Page 1

Application Guide

Low pressure lift ejector system

Multi Ejector solution incl. Multi Ejector Low

Pressure (LP 935/1435/1935) and AK-PC 782A

Page 2

Application Guide | Low pressure lift ejector system

Contents 1. General description ..........................................................................................................................................................3

1.1 System design with Low Pressure lift ejector ..............................................................................................3

1.2 Example system load ...........................................................................................................................................4

MT (Medium Temperature) evaporators load 50 kW ................................................................................4

LT (Low Temperature) evaporators load 10 kW ..........................................................................................4

1.3 Overall control strategy and objectives ........................................................................................................5

2. Configuration PC782A .....................................................................................................................................................5

2.1 Select plant type ....................................................................................................................................................5

2.2 Suction group MT (Capacity control) .............................................................................................................6

2.3 HP control .................................................................................................................................................................7

2.4 Condenser fan control .........................................................................................................................................7

2.5 Receiver control .....................................................................................................................................................8

2.6 IO configuration .....................................................................................................................................................9

3. What is an ejector, and how does it work? ..........................................................................................................10

3.1 Danfoss Multi Ejector design ..........................................................................................................................10

3.2 Multi Ejector Capacity Control ....................................................................................................................... 11

3.3 How does the Multi Ejector solution work? .............................................................................................. 11

4. Coolselector®2 Selecting components ................................................................................................................. 12

4.1 LP ejector selection ............................................................................................................................................ 12

4.2 GBV, Gas By-Pass #1 valve selection ............................................................................................................ 13

4.3 Check valve selection ........................................................................................................................................14

4.4 Evaporator EEV selection ................................................................................................................................. 15

5. Multi Ejector Solution™ ................................................................................................................................................ 16

2 | AB322920563002en-000103 © Danfoss | DCS (vt) | 2020.08

Page 3

Application Guide | Low pressure lift ejector system

1. General description

1.1 System design with Low

Pressure lift ejector

Low pressure lift ejector systems are simpler

systems than high-pressure ejector systems,

because they do not need the parallel

compressor in order to work and give an energy

saving (see diagram on next page). In winter

time, the system works like a normal booster

system where the gas bypass valve controls the

receiver pressure with set pressure differential,

and the evaporation pressure is controlled by

adjusting the compressor capacity according to

the needed MT evaporators’ suction pressure.

The LP ejector can be considered as an add-on

to the standard system, however there are some

additional components, and a different control

strategy needs to be applied.

Below are the most important points to take

into account when designing such a system (see

diagrams on page 4):

Setpoints and operational modes

As described, an LP ejector system can operate

with two different modes: the standard mode in

low ambient temperatures and the ejector mode

in high temperatures. How it changes from one

mode to the other and the setpoint and signals

required for this are listed below:

• In the winter condition, the ejector is working

as a high-pressure valve and is not providing

any or not enough suction mass flow to put

the system into ejector operation. The system

is performing as a standard system, but with

receiver pressure controlled with a pressure

differential of 3 bar between the pressure

in the receiver (P-rec) and the common MT

evaporators’ suction line. The pressure signal

is coming from the sensor located before the

check valve (Po-MT). The pressure in the gas

cooler is controlled based on the refrigerant

outlet temperature (Sgc) and the optimum COP

algorithm.

• Ambient temperatures of 17 – 18 °C result in

24 – 25 °C out of the gas cooler measured by

the temperature sensor Sgc, corresponding

to gas cooler pressure 64 to 66 bar(a). At

ambient temperatures of 17 – 18 °C there is

enough expansion work in the system for the

LP ejector to take all the mass flow from the

MT evaporators and lift it to the receiver. Since

the gas bypass valve is controlled on the basis

of pressure difference between the receiver

and MT evaporator pressure, and not fixed

pressure, the valve will start to open more and

more. Setpoint for the valve would typically be

3 bar difference and if the ejector can provide

a higher lift, the gas bypass valve will be 100%

open.

Components

The system requires some additional

components. Additionally the design criteria for

some components are different:

• Gas Bypass Valves: It will be challenging

to have one valve fulfilling good control in

both Standard and Ejector mode. In the first

mode there is limited amount of gas released

to suction MT compressors with a constant

pressure difference of 3 bar, while in the second

At 23 – 25 °C out of the gas cooler, the ejector

starts to pump all gas from the MT evaporators

and lift to the receiver with a pressure lift of

approximately 3 bar. The consequence of this is

a better COP of the system. The higher suction

pressure will also result in higher mass flow in the

same compressor and thereby a first cost saving

due to a smaller installed capacity. The first cost

saving can be as much as 30% at high ambient

temperatures and 15% energy saving compared

to a booster system.

one (LP ejector mode) there is a large amount

of gas with a minimum possible pressure

drop; our solution is with 2 x Gas Bypass Valves

(GBV). GBV #1 is a standard one and works in

all conditions, and GBV #2 mounted in parallel

with big KV value operating when the system

turns into LP Ejector mode. The idea is to have

as little as possible pressure drop across the two

GBVs, as this pressure drop will count as loss to

the LP ejector’s recovered work.

