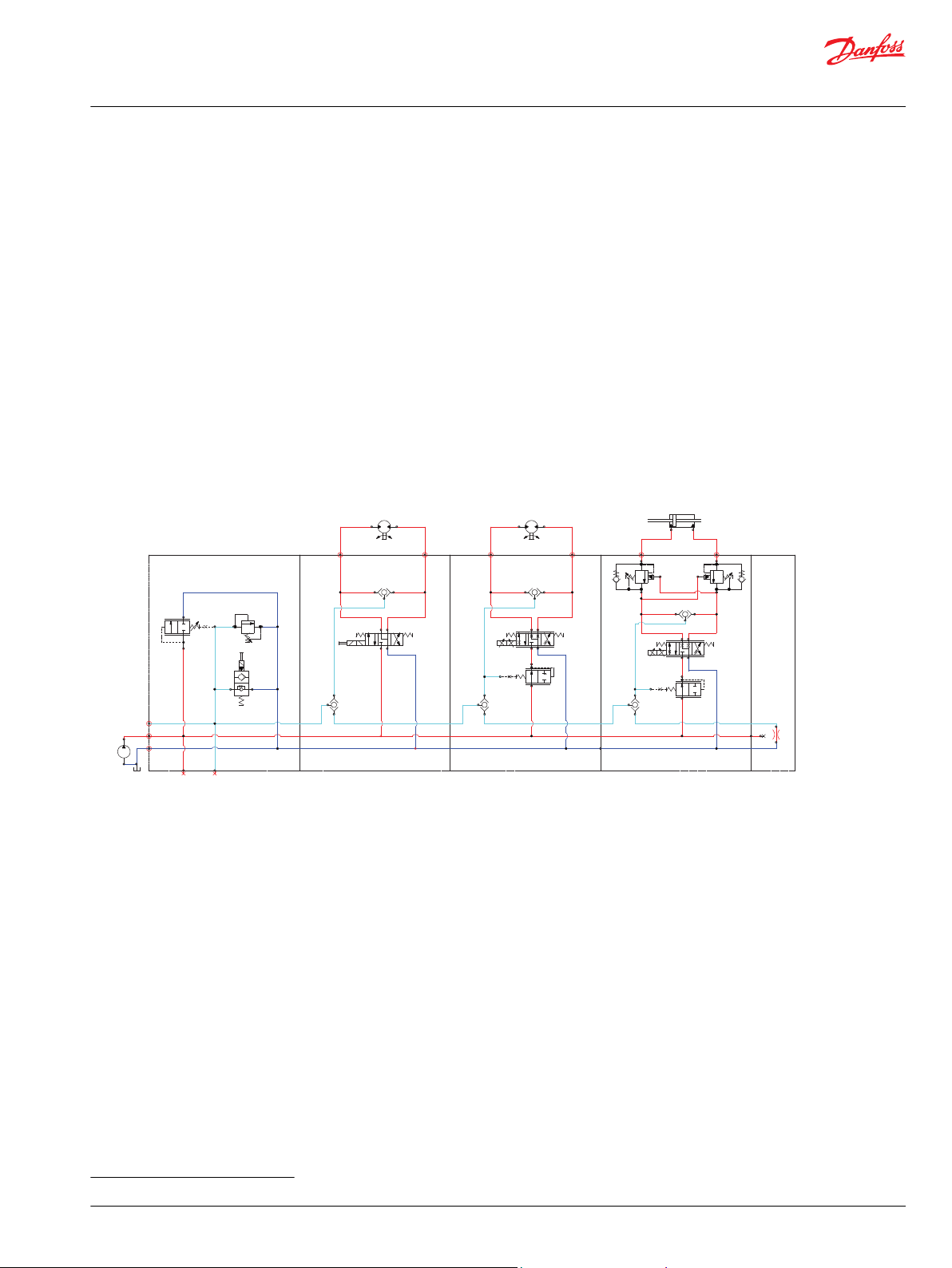

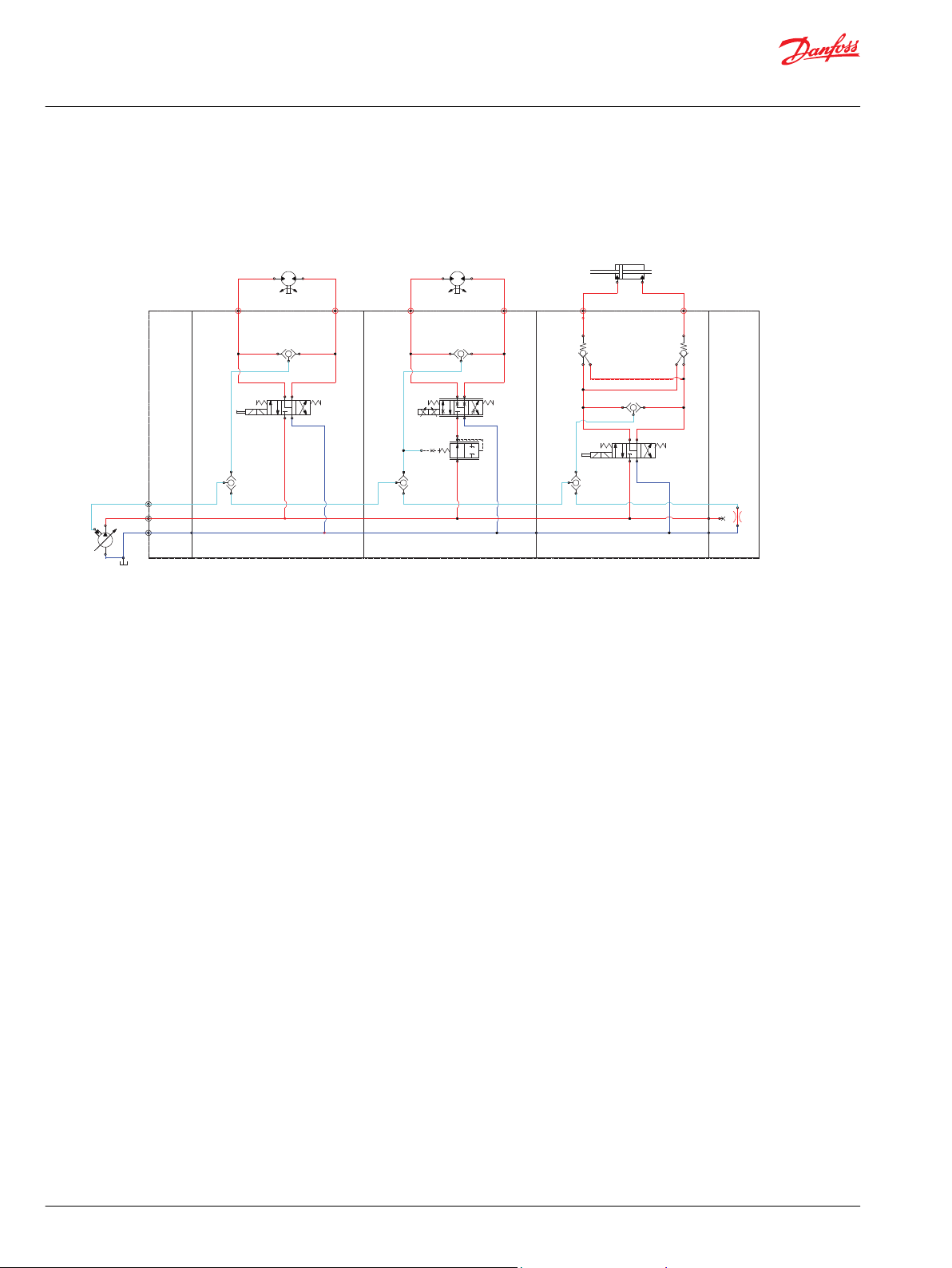

System configuration guidelines

Every MVB assembly is composed of the following base parts:

•

An inlet section or a PVG 32/16 interface

•

One or more work sections

•

An end plate

Work sections are available with the following functions:

