Page 1

MAKING MODERN LIVING POSSIBLE

Service Manual

Closed Circuit Axial Piston Pumps

LPV

powersolutions.danfoss.com

Page 2

Service Manual LPV Closed Circuit Axial Piston Pumps

Revision history Table of revisions

Date Changed Rev

July 2015 Danfoss layout 0100

November 2006 First printing A

2 11004904 • Rev 0100 • July 2015

Page 3

Service Manual

LPV Closed Circuit Axial Piston Pumps

Contents

Introduction

Overview..............................................................................................................................................................................................4

Warranty.............................................................................................................................................................................................. 4

General instructions........................................................................................................................................................................ 4

Safety Precautions............................................................................................................................................................................5

Symbols used in Danfoss literature............................................................................................................................................6

Design...................................................................................................................................................................................................6

Direct displacement drive system..............................................................................................................................................8

LPV Pump schematic diagram.....................................................................................................................................................8

Operation

HPRV (High pressure relief valve)............................................................................................................................................... 9

Bypass function.................................................................................................................................................................................9

CPRV (Charge pressure relief valve)........................................................................................................................................ 10

Loop flushing valve.......................................................................................................................................................................10

Neutral return mechanism..........................................................................................................................................................11

Technical specifications

Specifications...................................................................................................................................................................................12

Fluid and filter recommendations

Fluid and filter recommendations........................................................................................................................................... 15

Startup procedures

General ..............................................................................................................................................................................................16

Start-up procedure........................................................................................................................................................................16

Pressure measurements

Required tools.................................................................................................................................................................................17

Port locations and gauge installation.....................................................................................................................................17

Troubleshooting

Overview........................................................................................................................................................................................... 18

System operating hot...................................................................................................................................................................18

Transmission operates normally in one direction only....................................................................................................18

System will not operate in either direction.......................................................................................................................... 18

System noise or vibration........................................................................................................................................................... 19

Sluggish system response...........................................................................................................................................................19

Adjustments

Pump adjustment.......................................................................................................................................................................... 20

Standard procedures, inspections, and adjustments....................................................................................................... 20

Charge pressure relief valve adjustments.............................................................................................................................20

System check and HPRV.............................................................................................................................................................. 22

Checking for proper HPRV valve operation.................................................................................................................... 22

Loop flushing valve.......................................................................................................................................................................22

Neutral return mechanism..........................................................................................................................................................23

Leveling swashplate with pump installed on machine....................................................................................................24

Minor repair

Input shaft and seal.......................................................................................................................................................................25

Trunion seal......................................................................................................................................................................................29

High Pressure Relief Valves.........................................................................................................................................................30

Charge pressure relief valve.......................................................................................................................................................31

Loop flushing valve.......................................................................................................................................................................32

Bypass valve.....................................................................................................................................................................................33

Coupling............................................................................................................................................................................................34

Torque chart

Fasteners and plugs...................................................................................................................................................................... 35

Fastener size and torque chart..................................................................................................................................................35

Plug size and torque chart..........................................................................................................................................................35

11004904 • Rev 0100 • July 2015 3

Page 4

Service Manual

Introduction

Overview

Warranty

LPV Closed Circuit Axial Piston Pumps

This manual includes information for the installation, maintenance, and minor repair of the LPV pump. It

includes a description of the unit and its individual components, troubleshooting information, and minor

repair procedures.

Performing minor repairs requires the unit to be removed from the vehicle/machine. Thoroughly clean

the unit before beginning maintenance, or repair activities. Since dirt and contamination are the greatest

enemies of any type of hydraulic equipment, follow cleanliness requirements strictly. This is especially

important when changing the system filter and when removing hoses or plumbing.

A worldwide network of Danfoss Global Service Partners is available for major repairs. Danfoss Global

Service Partners are trained by the factory and certified on a regular basis. You can locate your nearest

Global Service Partner using the distributor locator at www.sauer-danfoss.com. Click on the Sales and

Service link.

Performing installation, maintenance, and minor repairs according to the procedures in this manual will

not affect your warranty. Major repairs requiring the removal of a unit’s rear cover or front flange voids

the warranty unless done by a Danfoss Global Service Partner.

General instructions

Follow these general procedures when repairing Series LPV variable displacement closed circuit pumps.

Remove the unit

Prior to performing major repairs, remove the unit from the vehicle/machine. Chock the wheels on the

vehicle or lock the mechanism to inhibit movement. Be aware that hydraulic fluid may be under high

pressure and / or hot. Inspect the outside of the pump and fittings for damage. Cap hoses after removal

to prevent contamination.

Keep it clean

Cleanliness is a primary means of assuring satisfactory pump life, on either new or repaired units. Clean

the outside of the pump thoroughly before disassembly. Take care to avoid contamination of the system

ports. Cleaning parts by using a clean solvent wash and air drying is usually adequate.

As with any precision equipment, all parts must be kept free of foreign materials and chemicals. Protect

all exposed sealing surfaces and open cavities from damage and foreign material. If left unattended,

cover the pump with a protective layer of plastic.

Lubricate moving parts

During assembly, coat all moving parts with a film of clean hydraulic oil. This assures that these parts will

be lubricated during start-up.

Replace all O-rings and gaskets

4 11004904 • Rev 0100 • July 2015

Page 5

W

W

W

W

W

Service Manual

Introduction

Safety Precautions

LPV Closed Circuit Axial Piston Pumps

It is recommended that all O-rings be replaced. Lightly lubricate all O-rings with clean petroleum jelly

prior to assembly.

Secure the unit

For major repair, place the unit in a stable position with the shaft pointing downward. It will be necessary

to secure the pump while removing and torquing the endcap bolts.

Always consider safety precautions before beginning a service procedure. Protect yourself and others

from injury. Take the following general precautions whenever servicing a hydraulic system.

Unintended Machine Movement

Warning

Unintended movement of the machine or mechanism may cause injury to the technician or bystanders.

To protect against unintended movement, secure the machine or disable/disconnect the mechanism

while servicing.

Flammable Cleaning Solvents

Warning

Some cleaning solvents are flammable. To avoid possible fire, do not use cleaning solvents in an area

where a source of ignition may be present.

Fluid Under Pressure

Warning

Escaping hydraulic fluid under pressure can have sufficient force to penetrate your skin causing serious

injury and/or infection. This fluid may also be hot enough to cause burns. Use caution when dealing with

hydraulic fluid under pressure. Relieve pressure in the system before removing hoses, fittings, gauges, or

components. Never use your hand or any other body part to check for leaks in a pressurized line. Seek

medical attention immediately if you are cut by hydraulic fluid.

Personal Safety

Warning

Protect yourself from injury. Use proper safety equipment, including safety glasses, at all times.

Hazardous Material

Warning

Hydraulic fluid contains hazardous material. Avoid prolonged contact with hydraulic fluid. Always

dispose of used hydraulic fluid according to state, and federal environmental regulations.

11004904 • Rev 0100 • July 2015 5

Page 6

Service Manual

LPV Closed Circuit Axial Piston Pumps

Introduction

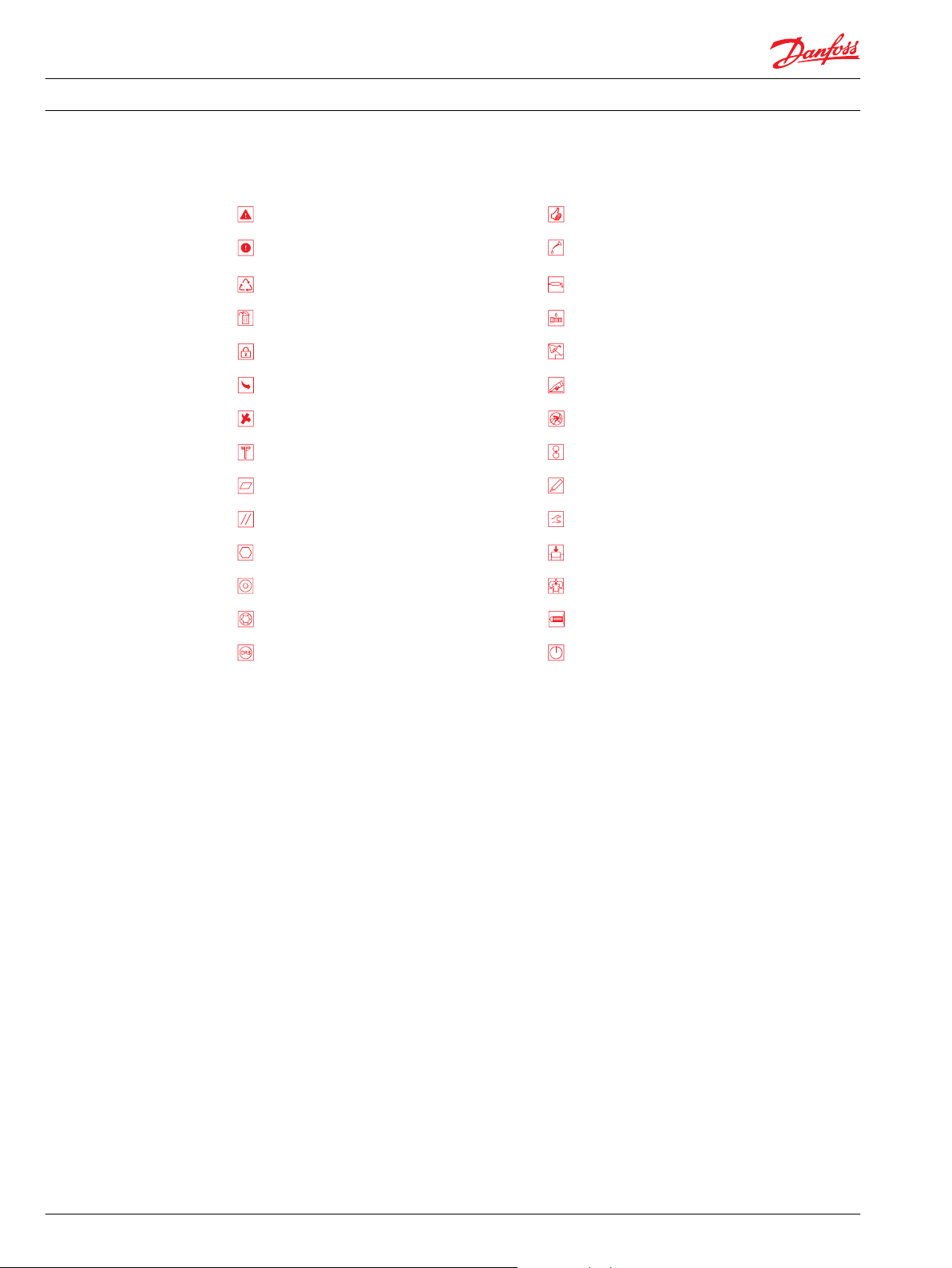

Symbols used in Danfoss literature

WARNING may result in injury Tip, helpful suggestion

CAUTION may result in damage to product or

property

Reusable part Apply grease / petroleum jelly

Non-reusable part, use a new part Apply locking compound

Non-removable item Inspect for wear or damage

Option - either part may exist Clean area or part

Superseded - parts are not interchangeable Be careful not to scratch or damage

Measurement required Note correct orientation

Flatness specification Mark orientation for reinstallation

Parallelism specification Torque specification

External hex head Press in - press fit

Internal hex head Pull out with tool – press fit

Torx head Cover splines with installation sleeve

O-ring boss port Pressure measurement/gauge location or

Lubricate with hydraulic fluid

specification

The symbols above appear in the illustrations and text of this manual. They are intended to communicate

helpful information at the point where it is most useful to the reader. In most instances, the appearance

of the symbol itself denotes its meaning. The legend above defines each symbol and explains its purpose.

