Page 1

MultiAxis

-Steer

EHI Electrohydraulic steering valve with PVED

controller

Technical Information

FW 1.00

TM

-CLS

- user and safety manual

Page 2

MultiAxis-Steer technical information

Document references

Date

Page

Changed

ECO No.

Rev.

Revisions

Revision History

Table of Revisions

04 Oct. 2019 First release:

FW 1.00

© 2019 Danfoss A/S. All rights reserved

All trademarks in this material are properties of their respective owners.

PLUS+1, GUIDE and Sauer-Danfoss are trademarks of Danfoss A/S.

0104

BC321571012557en-000104 © Danfoss | Nov 2019 | 2

Page 3

MultiAxis-Steer technical information

Document references

PVED-CLS MultiAxis-Steer communication protocol

Revision 1.02 29 Oct 2019

PVED-CLS Technical Specification

BC00000355

PVED-CLS MultiAxis-Steer firmware release note

1.02 29 Oct. 2019

This documentation is related to the following software version:

See MultiAxis-Steer firmware revision in Document references

Warning

Identifies information about practices or circumstances that can lead

Identifies a typical use of a functionality or parameter value. Use

process of the system.

Document references

Software reference

Errata information

Literature

Document Revision

PVED-CLS KWP2000 protocol Revision 1.79 02 May 2018

PVED-CLS User manual Revision 1.7 14 Jan 2019

EHi steering valve technical information BC00000379

The latest errata information is always available on the Danfoss homepage: www.danfoss.com

It contains errata information for:

• PVED-CLS boot loader

• PVED-CLS application

• Documentation

• PLUS+1® Service tool

• Other topics related to the steering system

If further information to any errata is required, please contact your nearest Danfoss Product

Application Engineer

Important User Information

Danfoss is not responsible or liable for indirect or consequential damages resulting from the use or application of

this equipment.

The examples and diagrams in this manual are included for illustration purposes. Due to the many variables and

requirements associated with any particular installation, Danfoss cannot assume responsibility or liability for the

actual used bases on the examples and diagrams.

Reproduction of whole or part of the contents of this safety manual is prohibited.

The following notes are used to raise awareness of safety considerations.

Identifies information about practices or circumstances that can

cause a hazardous situation, which may lead to personal injury or

death, damage or economic loss.

Attention

to personal injury or death, property damage, or economic loss.

Attentions help you identify a hazard, avoid a hazard, and recognize

the consequence.

Important

Recommendation

Identifies information that is critical for successful application and

understanding of the product.

recommendations as a starting point for the final configuration

BC321571012557en-000104 © Danfoss | Nov 2019 | 3

Page 4

MultiAxis-Steer technical information

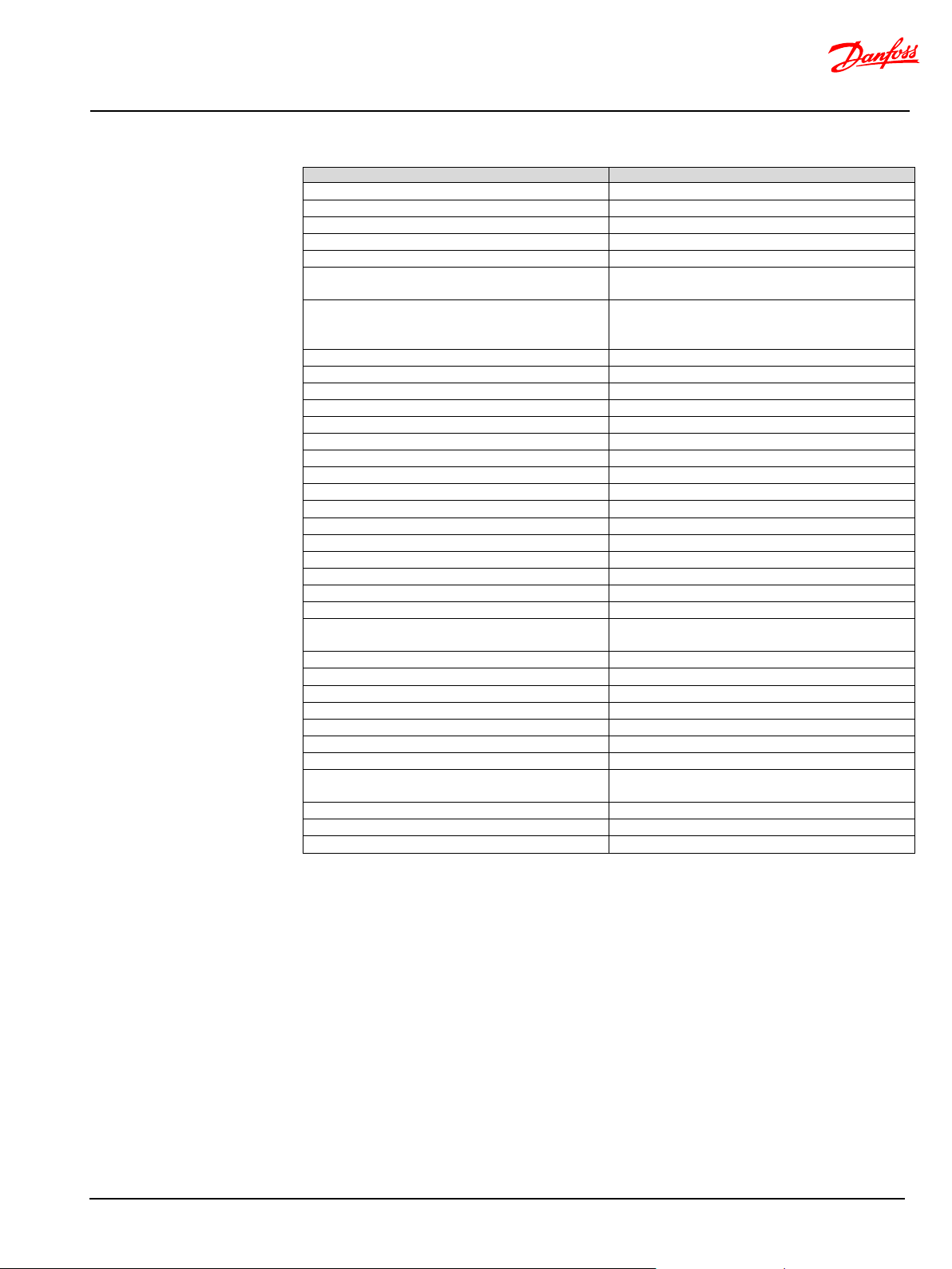

Terms and abbreviations

Abbiviation

Meaning

AgPL

Agricultural Performance Level per ISO 25119

CAT

Safety category per ISO 13849 and ISO 25119

CCF

Common Cause Failure

COV

Cut-Off Valve

DC

Diagnostic Coverage

CLS, includes the de-engergize

Infers: Block hydraulic pilot pressure by switching off

PVED-CLS will remain powered on.

ECU

Electronic Control Unit

EH

Electro-Hydraulic

EHi-E

Electro-Hydraulic Inline Valve – Electronic Override

FMEA

Failure Mode and Effects Analysis

FMEDA

Failure Mode and Effects and Diagnostic Analysis

IR

Internal Resolution [-1000;1000]

MMI

Man-Machine Command Interface

MTTFd

Mean time to potentially dangerous failure

N-Axis

Multi-axis, more than one axis is steered

OEM

Original Equipment Manufacturer

OSPE

Orbital Steering Product – Electro-hydraulic

PFD

Probability of dangerous failure on Demand

PFH

Probability for dangerous failure per hour

PL

Performance level per ISO 13849

POST

Power On Self Test

PSAC

Parameter Sector Access Code

here the valve controller

SASA

Steering Angle Sensor Absolute

SC

Systematic capability

SEHS

Safe Electro-Hydraulic Steering

SFF

Safe Failure Fraction

SIL

Safety Integrity Level

SPN

Suspect Parameter Number

SVB

Solenoid Valve Bridge

Solenoid Valve Control – Control algorithm for PVEDCLS

VAA

Virtual Axis Angle

VAP

Virtual Axis Position

WAS

Wheel Angle Sensor

Terms and abbreviations

de-power

de-energize

PVED-CLS

Infers: Disconnect electrical power supply to PVED-

electrical power supply to EHi and cut-off valve. The

Proportional Valve Digital – Closed Loop - Safety –

BC321571012557en-000104 © Danfoss | Nov 2019 | 4

SVC

Page 5

MultiAxis-Steer technical information

Contents

Contents

Document references 3

Software reference ....................................................................................................................................................... 3

Errata information......................................................................................................................................................... 3

Important User Information ...................................................................................................................................... 3

Terms and abbreviations 4

Contents 5

Introduction 9

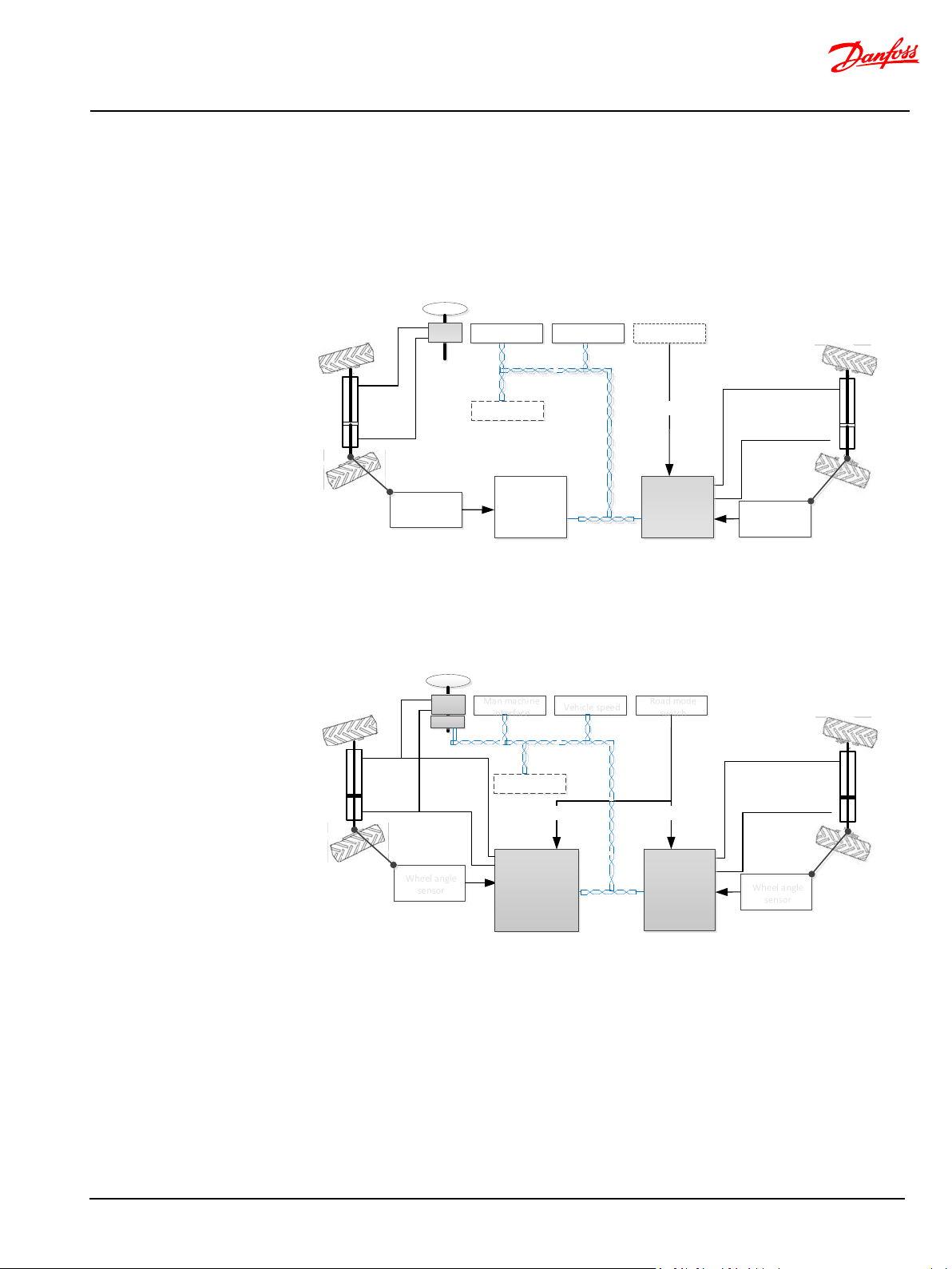

N-Axis system principal 10

N-Axis system configurations.................................................................................................................................. 10

