Page 1

Service Kit Instructions

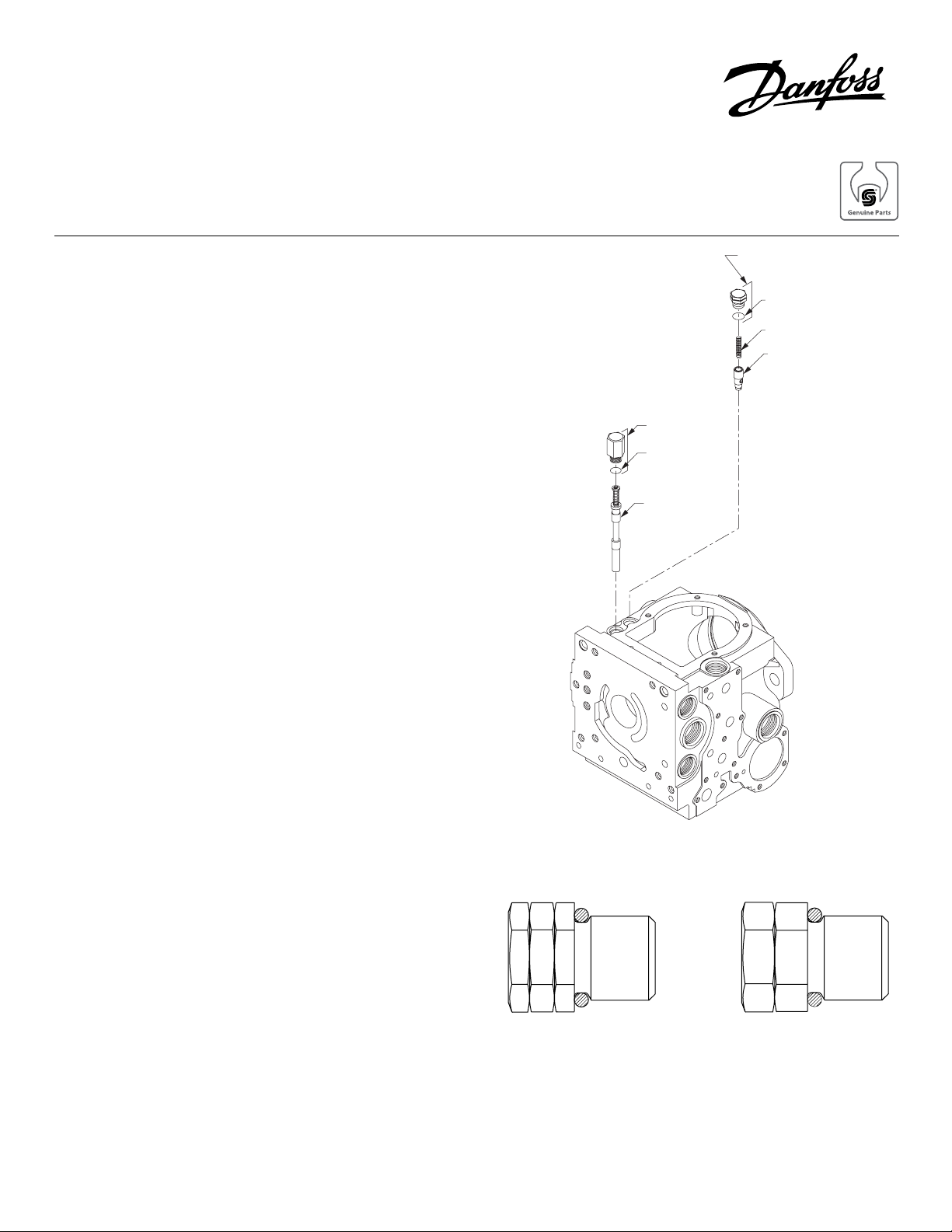

Series 42

Loop flushing valve

PURPOSE:

The loop flushing consists of the loop flushing shuttle valve

and the loop flushing relief valve. The assemblies may be

removed for cleaning and installation of new O-rings. The

relief valve poppet may be exchanged for one with a different

flow rating. Sauer-Sundstrand strongly recommends using all

new hardware include in the kit.

PROCEDURE:

Loop Flushing Valve

1. Remove the loop flushing valve plug from the pump

housing (1 1/16 in Hex). Remove the O-ring from the

plug.

2. Remove the loop flushing valve spool assembly from

the housing.

3. Inspect the parts for damage or foreign material. The

centering spring must be securely retained to the

spool by the washer.

4. Install the loop flushing valve spool assembly into its

bore. Install a new O-ring on the loop flushing plug

and torque to 27-37 Nm (20-35 ft•lbf).

Loop Flushing

Relief Plug

O-Ring

Spring

Poppet

Loop

Flushing Plug

O-Ring

Loop Flushing

Spool Assembly

Loop Flushing Relief Valve

1. Remove the loop flushing relief valve external hex

plug (5/8 in Hex) from the pump housing. Remove the

O-ring from the plug.

2. Remove the spring and poppet from the housing.

3. Remove and discard all shims which are found

between the spring and valve plug.

4. Inspect the poppet and mating seat in the housing for

damage or foreign material. Inspect the orifice in the

valve poppet.

6. Install a new O-ring on the valve plug. Reinstall the

poppet, spring, and plug (with O-ring) into the pump

housing. Torque plug to 21-34 Nm (15-25 ft•lbf).

Note:

There are two valve plugs in each kit. In order to

determine which plug to use it is necessary to know

the charge pressure. If the charge pressure is greater

than 18 bar, use the plug with two identifying grooves.

If the charge pressure is less than 18 bar, use the plug

with one identifying groove.

Loop Flushing Valve Components

rab 81 wolebevoba dna rab 81

Relief Valve Plugs

© Danfoss, 2013 BLN-10121 • Rev AA • September 2013 1

Loading...

Loading...