Page 1

Technical Information

Axial Piston Pumps

LPV

www.danfoss.com

Page 2

Technical Information

LPV Axial Piston Pumps

Revision history Table of revisions

Date Changed Rev

April 2021 Changed document number from 'BC00000044' and '520L0954' to 'BC152886483590' and

removed obsolete end cap options

May 2018 add straight keyed shaft 0103

September 2017 update model code 0102

July 2015 Danfoss Layout 0100

January 2009 neutral assist return mechanism - changes AF

October 2008 added serial number plate drawing AE

April 2008 changes to auxilliary mounting dimensions AD

August 2007 revised endcap and loop flusing options in model code AC

May 2007 correct displacement errors AB

July 2006 First edition A-0

0301

2 | © Danfoss | April 2021 BC152886483590en-000301

Page 3

Technical Information

LPV Axial Piston Pumps

Contents

General description

Operating parameters

System design parameters

Operation

Technical specifications

Product coding

Features and options

Installation drawings

Overview..............................................................................................................................................................................................4

Design...................................................................................................................................................................................................4

Typical applications.........................................................................................................................................................................4

LPV product specifications............................................................................................................................................................4

Design...................................................................................................................................................................................................6

Direct displacement drive system..............................................................................................................................................7

LPV Pump schematic diagram.....................................................................................................................................................7

Overview..............................................................................................................................................................................................8

Input speed.........................................................................................................................................................................................8

System pressure................................................................................................................................................................................8

Pressure Ratings................................................................................................................................................................................8

Viscosity............................................................................................................................................................................................... 8

Temperature.......................................................................................................................................................................................9

Case pressure.....................................................................................................................................................................................9

Independent braking system.......................................................................................................................................................9

Reservoir.............................................................................................................................................................................................. 9

Case drain......................................................................................................................................................................................... 10

Charge flow requirements..........................................................................................................................................................10

Loop flushing...................................................................................................................................................................................10

Bearing loads and life................................................................................................................................................................... 10

Applications with external shaft loads..............................................................................................................................10

Hydraulic unit life...........................................................................................................................................................................12

Mounting flange loads.................................................................................................................................................................12

Estimating overhung load moments.................................................................................................................................12

Input shaft torque rating and spline lubrication................................................................................................................ 13

Understanding and minimizing system noise.....................................................................................................................13

Sizing equations.............................................................................................................................................................................14

Fluids.................................................................................................................................................................................................. 14

Filtration system.............................................................................................................................................................................15

Charge filtration........................................................................................................................................................................ 15

Suction filtration....................................................................................................................................................................... 16

HPRV (High pressure relief valve).............................................................................................................................................17

Bypass function...............................................................................................................................................................................17

CPRV (Charge pressure relief valve)........................................................................................................................................ 17

Loop flushing valve.......................................................................................................................................................................18

Neutral return mechanism..........................................................................................................................................................18

Specifications...................................................................................................................................................................................20

LPV Model Code............................................................................................................................................................................. 23

Controls............................................................................................................................................................................................. 26

Direct displacement control.................................................................................................................................................26

Features and benefits..............................................................................................................................................................26

Control handle requirements...............................................................................................................................................26

Input shafts.......................................................................................................................................................................................26

Auxiliary mounting pads.............................................................................................................................................................27

SAE-A Auxiliary mounting..................................................................................................................................................... 27

LPV Installation drawings............................................................................................................................................................29

LPV Schematic.................................................................................................................................................................................30

©

Danfoss | April 2021 BC152886483590en-000301 | 3

Page 4

Technical Information

LPV Axial Piston Pumps

General description

Overview

Design

LPV is a family of variable displacement, axial piston pumps for closed circuit applications. The LPV family

is uniquely designed to optimize performance, size, and cost, matching the work requirements of the

demanding turf care and utility vehicle marketplace. This document gives the detailed specifications and

features for LPV pumps.

High performance

Displacements 25 cm³/rev [1.53 in3/rev], 30 cm³/rev [1.83 in3/rev], 35 cm³/rev [2.14 in3/rev]

•

Speeds up to 3600 rpm

•

Pressures up to 210 bar [3045 psi] continuous, and 345 bar [5000 psi] peak

•

Direct displacement control

•

Latest technology

Customer-driven using quality function deployment (QFD) and design for manufacturability (DFM)

•

techniques

Optimized valve plates for quiet operation

•

Compact package size minimizing installation space requirements

•

Single piece rigid housing to reduce noise and leak paths

•

Integrated neutral return mechanism for simplified installation

•

Optional loop flushing for circuit flexibility

•

Typical applications

LPV product specifications

Reliability

Designed to rigorous standards

•

Proven in both laboratory and field

•

Manufactured to rigid quality standards

•

Long service life

•

Turf care

•

Utility vehicles

•

Basic units

The LPV pumps provide an infinitely variable speed range between zero and maximum in both forward

and reverse modes of operation.

LPV pumps are compact, high power density units. All models use the parallel axial piston/slipper

concept in conjunction with a tiltable swashplate to vary the pump's displacement. Reversing the angle

of the swashplate reverses the flow of fluid from the pump, reversing the direction of rotation of the

output motor.