• Another option is to use a 2-way ball valve

motor mounted in parallel to GBV #1 which

can give even better system performance as

the pressure drop in the gas bypass line will be

minimal.

• Pressure sensors: The reference sensor for

controlling MT compressors should be mounted

on the common MT evaporators’ suction line

“Po_MT”, before the check valve. In systems

with MT and LT evaporators it can happen

that the MT evaporator load drops below the

minimum MT compressor capacity which will

lead to pump down situation and possible

turning off of the MT compressors. On the other

hand, LT evaporators can have a load and LT

compressors will run. To protect LT compressors’

from high pressure cut-out, a new Psuc_MT

sensor is introduced. If the pressure exceeds

the set offset pressure, the Psuc_MT will

become reference sensor for controlling the MT

compressors.

• Electronic Expansion Valves and evaporators:

The LP ejector pressure lift is relatively low.

Therefore, the system needs to be designed

accordingly, and the EEV (Electronic Expansion

Valve) for MT evaporators should be selected

according to the system requirements and

limitation. The pressure losses in evaporator

and distributors should be investigated and

designed to be a portion of the minimum

pressure lift that the ejector can provide (3

bar). Larger evaporators and distributors

may provide too high pressure loss for the LP

system. If the losses in the evaporator are high,

then it should be ensured that the system

will operate with high pressure in the gas

cooler to provide adequate pressure lift. That

can either occur when there is high ambient

temperature or when Heat Recovery is activated

in the system. The pressure losses should be

considered in the selection of the EEV

• Compressors: Compressor selection is made

using the receiver pressure at the highest

ambient temperature (design condition). This is

© Danfoss | DCS (vt) | 2020.08 AB322920563002en-000103 | 3

Page 4

80G425

80G424

80G426

160.0

Pressure bar(a)

Enthalpy kJ/kg

Danfoss

80G427

5.0

10.0

20.0

40.0

80.0

160.0

150.0250.0 350.0450.0 550.0

Pressure bar(a)

