Page 1

LonWorks® 78 kbps and 1.25 Mbps

Option Card

Instruction Manual

Page 2

DANGER

!

Rotating shafts and electrical equipment can

be hazardous. Therefore, it is strongly

recommended that all electrical work conform

to the National Electrical Code (NEC) and all

local regulations. Installation, start-up and

maintenance should be performed only by

qualified personnel.

VLT® 5000 / VLT® 6000

does not disconnect the equipment from the AC line and

is not to be used as a safety switch.

3. Correct protective grounding of the equipment must be

established. The user must be protected against supply

voltage and the motor must be protected against

overload in accordance with applicable national and local

regulations.

4. Ground currents are higher than 3 mA.

Factory recommended procedures, included in this manual,

should be followed. Always disconnect electrical power before

working on the unit.

Although shaft couplings or belt drives are generally not

furnished by the manufacturer, rotating shafts, couplings and

belts must be protected with securely mounted metal guards

that are of sufficient thickness to provide protection against

flying particles such as keys, bolts and coupling parts. Even

when the motor is stopped, it should be considered “alive”

as long as its controller is energized. Automatic circuits may

start the motor at any time. Keep hands away from the output

shaft until the motor has completely stopped and power is

disconnected from the controller.

Motor control equipment and electronic controls are

connected to hazardous line voltages. When servicing drives

and electronic controls, there will be exposed components

at or above line potential. Extreme care should be taken to

protect against shock. Stand on an insulating pad and make

it a habit to use only one hand when checking components.

Always work with another person in case of an emergency.

Disconnect power whenever possible to check controls or

to perform maintenance. Be sure equipment is properly

grounded. Wear safety glasses whenever working on electric

control or rotating equipment.

Safety Guidelines

1. The drive must be disconnected from the AC line before

any service work is done.

2. The “Stop/Off” key on the local control panel of the drive

W arnings Against Unintended

Start

1. While the drive is connected to the AC line, the motor

can be brought to a stop by means of external switch

closures, serial bus commands or references. If personal

safety considerations make it necessary to ensure that

no unintended start occurs, these stops are not sufficient.

2. During programming of parameters, the motor may start.

Be certain that no one is in the area of the motor or

driven equipment when changing parameters.

3. A motor that has been stopped may start unexpectedly

if faults occur in the electronics of the drive, or if an

overload, a fault in the supply AC line or a fault in the

motor connection or other fault clears.

4. If the “Local/Hand” key is activated, the motor can only

be brought to a stop by means of the “Stop/Off” key or

an external safety interlock.

NOTE:

It is responsibility of user or person installing

drive to provide proper gr ounding and branch

circuit protection for incoming power and

motor overload according to National Electrical

Code (NEC) and local codes.

The Electronic Thermal Relay (ETR) is UL listed. VLTs provide

Class 20 motor overload protection in accordance with the

NEC in single motor applications, when VLT 6000 parameter

117 (VLT 5000 parameter 128) is set for ETR Trip 1 and

parameter 105 is set for rated motor (nameplate) current.

DANGER

!

Touching electrical parts may be fatal – even after equipment has been

disconnected from AC line. To be sure that capacitors have fully discharged, wait 14 minutes after power has been removed before touching

any internal component.

2

MG.60.E4.02 - VLT is a registered Danfoss trademark

Page 3

Overview

Introduction............................................................................................. 5

About This Manual .................................................................................. 5

Assumptions ........................................................................................... 5

What You Should Already Know ............................................................ 5

References .............................................................................................. 5

LonWorks Overview................................................................................ 6

LON Concept........................................................................................... 6

Applications ............................................................................................ 6

VLT LonWorks Option Card.................................................................... 7

Node Arrangements................................................................................ 7

Message Passing .................................................................................... 7

Collision Detection ................................................................................. 8

Network Management............................................................................. 8

Routers and Bridges............................................................................... 9

Installation

Wiring Installation................................................................................... 10

Card Installation...................................................................................... 10

T ools Required ........................................................................................ 10

VL T LonW orks Option Card.......................................................................11

Installation Instructions ......................................................................... 12

Network Initialization of LonW orks Option Car d .................................. 19

LonMark XIF Files ................................................................................... 19

VLT® 5000 / VLT® 6000

Table of Contents

T wisted Pair Netw ork Configuration

78 kbps and 1.25 Mbps T ransf ormer Coupled Twisted Pair Model ....... 20

Double Terminated Bus Topology........................................................... 20

T erminator Switch ................................................................................... 20

Performance Specification...................................................................... 2 1

Communication on TP/XF-78 and TP/XF-1250 Channels ...................... 21

Diagnostic LEDs

LonWorks Car d Diagnostic LEDs ........................................................... 22

Status LED ............................................................................................... 22

Service LED ............................................................................................. 22

Service LED Patterns and Descriptions ................................................. 23

MG.60.E4.02 - VLT is a registered Danfoss trademark

3

Page 4

Interface/Network Variables

VL T Adjustable Frequency Drive

and LonWorks Netw ork Configuration ................................................... 24

Network Drive Control Input ................................................................... 24

Drive Feedback to Network ..................................................................... 27

Drive Status Bit Definitions..................................................................... 28

Network Timer Functions....................................................................... 30

VL T P arameter Access ............................................................................ 31

Parameter Access Error Codes............................................................... 32

Parameter Access Command and Response Examples........................ 32

Standard Object Support ........................................................................ 3 4

Alarm Descriptions.................................................................................. 35

Parameters

Parameter List ......................................................................................... 36

Parameter Description............................................................................. 3 6

Decommissioning VLT Adjustable Frequency Drive

Decommissioning VL T Drive from LonW orks Network ......................... 39

VLT® 5000 / VLT® 6000

4

MG.60.E4.02 - VLT is a registered Danfoss trademark

Page 5

VLT® 5000 / VLT® 6000

Introduction

About This

Manual

This manual provides comprehensive

instructions on the installation and set up of

the LonWorks Option Card for the VLT 5000

and the VLT 6000 Adjustable Frequency Drive

to communicate over a LonWorks network.

For specific information on installation and

operation of the adjustable frequency drive,

refer to the VLT 5000 Installation, Operation

and Instruction Manual or VLT 6000

Installation, Operation and Instruction Manual.

This manual is intended to be used for both

instruction and reference. It only briefly

touches on the basics of the LonWorks

protocol whenever it is necessary for gaining

an understanding of the LonWorks profile for

drives and the LonWorks Option Card for the

Adjustable frequency drive.

This manual is also intended to serve as a

guideline when you specify and optimize your

Portions of this manual are printed with the

permission of the Echelon Corporation and the

National Electrical Contractors Association of

the USA (NECA).

Echelon®, LonTalk®, Neuron® and LonWorks

are registered trademarks of the Echelon

Corporation. VLT® is a registered trademark

of Danfoss Inc.

communication system. Even if you are an

experienced LonWorks programmer, we

suggest that you read this manual in its entirety

before you start programming, since important

information can be found in all sections.

®

Assumptions

What Y ou

Should

Already Know

References

This manual assumes that you have a

controller node that supports the interfaces

in this document and that all the requirements

stipulated in the controller node, as well as

The Danfoss LonWorks Option Card is

designed to communicate with any controller

node that supports the interfaces defined in

LonMaker™ for Windows® User's Guide.

VLT® 5000 Installation, Operation and

Instruction Manual

(Referred to as the VLT Instruction Manual in

this document.)

VLT ®6000 Installation, Operation and

Instruction Manual

(Referred to as the VLT Instruction Manual in

this document.)

the Adjustable Frequency Drive, are strictly

observed along with all limitations therein.

this document. It is assumed that you have

full knowledge of the capabilities and

limitations of the controller node.

MG.60.E4.02 - VLT is a registered Danfoss trademark

5

Page 6

VLT® 5000 / VLT® 6000

LonWorks

Overview

LON

Concept

LonWorks is both an existing standard and

hardware developed by Echelon Corporation.

Echelon's stated goal is to establish a commodity solution to the presently daunting

problems of designing and building control

networks.

The result is LonMark Interoperability which

makes it possible for independent network

devices to operate together over a

LonWorks network. The LonMark program

was developed to address interoperability

issues. As a result, the LonMark

Interoperability Association Task Groups

(LonUsers Groups) were developed. The

task groups determine that each device on

the network has an object definition, create

The LonWorks communications structure is

similar to that of a local area network (LAN)

in that messages are continually exchanged

between a number of processors. A

LonWorks system is a determined local

operating network (LON). LON technology

offers a means for integrating various

distributed systems that perform sensing,

monitoring, control, and other automated

functions. A LON allows these intelligent

devices to communicate with one another

through an assortment of communications

media using a standard protocol.

LON technology supports distributed, peerto-peer communications. That is, individual

standards and models to be used by

particular applications and create a common

platform for presenting data. A standard

network variable type (SNVT) facilitates

interoperability by providing a well defined

interface for communication between

devices made by different manufacturers.

The VLT Adjustable Frequency Drive

supports the node object and controller

standard object definitions of LonMark

Interoperability.

Customers are currently using LonWorks for

process control, building automation, motor

control, elevator operation, life safety

systems, power and HVAC distribution and

similar intelligent building applications.

network devices can communicate directly

with one another without need for a central

control system. A LON is designed to move

sense and control messages which are

typically very short and which contain

commands and status information that

trigger actions. LON performance is viewed

in terms of transactions completed per

second and response time. Control systems

do not need vast amounts of data, but they

do demand that the messages they send

and receive are absolutely correct. The critical

factor in LON technology is the assurance

of correct signal transmission and verification.

Applications

6

An important LonWorks benefit is the

network’s ability to communicate across

different types of transmission media. The

NEURON chip is the heart of the LonWorks

system. The NEURON chip's communication port allows for the use of

transceivers for other media (such as coax

and fiber optic) to meet special needs.

LonWorks control devices are called nodes.

Physically, each node consists of a NEURON

chip and a transceiver. With proper design,

the nodes become building blocks that can

be applied to control a variety of tasks, such

as lighting or ventilating, integrating a variety

of communications media.

The tasks which the nodes perform are

determined by how they have been

connected and configured. Because

hardware design, software design, and

network design may be independent in a

LonWorks-based system, a node’s function

can be programmed to accommodate the

networks in which it will be used.

MG.60.E4.02 - VLT is a registered Danfoss trademark

Page 7

VLT® 5000 / VLT® 6000

VLT LonWorks

Option Card

The Danfoss VLT LonWorks option card is

comprised of a control card with a NEURON

chip and a memory card. When installed into

the VLT adjustable frequency drive, the unit

enables the drive to communicate with other

devices on the LON. The VLT drive is designed

to provide precision control of standard

induction electrical motors. The drive receives

three reference signals along with start/stop

and reset commands from the network. The

drive also receives a 16-bit control word that

provides full operational control of the drive.

(See Network Drive Control Input for additional

details.)

In response, the drive provides 16 output

network variables containing important drive

and motor data. (See Drive Feedback to

Network.) Output to the network includes

drive status, current, voltage, motor and

inverter thermal status, and alarms and

warnings.

LonWorks supports many different types of

transmission media. A LonWorks network

physical layer option can be transformer

coupled twisted pair (78 kbps and 1.25

Mbps), free topology, link power, power line,

RF, RS-485, fiber optic, coaxial, or infrared.

The VLT LonWorks option supports four

transmission media with three versions of the

VLT LonWorks option card. The VLT

LonWorks option card versions are:

1. Free topology, which also operates on

a link power network.

2. 78 kbps transformer coupled twisted

pair.

3. 1.25 Mbps transformer coupled twisted

pair.

A router is required to interface to a LonWorks

network when not supported by one of the

three option card versions.

Node

Arrangements

Message

Passing

LonWorks nodes can be addressed either

individually or in groups. A group can contain

up to 64 nodes, and one LonWorks network

can support 255 groups. Furthermore, any

node can be part of 15 different groups. A

subnet, very similar to a group, can contain

127 nodes. A domain is the largest

arrangement of nodes with a single domain

able to handle 255 subnets. Thus a domain

can handle 32,385 separate nodes. A single

node may be connected to no more than two

domains.

The group structure has the advantage of

allowing a number of nodes to be reached at

only one address. This method reduces the

There are a number of trade-offs between

network efficiency, response time, security,

and reliability. Generally, LonWorks defaults to

the greatest degree of safety and verification

for all communications over the LON network.

The LonTalk protocol, built into the chips, is

the operating system that coordinates the

LonWorks system. It offers four basic types

of message service.

record keeping inside each chip to a minimum,

allowing faster operation. However, high

efficiency individual addressing can be done

at all levels of a LonWorks system. The

address table of a node contains entries for

the group type and size and tells the node

how many acknowledgments to expect when

it sends a message. It also tells the NEURON

chip which domain to use and the node group

member number, which identifies an

acknowledgment as coming from the node.

The address also contains a transmit timer, a

repeat timer, a retry counter, a receive timer,

and the group ID.

The most reliable service is acknowledged (or

end-to-end acknowledged service), where a

message is sent to a node or group of nodes

and individual acknowledgments are expected from each receiver. If an

acknowledgment is not received from all destinations, the sender times out and re-tries

the transaction. The number of retries and

time-out duration are both selectable. Ac-

MG.60.E4.02 - VLT is a registered Danfoss trademark

7

Page 8

VLT® 5000 / VLT® 6000

Message

Passing

(continued)

Collision

Detection

knowledgments are generated by the network

host processor without intervention of the application. Transaction IDs are used to keep

track of messages and acknowledgments so

that the application does not receive duplicate messages.

An equally reliable service is request/response,

where a message is sent to a node or group

of nodes and individual responses are expected from each receiver. Incoming

messages are processed by the application

on the receiving side before a response is

generated. The same retry and time-out options are available as with acknowledged

service. Responses may include data, so that

this service is particularly suitable for remote

procedure call or client/server applications.

The LonTalk protocol uses a unique collision

avoidance algorithm which allows an

overloaded channel to carry near to its

maximum capacity, rather than reducing its

throughput due to excessive collisions

between messages. When using a

communications medium that supports

collision detection, such as twisted pair, the

LonTalk protocol can optionally cancel

transmission of a packet as soon as a collision

is detected by the transceiver. This option

Next in reliability is unacknowledged repeated.

Messages are sent multiple times to a node

or a group of nodes with no response

expected. This service is typically used when

broadcasting to large groups of nodes when

traffic generated by all the responses would

overload the network.

The final method in reliability is unac-

knowledged, where a message is sent once

to a node or group of nodes and no response

is expected. This option is typically used when

the highest performance is required, network

bandwidth is limited, and the application is

not sensitive to the loss of a message.

allows the node to immediately retransmit any

packet that has been damaged by a collision.

Without collision detection, the node would

wait the duration of the retry time to notice

that no acknowledgment was received. At that

time it would retransmit the packet, assuming

acknowledge or request/response service.

For unacknowledged service, an undetected

collision means that the packet is not received

and no retry is attempted.

Network

Management

8

Depending on the level of a given application,

a LonWorks network may or may not require

the use of a network management node. A

network management node performs

management functions, such as:

• Find unconfigured nodes and

download their network addresses.

• Stop, start, and reset node

applications.

• Access node communication statistics.

• Configure routers and bridges.

• Download new applications programs.

• Extract the topology of a running

network.