Design

LPV represents a family of hydrostatic pumps for low to medium power applications with maximum

pressures up to 345 bar [5000 psi]. These pumps can be applied with other products in a system to

transfer and control hydraulic power.

LPV pumps provide an infinitely variable speed range between zero and maximum in both forward and

reverse modes of operation. LPV pumps come in three displacements (25 cm3 [1.53 in3], 30 cm3 [1.83

in3], and 35 cm3 [2.32 in3]).

LPV pumps are compact, high power density units. All models use the parallel axial piston / slipper

concept in conjunction with a tiltable swashplate to vary the pump’s displacement. Reversing the angle

of the swashplate reverses the flow of fluid from the pump, reversing the direction of rotation of the

motor output.

LPV pumps are provided with an internal neutral return mechanism for ease of installation, and are

available with optional loop flushing for circuit flexibility. LPV pumps are designed to receive charge flow

from an auxiliary circuit or from a gear pump mounted on the auxiliary mounting pad. LPV pumps feature

an SAE A auxiliary mounting pad to accept auxiliary hydraulic pumps for use in complementary hydraulic

systems.

LPV pumps include a trunnion style direct displacement control.

6 11004904 • Rev 0100 • July 2015

Page 7

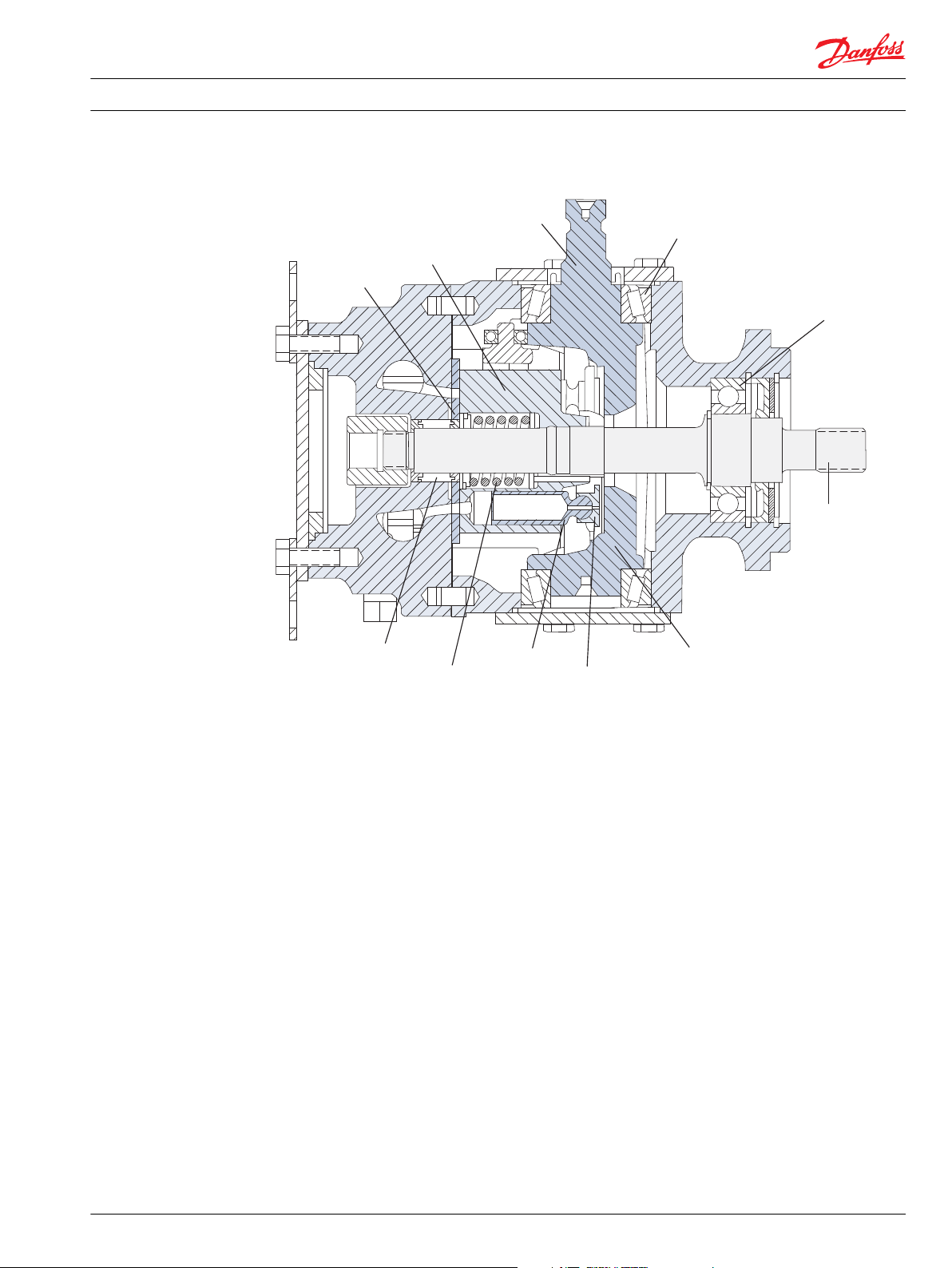