•

On-off

•

On-off with integrated load holding

•

Proportional compensated

•

Proportional compensated with integrated load holding

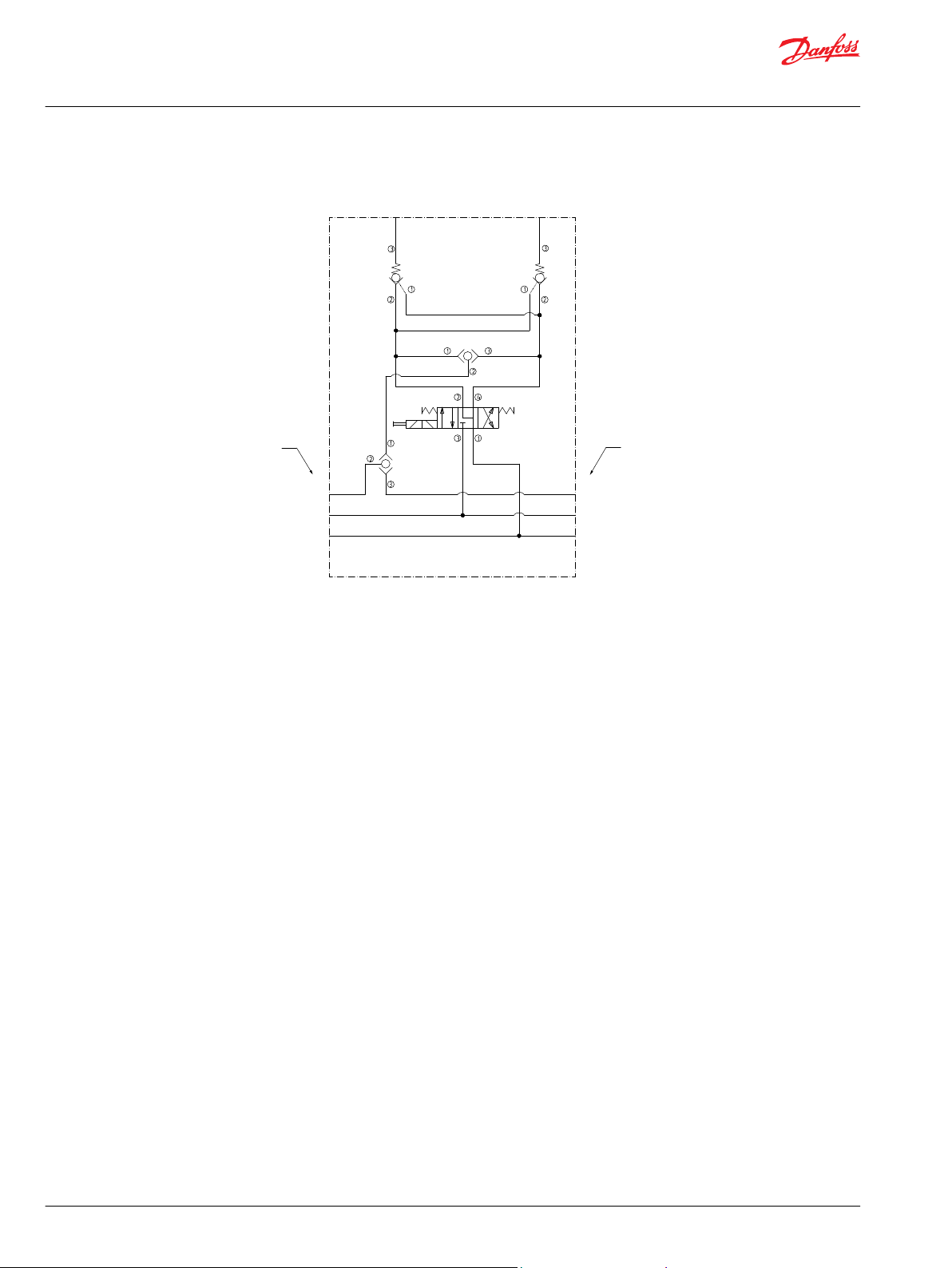

Configuration example 1

3-function assembly for fixed displacement pump with 1 on-off directional controlled section, 1 proportional section, 1 proportional

section with load holding function. System is provided with a shut-off valve, a relief valve and a logic element to bypass excessive flow.

Proportional sections are locally compensated.

*

©

Danfoss | September 2020 BC353276907439en-000101 | 5

*

Load holding module allows the use of either counterbalance or pilot operated check valves

Page 6

MVB10- I

SH2

SH1

SV1

MVB 10-W

LE1

MVB 10-W-C

SH4

SH3

PSV 2

B1 A1 B2 A2

MVB10- E

Orifice

Provision

B3 A3

Ls

P

T

Load Sen sing Pump

Tank

SH6

SH5

SV3

PC1 PC2

MVB 10-W-LH-R PC0 6

Technical Information

MVB10 Module Valve Block

MVB10 Module HIC System

Configuration example 2

3-function assembly for LS pump with 1 on-off directional controlled section, 1 proportional section and 1 on-off section with load

holding. Proportional sections are locally compensated.

6 | © Danfoss | September 2020 BC353276907439en-000101

Page 7

LS

T

P

LS

T

P

MVB10

interface

RV

SV

LE

MP

MLS

Technical Information

MVB10 Module Valve Block

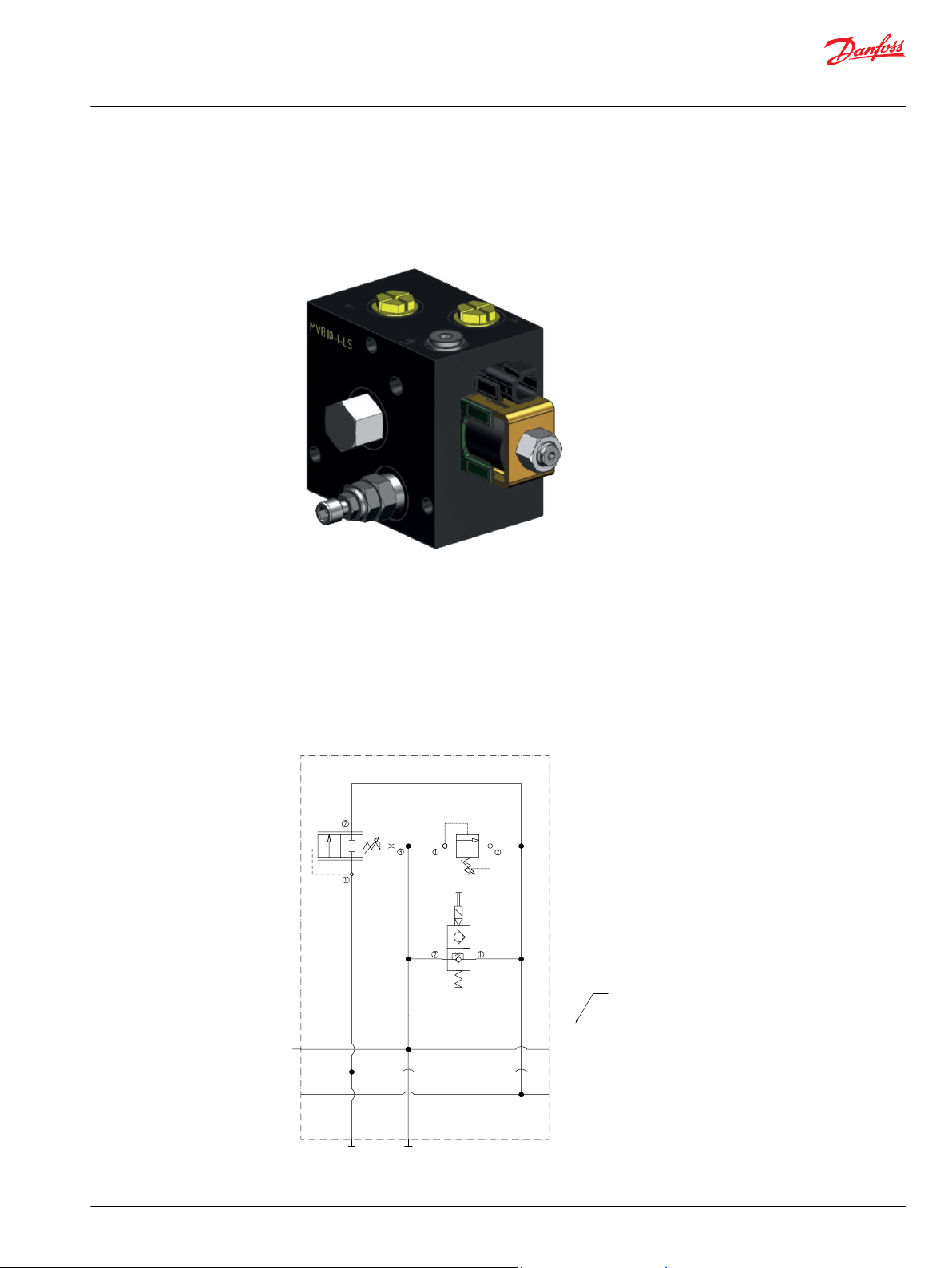

Inlet module

MVB10-I-LS

Operation

This inlet module is designed to operate in systems using either a fixed or variable displacement pump.

Threaded ports are provided for external connection to the P, T and LS lines.

For applications with a fixed pump, the enable valve (SV) will allow all flow to bypass to tank at low

pressure when de-energized. When energized, a logic element (LE) is used to efficiently bypass excess

flow not used by the work sections to tank. The included LS relief valve (RV) limits the overall system

pressure. This inlet section can also be configured to be applied with a variable displacement pump by

replacing the logic element(LE) with a closed cavity plug (CP10-B- 3S-B).