N-Axis master [hydrostatic] steering system ................................................................................................ 10

N-Axis master [electro hydraulic] steering system ..................................................................................... 10

N-Axis master functions ............................................................................................................................................ 11

N-Axis slave function ................................................................................................................................................. 11

Man Machine Interface (MMI) ................................................................................................................................. 11

Vehicle speed sensor ................................................................................................................................................. 11

Wheel angle sensor .................................................................................................................................................... 11

Road switch................................................................................................................................................................... 12

Active de-energize (immediate) ....................................................................................................................... 12

Active de-energize (automatic return to straight) ...................................................................................... 12

Full electrical de-power/de-energize .............................................................................................................. 12

Advise for system integrators ........................................................................................................................... 12

Service tool ................................................................................................................................................................... 12

N-Axis CAN network ................................................................................................................................................... 13

CAN message data flow ...................................................................................................................................... 13

N-Axis CAN messages .......................................................................................................................................... 13

Operation state machine .................................................................................................................................... 14

States .................................................................................................................................................................. 14

Operation state machine – fault handling .................................................................................................... 17

States .................................................................................................................................................................. 17

Functional safety 18

Certification (pending) .............................................................................................................................................. 18

System integrator responsibility ............................................................................................................................ 18

Safety function overview .......................................................................................................................................... 19

Functional safety specification ............................................................................................................................... 20

Safe state ................................................................................................................................................................. 20

N-Axis steering operation while in safe state ......................................................................................... 20

Safe state leakage performance ................................................................................................................. 20

Reset and recovery from safe state.................................................................................................................. 20

Safety function response time .......................................................................................................................... 20

Monitoring function response time ................................................................................................................ 21

N-Axis safe EH steering.............................................................................................................................................. 22

Safe EH-steering / N-Axis closed loop cylinder position control ...................................................... 22

N-Axis safety related control functions ................................................................................................................ 24

Safe vehicle speed dependent Virtual Axis Position (VAP) limit ............................................................. 24

Realizing a safe MMI interface ..................................................................................................................... 24

Operation .......................................................................................................................................................... 24

Parameters ........................................................................................................................................................ 25

Parameter tuning guideline ......................................................................................................................... 26

Operation when number of slaves > 1 ..................................................................................................... 26

Safe vehicle speed dependent Virtual Axis Position (VAP) change rate .............................................. 27

Realizing a safe MMI interface ..................................................................................................................... 27

Operation .......................................................................................................................................................... 27

Parameter .......................................................................................................................................................... 28

Parameter tuning guideline ......................................................................................................................... 28

Operation when number of slaves > 1 ..................................................................................................... 29

Safe vehicle speed dependent Virtual Axis Angle (VAA) limit................................................................. 30

Realizing a safe MMI interface ..................................................................................................................... 30

BC321571012557en-000104 © Danfoss | Nov 2019 | 5

Page 6

MultiAxis-Steer technical information

Contents

Operation .......................................................................................................................................................... 30

Parameter .......................................................................................................................................................... 31

Parameter tuning guideline ......................................................................................................................... 31

Operation when number of slaves > 1 ..................................................................................................... 32

Safe vehicle speed dependent Virtual Axis Angle (VAA) change rate .................................................. 32

Realizing a safe MMI interface ..................................................................................................................... 32

Operation .......................................................................................................................................................... 32

Parameter .......................................................................................................................................................... 33

Parameter tuning guideline ......................................................................................................................... 34

Operation when number of slaves > 1 ..................................................................................................... 34

Safe vehicle speed dependent closed loop gain limitation ..................................................................... 35

Realizing a safe closed-loop position control of the slave axis ......................................................... 35

Operation .......................................................................................................................................................... 35

Parameters ........................................................................................................................................................ 36

Parameter tuning guideline ......................................................................................................................... 36

Operation when number of slaves > 1 ..................................................................................................... 37

Safe vehicle speed dependent wheel angle setpoint limitation ............................................................ 37

Realizing a safe closed-loop position control of the slave axis ......................................................... 37

Operation .......................................................................................................................................................... 37

Parameters ........................................................................................................................................................ 38

Parameter tuning guideline ......................................................................................................................... 38

Operation when number of slaves > 1 ..................................................................................................... 39

Safe N-Axis steering angle initialization (pre-operational) ...................................................................... 39

Operation .......................................................................................................................................................... 39

Parameters ........................................................................................................................................................ 39

Parameter tuning guideline ......................................................................................................................... 39

Operation when number of slaves > 1 ..................................................................................................... 39

System Architecture 40

System diagrams ......................................................................................................................................................... 40

N-Axis master [hydrostatic] ................................................................................................................................ 40

N-Axis master [electro-hydraulic]..................................................................................................................... 40

PVED-CLS steering controller .................................................................................................................................. 40

Connector interface ............................................................................................................................................. 40

Technical specification ........................................................................................................................................ 40

DC Power supply ................................................................................................................................................... 40

Road-switch de-power / de-energize architectures ......................................................................................... 41

ON/OFF switch interface - Active de-energize (immediate) .................................................................... 41

Operation .......................................................................................................................................................... 41

Interface ............................................................................................................................................................. 42

Monitoring ........................................................................................................................................................ 42

ON/OFF switch interface - Active de-energize (automatic return to straight) ................................... 44

Operation .......................................................................................................................................................... 44

Monitoring ........................................................................................................................................................ 45

ON/OFF switch interface - Full electrical de-power/de-energize ........................................................... 45

Zero-leakage valve configuration (option) ................................................................................................... 46

Background ....................................................................................................................................................... 46

Pilot operated check valves ......................................................................................................................... 46

Architecture for zero-leakage performance ........................................................................................... 46

Reliability block diagram .............................................................................................................................. 47

Safety requirements for additional circuitry for SIL3/PL e ........................................................................ 48

Input - Sensor sub-system and monitoring ........................................................................................................ 49

N-Axis master - CAN interface ........................................................................................................................... 49

CAN interface ................................................................................................................................................... 50

Monitoring ........................................................................................................................................................ 50

Vehicle speed sensor – CAN interface ............................................................................................................ 50

CAN interface ................................................................................................................................................... 51

Monitoring ........................................................................................................................................................ 52

Man Machine Interface – CAN interface ........................................................................................................ 52

CAN interface ................................................................................................................................................... 53

Monitoring ........................................................................................................................................................ 54

BC321571012557en-000104 © Danfoss | Nov 2019 | 6

Page 7

MultiAxis-Steer technical information

Contents

Wheel Angle Sensor (WAS) – Analog interface ............................................................................................ 54

Analogue interface ......................................................................................................................................... 55

Monitoring ........................................................................................................................................................ 55

Input range check ........................................................................................................................................... 55

WAS channel cross-check ............................................................................................................................. 56

Micro-controller cross-check of scaled wheel angle ............................................................................ 56

Out of calibration check ................................................................................................................................ 56

Wheel Angle Sensor (WAS) – CAN interface ................................................................................................. 56

CAN interface ................................................................................................................................................... 57

Monitoring ........................................................................................................................................................ 58

Input range check ........................................................................................................................................... 58

Micro-controller WAS channel cross-check ............................................................................................ 58

Out of calibration check ................................................................................................................................ 59

Output - Valve sub-system and monitoring ....................................................................................................... 59

Sensor 5V DC power supply............................................................................................................................... 59

EHi Cut-off valve .................................................................................................................................................... 59

Interface ............................................................................................................................................................. 60

Configuration for EHi-E valve sub-systems ............................................................................................. 60

Monitoring for EHi-E valve sub-systems .................................................................................................. 61

EHi-valve monitoring ........................................................................................................................................... 61

EH-valve main spool control principle ..................................................................................................... 61

EH-valve main spool monitoring –EHi-E valve sub-systems .............................................................. 61

Environmental control measures ........................................................................................................................... 63

PCB overheating shut-down ............................................................................................................................. 63

PCB average over-temperature warning ....................................................................................................... 63

DC power supply ................................................................................................................................................... 63

System set-up 65

Installation .................................................................................................................................................................... 65

PVED-CLS Connector interface ......................................................................................................................... 65

LED diagnostic ....................................................................................................................................................... 65

Calibration ..................................................................................................................................................................... 65

Straight heading calibration .............................................................................................................................. 65

System integration and testing .............................................................................................................................. 65

Vehicle Fault Insertion Testing .......................................................................................................................... 66

Safety validation testing ..................................................................................................................................... 66

Service part handling and repair instruction ...................................................................................................... 66

Safety validation steps after replacing a PVED-CLS with a service part ............................................... 66

Service Tool (detailed) ............................................................................................................................................... 67

Appendix 68

Component identification via CAN bus ............................................................................................................... 68

Valve assembly barcode label ........................................................................................................................... 68

Bootloader and application software identification .................................................................................. 68

PVED-CLS component identification and serial number .......................................................................... 69

PLUS+1 Service tool identification page ....................................................................................................... 69

J1939 request PGN for software ID and component ID ............................................................................ 69

EEPROM parameters .................................................................................................................................................. 70

EEPROM layout ...................................................................................................................................................... 70

Safety parameterization............................................................................................................................................ 71

Safety parameterization procedure ................................................................................................................ 71

Boot Data ....................................................................................................................................................................... 73

Sector CRC Sign Data ................................................................................................................................................. 74

Hydraulic Config .......................................................................................................................................................... 75

Valve Calibration Data ............................................................................................................................................... 78

CAN WAS Calibration Data ....................................................................................................................................... 78

Analog Sensor Calibration Data ............................................................................................................................. 79

Peripherals Config ...................................................................................................................................................... 79

N-Axis Protocol Data .................................................................................................................................................. 80

Internal Monitoring .................................................................................................................................................... 82

Production/Calibration Flag .................................................................................................................................... 84

Auto Calibration Config ............................................................................................................................................ 84

BC321571012557en-000104 © Danfoss | Nov 2019 | 7

Page 8

MultiAxis-Steer technical information

Contents

N-Axis .............................................................................................................................................................................. 87

PLM metadata .............................................................................................................................................................. 90

OEM Data ....................................................................................................................................................................... 93

Signature CRC calculation ........................................................................................................................................ 95

Diagnostic Trouble Codes ........................................................................................................................................ 96

Error codes .............................................................................................................................................................. 96

FMI list..................................................................................................................................................................... 102

TROUBLESHOOTING – TYPICAL FAULTS ............................................................................................................ 103