Enthalpy kJ/kg

Application Guide | Low pressure lift ejector system

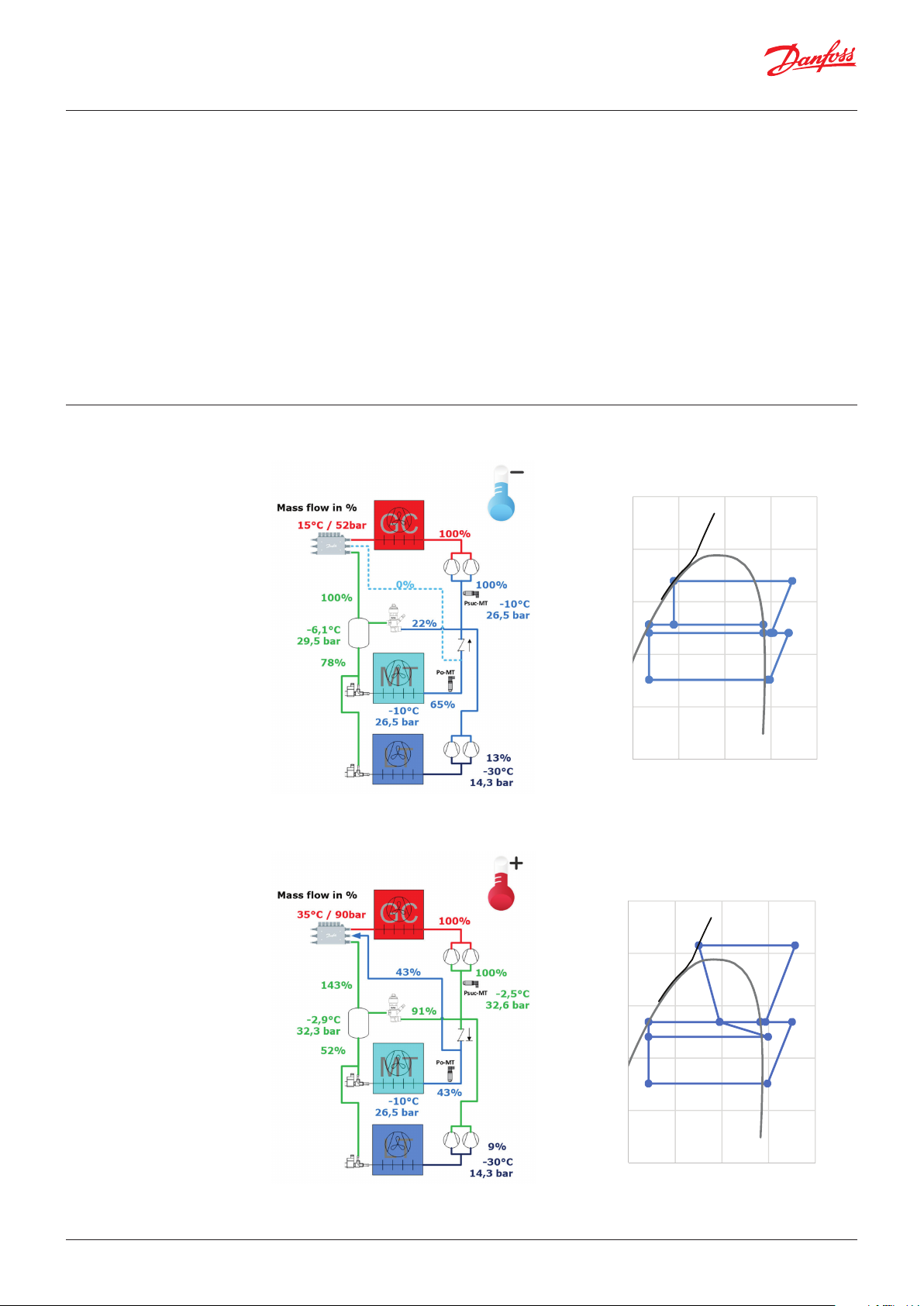

1.2 Example system load

typically 6 – 7.5 bar higher than the evaporation

pressure and will yield smaller compressors

typically 20 – 30%, resulting in reduction of the

first cost of the system. The small compressor

steps in the system can be useful in the part

load situation during the cold periods.

Oil management

In booster/winter mode, the system has a safe

oil return, but when the system is in Ejector

mode, the oil will end in the receiver and will

stay there if no action is taken on it. There are

many ways to recover the oil and get it back to

the compressor. If the oil separator has a low

efficiency, the oil problem will be bigger. Part of a

safe oil return can be the LT compressors. The LT

compressors receive an oil-rich gas mixture from

MT (Medium Temperature) evaporators load 50 kW

LT (Low Temperature) evaporators load 10 kW

Danfoss

the LT evaporators. The oil is passed through the

LT compressors and can be transferred to the MT

compressors as LT discharge is connected directly

to the MT compressor suction. However, as the LT

evaporators’ load varies during the year, sufficient

oil return cannot be expected. That depends on

the load ratio between the MT and LT compressor

capacity, the oil quantity in the system and the

efficiency of the oil separator.

To be certain, an oil recovery system is needed.

By using the second pressure differential

reference “DeltaP High” and a low oil level sensor

mounted on the oil receiver, the system can

be changed from LP Ejector mode to Standard

mode. This ensures that oil will return to the MT

compressors.

Danfoss

80.0

Pressure in receiver controlled by pressure differential.