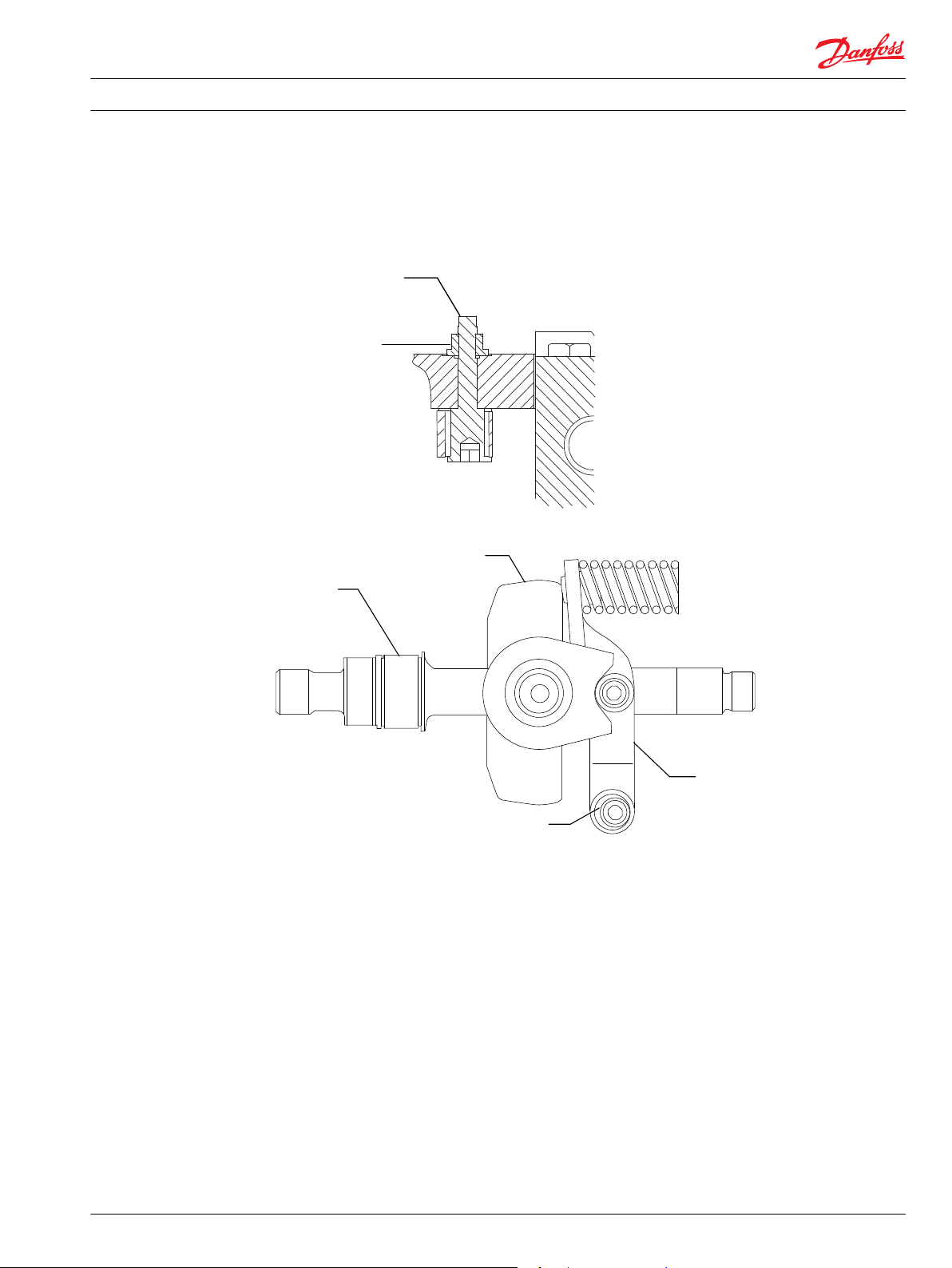

P106 271E

Input shaft

Ball bearing

Needle bearing

Tapered roller bearing

Cylinder block

Valve plate

Cylinder block spring

Piston

Slipper

Swashplate

Trunion

Service Manual LPV Closed Circuit Axial Piston Pumps

Introduction

LPV cross section

11004904 • Rev 0100 • July 2015 7

Page 8

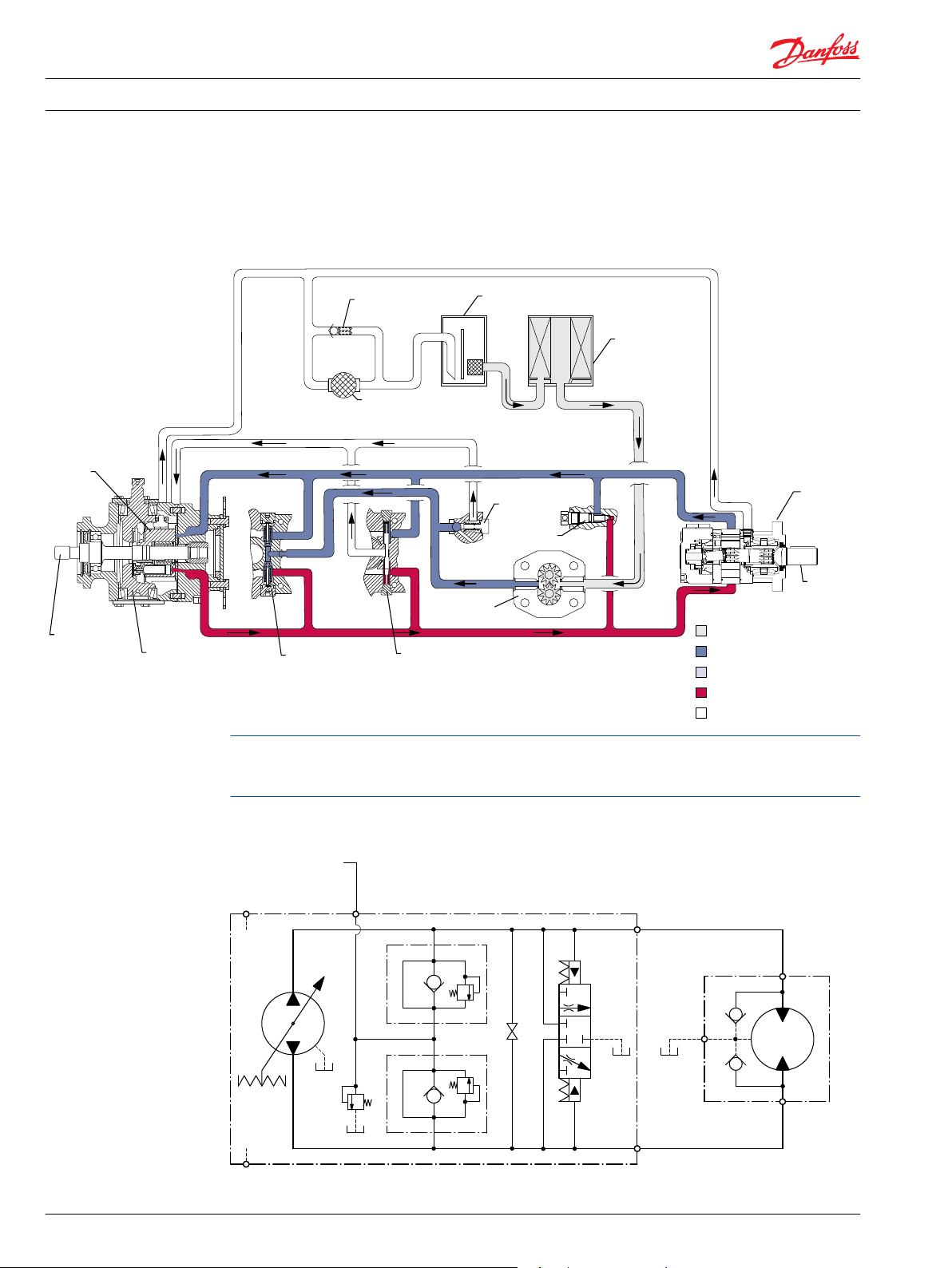

Variable

displacement

pump

Input

shaft

Cylinder

block

assembly

HPRV valves

Loop flushing valves

OMS

orbital

motor

Suction flow

Servo pressure

High pressure

Case flow

Charge pressure

Output

shaft

Filter

Charge

pump

Reservoir

Heat

exchanger

Heat exchanger

bypass

Charge relief

valve

Bypass

valve

P100 586E

L1

L2

Charge pressure

inlet

Port A

Port B

P106 287E

Service Manual

LPV Closed Circuit Axial Piston Pumps

Introduction

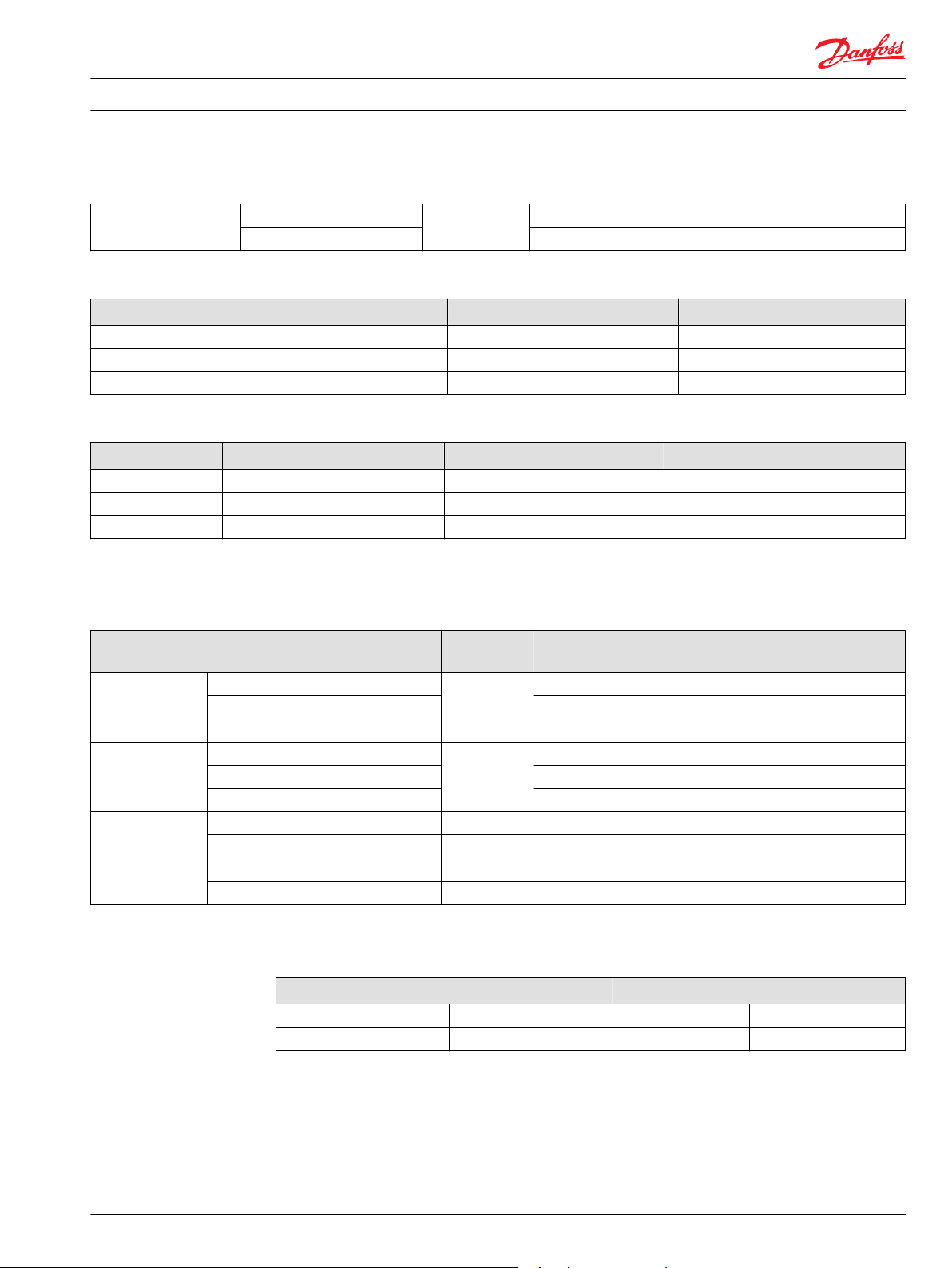

Direct displacement drive system

The direct displacement control varies the swashplate angle. Swashplate angle determines pump flow

and motor speed.

Pictorial circuit diagram

The diagram shows an LPV pump driving an OMR motor. The system shown uses an external charge

pump and external filter. Charge pressure relief valves, high pressure relief valves, and loop flushing

valves are shown separated from the pump to provide clarity to the hydraulic system.