MG.60.E4.02 - VLT is a registered Danfoss trademark

Page 9

VLT® 5000 / VLT® 6000

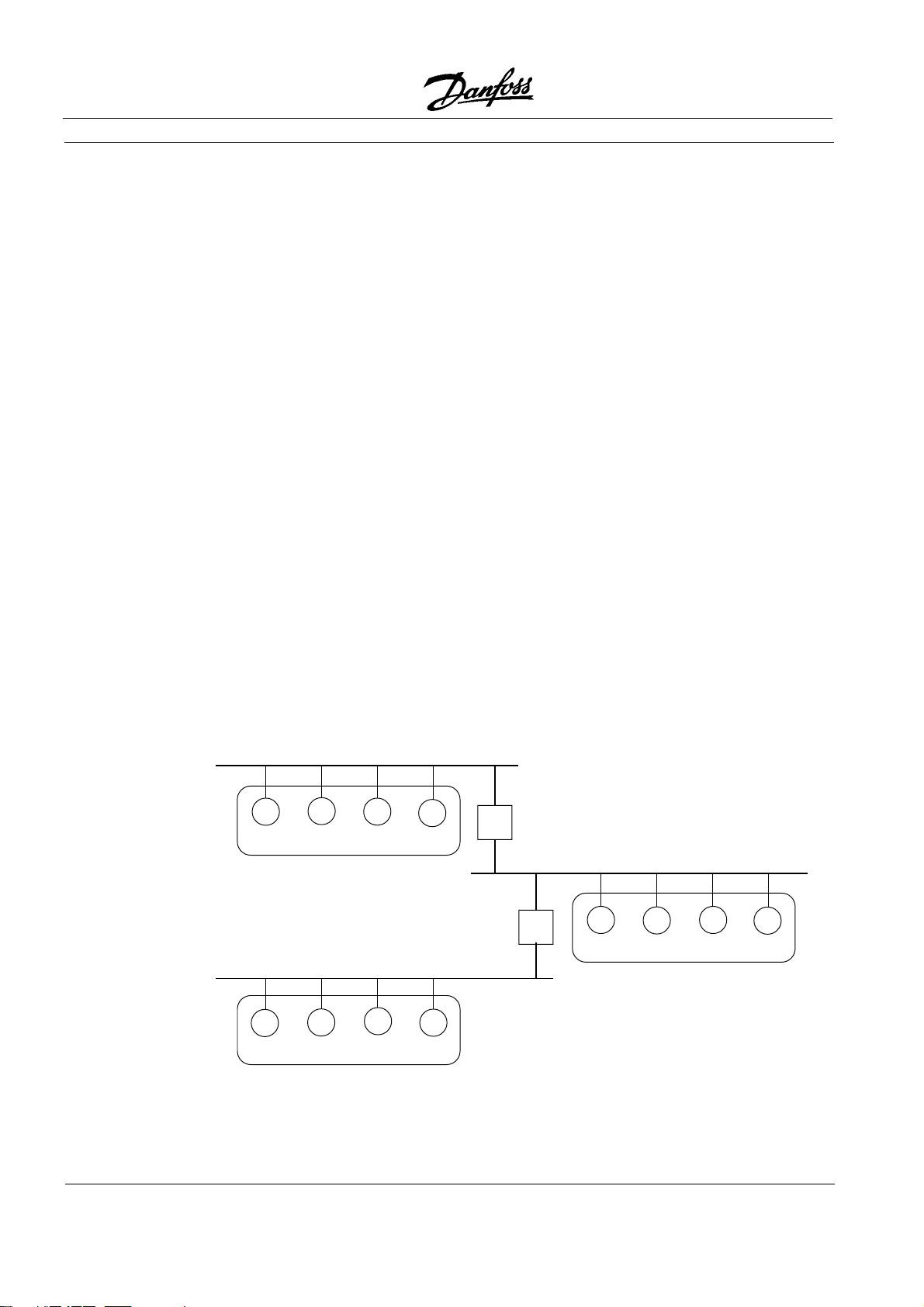

Routers and

Bridges

A router (or bridge) is a special node that

consists of two connected NEURON chips, each

connected to a separate channel (see figure

below). Routers and bridges pass packets

back and forth between these channels. There

are four types of routers. A repeater is the

simplest form of router, simply forwarding all

packets between the two channels. A bridge

simply forwards all packets which match its

domains between the two channels. Using a

bridge or repeater, a subnet can exist across

multiple channels. A learning router monitors

the network traffic and learns the network

topology at the domain/subnet level. The

learning router then uses its knowledge to

selectively route packets between channels.

Like a learning router, a configured router

selectively routes packets between channels

by consulting internal routing tables. Unlike a

learning router, the contents of the internal

routing tables are specified using network

management commands.

Initially, each router sets its internal routing tables

to indicate that all subnets could lie on either side

of the router. Suppose that node 6, in the figure

below, generates a message bound for node 2.

Learning router 1 initially picks up the message.

It examines the source subnet field of the

message and notes in its internal routing tables

that subnet 2 lies below it. The router then

compares the source and destination subnet IDs

and, since they are different, the message is

passed on. Meanwhile, learning router 2 also

passes the message on, making an appropriate

notation in its internal routing tables regarding the

location of subnet 2.

Suppose now that node 2 generates an

acknowledgment. This acknowledgment is

picked up by learning router 1, which now notes

the location of subnet 1. Learning router 1

examines its internal routing tables, and, noting

that subnet 2 lies below, passes the message

on. When the message appears on subnet 2, it

is noted by both node 6 (the destination) and

learning router 2. Learning router 2 does not pass

it on but merely notes that subnet 1, like subnet

2, lies somewhere above. Learning router 2 will

not learn of the existence or location of subnet 3

until a message is originated from there. Subnets

cannot cross routers. While bridges and

repeaters allow subnets to span multiple

channels, the two sides of a router must belong

to separate subnets. Since routers are selective

about the packets they forward to each channel,

the total capacity of a system can be increased

in terms of nodes and connections.

Channel

1 2 3 4

Subnet 1

Channel

9 10 11 12

Subnet 3

MG.60.E4.02 - VLT is a registered Danfoss trademark

Learning

R

Router 1

Learning

Router 2

Learning Routers

Source: Echelon Corp.

R

Channel

5 6 7 8

Subnet 2

9

Page 10

Wiring

CAUTION

!

CAUTION

!

Installation

WW

iringiring

W

iring

WW

iringiring

The adjustable frequency drive generates a

carrier frequency with a pulse frequency

between 3 kHz and 14 kHz. This results in

radiated frequency noise from the motor

cables. It is very important that the LonWorks

cable be isolated as much as possible from

the drive output cabling to the motor. Use

shielded wire rather than twisted-pair. Do not

run LonWorks cabling and motor cables in

parallel or in close proximity to one another.

Ensure that the drive is properly grounded.

VLT® 5000 / VLT® 6000

Card

Installation

The following section describes the installation

procedures for the LonWorks option card (see

following illustration). For additional information

on installation and operation of the VLT

adjustable frequency drive, refer to the VLT

Instruction Manual.

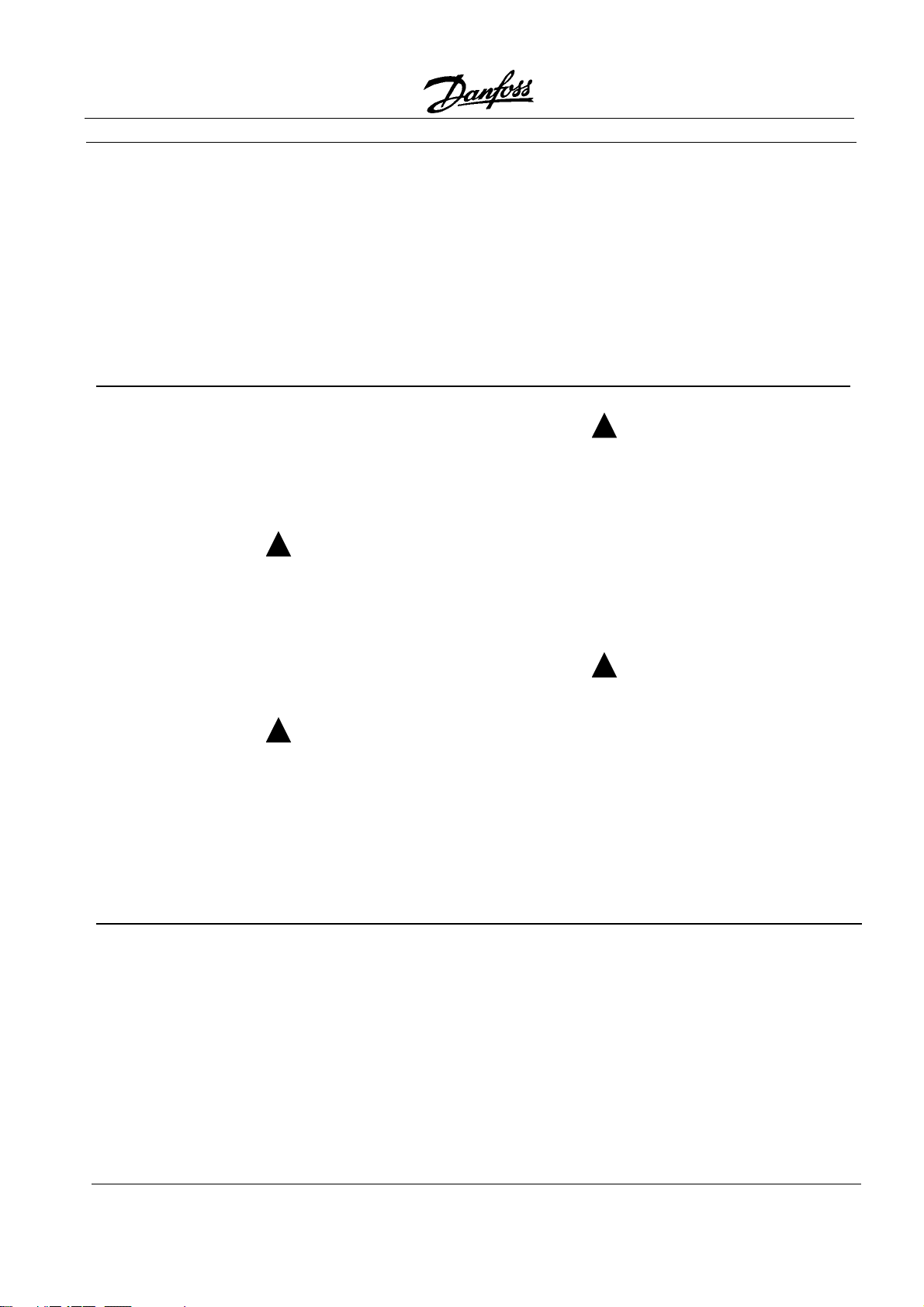

DANGER

!

VLT adjustable frequency drive

contains dangerous voltages

when connected to line power.

After disconnecting from line,

wait at least 14 minutes before

touching any electrical components.

WARNING

!

Only a competent electrician

should carry out electrical

installation. Impr oper installation

of motor or VLT can cause

equipment failure, serious injury

or death. Follow this manual,

National Electrical Code (USA)

and local safety codes.

Electronic components of VLT

adjustable frequency drives are

sensitive to electrostatic discharge (ESD). ESD can reduce

performance or destro y sensitive

electronic components. Follow

proper ESD procedures during

installation or servicing to

prevent damage.

It is responsibility of user or

installer of VLT adjustable

frequency drive to provide pr oper

grounding and motor overload

and branch protection according

to National Electrical Code (USA)

and local codes.