BC321571012557en-000104 © Danfoss | Nov 2019 | 8

Page 9

MultiAxis-Steer technical information

Introduction

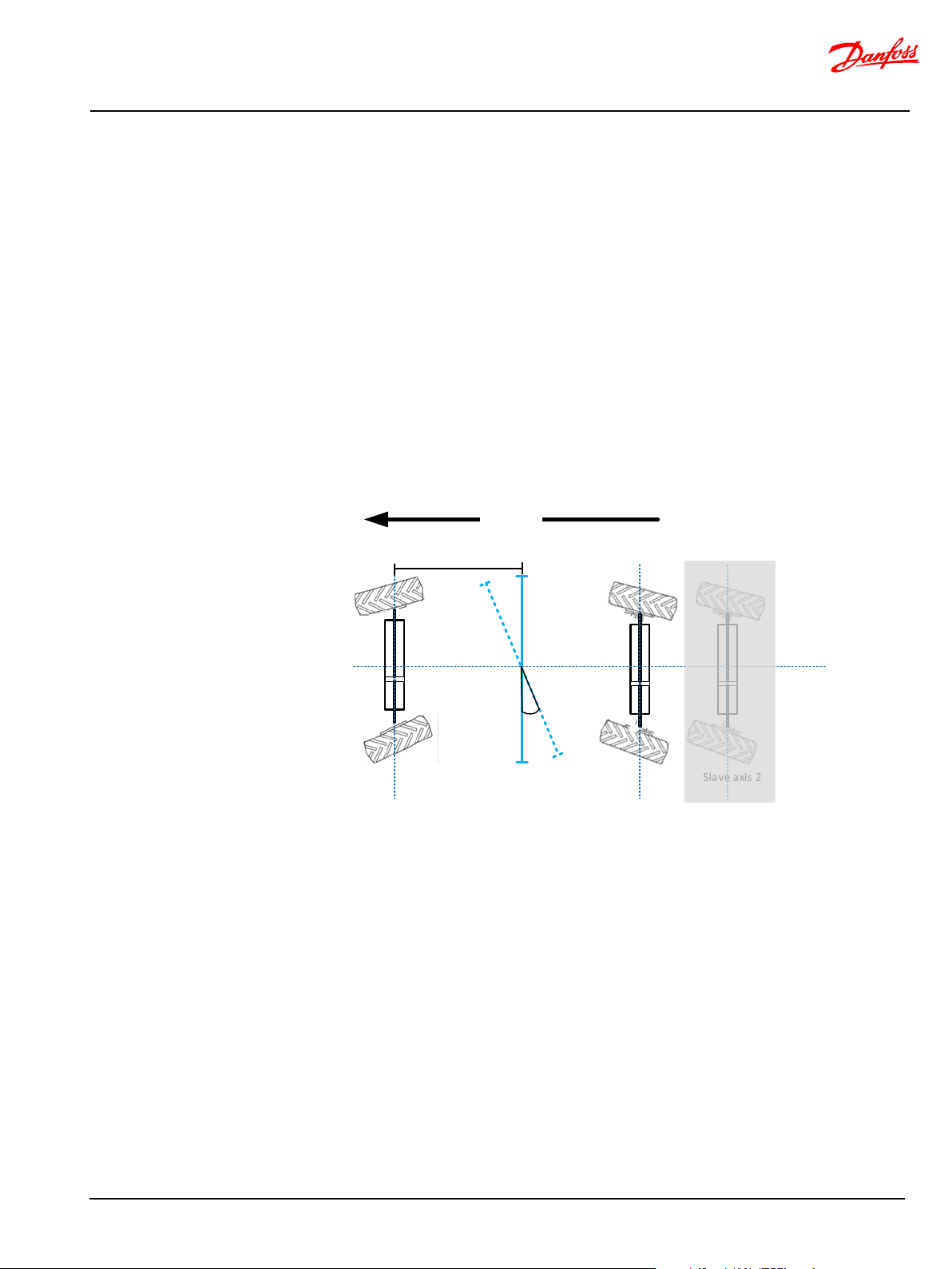

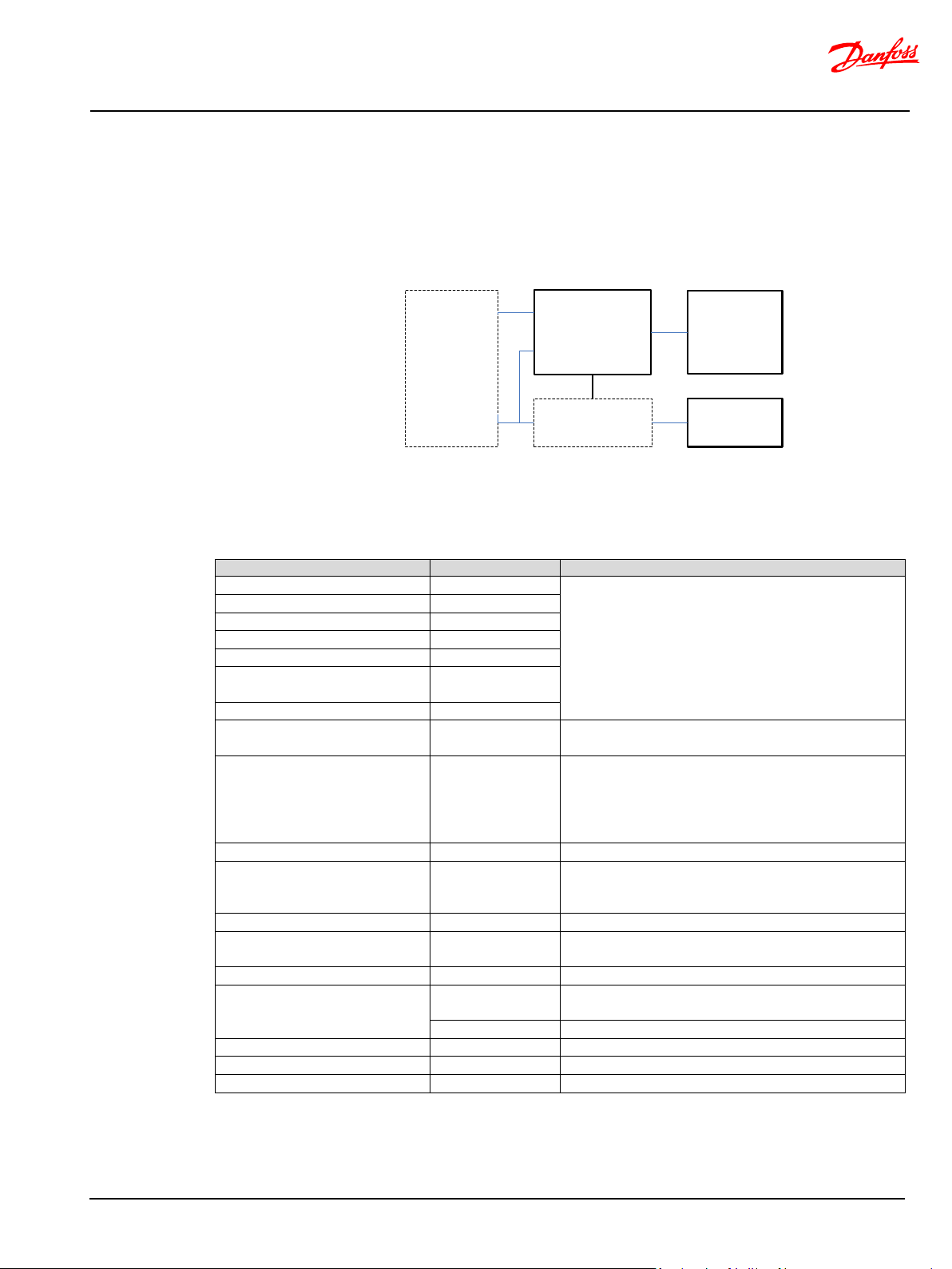

Master axis

Slave axis 1

Slave axis 2

VA

Virtual Ax is

VAP

VAA

forward

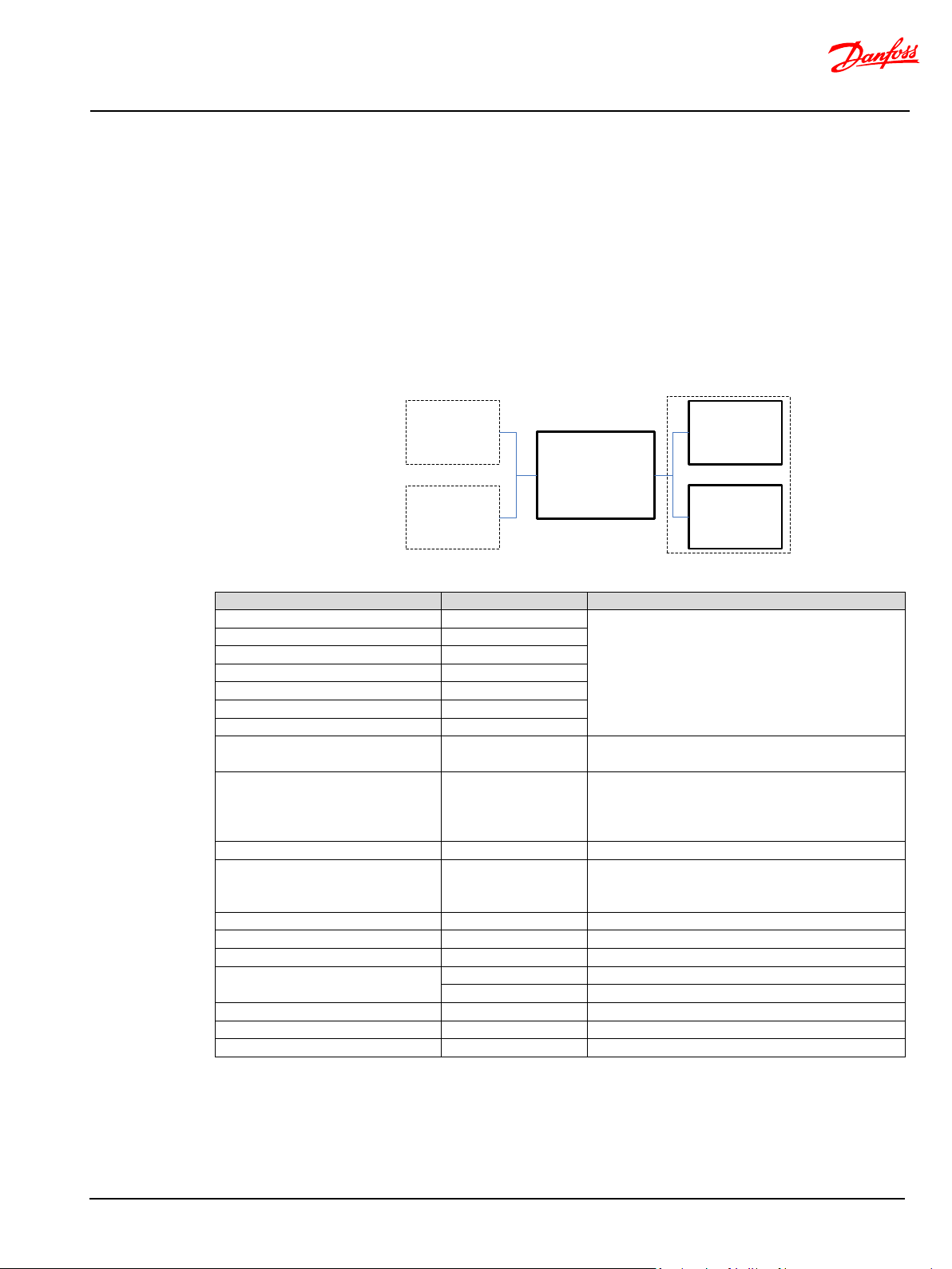

Introduction

MultiAxis vehicle steering is adding steering functionality to have steering on one or more steering axis

than the master axis.

Throughout this document, and in referenced documentation, N-axis or NAXIS are used as

synonyms for MultiAxis steering mainly referencing one or more additional (n) “slave” axis.

Any possibly vehicle steering mode can be achieved with N-Axis steering by the N-Axis MMI command

CAN message, containing the Virtual Axis Position (VAP) and the Virtual Axis Angle (VAA). See Figure 1.

The data set, given by VAP and VAA, can result in steering modes such as:

• 2-wheel steering (normal)

• Round/4-wheel steering

• Crab steering

• Dog steering

• Customized steering modes

The steering modes can be altered dynamically and seamlessly by the operator during operation by

transmitting VAP and VAA data set which results in the requested steering mode.

BC321571012557en-000104 © Danfoss | Nov 2019 | 9

Figure 1 N-Axis steering variables VAP and VAA

The blue line is the Virtual Axis which can be shifted horizontally along the wheel base (VAP) and

angled relative to the wheel base (VAA). Shifting VAP to the physical slave axis position in a single slave

system will result in 2-wheel steering.

Page 10

MultiAxis-Steer technical information

N-Axis system principal

Wheel an gle

sensor

N-axis s lave

PVE D

-CLS

EHi Valve

Man machine

int erfac e

CAN bus

Slave axis

Mas ter axi s

Road mode

swi tch

Steering wheel

OSP

Wheel an gle

sensor

N-axis m aster

(OEM )

Veh icle speed

ON/ OF F

Service tool

ON/ OF F

Veh icle speed

Wheel an gle

sensor

N-axis s lave

PVED-CLS &

EHi valve

Man machine

int erfac e

CAN bus

Slave axis

Mas ter axi s

Road mode

swi tch

Steering wheel

OSP (E)

Wheel an gle

sensor

N-axis m aster

PVED-CLS &

OSPE/EHi valve

SASA

Service tool

ON/ OF F

N-Axis system principal

A N-Axis slave steering sub-system may work with both a N-Axis master [hydrostatic] and N-Axis

master [electro hydraulic]. The below functions shall be performed by the system components outlined

in N-Axis system configurations.

N-Axis system configurations

N-Axis master [hydrostatic] steering system

In a N-Axis master, [hydrostatic] steering sub-systems, the master axis is actuated by a hydro-static

steering unit. All N-Axis master functions must be provided by the OEM controller working as N-Axis

master.

N-Axis master [electro hydraulic] steering system

In a N-Axis master [electro hydraulic] steering system, both the master and slave axis are electrohydraulic steering sub-systems e.g. by applying a PVED-CLS with an OSPE valve or a PVED-CLS with an

OSP and EHi inline valve enabling auto-guidance or other high level steering functionalities.

Refer to [PVED-CLS User manual ] for high-level electro-hydraulic steering master axis functionalites.