4 | © Danfoss | April 2021 BC152886483590en-000301

Page 5

Made in USA

Place of Manufac tur

e

Part Number

Serial

Number

Model

Code

LPVAAADAEACCABDDD

P107852

83002847

A084012345

RAFFBNNN***

Technical Information

LPV Axial Piston Pumps

General description

LPV pump

Serial number plate

©

Danfoss | April 2021 BC152886483590en-000301 | 5

Page 6

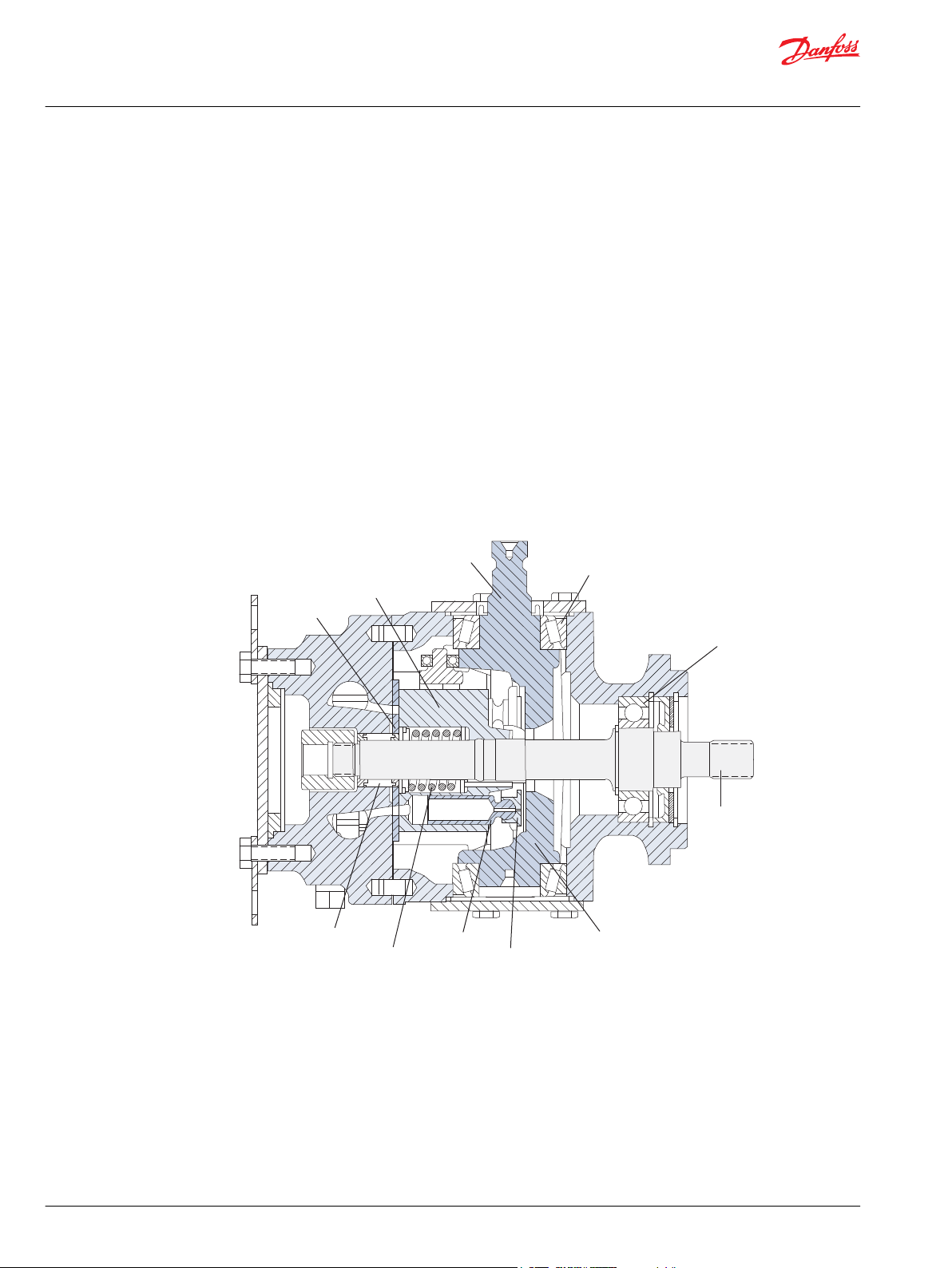

P106271

Input shaft

Ball bearing

Needle bearing

Tapered roller bearing

Cylinder block

Valve plate

Cylinder block spring

Piston

Slipper

Swashplate

Trunion

Technical Information

LPV Axial Piston Pumps

General description

Design

LPV is a family of hydrostatic pumps for low to medium power applications with maximum loads of 345

bar [5000 psi]. You can apply these pumps with other products in a system to transfer and control

hydraulic power.

LPV pumps provide an infinitely variable speed range between zero and maximum in both forward and

reverse modes of operation. LPV pumps come in three displacements (25 cm3 [1.53 in3], 30 cm3 [1.83 in3],

and 35 cm3 [2.14 in3]).

LPV pumps are compact, high power density units. All models use the parallel axial piston / slipper

concept in conjunction with a tiltable swashplate to vary the pump's displacement. Reversing the angle

of the swashplate reverses the flow of fluid from the pump, reversing the direction of rotation of the

motor output.

LPV pumps have an internal neutral return mechanism for ease of installation, and are available with

optional loop flushing for circuit flexibility. LPV pumps can receive charge flow from an auxiliary circuit or

from a gear pump mounted on the auxiliary mounting pad. LPV pumps feature an SAE A auxiliary

mounting pad to accept auxiliary hydraulic pumps for use in complementary hydraulic systems.

LPV pumps include a trunnion style direct displacement control.

LPV cross section

6 | © Danfoss | April 2021 BC152886483590en-000301

Page 7

Variable

displacement

pump

Input

shaft

Cylinder

block

assembl y

HPRV valves

Loop flushing valves

OMR

orbital

motor

Suction flow

Servo pressur e

High pressur e

Case flow

Charge pressur e

Output

shaft

Filter

Charge

pump

Reservoir

Heat

exchanger

Heat exchanger

bypass

Charge relief

valve

Bypass

valve

P100586

Charge pressure

inlet

Port A

Port B

P106287

L2

L1

Technical Information

LPV Axial Piston Pumps

General description

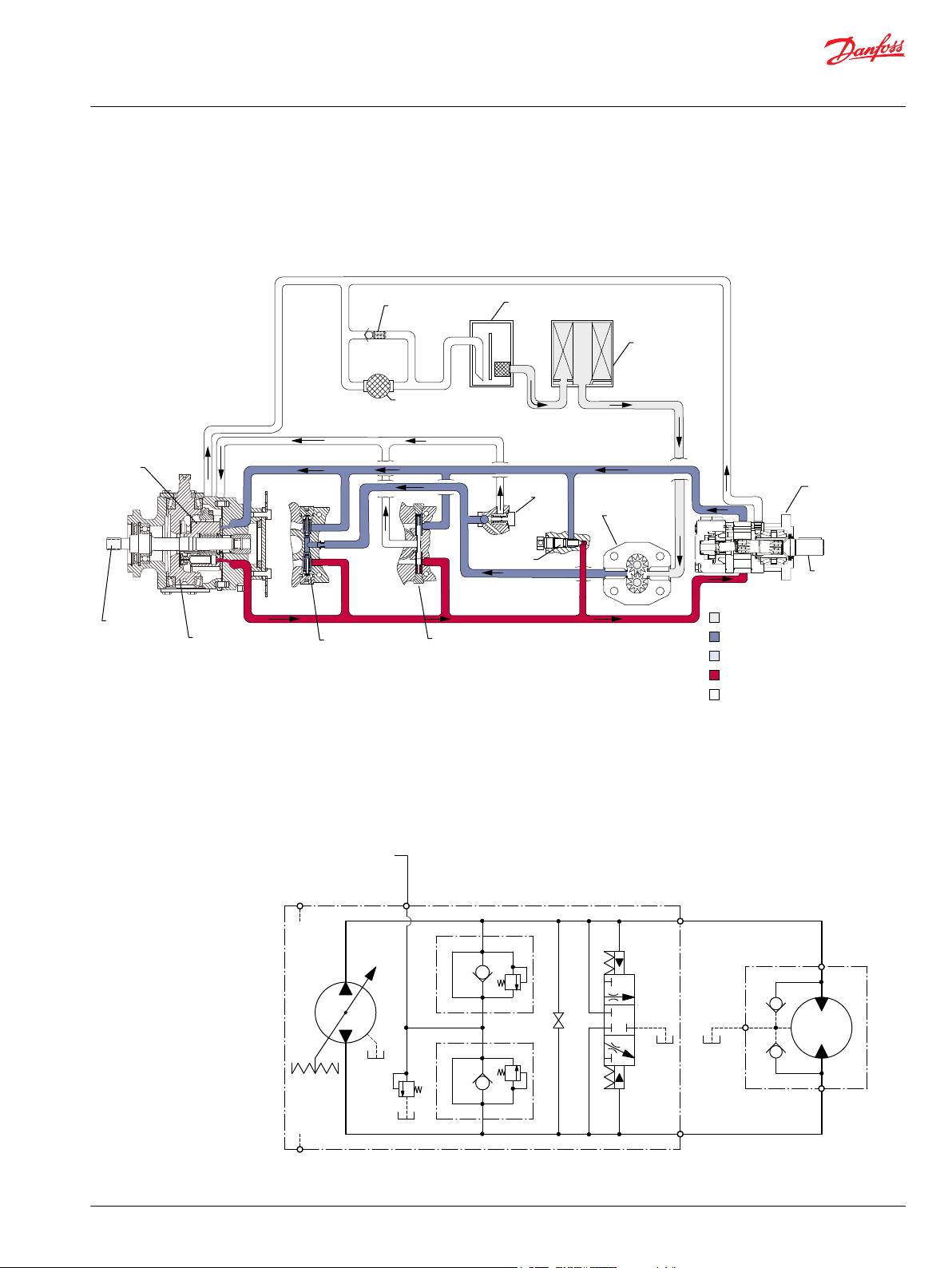

Direct displacement drive system

The direct displacement control varies the swashplate angle. Swashplate angle determines pump flow

and motor speed.

Pictorial circuit diagram

The diagram shows an LPV pump driving an OMR motor. The system shown uses an external charge pump and external filter. Charge

pressure relief valves, high pressure relief valves, and loop flushing valves are shown separated from the pump to provide clarity to the

hydraulic system.