Tools

Required

10

Flat-head screw driver

Torx T-10 screw driver

Torx T-20 screw driver

MG.60.E4.02 - VLT is a registered Danfoss trademark

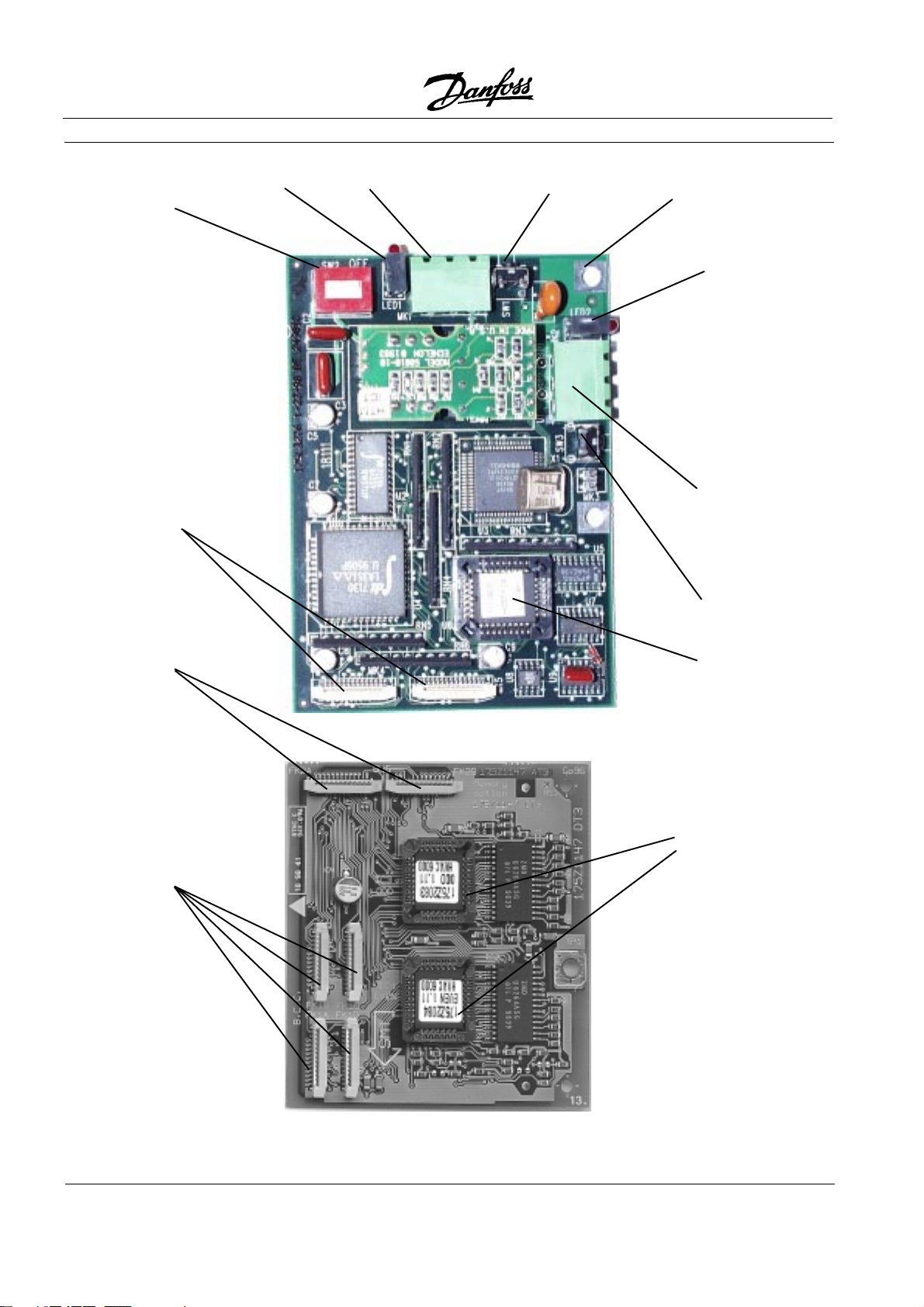

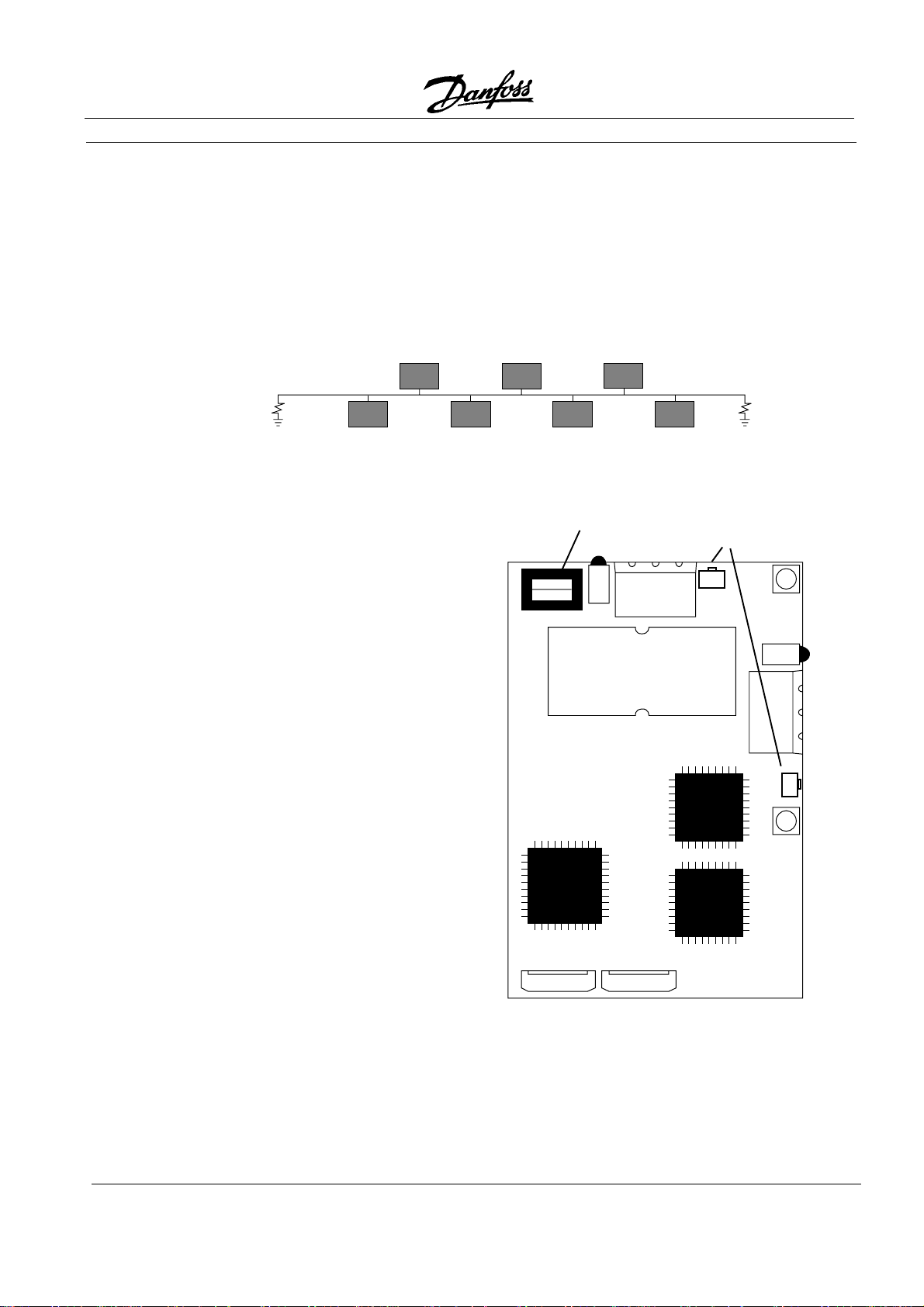

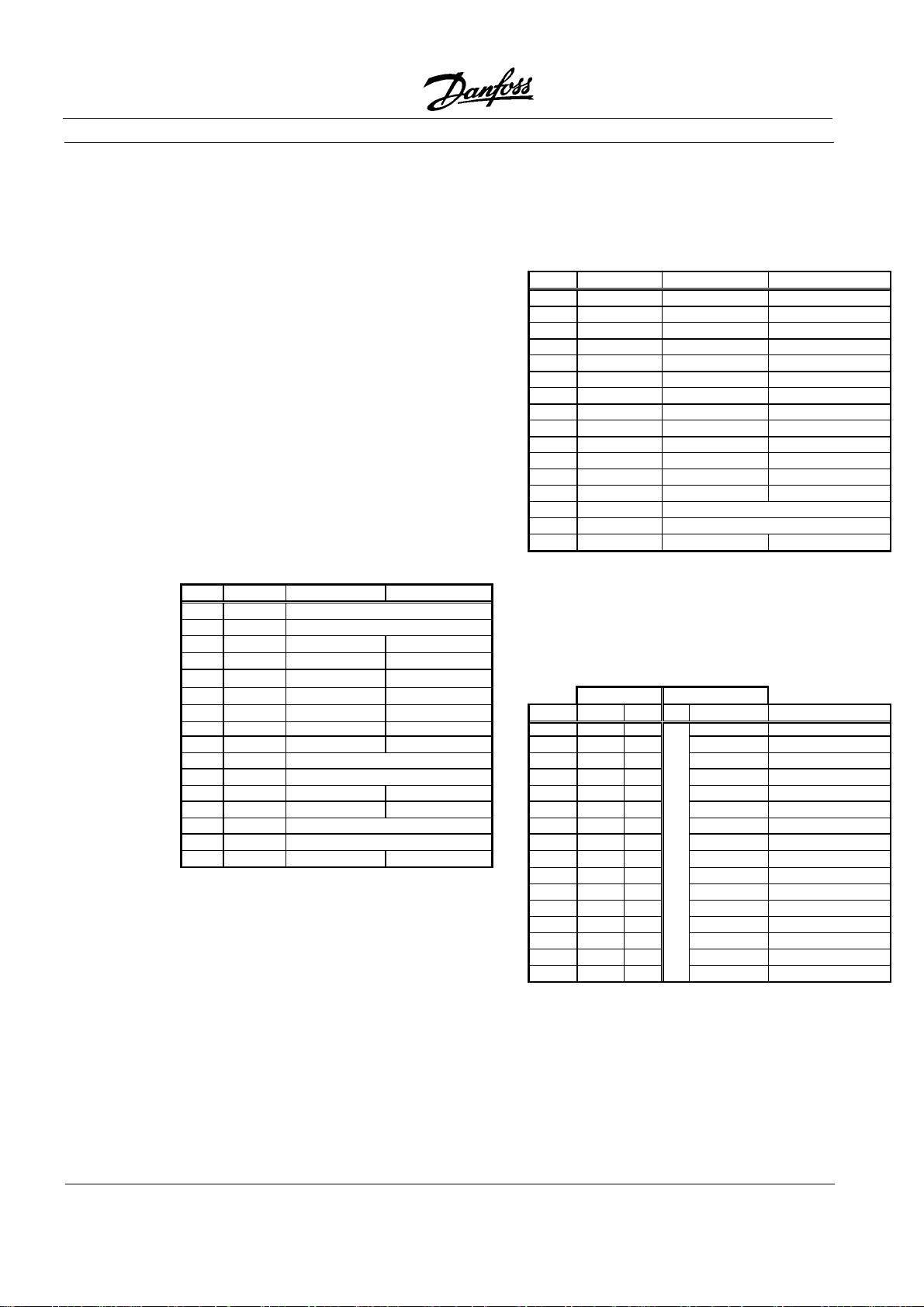

Page 11

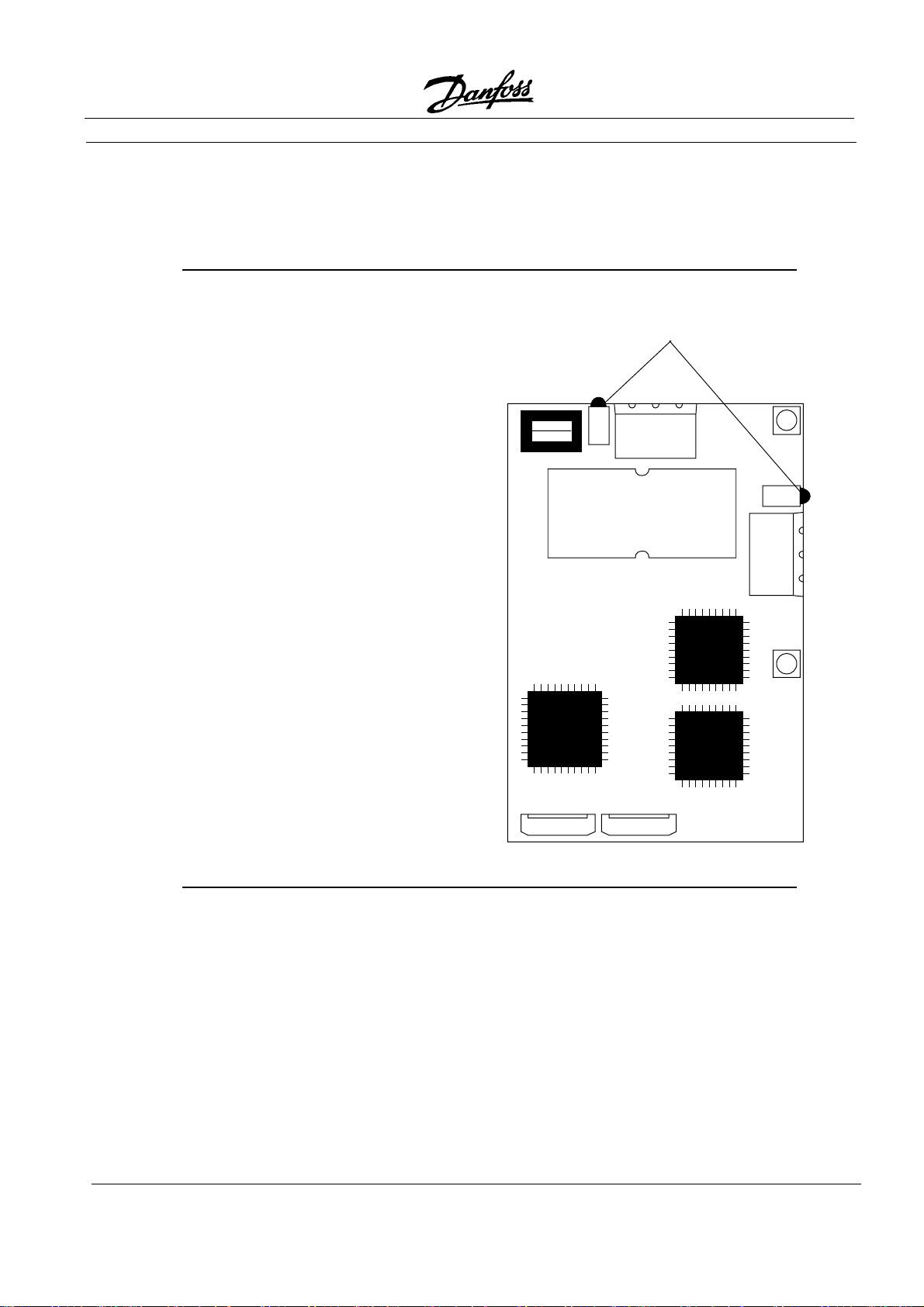

VLT® 5000 / VLT® 6000

Terminator

Switch

Ribbon

Cable

Socket

(to Memory

Board)

LEDs

Terminal

Connector

Service Pin

Switch SW1

Mounting Hole

LEDs

Terminal

Connector

Service Pin

Switch SW3

Ribbon

Cable

Socket

(to Control

Board)

Ribbon

Cable

Socket

(to drive

control

board)

Host

Chip

LonWorks Control Board

Drive

Memory

VLT LonWorks Option Card

(Free T opology Model)

MG.60.E4.02 - VLT is a registered Danfoss trademark

Memory Board

11

Page 12

Installation Instructions

VLT® 5000 / VLT® 6000

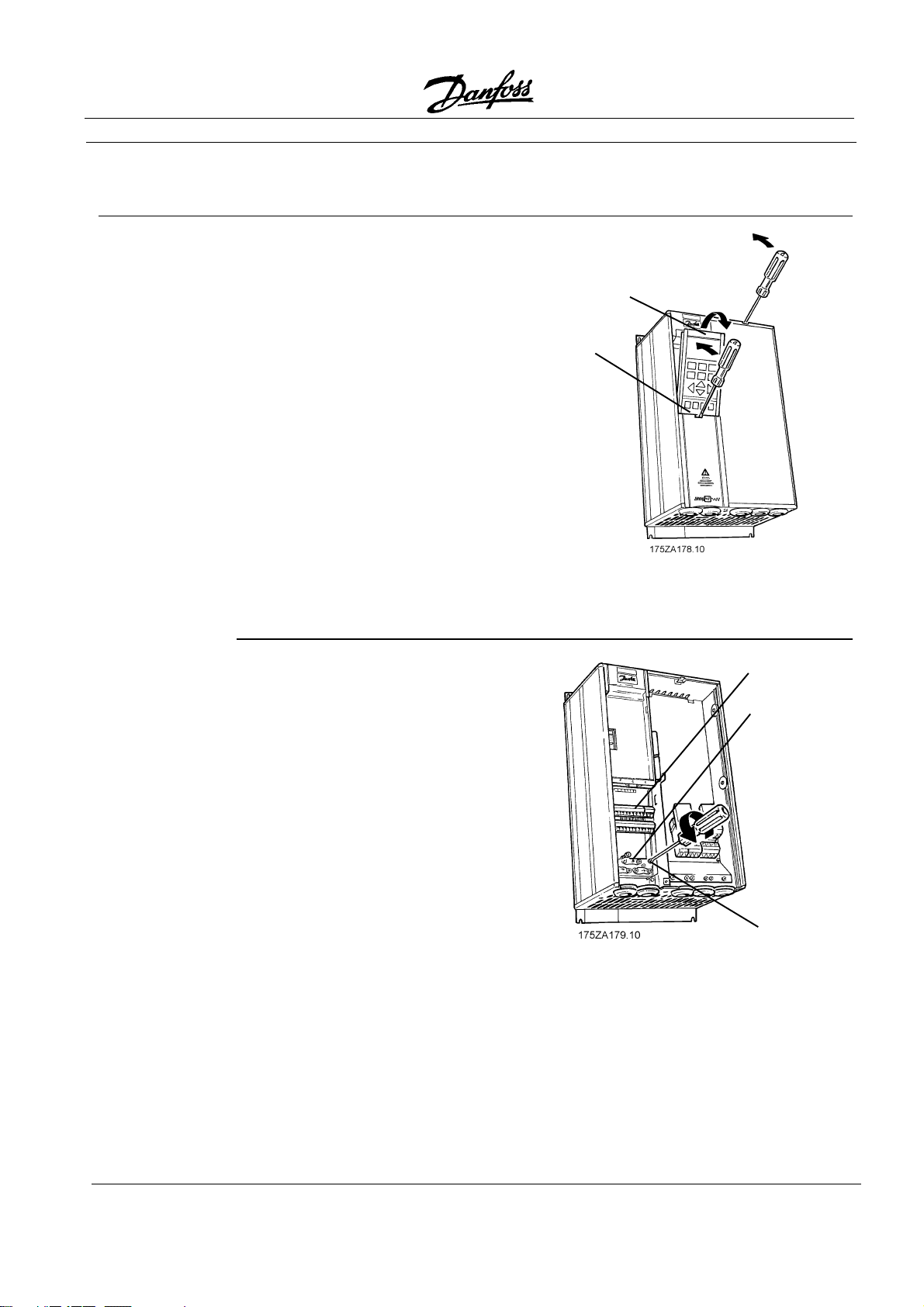

1. Access to

Control

Card

Cassette

2. Disconnect

Control

Card

Cassette

IP20/NEMA 1 and Bookstyle

• Remove Local Control Panel (LCP) by

pulling out from top of display (A) by

hand. LCP connector on panel back

will disconnect.

