Page 1

Service Kit Instructions

Series 90

Multi-function valve replacement and adjustment

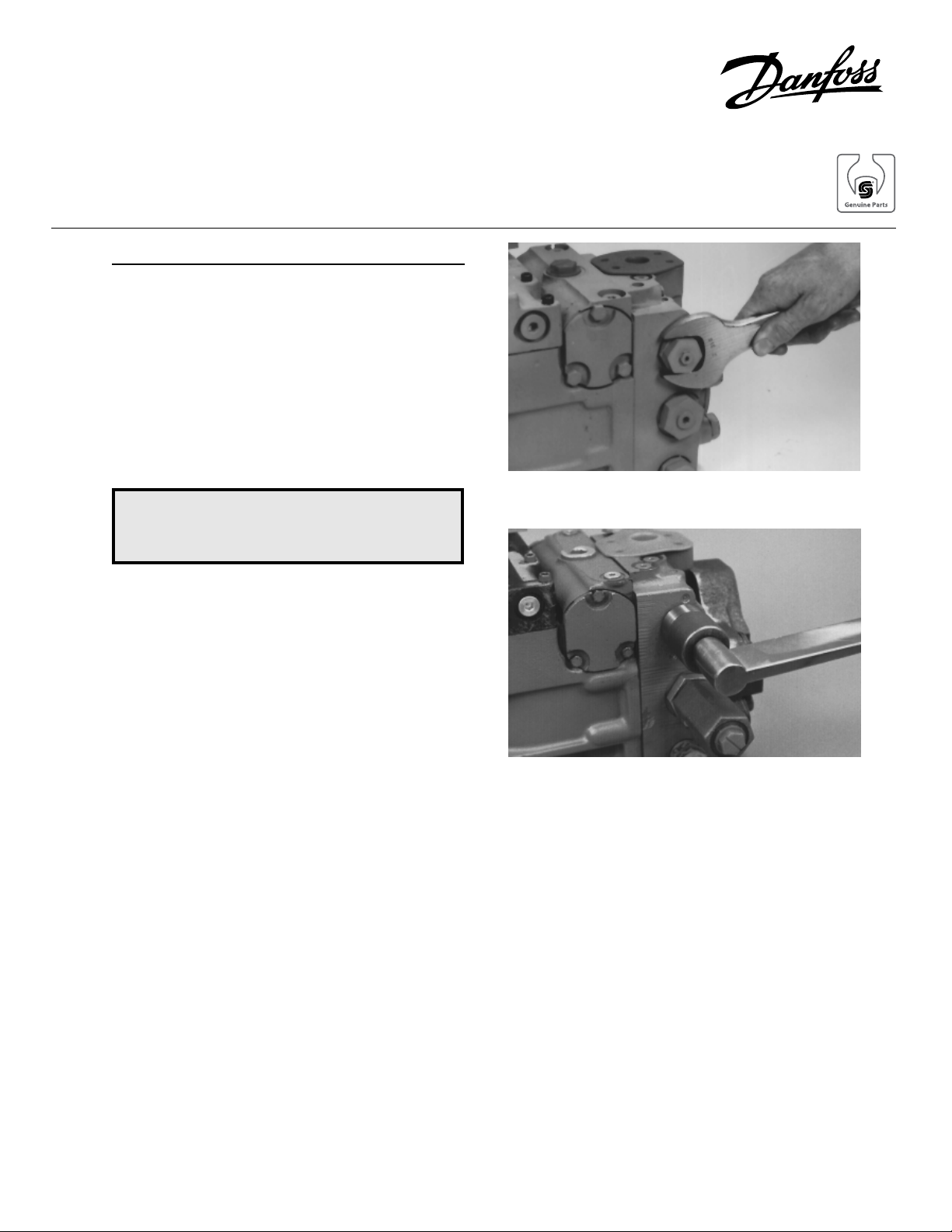

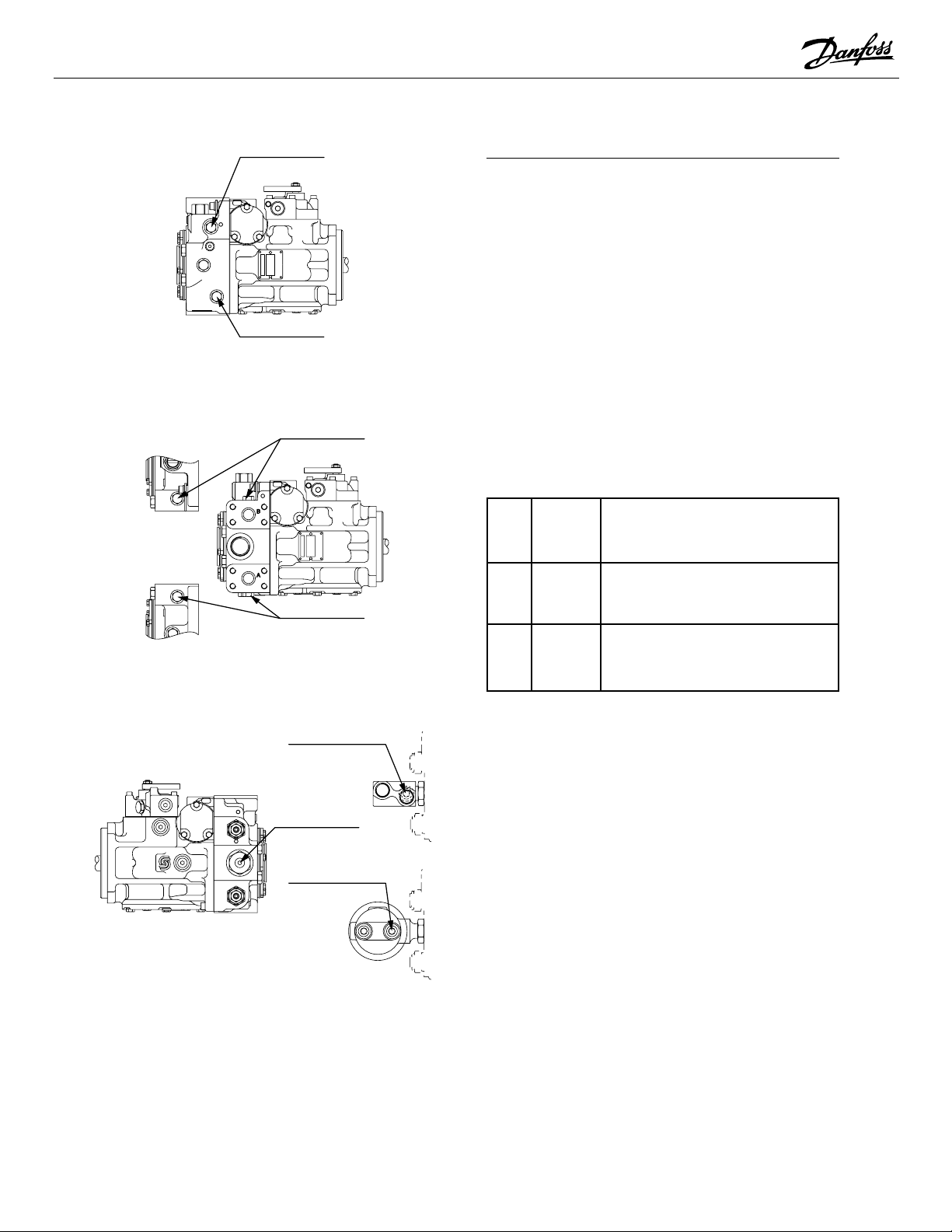

Removal and Installation

The multi-function valve cartridge is removed with an

1-1/4 inch (030 through 100 frame size pumps) or a 41

mm (130 through 250 frame size pumps) hex wrench

on the largest hex on the cartridge.

Inspect replacement cartridge for damage to parts

and O-rings.

Install cartridge in multi-function valve cavity and

torque to 79 Nm (58 lbsf•ft) for 030 through 100 frame

size pumps or 210 Nm (155 lbsf•ft) for 130 through

250 frame size pumps.

CAUTION

Do not over-torque the Multi-function Valve

Cartridge.

Fig. 1 - Remove Multi-function Valve Cartridge

(Typical)

© Danfoss, 2013

Fig. 2 - Install and Torque Cartridge (Typical)

BLN-10081 • Rev BA • September 2013

1

Page 2

Gauge port M2

System pressure B

Gauge port M1

System pressure A

Fig. 3 - Gauge Connections: Variable Pump

with Radial Port End Cap (Typical)

Gauge port M2

System pressure B

Multi-function Valve Adjustment

Multi-function valves sold as spare parts are NOT

adjusted at the factory. A typical adjustment procedure is described in the following sections. Refer to

the technical information for your vehicle or machine

for the correct high pressure setting and any special

procedures.

Gauge Installation

It will be necessary to install a high pressure gauge

into the system pressure gauge ports to check the

high pressure setting of the multi-function valves.

This setting is referenced to charge pressure.

Snubbers are recommended to protect pressure

gauges. Frequent gauge calibration is necessary to

insure accuracy.