Parameter DeltaP low = 3 bar

40.0

20.0

10.0

5.0

150.0250.0 350.0450.0 550.0

Danfoss

4 | AB322920563002en-000103 © Danfoss | DCS (vt) | 2020.08

Pressure in receiver result of LP ejector lift > 3 bar

Page 5

Application Guide | Low pressure lift ejector system

1.3 Overall control strategy

and objectives

2. Configuration PC782A

The overall control objective is to maintain a

sufficiently low pressure difference between

the receiver pressure (Prec) and the evaporation

pressure (Po-MT) in order for the LP-ejector to lift

the total refrigerant flow from the refrigerated

cabinets up the receiver pressure level. The

designated MT-compressor will in this case

compress the gas (vapor) refrigerant directly from

the receiver. The pressure difference between

the sensors Prec and Po-MT, should however be

large enough for the injection valves to supply

the required refrigerant flow to the refrigerated

cabinets. If the motive energy for the ejector is

not big enough to perform the required pressure

lift, the check valve will open and the MT

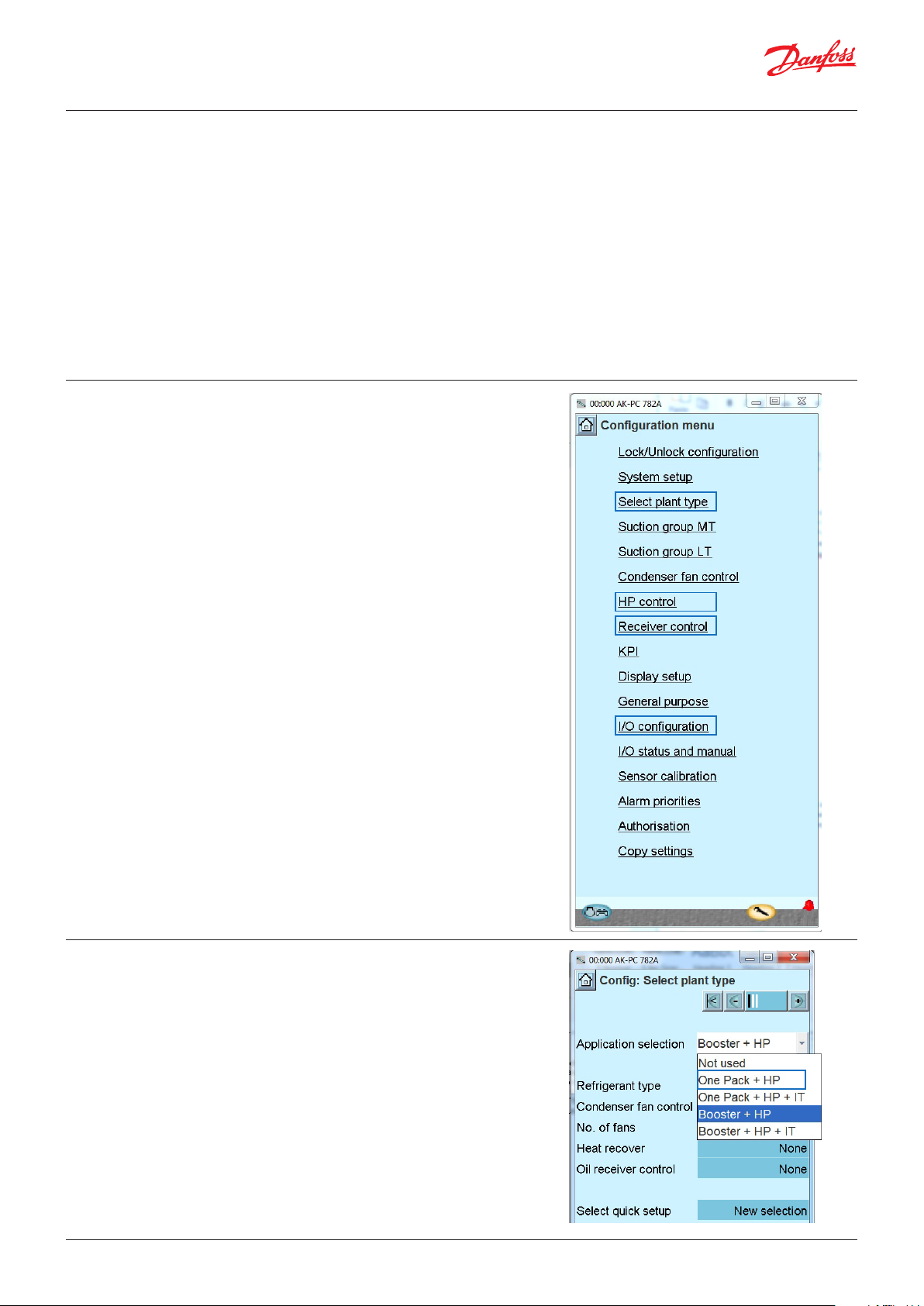

In the PC782A, the LP-system is not considered as

a dedicated “Plant type” but rather a special case

of a booster system (without IT compressor). This

means that in order to support the LP-ejector

system, a number of configurations need to be

made in respectively: ”Select Plant Type”, “Suction

Group MT”, “HP-control”, “Receiver control” and

“I/O configuration”.

compressor will take the refrigerant flow directly

from the refrigerated cabinets (instead of the

ejector).

Note that in LP ejector mode, the check valve

restricts the flow direction from the compressor

suction port (Psuc-MT) towards the MT

evaporator outlet (Po-MT). This means that if the

suction pressure (Psuc-MT) increases, it cannot

be detected in the Po-MT measurement. It is

therefore important to device a control strategy

that keeps Psuc_MT in control as well.

In the section below the control strategy and

configuration of the PC782A to support the LPejector application will be described.

2.1 Select plant type

© Danfoss | DCS (vt) | 2020.08 AB322920563002en-000103 | 5

The LP-ejector system is considered a Booster/

One pack system without any IT compressors,

therefore it is only possible to configure the Delta

P control of the receiver from these plant type

selections: "One Pack + HP" and "Booster + HP".

Page 6

80G428

Application Guide | Low pressure lift ejector system

2.2 Suction group MT

(Capacity control)

The control objective for the compressor capacity

control is to maintain a given reference for the

evaporation pressure (measured with the PoMT sensor as indicated in the drawing to the

right) by adjusting the MT compressor capacity.

Meanwhile it should be ensured that the suction

pressure (measured by Psuc-MT) is limited.