LPV Pump schematic diagram

©

Danfoss | April 2021 BC152886483590en-000301 | 7

Page 8

W

Technical Information

LPV Axial Piston Pumps

Operating parameters

Overview

Input speed

This section defines the operating parameters and limitations for LPV pumps with regard to input speeds

and pressures. For actual parameters, refer to Technical specifications on page 20.

The table in Technical specifications on page 20, gives rated and maximum speeds for each

displacement. Not all displacements operate under the same speed limits. Definitions of these speed

limits appear below.

Continuous speed is the maximum recommended operating speed at full power condition. Operating at

or below this speed should yield satisfactory product life. Do not exceed maximum pump speed during

unloaded, on-road travel over level ground.

Maximum speed is the highest operating speed permitted. Exceeding maximum speed reduces pump

life and can cause loss of hydrostatic power and braking capacity. Never exceed the maximum speed

limit under any operating conditions.

Warning

Unintended vehicle or machine movement hazard.

The loss of hydrostatic drive line power, in any mode of operation (forward, neutral, or reverse) may cause

the system to lose hydrostatic braking capacity. You must provide a braking system, redundant to the

hydrostatic transmission, sufficient to stop and hold the vehicle or machine in the event of hydrostatic

drive power loss.

System pressure

Pressure Ratings

The table in Technical specifications on page 20, gives maximum and maximum working pressure

ratings for each displacement. Not all displacements operate under the same pressure limits. Definitions

of the operating pressure limits appear below.

System pressure is the differential pressure between high pressure system ports. It is the dominant

operating variable affecting hydraulic unit life. High system pressure, which results from high load,

reduces expected life. Hydraulic unit life depends on the speed and normal operating, or weighted

average, pressure that can only be determined from a duty cycle analysis.

Application pressure is the high pressure relief or pressure limiter setting normally defined within the

order code of the pump. This is the applied system pressure at which the driveline generates the

maximum calculated pull or torque in the application.

Maximum Working pressure is the highest recommended application pressure. Maximum working

pressure is not intended to be a continuous pressure. Propel systems with application pressures at, or

below, this pressure should yield satisfactory unit life given proper component sizing.

Maximum pressure is the highest allowable application pressure under any circumstance. Application

pressures above maximum working pressure will only be considered with duty cycle analysis and factory

approval.

Minimum low loop pressure must be maintained under all operating conditions to avoid cavitation.

All pressure limits are differential pressures referenced to low loop (charge) pressure. Subtract low loop

pressure from gauge readings to compute the differential.

Viscosity

Maintain fluid viscosity within the recommended range for maximum efficiency and bearing life.

Minimum viscosity should only occur during brief occasions of maximum ambient temperature and

8 | © Danfoss | April 2021 BC152886483590en-000301

Page 9

C

W

Technical Information

LPV Axial Piston Pumps

Operating parameters

Temperature

Case pressure

severe duty cycle operation. Maximum viscosity should only occur at cold start. Limit speeds until the

system warms up. Refer to Specifications on page 20, for specifications.

Maintain fluid temperature within the limits shown in the table. Technical specifications on page 20.

Minimum temperature relates to the physical properties of the component materials. Cold oil will not

affect the durability of the pump components, however, it may affect the ability of the pump to provide

flow and transmit power. Maximum temperature is based on material properties. Don't exceed it.

Measure maximum temperature at the hottest point in the system. This is usually the case drain. Refer to

Specifications on page 20, for specifications.

Ensure fluid temperature and viscosity limits are concurrently satisfied.

Do not allow case pressure to exceed ratings under normal operating conditions. During cold start, keep

case pressure below maximum intermittent case pressure. Size drain plumbing accordingly.

Caution

Independent braking system

Reservoir

Possible component damage or leakage.

Operation with case pressure in excess of stated limits may damage seals, gaskets, and/or housings,

causing external leakage. Performance may also be affected since charge and system pressure are

additive to case pressure.

Warning

Unintended vehicle or machine movement hazard.

The loss of hydrostatic drive line power, in any mode of operation (forward, neutral, or reverse) may cause

the system to lose hydrostatic braking capacity. You must provide a braking system, redundant to the

hydrostatic transmission, sufficient to stop and hold the vehicle or machine in the event of hydrostatic

drive power loss.

The reservoir provides clean fluid, dissipates heat, and removes trapped air from the hydraulic fluid. It

allows for fluid volume changes associated with fluid expansion and cylinder differential volumes.

Minimum reservoir capacity depends on the volume needed to perform these functions. Typically, a

capacity of 5/8 of the charge pump flow (per minute) is satisfactory for a closed reservoir. Open circuit

systems sharing a common reservoir require greater fluid capacity.

Locate the reservoir outlet (suction line) near the bottom, allowing clearance for settling foreign particles.

Use a 100 - 125 µm screen covering the outlet port.

Place the reservoir inlet (return lines) below the lowest expected fluid level, as far away from the outlet as

possible. Use a baffle (or baffles) between the reservoir inlet and outlet ports to promote de-aeration and

reduce fluid surging.

©

Danfoss | April 2021 BC152886483590en-000301 | 9

Page 10

Technical Information

LPV Axial Piston Pumps

System design parameters

Case drain

Charge flow requirements

Connect the case drain line to one of the case outlets to return internal leakage to the system reservoir.

Use the higher of the outlets to promote complete filling of the case. Case drain fluid is typically the

hottest fluid in the system. Return case drain flow through the heat exchanger to the reservoir.

All LPV pumps applied in closed circuit installations require charge flow. The charge pump provides flow

to make up internal leakage, maintain a positive pressure in the main circuit, provide flow for cooling and

filtration, replace any leakage losses from external valving or auxiliary systems, and to provide flow and

pressure for the control system.

Many factors influence the charge flow requirements and charge pump size selection. These factors

include system pressure, pump speed, pump swashplate angle, type of fluid, temperature, size of heat

exchanger, length and size of hydraulic lines, control response characteristics, auxiliary flow

requirements, hydrostatic motor type, etc. When sizing and selecting hydrostatic units for an application,

it is frequently not possible to have all the information necessary to accurately evaluate all aspects of

charge pump size selection.

Maintain charge pressure at the level specified in the table Technical specifications on page 20 under all

operating conditions to prevent damage to the transmission. Danfoss recommends testing under actual

operating conditions to verify this.

Charge pump displacement should be at least 10% of the total displacement of all axial piston

components in the system. However, unusual application conditions may require a more detailed review

of charge pump sizing. Refer to Selection of Drive line Components, BLN-9985, for a more detailed

selection procedure, or contact your Danfoss representative for assistance.

Loop flushing

Bearing loads and life

Closed circuit systems may require loop flushing to meet temperature and cleanliness requirements. A

loop flushing valve removes hot fluid from the low pressure side of the system loop for additional cooling

and filtering. Ensure the charge pump provides adequate flow for loop flushing and the loop flushing

valve does not cause charge pressure to drop below recommended limits.

LPV utilizes a special loop flushing spool design. On dual path systems, take special care to verify

acceptable performance.

Bearing life is a function of speed, system pressure, charge pressure, and swashplate angle, plus any

external side or thrust loads. The influence of swashplate angle includes displacement as well as

direction. External loads are found in applications where the pump is driven with a side/thrust load (belt

or gear) as well as in installations with misalignment and improper concentricity between the pump and

drive coupling. All external side loads will act to reduce the normal bearing life of a pump. Other life

factors include oil type and viscosity.

In vehicle propel drives with no external shaft loads and where the system pressure and swashplate angle

are changing direction and magnitude regularly, the normal L20 bearing life (80 % survival) will exceed

the hydraulic load-life of the unit.

In non propel drives such as vibratory drives, conveyor drives, or fan drives, the operating speed and

pressure are often nearly constant and the swashplate angle is predominantly at maximum. These drives

have a distinctive duty cycle compared to a propulsion drive. In these types of applications a bearing life

review is recommended.