LPV Pump schematic diagram

8 11004904 • Rev 0100 • July 2015

Page 9

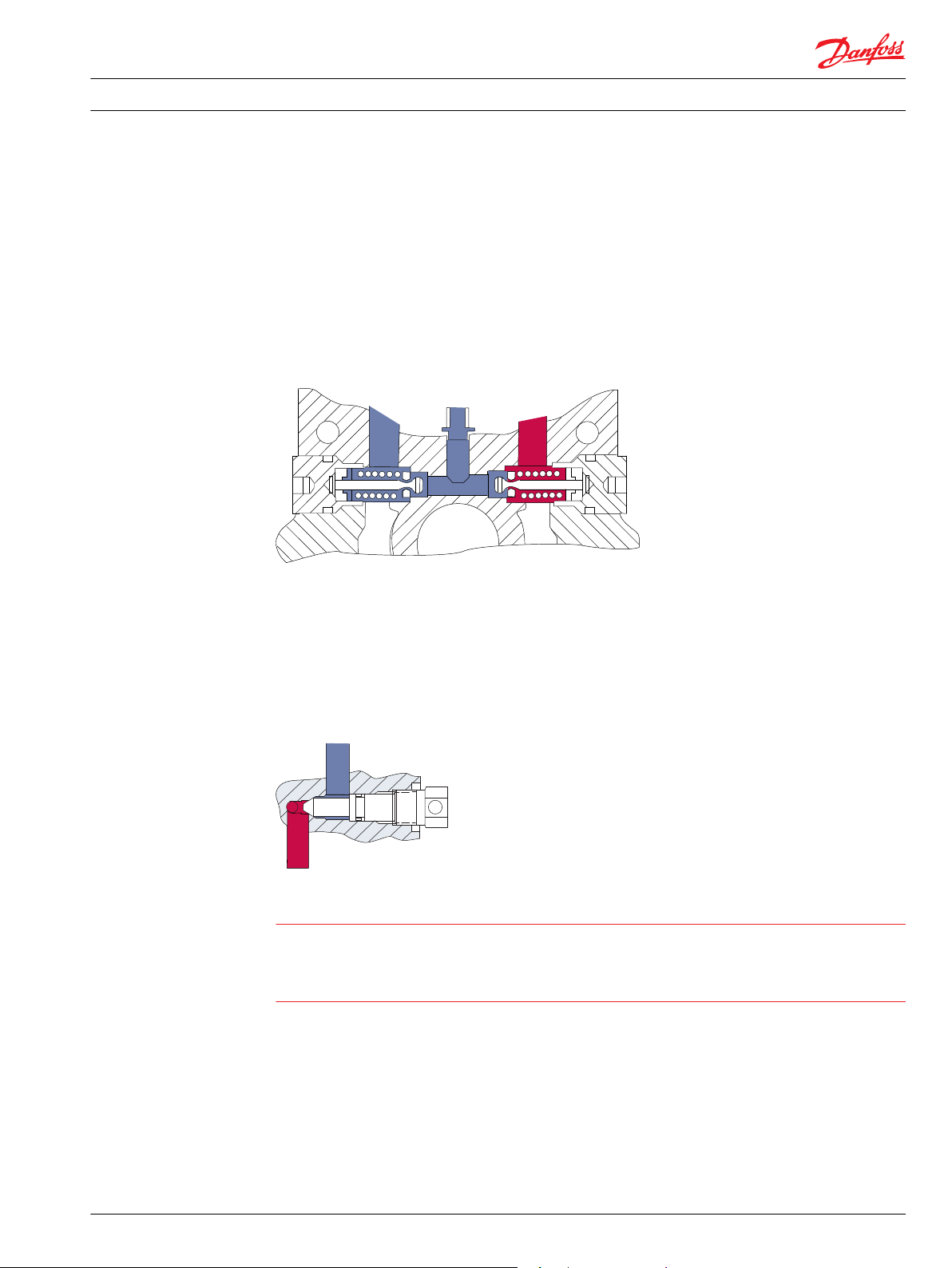

P106 273E

P106 286E

C

Service Manual

LPV Closed Circuit Axial Piston Pumps

Operation

HPRV (High pressure relief valve)

LPV pumps are equipped with a combination high pressure relief and charge check valve. The highpressure relief function is a dissipative (with heat generation) pressure control valve for the purpose of

limiting excessive system pressures. The charge check function acts to replenish the low-pressure side of

the working loop with charge oil. Each side of the transmission loop has a dedicated HPRV valve that is

non-adjustable with a factory set pressure. When system pressure exceeds the factory setting of the

valve, oil is passed from the high pressure system loop, into the charge gallery, and into the low pressure

system loop via the charge check.

HPRV valve

Bypass function

The LPV contains a dedicated bypass valve. The bypass function is activated when the bypass valve is

mechanically backed out 3 full turns (maximum). The bypass function allows a machine or load to be

moved without rotating the pump shaft or prime mover.

Bypass valve

Caution

Excessive speeds and extended load/vehicle movement must be avoided. The load or vehicle should be

moved not more than 20% of maximum speed and for a duration not exceeding 3 minutes. Damage to

drive motor(s) is possible. When the bypass function is no longer needed care should be taken to reseat

the bypass valves to the normal operating position.

11004904 • Rev 0100 • July 2015 9

Page 10

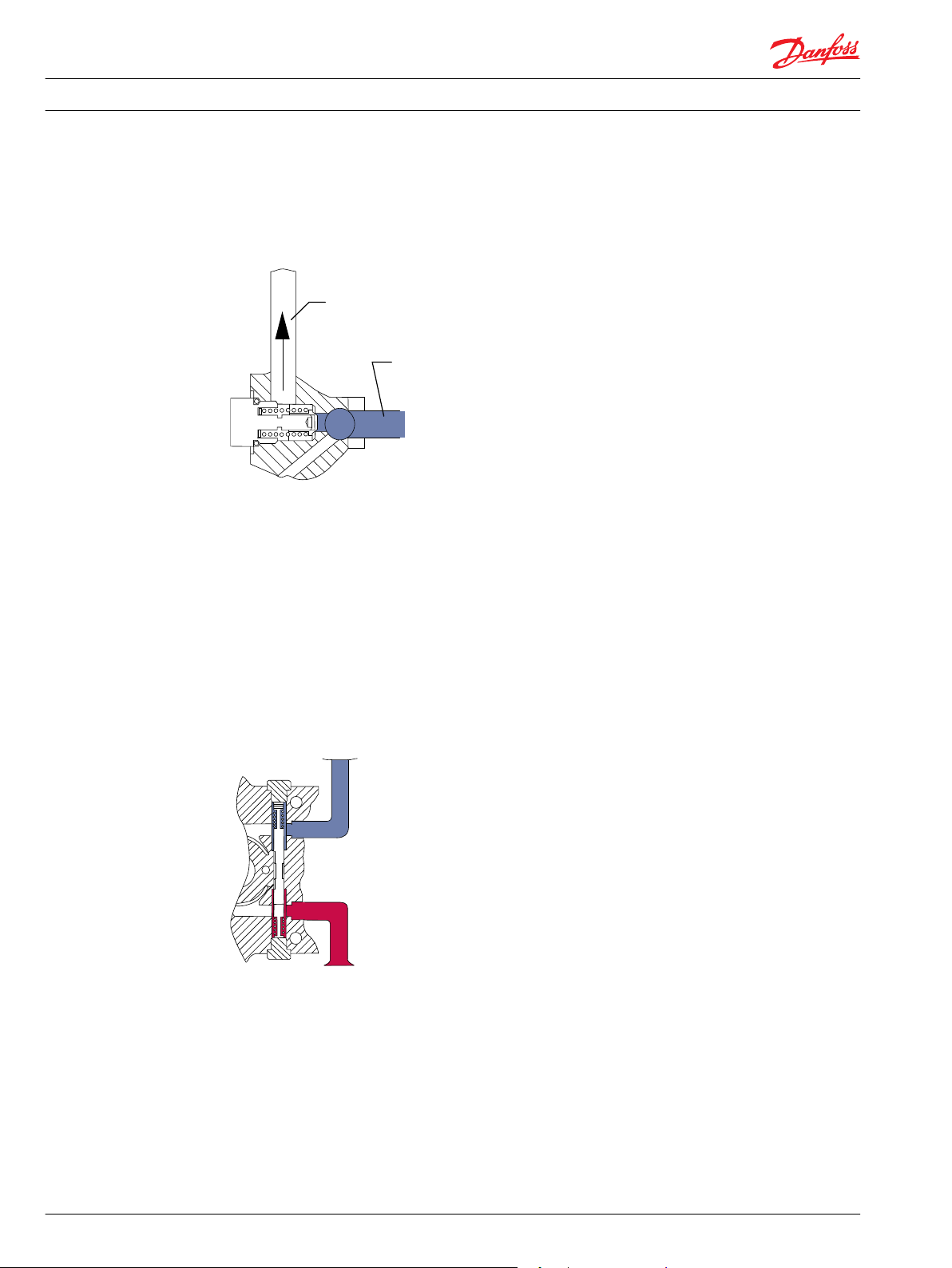

P106 274E

Charge

pressure

Case

pressure

P106 276E

Service Manual

LPV Closed Circuit Axial Piston Pumps

Operation

CPRV (Charge pressure relief valve)

An internal charge relief valve regulates charge pressure. Charge pressure is supplied to maintain a

minimum pressure in the low side of the transmission loop.

CPRV valve

Minimum charge pressure is the lowest pressure allowed to maintain a safe working condition in the low

side of the loop.

Maximum charge pressure is the highest charge pressure allowed by the charge relief adjustment, and

which provides normal component life. The charge pressure setting listed in the order code is the set

pressure of the charge relief valve with the pump in neutral, operating with 5 gpm of charge flow. The

charge pressure setting is referenced to case pressure. Charge pressure is the differential pressure above

case pressure.

Loop flushing valve

LPV pumps incorporate an optional integral loop flushing valve, which removes heat and contaminants

from the main loop at an increased rate.

Loop flushing valve

10 11004904 • Rev 0100 • July 2015

Page 11

P106 277E

Adjusting cam

Lock/seal nut

Shaft

Swashplate

Neutral

return

arm

Adjusting cam

P106 278E

Service Manual LPV Closed Circuit Axial Piston Pumps

Operation

Neutral return mechanism

The neutral return mechanism is designed to mechanically return the pump to zero displacement. A cam

allows precise zero displacement adjustment.

Neutral return adjusting cam

Neutral return mechanism

11004904 • Rev 0100 • July 2015 11

Page 12

Service Manual LPV Closed Circuit Axial Piston Pumps

Technical specifications

Specifications

General specifications

Design Axial piston pump of trunion swashplate design with variable displacement

Direction of rotation Clockwise, counterclockwise

pipe connections Main pressure ports: SAE straight thread O-ring boss

Recommended installation position Pump installation recommended with control position on the top or side.

Consult Danfoss for non conformance to these guidelines.

The housing must always be filled with hydraulic fluid.