• Remove protective cover by gently

prying with a screw driver at notch (B)

and lift cover out of guide pin fittings.

IP54/NEMA 12

• Open front panel of drive by loosening

captive screws and swing open.

• Disconnect Local Control Panel (LCP)

cable from drive control card.

• Remove control wiring by unplugging

connector terminals (A).

• Remove grounding clamps (B) by

removing two screws holding each in

place. Save screws for reassembly.

• Loosen two captive screws (C) securing

cassette to chassis.

(A)

(B)

(A)

(B)

12

(C)

MG.60.E4.02 - VLT is a registered Danfoss trademark

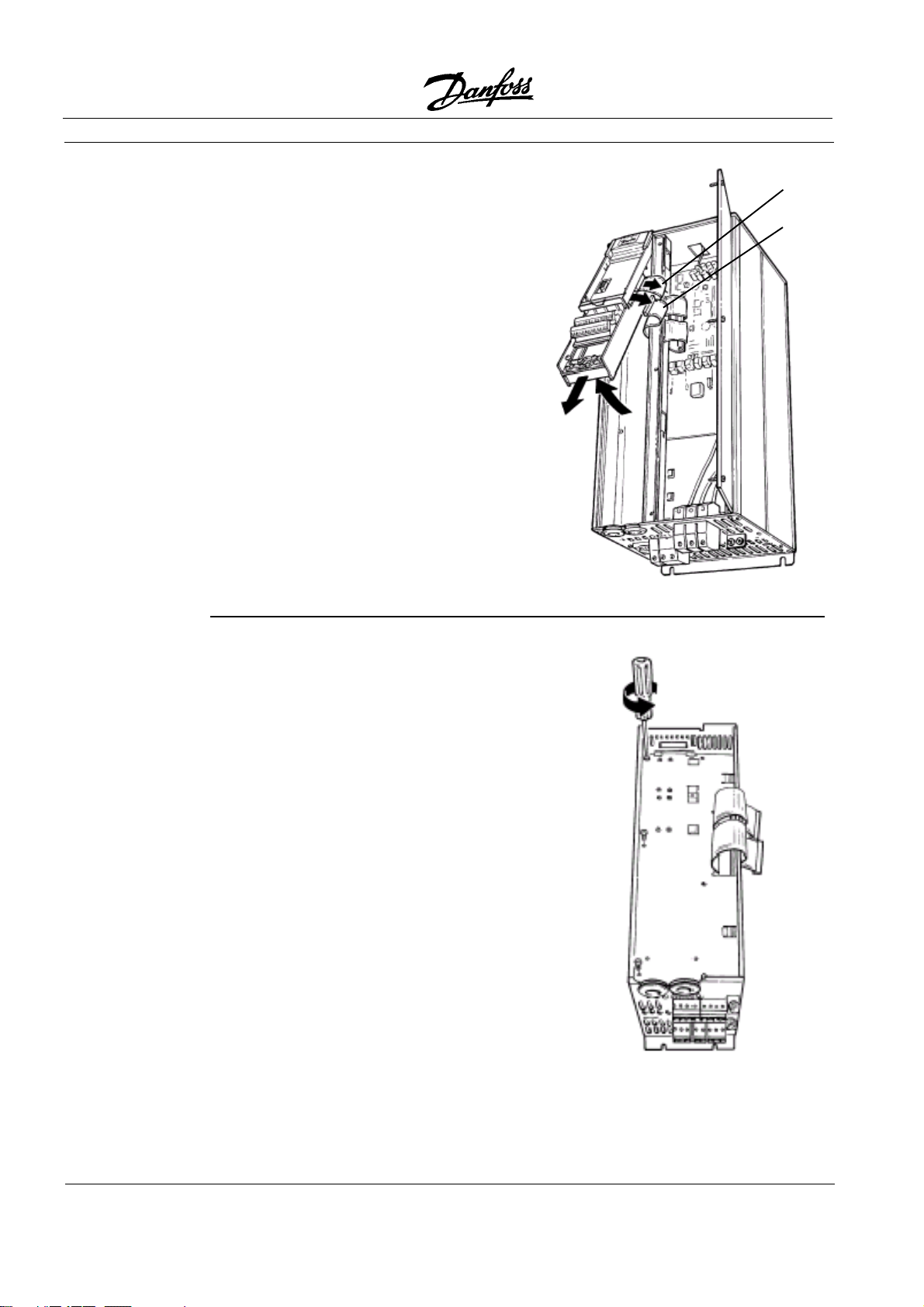

Page 13

VLT® 5000 / VLT® 6000

3. Remove

Cassette

and Ribbon

Cables

• Lift control card cassette from bottom.

• Unplug two ribbon cables (A) and (B)

from control board.

• Unhinge cassette at top to remove.

NOTE

Ribbon cables will need to be

reconnected to same connections from which removed.

(A)

(B)

4. Chassis

Ground

Connections

NOTE

Ground strips are used on 208 V

drives of 22 kW (30 HP) or less

and on 460 V drives of 45 kW

(60 HP) or less. For all other

drives, go to step 6.

• Location of holes to mount grounding

strips can vary with drive configuration.

When applicable, remove mounting

screws and washers located in chassis

using Torx T-20 screw driver and save

for reassembly. Otherwise, grounding

strips attach with screws and washers

provided, as shown in step 5.

MG.60.E4.02 - VLT is a registered Danfoss trademark

13

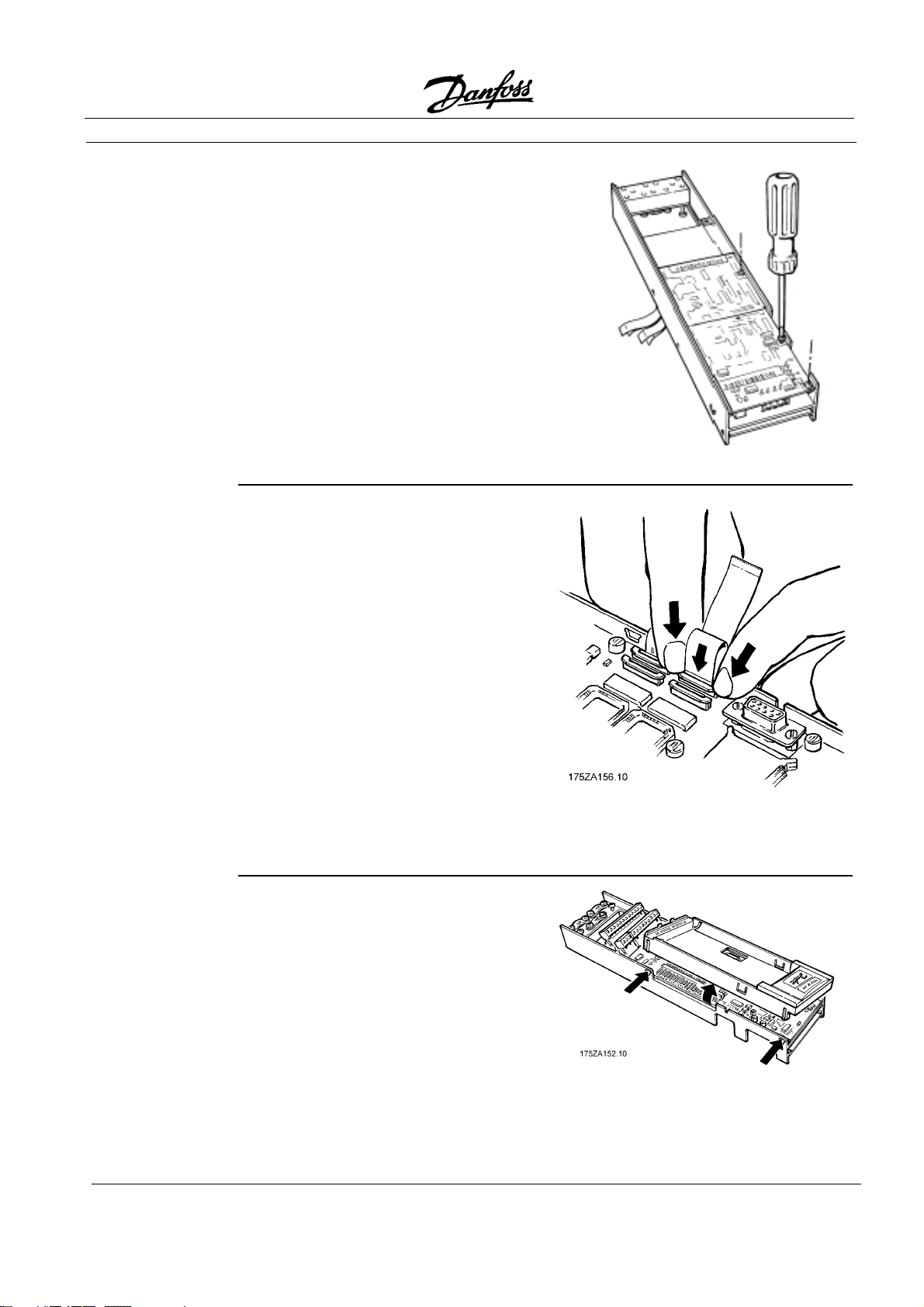

Page 14

VLT® 5000 / VLT® 6000

5. Install

Chassis

Ground

Connections

• Align ground strips over screw holes.

Strip with fewest contact points mounts

on cable side of chassis. Tabs on

grounding strips point toward outside

of chassis.

• Replace screws removed in step 4 and

add additional screws and washers

provided, as necessary. Tighten to

0.9 Nm (8 in-lbs) using Torx T-20 screw

driver.

Ground

Strips

6. Install

Ribbon

Cables

between

Option

Cards

• Attach ribbon cables between

LonWorks control card and memory

card.

• Be sure exposed wire portion of ribbon

cable (A) is facing front of socket (B).

Do not remove blue insulation covering

end of ribbon cable.

• Pull up collar (C) of ribbon cable socket,

insert cable and push collar closed.

• Repeat procedure for all ribbon cables.

IP20/NEMA 1 and IP54/NEMA 12

• Remove terminal connector from

terminal block (D) and connect to

terminal block (E) at this time for ease

of access.

(D)

(E)

14

MG.60.E4.02 - VLT is a registered Danfoss trademark

Page 15

VLT® 5000 / VLT® 6000

7. Remove

LCP Cradle

8. Ribbon

Cable

Routing

IP20/NEMA 1 and Bookstyle

• Carefully push in tabs at corners of LCP

cradle to release clips. Pull out to

disengage clips and lift cradle free.

• Route ribbon cables from LonWorks

memory card through slot at side of

control board cassette.

9. Insert

LonWorks

Card

MG.60.E4.02 - VLT is a registered Danfoss trademark

• Insert edge of LonWorks cards into slot

in side of cassette and align screw

holes.

15

Page 16

VLT® 5000 / VLT® 6000

10. Secure

LonW orks

Card

11. Install

Ribbon

Cable on

VLT Control

Board

• Secure LonWorks card with 3

self-tapping screws and washers

provided using Torx T-10 screw driver.

Tighten to 8 in-lbs (0.9 Nm).

• Be sure not to twist or crimp ribbon

cables.

• Insert cables into corresponding

sockets and fasten in accordance with

directions in step 5.

12. Install

LCP Cradle

16

IP20/NEMA 1 and Bookstyle

• Insert cradle clips into holes in cassette.

• Push down on cradle to snap it into

place.

MG.60.E4.02 - VLT is a registered Danfoss trademark

Page 17

VLT® 5000 / VLT® 6000

13. Install

Spring

T ension

Clip

IP20/NEMA 1 and IP54/NEMA 12

• Spring tension clip (A) is used as a cable

strain relief and ground point for

shielded cable.

• Insert clip through inner wall of chassis

at slot provided.

• Compress spring into clip at outer wall

of chassis.

(A)

14. Install

Ribbon

Cables

• Connect ribbon cables.

• Connect control card cassette to hinge

at top of drive and fit into chassis.

NOTE

Ribbon cables must be reconnected to same connections from

which removed.

MG.60.E4.02 - VLT is a registered Danfoss trademark

17

Page 18

VLT® 5000 / VLT® 6000

15. Install

Control Card

Cassette

16. Plug in

T erminal

Connector

• Fasten control card cassette by

alternately tightening two captive

screws (A). Tighten to 0.9 Nm (8 in-lbs).

• Route control wires through clamp

fasteners (B) and secure clamps with

two screws.

• Connect control terminals (C) by firmly

pressing them into connector

receptacles.

• Connect signal wire NET A to terminal

79 and NET B to 80 of terminal

connector. (In free topology model,

connections can be reversed.)

(C)

(A)

(B)

61

80

79

IP20/NEMA 1 and IP54/NEMA 12

• Plug network connector into terminal

block at side of control card cassette.

• Insert LonWorks cable between inner

wall of chassis and spring tension clip.

NOTE

Shielded cable is recommended.

Ground shielded cable at spring

tension clip location or ground at

cable clamp by removing cable

insulation at contact point. Do not

use connector terminal 61.

Bookstyle

• Remove knockout from top of drive (A).

• Route control wires through clamp

fasteners (B) on cable plate and secure

clamps with screws. Tighten to 0.9 Nm

(8 in-lbs).

• Secure cable plate to drive with screws

and screw holes provided. Tighten to

0.9 Nm (8 in-lbs).

• Plug network connector (C) into

terminal block at top of control card

cassette.

(A)

Shield 61

NET B 80

NET A 79

(B)

(C)

18

MG.60.E4.02 - VLT is a registered Danfoss trademark

Page 19

VLT® 5000 / VLT® 6000

Network

Initialization

of LonW orks

Option Card

LonMark

XIF Files

The LonWorks option card contains a NEURON

chip with a unique address. After hardware

installation, initialize the LonWorks option card.

Addressing nodes on the LonWorks network

is performed at installation time by an

installation tool or network management tool.

Addressing requires the retrieval of a node’s

NEURON ID. The NEURON ID is a 48 bit number

that identifies every manufactured NEURON

chip. There are several methods by which the

network software will initialize the drive

automatically. The network can recognize the

drive without action beyond proper

installation. The card is then ready to be

programmed for network operation. The VLT

LonWorks option supports three additional

methods of addressing a node:

1. Service Pin - There are two

momentary-contact service switches that

send the NEURON ID over the network. If the

network software prompts the action, press

A LonMark interface file (.XIF extension)

provides the host processor with device

information. With this, it is possible to design

a LonWorks network without the adjustable

frequency drive being physically present.

The VLTLON.XIF can be downloaded from

the Internet site www.danfoss.com/drives. The

LonWorks option card does not contain an

internal interface file.

either service pin (SW1 or SW3) to transmit

the NEURON ID over the network. The service

pin locations are shown in the illustration in

Terminator and Service Switch Locations in

this manual.

2. Query and Wink - The LonWorks option

card is shipped with a domain of “0” and

subnet of “1.” Upon receiving the wink

command, the on-board green status LED

flashes so that the installer can locate the

node. The chip sends out its Neuron ID over

the network in response to the query

command.

3. NEURON ID Label - The VLT LonWorks

option card has a NEURON ID label that

displays the NEURON ID as a 12 digit

hexadecimal number. The installer can

manually enter the NEURON ID during

installation.

The VLT LonWorks network interface consists

only of SNVTs. The SNVTs support the

LonMark Controller Profile along with VLT

configuration, control and monitoring

capabilities. Any combination of SNVTs can

be used to operate the VLT.