BC321571012557en-000104 © Danfoss | Nov 2019 | 10

Page 11

MultiAxis-Steer technical information

N-Axis system principal

N-Axis master functions

N-Axis slave function

An N-Axis master performs the following functions:

• Actuate the master steering axis

• Measure the master axis wheel angle and transmit it onto the CAN bus

• Transmit N-Axis master status information onto the CAN bus to the N-Axis slave

N-Axis master functionality shall be realized in the target system by the OEM or by applying a PVEDCLS in ‘N-Axis master’ mode (planned software extension).

Refer to [PVED-CLS MultiAxis-Steer communication protocol].

An N-Axis slave performs the following functions:

• Actuate the slave axis

• Receive N-Axis Man Machine Interface (MMI) commands

• Measure the slave axis wheel angle

• Execute slave-to-master wheel angle alignment initialization

• Perform closed-loop steering control of the slave axis cylinder

• Inputs for closed-loop steering control are:

o Master axis wheel angle

o Virtual Axis Position (VAP) from MMI

o Virtual Axis Angle (VAA) from MMI

o Wheel angle limitations from other N-Axis slaves (n > 1)

o Vehicle speed data

• Execute N-Axis safety related control functions

• On-road operation mode

• Apply wheel angle limitation on demand

• Apply self-centering (graceful degradation)

• Transmit N-Axis slave network status CAN message

• Auto-calibration functionality

Man Machine Interface (MMI)

The MMI performs the following functions:

The MMI functionality shall be realized in the target system by the OEM.

Refer to [PVED-CLS MultiAxis-Steer communication protocol].

Vehicle speed sensor

The vehicle speed sensor sub-system performs the following function:

The vehicle sensor sub-system shall be shall be realized in the target system by the OEM.

Refer to [PVED-CLS MultiAxis-Steer communication protocol].

Wheel angle sensor

A wheel angle sensor shall acquire the wheel angle of the front and slave axis respectively.

The wheel angle sensor may:

The vehicle sensor sub-system shall be shall be realized in the target system by the OEM.

Refer to [PVED-CLS MultiAxis-Steer communication protocol] for CAN based wheel angle sensors.

• Cyclically transmission of the N-Axis MMI control message

• Control of the N-Axis steering mode set-point (VAP and VAA)

• Control of wheel angle limit on-demand

• Aqcusition and transmission of the vehicle propulsion speed onto the CAN bus

• Redundant analog 0-5V with crossed output characteristic

• CAN based

BC321571012557en-000104 © Danfoss | Nov 2019 | 11

Page 12

MultiAxis-Steer technical information

N-Axis system principal

Road switch

The road switch performs the following functions in respect to slaves axis:

• Activate N-Axis slave steering

• De-activate N-Axis slave steering

More activation/de-activation options are possible:

Active de-energize (immediate)

Disable N-Axis slave steering for reaching a safe operation mode for public road usage.

PVED-CLS will remain powered and transmit status and sensor information on the CAN bus.

See [Road-switch de-power / de-energize architectures

ON/OFF switch interface - Active de-energize (immediate)] on page 41.

Active de-energize (automatic return to straight)

Disable N-Axis slave steering with auto-centering to straight and subsequent reaching a safe operation

mode for public road usage

PVED-CLS will remain powered and transmit status and sensor information on the CAN bus.

See [ON/OFF switch interface - Active de-energize (automatic return to straight)] on page 44.

Full electrical de-power/de-energize

Full electrically de-power/de-energize the N-Axis slave to assume a safe state. The PVED-CLS and valves

are not powered. No slave axis functionality is available.

See [ON/OFF switch interface - Full electrical de-power/de-energize] on page 45.

Zero-leakage de-power/de-energize architecture option

Applications which require lower rear axis drift while N-Axis is inactive or de-energized, require

additional zero-leakage check valves. See [Zero-leakage valve configuration (option)] on page 46.

Advise for system integrators

Important

For systems, where a road switch is required, it must be analysed if cylinder drift, while de-energzied, is

acceptable. If cylinder drift cannot be tolerated, additional check valves may be needed for zeroleakage performance.

Service tool

The service tool provides a mean to perform calibration and diagnostic during installation and

performs the following functions:

• The road switch is optional in N-Axis steering systems.

• The OEM system integrator shall take the decision on the need for a road switch based on the

hazard and risk analysis for the particular vehicle.

• Factors such as maximum vehicle speed, weights, vehicle use profiles may be part of the

considerations.

• The road switch may also operate on N-axis master [electro-hydraulic] steering systems.

• See [Safe state leakage performance] on page 20 for cylinder drift during de-activation.

The system integrator shall ensure that the PVED-CLS and valve sub-system are used in a

suitable mode while the vehicle is being used on public roads.

• Configure parameter settings

• Read out error codes

• Diagnostic

• Valve spool auto-calibration

• Wheel angle sensor calibration

• Perform manual calibrations

• Program multiple parameters

• Flash firmware

BC321571012557en-000104 © Danfoss | Nov 2019 | 12

Page 13

MultiAxis-Steer technical information

N-Axis system principal

=

nAxis master network message

Message content:

Master axis wheel angle

Operation mode/Safe state

indica tion

MMI

Master axis c ontroller Slave #1 Slave #2 Slave #3

=

nAxis MMI message

Message content: Placement of

virtual axis positi on VAP, virtual axis

anlgel VAA and enable/dis able N-Axis

wheel angle li mit"

=

nAxis slave network message

Message conten t:

Limiting slave (ID and WA Right)

Limiting slave (ID and WA Left)

Safe state indication

=

nAxis operational status message

Message conten t:

N-axis operatio n status

Calibration status

Safe state indication

CAN message

Function description

N-Axis MMI

The MMI message contains the VAP and VAA which sets the vehicle steering mode.

Refer to [PVED-CLS MultiAxis-Steer communication protocol].

N-Axis master net work message

The N-Axis master message contains the master axis steering angle and the operation

Refer to [PVED-CLS MultiAxis-Steer communication protocol].

N-Axis slave network message

The N-Axis slave network message(s) contains the identifier of the slave which has

Refer to [PVED-CLS MultiAxis-Steer communication protocol].

N-Axis master/slave operation

Primary and redundant master and slave(s) operation status message [STAT_MSG_OP]

N-Axis operation status messages are for information only.

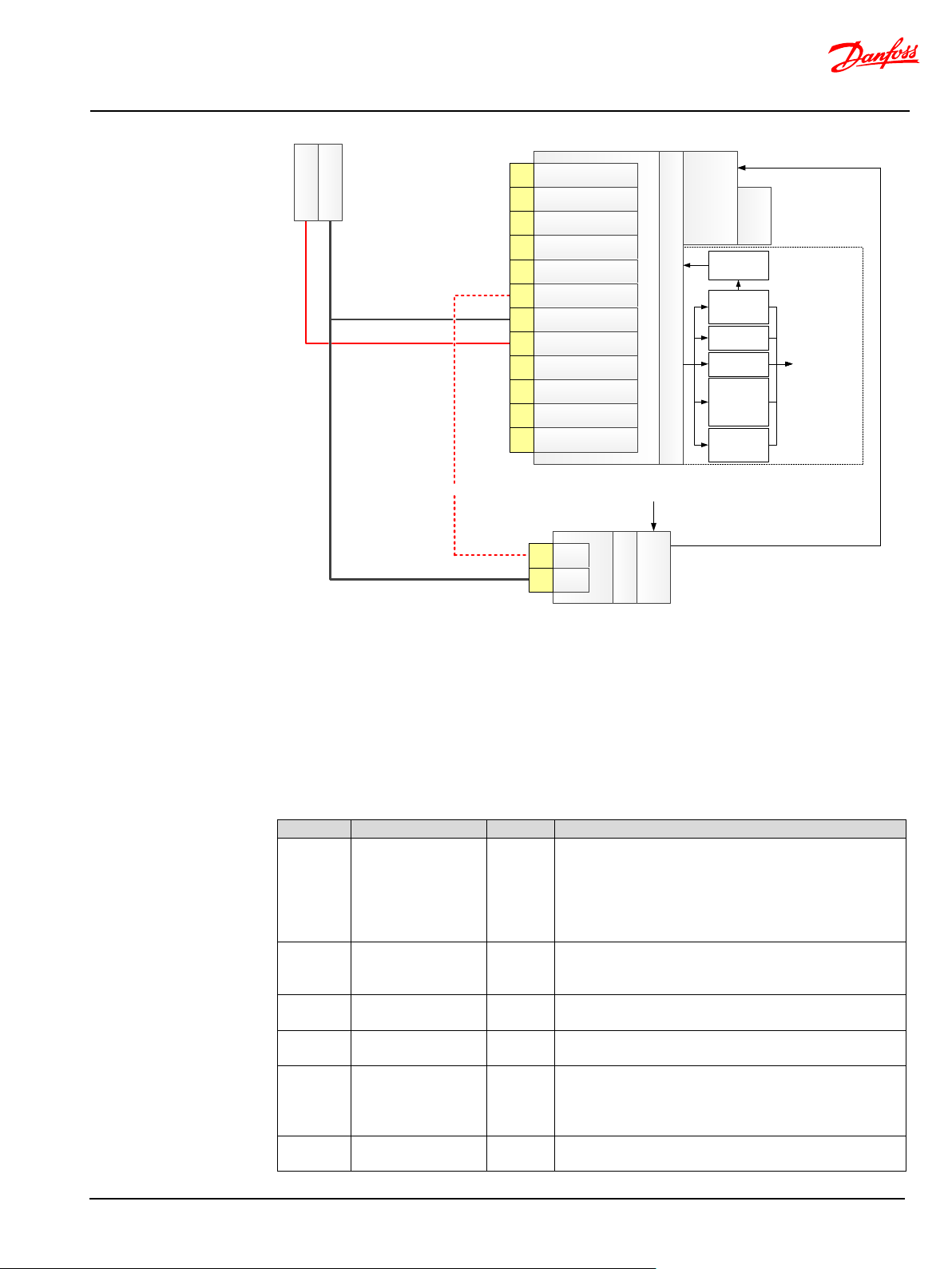

N-Axis CAN network

CAN message data flow

Four levels of CAN messages are flowing in an N-Axis steering system.

Figure 2 N-Axis CAN message network

N-Axis CAN messages

A pre-configured wheel angle limit can be enabled/disabled by the MMI which will take

priority over other wheel angle limitations in the N-Axis.

The N-Axis MMI message is only received by the N-Axis slaves (one or more).

NAXIS MMI PRIMARY MESSAGE [NAXIS_MMI_P]

NAXIS MMI REDUNDANT MESSAGE [NAXIS_MMI_R]

mode or safe state indication.

NAXIS MASTER PRIMARY MESSAGE [NAXIS_MASTER_P]

NAXIS MASTER REDUNDANT MESSAGE [NAXIS_MASTER_R]

reached its wheel angle limit (R/L) and the operation mode or safe state indication from

that particular N-Axis slave.

Any N-Axis can at some point reach a wheel angle restriction which limits the entire NAxis steering behavior i.e. not allowing further N-Axis steering to the direction which has

reached a limit.

A slave shall receive and forward the received wheel angle limit from a slave or transmit

its own limit if this is the tightest wheel angle limit.

Note that the N-Axis slave network messages are only sent when the number of N-Axis

slaves is > 1.

NAXIS WHEEL ANGLE LIMIT PRIMARY MESSAGE [NAXIS_MWA_LIMIT_P]

NAXIS WHEEL ANGLE LIMIT REDUNDANT MESSAGE [NAXIS_MWA_LIMIT_R]

BC321571012557en-000104 © Danfoss | Nov 2019 | 13

status message

Operational status message from the master and the slaves. Status message on N-Axis

steering mode, calibration status and safe sate indication.

