Page 1

Option 3

Option 2

Service Kit Instructions

Series 42

Loop flushing

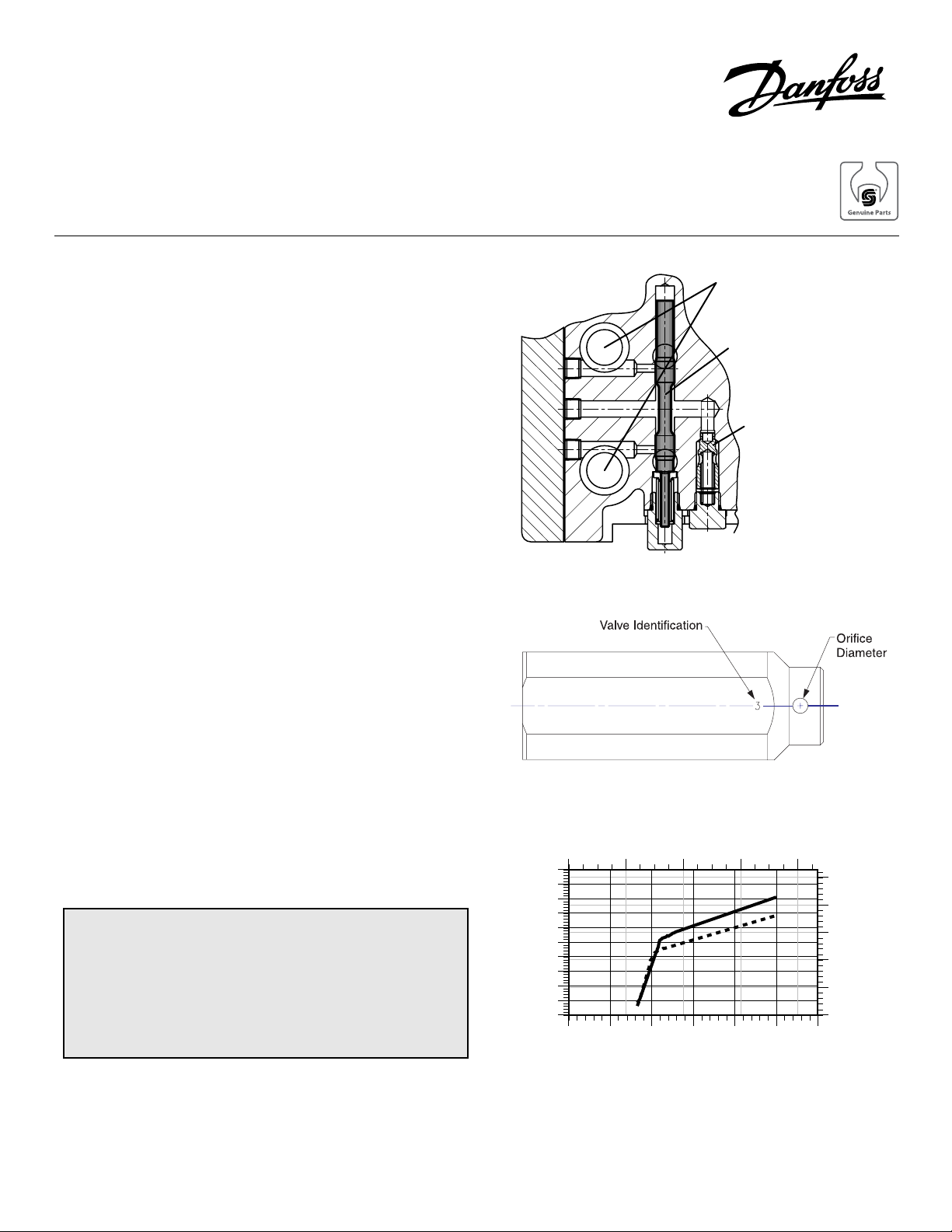

Series 42 pumps may incorporate an integral loop flushing

valve for those applications that require additional fluid to be

removed from the system power loop.

The loop flushing valve will remove heat and contaminants

from the main power loop at a rate faster than otherwise

possible. The loop flushing valve poppet includes an orifice

which removes a set volume of fluid from the power loop. This

fluid is in turn made up by the charge pump.

An assessment of the application cooling requirements and

system cooling capacity should be completed prior to installation of the components in the application. A flushing flow of

5 to 8 L/min (1.5-2 gpm) is generally suitable for most

applications. Please refer to Sauer-Sundstrand BLN-9886

and BLN-10092 or contact your technical support personnel

for further assistance.

This kit contains two relief valves. The valves are marked with

a 2 or a 3. Valve 2 (Options #2) contains a 1.2 mm (0.047 inch)

orifice, while valve 3 (Option #3) contains 1.4 mm (0.055 inch)

orifice. Using the cooling assessment analysis from above

and the graph at the right, a combination of orifice size and

charge pressure relief setting can be used to obtain the desire

cooling flow.

System (Loop) Ports

Loop Flushing Shuttle

Valve

Loop Flushing

Relief Valve

Loop Flushing Assembly

BLN-10121 contains specific information on the procedure for

installing the relief valve and associated hardware in the

Series 42 pump.

Relief Valve

When a Series 42 pump is used with a loop flushing valve

either located in a motor or installed remotely, the setting of

the loop flushing valve should be equal to or less than the

charge pressure setting of the pump.

WARNING

Incorrect charge pressure settings may result in the

inability to build required system pressure and /or

inadequate loop flushing flows. Correct charge pressure must be maintained under all conditions of operations to maintain pump control performance.

(psi)

0 100 200 300 400

10

9

8

7

6

5

4

3

2

1

Loop Flushing Flow (L/min)

0

0 5 10 15 20 25 30

Charge Pressure

(bar)

Loop Flushing Flow

2.5

2

1.5

1

0.5

0

(gpm)

© Danfoss, 2013 BLN-10122 • Rev AA • September 2013 1

Loading...

Loading...