Inlet module with compensation, relief and enable valve

©

Danfoss | September 2020 BC353276907439en-000101 | 7

Page 8

LIFTING HOLE M10

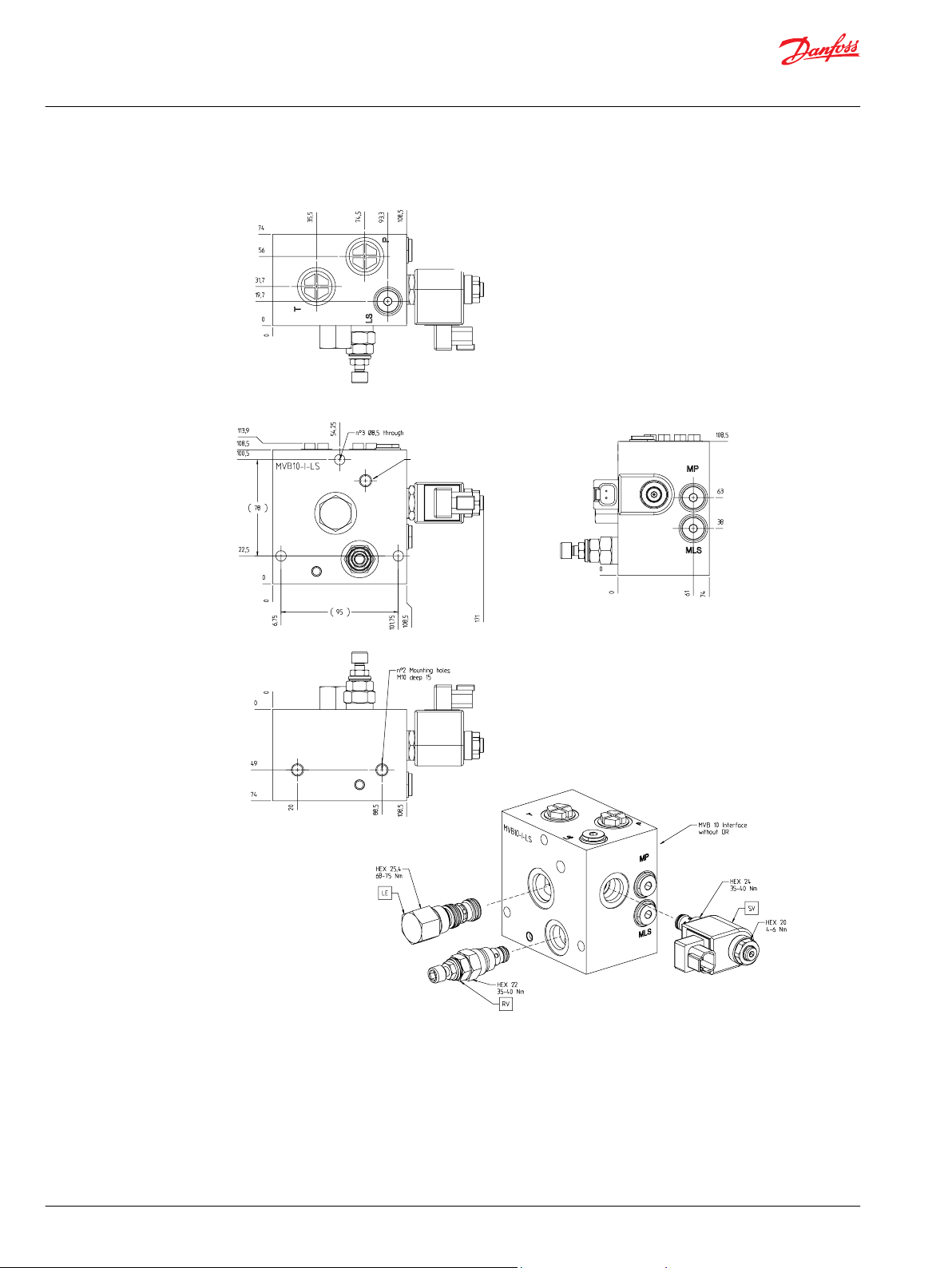

Technical Information

MVB10 Module Valve Block

Inlet module

MVB10-I-LS dimension drawing

8 | © Danfoss | September 2020 BC353276907439en-000101

Page 9

LS

T

P

MVB10

interface

LS

T

P

Technical Information

MVB10 Module Valve Block

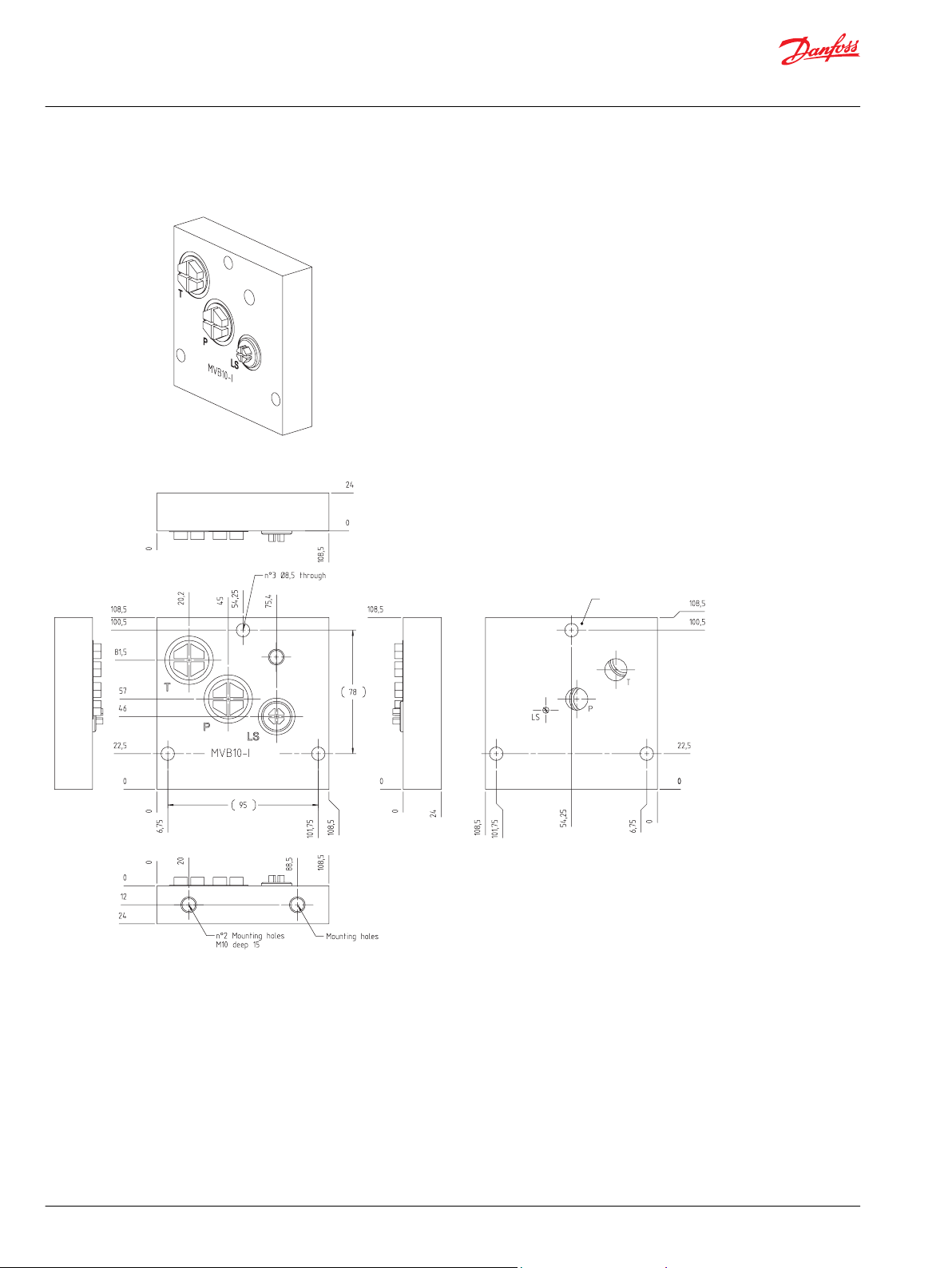

Inlet module

MVB10-I

Operation

This inlet module provides standard port connections to the P, T and LS lines in the MVB10 stack. It does

not include any active components.

Standard inlet module

©

Danfoss | September 2020 BC353276907439en-000101 | 9

Page 10

MVB10 interface

Technical Information

MVB10 Module Valve Block

Inlet module

MVB10-I dimension drawing

10 | © Danfoss | September 2020 BC353276907439en-000101

Page 11

LS

T

P

LS

T

P

LS

T

P

LS

T

P

MVB10-I

MVB10-I-LS

MP

MLS

LS

RV

SV

Technical Information

MVB10 Module Valve Block

Inlet module

Inlet module component selection

The options for the inlet module area standard version equipped only with ports or an LS version

equipped with cartridge valves.

For the valve selection:

•

•

•

Inlet module component selection

The relief valve (RV) will limit system pressure through regulating the pressure in the LS passage. If

the LS pressure is controlled by an external component,this can be replaced with a plug

The logic element (LE) will bypass excess flow to tank when applied with a fixed pump. LE can be

replaced with a plug when applied with a variable displacement pump. In this case we recommend

an external relief valve to protect the circuit

The enable valve (SV) will allow flow to be bypassed at low pressure when de-energized through

connecting the LS signal to tank. It will also disable the system in the case of power loss

Cartridges shown in red are not included as a part of the base module and must be purchased separately.

Refer to Inlet module component selection on page 11 for available options.