Physical properties

Displacement

Feature Unit 25 30 35

Maximum Displacement cm³ [in³] 25 [1.53] 30 [1.83] 35 [2.14]

Flow at rated speed (theoretical) l/min

[US gal/min]

Input torque at maximum displacement (theoretical) N•m/ bar

[lbf•in/1000 psi]

Mass moment of inertia of internal rotating components kg•m²

[slug•ft²]

Weight kg [lb] 23 [51]

Rotation Clockwise, Counterclockwise

Mounting SAE B 2 bolt

Auxiliary mounting SAE J744 A 9T, SPCL 11T

System ports (type) 1 1/16-12 UNF-2B ORB

System ports (location) Twin radial

Control types Direct displacement control

Shafts Splined Splined SAE13 tooth, 15 tooth

Case drain ports 1 1/16-12 SAE ORB

85.2

[22.5]

0.4

[244]

0.001670

[0.0012]

104.9

[27.7]

0.5

[291]

0.001580

[0.00120]

137.0

[36.2]

0.6

[340]

0.001530

[0.00113]

Operating parameters

Displacement

Rating Units 25 30 35

Input speed minimum min-1 (rpm) 500 500 500

continuous 3400 3500 3600

maximum 3950 4150 4300

Working pressure continuous bar [psi] 210 [3045] 175 [2540] 140 [2030]

maximum 345 [5000]

External shaft loads External moment (Me) N•m [lbf•in] 7.7 [68]

Thrust in (Tin), out (Tout) N [lbf] 750 [169]

Bearing life (max.

swashplate angle and

max. continuous speed)

Charge pressure minimum bar [psi] 6 [87]

12 11004904 • Rev 0100 • July 2015

at 210 bar [3045 psi] B10 hours 120,000 63,000 37,000

maximum 20 [300]

Page 13

Service Manual LPV Closed Circuit Axial Piston Pumps

Technical specifications

Operating parameters (continued)

Case pressure rated bar [psi] 2 [29]

maximum 6 [87]

Sound levels

dB(A) 100 bar [1450 psi] 200 bar [2900 psi] 300 bar [3451 psi]

Displ. cm³ [in³] 1000 min-1(rpm) 1000 min-1(rpm) 1000 min-1(rpm)

25 [1.53] 62 66 68

35 [2.14] 61 66 69

1

Sound levels

dB(A) 100 bar [1450 psi] 200 bar [2900 psi] 300 bar [3451 psi]

Displ. cm³ [in³] 3000 min-1(rpm) 3000 min-1(rpm) 3000 min-1(rpm)

25 [1.53] 70 74 76

35 [2.14] 71 75 80

1

Sound data was collected in a semi-anechoic chamber. Values have been adjusted (-3 dB) to reflect

anechoic levels.

Fluid specifications

Feature Unit Displacement cm³ [in³]

25 [1.53], 30 [1.83], 35 [2.14]

Viscosity Minimum mm 2/s [SUS] 7 [47]

Recommended range 12-60 [66-278]

Maximum 1600 [7500]

Temperature Range2Minimum C° [F°] -40 [-40]

Rated 82 [180]

Maximum intermittent 100 [212]

Filtration Cleanliness per ISO 4406 22/18/13

Efficiency (charge pressure filtration) β-ratio β

Efficiency (suction filtration) β

Recommended inlet screen mesh size μ m 100 - 125

= 75 (β10≥ 10)

15-20

= 75 (β10≥ 2)

35-45

2

At the hottest point, normally case drain port.

Mounting flange allowable overhung parameters

Continuous load moment (Mc) Shock load moment (Ms)

N•m [lbf•in] N•m [lbf•in]

361 [3200] 617 [5470]

11004904 • Rev 0100 • July 2015 13

Page 14

Service Manual LPV Closed Circuit Axial Piston Pumps

Technical specifications

Mounting flange G-factors for sample applications

Application Continuous (vibratory)

acceleration (Gc)

Skid steer loader 6 10

Trencher

(rubber tires)

Asphalt paver 6 6

Windrower 6 5

Aerial lift 6 4

Turf care vehicle 6 4

Vibratory roller 6 10

Applications experiencing extreme resonant vibrations may require additional pump support. Refer to

LPV Technical Information 520L0954 for information concerning mounting flange loads.

6 8

Maximum (shock) acceleration

(Gs)

14 11004904 • Rev 0100 • July 2015

Page 15

C

W

W

Service Manual

LPV Closed Circuit Axial Piston Pumps

Fluid and filter recommendations

Fluid and filter recommendations

To ensure optimum life, perform regular maintenance of the fluid and filter. Contaminated fluid is the

main cause of unit failure. Take care to maintain fluid cleanliness when servicing.

Check the reservoir daily for proper fluid level, the presence of water, and rancid fluid odor. Fluid

contaminated by water may appear cloudy or milky or free water may settle in the bottom of the

reservoir. Rancid odor indicates the fluid has been exposed to excessive heat. Change the fluid

immediately if these conditions occur. Correct the problem immediately.

Inspect vehicle for leaks daily.

Fluid and filter change interval

Reservoir type Max oil change interval

Sealed 2000 hours

Breather 500 hours

Change the fluid and filter per the vehicle/machine manufacturer’s recommendations or at these

intervals:

First fluid change recommended at 500 hours.

Caution

High temperatures and pressures will result in accelerated fluid aging. More frequent fluid changes may

be required.

Change the fluid more frequently if it becomes contaminated with foreign matter (dirt, water, grease,

etc.) or if the fluid is subjected to temperature levels greater than the recommended maximum.

Dispose of used hydraulic fluid properly. Never reuse hydraulic fluid.

Change filters whenever the fluid is changed or when the filter indicator shows that it is necessary to

change the filter. Replace all fluid lost during filter change.

Warning

Hazardous material

Hydraulic fluid contains hazardous material. Avoid contact with hydraulic fluid. Always dispose of used

hydraulic fluid according to state, and federal environmental regulations.

Hazardous material

Warning

W Warning

Hydraulic fluid contains hazardous material. Avoid contact with hydraulic fluid. Always dispose of used

hydraulic fluid according to state, and federal environmental regulations.

11004904 • Rev 0100 • July 2015 15

Page 16

W

W

C

C

Service Manual

Startup procedures

General

Start-up procedure

LPV Closed Circuit Axial Piston Pumps

Follow this procedure when starting-up a new pump installation or when restarting an installation in

which the pump has been removed and re-installed on a machine. Ensure pump has been thoroughly

tested on a test stand before installing on a machine.

Warning

Unintended movement of the machine or mechanism may cause injury to the technician or bystanders.

To protect against unintended movement, secure the machine or disable/disconnect the mechanism

while servicing.

Prior to installing the pump, inspect for damage that may have occurred during shipping.

1. Ensure that the machine hydraulic oil and system components (reservoir, hoses, valves, fittings, and

heat exchanger) are clean and free of any foreign material.

2. Install new system filter element(s) if necessary. Check that inlet line fittings are properly tightened

and there are no air leaks.

3. Install the pump. Install a 50 bar [1000 psi] gauge in the charge pressure gauge port M3.

4. Fill the housing by adding filtered oil in the upper case drain port.

5. Fill the reservoir with hydraulic fluid of the recommended type and viscosity. Use a 10-micron

reservoir filler filter. Ensure inlet line from reservoir to pump is filled.

6. Disconnect the pump from control.

After start-up the oil level in the reservoir may drop due to filling of the system components. Check

the level in the reservoir to maintain a full oil level throughout the start-up.

Warning

Damage to hydraulic components may occur if the oil supply is not maintained.

7. Use a common method to disable the engine to prevent the engine from starting. Crank the starter

for several seconds. Do not to exceed the engine manufacturer’s recommendation. Wait 30 seconds

and then crank the engine a second time as stated above. This operation helps remove air from the

system lines. Refill the reservoir to recommended full oil level.

8. When charge pressure begins to appear, enable and start engine. Let the engine run for a minimum

of 30 seconds at low idle to allow the air to work itself out of the system. Check for leaks at all line

connections and listen for cavitation. Check for proper fluid level in reservoir.

Caution

Air entrapment in oil under high pressure may damage hydraulic components.

Caution

Do not run at maximum pressure until system is free of air and fluid has been thoroughly filtered.

9. When adequate charge pressure is established, increase engine speed to normal operating rpm to

further purge residual air from the system.

10. Shut off engine. Connect pump control. Start engine, checking to be certain pump remains in neutral.

Run engine at normal operating speed and carefully check for forward and reverse control operation.

11. Continue to cycle between forward and reverse for at least five minutes to bleed all air and flush

system contaminants out of loop.

Normal charge pressure fluctuation may occur during forward and reverse operation.

12. Check that the reservoir is full. Remove charge pressure gauge. The pump is now ready for operation.

16 11004904 • Rev 0100 • July 2015

Page 17

P106 323E

1 1/16 -12

SAE straight thread

O-ring boss

case drain

7/8 -14

SAE straight thread

O-ring boss

charge inlet

7/8 -14

SAE straight thread

O-ring boss

charge pressure

relief valve

1 1/16 -12

SAE straight thread

O-ring boss

system port A

1 1/16 -12

SAE straight thread

O-ring boss

system port B

1 1/16 -12

SAE straight thread

O-ring boss

case drain (alternate)

Service Manual LPV Closed Circuit Axial Piston Pumps

Pressure measurements

Required tools

The service procedures described in this manual can be performed using common mechanic’s hand

tools. Special tools, if required, are shown. When testing system pressures, calibrate pressure gauges

frequently to ensure accuracy. Use snubbers to protect gauges.

Port locations and gauge installation

The following table and drawing show the port locations and gauge sizes needed.

Port information

Port

identifier

Case drain 1 1/16-12 UNF 2B 15 mm internal hex Case drain 10 [100]

Port A, Port B 1 1/16-12 UNF 2B N/A System pressure 600 [10,000]

Charge inlet 7/8-14 UNF 2B N/A Charge pressure 50 [1000]

Port locations

Port size Wrench size Pressure obtained Gauge size, bar

[psi]

11004904 • Rev 0100 • July 2015 17

Page 18

W

Service Manual LPV Closed Circuit Axial Piston Pumps

Troubleshooting

Overview

This section provides general steps to follow if undesirable system conditions are observed. Follow the

steps listed until the problem is solved. Some of the items will be system specific. For areas covered in

this manual, a section is referenced. Always observe the safety precautions listed in Safety precautions,

and related to your specific equipment.

Warning

Unintended movement of the machine or mechanism may cause injury to the technician or bystanders.

To protect against unintended movement, secure the machine or disable/disconnect the mechanism

while servicing.

System operating hot

Item Description Action

Oil level in reservoir. Insufficient hydraulic fluid will not meet

cooling demands of system.