The check valve ensures that the flow can

only go from the location of the Po-MT sensor

towards the Psuc-MT sensor and not reverse. This

efficiently means that:

Psuc-MT ≥ Po-MT

Control sensors

Choosing Po-MT as the control sensor ensures

that the evaporation pressure is controlled

as desired, however this leaves Psuc-MT

uncontrolled which means that it will not be

protected against high pressure. This can lead

to dangerous situations especially in situations

where the LT compressors are starting, and the

MT compressors are at a standstill. As the LT

discharge port is connected to the MT comp.

suction port, it is not detected by the Po-MT

sensor if the LT starts and the Psuc-MT increases.

Hence, Po-MT and Psuc-MT are both used as

control sensors in such a way that the one with

the “most critical” reading is used as input for the

MT compressor capacity control.

The “most critical” sensor value is determined

in the following way: The maximum expected

pressure lift that the LP-ejector is capable of is

P_max=8 bar (“Psuc max offset”), so this will

also be the maximum pressure difference that

should be expected/allowed between Psuc-MT

and Po-MT under normal operation.

Danfoss

This means that the capacity control has two

objectives:

1. Keep Po-MT close to the Po-MT reference (“ToMT reference”)

2. Keep Psuc-MT close to the Psuc-MT reference

(“Tsuc reference”), where

Psuc reference=Po-MT reference+Psuc max offset

The decision of which is “most critical” is simply

determined by which of the two controller

objectives that has the largest control error.

Under the suction group for the MT, the selection

of running with two control sensors, Po and

Psuc, is made. By selecting “Po-MT + Psuc-MT”

as control sensor, the capacity control and the

receiver control are prepared for the DeltaP

control intended for the LP-ejectors. With this

selection, the setting of “Psuc max offset” appears

below - the default value is 8 bar.

6 | AB322920563002en-000103 © Danfoss | DCS (vt) | 2020.08

Page 7

80G429

Application Guide | Low pressure lift ejector system

2.3 HP control

2.4 Condenser fan control

As for all the Multi Ejector types the LP-ejector

is used as actuator for controlling the gas

cooler pressure. This means that the individual

ejector step will be coupled in and out in order

to maintain the optimal gas cooler pressure

(Pgc,ref) according to ambient temperature (Sc3)

and temperature reference out of gas cooler (Sgc,

ref).

The set-up is the same as for a booster system.

Note the Pgc,ref is determined based on Sgc,ref,

which is again determined based on Sc3

(ambient temperature). In case the measured Sgc

drifts more than 2K above the Sgc,ref, the Pgc,ref

will follow the measured Sgc instead of the Sgc,

ref.

Danfoss

© Danfoss | DCS (vt) | 2020.08 AB322920563002en-000103 | 7

Page 8

Application Guide | Low pressure lift ejector system

2.5 Receiver control

The receiver pressure is controlled using the

gas bypass valve (GBV). One or two valves in

sequential control mode might be used mainly to

ensure low pressure drop across the GBV in the

ejector mode where the MT compressor sucks

directly from the receiver through the GBV.

The receiver pressure is controlled with a fixed

“Delta P Low”(default 5 bar, but in a real system

preferably 3 bar) over the expansion valves and

MT evaporators.

Prec reference = Po-MT reference + Delta P low

Note that reference calculation for the receiver

is based on the reference of “Po-MT” and not

the measured value, meaning that the “Prec

reference” will remain constant irrespectively of

the actual value of Po-MT. This avoids the risk of

Prec getting pulled down into the neutral zone of

the MT compressors, e.g. during a pump down,

which would lead to a critical deadlock situation

where no cooling is provided.

By setting the control sensor to “Po-MT +

Psuc-MT” the receiver is prepared for Delta P

control. In the receiver two predefined Delta P

references “Delta P low” and “Delta P high” are

configured. It is possible to switch between the

two references by activating a digital input (DI).

“Delta P High enable” is now visible under the I/O

configuration.

Oil return

In the ejector mode, oil will accumulate in the

receiver and not return to the MT compressors.

Therefore, a special oil return strategy must be

devised. An oil-return cycle must be executed

when the low oil level switch in the oil receiver

indicates critical oil level. Oil-return strategy

efficiently means shifting to standard mode. This

can be done by increasing the receiver pressure

to a level where the LP-ejector cannot lift (to the

“Delta P high” setpoint). This means that GBV

will start closing and the check valve will open,

allowing the oil to return to the MT compressor

from the evaporator outlet.

Vrec output type

In winter mode, the GBV#1 secures that the

receiver pressure is maintained around the

requested setpoint. In the LP ejector mode

it will not be possible for the GBV#1 to keep

the receiver pressure at or below its reference

though the valve/valves are fully open. This is

because the LP-ejector in this scenario can lift

the total evaporated flow of refrigerant out of

the MT evaporators up and above the “Prec

reference”. This will cause the receiver control to

saturate the GBVs at 100% and the check valve

to close, bringing the system into LP ejector

mode. In ejector mode, the MT compressors

will remove the gas (vapor) refrigerant directly

from the receiver (as the check valve is closed),

but they will do so through the fully open GBV.