Inlet module component selection

Model code Description Part number

Body Type

MVB10-I-4B Standard Inlet Section. P and T: 1/2 BSP. LS: 1/4 BSP 11193649

MVB10-I-10S Standard Inlet Section. P and T: #10 SAE. LS: #6 SAE 11198412

MVB10-I-LS-4B Inlet section with compensation: relief and shut off options. P and T:1/2

MVB10-I-LS-10S Inlet section with compensation: relief and shut off options. P and T: #10

SV - Solenoid Valve (for additional options, see M13 & R13 coil catalog pages)

CP08-B-2-B No solenoid valve - Plug - Buna seals 920554

SVP08-NO-00-00-B-00 Solenoid valve - push pin override - no screen - Buna seals 805315219

SV - Solenoid Valve Coil (for additional options, see SVP08-NO technical information)

M13-24D-20W-DN Standard Coil: DIN 43650 connector, 24V 171139819

©

Danfoss | September 2020 BC353276907439en-000101 | 11

BSP ports. LS, MLS, MP: 1/4 BSP

SAE. LS, MLS, MP: #6 SAE

11189404

11195194

Page 12

Technical Information

MVB10 Module Valve Block

Inlet module

Inlet module component selection (continued)

Model code Description Part number

M13-12D-20W-DN Standard Coil: DIN 43650 connector, 12V 171140019

M13-24D-20W-DE Standard Coil: Deutsch DT04-2P connector, 24V 17114131

M13-12D-20W-DE Standard Coil: Deutsch DT04-2P connector, 12V 17114141

R13-24D-16W-DE Robust Coil: Deutsch DT04-2P connector, 24V 171180419

R13-12D-16W-DE Robust Coil: Deutsch DT04-2P connector, 12V 171180619

RV - Relief Valve (for additional options, see RV08-DR catalog page)

CP08-B-2-B No Relief valve - Plug - Buna seals 920554

RV08-DR-2-E-100-B-00 Relief valve: external screw adjustment, Buna seals, 100 bar setting 810216519

RV08-DR-2-E-110-B-00 Relief valve: external screw adjustment, Buna seals, 110 bar setting 83054656

RV08-DR-2-E-120-B-00 Relief valve: external screw adjustment, Buna seals, 120 bar setting 83014557

RV08-DR-3-E-130-B-00 Relief valve: external screw adjustment, Buna seals, 130 bar setting 83051234

RV08-DR-3-E-140-B-00 Relief valve: external screw adjustment, Buna seals, 140 bar setting 83016195

RV08-DR-3-E-150-B-00 Relief valve: external screw adjustment, Buna seals, 150 bar setting 83006885

RV08-DR-3-E-160-B-00 Relief valve: external screw adjustment, Buna seals, 160 bar setting 83022156

RV08-DR-3-E-170-B-00 Relief valve: external screw adjustment, Buna seals, 170 bar setting 83024408

RV08-DR-3-E-180-B-00 Relief valve: external screw adjustment, Buna seals, 180 bar setting 83024684

RV08-DR-3-E-190-B-00 Relief valve: external screw adjustment, Buna seals, 190 bar setting 83006694

RV08-DR-3-E-200-B-00 Relief valve: external screw adjustment, Buna seals, 200 bar setting 810217319

RV08-DR-3-E-210-B-00 Relief valve: external screw adjustment, Buna seals, 210 bar setting 83018587

LS - Compensator (for additional options, see HLE10-CPC and HLEA10-CPC catalog pages)

CP10-B-3S-B No compensator - plug - Buna seals 11018366

HLE10-CPC-15-B-00 Compensator - 15 bar bias spring - Buna seals 83038529

HLEA10-CPC-E-15-B-00 Adjustable compensator - 15 bar setting - Buna seals 83033826

12 | © Danfoss | September 2020 BC353276907439en-000101

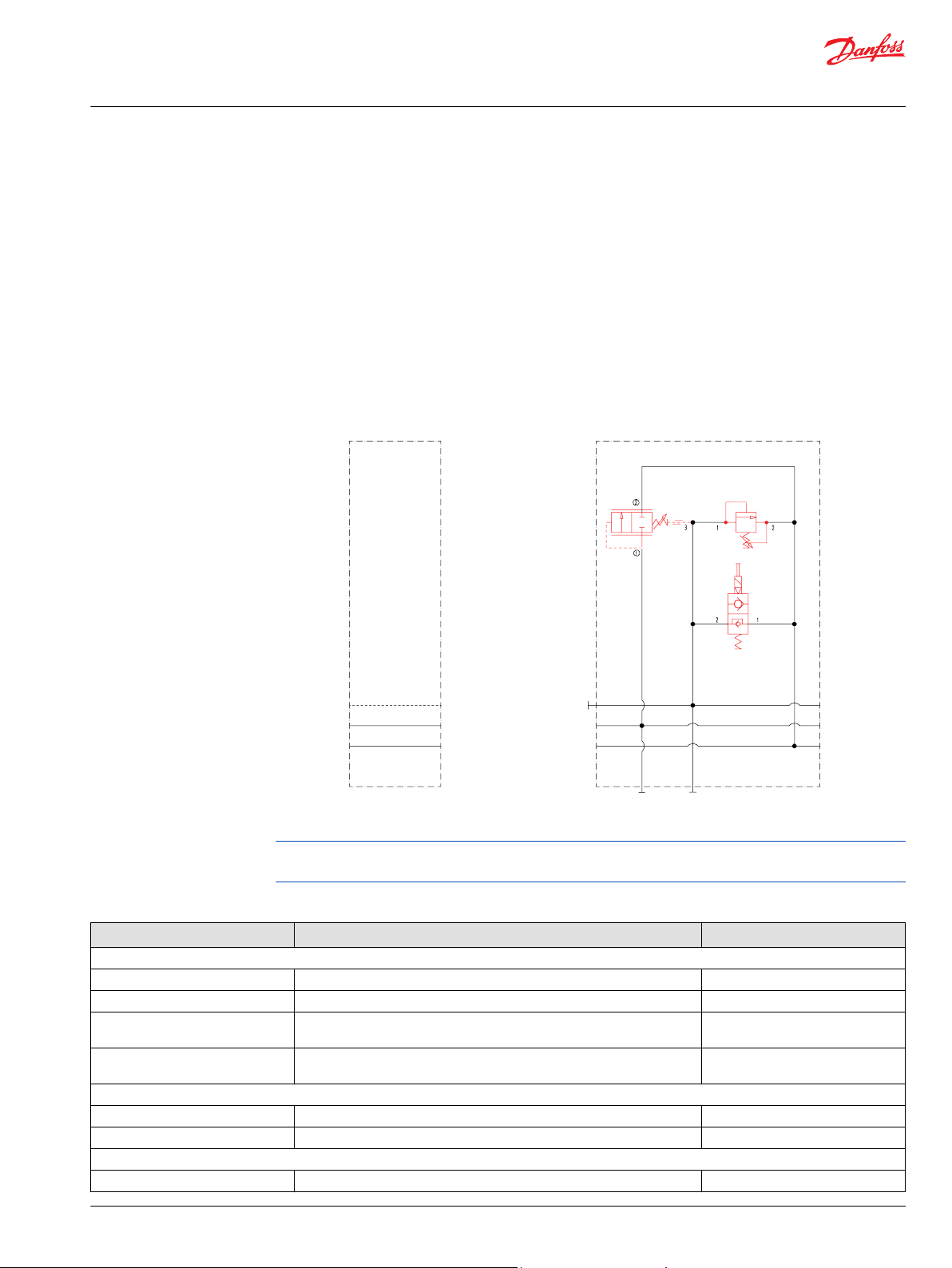

Page 13

MVB10

interface

PVG 32

interface

LS

T

P

LS

T

P

PP

T0

Technical Information

MVB10 Module Valve Block

Interface module

MVB10-IF

Operation

This connection interface does not include any active components and may be used to connect MVB10

modules with PVG32/16 modules. The unique synergy between the MVB10 and the Danfoss PVG product

line allows the use of the same tie-rods kits across both product groups. This enables assemblies the

flexibility to be expanded across both product lines to meet the configuration requirements.

Before combining MVB10 sections with products from the Danfoss PVG product families, carefully read

and consider the relevant operating instructions provided by Danfoss. Failure to comply with these

instructions may result in performance or safety issues.

Standard inlet module

©

Danfoss | September 2020 BC353276907439en-000101 | 13

Page 14

Technical Information

MVB10 Module Valve Block

Interface module

MVB10-IF dimension drawing

Application awareness

Standard open center PVG inlets use a 10 bar (145 psi) compensating element. When using a

compensated MVB10 work section with this inlet, a compensator of 7 bar (100 psi) or less is

recommended.

The PVG and the MVB10 will share a common inlet when used with the standard interface plate (MVB10IF). The maximum pressure rating of the entire stack will be 210 bar (3000 psi).

When a non-compensated work section is applied with a high inlet pressure and low load pressure, the

high pressure differential can cause the flow rate to exceed catalog rating of the solenoid. The operating

envelope of the solenoid valve should be followed to ensure proper shifting. Careful evaluation should

be given to applications using pressure compensated pumps as well as those requiring simultaneous use

of multiple functions with differing loads. In these types of applications where there is a risk of

overflowing the solenoid, a compensated or flow control work section can be used.

Interface module component selection

Model code Description Part number

MVB10-IF PVG Interface Plate 11187916

14 | © Danfoss | September 2020 BC353276907439en-000101

Page 15

LS

T

P

MVB10

interface

LS

T

P

MVB10

interface

SH1

SH2

SV

B

A

MVB10-W

Technical Information

MVB10 Module Valve Block

Working module

MVB10-W

Operation

This work section provides on-off directional control of a double acting actuator.

This is a non-compensated module. High pressure differentials across this section can cause the flow rate

to exceed catalog rating of the solenoid. The operating envelope of the solenoid valve should be

followed to ensure proper shifting. For valve operating limits,review the solenoid valve catalog page. For

additional information, see the application note in the Component Selection section of this catalog.