Applications with external shaft loads

LPV pumps have bearings that can accept some external radial and thrust loads. When external loads are

present, the allowable radial shaft loads are a function of the load position relative to the mounting

10 | © Danfoss | April 2021 BC152886483590en-000301

Page 11

0° Re

180° Re

90° Re

270° Re

Axis of

swashplate

rotation

End view

of shaft

P100595

Orient radial shaft

load to 90° or 270°

(opposite of

block load)

Technical Information

LPV Axial Piston Pumps

System design parameters

flange, the load orientation relative to the internal loads, and the operating pressures of the hydraulic

unit. In applications with external shaft loads, you can minimize the impact on bearing life with proper

orientation of the load.

Optimum pump orientation is a consideration of the net loading on the shaft from the external load, the

pump rotating group and the charge pump load.

In applications where the pump is operated such that nearly equal amounts of forward vs reverse

•

swashplate operation is experienced; bearing life can be optimized by orientating the external side

load at 0° or 180° such that the external side load acts 90° to the rotating group load.

In applications where the pump is operated such that the swashplate is predominantly (> 75 %) on

•

one side of neutral (ie vibratory, conveyor, typical propel); bearing life can be optimized by

orientating the external side load generally opposite (90° or 270°) the internal rotating group load.

The direction of internal loading is a function of rotation and which system port has flow out. Contact

Danfoss for a bearing life review if external side loads are present.

You can calculate the maximum allowable radial load (Re), using the formula below, the maximum

external moment (Me) from the table on the next page, and the distance (L) from the mounting flange to

the load.

Re = Me / L

Avoid thrust loads in either direction.

If continuously applied external radial loads are 25% of the maximum allowable or more, or thrust loads

are known to occur, contact your Danfoss representative for an evaluation of unit bearing life.

Tapered output shafts or clamp-type couplings are recommended for applications where radial shaft side

loads are present.

Direction of external shaft load

Shaft loading parameters

R

e

M

e

L Distance from mounting flange to point of load

F

b

T

e

Maximum radial load

Maximum external moment

Force of block

Thrust load

Maximum external shaft moments

LPV

©

Danfoss | April 2021 BC152886483590en-000301 | 11

Me /N•m [in•lbf] 101 [890]

Page 12

R

T

P106280

L

e

F

e

b

0

180

90

270

Re Re

Re

Re

Technical Information

LPV Axial Piston Pumps

System design parameters

Hydraulic unit life

Diagram of external radial shaft loads

Hydraulic unit life is the life expectancy of the hydraulic components. It is a function of speed and

system pressure. System pressure is the dominant operating variable. High pressure, which results from

high load, reduces expected life.

Design the hydraulic system to a projected machine duty cycle. Know the expected percentages of time

at various loads and speeds. Ask your Danfoss representative to calculate an appropriate pressure based

your hydraulic system design. If duty cycle data is not available, input power and pump displacement are

used to calculate system pressure.

All pressure limits are differential pressures (referenced to charge pressure) and assume normal charge

pressure.

LPV pumps will meet satisfactory life expectancy if applied within the parameters specified in this

bulletin. For more detailed information on hydraulic unit life see Pressure and Speed Limits,

BC152886484313.

Mounting flange loads

Estimating overhung load moments

Adding auxiliary pumps and/or subjecting pumps to high shock loads may result in excessive loading of

the mounting flange. Applications which experience extreme resonant vibrations or shock may require

additional pump support. You can estimate the overhung load moment for multiple pump mounting

using the formula below.

MS = GS (W1L1 + W2L2 + ... +WnLn)

MC = GC (W1L1 + W2L2 + ... +WnLn)

Where:

MC = Rated load moment N•m [lbf•in]

MS = Shock load moment N•m [lbf•in]

GC = Rated (vibratory) acceleration (G’s)* m/s2 [ft/s2]

GS = Maximum (shock) acceleration (G’s)* m/s2 [ft/s2]

Wn = Weight of nth pump

Ln = Distance from mounting flange to CG (center of gravity) of nth pump

(Refer to Installation drawings on page 29 to locate CG of pump.)

* Carry out calculations by multiplying gravity (g = 9.81 m/s2 [32 ft/s2]) with a given factor. This factor depends

on the application.

Refer to Specifications on page 20, for allowable overhung load moment values.

12 | © Danfoss | April 2021 BC152886483590en-000301

Page 13

P106285

Center of gravity - pump 1

Center of gravity - pump 2

L 1

L 2

Mounting flange

Technical Information

LPV Axial Piston Pumps

System design parameters

Shaft loading parameters

Input shaft torque rating and spline lubrication

A spline running in oil-flooded environment provides superior oxygen restriction in addition to

contaminant flushing. An oil-flooded spline is found in a pump to pump drive (mounted on the auxiliary

pad of another pump). An oil-flooded spline connection can withstand a continuously applied torque up

to the published maximum rating. Maximum torque ratings are based on torsional fatigue strength of

the shaft and assume a maximum of 200,000 load reversals.

Coupling arrangements that are not oil-flooded require a reduced torque rating due to spline tooth wear.

Contact your Danfoss representative for torque ratings if your application involves non oil-flooded

couplings.

Danfoss recommends mating splines adhere to ANSI B92.1-Class 5. Danfoss external splines are modified

class 5 fillet root side fit. The external major diameter and circular tooth thickness dimensions are reduced

to ensure a good clearance fit with the mating spline. See Input shafts on page 26 for full spline

dimensions and data.

Maintain a spline engagement at least equal to the pitch diameter to maximize spline life. Spline

engagement of less than ¾ pitch diameter is subject to high contact stress and spline fretting.

Alignment between the mating spline's pitch diameters is another critical factor in determining the

operating life of a splined drive connection. Plug-in, or rigid spline drive installations can impose severe

radial loads on the shaft. The radial load is a function of the transmitted torque and shaft eccentricity.

Increased spline clearance will not totally alleviate this condition; but, increased spline clearance will

prevent mechanical interference due to misalignment or radial eccentricity between the pitch diameters

of the mating splines. Maximize spline life by adding an intermediate coupling between the bearing

supported splined shafts.

Torques are additive for multiple pump installations. Ensure total through torque for the main pump and

auxiliary pump does not exceed published maximum shaft torque. See Input shafts on page 26 for shaft

torque ratings.

Understanding and minimizing system noise

©

Danfoss | April 2021 BC152886483590en-000301 | 13

A table in the Specifications on page 20, gives sound levels for each displacement. Sound level data are

collected at various operating speeds and pressures in a semi-anechoic chamber. Many factors contribute

to the overall noise level of any application. Here is some information to help understand the nature of

noise in fluid power systems, and some suggestions to help minimize it.

Noise is transmitted in fluid power systems in two ways: as fluid borne noise, and structure borne noise.

Fluid-borne noise (pressure ripple or pulsation) is created as pumping elements discharge oil into the

pump outlet. It is affected by the compressibility of the oil, and the pump's ability to transition pumping

Page 14

Technical Information

LPV Axial Piston Pumps

System design parameters

Sizing equations

elements from high to low pressure. Pulsations travel through the hydraulic lines at the speed of sound

(about 1400 m/s [4600 ft/sec] in oil) until there is a change (such as an elbow) in the line. Amplitude varies

with overall line length and position.

Structure-borne noise is transmitted wherever the pump casing connects to the rest of the system. The

way system components respond to excitation depends on their size, form, material, and mounting.

System lines and pump mounting can amplify pump noise. Follow these suggestions to help minimize

noise in your application:

Use flexible hoses.

•

Limit system line length.

•

If possible, optimize system line position to minimize noise.

•

If you must use steel plumbing, clamp the lines.

•

If you add additional support, use rubber mounts.

•

Test for resonants in the operating range, if possible avoid them.