Echelon Corporation has also developed a set

of free plug-ins available through their web site

at www.echelon.com/plugin/default.htm. Also

intended for network design, these plug-ins

provide easy access to screens which simplify

the process of manually setting up the drive,

testing, and monitoring operation.

The drive may also be added to the network

upon initialization.

MG.60.E4.02 - VLT is a registered Danfoss trademark

19

Page 20

VLT® 5000 / VLT® 6000

78 kbps and

1.25 Mbps

Transformer

Coupled

Twisted Pair

Model

Doubly Terminated

Bus Topology

T erminator

and Service

Switch

Locations

The 78 kbps and 1.25 Mbps Transformer

Coupled Twisted Pair model system is

designed to support doubly terminated bus

topology.

TRANSCEIVER

TERMINATION

The terminator switch location for the 78 kbps

or 1.25 Mbps Transformer Coupled Twisted

Pair model is shown below.

TT

erminator Switcherminator Switch

T

erminator Switch

TT

erminator Switcherminator Switch

TERMINATION

Service Pin SwitchesService Pin Switches

Service Pin Switches

Service Pin SwitchesService Pin Switches

Switch 1:Switch 1:

Switch 1:

Switch 1:Switch 1:

Network TNetwork T

Network T

Network TNetwork T

The VLT LonWorks node is

terminated.

Network TNetwork T

Network T

Network TNetwork T

The VLT LonWorks node is not

terminated. Factory setting.

ermination ONermination ON

ermination ON

ermination ONermination ON

ermination OFFermination OFF

ermination OFF

ermination OFFermination OFF

78 kbps and 1.25 Mbps LonWorks

Control Card

20

MG.60.E4.02 - VLT is a registered Danfoss trademark

Page 21

VLT® 5000 / VLT® 6000

CAUTION

!

Performance

Specification

Communication on TP/

XF-78 and

TP/XF-1250

Channels

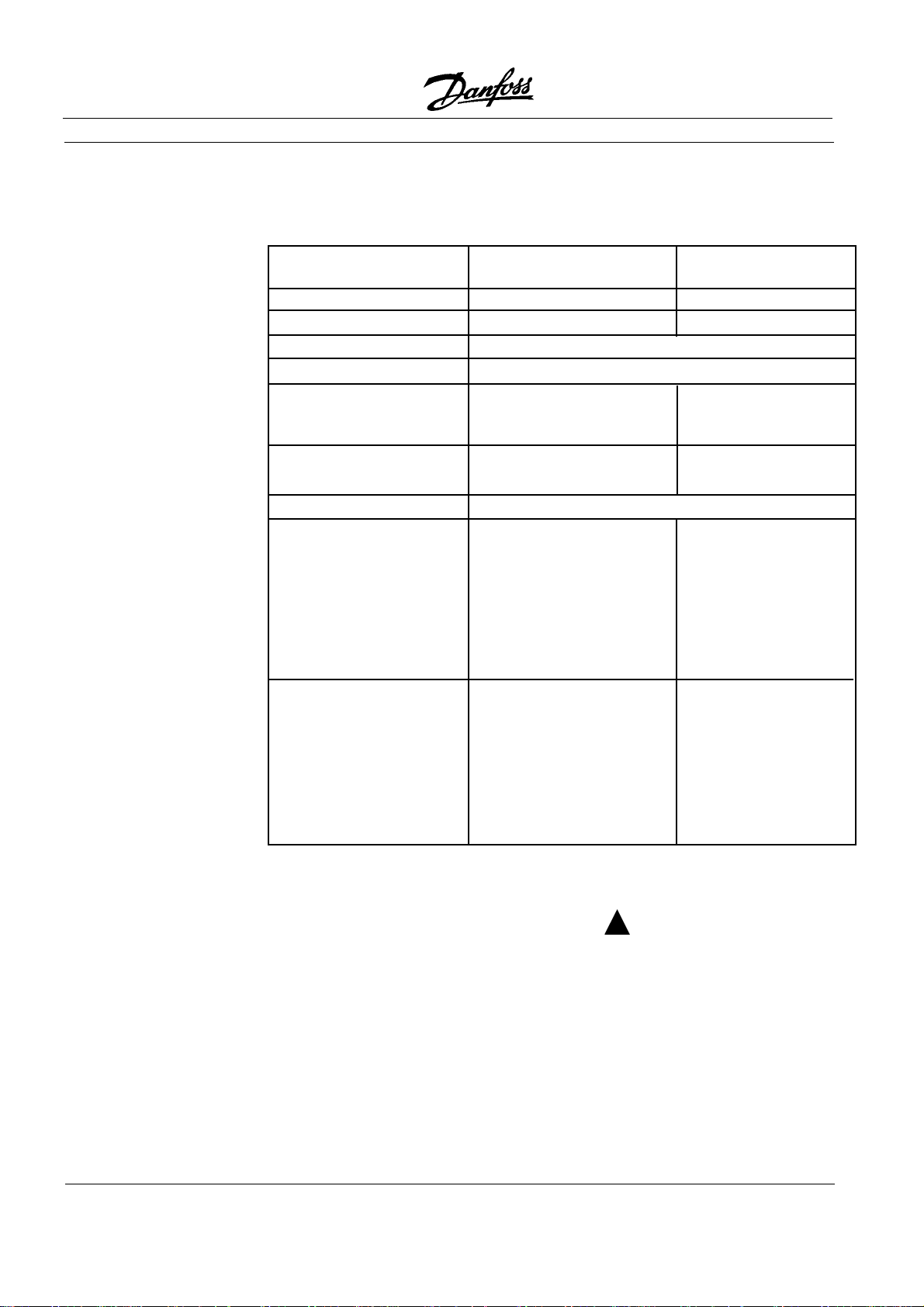

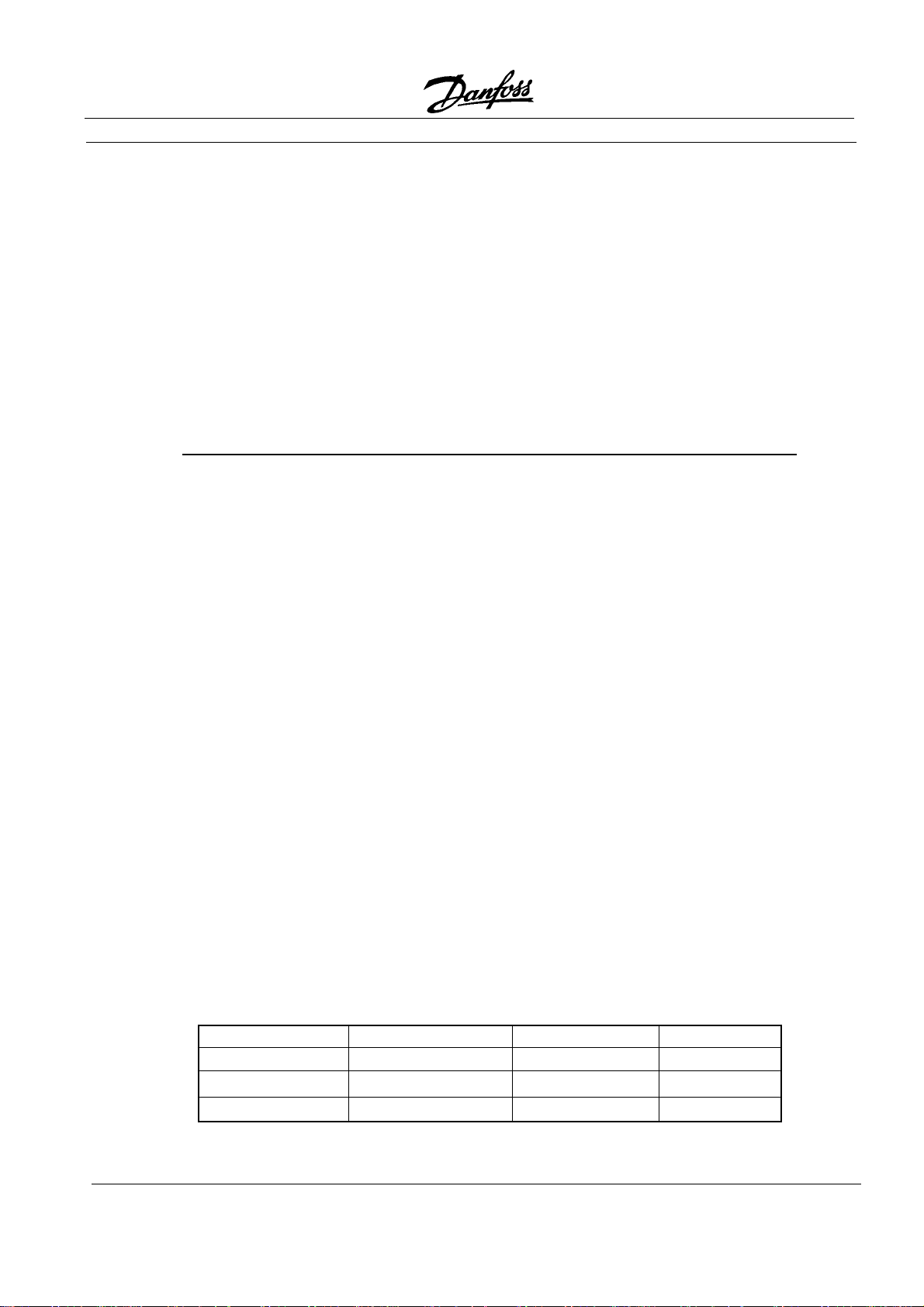

The table below provides a summary of the

performance specifications for the 78 kbps and

PerformancePerformance

Performance

PerformancePerformance

SpecificationsSpecifications

Specifications

SpecificationsSpecifications

TP/XF-78TP/XF-78

TP/XF-78

TP/XF-78TP/XF-78

1.25 Mbps transformer-coupled twisted pair

channels.

TP/XF-1250TP/XF-1250

TP/XF-1250

TP/XF-1250TP/XF-1250

Transmission Speed 78kbps 1.25Mbps

Nodes per Channel 64 64

Network Bus Wiring UL Level IV, 0.65 mm (22 AWG) shielded

Network Stub Wiring UL Level IV, 0.5 mm (22 or 24 AWG) shielded

Network Bus Length

Typical

Worst case

Maximum Stub Length

1

2

2000m (6,560 ft) 500m (1,640 ft)

1330m (4,360 ft) 125m (410 ft)

3

3m (10 ft) 0.3m (0 to 70°C)

1 ft (32°F to 158°F)

Network Terminators Required at both ends of the network

Temperature

Operating 0 to 70°C (64 nodes) 0 to +70°C (64 nodes)

(32°F to 158°F) (32°F to 158°F)

Non-operating –40 to +85°C (44 nodes) –20 to +85°C (32 nodes)

(–40°F to +185°F) (–4°F to +185°F)

–40 to +70°C (20 nodes)

(–40°F to +158°F)

Electrostatic Discharge

to Network Connectors

No Errors to 15,000 V to 15,000 V

No Hard Failures to 20,000 V to 20,000 V

Isolation between Network

and I/O Connectors

0 - 60Hz (60 seconds) 1,000 VRMS 1,000 VRMS

0 - 60Hz (continuous) 277 VRMS 277 VRMS

MG.60.E4.02 - VLT is a registered Danfoss trademark

1

Typical conditions are 20°C (68°F), +5 VDC

supply voltage, normal wire temperature,

and 64 evenly distributed nodes.

2

Worst case conditions are the combined

effect of worst case conditions of all the

above performance parameters — nodes

per channel, network bus length, stub

length, temperature, etc.

3

The stub length in the table assumes a mutual

capacitance of 56 pF/m (17 pF/ft) for the

twisted pair stub cable. Actual lengths may

be shorter or longer depending on the

actual, measured value.

It is necessary to terminate theIt is necessary to terminate the

It is necessary to terminate the

It is necessary to terminate theIt is necessary to terminate the

ends of a TP/XF-78 or TP/XF-1250ends of a TP/XF-78 or TP/XF-1250

ends of a TP/XF-78 or TP/XF-1250

ends of a TP/XF-78 or TP/XF-1250ends of a TP/XF-78 or TP/XF-1250

twisted pair bus to minimizetwisted pair bus to minimize

twisted pair bus to minimize

twisted pair bus to minimizetwisted pair bus to minimize

rr

eflections. Failureflections. Failur

r

eflections. Failur

rr

eflections. Failureflections. Failur

bus will degrade networkbus will degrade network

bus will degrade network

bus will degrade networkbus will degrade network

performance.performance.

performance.

performance.performance.

e to terminate thee to terminate the

e to terminate the

e to terminate thee to terminate the

21

Page 22

VLT® 5000 / VLT® 6000

LonW orks

Card

Diagnostic

LEDs

Status LED

The LonWorks board includes two LEDs to

display the communication status of the

board, display the state of the NEURON chip,

and respond to the network management

The Status LED patterThe Status LED patter

The Status LED patter

The Status LED patterThe Status LED patter

ONON

ON

ONON

There is power on the board but

there has not been any

communication to an input network

variable in the last 2 seconds.

Flashing 10 times per secondFlashing 10 times per second

Flashing 10 times per second

Flashing 10 times per secondFlashing 10 times per second

There is regular network

communication to the VLT's input

network variables.

Flashing intermittentlyFlashing intermittently

Flashing intermittently

Flashing intermittentlyFlashing intermittently

There is network communication to

the VLT's input network variables but

input network variables are received

at a period greater than 2 seconds.

ns arns ar

ns ar

ns arns ar

e:e:

e:

e:e:

“wink” command. The onboard LEDs are the

Service LED (LED 1, red) and the Status LED

(LED 2, green).

LEDsLEDs

LEDs

LEDsLEDs

Service LED

Flashing 5 times per secondFlashing 5 times per second

Flashing 5 times per second

Flashing 5 times per secondFlashing 5 times per second

The response to the network

management “Wink” command. The

VLT LonWorks node must be reset to

leave the wink state.

OFFOFF

OFF

OFFOFF

No power on board or hardware fault.