Heat exchanger. Heat exchanger not sufficiently cooling

the system.

Charge pressure. Low charge pressure will overwork system. Measure charge pressure. Inspect and

Charge pump inlet vacuum. High inlet vacuum will overwork system. A dirty filter will

increase the inlet vacuum. Inadequate line size will restrict

flow.

System relief pressure

settings.

System pressure. Frequent or long term operation over system relief setting

If the system relief valves are worn, contaminated or, valve

settings are too low, the relief valves will be overworked.

will create heat in system

Fill reservoir to proper level.

Check air flow and input air temperature

for heat exchanger. Clean, repair or

replace heat exchanger.

adjust or replace charge relief valve. Inspect charge pump.

Repair or replace charge pump.

Check charge inlet vacuum. If high,

inspect inlet filter and replace as necessary.

Check for adequate line size, length

or other restrictions

Verify settings of high pressure relief valves and

replace valves as necessary.

Measure system pressure. If pressure

is too high, reduce loads.

Transmission operates normally in one direction only

Item Description Action

Control linkage Control linkage operating improperly Repair/replace control linkage

Interchange high pressure

relief valves

Ensure bypass valve is

closed.

Interchanging the high pressure relief valves will show if

the problem is related to the valve function.

Open bypass will cause both directions to be inoperative. Close/repair bypass function.

System will not operate in either direction

Item Description Action

Ensure bypass valve is

closed.

Charge pressure with pump

in neutral

18 11004904 • Rev 0100 • July 2015

If bypass valve is open, the system loop will be

depressurized.

Low charge pressure insufficient to recharge system loop Measure charge pressure with the pump in neutral. If

If the problem changes direction, replace the valve that

does not operate correctly.

Close bypass valve.

pressure is low, go to Pump charge relief valve

Page 19

Service Manual LPV Closed Circuit Axial Piston Pumps

Troubleshooting

Item Description Action

Charge pressure with pump

in stroke

Pump charge relief valve. A pump charge relief valve that is leaky, or contaminated,

Charge pump inlet filter. A clogged filter will under supply system loop. Inspect filter and replace if necessary.

Charge pump. A malfunctioning charge pump will provide insufficient

System pressure Low system pressure does not provide enough power to

System relief valves Defective high pressure relief valves cause system pressure

System noise or vibration

Low charge pressure resulting from elevated loop leakage. Isolate pump from motor by blocking system ports. With

pump in partial stroke and engaged for only a few seconds,

check pump charge pressure. Low charge pressure

indicates a malfunctioning pump. Continue to next step.

Good charge pressure indicates a malfunctioning motor or

other system component. Check motor charge relief

operation (if present).

Adjust or replace pump charge relief valve as necessary

or set too low will depressurize the system.

Repair or replace the charge pump.

charge flow.

Measure system pressure. Continue to next step.

move load

Repair or replace high pressure relief valves.

to be low

Item Description Action

Reservoir oil level Low oil level leads to cavitation. Fill reservoir.

Aeration of the oil/pump

inlet vacuum

Cold oil If oil is under cold conditions, it may be too viscous for

Pump inlet vacuum High inlet vacuum causes noise/cavitation. Check that inlet line is not restricted and is proper size.

Shaft couplings A loose shaft coupling will cause excessive noise. Replace loose shaft coupling. Replace pump or motor.

Shaft alignment Misaligned shafts creates noise Align shafts.

Charge/system relief valves Unusual noise may indicate sticking valves. Possible

Air in system decreases efficiency of units and controls. Air

in system is indicated by excessive noise in pump, foaming

in oil, and hot oil.

proper function and pump cavitates

contamination.

Find location where air is entering into the system and fix.

Check that inlet line is not restricted and is proper size.

Allow the oil to warm up to its normal operating

temperature with engine at idle speed.

Check filter and bypass valves (if present).

Clean/replace valves and test pump.

May be a normal condition.

Sluggish system response

Item Description Action

Oil level in reservoir Low oil level will cause sluggish response Fill reservoir

High pressure relief valves Incorrect pressure settings will affect system reaction time Adjust or replace high pressure relief valves

Low prime mover speed Low engine speed will reduce system performance Adjust engine speed

Air in system Air in system will produce sluggish system response Fill tank to proper level. Cycle system slowly for several

Pump inlet vacuum Inlet vacuum is too high resulting in reduced system

pressure.

minutes to remove air from system

Measure charge inlet vacuum. Inspect line for proper sizing.

Replace filter. Confirm proper bypass operation.

11004904 • Rev 0100 • July 2015 19

Page 20

C

Service Manual

LPV Closed Circuit Axial Piston Pumps

Adjustments

Pump adjustment

This section offers instruction on inspection and adjustment of pump components. Read through the

entire topic before beginning a service activity. Refer to Pressure measurements on page 17, for location of

gauge ports and suggested gauge size.

Standard procedures, inspections, and adjustments

Caution

Contamination can damage internal components and void the manufacturer’s warranty. Take

precautions to ensure system cleanliness when removing and reinstalling system lines

1. With the prime mover off, thoroughly clean all dirt and grime from the outside of the pump.

2. If removing the pump, tag each hydraulic line connected to the pump. If hydraulic lines are

disconnected, plug each open port, to ensure that dirt and contamination do not get into the pump.

3. Ensure the surrounding areas are clean and free of contaminants such as dirt and grime.

4. Inspect the system for contamination.

5. Look at the hydraulic fluid for signs of system contamination, oil discoloration, foam in the oil, sludge,

or small metal particles.

6. If there are signs of contamination in the hydraulic fluid, all filters must be replaced and the hydraulic

system must be drained and filled with the correct hydraulic fluid.

7. Flush the lines before replacing the hydraulic fluid.

8. Before re-installing the pump, perform a leakage test per Sauer-Danfoss leakage test HPP 112.

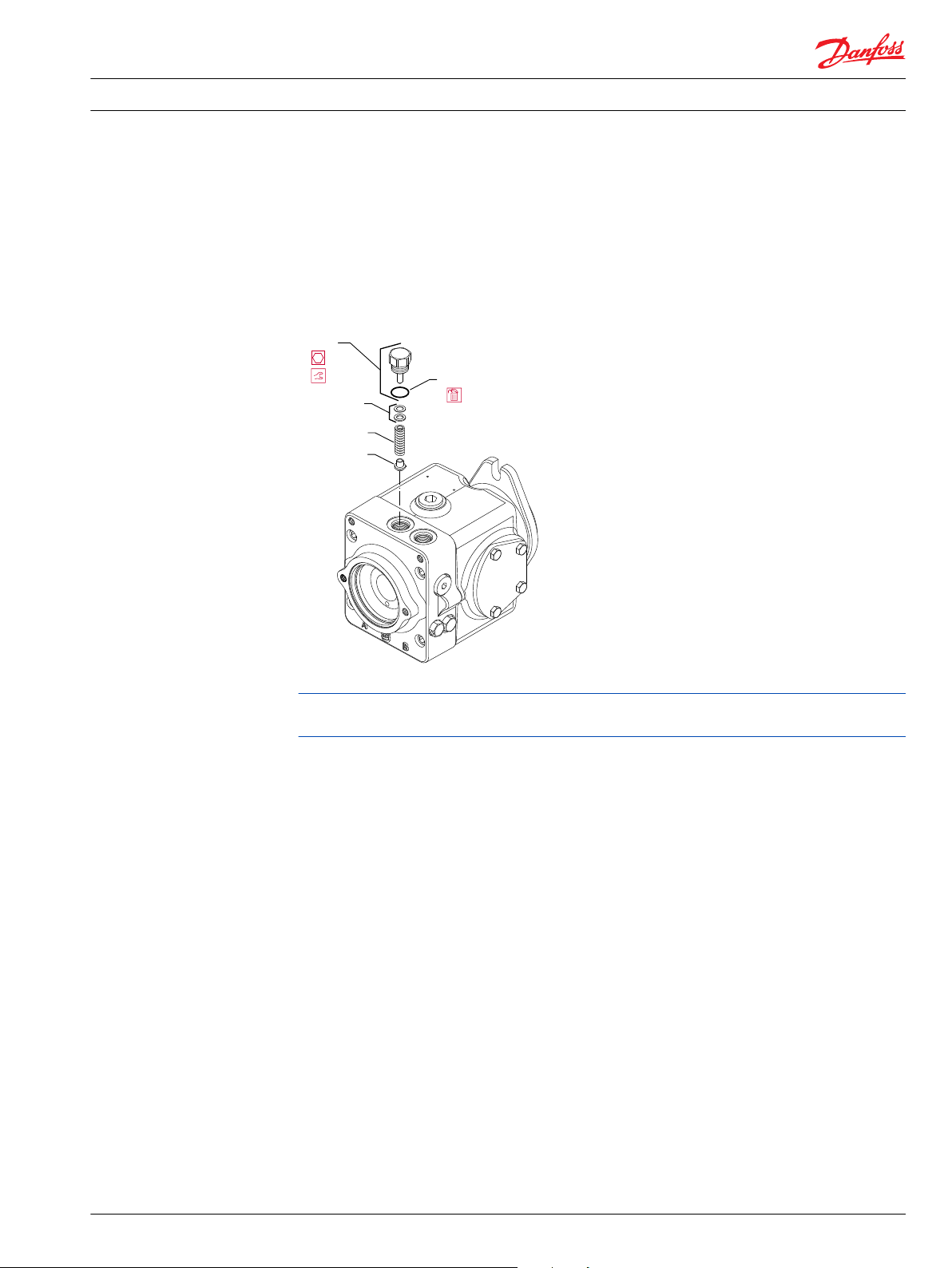

Charge pressure relief valve adjustments

The following procedure explains how to check proper operation of the charge pressure relief valve.

Correct charge pressure is the measured pressure minus case drain pressure.

20 11004904 • Rev 0100 • July 2015

Page 21

E101 440E

H01

H07

H06

H01A

H08

1 in

81 N•m

[60 lbf•ft]

Service Manual

Adjustments

LPV Closed Circuit Axial Piston Pumps

1. Validate that external charge pump is operating properly.

2. Install a 50 bar [1000 psi] pressure gauge (tee) in charge pressure inlet port. Install a 10 bar [100 psi]

gauge at one of the case pressure ports. Operate the system with the pump in neutral (zero

displacement) when measuring charge pressure.