Non-compensated working module

©

Danfoss | September 2020 BC353276907439en-000101 | 15

Page 16

Technical Information

MVB10 Module Valve Block

Working module

MVB10-W dimension drawing

16 | © Danfoss | September 2020 BC353276907439en-000101

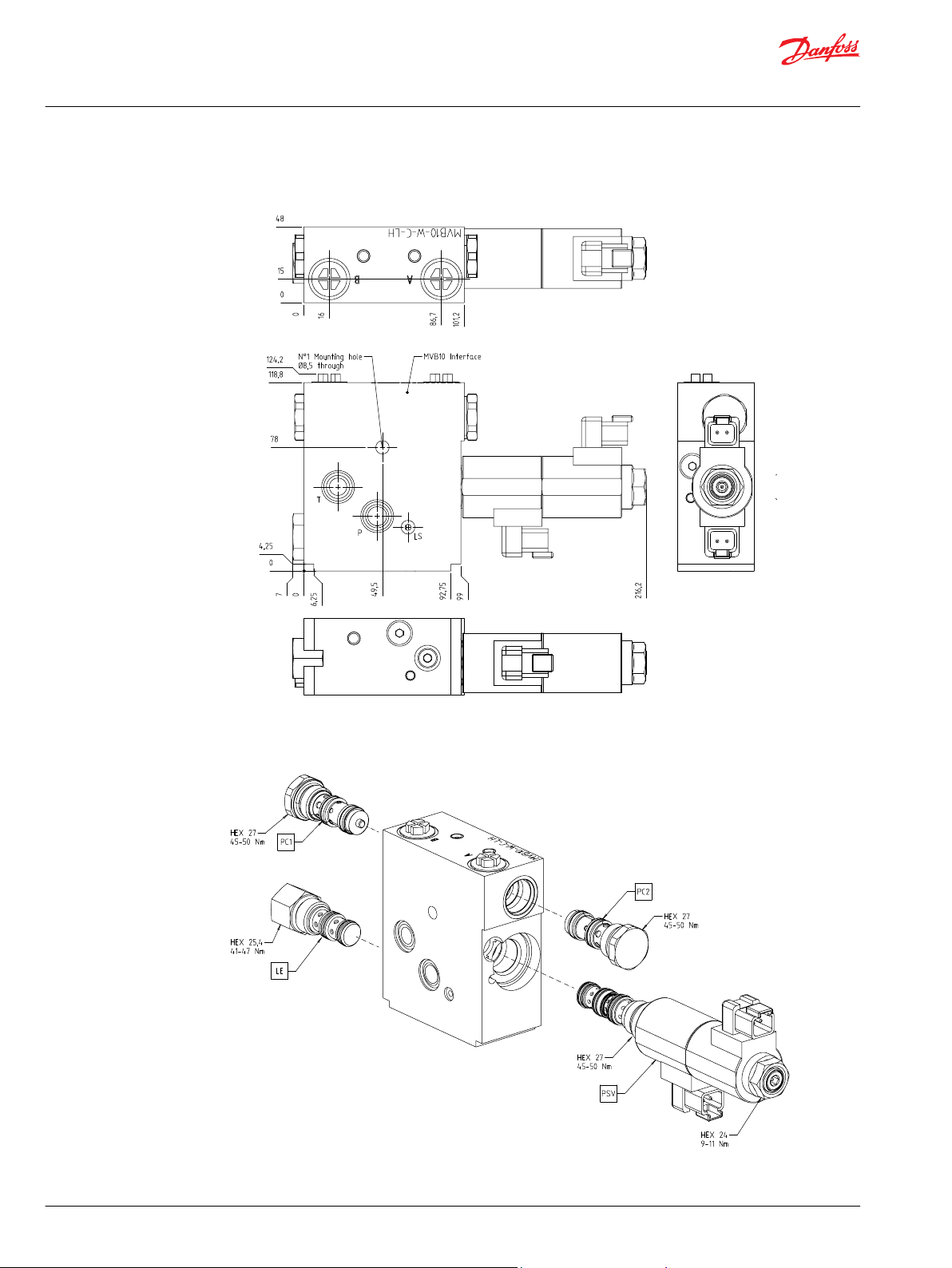

Page 17

LS

T

P

MVB10

interface

LS

T

P

MVB10

interface

MVB10-W-C

B A

SH1

SH2

PSV

LE1

Technical Information

MVB10 Module Valve Block

Working module

MVB10-W-C

Operation

This pressure compensated work section provides proportional load-independent directional control of a

double acting actuator.

Compensated working module

©

Danfoss | September 2020 BC353276907439en-000101 | 17

Page 18

Technical Information

MVB10 Module Valve Block

Working module

MVB10-W-C dimension drawing

18 | © Danfoss | September 2020 BC353276907439en-000101

Page 19

LS

T

P

MVB10

interface

LS

T

P

MVB10

interface

MVB10-W-LH-VCB06

B A

SH1

SH2

SV

CB2

CB1

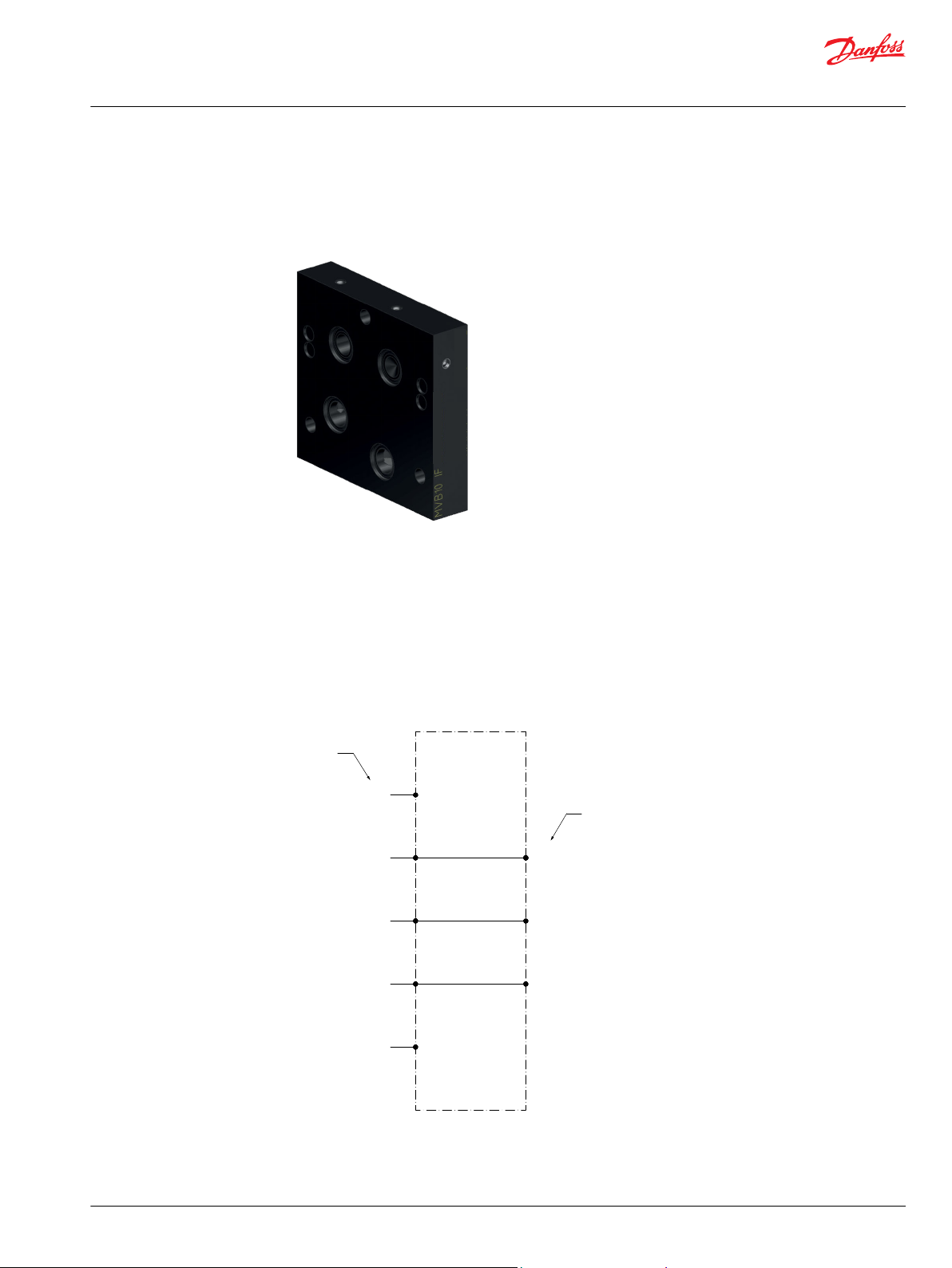

Technical Information

MVB10 Module Valve Block

Working module

MVB10-W-LH with counterbalance valves

Operation

This work section provides on-off directional control of a double acting actuator. A load holding cartridge

keeps an actuator in position by preventing any leakage that may cause drifting.

Counter balance valves help control the movement of lowering or runaway loads by restricting the flow

returning to tank from the actuator. They also provide an antishock function by limiting the maximum

pressure inside the actuator.

To ensure proper operation, this load holding module should always be specified with a directional

control valve which connects the work ports to tank in the neutral position.

This is a non-compensated module. High pressure differentials across this section can cause the flow rate

to exceed catalog rating of the solenoid. The operating envelope of the solenoid valve should be

followed to ensure proper shifting. For valve operating limits, review the solenoid valve catalog page. For

additional information, see the application note in the Component Selection section of this catalog.