•

Use these equations to help choose the right pump size and displacement for your application. An

evaluation of the machine system to determine the required motor speed and torque to perform the

necessary work function initiates the design process. Refer to Selection of drive line components,

BLN-9985, for a more complete description of hydrostatic drive line sizing. First select motor size to

transmit the maximum required torque. Then select pump as a flow source to achieve the maximum

motor speed.

Fluids

Ratings and performance data are based on operating with hydraulic fluids containing oxidation, rust

and foam inhibitors. These fluids must possess good thermal and hydrolytic stability to prevent wear,

erosion, and corrosion of pump components. Never mix hydraulic fluids of different types.

Fire resistant fluids are also suitable at modified operating conditions. Please see Hydraulic Fluids and

Lubricants Technical Information, BC152886484524, for more information. Refer to Experience with

14 | © Danfoss | April 2021 BC152886483590en-000301

Page 15

Technical Information

LPV Axial Piston Pumps

System design parameters

Filtration system

Biodegradable Hydraulic Fluids Technical Information, 520L0465, for information relating to

biodegradable fluids.

The following hydraulic fluids are suitable:

Hydraulic Oil ISO 11 158 - HM (Seal compatibility and vane pump wear resistance per DIN 51 524-2

•

must be met)

Hydraulic Oil ISO 11 158 - HV (Seal compatibility and vane pump wear resistance per DIN 51 524-3

•

must be met)

Hydraulic Oil DIN 51 524-2 - HLP• Hydraulic Oil DIN 51 524-3 - HVLP

•

Automatic Transmission Fluid (ATF) A Suffix A (GM)

•

Automatic transmission fluid Dexron II (GM), which meets Allison C-3 and Caterpillar TO-2 test

•

Automatic transmission fluid M2C33F and G (Ford)

•

Engine oils API classification SL, SJ (for gasoline engines) and CI-4, CH-4, CG-4, CF-4 and CF (for diesel

•

engines)

Super Tractor Oil Universal (STOU) special agricultural tractor fluid

•

To prevent premature wear, ensure only clean fluid enters the hydrostatic transmission circuit. Danfoss

reccommends a filter capable of controlling the fluid cleanliness to ISO 4406 class 22/18/13 (SAE J1165) or

better, under normal operating conditions.

Filtration strategies include suction or pressure filtration. The selection of a filter depends on a number of

factors including the contaminant ingression rate, the generation of contaminants in the system, the

required fluid cleanliness, and the desired maintenance interval. Select filters to meet the above

requirements using rating parameters of efficiency and capacity.

You can express measured filter efficiency with a Beta ratio1 (βX). For simple suction-filtered closed circuit

transmissions and open circuit transmissions with return line filtration, a filter with a β-ratio within the

range of β

circuits with cylinders being supplied from the same reservoir, we recommend a considerably higher

filter efficiency. This also applies to systems with gears or clutches using a common reservoir. These

systems typically require a charge pressure or return filtration system with a filter β-ratio in the range of

β

= 75 (β10 ≥ 10) or better.

15-20

Because each system is unique, only a thorough testing and evaluation program can fully validate the

filtration system. Please see Design Guidelines for Hydraulic Fluid Cleanliness Technical Information,

BC152886482150 for more information.

Ensure fluid entering pump is free of contaminants to prevent damage (including premature wear) to the

system. LPV pumps require system filtration capable of maintaining fluid cleanliness at ISO 4406-1999

class 22/18/13 or better.

Consider these factors when selecting a system filter:

Cleanliness specifications

•

Contaminant ingression rates

•

Flow capacity

•

Desired maintenance interval

•

= 75 (β10 ≥ 2) or better should be satisfactory. For some open circuit systems, and closed

35-45

Locate filter either on the inlet (suction filtration) or discharge (charge pressure filtration) side of the

charge pump. Either strategy is applicable for LPV pumps.

Charge filtration

The pressure filter is remotely mounted in the circuit after the charge pump, as shown in the

accompanying illustration.

1

Filter βx-ratio is a measure of filter efficiency defined by ISO 4572. It is defined as the ratio of the number of particles greater than a

given diameter (“x” in microns) upstream of the filter to the number of these particles downstream of the filter.

©

Danfoss | April 2021 BC152886483590en-000301 | 15

Page 16

Reservoir

Filter

with bypass

Charge

pump

Charge relief

valve

To pump case

To Low Pressure

side of loop

and ser vo contro l

Strainer

P106279

Reservoir

Filter

Charge

pump

Charge relief

valve

To pump case

To low pressure

side of loop

and ser vo contro l

Strainer

P106352

Technical Information

LPV Axial Piston Pumps

System design parameters

Filters used in charge pressure filtration circuits must be rated to at least 34.5 bar [500 psi] pressure.

Danfoss recommends locating a 100 - 125 µm screen in the reservoir or in the charge inlet line when

using charge pressure filtration.

A filter bypass valve is necessary to prevent damage to the system. In the event of high pressure drop

associated with a blocked filter or cold start-up conditions, fluid will bypass the filter. Avoid working with

an open bypass for an extended period. We recommend a visual or electrical bypass indicator. Proper

filter maintenance is mandatory.

Charge filtration

Suction filtration

The suction filter is placed in the circuit between the reservoir and the inlet to the charge pump as shown

in the accompanying illustration.

Suction filtration

16 | © Danfoss | April 2021 BC152886483590en-000301

Page 17

P106273

P106286

C

Technical Information

LPV Axial Piston Pumps

Operation

HPRV (High pressure relief valve)

LPV pumps are equipped with a combination high pressure relief and charge check valve. The highpressure relief function is a dissipative (with heat generation) pressure control valve for the purpose of

limiting excessive system pressures. The charge check function acts to replenish the low-pressure side of

the working loop with charge oil. Each side of the transmission loop has a dedicated HPRV valve that is

non-adjustable with a factory set pressure. When system pressure exceeds the factory setting of the

valve, oil is passed from the high pressure system loop, into the charge gallery, and into the low pressure

system loop via the charge check. The high pressure relief valve used on LPV is designed to remove

pressure spikes for short periods of time. Operating over the high pressure relief valve for extended

periods may damage the pump.

HPRV valve

Bypass function

The LPV contains a dedicated bypass valve. the bypass function is activated when the bypass valve is

mechanically backed out 3 full turns (maximum). The bypass function allows a machine or load to be

moved without rotating the pump shaft or prime mover.

Bypass valve

Excessive speed or extended movement will damage the pump and motor(s)

Avoid excessive speeds and extended load/vehicle movement. Do not move the load or vehicle more

than 20 % of maximum speed or for longer than 3 minutes. When the bypass function is no longer

needed, reseat the bypass valve to the normal operating position.

CPRV (Charge pressure relief valve)

An internal charge relief valve regulates charge pressure. The charge pump supplies pressure to maintain

a minimum pressure in the low side of the transmission loop.

Caution

©

Danfoss | April 2021 BC152886483590en-000301 | 17

Page 18

P106274

P106276

W

Technical Information

LPV Axial Piston Pumps

Operation

CPRV valve

Minimum charge pressure is the lowest pressure allowed to maintain a safe working condition in the

low side of the loop.

Maximum charge pressure is the highest charge pressure allowed which provides normal component

life. Elevated charge pressure can be used as a secondary means to reduce the swashplate response time.

The charge pressure setting listed in the order code is the set pressure of the charge relief valve with the

pump in neutral, operating with 5 gpm of charge flow. The charge pressure setting is referenced to case

pressure. Charge pressure is the differential pressure above case pressure.

LPV is designed for a maximum charge flow of 57 L/min [15 US gal/min].

Loop flushing valve

Neutral return mechanism

LPV pumps incorporate an optional integral loop flushing valve, which removes heat and contaminants

from the main loop.

LPV utilizes a special loop flushing spool design. On dual path systems, take special care to verify

acceptable performance.

Loop flushing valve

The neutral return mechanism mechanically returns the pump to zero displacement. A cam allows

precise zero displacement adjustment.