It is therefore important in the ejector mode to

reduce the pressure drop across the GBV(s), as

this results in increased compressor work. This

is the reasoning for the request for supporting

two sequential operated GBVs. The GBVs can be

different sizes.

Separator

Receiver

Danfoss

80G431

8 | AB322920563002en-000103 © Danfoss | DCS (vt) | 2020.08

Page 9

80G430

Application Guide | Low pressure lift ejector system

As with 2 Stepper (sequential) the requested

Opening Degree is split evenly. The “Kp” default

was 7 but should now be 7/2=3.5

Delta P low

“Delta P low” is the intended setpoint for

operation when the LP-ejector is sufficient (lifting

the total mass flow to the receiver).

Note: The “Delta P low” setting must be larger

than half the neutral zone of the MT capacity

control (which is

5K

= 2.5 ~ 2.3 bar

2

),

hence avoiding that the receiver pressure

can enter the neutral zone of the MT. This can

otherwise lead to a situation where the MT

compressor will not start after a standstill. The

setpoint for “Delta P low” should be lower than

the pressure lift that the ejector is capable of, but

large enough to secure the necessary pressure

drop over the expansion valves. Recommended

setting is 3 bar (default setting is 5 bar).

Delta P high

“Delta P high” is the setpoint that the receiver

will follow when the DI “Delta P High enable” is

enabled. The intention is that if the oil level in

the oil receiver is low, this DI is triggered causing

the reference to go to a level higher than what

the ejector is capable of lifting (more than 8 bar,

the “Psuc Max Offset” ).This efficiently causes

the check valve to open (see description in the

receiver control), enabling the oil return to the

compressor. Default setting is 10 bar (larger than

“Psuc Max Offset” default 8 bar).

Delta P high delay

“Delta P high delay” is a user defined delay timer

which delays the switchback from the “Delta P

high” to the “Delta P low” setpoint. The intention

is that if the “Delta P high” has been triggered due

to a low oil-receiver level, then the system should

stay in this “oil-return mode” for a certain time

(Delta P high delay) after the low oil level has

disappeared. This in order to secure a sufficient

return of oil (see also section below on oil return).

Default setting is 0 min.

Danfoss

2.6 IO configuration

When the AK-PC controller has been configured

for control of an LP ejector system, several input

and output need to be configured.

This includes the new Psuc_MT sensor (analogue

input), the signal for changing mode for oil return

(digital input) and the output used for controlling

the Multi Ejector (Digital Output).

The outputs used for controlling the smallest

ejectors must be of the Solid State Relay type

(SSR).

In this example the four smallest ejectors are

configured to be controlled by the four SSR

outputs available on the AK-PC controller (IO

points 1-12 to 1-14).

The ejector always has higher priority than the

HP valve. So although it is configured, it will not

be used except in the P-bands at high/low Pgc.

In most cases it is preferred to operate without

the HP valve. In this case the output type for the

HP valve can be left unconfigured.

© Danfoss | DCS (vt) | 2020.08 AB322920563002en-000103 | 9

Page 10

Danfoss

P

32F870.10

Application Guide | Low pressure lift ejector system

3. What is an ejector, and

how does it work?

An ejector is a device that utilizes the energy

from the high pressure work. The ejector converts

the high pressure potential energy in the motive

flow (primary) into kinetic energy, drawing a flow

from the suction port (secondary flow).

The process, shown in the diagram to the right, is

driven by the high pressure CO gas leaving the

gas cooler. The gas enters the ejector at the high

pressure port (PH) and flows through the throat,

causing the flow to accelerate. At the exit of the

ejector nozzle, the gas is at supersonic speed,

creating a low pressure (PS). As low pressure (PS)

is lower than the pressure (PL) at the suction

(secondary) nozzle, CO is flowing from the

suction port into the ejector. The two flows are

mixed in the mixing chamber and the pressure

is gradually increased. The flow finally enters the

diffuser at the end of the ejector. Because of the

conic diffuser shape, the flow gradually slows

down, and the pressure is increased. This means

that the kinetic energy of the flow (velocity)

is converted to potential energy (pressure).

After leaving the diffuser, the gas is at a higher

pressure (PD) than the suction pressure (PL).

32F996.12

Nozzle Throat Exit Mixing chamber Diffuser

H

P

P

Pressure

P

P

H

D

L

S

Intake due to

pressure differential

P

S

P

L

Pressure increase due to

reducing flow velocity

P

D

3.1 Danfoss Multi Ejector

design

All ejectors in the Danfoss portfolio have a high

pressure inlet for CO gas coming from the gas

cooler, a suction inlet from MT evaporators and

an outlet for returning the gas and liquid to the

receiver.