Gauge Information

Top View

Gauge port M1

System pressure A

Bottom View

Fig. 4 - Gauge Connections: Variable Pump

with Twin Port End Cap (Typical)

Gauge port M3

Charge pressure

after filter

Remote

Gauge port M3

Charge pressure

Gauge port M3

Charge pressure

after filter

Suction Filtration

Right Side View

Integral

System 600 bar or 10,000 psi gauge

M1 Pressure 9/16 — 18 O-ring fitting

Port “A”

System 600 bar or 10,000 psi gauge

M2 Pressure 9/16 — 18 O-ring fitting

Port “B”

Charge 60 bar or 1000 psi gauge

M3 Pressure 9/16 — 18 O-ring fitting or tee into

line from charge pressure filter

Fig. 5 - Charge Pressure Gauge Connections:

Variable Pump (Typical)

© Danfoss, 2013

Pressure Filtration

Rear View

BLN-10081 • Rev BA • September 2013

2

Page 3

Multi-function Valve Pressure Adjustment

Adjustment of the pressure limiter and high pressure

relief valve pressure setting is accomplished by the

same procedure.

In order to set the pressure setting on the pressure

limiter or high pressure relief valve, the motor output

shaft must be locked so it does not rotate. This may

be accomplished by locking the vehicle’s brakes or

rigidly fixing the work function so it cannot rotate.

WARNING

Take necessary precautions that the motor

shaft remains locked during the adjusting procedure.

Install two (2) 600 bar or 10,000 psi pressure gauges

in the high pressure gauge ports. Install a 60 bar or

1000 psi pressure gauge in the pump charge pressure gauge port.

Start the prime mover and operate at normal speeds.

Loosen locking nut (smallest hex on multi-function

valve) with a 19 mm wrench for all 030 through 100

frame size units, a 24 mm wrench for 130 through 250

frame size units with “Range 1” valves, or a 13 mm

wrench for 130 through 250 frame size units with

“Range 2” valves.

Insert a 5 mm (all 030 through 100 units), 8 mm (130

through 250 frame size units with “Range 1” valves),

or 4 mm (130 through 250 frame size units with

“Range 2” valves) internal hex wrench into the pressure adjusting screw.

Fig. 6 - Multi-function

Valves (Typical for all

030 through 100, and

130 through 250

“Range 1”)

Fig. 8 - Loosen

Pressure Adjusting

Screw Locknut (Typical

for all 030 through 100,

and 130 through 250

“Range 1”)

Fig. 7 - Multi-function

Valves (Typical for 130

through 250 “Range 2”)

Fig. 9 - Loosen

Pressure Adjusting

Screw Locknut (Typical

for 130 through 250

“Range 2”)

NOTE: A plastic dust plug may be installed in the

© Danfoss, 2013

adjusting screw used on 030 through 100

units

and “Range 1” 130 through 250 units.

BLN-10081 • Rev BA • September 2013

3

Page 4

Fig. 10 - Rotate

Pressure Adjusting

Screw (Typical for all

030 through 100, and

130 through 250

“Range 1”)

Fig. 12 - Tighten

Pressure Adjusting

Screw Locknut (Typical

for all 030 through 100,

and 130 through 250

“Range 1”)

Fig. 11 - Rotate

Pressure Adjusting

Screw (Typical for 130

through 250 “Range 2”)

Fig. 13 - Tighten

Pressure Adjusting

Screw Locknut (Typical

for 130 through 250

“Range 2”)

Activate or move the input signal to the control so that

pressure increases in the high pressure closed circuit

to the pressure limiter pressure setting. The pressure

limiter setting is reached when the pressure stops

increasing and remains steady at a given pressure

level (as shown on the gauges). The pressure limiter

pressure setting is referenced to charge pressure.

Release system pressure and rotate the pressure

adjusting screw with the internal hex wrench. Recheck the setting.

NOTE: Clockwise rotation of the pressure adjust-

ment screw will increase the pressure setting, and counterclockwise rotation will decrease the pressure setting. Each complete

rotation of the pressure adjusting screw

changes the pressure setting by approximately 93 bar (1350 psi).

Repeat this procedure until the desired pressure

level is established (as shown on the gauges).

While holding the internal hex wrench and pressure

adjusting screw in the same position, tighten the

pressure adjusting screw lock nut to 16 Nm (12 lbsf•ft)

on all 030 through 100 units and 130 through 250

frame size units with “Range 1” valves, or 3 Nm (26

lbsf•in) on 130 through 250 frame size units with

“Range 2” valves. Do not over-torque.

Activate or move the input signal so pump returns to

the neutral position. The pressure in the high pressure circuit should return to the charge pressure

setting.

To verify the actual pressure setting, actuate

or move the input signal to the control such that the

pump again develops pressure in the high pressure

circuit to the newly adjusted pressure limiter pressure

setting. Then allow the pump to return to its neutral

position.

© Danfoss, 2013

The same procedure is used for setting the pressure

of the other multi-function valve, but the input control

signal must be activated or moved in the opposite

direction so that the pressure develops in the opposite high pressure side of the closed circuit.

Shut down the prime mover and remove the gauges

and install the gauge port plugs. Replace the plastic

dust plugs (if used).

BLN-10081 • Rev BA • September 2013

4

Loading...

Loading...