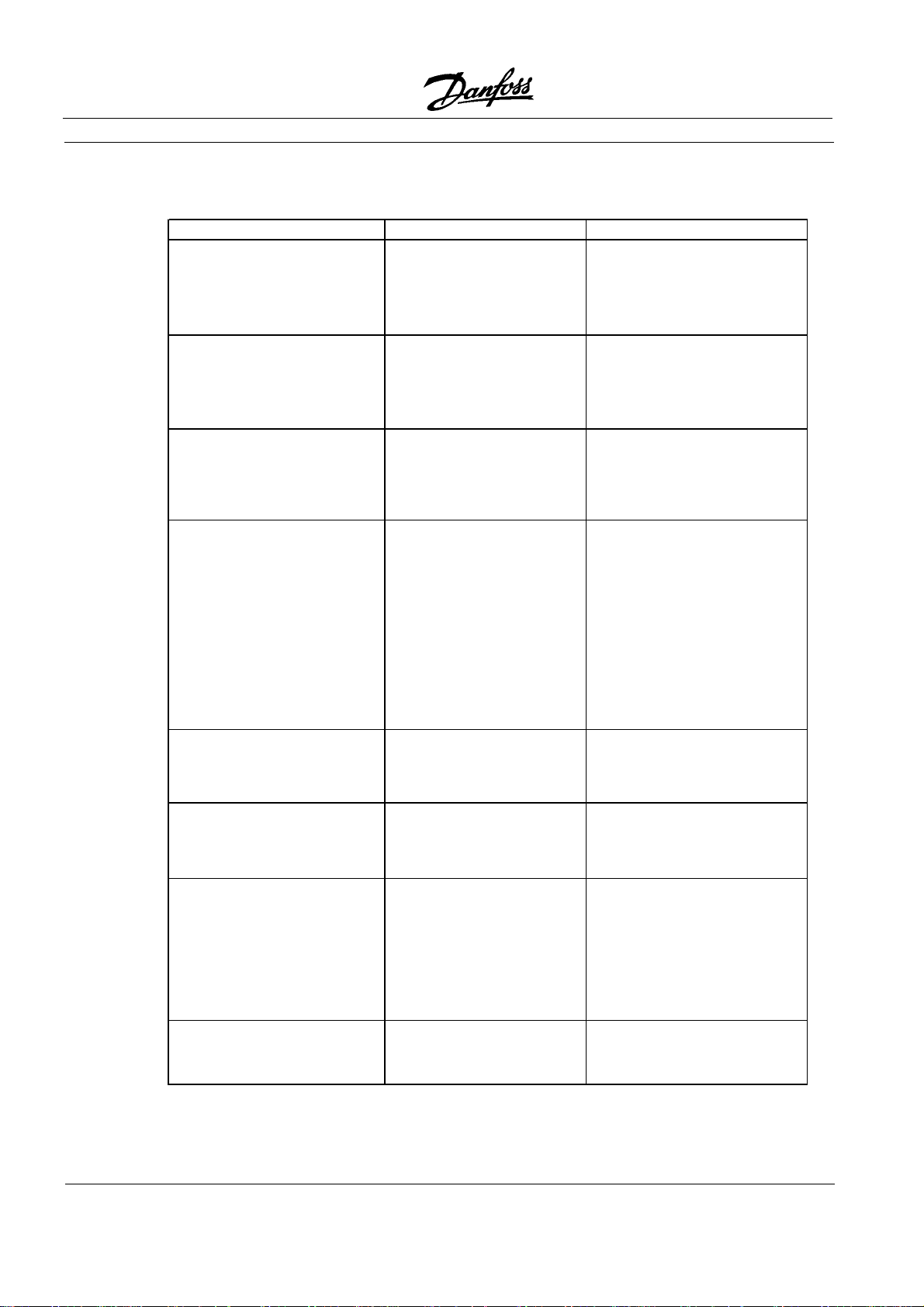

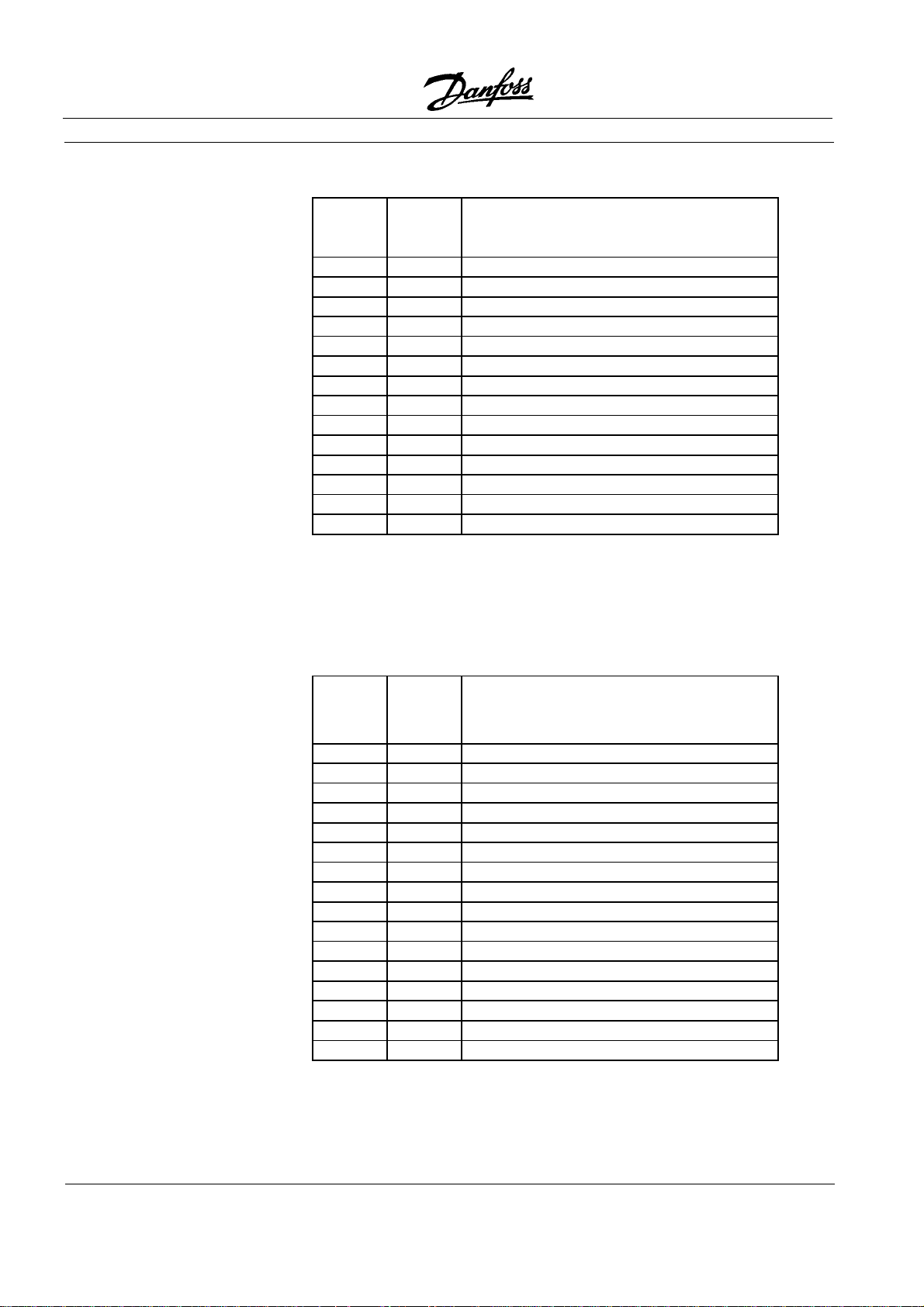

The Service LED displays the state of the

NEURON chip. The following table shows the

Service LED patterns for various states and

defines their meaning.

22

MG.60.E4.02 - VLT is a registered Danfoss trademark

Page 23

Service LED

Patterns and

Descriptions

LED Pattern Operation Description

Continuously ON Power-up of Neuron 3120xx

chip-based node or Neuron

3150 chip-based node with

any PROM

VLT® 5000 / VLT® 6000

Use EEBLANK and follow

reinitialization procedure.

Continuously OFF Power-up of Neuron 3120xx

chip-based node or Neuron

3150 chip-based node with

any PROM

ON for one second at power-up

followed by approximately 2

seconds OFF, then stays ON

Short flash every 3 seconds Anytime

Flashing at 1 second intervals Anytime Indicates node is unconfigured

Power-up/Reset May be caused by Neuron chip

Indicates bad node hardware.

firmware when mismatch occurs

in application checksum.

Indicates watchdog timer resets

occurring.

Possible corrupt EEPROM.

For Neuron 3150 chip-based

node, use EEBLANK and follow

reinitialization procedure.

but has an application. Proceed

with loading node.

Brief flash at power-up. OFF

duration approximately 10

seconds after which stays ON

Brief flash at power-up. OFF

duration approximately 1 to 15

seconds, depending on

application size and system

clock. LED then begins flashing

at 1 second intervals.

Brief flash at power-up followed

by OFF

MG.60.E4.02 - VLT is a registered Danfoss trademark

Using EEBLANK or Neuron

3150 chip-based node

First power-up with new

PROM on Neuron 3150 chipbased custom node.

Unconfigured firmware state

exported.

Indicate completion of blanking

process.

Indicates unconfigured state.

Node is configuring and running

normally.

Service LED Pattern Descriptions

23

Page 24

VLT® 5000 / VLT® 6000

VLT adjustable

frequency drive

and LonWorks

Network

Configuration

Network

Drive

Control

Input

The VLT LonWorks option card supports

LonMark network design to improve

interoperability. The Controller Object contains

the VLT Adjustable Frequency Drive profile.

The configuration parameters are network

The most common functions for controlling

the VLT Adjustable Frequency Drive from the

LonWorks network are made readily available.

Those functions and their descriptions are

presented in the table below. The control word

function accesses additional drive capabilities

for network control.

The choice of open loop or closed loop

operation of the drive is selected in parameter

100, Configuration.

Using nviRefPcnt, the drive's reference is

expressed as a percentage of the reference

range. The range is set using parameters 204,

Min. Reference and 205, Max. Reference. In

open loop operation, reference represents the

drive's desired output speed. In this case, set

Min. Reference to 0 Hz and Max. Reference

equal to Max. Frequency in parameter 202.

In closed loop operation, reference represents

the desired setpoint. It is recommended that

parameters 204 and 205 be set equal to

parameters 201, Min. Frequency and 202,

Max. Frequency.

variable inputs to the VLT. Configuration of

parameters needs setting only one time,

usually at installation.

analog input terminals should not be used for

reference signals. The default setting (0%)

should be maintained for preset references in

parameters 211 (215) through 214 (218). Also,

in closed loop operation, the default setting

(0.0) should be maintained for drive setpoints

in parameters 418 (215) and 419 (218).

Start/Stop and Reset fault

SNVT_lev_disc. ST_OFF and ST_NUL are

interpreted as low or “0.” ST_LOW, ST_MED,

ST_HIGH, and ST_ON are interpreted as high

or “1.”

NOTE

T o optimize network performance

and for proper drive operation,

use only one of following input

reference commands.

Reference 1

Network variable nviRefPcnt is a signed value.

It represents the desired percentage of the

VLT drive's reference range.

24

All references provided to the drive are added

to the total reference value. If reference is to

be controlled by the LonWorks bus only,

ensure that all other reference inputs are zero.

This means that digital input terminals and

Function SNVT type Variable Name Units Max Min

Start/Stop SNVT_lev_disc nviStartStop Boolean Start Stop

*Reset fault SNVT_lev_disc nviResetFault Boolean Reset Enable

Reference 1 SNVT_lev_percent nviRefPcnt 0.005% 163.835 –163.840

Reference 2 SNVT_angle_vel nviRefRads 0.1 rad/sec 3276.7 –3276.8

Reference 3 SNVT_freq_hz nviRefHz 0.1 Hz 6553.5 0

Control word SNVT_state nviControlword 16 Boolean NA NA

* Reset on a transition from 0 to 1. A “0” must be sent after reset to enable the next reset.

Network Variable Inputs to VLT

VLT 5000 parameters are shown in parenthesis, where applicable.

MG.60.E4.02 - VLT is a registered Danfoss trademark

Page 25

VLT® 5000 / VLT® 6000

p

p

p

p

p

q

q

p

p

g

g

g

g

)

)

)

p

)

)

)

)

g

g

g

g

g

g

e

e

Network

Drive

Control

Input

(continued)

Reference 2

Network variable nviRefRads is a signed value.

A negative value is interpreted as zero. It

represents the desired output frequency of the

drive in radians/second in open loop. It is rarely

used in closed loop.

Reference 3

Network variable nviRefHz is an unsigned

value. It represents the output frequency of

the drive in Hz in open loop. It is rarely used in

closed loop mode.

Control Word

The input network variable nviControlWord is

a 16-bit word that provides additional

operational control of the drive, as listed in

the table below. The settings shown represent

the Coast Stop command

Bit

Bit Setting

Setting 00001

BitBit

SettingSetting

00

00 0000Preset Ref. LSB

0000

01

01 0000Preset Ref. MSB

0101

02

02 1111DC Brake

0202

03

03 0000 Coast Stop

0303

04

04 1111Quick Stop

0404

05

05 1111 Freeze Freq.

0505

06

06 0000Ramp Stop

0606

07

07 0000 no Reset

0707

08

08 0000no Jog

0808

09

09 0000 no function

0909

10

10 1111 see Parm. 805

1010

11

11 0000 Relay 1 OFF

1111

12

12 0000 Relay 2 OFF

1212

13

13 0000 Setup LSB

1313

14

14 0000 Setup MSB

1414

15

15 0000no Reversing

1515

Preset Ref. LSB

Preset Ref. LSBPreset Ref. LSB

Preset Ref. MSB

Preset Ref. MSBPreset Ref. MSB

DC Brake no DC Brake

DC BrakeDC Brake

Coast Stop no Coast Stop

Coast StopCoast Stop

Quick Stop no Quick Stop

Quick StopQuick Stop

Freeze Freq. no Freeze Freq.

Freeze Freq.Freeze Freq.

Ramp Stop Start

Ramp StopRamp Stop

no Reset Reset

no Resetno Reset

no Jog Jog

no Jogno Jog

no function 02

no functionno function

see Parm. 805 03

see Parm. 805see Parm. 805

Relay 1 OFF Relay 1 ON

Relay 1 OFFRelay 1 OFF

Relay 2 OFF Relay 2 ON

Relay 2 OFFRelay 2 OFF

no Reversing Reversing

no Reversingno Reversing

Setup LSB 06

Setup LSBSetup LSB

Setup MSB 07

Setup MSBSetup MSB

1

11

no DC Brake

no DC Brakeno DC Brake

no Coast Stop

no Coast Stopno Coast Stop

no Quick Stop

no Quick Stopno Quick Stop

no Freeze Freq. nviStartStop

no Freeze Freq.no Freeze Freq.

Start Bit

StartStart

Reset 00

ResetReset

Jog 01

JogJog

Relay 1 ON 04

Relay 1 ONRelay 1 ON

Relay 2 ON 05

Relay 2 ONRelay 2 ON

Reversing 08

ReversingReversing

Control Word Bit Descriptions

for Coast Stop

The VLT 5000 allows the choice between two

control word profiles, selected in parameter 512,

Telegram Profile. The table below defines the

Profidrive control word used for transmitting

commands to the drive using the Profibus

protocol.

Bit

Bit 1111

BitBit

00

00 ON 1

0000

01

01 ON 2

0101

02

02 ON 3

0202

03

03 Enable

0303

04

04 Ramp

0404

05

05 Ramp Enable

0505

06

06 Start

0606

07

07 Reset

0707

08

08 ON

0808

09

09 ON

0909

10

10 Valid

1010

11

11 Slow down

1111

12

12 Catch up

1212

13

13

1313

14

14

1414

15

15 Reversing

1515

Valu

Value

ValueValu

32768

32768

3276832768

16384

16384

1638416384

8192

8192

81928192

4096

4096

40964096

2048

2048

20482048

1024

1024

10241024

512

512

512512

256

256

256256

128

128

128128

64

64

6464

32

32

3232

16

16

1616

8888

4444

2222

1111

0000

OFF 1

OFF 1

OFF 1OFF 1

OFF 2

OFF 2

OFF 2OFF 2

OFF 3

OFF 3

OFF 3OFF 3

Motor coastin

Motor coastin

Motor coastin

Motor coastin

Quick stop

Quick stop

Quick sto

Quick sto

Freeze out freq.

Freeze out fre

Freeze out fre

sto

Ramp sto

Ram

Ramp sto

Ramp sto

No function

No function

No functionNo function

Jo

1 OFF

1 OFF

Jo

Jo

1 OFFJog 1 OFF

2 OFF

2 OFF

Jo

Jo

Jo

2 OFFJog 2 OFF

Data not valid

Data not valid

Data not validData not valid

No function

No function

No functionNo function

No function

No function

No functionNo function

No function

No function

No functionNo function

Setup 1 (LSB)

Setup 1 (LSB

Setup 1 (LSB

Setup 1 (LSB

Setup 2 (MSB

Setu

Setup 2 (MSB

Setup 2 (MSB

.