Page 14

MultiAxis-Steer technical information

N-Axis system principal

Pre

-operational

Power on

application start

Reset/soft

-reset

No error

|Wheel angle| <

NAXIS_PREOP_EXIT_WA_TOL_dDeg (P3910)

②

Initializat ion

POST

①

Condi tion 1: Vehicle speed <

[NAXIS_ONROAD_VSP_TRIG_MEAN_KMPH (P3908) - 0.5·NAXIS_ONROAD_VSP_T RIG_HYSTER_KMPH (P3907)]

OR

Condi tion 2: Road swit ch is present (P 3237=255) AND Road swit ch state is ‘N-axis act ive/ ON’

Operational

③

On-road stat e

④

On-road locked sta te

⑤

Condi tion 1: |wheel angle| ≤ NAXIS_ONROAD_MAX_WA_dDeg (P3909)

OR

Condi tion 2: NAXIS_ WHEELS_STRAIGHT _ROAD_SWITCH_TIMEOUT_10MS (P 3094)

Vehicle speed >

[NAXIS_ONROAD_VSP_TRIG_MEAN_KMPH (P3908) + 0.5·NAXIS_ONROAD_VSP_T RIG_HYSTER_KMPH (P3907)]

Ro ad swi tc h: N -axis ac tive /ON

Ro ad swi tc h: N -axis ina ct ive/OFF

Hig h-prio rity N-axis control

Road switch i s present (P3237=255)

AND

Road switch state is ‘N-axis in acti ve /OFF’

Power-on-self-tests are executed to ensure that the hardware, software and valves work to the

10 seconds after address claim, the application shall enter the safe state.

Prior to executing closed-loop slave axis position control in Operation state, the slave axis angles are

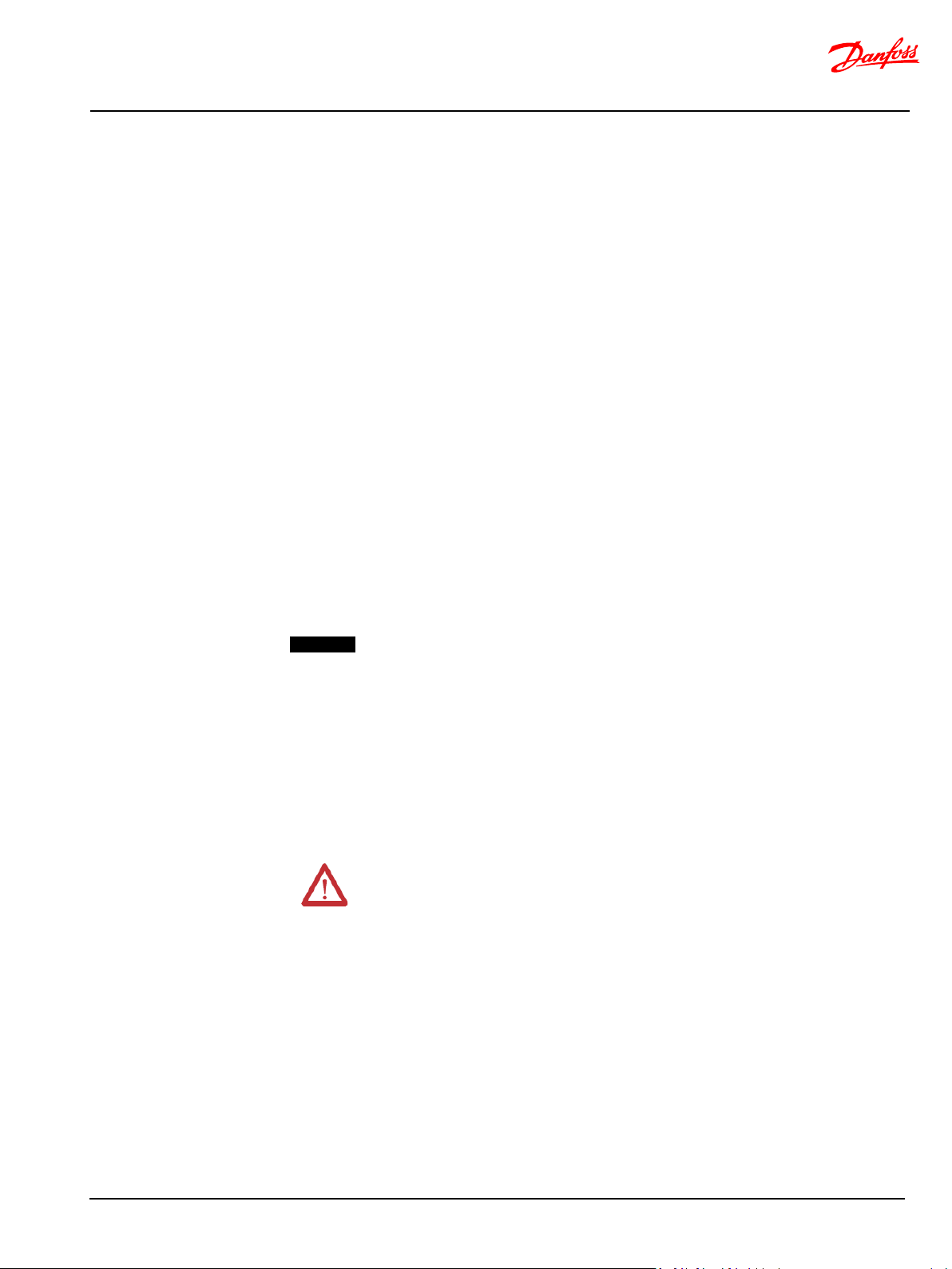

N-Axis operation

Operation state machine

Figure 3 N-axis operation state machine

States

State # Description

Initialization

POST

1

specifications.

If a fault is detected the PVED-CLS enters the safe state (fail state) and issue a DTC on the CAN bus.

After transmitting the address claim message, the application shall wait up to 10 seconds for N-Axis

slave input signals:

MMI messages, vehicle speed CAN messages, analogue WAS signals, CAN based WAS signals (if

configured), N-Axis master messages, N-Axis master wheel angle limit messages (when the number

of slave axis > 1) and road switch signals.

Monitoring is applied on each signal/message upon reception of the first valid signal or message.

After a fixed 10 seconds time-out period, the software assumes that all signal and messages are

Preoperational

BC321571012557en-000104 © Danfoss | Nov 2019 | 14

present and starts individual monitoring of these. Should one or more sensors fail to be ready within

2

aligned to the master axis steering angle for the current N-Axis steering mode set-point (VAP, VAA).

Page 15

MultiAxis-Steer technical information

N-Axis system principal

State

#

Description

The alignment is performed by letting master axis steering motion work as a gate for closed-loop

parameter P3910. Hereafter the N-Axis resumes to operational state.

stable information status on displays etc.

On-road state is an intermediate state where the slave axis is controlled to its straight position. Once

The surrounding system shall take appropriate action in case the slave axis enters safe

position control of the N-Axis slave; the slave axis steering angle will not change position unless the

master axis is changing position similar to “inching” the slave axis to the correct position.

This operation is continued until the slave axis position is inside a tolerable range given by the

Operational 3 Active closed-loop control of the slave axis position.

The control parameters shall undergo tuning to achieve a controllable steering for any N-Axis

steering mode change.

The input for the closed-loop control algorithm is:

• Master axis wheel angle

• Virtual Axis Position (VAP) from MMI

• Virtual Axis Angle (VAA) from MMI

• Wheel angle limitations from other N-Axis slaves (n > 1)

• Vehicle speed data

The closed-loop control performance is configurable by the parameters listed in [Safe vehicle speed

dependent closed loop gain limitation].

Typically the closed-loop control of the slave axis is configured to approach a sole front axis steering

system (VAA=0 and VAP = slave axis position) proportionally to increasing vehicle speed.

The maximum vehicle speed where N-Axis operation shall revert to a sole front axis steering system

is set by parameter P3908. Exceeding this speed + 0.5·P3907 (half of the vehicle speed hysteresis

band) will result in a jump to on-road state.

The hysteresis band shall be configured to avoid state bouncing which may be useful for displaying

On-road

state

4

straight position is reached, the software automatically transits to ‘On-road locked state’ which is the

state suitable for higher vehicle speeds.

Two conditions trigger a transition to on-road state:

1) A transition from Operation state (described above)

2) Commanding ‘on-road’-mode by means of the manually operated road switch

(parameter P3237)

On-road state operation:

• Command straight position by forcing VAA is forced to 0 and VAP is forced to the slave

axis position (P3896).

• A timer (P3094) is started to open a time window in which the slave axis shall reach

straight position

Setting P3094 = 0 will, on switching to on-road mode, disable closed-loop slave axis operation and

result in an immediate transition to On-road locked state regardless of the slave axis position. No alarm

will be raised if the slave axis angle is not centered. This setting shall be used when the road switch

immediately cuts power to the cut-off solenoid valve and thus makes closed-loop control impossible.

Important The surrounding system shall observe the slave axis position and take appropriate action

in case the slave axis is not in a position which is suitable for operation at higher speeds.

Setting P3094 to a time (e.g. 5000ms) in which it can be expected that the slave axis has been steered

to the straight position, enables achieving automatic slave axis self-centering and transition to onroad locked state. If a road switch is present in the system (P3237=255), then cutting power to the cutoff solenoid valve shall be equally delayed e.g. by applying timed delay relays.

If timer P3094 (set to a non-zero value) times out and the slave axis is not inside a configured straight

range (P3909), then the N-Axis slave will enter safe state and issue a diagnostic trouble code.

Important

state.

Exit from on-road safe state:

• If the vehicle speed drops below P3908 – 0.5·P3907 (half of the vehicle speed hysteresis

band), the software will exit and resume N-Axis operation by jumping to Pre-operational.

• If the road switch is set to ‘N-Axis active/ON’

BC321571012557en-000104 © Danfoss | Nov 2019 | 15

Page 16

MultiAxis-Steer technical information

N-Axis system principal

State

#

Description

• If the road switch is set to ‘N-Axis active/ON’

On-road

locked state

5 In on-road locked state, both the EH proportional valve and the cut-off valve are de-energized, to

block steering flows to the slave axis. The hardware is powered but N-Axis closed-loop control is

suspended. Internal and external monitoring of the electronics and interfacing signals is active.

Sensors are sampled and data is broadcast onto the CAN bus.

The slave axis cylinder position is not monitored and purely hydro-mechanically fixed in its position.

For leakage considerations, see Zero-leakage valve configuration (option) on page 46.

Exit from On-road locked state:

• If the vehicle speed drops below P3908 – 0.5·P3907 (half of the vehicle speed hysteresis

band), the software will exit and resume N-Axis operation by jumping to Pre-operational.

BC321571012557en-000104 © Danfoss | Nov 2019 | 16

Page 17

MultiAxis-Steer technical information

N-Axis system principal

Pre-safe state enables the N-Axis system to fail gracefully.

Vehicle speed CAN message

Safe state is reached when the no flow is output to the slave axis steering cylinder.

spring force)

Co nidti on 1: |wheel angle|≤ NAXIS_ONROAD_MAX_WA_dDeg (P3909)

OR

Co nditi on 2: NAXIS_WHEELS_STRAIGHT_VSP_SAFESTATE_TIMEOUT_10MS (P3096)