Load holding with counterbalance

©

Danfoss | September 2020 BC353276907439en-000101 | 19

Page 20

Technical Information

MVB10 Module Valve Block

Working module

MVB10-W-LH with counterbalance valves dimension drawing

20 | © Danfoss | September 2020 BC353276907439en-000101

Page 21

Technical Information

MVB10 Module Valve Block

Working module

MVB10-W-LH with pilot check valves

Operation

This work section provides on-off directional control of a double acting actuator. A load holding cartridge

keeps an actuator in position by preventing any leakage that may cause drifting.

Pilot operated check valves minimize the restriction of flow to and from the actuator and therefore help

achieve the best energy efficiency in simple load control situations.

To ensure proper operation, this load holding module should always be specified with a directional

control valve which connects the work ports to tank in the neutral position.

This is a non-compensated module. High pressure differentials across this section can cause the flow rate

to exceed catalog rating of the solenoid. The operating envelope of the solenoid valve should be

followed to ensure proper shifting. For valve operating limits, review the solenoid valve catalog page. For

additional information, see the application note in the Component Selection section of this catalog.

©

Danfoss | September 2020 BC353276907439en-000101 | 21

Page 22

LS

T

P

MVB10

interface

LS

T

P

MVB10

interface

MVB10-W-LH-RPC06

B A

SH1

SH2

SV

PC2

PC1

Technical Information

MVB10 Module Valve Block

Working module

Load holding with pilot check valves

22 | © Danfoss | September 2020 BC353276907439en-000101

Page 23

Technical Information

MVB10 Module Valve Block

Working module

MVB10-W-LH with pilot check valves dimension drawing

©

Danfoss | September 2020 BC353276907439en-000101 | 23

Page 24

Technical Information

MVB10 Module Valve Block

Working module

MVB10-W-C-LH with counterbalance valves

Operation

This pressure compensated work section provides proportional load-independent directional control of a

double acting actuator. A load holding device keeps an actuator in position by preventing any leakage

that may cause drifting.

Counterbalance valves help control the movement of lowering or run-away loads by restricting the flow

returning to tank from the actuator. They also provide an antishock function by limiting the maximum

pressure inside the actuator.

To ensure proper operation, this load holding module should always be specified with a directional

control valve which connects the work ports to tank in the neutral position.

24 | © Danfoss | September 2020 BC353276907439en-000101

Page 25

LS

T

P

MVB10

interface

LS

T

P

MVB10

interface

MVB10-W-C-LH-VCB06

B A

SH1

SH2

PSV

CB2

CB1

LE1

Technical Information

MVB10 Module Valve Block

Working module

Compensated working module load holding with pilot check valve

©

Danfoss | September 2020 BC353276907439en-000101 | 25

Page 26

Technical Information

MVB10 Module Valve Block

Working module

MVB10-W-C-LH with counterbalance valve dimension drawing

26 | © Danfoss | September 2020 BC353276907439en-000101

Page 27

LS

T

P

MVB10

interface

LS

T

P

MVB10

interface

MVB10-W-C-LH-RPC06

B A

SH1

SH2

PSV

PC2

PC1

LE1

Technical Information

MVB10 Module Valve Block

Working module

MVB10-W-C-LH with pilot check valves

Operation

This pressure compensated work section provides proportional load-independent directional control of a

double acting actuator. A load holding device keeps an actuator in position by preventing any leakage

that may cause drifting.

Pilot operated check valves minimize the restriction of flow to and from the actuator and therefore help

achieve the best energy efficiency in simple load control situations.

To ensure proper operation, this load holding module should always be specified with a directional

control valve which connects the work ports to tank in the neutral position.

Compensated working module

©

Danfoss | September 2020 BC353276907439en-000101 | 27

Page 28

Technical Information

MVB10 Module Valve Block

Working module

MVB10-W-C-LH with pilot check valves dimension drawing

28 | © Danfoss | September 2020 BC353276907439en-000101

Page 29

P

T

LS

3

2

1

2

4

3 1

SV1

3

2

1

B A

P

T

LS

MVB10-W-F

2

1

FC1

MVB10

interface

MVB10

interface

Technical Information

MVB10 Module Valve Block

Working module

MVB10-W-F

Operation

This work section provides on-off directional control of a double acting actuator. The flow control before

the directional valve will limit the flow through the section to the actuator. An SDC10-2 cavity is provided

for the flow control valve, allowing the use of a pressure compensated flow control or non-compensated,

adjustable needle valve.

High pressure differentials across this section can cause the flow rate to exceed catalog rating of the

solenoid when used with non-compensated flow controls. The operating envelope of the solenoid valve

should be followed to ensure proper shifting. For valve operating limits, review the solenoid valve

catalog page. For additional information, see the application note in Working module component selection

on page 37.

Flow control working module

©

Danfoss | September 2020 BC353276907439en-000101 | 29

Page 30

Technical Information

MVB10 Module Valve Block

Working module

MVB10-W-F dimension drawing

30 | © Danfoss | September 2020 BC353276907439en-000101

Page 31

Technical Information

MVB10 Module Valve Block

Working module

MVB10-W-F-LH with counterbalance valves

Operation

This work section provides on-off directional control of a double acting actuator. The flow control before

the directional valve will limit the flow through the section to the actuator. An SDC10-2 cavity is provided

for the flow control valve, allowing the use of a pressure compensated flow control or non-compensated,

adjustable needle valve. A load holding cartridge keeps an actuator in position by preventing any

leakage that may cause drifting.

Counter balance valves help control the movement of lowering or runaway loads by restricting the flow

returning to tank from the actuator. They also provide an antishock function by limiting the maximum

pressure inside the actuator.

To ensure proper operation, this load holding module should always be specified with a directional

control valve which connects the work ports to tank in the neutral position.

High pressure differentials across this section can cause the flow rate to exceed catalog rating of the

solenoid when used with non-compensated flow controls. The operating envelope of the solenoid valve

should be followed to ensure proper shifting. For valve operating limits, review the solenoid valve

catalog page. For additional information, see the application note in Working module component selection

on page 37.

©

Danfoss | September 2020 BC353276907439en-000101 | 31

Page 32

P

T

LS

3

2

1

2

4

3 1

SV

3

2

1

B A

1

2

3

CB2

P

T

LS

1

2

3

CB1

MVB10-W-F-LH-VCB06

2

1

FC

MVB10

interface

MVB10

interface

Technical Information

MVB10 Module Valve Block

Working module

Flow control and load holding with counterbalance

32 | © Danfoss | September 2020 BC353276907439en-000101

Page 33

Technical Information

MVB10 Module Valve Block

Working module

MVB10-W-F-LH with counterbalance valve dimension drawing

©

Danfoss | September 2020 BC353276907439en-000101 | 33

Page 34

Technical Information

MVB10 Module Valve Block

Working module

MVB10-W-F-LH with pilot check valves

Operation

This work section provides on-off directional control of a double acting actuator. The flow control before

the directional valve will limit the flow through the section to the actuator. An SDC10-2 cavity is provided

for the flow control valve, allowing the use of a pressure compensated flow control or non-compensated,

adjustable needle valve. A load holding cartridge keeps an actuator in position by preventing any

leakage that may cause drifting.

Pilot operated check valves minimize the restriction of flow to and from the actuator and therefore help

achieve the best energy efficiency in simple load control situations.

To ensure proper operation, this load holding module should always be specified with a directional

control valve which connects the work ports to tank in the neutral position.

High pressure differentials across this section can cause the flow rate to exceed catalog rating of the

solenoid when used with non-compensated flow controls. The operating envelope of the solenoid valve

should be followed to ensure proper shifting. For valve operating limits, review the solenoid valve

catalog page. For additional information, see the application note in Working module component selection

on page 37.

34 | © Danfoss | September 2020 BC353276907439en-000101

Page 35

P

T

LS

3

2

1

2

4

3 1

SV1

3

2

1

B A

P

T

LS

MVB10-W-F-LH-RPC06

2

1

FC1

2

1

3

PC1

2

1

3

PC2

MVB10

interface

MVB10

interface

Technical Information

MVB10 Module Valve Block

Working module

Flow control and load handling with pilot check valves

©

Danfoss | September 2020 BC353276907439en-000101 | 35

Page 36

Technical Information

MVB10 Module Valve Block

Working module

MVB10-W-F-LH with pilot check valves dimension drawing

36 | © Danfoss | September 2020 BC353276907439en-000101

Page 37

Technical Information

MVB10 Module Valve Block

Working module

Working module component selection

The working modules can have on/off or proportional compensated directional control, with or without

load holding.

The design of a new valve stack begins with the selection of the empty module, according to the required

function.

The load sense shuttle valves are included in all base modules and do not need to be specified separately.

It is possible to select the required components that can be specified in the module.

All of the solenoid and proportionals valves in the table can fit in all modules.

All of the logic elements in the table are compatible with all pressure compensated modules (-C).

All of the load holding valves in the table, both pilot operated check or counterbalance valves, are

compatible with all load holding modules(-LH).

When a non-compensated work section is applied with a high inlet pressure and low load pressure, the

high pressure differential can cause the flow rate to exceed catalog rating of the solenoid.