.Freeze out freq.

2 (MSB

ON 1

ON 1ON 1

ON 2

ON 2ON 2

ON 3

ON 3ON 3

Enable

EnableEnable

Ramp

RampRamp

Ramp Enable

Ramp EnableRamp Enable

Start

StartStart

Reset

ResetReset

ON

ONON

ON

ONON

Valid

ValidValid

Slow down

Slow downSlow down

Catch up

Catch upCatch up

Reversing

ReversingReversing

Profidrive Control W ord Bit

Descriptions

The equivalent control word bit settings to

start and stop the drive (nviStartStop) and to

reset after a fault (nviResetFault) are described

in the table below.

nviStartStop nviResetFault

nviStartStopnviStartStop

Bit 00001

BitBit

00 00000

0000

01 00000

0101

02 11111

0202

03 11111

0303

04 11111

0404

05 11111

0505

06 00001

0606

07 00000

0707

08 00000

0808

09

09 00000

0909

10

10 11111

1010

11

11 00000

1111

12

12 00000

1212

13

13 00000

1313

14

14 00000

1414

15

15 00000

1515

nviResetFault

nviResetFaultnviResetFault

10

01

11

00

00

00

00

00

11

11

11

11

11

11

11

11

10

11

01

00

00

00

00

00

11

11

00

00

00

00

00

00

00

00

00

00

1 Description

Description

11

DescriptionDescription

0Preset Ref LSB

Preset Ref LSB

00

Preset Ref LSBPreset Ref LSB

0Preset Ref MSB

Preset Ref MSB

00

Preset Ref MSBPreset Ref MSB

1No DC Brake

No DC Brake

11

No DC BrakeNo DC Brake

1 No Coast Stop

No Coast Stop

11

No Coast StopNo Coast Stop

1 No Quick Stop

No Quick Stop

11

No Quick StopNo Quick Stop

1 No Freeze Freq.

No Freeze Freq.

11

No Freeze Freq.No Freeze Freq.

0Start

Start

00

StartStart

1 Reset

Reset

11

ResetReset

0Jog

Jog

00

JogJog

0 No function

No function

00

No functionNo function

1Bit 10

Bit 10

11

Bit 10Bit 10

0 Relay 1 On

Relay 1 On

00

Relay 1 OnRelay 1 On

0 Relay 2 On

Relay 2 On

00

Relay 2 OnRelay 2 On

0 Setup LSB

Setup LSB

00

Setup LSBSetup LSB

0Setup MSB

Setup MSB

00

No value is written to the control word

No value is written to the control word

No value is written to the control word

No value is written to the control word

Setup MSBSetup MSB

0 Reversing

Reversing

00

ReversingReversing

Start/Stop and Fault Reset Control W ord

Bit Descriptions

NOTE

Drive always stops and ignores

serial bus commands to run when

OFF/STOP or STOP/RESET

function is activated from drive

keypad.

VLT 5000 parameters are shown in parenthesis, where applicable.

MG.60.E4.02 - VLT is a registered Danfoss trademark

25

Page 26

Precedence of the stop commands is:

1. Coast stop

2. Quick stop

3. DC brake stop

4. Ramp stop

Coast stop

The drive output stops immediately and

the motor coasts to a stop.

• Drive display show UN.READY (unit

ready) when coast stop is active.

• Drive cannot run in any mode.

• Parameter 503 (502), Coasting stop,

determines interaction with

input 27.

Quick stop

The drive output frequency ramps down

to 0 Hz according to time set in parameter

207 (212), Ramp Down Time.

• Drive display shows STOP.

• Drive cannot run in AUTO mode but

can run in HAND mode.

VLT® 5000 / VLT® 6000

Ramp stop

The drive output frequency ramps down to

0 Hz according to time set in parameter

207, Ramp Down Time.

• Factory setting is 60 sec for fan

applications and 10 sec for most

pump applications.

• Drive display shows STAND BY.

• Drive can run in HAND mode or

AUTO through a digital input

command.

• Parameter 505, Start, determines

interaction with input 18.

DC brake stop

The drive brakes the motor to a stop using

DC injection braking.

• Parameters 114 (125) and 115 (126)

determine amount and time of DC

current applied for braking.

• Drive display shows DC STOP.

• Drive cannot run in AUTO mode but

can run in HAND mode.

• Parameter 504, DC Brake,

determines interaction with input

27.

26

MG.60.E4.02 - VLT is a registered Danfoss trademark

Page 27

VLT® 5000 / VLT® 6000

Drive

Feedback to

Network

The VLT LonWorks option provides 16 output

variables to the network containing important

drive and motor feedback data. Feedback data

is sent when there is a change in value. The

VLT LonWorks option will only transmit bound

network variables. Since some data changes

continuously, the transmission rate of those

variables is limited. Min send time specifies

the minimum time between transmissions of

The Drive Outputs (1, 2, or 3) will have a

maximum time between transmission set by the

Max send time. This function acts as a transmit

heartbeat and allows a controller node to

determine the health of the controller/VLT

connection. The Max send time function is

disabled when the configuration network

variable nciMaxsendT is not configured or is set

to “0.”

variables.

Function SNVT type Variable Name Units Max Min

Drive status SNVT_state nvoDrvStatus 16 Boolean NA NA

Drive output 1 SNVT_lev_percent nvoOutputPcnt 0.005% 163.835 –

Current SNVT_amp nvoDrvCurnt 0.1 amps 3276.7 0

Energy SNVT_elec_kwh nvoDrvEnrg 1 kWh 65,535 0

Power SNVT_power_kilo nvoDrvPwr 0.1 kW 6553.5 0

Statusword SNVT_state nvoStatusWord 16 Boolean NA NA

Drive output 2 SNVT_angle_vel nvoOutputRads 0.1 rad/sec 3276.7 –3276.8

Drive output 3 SNVT_freq_hz nvoOutputHz 0.1 Hz 6553.5 0

Output voltage SNVT_volt nvoVoltage 0.1 V 3276.7 –3276.8

Digital input SNVT_state nvoDigitlInput 16 Boolean NA NA

Alarm SNVT_state nvoAlarmWord 16 Boolean NA NA

Warning 1 SNVT_state nvoWarning1 16 Boolean NA NA

Warning 2 SNVT_state nvoWarning2 16 Boolean NA NA

DC voltage SNVT_volt nvoDCVolt 0.1 V 3276.7 0

Motor temp SNVT_lev_cont nvoTempMtr 0.5 % 100 0

Inverter temp SNVT_lev_cont nvoTempInvrtr 0.5 % 100 0

163.840

Drive status

NvoDrvStatus, nvoStatusWord, nvoDigitalInput, nvoAlarmWord, nvoWarning1 and

nvoWarning2 are all 16 bit Boolean values

using the SNVT_state variable type. Individual

bits represent specific drive status states. The

tables provided in Drive Status Bit Definitions

define each bit.

Drive output 1

Network variable nvoOutputPcnt provides an

analog indication of drive operation. In open

loop, this is the drive output frequency in

percentage within the reference range. To

avoid negative numbers, or numbers above

100%, set parameter 204, Min. Reference to

0 Hz, and parameter 205, Max. Reference

equal to parameter 202, Max. Frequency.

VLT 5000 parameters are shown in parenthesis, where applicable.

MG.60.E4.02 - VLT is a registered Danfoss trademark

Network Variable Outputs from VLT

In closed loop, this is the drive's feedback

signal within the reference range. For best

operation, set Min. Reference to equal

parameter 413 (414), Min. Feedback, and

Max. Reference to equal parameter 414 (415),

Max. Feedback.

Drive output 2 and Drive Output 3

Output 2 is useful in open loop to report the

drive's output frequency in rad/sec. Output 3

in open loop reports the drive's output in Hz.

Note that in closed loop nvoOutputHz will

report the actual Feedback and not the output

frequency. For best results, set Min. Reference

to 0 Hz and Max. Reference equal to Max.

Frequency. These variable are rarely used in

closed loop.

27

Page 28

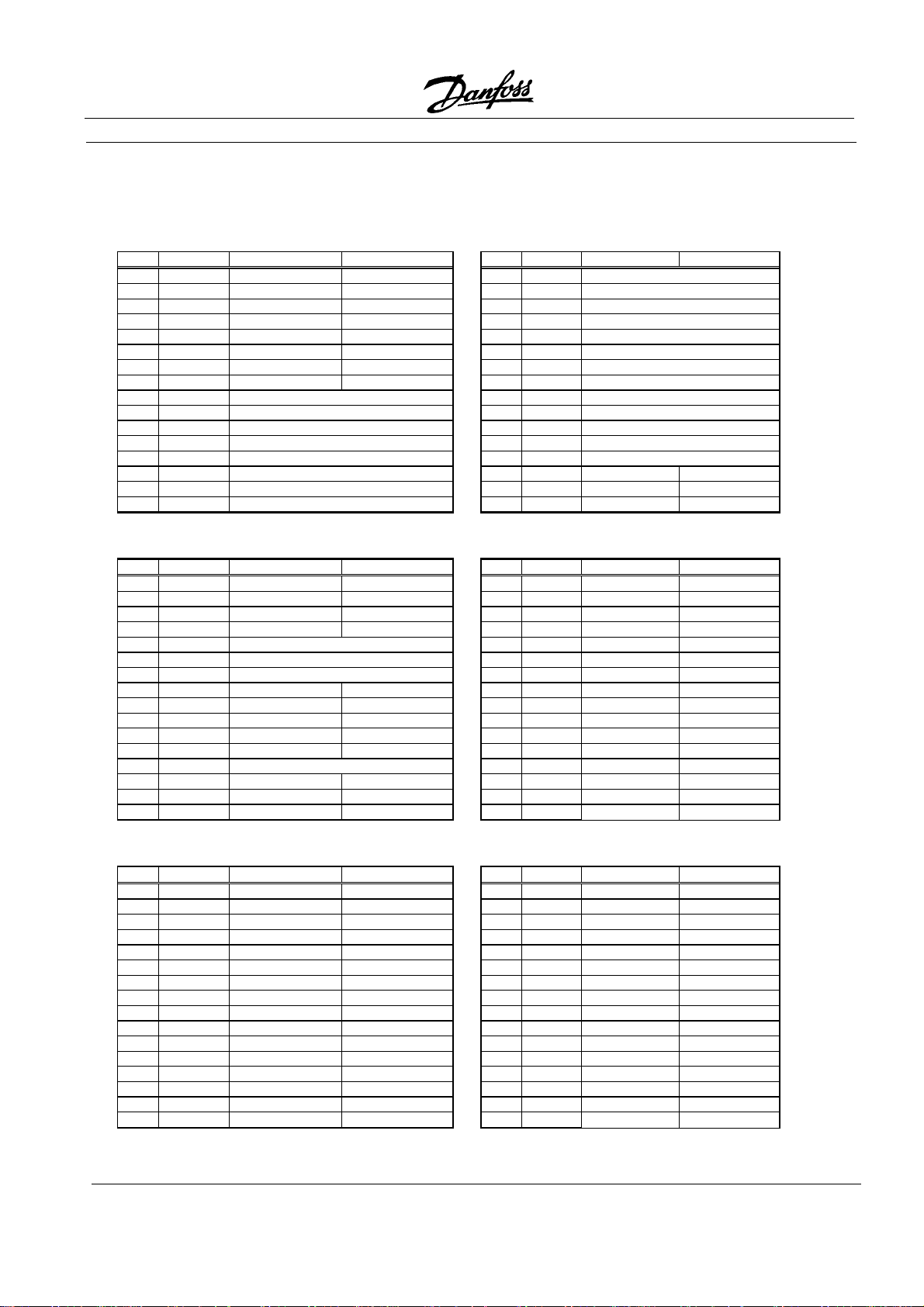

VLT 6000 Drive

Status Bit

Definitions

Bit Value 0 1 Bit Value 0 1

00 32768 33 OFF 33 ON 00 32768

01 16384 32 OFF 32 ON 01 16384

02 8192 29 OFF 29 ON 02 8192

03 4096 27 OFF 27 ON 03 4096

04 2048 19 OFF 19 ON 04 2048

05 1024 18 OFF 18 ON 05 1024

06 512 17 OFF 17 ON 06 512

07 256 16 OFF 16 ON 07 256

08 128 no function 08 128

09 64 no function 09 64

10 32 no function 10 32

11 16 no function 11 16

12 8 no function 12 8

13 4 no function 13 4 Stopped Running

14 2 no function 14 2 No Warning Warning

15 1 no function 15 1 no Alarm Alarm

Bit Value 0 1 Bit Value 0 1

00 32768 Alarm Ctrl. Ready 00 32768 normal Unknown Fault

01 16384 Alarm Drive Ready 01 16384 normal Trip Lock

02 8192 Safety Open Safety Closed 02 8192 normal AMA Fault

03 4096 No Alarm Alarm 03 4096 normal HPFB Timeout

04 2048 04 2048 normal RS-485 Timeout

05 1024 05 1024 normal ASIC Fault

06 512 06 512 normal Short circuit

07 256 no Warning Warning 07 256 normal SMPS Fault

08 128 Not at Ref. at Ref. 08 128 normal Ground Fault

09 64 Hand Mode Auto Mode 09 64 normal Overcurrent

10 32 Fr. Range Warn Freq. in Range 10 32 normal Current limit

11 16 Stopped Running 11 16 normal Mtr. Thermistor

12 8 no used 12 8 normal Motor thermal

13 4 normal Voltage Warn. 13 4 normal Undervoltage

14 2 normal Current lim. 14 2 normal Overvoltage

15 1 normal Therm. Warning 15 1 normal In. Phase loss

no function

no function

no function

no function

no function

no function

no function

no function

no function

no function

no function

no function

no function

nvoDigitalInput

not used

not used

not used

nvoDrvStatus

nvoStatusWord nvoAlarmWord

VLT® 5000 / VLT® 6000

Bit Value 0 1 Bit Value 0 1

00 32768 normal Ref. High 00 32768 normal Autoramping

01 16384 normal Ctrl. Crd. Fault 01 16384 normal Start Delay

02 8192 normal Pwr. Crd. Fault 02 8192 normal Sleep Boost

03 4096 normal HPFB Timeout 03 4096 normal Sleep

04 2048 normal RS-485 Timeout 04 2048 normal AMA Done

05 1024 normal Overcurrent 05 1024 normal AMA Running

06 512 normal Current limit 06 512 normal Rev. Start

07 256 normal Thermistor O.T. 07 256 no Ramp Ramping

08 128 normal Motor O.T. 08 128 Forward Reverse

09 64 normal Inverter O.T. 09 64 not at Ref. at Reference

10 32 normal U.V. Alarm 10 32 Stopped Running

11 16 normal O.V. Alarm 11 16 Remote Ref. Local Ref.