Reset, soft-rese t, power-cycle

External failures

Pre-safe stat e

⑥

Safe st ate

⑦

Int erna l f ail ures

Co nidt ion 1: |wheel angle|≤ (P3909) On-R o ad t o O n -R oad -locked Max WA

OR

Co ndit ion 2: (P3096) Sl av e positi on with re spec t to mast er

Reset, soft-rese t, power

-cycle

External failures

Pre-safe stat e

⑥

Safe st ate

⑦

Int erna l f ail ures

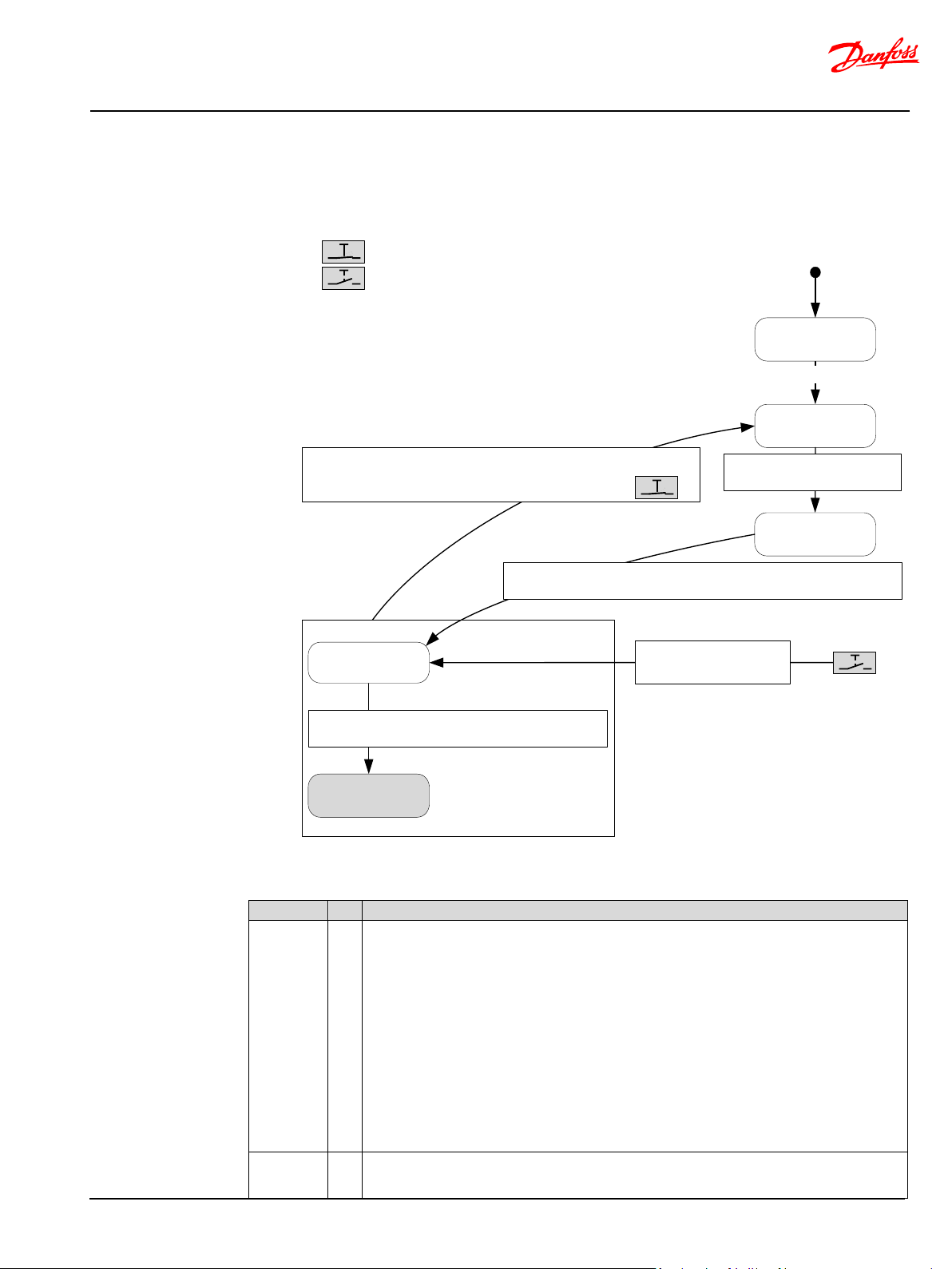

Operation state machine – fault handling

States

State # Description

Pre-safe state 6

Safe state 7

On detecting any failure classified as ‘external’, the slave axis is steered to straight

whereafter the software jumps to safe state.

Operation in Pre-safe state:

• Command straight position by forcing VAA is forced to 0 and VAP is forced to

the slave axis position (P3896).

• A timer (P3096) is started to open a time window in which the slave axis shall

reach straight position.

If timer P3096 times out and the slave axis is not inside a configured straight range (P3909),

then the N-Axis slave will enter safe state.

Failures on the following signals are classified as external:

• N-Axis MMI CAN message

• N-Axis master network CAN message

• N-Axis slave network CAN message

•

The safe state is achieved by at least one of the below two actions:

• De-energizing the EH proportional valve (EH spool is pushed to neutral by a

spring force)

• De-energizing the cut-off valve (COV spool is pushed to closed position by a

BC321571012557en-000104 © Danfoss | Nov 2019 | 17

Page 18

MultiAxis-Steer technical information

Functional safety

Functional safety

Certification (pending)

The PVED-CLS N-Axis steering valve controller is certified for use in off-road safety applications up SIL2

according to IEC 61508, PL d according to ISO 13849 and AgPL d according to ISO 25119.

Architectures for risk reduction up to SIL3/PL e/AgPL e is specified.

The certificate for the PVED-CLS valve controller can be found in the document PVED-CLS Functional

Safety Annex. The PVED-CLS Functional Safety Annex can be found on the Danfoss homepage:

www.danfoss.com

The certificate scope is for the generic PVED-CLS valve controller for use in safety-related applications

as follows; for off-road applications, safe electro-hydraulic steering is ensured by metering out a safe

steering flow as a function of selected steering mode, input steering command, vehicle speed and

steered wheel angle.

For on-road operation, functional safety is achieved by de-energizing the PVED-CLS valve controller.

Important

The certificate does not cover safe on-road system to SIL 3, PL e and AgPL e in its entirety as it requires

external circuitry, which is not in scope of the assessment.

The certification is not a guarantee for that the realized functional safety is sufficient for any machine.

The OEM system integrator is responsible for analyzing the hazard and risks for a particular machine

and evaluate if the risks are sufficiently reduced by the provided safety functions. The application of

the PVED-CLS and valve sub-system is subject for a separate safety life-cycle.

System integrator responsibility

Attention

It is within the responsibility of the OEM system integrator to:

• Having an organization that is responsible for functional safety of the system.

• Ensuring that only authorized and trained personnel perform functional safety related work.

• Choosing reliable components.

• Completing a system hazard & risk analysis and derive the required risk reduction targets.

• Reassessing the hazard & risk every time the system is changed.

• Ensuring that the derived risks are properly reduced by the safety functions provided by the

PVED-CLS valve controller.

• Certification and homologation of the entire system to the desired risk reduction level.

• Installation, set-up, safety assessment and validation of the interfacing sensor sub-systems.

• Parameter configuration of the application software in accordance with this safety manual.

• Validating that the safety functions reduce the risks as expected.

• Any related non-safety standards should be fulfilled for the application and its components.

• Verify the environmental robustness suitability of the PVED-CLS to installation in the final

system in its surrounding environment.

• Periodically inspect for errata information updates.

BC321571012557en-000104 © Danfoss | Nov 2019 | 18

Page 19

MultiAxis-Steer technical information

Functional safety

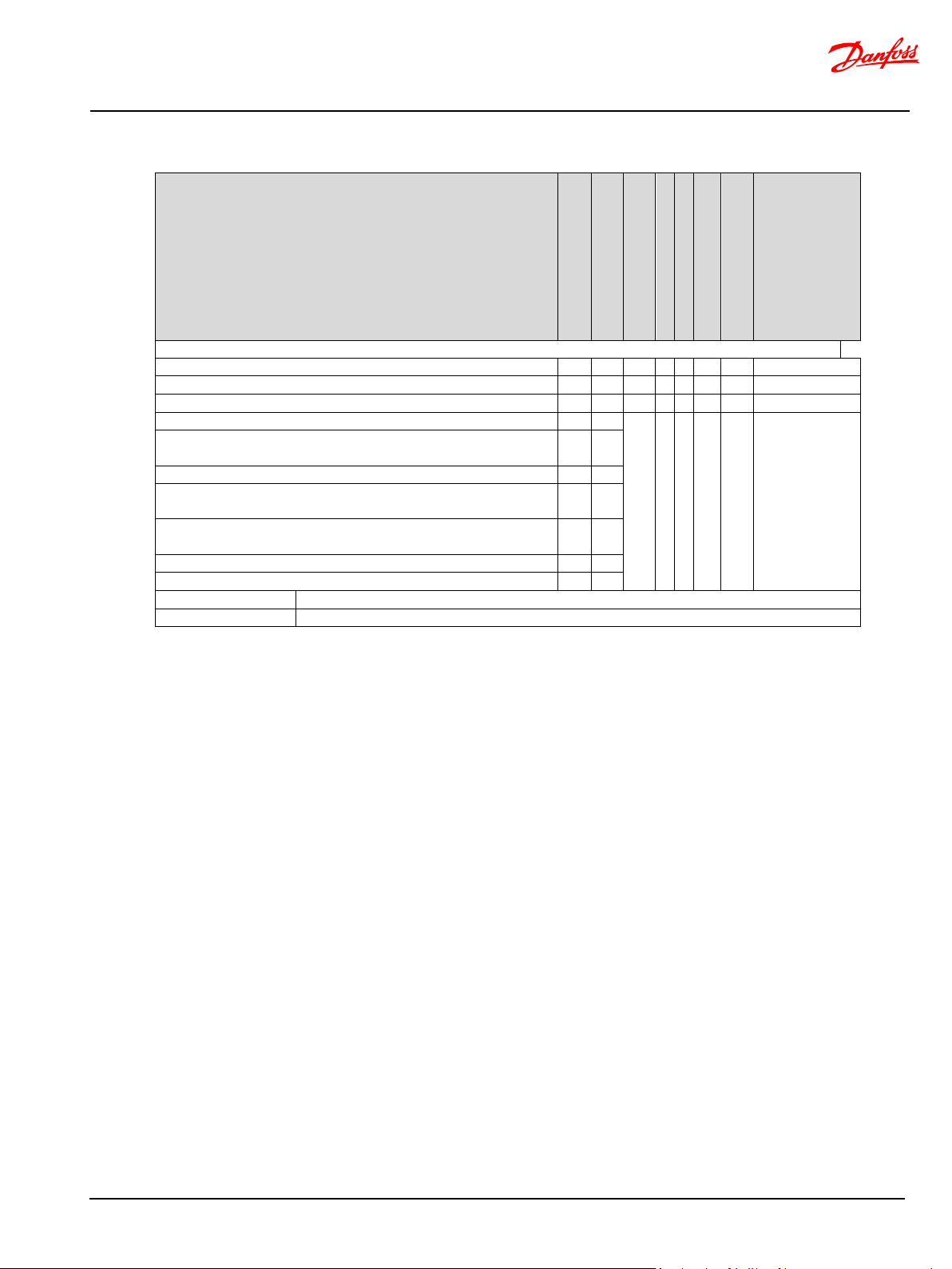

System/Sensor interface

Road switch Relay circuitry

Master wheel angle

N-Axis slave wheel

Vehicle speed sensor SIL2, PL d, AgPL d

SIL3, PL e, AgPL e

Safety function/safety related control function

Safe on-road mode / active de-energization

• • x On-road mode (no road switch installed)

• • • • x Safe EH N-Axis steering

• • • • x Safe vehicle speed dependent virtual axis position (VAP) limit

Safe vehicle speed dependent virtual axis position (VAP) change

rate.

Safe vehicle speed dependent virtual axis angle (VAA) limit.

Safe vehicle speed dependent virtual axis angle (VAA) change

rate.

Safe vehicle speed dependent closed-loop control gain

limitation

Safe vehicle speed dependent wheel angle set-point limitation

Safe N-Axis steering angle initialization (pre-operational).

•

Element of safety function

x

Highest achievable risk reduction

Safety function overview

N-Axis MMI message

• • • • x

BC321571012557en-000104 © Danfoss | Nov 2019 | 19

Page 20

MultiAxis-Steer technical information

Functional safety

Safety function

Fault reaction/risk

mitigation

Safety response time

Safe on-road mode / active de-energization

(immediate)

Functional safety specification

Safe state

N-Axis steering operation while in safe state

Safe state leakage performance

The safe state is achieved when no steering flow is provided to/from the steering cylinder and the NAxis slave cylinder is fixed at its position.

Achieving the safe state relies on a de-energize/fail safe princicple.

To reach the safe state, all safety controlled outputs, i.e. solid state power switches controlling the EHi

valve, are de-energized.

For the EHi valve, the safe state is achieved by one or both of the following states:

• The EH-valve main spool of the EH steering valve is in neutral position.

• Cut-off valve spool is in blocked position.

If the PVED-CLS hardware or software detects a failure or fails to function, the safe state will be

demanded. One or more diagnostic trouble codes related to the detected failure will be broadcast on

the CAN bus. Refer to [Diagnostic Trouble Codes] on page 96.

If an N-Axis steering system enters safe state, N-Axis angle(s) closed-loop control of all N-Axis stops,

and the respective N-Axis slave steering angles will freeze.

The operator will detect this as a different vehicle steering behavior when steering the vehicle. The

difference in perceived steering behavior will increase with the operators steering input command

change. This property shall be considered for ensuring vehicle steering controllability in N-Axis safe

state.

Important

The surrounding system shall take appropriate action if an N-Axis slave enters safe state e.g. raising the

attention at the operator by means of an acoustic and visual alarm.

In the safe state the cylinder is isolated and fixed in position. External forces on the steered wheels may

cause slow cylinder position drift due to hydraulic leakage.

The maximum leakage is 150ml/min at 150bar cylinder port pressure at ~21cSt (Tellus 32, 50°C).

In application where ~zero cylinder drift is required, additional pilot-operated check valves shall be

considered on the cylinder ports. See page 46.