The coils activating the individual ejectors are

available from 110 – 230 V, 50 and 60 Hertz.

The gas ejectors are delivered with three pressure

transmitters, used for pressure control in the pack

controller.

Each block has a variable number of ejectors of

different sizes mounted vertically.

Coils adv. (230 V DIN and 120 V UL all 50 – 60 Hz)

HP Pressure

transmitter

MT Pressure

transmitter

Multi Ejectors LP are available with 4 to 6 ejectors.

The capacity demand is matched by using

different numbers and combinations of ejectors.

The characteristics of the ejectors remain the

same no matter how many ejectors are in use.

On each individual ejector a built-in non-return

valve prevents backflow, removing the need for

external check valves in suction lines.

Each individual ejector and the strainer are easily

serviced by simply removing the four mounting

screws, using a flat screwdriver to lift the ejector

or strainer, and pulling it out of the block. The

strainer can easily be taken apart for cleaning or

replacement.

Strainer

HP inlet from

gas cooker

Suction inlet from

MT evaporator

Danfoss

Outlet to

receiver

Receiver pressure

transmitter

All pressure transmitters MBS 8250 with round Packard, radiometric output and 7/16-20 UNF (same type as CCMT valves)

10 | AB322920563002en-000103 © Danfoss | DCS (vt) | 2020.08

Page 11

2500

Step

6

5

4

3

2

1

Mass flow [kg/hr @ 90 bar 35C]

Application Guide | Low pressure lift ejector system

3.2 Multi Ejector Capacity

Control

3.3 How does the Multi

Ejector solution work?

Multi Ejector capacity control is achieved

through a binary coupling of various capacities

of a number of ejectors. The Multi Ejector LP, for

2000

example, comes in three versions. The 4-ejector

version has ejectors providing 60 kg/h, 125 kg/h,

1500

250 kg/h and 500 kg/h resulting in a total of 935

kg/h of motive mass flow.

The 5-ejector version has an additional 500 kg/h

ejector providing a total of 1435 kg/h of motive

1000

500

mass flow.

0

The 6-ejector version has two additional 500 kg/h

ejectors providing a total of 1935 kg/h of motive

mass flow. This allows to modulate capacity in

32 steps between 0 and 1935 kg/h. But if more

capacity is required, a second Multi Ejector can

be added which will be controlled parallel to the

first one.

12345678910 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

LP 60 Ejector 1

LP 125 Ejector 2

LP 250 Ejector 3

LP 500 Ejector 4, 5, 6

The AK-PC equalizes the number of on/off switches between

equal sized ejectors to optimize the electrical and mechanical

lifetime of the AK-PC.

There are 4 different ejector cartridge sizes for LP Multi Ejectors (approx. 60, 125, 250 and 500 kg/h).

The largest ejectors are placed closest to the connectors.

Multi Ejector blocks

Type Code no. Product name

CTM 6 032F5678 CTM Multi Ejector LP 935 60 125 250 500

CTM 6 032F5693 CTM Multi Ejector LP 1435 60 125 250 500 500

CTM 6 032F5679 CTM Multi Ejector LP 1935 60 125 250 500 500 500

Ejector 1 Ejector 2 Ejector 3 Ejector 4 Ejector 5 Ejector 6

kg/h kg/h kg/h kg/h kg/h kg/h

Danfoss

84B8247

Ejector

Ejector

Ejector

Ejector

Ejector

Ejector

The flow enters the Multi Ejector through the

strainer in front of the high pressure inlet. The AKPC controller decides which ejector is activated to

meet the requested capacity. Through the open

nozzle, the high-pressure flow is transformed into

high velocity flow. The high velocity creates a

very low pressure, making the suction of the MT

possible.

OFF OFF OFF ON ON ON

High

pressure inlet

MT

pressure inlet

Receiver

pressure inlet

The flow from the MT suction inlet enters

the ejector through the check valve, mixing

with the high velocity flow. The mixed flow is

slowed down in the diffuser part of the ejector,

transforming the velocity to pressure. From here

the mixed flow is lead to the receiver and thereby

recovering a part of the expansion work.

Danfoss

84B8248

© Danfoss | DCS (vt) | 2020.08 AB322920563002en-000103 | 11

Page 12

Application Guide | Low pressure lift ejector system

4. Coolselector®2

Selecting components

4.1 LP ejector selection

DeltaP … LP ejector pressure lift

DeltaP=P_receiver – Po_MT = 32,3-26,5 = 5,8 bar

m_comp_MT … Motive flow

m_evap_MT … Suction flow

m_BP … Gas By-pas flow

er … Entrainment ratio

m

evapMT

er = = = 0,43

m

compMT

719

1656

Gas quality in receiver

m

compMT

BP

+ m

evapMT

x = = = 0,636 ~ 0,64

m

1512

1656 + 719

Operating envelope

12 | AB322920563002en-000103 © Danfoss | DCS (vt) | 2020.08

Page 13

Application Guide | Low pressure lift ejector system

4.2 GBV, Gas By-Pass #1

valve selection

Select Gas By-Pass valve like for standard Booster system, because even you will run in summer time

in LP ejector mode; there will be a time where we will turn the system to standard operation with Prec

Delta P high to get oil back.