Maximum return force of the neutral return mechanism is 5.65 N•m [50 lbf•in]

Warning

Failure of the pump to return to neutral in the absence of control input will cause unintended

vehicle movement. Some control systems may require an additional neutral return mechanism to

overcome friction in the control linkage. Verify pump returns to neutral under all operating conditions

when the control is released.

18 | © Danfoss | April 2021 BC152886483590en-000301

Page 19

P106277

Adjusting screw

Lock/seal nut

Shaft

Swashplate

Neutral

return

arm

Adjusting cam

P106278

Technical Information

LPV Axial Piston Pumps

Operation

Neutral return adjustment screw

Neutral return mechanism

©

Danfoss | April 2021 BC152886483590en-000301 | 19

Page 20

Technical Information

LPV Axial Piston Pumps

Technical specifications

Specifications

General specifications

Design Axial piston pump of trunion swashplate design with variable displacement

Direction of rotation Clockwise, counter-clockwise

Port connections Main pressure ports: SAE straight thread O-ring boss

Recommended installation

position

Pump installation recommended with control position on the bottom or side.

Consult Danfoss for non conformance to these guidelines. The housing must always

be filled with hydraulic fluid.

Physical properties

Displacement

Feature Unit 25 30 35

Maximum displacement cm³ [in³] 25 [1.53] 30 [1.83] 35 [2.14]

Flow at rated speed (theoretical) l/min

[US gal/min]

Input torque at maximum displacement

(theoretical)

Mass moment of inertia of internal rotating

components

Weight kg [lb] 23 [51]

Rotation Clockwise, counter-clockwise

Mounting SAE B 2 bolt

Auxiliary mounting SAE J744 A 9T, SPCL 11T

System ports (type) 1 1/16-12 UNF-2B ORB

System ports (location) Twin radial

Control types Direct displacement control

Shafts Splined SAE 13 tooth, 15 tooth

Case drain ports 1 1/16-12 SAE ORB

N•m/ bar

[lbf•in/1000 psi]

kg•m²

[slug•ft²]

85.2

[22.5]

0.4

[244]

0.001670

[0.0012]

104.9

[27.7]

0.5

[291]

0.001580

[0.00120]

137.0

[36.2]

0.6

[340]

0.001530

[0.0011]

Operating parameters

Displacement

Rating Units 25 30 35

Input speed

Pressure maximum working bar [psi] 400 [5800] 350 [5075] 300 [4350]

External shaft loads External moment (Me) N•m [lbf•in] 7.7 [68]

Bearing life (max.

swashplate angle

and max.

continuous speed)

Charge pressure minimum bar [psi] 6 [87]

2

minimum min-1 (rpm) 500 500 500

continuous 3400 3500 3600

maximum 3950 4150 4300

maximum 415 [6020] 400 [5800] 350 [5075]

Thrust in (Tin), out (Tout) N [lbf] 750 [169]

at 210 bar [3045 psi] B10 hours 120,000 63,000 37,000

maximum 30 [435]

20 | © Danfoss | April 2021 BC152886483590en-000301

Page 21

Technical Information

LPV Axial Piston Pumps

Technical specifications

Operating parameters (continued)

Displacement

Rating Units 25 30 35

Case pressure rated bar [psi] 2 [29]

maximum 6 [87]

Sound levels

dB(A) 100 bar [1450 psi] 200 bar [2900 psi] 300 bar [4350 psi]

Displ. cm³ [in³] 1000 min-1(rpm) 1000 min-1(rpm) 1000 min-1(rpm)

25 [1.53] 62 66 68

35 [2.14] 61 66 69

dB(A) 100 bar [1450 psi] 200 bar [2900 psi] 300 bar [4350 psi]

Displ. cm³ [in³] 3000 min-1(rpm) 3000 min-1(rpm) 3000 min-1(rpm)

25 [1.53] 70 74 76

35 [2.14] 71 75 80

1

Sound data was collected per ISO 4412-1 in a semi-anechoic chamber. Values have been adjusted (-3 dB)

1

to reflect anechoic levels.

Fluid specifications

Feature Unit Displacement cm³ [in³]

25 [1.53], 30 [1.83], 35 [2.14]

Viscosity Minimum mm2/sec

Recommended range 12-60 [66-278]

Maximum 1600 [7500]

Temperature

2

Range

Filtration Cleanliness per ISO 4406 22/18/13

Minimum °C [°F] -40 [-40]

Rated 82 [180]

Maximum intermittent 100 [212]

Efficiency (charge pressure

filtration)

Efficiency (suction filtration) β

Recommended inlet screen

mesh size

[SUS]

β-ratio β

μm 100 - 125

7 [47]

= 75 (β10≥ 10)

15-20

= 75 (β10≥ 2)

35-45

2

At the hottest point, normally case drain port.

Mounting flange - allowable overhung parameters

Continuous load moment (Mc) Shock load moment (Ms)

N•m [lbf•in] N•m [lbf•in]

361 [3200] 617 [5470]