Reset and recovery from safe state

Safety function response time

BC321571012557en-000104 © Danfoss | Nov 2019 | 20

The PVED-CLS cannot leave the safe state by normal application interaction but requires a reset.

Resetting the PVED-CLS valve controller from safe state can be done by any of the below methods:

• Power-cycling battery supply to the PVED-CLS

• Performing a soft-reset by J1939 CAN command [PVED-CLS MultiAxis-Steer communication

protocol].

• Perform a jump to and out of boot-loader via KWP2000 start and stop diagnostic session

services [PVED-CLS KWP2000 protocol].

All the above-mentioned methods to reset the PVED-CLS from safe state, will force a full Power-on-SelfTest (POST) of the PVED-CLS and valve.

The safety response time is defined as the period of time between a failure is first observed by the

diagnostics and the time by which the safe state has been achieved, e.g. de-energizing the solenoid

valves to bring the valve spool(s) within the hydraulic deadband (no steering flow output).

Safe on-road mode 70 ms

Page 21

MultiAxis-Steer technical information

Functional safety

Safe EH-steering / N-Axis closed loop

Control loop time: 10ms

Monitoring

mitigation

Monitoring response time

EHi valve

Internal hardware and

software

Safe state

160 ms

External sensor monitoring

(note 1)

160 ms

Valve main spool monitoring

250 ms (note 2)

Solenoid valve connection

monitoring

560 ms

cylinder position control

The safety related control function ‘Safe EH-steering’ is executed every 10ms and executes safe closedloop cylinder position control.

The reaction time for the EHi valve spool to reach neutral position (safe state) from full stroke is

typically 60ms for normal working temperature/viscosity.

The ‘Safe on-road mode’ is demanded by the road switch and switches to safe on-road mode within a

10ms control loop period (react and switch off valve drivers) plus the time it takes for the valve spool to

close the steering flows (maximum spool stroke).

Monitoring function response time

The monitoring funciton response time is defined as the period of time between a failure is first

observed by the diagnostics and the time by which the safe state has been achieved, e.g. deenergizing the solenoid valves to bring the valve spool(s) within the hydraulic deadband (no steering

flow output).

The reaction time for the EHi valve spool to reach neutral position (safe state) from full stroke is

typically 60ms for normal working temperature/viscosity.

Safe state 160 ms

Fault reaction/risk

Note 1: Sensor CAN message time-outs are configurable which has a direct impact on the fault reaction

time.

Note 2: The spool monitoring fault reaction times are valid when the hydraulics has reached normal

working temperature/viscosity.

BC321571012557en-000104 © Danfoss | Nov 2019 | 21

Page 22

MultiAxis-Steer technical information

Functional safety

PVED-CLS

Ext. Primary

sensor

Ext.

Redundant

sensor

EH-valve

Cut-off valve

Safety parameter

Specification

Description

SIL

2

characteristics.

PFH

5.77∙10-8 [1/h]

Component type

B

SFF

98 %

DC

97 %

Architecture /category (IEC 61508)

1oo2

Proof test interval/mission time

20 years

Reliability handbook

Siemens SN29500

Calculations are performed at an average

temperature equal to 80 °C

Fault exclusion

Mechanical valve

valve, cut-off spool)

block the EH steering flow to the cylinder.

OSPE EH-valve test

On-line testing

Direct monitoring by a LVDT sensor.

OSPE Cut-off valve test

Intermittent full

stroke test.

Indirect monitoring by test pilot pressure test. Test

road mode and

prior to executing off-road steering functionality.

AgPL/PL

d

Maximum achievable performance level

MTTFd per channel

36 years

ISO 13849, ISO 25119

DCavg per channel

97 % / (95 %)

ISO 13849 / (ISO 25119, lowest of the two channels)

PVED-CLS and valve sub-system

3

ISO 13849, ISO 25119

2

When using with EHPS valve. ISO 13849, ISO 25119

CCF analysis

>65

ISO 13849, ISO 25119

Software Requirement Level

SIL2 / SRL3

IEC 61508, ISO 13849 / ISO 25119

Systematic Capability (SC)

2

IEC 61508

N-Axis safe EH steering

Safe EH-steering / N-Axis closed loop cylinder position control

The safety functions of the N-Axis steering system is to provide :

• “Safe EH steering” (in general) and

• “Safe N-Axis on-road mode”

in multiple axis steering systems.

The probabilistic calculations are based on FMEDA calculations according to IEC 61508.

The calculations are valid for off-road application mode and related safety functions.

All safety functions and related hardware are included.

Sensor sub-systems as well as road switch are not included as it depends on the system.

The CAN bus contributes less than 1% of SIL2 due to the applied safety protocol and is thus omitted in

safety related calculations.

Category

Figure 4 Simplified reliability block diagram

IEC 61508 ed. 1

The FMEDA calculation assumes the use of

redundant analogue WAS with inverted

parts (EH-valve, EHmain spool, cut-off

On demanding the safe state, both valves do not

fail simultaneously. At least one valve will always

performed on changing to off-

Source: Danfoss PVED-CLS/OSPE/EHPS/EHi FMEDA.

BC321571012557en-000104 © Danfoss | Nov 2019 | 22

Page 23

MultiAxis-Steer technical information

Functional safety

PVED-CLS

Road switch

EH-valve

Cut-off valve

External logic

Safety parameter

Specification

Description

SIL

2

interface.

PFH

6.08∙10-8 [1/h]

Component type

B

SFF

98 %

DC

97 %

Architecture /category (IEC

61508)

1oo2

Proof test interval/mission time

20 years

Reliability handbook

Siemens SN29500

Calculations are performed at an average temperature

equal to 80 °C

Fault exclusion

Mechanical valve

main spool,

off spool)

On demanding the safe state, both valves do not fail

test.

OSPE EH-valve test

On-line testing

Direct monitoring by a LVDT sensor.

OSPE Cut-off valve test

Intermittent full

stroke test.

Indirect monitoring by test pilot pressure test. Test

executing off-road steering functionality.

AgPL/PL

d

Maximum achievable performance level

MTTFd per channel

57 years

Optimized value for this Safety function.

ISO 13849, ISO 25119.

DCavg per channel

97 % / (95 %)

ISO 13849 / (ISO 25119, lowest of the two channels)

PVED-CLS and valve sub-system

3

When using with OSPE, EHi-E or EHi-H valve. ISO 13849,

ISO 25119

2

When using with EHPS valve. ISO 13849, ISO 25119

CCF analysis

>65

ISO 13849, ISO 25119

Software Requirement Level

SIL2 / SRL3

IEC 61508, ISO 13849 / ISO 25119

Systematic Capability (SC)

2

IEC 61508

Safe N-Axis on-road mode / N-Axis active de-energize (shut-off)

Additional circuitry is needed for systems where the hazard & risk outcome points to a higher risk

reduction (avoiding unintended steering) than the PVED-CLS can provide. External logic shall be

installed to have the PVED-CLS powered while being in a de-energized state.

The probabilistic calculations are based on FMEDA calculations according to IEC 61508.

Non-relevant safety parts in the PVED-CLS are excluded in the calculation of the safety related

specifications.

Figure 5 Simplified reliability block diagram

The below data is valid for the safe on-road switch channel containing the PVED-CLS and solenoid

valve bridge. For specification on the electro-mechanical channel see section Safety requirements for

additional circuitry for SIL3/PL e on page 48.

IEC 61508 ed. 1

The FMEDA calculation assumes the use of redundant

analogue WAS with inverted characteristics.

All circuitry including circuitry for diagnostics is

included except LED, temperature sensor and JTAG

parts (EH-valve,

EHcut-off valve, cut-

simultaneously. At least one valve will always block the

EH steering flow to the cylinder. Fault accumulation is

addressed by OSPE EH-valve and OSPE Cut-off valve

performed on changing to off-road mode and prior to

Category

Source: Danfoss PVED-CLS/OSPE/EHPS/EHi FMEDA.

BC321571012557en-000104 © Danfoss | Nov 2019 | 23

Page 24

MultiAxis-Steer technical information

Functional safety

VAP

VAA

M MI CAN

monitoring

WAS CAN

monitoring

WAS Analog

monitoring

Safe v ehic l e speed

d epend ent

VA P

limit

Safe v ehic l e speed

d epe nd ent V A P

cha nge ra te limit

Safe v ehic l e speed

d epend ent

VAA

limit

Safe v ehic l e speed

d epe nd ent V A A

cha nge ra te limit

Whe el angle limit on demand (on/off)