3. Verify correct charge pressure per model code. Pressure measurements assume 5 Gal(US)/Min. charge

flow, a reservoir temperature of 50°C (120°F), and are referenced to case pressure.

Charge pressure relief valve

Pressure listed in model code assumes a charge flow of 19 l/min [5 Gal(US)/Min]. At higher charge

flows, the charge pressure will rise over the rated setting.

4. If measured pressure is not correct, disassemble valve and look for signs of wear or contamination.

Refer to Charge pressure relief valve on page 31, for wrench sizes and torque settings.

5. If valve is worn, replace entire valve.

6. Valve may be adjusted using available shim kit.

7. When the desired charge pressure setting is achieved, remove the gauges.

11004904 • Rev 0100 • July 2015 21

Page 22

P106 333E

HPRV valves

P106 335E

Loop flushing valve

Service Manual

Adjustments

System check and HPRV

LPV Closed Circuit Axial Piston Pumps

Whenever an HPRV valve has been replaced or opened, the pump should be operated in its full range of

functions to ensure proper machine operation. The HPRV valves are pre-set at the factory, no adjustment

is possible.

Checking for proper HPRV valve operation

For suspected HPRV valve malfunction, replace valve with identical relief setting and test operation of

pump.

HPRV valves

Loop flushing valve

The loop flushing valve in not adjustable. If loop flushing malfunction is suspected, disassemble valve

and check for worn, damaged or scored components. Replace parts if necessary. Refer toLoop flushing

valve on page 32 for disassembly procedures.

Loop flushing valve

22 11004904 • Rev 0100 • July 2015

Page 23

P106 336E

Neutral

return

adjustment

P106 277E

Adjusting cam

Lock/seal nut

Shaft

Swashplate

Neutral

return

arm

Adjusting cam

P106 278E

Service Manual

Adjustments

Neutral return mechanism

LPV Closed Circuit Axial Piston Pumps

The neutral return mechanism is designed to mechanically return the pump to zero displacement. A cam

allows precise zero displacement adjustment. If pump does not return to neutral, loosen locknut and turn

adjusting screw until creep is eliminated. Torque locknut to 22 Nm [16 lbf•ft]. If neutral adjustment is not

possible, pump teardown is necessary. See your nearest Danfoss Global Service Provider.

Neutral return adjustment

Neutral return adjusting screw

Neutral return mechanism

11004904 • Rev 0100 • July 2015 23

Page 24

Service Manual LPV Closed Circuit Axial Piston Pumps

Adjustments

Neutral return adjustment

1. For propel applications, raise the wheels off the ground and secure the vehicle so you can operate it

safely. Other applications: take necessary steps to ensure you can operate the machine safely during

this procedure.

2. Remove the control linkage and check for creep. If the wheels/ mechanism move while the control

linkage is disconnected, loosen the locknut and turn the adjusting screw clockwise or

counterclockwise. You will achieve maximum adjustment with only 1/4 turn in either direction.

3. If creep is eliminated by adjustment, torque the locknut to 22 N•m [16 lbf•ft] while holding the

adjustment screw secure. If creep cannot be eliminated, then the pump requires major repair.

Remove the unit and refer to Sauer-Danfoss Global Service Partner for repairs.

Leveling swashplate with pump installed on machine

Leveling the swashplate (adjusting neutral return mechanism) with the pump installed on the machine is

the same procedure as adjusting on the test stand. A cam allows precise zero displacement adjustment.

Block wheels off the ground. Disconnect control linkage from pump trunion. If machine creeps, loosen

locknut and turn adjusting screw until creep is eliminated. If neutral adjustment is not possible, pump

teardown is necessary. See your nearest Danfoss Global Service Provider.

It may be necessary to disconnect the control linkage to eliminate possible linkage drag.

24 11004904 • Rev 0100 • July 2015

Page 25

C

E101 438E

D03

D02

D01

S09

S08

S07

S06

E01

Service Manual LPV Closed Circuit Axial Piston Pumps

Minor repair

Input shaft and seal

Shaft seal removal

1. Orient pump with the shaft pointing up.

2. Remove retaining ring (D03) using retaining ring pliers to release the shaft seal components. Discard

retaining ring.

Caution

Do not damage the housing bore, shaft or bearing when removing the shaft and shaft seal.

3. Remove the seal support washer (D02). Use a small hook if necessary.

4. Install a special fitting with air chuck into a case drain port.

5. Use air pressure to push out shaft seal (D01). Discard seal.

6. Remove special fitting and replace with original plug.

Remove shaft /seal/bearing

11004904 • Rev 0100 • July 2015 25

Page 26

C

E01

P106 291E

Service Manual LPV Closed Circuit Axial Piston Pumps

Minor repair

Input shaft removal

1. Remove retaining ring (S09) using retaining ring pliers.

2. Pull shaft (E01) with bearing (S07) out of the pump. If necessary, tap on the shaft to dislodge it from

the internal pump components.

Caution

If the shaft is to be replaced without complete pump disassembly, do not move or rotate the pump

once the shaft is removed. This may dislodge internal components, making reassembly impossible.

3. Remove retaining ring (S08) using retaining ring pliers.

4. Press bearing off the shaft using the inner race.

5. Remove retaining ring (S06) from the shaft using retaining ring pliers.

Shaft inspection

Check to see that the shaft (E01) and its splines are straight and free of damage or heavy wear. Inspect

the shaft surface where it meets the shaft seal. Replace the shaft if a groove exists at the sealing land

surface that may let dirt into or hydraulic fluid out of the unit. Clean the sealing area with a

nonabrasive material if necessary. Lubricate the shaft with a light coat of hydraulic fluid before reassembly.

Inspect shaft

26 11004904 • Rev 0100 • July 2015

Page 27

P106 292E

S07

C

Service Manual

Minor repair

LPV Closed Circuit Axial Piston Pumps

Shaft bearing inspection

Clean bearing with a solvent and lubricate with hydraulic fluid. Inspect for wear, or pitting.

Replace bearing if cleaning exposes wear or damage to bearing.

Inspect shaft bearing

Shaft and seal reassembly

1. Orient pump with the shaft end pointing up.

2. Install first bearing retaining ring (S06) using retaining ring pliers.

3. Lubricate bearing (S07) with hydraulic fluid. Press bearing onto shaft by applying force to inner race.

4. Install second bearing retaining ring (S09) using retaining ring pliers.

5. For protection, cover end of shaft with installation sleeve or packaging tape.

6. Install shaft (S01) with bearing into housing. It may be necessary to tap the shaft to seat the bearing.

Caution

Do not damage the housing bore, shaft or bearing when installing the shaft and shaft seal.

7. Using retaining ring pliers, install first seal retaining ring (S09).

11004904 • Rev 0100 • July 2015 27

Page 28

E101 461E

D03

D02

D01

S09

S08

S07

S06

E01

Service Manual LPV Closed Circuit Axial Piston Pumps

Minor repair

8. Lubricate the seal (D01) using hydraulic fluid. Press seal into housing until it bottoms out. Press evenly

to avoid binding and damaging the seal.

9. Install the seal support washer (D02).

10. Install the second seal retaining ring (D03) using retaining ring pliers.

Install shaft /seal/bearing

28 11004904 • Rev 0100 • July 2015

Page 29

N04

N02

N03

N01

E101 493E

13 mm

33 N•m

[24 lbf•ft]

Service Manual

Minor repair

Trunion seal

LPV Closed Circuit Axial Piston Pumps

Removal

1. Remove four trunnion cover bolts (N03) using a 13 mm hex wrench.

2. Remove trunnion cover (N01). Remove and discard O-ring (N04).

3. Press the lip seal (N02) out of the trunnion cover (N01); discard.

Inspection

Inspect seal land on trunnion shaft and trunnion cover for rust, wear, or contamination. Polish seal

land on trunnion shaft if necessary.

Reassembly

1. Press new trunnion seal (N02) into cover (N03).

2. Install new O-ring (N04). Retain with petroleum jelly.

3. Cover the trunnion shaft with an installation sleeve or wrap with packaging tape to prevent damage

to seal.

4. Install trunnion cover and seal assembly (N01) to housing.

5. Install four trunnion cover bolts using a 13mm hex wrench. Torque to 33 N•m [24 lbf•ft].

11004904 • Rev 0100 • July 2015 29

Page 30

E101 441E

M023

M20

M022

M023

M10

M022

5/16 in

5/16 in

Service Manual

Minor repair

High Pressure Relief Valves

LPV Closed Circuit Axial Piston Pumps

Removal

1. Mark the location of each system check relief valve for proper reassembly.

2. Using a 5/16 internal hex wrench, remove system check relief valves (M10) and (M20).

3. Remove and discard O-rings (M022) and (M023).

Disassemble system check relief valves

Inspection

1. Inspect plug and cartridge. Replace O-rings before reassembly

2. Inspect internal parts of cartridge. If internal parts are worn or damaged, replace entire cartridge.

Reassembly

1. Lubricate and install new O-rings (M022) and (M023) onto each system check relief valve (M10) and

(M20).

2. Install the system check relief valves in their original location as noted during disassembly.

3. Use a 5/16 in internal hex wrench to torque valves to 81 N•m [60 lbf•ft].

30 11004904 • Rev 0100 • July 2015

Page 31

E101 440E

H01

H07

H06

H01A

H08

1 in

Service Manual

Minor repair

Charge pressure relief valve

LPV Closed Circuit Axial Piston Pumps

Removal

1. Using a 1 in hex wrench, remove the charge pressure relief valve plug (H01). Discard O-ring (H01A).

2. Charge relief valve shim kit (H06) remains in plug (H01). Remove shims by tapping the plug on the

workbench.