©

Danfoss | April 2021 BC152886483590en-000301 | 21

Page 22

Technical Information

LPV Axial Piston Pumps

Technical specifications

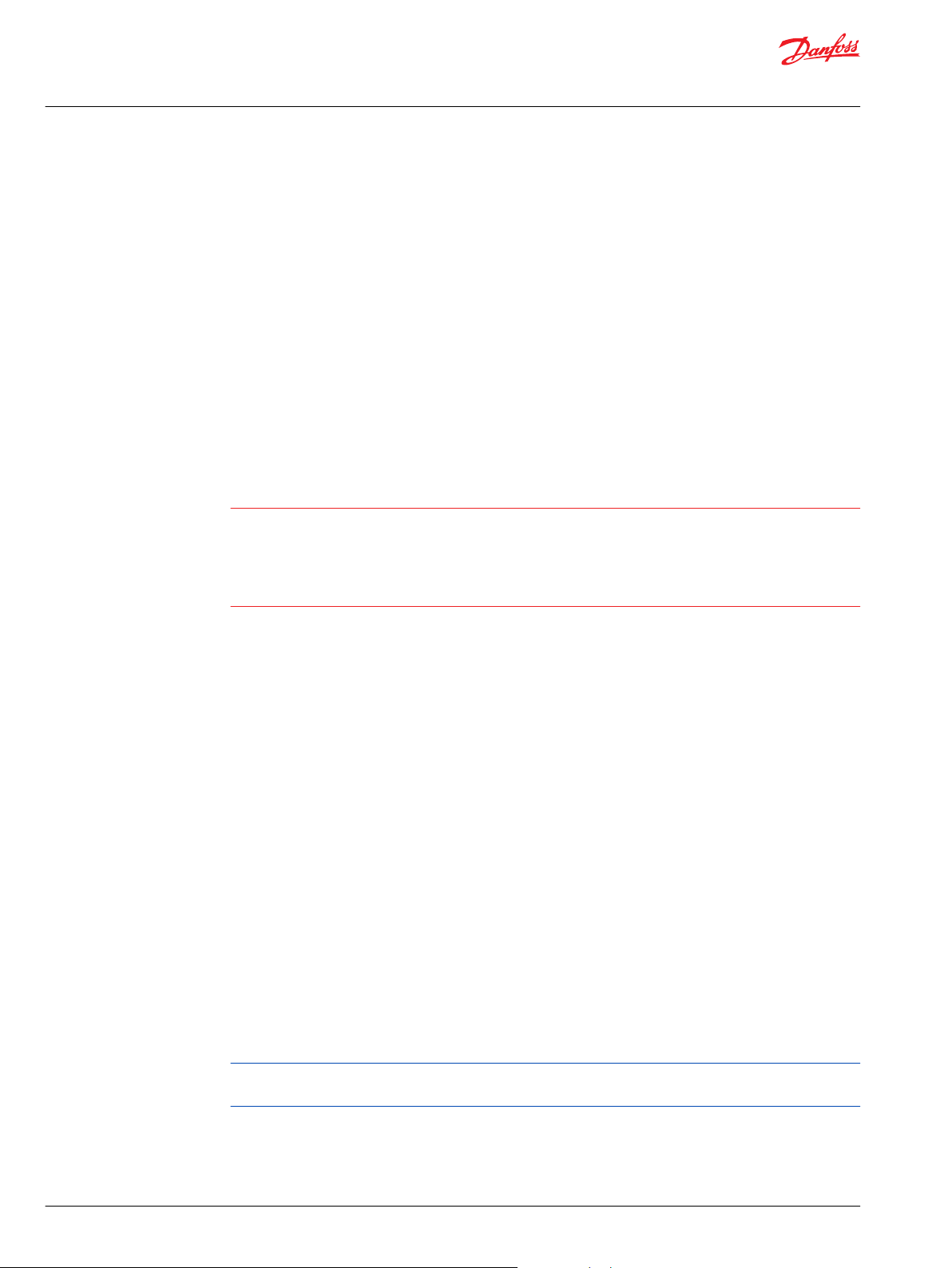

Mounting flange - G-factors for sample applications

Application Continuous (vibratory)

acceleration (Gc)

Skid steer loader 6 10

Trencher

(rubber tires)

Asphalt paver 6 6

Windrower 6 5

Aerial lift 6 4

Turf care vehicle 6 4

Vibratory roller 6 10

6 8

Maximum (shock) acceleration

(Gs)

Applications experiencing extreme resonant vibrations may require additional pump support. Refer to

System design parameters on page 10 for information concerning mounting flange loads.

22 | © Danfoss | April 2021 BC152886483590en-000301

Page 23

Swashplate Group

Seal Group

Input Shaft

Rotation, Kit, & Valveplate

Charge Pump

Charge Pressure

Neutral Assist

Bypass Valve

Control Handle

Auxiliary Mounting Flange

C D E F G H K L P S

L P V

■ ■ ■ ■ ■ □ □ □ □ □

□□

□□□

□□□

Special Features

(Non Hardware)

System Pressure

Protection

Special Hardware

Control Orifice

Z

Product

□□

Control Orientation & Type

□□

□□□

N

J

Endcap, Loop Flush,

& Aux Pad

MRT

Technical Information

LPV Axial Piston Pumps

Product coding

LPV Model Code

Product

Code Description

LPV LPV variable displacement pump

C Swashplate Group

Code Description

A Right hand swashplate

C Left hand swashplate

D Seal Group

Code Description

A Standard shaft seal

E Input Shaft Configuration

Code Description

A 13 Tooth splined 16/32 pitch

B 15 Tooth splined 16/32 pitch

C 20 Tooth splined 24/48 pitch

D Round straight key Dia. 22.2mm (key not supplied)

F Rotating kit, rotation and valveplate

Code Displacement

A CW rotation 25 cm³/rev [1.50 in³/rev]

B CW rotation 30 cm³/rev [1.83 in³/rev]

C CW rotation 35 cm³/rev [2.14 in³/rev]

D CCW rotation 25 cm³/rev [1.50 in³/rev]

E CCW rotation 30 cm³/rev [1.83 in³/rev]

F CCW rotation 035 cm³/rev [2.14 in³/rev]

J CW rotation 25 cm³/rev [1.50 in³/rev] low leakage

K CW rotation 30 cm³/rev [1.83 in³/rev] low leakage

L CW rotation 35 cm³/rev [2.14 in³/rev] low leakage

G Charge Pump Displacement

Code Description

A None

©

Danfoss | April 2021 BC152886483590en-000301 | 23

Page 24

Technical Information

LPV Axial Piston Pumps

Product coding

H Charge Pressure Relief Valve Setting

Code Description

C 9.0 bar [130 psi]

E 11.0 bar [160 psi]

G 14.0 bar [200 psi]

I 18.0 bar [260 psi]

K 23.0 bar [335 psi]

J End Cap and Loop Flushing

Code Description

AA High loop flushing, 7.6 l/min [2 US gal/min] at 260 psid charge, RH control, SAE A flange 0

Deg.

AB Low loop flushing, 3.8 l/min [1 US gal/min] at 260 psid charge, RH control, SAE A flange 0

Deg.

AC No loop flushing, RH control, SAE A flange 0 Deg.

DA High loop flushing, 7.6 l/min [2 US gal/min] at 260 psid charge, RH control, SAE A flange 90

Deg.

DB Low loop flushing, 3.8 l/min [1 US gal/min] at 260 psid charge, RH control, SAE A flange 90

Deg.

DC No loop flushing, RH control, SAE A flange 90 Deg.

EC No loop flushing, RH control, SAE B flange 0 Deg.

FA High loop flushing, 7.6 l/min [2 US gal/min] at 260 psid charge, single side only, SAE A

flange 90 Deg.

K Neutral Return

Code Description

C Neutral assist, standard

D Neutral assist, high force

L Bypass Valve

Code Description

A Bypass valve

M System Pressure Protection

Code Description

AAA None/none

BBB 175 bar [2540 psi]/175 bar [2540 psi]

BCC 190 bar [2755 psi]/190 bar [2755 psi]

BDD 210 bar [3045 psi]/210 bar [3045 psi]

BEE 230 bar [3325 psi]/230 bar [3325 psi]

BFF 250 bar [3625 psi]/250 bar [3625 psi]

BGG 280 bar [4060 psi]/ 280 bar [4060 psi]

BHH 300 bar [4350 psi]/300 bar [4350 psi]

BJJ 345 bar [5000 psi]/345 bar [5000 psi]

BMM 140 bar [2030 psi]/ 140 bar [2030 psi]

BRR 325 bar [4712 psi]/ 325 bar [4712 psi]

24 | © Danfoss | April 2021 BC152886483590en-000301

Page 25

Technical Information

LPV Axial Piston Pumps

Product coding

N Control Type and Orientation

Code Description

DR Direct displacement control, right side

DL Direct displacement control, left side

P Control

Code Description

A DDC

R Control Orifice Diameter

Code Description

FF N/A

S Housing and Auxiliary Mounting

Code Description

A SAE A, 11T spline, running cover

B SAE A, 9T spline, running cover

E SAE B, 13T spline, running cover

N SAE A, none, running cover

T Special Hardware Features

Code Description

NNN None

ZZ Special Features (non hardware)

Code Description

*** None

©

Danfoss | April 2021 BC152886483590en-000301 | 25

Page 26

20.637 [0.8125] pitch diameter

30° pressure angle

13 teeth

16/32 pitch

fillet root side fit

P106283

41.2 ± 0.8

[1.622 ± 0.03]

15.2 ± 0.09

[0.5984 ± 0.0035]

7.9 ± 0.8

[0.31 ± 0.03]

20.622 [0.8119] pitch diameter

30° pressure angle

15 teeth

16/32 pith

fillet root side fit

P106284

41.2 ± 0.8

[1.62 ± 0.03]

18.5 ± 0.09

[0.7283 ± 0.0035]

7.9 ± 0.8

[0.31 ± 0.03]

Technical Information

LPV Axial Piston Pumps

Features and options

Controls

Direct displacement control

The LPV pump features Direct Displacement Control (DDC). The swashplate angle is set directly by a

control lever or linkage attached directly to the swashplate trunion. Control lever movement changes the

displacement and flow direction of the pump by increasing or decreasing the swashplate angle.

The control input shaft is on the right hand side of the pump. Contact your Danfoss representative for

availability of left side control input.

Features and benefits

Simple, low cost design

•

Pump output is maintained regardless of load.

•

Pump will return to neutral if control input is removed (if equipped with optional neutral return

•

mechanism)

Control handle requirements

Maximum allowable trunnion torque is 79.1 N•m [700 lbf•in]. Minimum available centering moment is 5.7

N•m [50 lbf•in]. The actual value will vary due to the influence of pump operating conditions. Maximum

swashplate angle is ±18°. For mating dimensions, see Installation drawings on page 29.