N-axi s sl av e

WA s et

p oint

cal cula tio n

Safe v ehic l e

spe ed

d epend ent

whe el a n gle s et -

point limitation

Safe v ehic l e speed

d epe nd ent c l os ed -l oop

control gain limitation

Cali bration

+

-

∫

G

Cali bration

Veh ic le s pe ed

C AN m on i to ri n g

WAS_P

WAS_R

AD1

AD2

M MI_ P

M MI_ R

VS P_P

VS P_R

P323 9

Fro nt ax i s whee l angl e

P3923

Ca lcu la t e fl ow

com man d

Fl ow

com man d to

spool set-

p oi nt tra nsfe r

fu nct ion

Ca lcu la t e l im it ed

fl ow c o mma nd as

function of fr ont axis

steer in g s p eed

PRE _OPE RATI O NAL/

N-AXIS OPERATIONAL

SVC

N-axis master

C AN m on i to ri n g

MAS TER_P

MAS TER_R

N-axi s s lave

C AN m on i to ri n g

MWA_LIMIT_P

MWA_LIMIT_R

N

-ax i s netw ork – whe el an gle lim itat ion fro m ot he r sl aves

Ext ern al

i nte rfac e

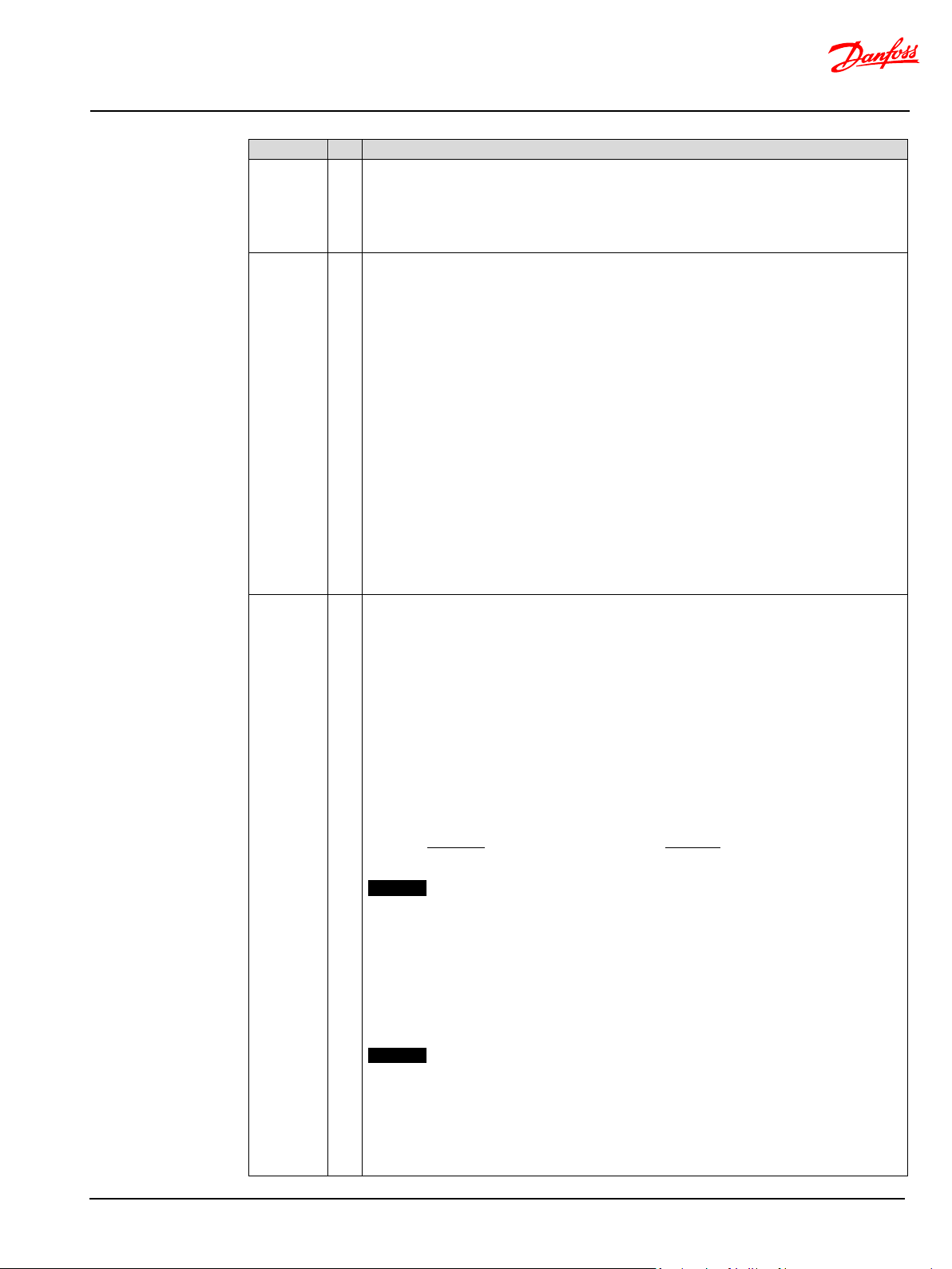

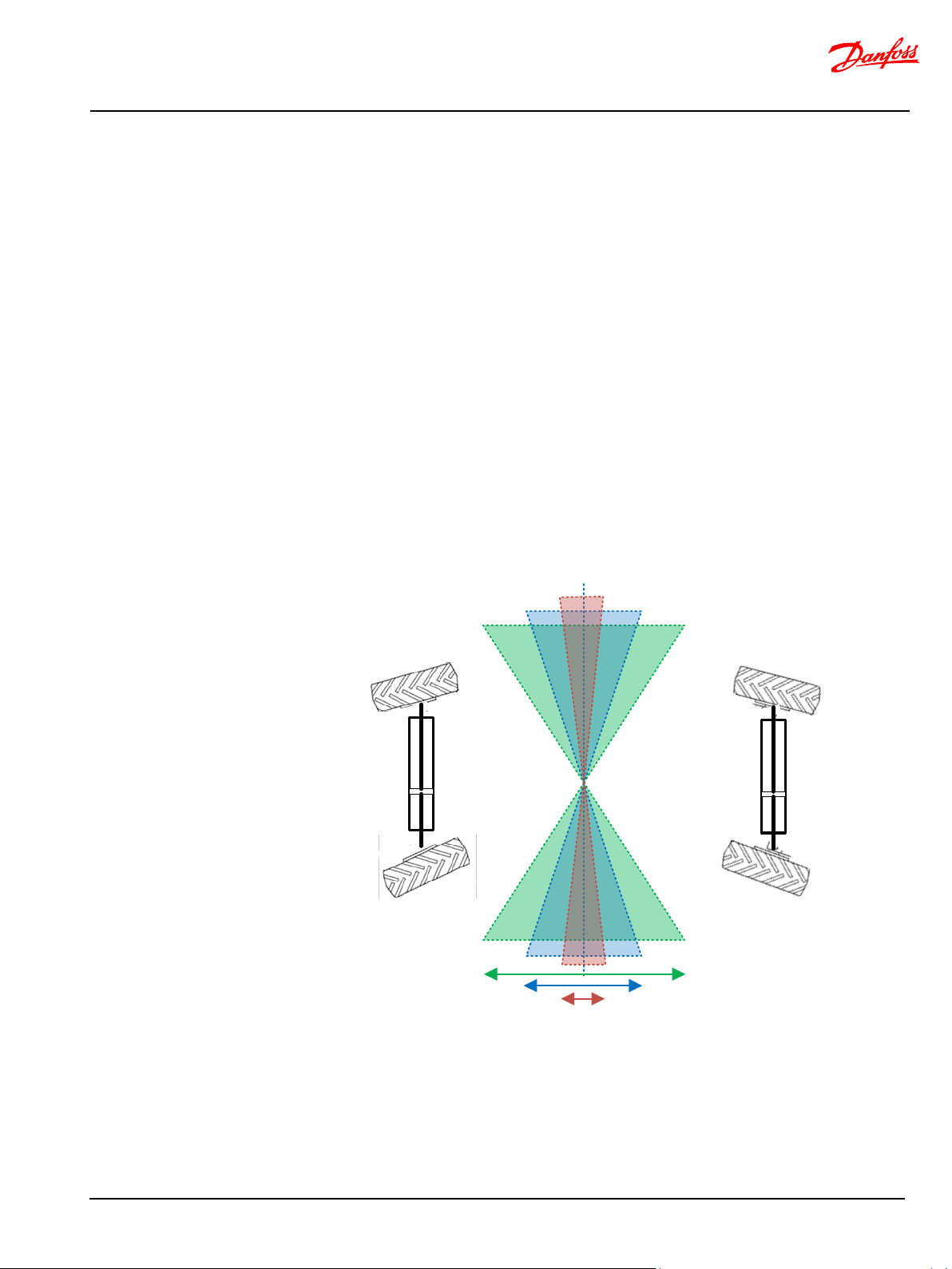

N-Axis safety related control functions

Figure 6 N-Axis EH safe steering block diagram

Blue blocks ( ) provide a link to the related chapter

Safe vehicle speed dependent Virtual Axis Position (VAP) limit

Realizing a safe MMI interface

Operation

BC321571012557en-000104 © Danfoss | Nov 2019 | 24

The safety related control function ‘Safe vehicle speed dependent Virtual Axis Position limit’ is an

instance of the safety functions for realizing a safe N-Axis MMI interface and work in a coordinated

fashion with

• [Safe vehicle speed dependent Virtual Axis Position (VAP) change rate],

• [Safe vehicle speed dependent Virtual Axis Angle (VAA) limit] and

• [Safe vehicle speed dependent Virtual Axis Angle (VAA) change rate].

A correctly configured safe MMI interface will allow any random VAP and VAA input value and change

rate while maintaining controllable N-Axis operation. No unintended change will lead to loss of

steering controllability.

The N-axis MMI interface can in such a case be regarded as non-critical for safe N-Axis operation.

The received VAP set-point is limited in accordance with a programmable safe VAP range envelope.

This may be useful in advanced N-Axis steering modes where VAP can be changed dynamically during

N-Axis operation and where there is no expectation to the VAP set-point. In such cases, a safe VAP

envelope can be configured.

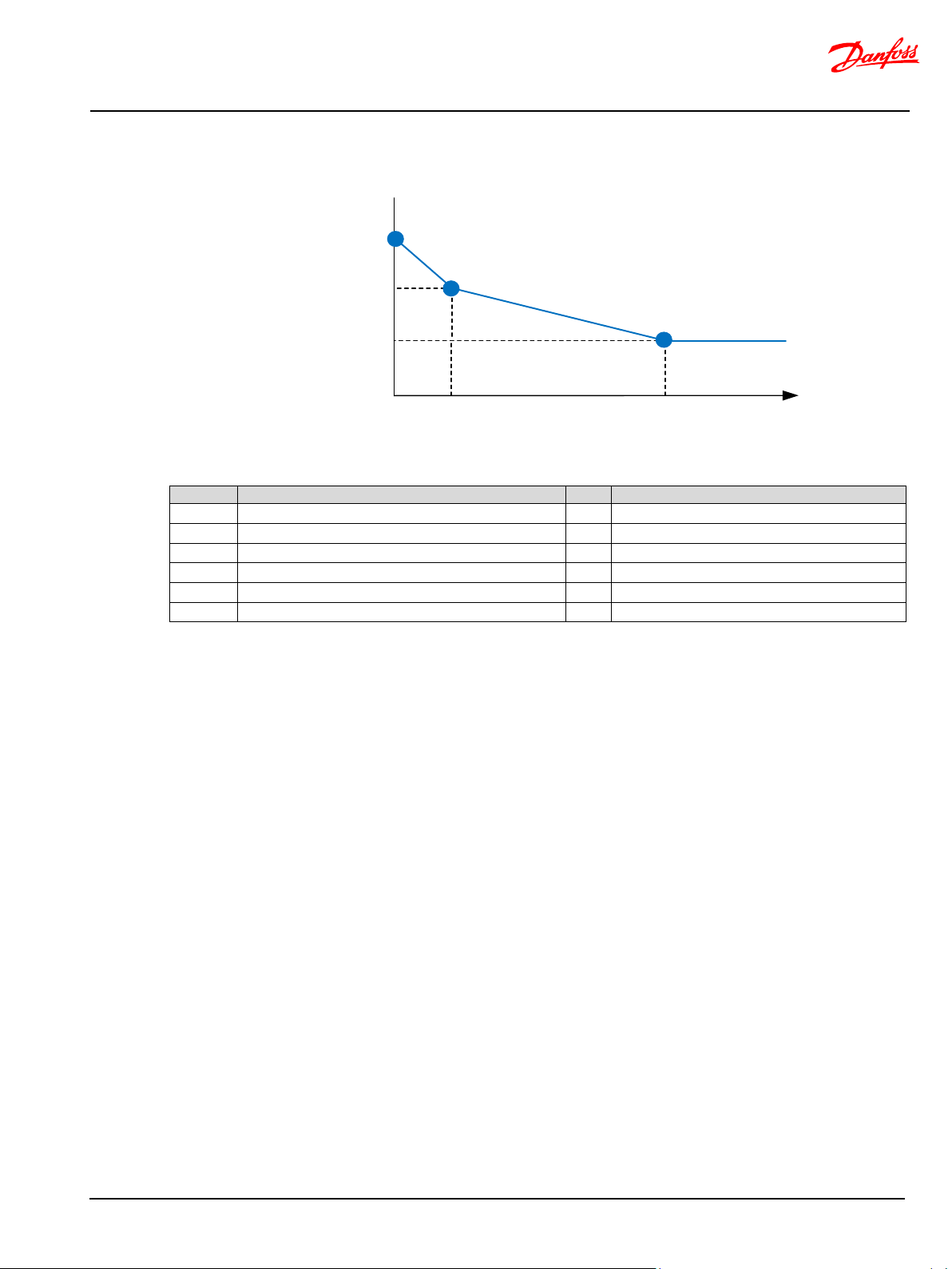

The safe VAP range is configurable as a three-piece linear characteristic as shown in Figure 8. The

software performs linear interpolation to calculate the limited VAP set-point which is used by the NAxis control algorithm.

Page 25

MultiAxis-Steer technical information

Functional safety

Mast er a xis

Slave axis

P3896 [ mm]

P3898 [ mm]

(+P3864 [mm], 0 [kmph])

(-P3864 [m m], 0 [kmph])

(+P3866 [mm], P3870 [kmph])

(-P3866 [m m], P3870 [kmph])

(-P3868 [m m], P3871 [kmph])

(+P3868 [mm], P3871 [kmph])

N-Axis Virtual Axis Po sition Clamp

Vehicle Speed

P3864

P3870

P3866

P3868

P3871

0

1

2

Address

Name

Unit

Description of parameter

Clamp the Virtual Axis Position at vehicle

value (P3864)

Clamp the Virtual Axis Position at vehicle

value (P3866)

Clamp the Virtual Axis Position at vehicle

value (P3868)

Parameters

The received VAP is limited to the range defined by the envelope shown in Figure 8.

P3864

Figure 7 Safe vehicle speed dependent Virtual Axis Position (VAP) limit operation

Figure 8 Safe vehicle speed dependent VAP range envelope

N-Axis - Virtual axis position clamp at

vehicle speed 0

speed 0 to the range defined by N-Axis

mm

center postion (P3898) +/- this

BC321571012557en-000104 © Danfoss | Nov 2019 | 25

P3866

P3868

N-Axis - Virtual axis position clamp at

vehicle speed 1

N-Axis - Virtual axis position clamp at

vehicle speed 2

speed 1 to the range defined by N-Axis

mm

center postion (P3898) +/- this

speed 2 to the range defined by N-Axis

mm

center postion (P3898) +/- this

Page 26

MultiAxis-Steer technical information

Functional safety

N-Axis - Vehicle speed 1 for virtual

axis position clamp

Vehicle speed 1 for Virtual Axis Position

clamp

N-Axis - Vehicle speed 2 for virtual

axis position clamp

Vehicle speed 2 for Virtual Axis Position

clamp

Slave position with respect to the

master

Virtual axis mean position with

respect to the master

Virtual axis mean position with resoect to

the master

P3870

P3871

P3896

P3898

Note: The PVED-CLS performs a plausibility check at start-up on all parameters according to the

following rule: P3864 ≥ P3866 ≥ P3868 AND P3870 < P3871

Parameter tuning guideline

Scenario 1: Advanced N-Axis steering - dynamic changing VAP during operation

The ‘VAP clamp at vehicle speed 0 kmph’ -range (P3864) is typically set to the maximum possible VAP