The operating envelope of the solenoid valve should be followed to ensure proper shifting. Careful

evaluation should be given to applications using pressure compensated pumps and those requiring

simultaneous use of multiple functions with differing loads. In these types of applications where there is a

risk of overflowing the solenoid, a compensated or flow control work section can be used.

©

Danfoss | September 2020 BC353276907439en-000101 | 37

Page 38

B A

B A

B A

B A

B A

MVB10-W-C-LH-RPC06

MVB10-W-C-LH-VCB06

MVB10-W-C

MVB10-W

MVB10-W-LH-RPC06

LS

T

P

LS

T

P

LS

T

P

LS

T

P

LS

T

P

LS

T

P

T

P

LS

T

P

LS

T

P

LS

T

P

SV

PSV

SV

PSV PSV

LE

PC1

PC2

LE LE

PC1 PC2

CB1

CB2

3

2

1

2 4

3

1

3

2

1

1

2

3

1

2

3

2

1

MVB10-W-F-LH-VCB06

LS

T

P

LS

T

P

B

A

FC

SV

CB1

CB2

Technical Information

MVB10 Module Valve Block

Working module

Working module component selection

Cartridges shown in red are not included as a part of the base module and must be purchased separately.

Refer to Working module component selection on page 39 for available options.

38 | © Danfoss | September 2020 BC353276907439en-000101

Page 39

Technical Information

MVB10 Module Valve Block

Working module

Working module component selection

Model code Description Part number

Body Type

MVB10-W-3B Working module, non compensated, A and B ports G3/8 BSP 11187533

MVB10-W-6S Working module, non compensated, A and B ports SAE#6 11195179

MVB10-W-C-3B Working module, compensated, A and B ports G3/8 BSP 11187535

MVB10-W-C-6S Working module, compensated, A and B ports SAE#6 11195178

MVB10-W-LH-3B Working module, non compensated, with load holding, A and B ports G3/8 BSP 11188879

MVB10-W-LH-6S Working module, non compensated, with load holding, A and B ports SAE#6 11195193

MVB10-W-C-LH-3B Working module, compensated, with load holding, A and B ports G3/8 BSP 11196245

MVB10-W-C-LH-6S Working module, compensated, with load holding, A and B ports SAE#6 11198419

MVB10-W-F-3B Working module, flow control, A and B ports G3/8 BSP 11229694

MVB10-W-F-6S Working module, flow control, A and B ports SAE#6 11202459

MVB10-W-F-LH-3B

MVB10-W-F-LH-6S

SV/PSV - Solenoid Valve - (for additional options, see SV10-34-05 and PSV10-34-05 catalog pages)

SV10-34-05-00-00-B-00 ON-OFF solenoid valve, 4 ways 3 positions, Buna seals 805314819

PSV10-34-05-00-00-22-B-00 Proportional solenoid valve, 4 ways 3 positions, Buna seals 850168919

SV10-34-05-00-00-PAP-00 ON-OFF solenoid valve, 4 ways 3 positions, Buna seals, Push/Pull Override 11181460

PSV10-34-05-00-00-22-B-PAP-00 Proportional solenoid valve, 4 ways 3 positions, Buna seals, Push/Pull Override 11227515

SV/PSV - Solenoid Valve Coil - (for additional options, see M16 and R16 catalog pages)

M16-12D-26W-DN Standard coil DIN 43650 connector, 12V 17114581

M16-24D-26W-DN Standard coil DIN 43650 connector, 24V 171146019

M16-12D-26W-DE Standard coil Deutsch DT04-2P connector, 12V 17114931

M16-24D-26W-DE Standard coil Deutsch DT04-2P connector, 24V 171149519

R16-12D-20W-DE Robust coil Deutsch DT04-2P connector, 12V 171185919

R16-24D-20W-DE Robust coil Deutsch DT04-2P connector, 24V 171183019

LE - Compensator - (for additional options, see CP700-4 catalog page)

CP700-4-B-0-150 Compensator - 10,3 bar bias spring - Buna Seals 133899

CP700-4-B-0-100 Compensator - 7,6 bar bias spring - Buna Seals 134241

CP10-B-3-B1 No compensator - Open plug 134493

PC/CB - Load Holding valve - (for additional options, see RPC06 and VCB06-EN catalog pages)

RPC06/0.5-00 Pilot Check valve - 0,5 bar - Buna Seals 11169090

RPC06/0.5-OR Pilot Check valve - 0,5 bar - Buna Seals - w/ piston Seal 11169102

RPC06/5-00 Pilot Check valve - 5 bar - Buna Seals 11169108

RPC06/5-OR Pilot Check valve - 5 bar - Buna Seals - w piston Seal 11169110

VCB06-EN-1-A-00-B 820202619

VCB06-EN-2-A-00-B Counterbalance valve - range 2 (70-210 bar) - Ratio A (7.1:1) - Buna

VCB06-EN-3-A-00-B Counterbalance valve - range 3 (105-350 Bar) - Ratio A (7.1:1) - Buna Seals 820202819

VCB06-EN-1-B-00-B Counterbalance valve - range 1 (25-140 bar) - Ratio B (4.1:1) - Buna Seals 820153929

VCB06-EN-2-B-00-B Counterbalance valve - range 2 (70-210 bar) - Ratio B (4.1:1) - Buna Seals 820158929

VCB06-EN-3-B-00-B Counterbalance valve - range 3 (105-350 Bar) - Ratio B (4.1:1) - Buna Seals 820159029

NCS06/0 Cavity Plug NCS06/0 920000619

FC - Flow Control - (for additional options, see CP300-1 and CP610-2 catalog pages)

CP300-1-B-0-2.4 Flow Control Valve - pressure compensated, 9 lpm - Buna Seals 83055469