12 8 normal U.V. Warning 12 8 normal OFF (HOA)

13 4 normal O.V. Warning 13 4 Auto Start/stop Hand

14 2 normal Input Phase Loss 14 2 normal Run Request

15 1 normal Live Zero 15 1 Run Permission no Run Perm.

nvoWarning1 nvoWarning2

28

MG.60.E4.02 - VLT is a registered Danfoss trademark

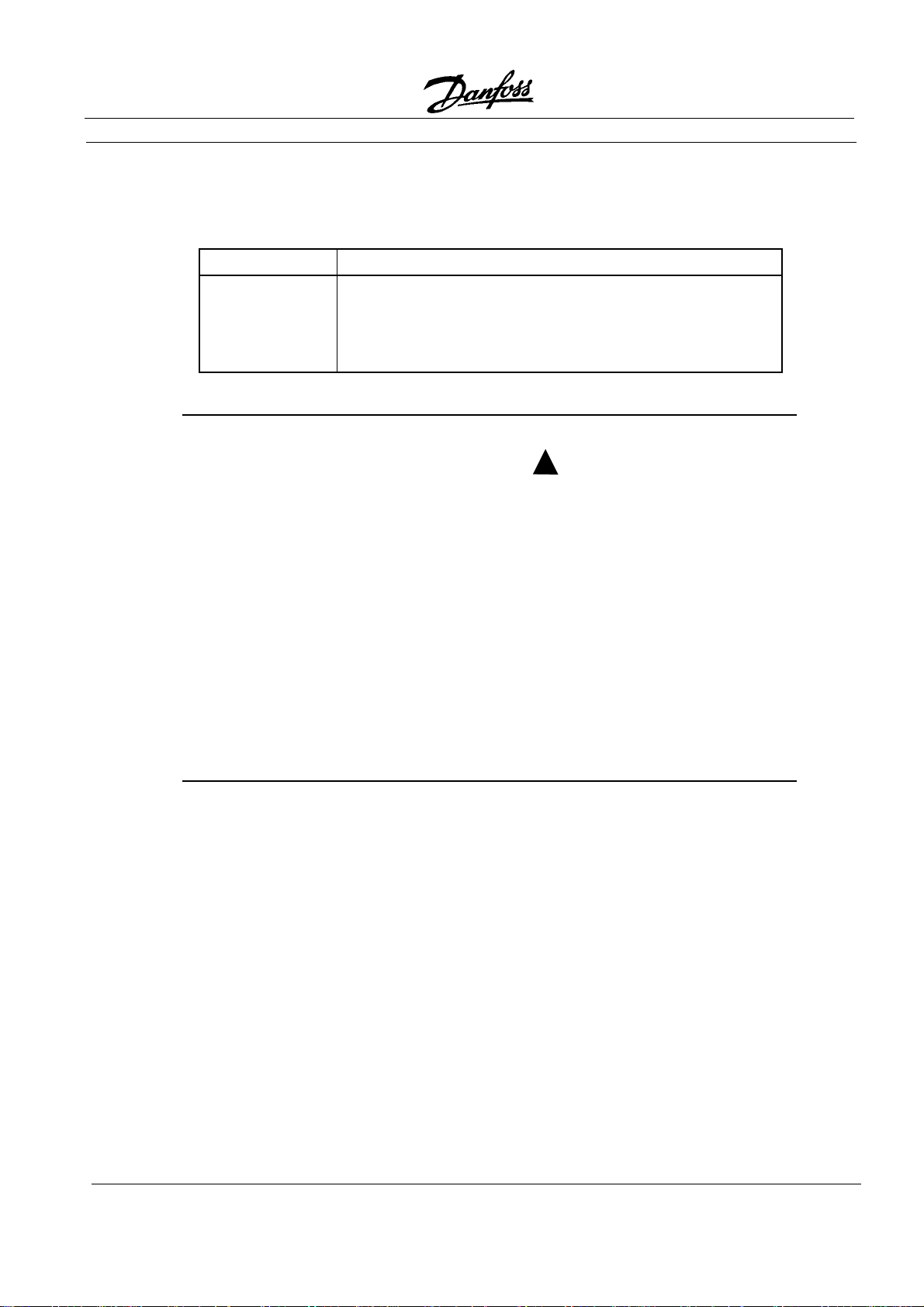

Page 29

VLT 5000 Drive

Status Bit

Definitions

Bit Value 0 1 Bit Value 0 1

00 32768 33 OFF 33 ON 00 32768

01 16384 32 OFF 32 ON 01 16384

02 8192 29 OFF 29 ON 02 8192

03 4096 27 OFF 27 ON 03 4096

04 2048 19 OFF 19 ON 04 2048

05 1024 18 OFF 18 ON 05 1024

06 512 17 OFF 17 ON 06 512

07 256 16 OFF 16 ON 07 256

08 128 no function 08 128

09 64 no function 09 64

10 32 no function 10 32

11 16 no function 11 16

12 8 no function 12 8 Remote Local

13 4 no function 13 4 Stopped Running

14 2 no function 14 2 No Warning Warning

15 1 no function 15 1 no Alarm Alarm

Bit Value 0 1 Bit Value 0 1

00 32768 Alarm Ctrl. Ready 00 32768 normal Brake Test fail

01 16384 Alarm Drive Ready 01 16384 normal Trip Lock

02 8192 Safety Open Safety Closed 02 8192 normal AMA Fault

03 4096 No Alarm Alarm 03 4096 normal AMA OK

04 2048 04 2048 normal Power Up Fault

05 1024 05 1024 normal ASIC Fault

06 512 06 512 normal HPFB Timeout

07 256 no Warning Warning 07 256 normal RS-485 Timeout

08 128 Not at Ref. at Ref. 08 128 normal Short circuit

09 64 Local Bus Control 09 64 normal Power Fault

10 32 Fr. Range Warn Freq. in Range 10 32 normal Ground Fault

11 16 Stopped Running 11 16 normal Over current

12 8 no used Stall, Autostart 12 8 normal Torque limit

13 4 normal Voltage Warn. 13 4 normal Motor Thermal

14 2 normal Current lim. 14 2 normal Motor Overload

15 1 normal Therm. Warning 15 1 normal Inverter Overload

nvoDigitalInput

nvoStatusWord

VLT® 5000 / VLT® 6000

no function

no function

no function

no function

no function

no function

no function

no function

no function

no function

no function

no function

nvoDrvStatus

not used

not used

not used

nvoAlarmWord

Bit Value 0 1 Bit Value 0 1

00 32768 normal Brake Test Fault 00 32768 normal Ramping

01 16384 normal Ctrl. Crd. Fault 01 16384 normal AMT

02 8192 normal Pwr. Crd. Fault 02 8192 normal Start Fwd/Rev

03 4096 normal HPFB Timeout 03 4096 normal Slow down

04 2048 normal RS-485 Timeout 04 2048 normal Catch up

05 1024 normal Overcurrent 05 1024 normal FB High

06 512 normal Torque limit 06 512 normal FB Low

07 256 normal Thermistor O.T. 07 256 normal Current High

08 128 normal Motor O.T. 08 128 normal Current Low

09 64 normal Inverter O.T. 09 64 normal Freq. High

10 32 normal U.V. Alarm 10 32 normal Freg. Low

11 16 normal O.V. Alarm 11 16 normal Brake Test OK

12 8 normal U.V. Warning 12 8 normal Braking Max.

13 4 normal O.V. Warning 13 4 normal Braking

14 2 normal Input Phase Loss 14 2 normal Discharge OK

15 1 normal No motor 15 1 normal Out Freq. Range

nvoWarning1

MG.60.E4.02 - VLT is a registered Danfoss trademark

nvoWarning2

29

Page 30

VLT® 5000 / VLT® 6000

Network

Timer

Functions

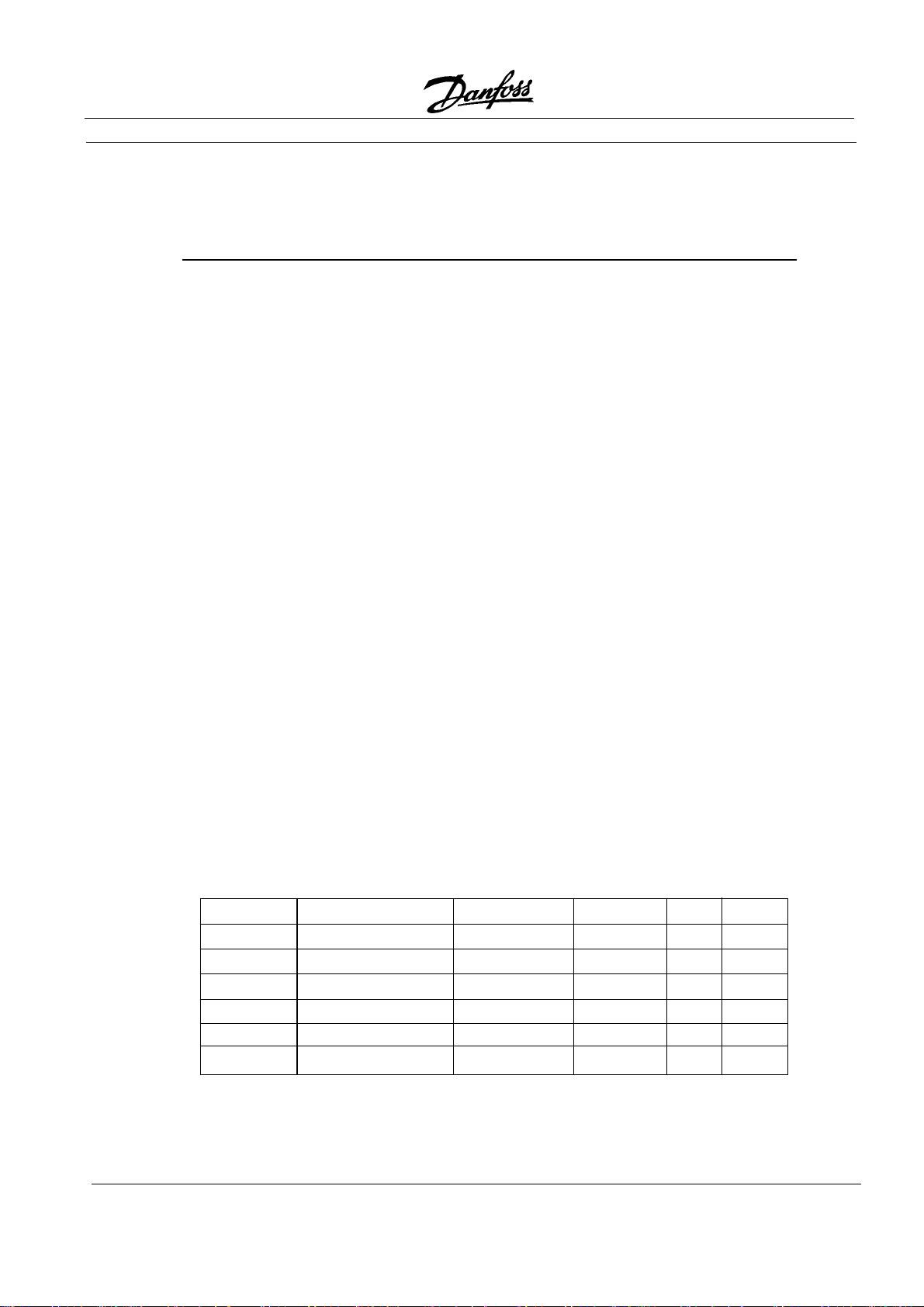

Function SNVT Variable Units Max Min Default

type Name

Min send SNVT nciMin- time 0 days 0 days 0 days

time _elapsed SendT 0 hours 0 hours 0 hours

_tm 1 min 0 min 0 min

5 sec 0 sec 0 sec

535 msec 100 msec

30 msec

Max SNVT nciMax- time 0 days 0 days 0 days

receive _elapsed ReceiveT 18 hours 0 hours 0 hours

time _tm 12 min 0 min 0 min

15 sec 1 sec 0 sec

0 msec 0 msec 0 msec

Max SNVT nciMax- time 0 days 0 days 0 days

send _elapsed SendT 0 hours 0 hours 0 hours

time _tm 1 min 0 min 0 min

5 sec 0 sec 0 sec

535 msec 100 msec

30 msec

1

78 kbps transformer coupled twisted pair and 78 Kbps free topology transceiver models.

2

1.25 Mbps transformer coupled twisted pair transceiver model.

2

2

1

1

500 msec

(Off)

0 msec

(Off)

Network Timer Functions

Min send time

Sets the minimum period between

transmissions for all output network variables,

using the network variable nciMinSendT. This

function is used to keep the transmission of

variables that change continuously from

dominating the network communication.

Max receive time

This drive function is replaced by the value

set in parameter 803, Bus Time Out. The

LonWorks option will initiate bus time out

activities when the time set in parameter 803

expires without receiving an input network

variable directed to the drive. This acts like a

LonWorks receive heartbeat. The action taken

by the drive is determined by the setting

selected in parameter 804, Bus time out

function. See the parameter description

section of this manual. The value of

nciMaxReceiveT has no effect on the

operation of the drive.

Max send time

This function sets the maximum time between

transmissions for the network variables Drive

Output 1, 2, and 3 using the configuration

network variable nciMaxSendT. It can be used

by the controller to monitor the health of the

VLT and controller connection. It acts like a

LonWorks send heartbeat.

The Max send time function is disabled when

nciMaxSendT is not configured or set to “0.”

30

MG.60.E4.02 - VLT is a registered Danfoss trademark

Page 31

VLT® 5000 / VLT® 6000

VL T

Parameter

Access

A controller node can monitor or modify any

VLT parameter by supporting the Parameter

access command and the Parameter access

response functions. These functions allow a

controller complete access to the features of

the VLT and the ability to configure drives with

predefined settings, using the network

variables nviParamCmd and nvoParamResp.

The following definitions describe how the

fields of SNVT_preset are used by the VLT

LonWorks option:

Learn

This field contains the function code for the

VLT. The values for this field are:

LN_RECALL (0),

LN_LEARN_CURRENT (1),

LN_LEARN_VALUE (2), and

LN_REPORT_VALUE (3).

LN_RECALL (0) and

LN_REPORT_VALUE (3)

are interpreted as read commands.

LN_LEARN_CURRENT (1) and

LN_LEARN_VALUE (2)

are interpreted as write commands.

Any other value in this field will result in an

error message in the Parameter access

response.

Selector

This field contains the VLT parameter

number, written in decimal notation, that is

to be written or read. Requests for

undefined parameters will result in an error

message in the Parameter access esponse.

The controlling device should compare the

parameter number of the response

message to the requested parameter

number to determine that the information

received is the requested information and

not a response to another controller or from

another VLT.

Value

This array contains the parameter

information to and from the VLT. All VLT

parameters use 16 bit signed or unsigned

values. The most significant 2 hex bytes of

data will be stored in value [0] and the least

significant 2 hex bytes of data will be stored

in value [3]. In the event of an error

message, the VLT will send 0xff in value [0]

and an error code in value [3]. The error

codes are defined in the section Parameter

Access Error Codes in this manual.

NOTE

Consult

Conversion Inde x

in

the VLT Instruction Manual

parameter table for correct

conversion factor f or reading and

writing to and from drive.

Day, Hour, Minute, Second, Millisecond

The time fields are not supported by the

VLT LonWorks option. The VLT will respond

to parameter access requests as soon as

they are received. Any values in the time

fields of the Parameter access command

will be ignored. All time fields will be set to

“0” in the Parameter access response.

Function SNVT type Variable Name

Parameter access command SNVT_preset nviParamCmd

Function SNVT type Variable Name

Parameter access response SNVT_preset nvoParamResp

MG.60.E4.02 - VLT is a registered Danfoss trademark

Network Variable Input to VLT

Network Variable Output from VLT

31

Page 32

VLT® 5000 / VLT® 6000

CAUTION

!

Parameter

Access

Error Codes

Parameter

Access

Command

and

Response

Examples

In the event of an error message in response

to a Parameter access command (see VLT

Parameter Access), the VLT sends 0xff in value

Parameter Access Error Codes

Exception Code Interpretation

1 Illegal function for the addressed node

2 Illegal data address (i.e., illegal parameter number)

3 Illegal data value

6 Busy