Input shafts

Shaft data

Code Description Maximum torque

N•m [lbf•in]

A 13 tooth spline

16/32 pitch

(ANSI B92.1 1966 - Class 6e)

B 15 tooth spline

16/32 pitch

(ANSI B92.1 1966 - Class 6e)

226 [2000]

362 [3200]

Drawing

26 | © Danfoss | April 2021 BC152886483590en-000301

Page 27

P108847

6.9 Max.

[0.27]

21.166 [0.8333] pitch diameter

30° pressure angle

20 teeth

24/48 pitch

fillet root side fit

48.6 Max.

[1.91]

22.48 ± 0.5

[0.89 ± 0.02]

41.9 [1.65] Max.

18.58 ± 0.1

[0.731 ± 0.005]

6.9 [0.27]

Max.

22.225

+0.03

0

[0.875 ]

+0.001

0

6.35

+0.05

0

[0.250 ]

+0.002

0

8.175 ± 0.325

[0.322 ± 0.013]

+0.05

0

19

[0.750 ]

+0.0180

0

9 tooth coupling

SAE-A 9T

16.47

[0.65]

P106322

11 tooth coupling

SAE-A SPCL 11T

31.8

[1.25]

19.77

[0.78]

13.5 [0.531]

minimum tooth

engagement

15 [0.590]

minimum tooth

engagement

31.8

[1.25]

88.62

[3.49]

82.6

[3.25]

1.96

[0.08]

O-ring seal required

82.22 [3.237] I.D. x

2.62 [0.103] dia. cross section

O-ring seal required

82.22 [3.237] I.D. x

2.62 [0.103] dia. cross section

82.6

[3.25]

88.62

[3.49]

1.96

[0.08]

*

* dimension is short of standard dimension

13 tooth coupling

ANSI B92.1B Class 7E

44.73 [1.761]

20.1 [0.792]

1.96 [0.77]

Ø107.82 [4.245]

Ø101.65 [4.002]

Technical Information

LPV Axial Piston Pumps

Features and options

Shaft data (continued)

Code Description Maximum torque

N•m [lbf•in]

C

20 tooth spline

24/48 pitch

(ANSI B92.1 1966 - Class 6e)

241 [2133]

Drawing

See Input shaft torque rating and spline lubrication on page 13 for an explanation of maximum torque.

Auxiliary mounting pads

Dimensions

©

D

Straight key

226 [2000]

22.2 mm [0874 in]

(ANSI B92.1 1966 - Class 6e)

SAE-A Auxiliary mounting

Danfoss | April 2021 BC152886483590en-000301 | 27

Page 28

mm

[in]

D

max

.

E

max.

Mounting

flange (ref.)

Undercut

spline

Sled-runner

spline

A Ø 82.55

[3.250]

R 0.8 [0.03] max.

B

max.

C

max.

Coupling

Recommended

cutter clearance

2.3 [0.090]

P101079

Technical Information

LPV Axial Piston Pumps

Features and options

Dimensions in mm [in]

The auxiliary pad operates under case pressure. Use an O-ring to seal the auxiliary pump mounting flange

to the pad.

The combination of auxiliary shaft torque and main pump torque must not exceed the maximum pump

input shaft rating. The table in Input shafts on page 26, gives input shaft torque ratings for each frame

size.

Mating pump specifications

Dimensions

Measurement SAE A (9T) or (11T)

units mm [in]

A 82.55

[3.250]

B 6.35

[0.250]

C 17.78

[0.700]

D* 31.75

[1.250]

E 17.78

[0.700]

* The 11 tooth auxiliary pad option requires a special short shaft on the mating pump due to reduced

clearance to the LPV pump shaft.

28 | © Danfoss | April 2021 BC152886483590en-000301

Page 29

182.9

[7.20]

1 1/16 -12

SAE straight thread

O-ring boss

case drain

2X 3/8 -16

UNC-2B THD

72.7

[2.86]

128.8

[5.07]

7/8 -14

SAE straight thread

O-ring boss

charge inlet

Charge pressure

relief valve

39.2

[1.54]

2X 58.9

[2.32]

94.3

[3.71]

125

[4.92]

182.9

[7.20]

246.3

[9.70]

92.1

[3.63]

18°

Max.

Displ.

18°

Max.

Displ.

F1

R1

111.1

[4.37]

82.6

[3.25]

128.8

[5.07]

2X 35.1

[1.38]

1 1/16 -12

SAE straight thread

O-ring boss

system port A

1 1/16 -12

SAE straight thread

O-ring boss

system port B

1 1/16 -12

SAE straight thread

O-ring boss

case drain (alternate)

Loop flushing valve

location

HPRV valve

P106281

Trunion

19.84 dia.

[0.781]

45°

15.82 [0.623]

(2) Places

CONTROL TRUNNION DETAIL

2X 3/8 -16 x 1

UNC THD

(hole is 20 mm deep)

Technical Information

LPV Axial Piston Pumps

Installation drawings

LPV Installation drawings

©

Danfoss | April 2021 BC152886483590en-000301 | 29

Page 30

2X 73

[2.87]

CW

P106281

CCW

HPRV valve

Bypass valve

Loop flushing valve

2X Ø14.3

+0.25

-0.12

[0.563

+0.010

-0.005

]

L1

L2

Charge pressure

inlet

Port A

Port B

P106270

Technical Information

LPV Axial Piston Pumps

Installation drawings

Shaft rotation

CW CCW

Handle angle F1 R1 R1 F1

Port flow A out in in out

B in out out in

LPV Schematic

30 | © Danfoss | April 2021 BC152886483590en-000301

Page 31

Danfoss

Power Solutions GmbH & Co. OHG

Krokamp 35

D-24539 Neumünster, Germany

Phone: +49 4321 871 0

Danfoss

Power Solutions ApS

Nordborgvej 81

DK-6430 Nordborg, Denmark

Phone: +45 7488 2222

Danfoss

Power Solutions (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239 6000

Danfoss

Power Solutions Trading

(Shanghai) Co., Ltd.

Building #22, No. 1000 Jin Hai Rd

Jin Qiao, Pudong New District

Shanghai, China 201206

Phone: +86 21 2080 6201

Products we offer:

Hydro-Gear

www.hydro-gear.com

Daikin-Sauer-Danfoss

www.daikin-sauer-danfoss.com

Cartridge valves

•

DCV directional control

•

valves

Electric converters

•

Electric machines

•

Electric motors

•

Gear motors

•

Gear pumps

•

Hydraulic integrated

•

circuits (HICs)

Hydrostatic motors

•

Hydrostatic pumps

•

Orbital motors

•

PLUS+1® controllers

•

PLUS+1® displays

•

PLUS+1® joysticks and

•

pedals

PLUS+1® operator

•

interfaces

PLUS+1® sensors

•

PLUS+1® software

•

PLUS+1® software services,

•

support and training

Position controls and

•

sensors

PVG proportional valves

•

Steering components and

•

systems

Telematics

•

Danfoss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and

electric components. We specialize in providing state-of-the-art technology and solutions

that excel in the harsh operating conditions of the mobile off-highway market as well as the

marine sector. Building on our extensive applications expertise, we work closely with you to

ensure exceptional performance for a broad range of applications. We help you and other

customers around the world speed up system development, reduce costs and bring vehicles

and vessels to market faster.

Danfoss Power Solutions – your strongest partner in mobile hydraulics and mobile

electrification.

Go to www.danfoss.com for further product information.

We offer you expert worldwide support for ensuring the best possible solutions for

outstanding performance. And with an extensive network of Global Service Partners, we also

provide you with comprehensive global service for all of our components.

Local address:

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without subsequent changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

©

Danfoss | April 2021 BC152886483590en-000301

Loading...

Loading...