CP610-2-B-0-K Needle Valve - adjustable, knob - Buna Seals 130453

Working module, flow control, with load holding, A and B ports G3/8 BSP

Working module, flow control, with load holding, A and B ports SAE#6

SealsCounterbalance valve - range 1 (25-140 bar) - Ratio A (7.1:1) - Buna Seals

11229782

11202460

820202719

©

Danfoss | September 2020 BC353276907439en-000101 | 39

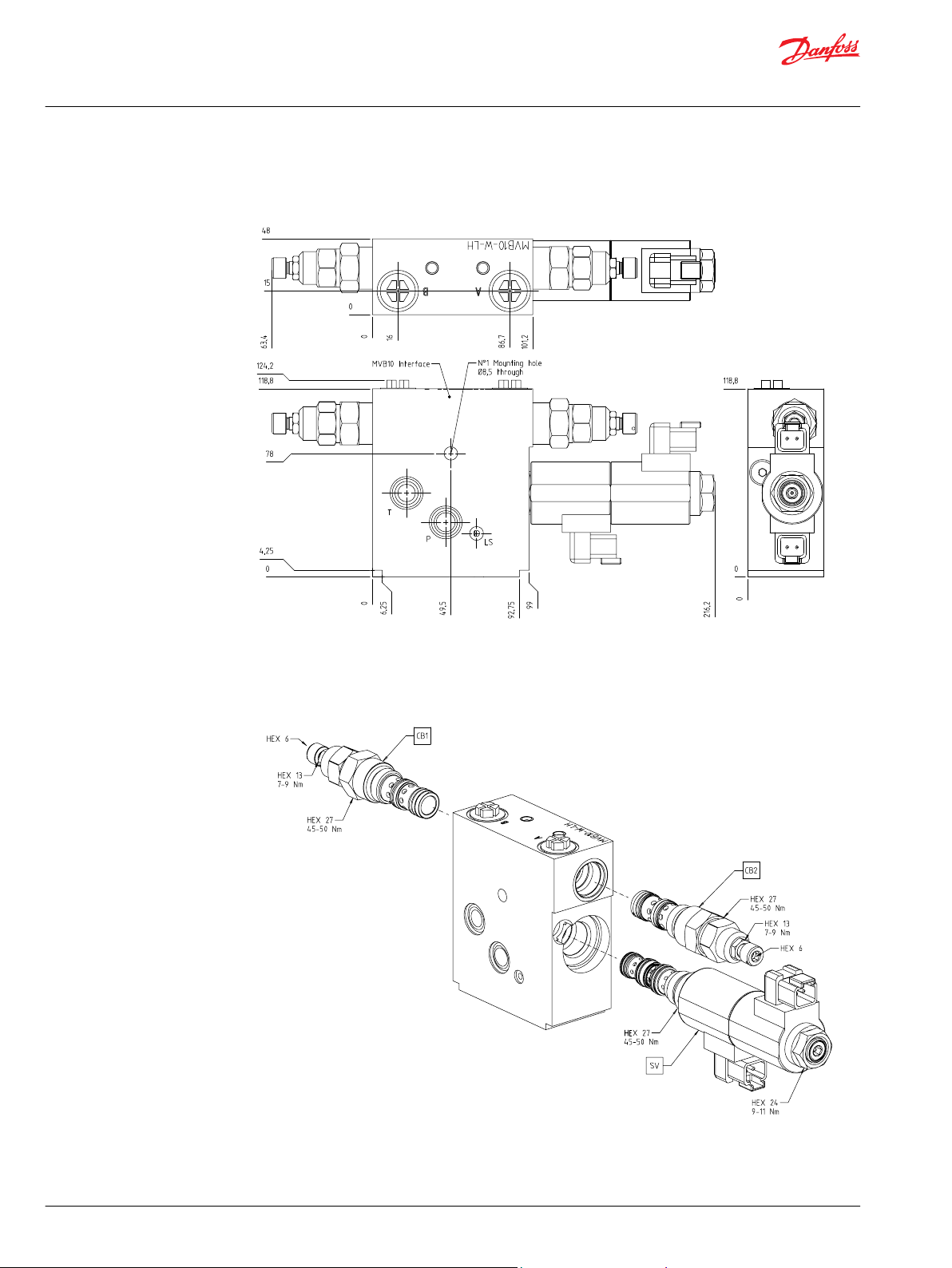

Page 40

P

T

LS

MVB10-E

1

2

M8 Orifice

Provision

MVB10

interface

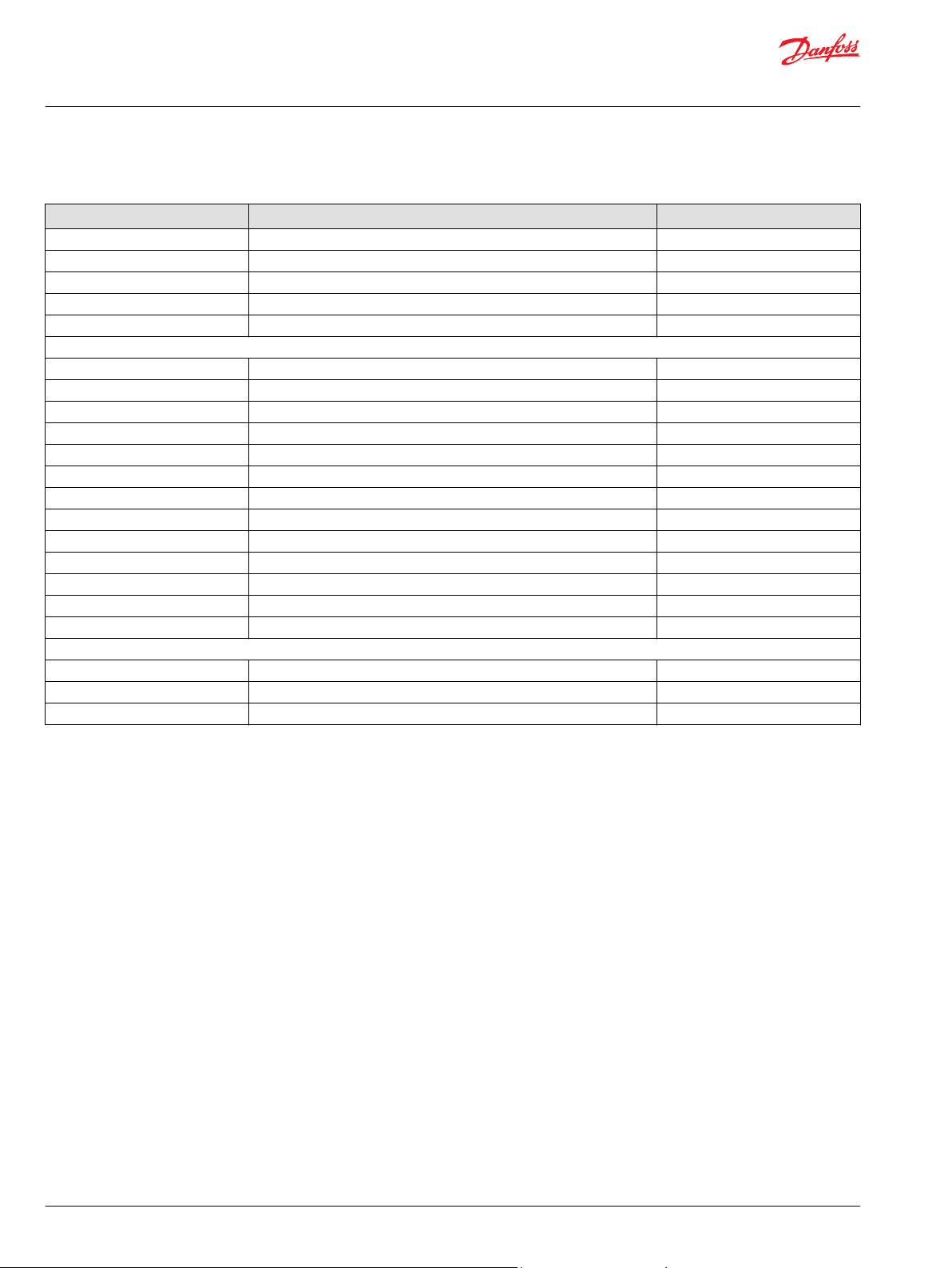

Technical Information

MVB10 Module Valve Block

End module

MVB10-E

Operation

This end plate section does not include any active components and may be used for closing a MVB10

assembly.

End plate section

40 | © Danfoss | September 2020 BC353276907439en-000101

Page 41

Technical Information

MVB10 Module Valve Block

End module

MVB10-E end module dimension drawing

End module component selection

Model code Description Part number

MVB10-E End plate 11187937

©

Danfoss | September 2020 BC353276907439en-000101 | 41

Page 42

Technical Information

MVB10 Module Valve Block

Tie rod kits (seals included)

Material number Order code / Nomenclature

157B8000 PVAS32-MOUNTING KIT-PVG L 054-072MM

157B8031 PVAS32-MOUNTING KIT-PVG L 078-096MM

157B8001 PVAS32-MOUNTING KIT-PVG L 102-120MM

157B8021 PVAS32-MOUNTING KIT-PVG L 126-144MM

157B8002 PVAS32-MOUNTING KIT-PVG L 150-168MM

157B8022 PVAS32-MOUNTING KIT-PVG L 174-192MM

157B8003 PVAS32-MOUNTING KIT-PVG L 198-216MM

157B8023 PVAS32-MOUNTING KIT-PVG L 222-240MM

157B8004 PVAS32-MOUNTING KIT-PVG L 246-264MM

157B8024 PVAS32-MOUNTING KIT-PVG L 270-288MM

157B8005 PVAS32-MOUNTING KIT-PVG L 294-312MM

157B8025 PVAS32-MOUNTING KIT-PVG L 318-336MM

157B8006 PVAS32-MOUNTING KIT-PVG L 342-360MM

157B8026 PVAS32-MOUNTING KIT-PVG L 366-384MM

157B8007 PVAS32-MOUNTING KIT-PVG L 390-408MM

157B8027 PVAS32-MOUNTING KIT-PVG L 414-432MM

157B8008 PVAS32-MOUNTING KIT-PVG L 438-456MM

157B8028 PVAS32-MOUNTING KIT-PVG L 462-480MM

157B8009 PVAS32-MOUNTING KIT-PVG L 486-504MM

157B8029 PVAS32-MOUNTING KIT-PVG L 510-528MM

157B8010 PVAS32-MOUNTING KIT-PVG L 534-552MM

157B8030 PVAS32-MOUNTING KIT-PVG L 558-576MM

157B8061 PVAS32-MOUNTING KIT-PVG L 582-600MM

157B8081 PVAS32-MOUNTING KIT-PVG L 606-624MM

157B8062 PVAS32-MOUNTING KIT-PVG L 630-648MM

157B8082 PVAS32-MOUNTING KIT-PVG L 654-672MM

42 | © Danfoss | September 2020 BC353276907439en-000101

Page 43

Danfoss

Power Solutions GmbH & Co. OHG

Krokamp 35

D-24539 Neumünster, Germany

Phone: +49 4321 871 0

Danfoss

Power Solutions ApS

Nordborgvej 81

DK-6430 Nordborg, Denmark

Phone: +45 7488 2222

Danfoss

Power Solutions (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239 6000

Danfoss

Power Solutions Trading

(Shanghai) Co., Ltd.

Building #22, No. 1000 Jin Hai Rd

Jin Qiao, Pudong New District

Shanghai, China 201206

Phone: +86 21 2080 6201

Products we offer:

Hydro-Gear

www.hydro-gear.com

Daikin-Sauer-Danfoss

www.daikin-sauer-danfoss.com

Cartridge valves

•

DCV directional control

•

valves

Electric converters

•

Electric machines

•

Electric motors

•

Gear motors

•

Gear pumps

•

Hydraulic integrated

•

circuits (HICs)

Hydrostatic motors

•

Hydrostatic pumps

•

Orbital motors

•

PLUS+1® controllers

•

PLUS+1® displays

•

PLUS+1® joysticks and

•

pedals

PLUS+1® operator

•

interfaces

PLUS+1® sensors

•

PLUS+1® software

•

PLUS+1® software services,

•

support and training

Position controls and

•

sensors

PVG proportional valves

•

Steering components and

•

systems

Telematics

•

Danfoss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and

electric components. We specialize in providing state-of-the-art technology and solutions

that excel in the harsh operating conditions of the mobile off-highway market as well as the

marine sector. Building on our extensive applications expertise, we work closely with you to

ensure exceptional performance for a broad range of applications. We help you and other

customers around the world speed up system development, reduce costs and bring vehicles

and vessels to market faster.

Danfoss Power Solutions – your strongest partner in mobile hydraulics and mobile

electrification.

Go to www.danfoss.com for further product information.

We offer you expert worldwide support for ensuring the best possible solutions for

outstanding performance. And with an extensive network of Global Service Partners, we also

provide you with comprehensive global service for all of our components.

Local address:

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without subsequent changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

©

Danfoss | September 2020 BC353276907439en-000101

Loading...

Loading...