Valves and Line Components

Transcritical gas bypass valves

Selection Sgc 40 °C ; DeltaP high 10 bar

Gas bypass line (transcritical system, R744, Gas bypass valve)

Selection Sgc 24 – 25 °C; DeltaP low 3 bar; Standard mode

LP ej selection to find out Sgc temperature when the ejector pressure lift exceeds DeltaP Low

DeltaP … LP ejector pressure lift

DeltaP=P_receiver – Po_MT = 29, 56-26, 5 ~ 3 bar

© Danfoss | DCS (vt) | 2020.08 AB322920563002en-000103 | 13

Page 14

Application Guide | Low pressure lift ejector system

GBV #1 selection

Gas bypass line (transcritical system, R744, Gas bypass valve)

Conclusion:

We receive very similar results for high ambient temperature and DeltaP high (10 bar) and at

temperature out of the gas cooler 24 – 25 °C and DeltaP low (3 bar)

4.3 Check valve selection

Valves and Line Components

Check valves

14 | AB322920563002en-000103 © Danfoss | DCS (vt) | 2020.08

Page 15

Application Guide | Low pressure lift ejector system

4.4 Evaporator EEV selection In section “System design with Low Pressure lift ejector” point 5 it was explained what the limitations

for selecting right AKVP/PS are. If e.g. the pressure differential Delta P Low is 3 bar and we assume the

pressure loss on suction line is 1 bar, and distributor + evaporator additionally 1 bar, then there is 1 bar

pressure difference for MT EEV left.

Valves and Line Components

Electronic expansion valves

Delta P Low = 3 bar

Pressure drop 2 bar for suction line + distributor + evaporator

1 bar pressure drop for AKV PS

© Danfoss | DCS (vt) | 2020.08 AB322920563002en-000103 | 15

Page 16

5. Multi Ejector Solution™

Danfoss offers a wide range of market leading Multi Ejectors. Supported by 3 MBS 8250 sensors, coils

with LED plug.

Multi Ejector LP 935

The Multi Ejector Low Pressure (LP) with a nominal motive mass flow capacity of 935

kg/h is the smallest in the LP range and consists of 4 LP ejectors, 2 blanks and 1 strainer.

It is recommended for stores with a refrigeration load in the range of 18 – 35 kW.

Multi Ejector LP 1435

The Multi Ejector Low Pressure (LP) with a nominal motive mass flow capacity of 1435

kg/h consists of 5 LP ejectors, 1 blank and 1 strainer.

It is recommended for stores with a refrigeration load in the range of 18 – 53 kW.

Multi Ejector LP 1935

The Multi Ejector Low Pressure (LP) with a nominal motive mass flow capacity of 1935

kg/h is the biggest in the LP range. It consists of 6 LP ejectors, and 1 strainer.

It is recommended for stores with a refrigeration load in the range of 18 – 72 kW.

Controller AK-PC 782A

Danfoss offers a wide range of market leading Pack Controllers.

Being the flagship and best in class controller for transcritical CO packs controls, the

AK-PC 782A offers the highest possible efficiency with the Multi Ejector, CTM.

The complete application control features:

• Complete booster pack control of up to 3 suction groups (max. 12 compressors) and

high pressure system

• Significant savings with heat recovery for tap water and heat reclaim

• Extensive control of oil flow and pressurization

• Best in class safety monitoring and fail-safe functions

• Minimal energy consumption while ensuring optimal food quality

• Auto-configured, easy-to-use graphical representation with Danfoss System Manager

• Independent, customized control and monitoring of auxiliary function

Temperature sensors and pressure transmitters

Danfoss offers a comprehensive range of sensors for temperature and pressure sensors

developed to meet the requirements of the entire pack application.

The sensor range delivers the following key features and benefits:

• Long term reliability minimize system downtime

• Robust construction protects again mechanical shock and vibration

• Temperature sensor design ensures fast response time and precise measurement

• Hermetically sealed pressure element ensures no leakage

• Pressure transmitter output calibrated for perfect fit to the application

• Pulse snubber ensures protection against liquid hammering, cavitation or pressure peaks

© Danfoss | DCS (vt) | 2020.08 AB322920563002en-000103 | 16

ADAP-KOOL®

Loading...

Loading...