3. Use a magnet to remove the spring (H07).

4. Use a magnet to remove the charge relief poppet (H08).

Charge pressure relief valve

Inspection

1. Inspect charge relief valve plug for wear or damage. Replace O-ring before reassembly

2. Inspect shim kit.

3. Inspect the spring. Replace spring if it is warped or bent.

4. Inspect charge relief valve poppet.

Reassembly

1. Insert charge relief valve poppet (H08) and spring (H07) into endcap.

2. Install shims (H06) into charge relief valve plug (H01).

3. Lubricate and install a new O-ring (H01A) onto the charge relief valve plug.

4. Install charge relief valve plug using a 1 in hex wrench. Torque to 81-203 N•m [60-150 lbf•ft].

11004904 • Rev 0100 • July 2015 31

Page 32

E101 442E

J08

J07

J06A

J06

11/16 in

J06

J07

J06A

11/16 in

Service Manual

Minor repair

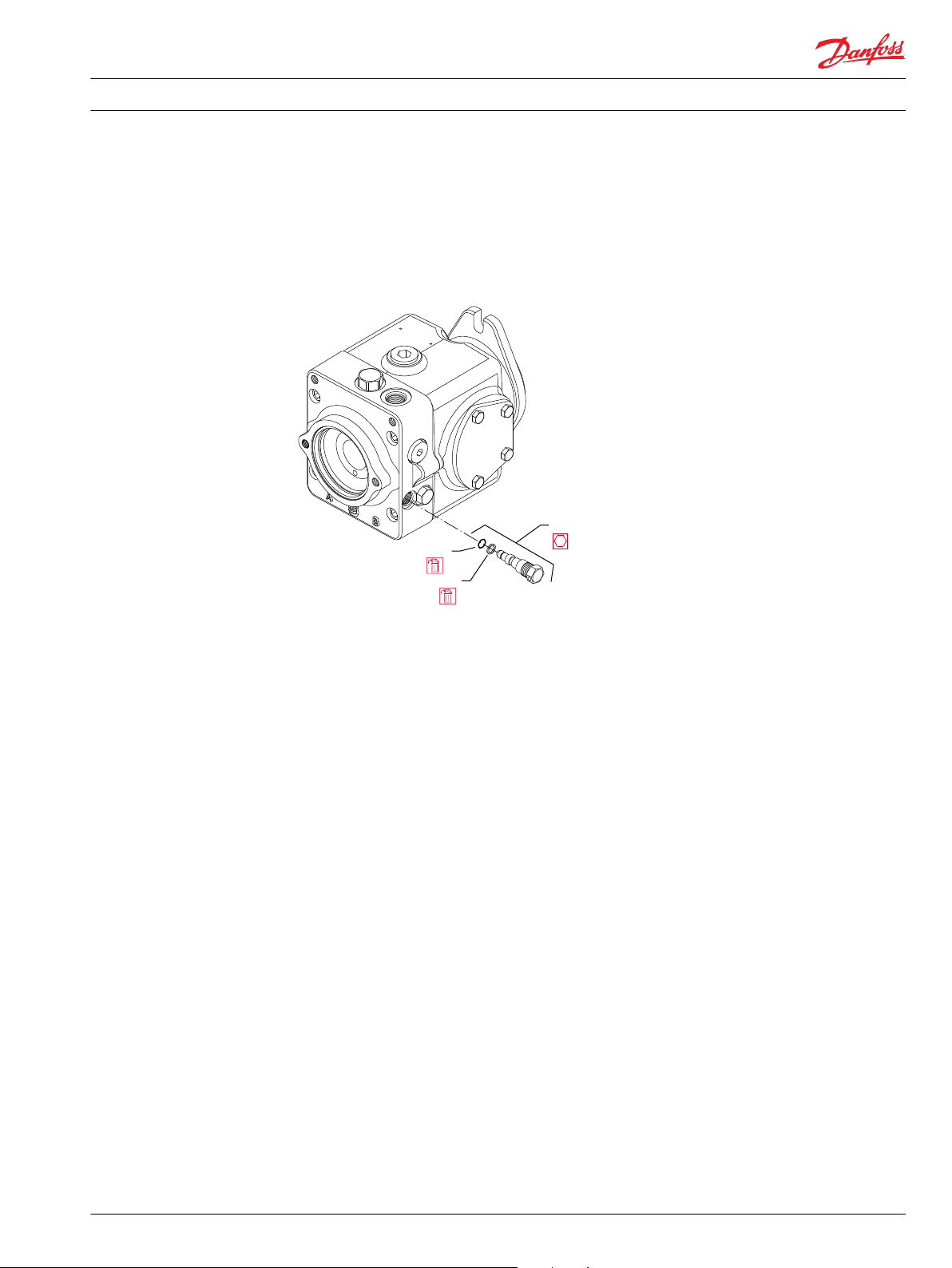

Loop flushing valve

LPV Closed Circuit Axial Piston Pumps

Removal

1. Using a 11/16 in hex wrench, remove the loop flushing valve plugs (J06). Discard Oring (J06A).

2. Use a magnet to remove springs (J07).

3. Use a magnet to remove loop flush spool (J08).

Disassemble loop flushing valve

Inspection

1. Inspect loop flushing valve plugs for damage or wear. Replace O-rings before reassembly.

2. Inspect the springs. Replace if warped or bent.

3. Inspect loop flush spool. If worn or damaged, replace the loop flush spool.

Reassembly

1. Insert loop flush spool (J08) and springs (J07) into endcap.

2. Lubricate and install new O-rings (J06A) onto loop flushing valve plug (J06).

3. Thread the loop flushing valve plugs into the housing.

4. Torque to 45 N•m [33 lbf•ft] using a 11/16 in hex wrench.

32 11004904 • Rev 0100 • July 2015

Page 33

E101 443E

1002

1003

L01

5/8 in

Service Manual

Minor repair

Bypass valve

LPV Closed Circuit Axial Piston Pumps

Removal

Using a 5/8 in hex wrench, remove the bypass valve cartridge (L01). Discard Oring (1003) and backup

ring (1002).

Bypass valve

Inspection

1. Inspect plug and cartridge. Replace O-rings before reassembly

2. Inspect internal parts of cartridge. If internal parts are worn or damaged, replace entire cartridge.

Reassembly

1. Install new O-ring (1003) and backup ring (1002).

2. Install the bypass valve cartridge (L01) using a 5/8 in hex wrench.

3. Torque to 20 N•m [15 lbf•ft].

11004904 • Rev 0100 • July 2015 33

Page 34

E101 439E

T03

Service Manual

Minor repair

Coupling

LPV Closed Circuit Axial Piston Pumps

Removal

1. Position pump so endcap is on top.

2. Remove coupling (T03). Use a small hook if necessary.

Inspection

Check coupling for abnormal or excessive wear. Look for cracks that indicate coupling fatigue. If wear

or damage is found, replace coupling.

Reassembly

Lubricate and install coupling (T03).

34 11004904 • Rev 0100 • July 2015

Page 35

P106 323E

M022/M023

High pressure

relief valve

J06

Loop flushing

valve plug

N03/N07

Trunnion

cover screw

T04

End cover

screw

K02

Neutral return

pivot

K08

Neutral return

seal nut

J04

Endcap screw

H01

Charge relief

valve plug

S04

O-ring plug, 1 1/16 - 12

S03

O-ring plug, 1 1/16 - 12

L01

Bypass valve

Service Manual LPV Closed Circuit Axial Piston Pumps

Torque chart

Fasteners and plugs

Fastener size and torque chart

Item Fastener Wrench size Torque

H01 Charge relief valve plug 1 in 81-203 N•m [60-150 lbf•ft]

J04 Endcap screw 8 mm internal hex 54 N•m [40 lbf•ft]

J06 Loop flushing valve plug 11/16 in 45 N•m [33 lbf•ft]

K02 Neutral return pivot 1/4 in N/A

K08 Neutral return seal nut 13 mm 22 N•m [16 lbf•ft]

L01 Bypass valve 11/16 in 20 N•m [15 lbf•ft]

M022/M023 High pressure relief valve 5/16 in internal hex 81 N•m [60 lbf•ft]

N03/N07 Trunnion cover screw 13 mm 33 N•m [24 lbf•ft]

T04 End cover screw 9/16 in 44 N•m [32 lbf•ft]

Plug size and torque chart

Item O-ring plug Wrench size Torque

S03, S04 1 1/16 - 12 15 mm internal hex 69 N•m [51 lbf•ft]

11004904 • Rev 0100 • July 2015 35

Page 36

Danfoss

Power Solutions GmbH & Co. OHG

Krokamp 35

D-24539 Neumünster, Germany

Phone: +49 4321 871 0

Danfoss

Power Solutions ApS

Nordborgvej 81

DK-6430 Nordborg, Denmark

Phone: +45 7488 2222

Danfoss

Power Solutions (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239 6000

Danfoss

Power Solutions Trading

(Shanghai) Co., Ltd.

Building #22, No. 1000 Jin Hai Rd

Jin Qiao, Pudong New District

Shanghai, China 201206

Phone: +86 21 3418 5200

Products we offer:

Comatrol

www.comatrol.com

Schwarzmüller-Inverter

www.schwarzmuellerinverter.com

Turolla

www.turollaocg.com

Hydro-Gear

www.hydro-gear.com

Daikin-Sauer-Danfoss

www.daikin-sauer-danfoss.com

Bent Axis Motors

•

Closed Circuit Axial Piston

•

Pumps and Motors

Displays

•

Electrohydraulic Power

•

Steering

Electrohydraulics

•

Hydraulic Power Steering

•

Integrated Systems

•

Joysticks and Control

•

Handles

Microcontrollers and

•

Software

Open Circuit Axial Piston

•

Pumps

Orbital Motors

•

PLUS+1® GUIDE

•

Proportional Valves

•

Sensors

•

Steering

•

Transit Mixer Drives

•

Danfoss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and

electronic components. We specialize in providing state-of-the-art technology and solutions

that excel in the harsh operating conditions of the mobile off-highway market. Building on

our extensive applications expertise, we work closely with our customers to ensure

exceptional performance for a broad range of off-highway vehicles.

We help OEMs around the world speed up system development, reduce costs and bring

vehicles to market faster.

Danfoss – Your Strongest Partner in Mobile Hydraulics.

Go to www.powersolutions.danfoss.com for further product information.

Wherever off-highway vehicles are at work, so is Danfoss. We offer expert worldwide support

for our customers, ensuring the best possible solutions for outstanding performance. And

with an extensive network of Global Service Partners, we also provide comprehensive global

service for all of our components.

Please contact the Danfoss Power Solution representative nearest you.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to

products already on order provided that such alterations can be made without changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

11004904 • Rev 0100 • July 2015 www.danfoss.com

Local address:

©

Danfoss A/S, 2014

Loading...

Loading...