Page 1

Logic Elements Technical Information

3

2

1

3

2

1

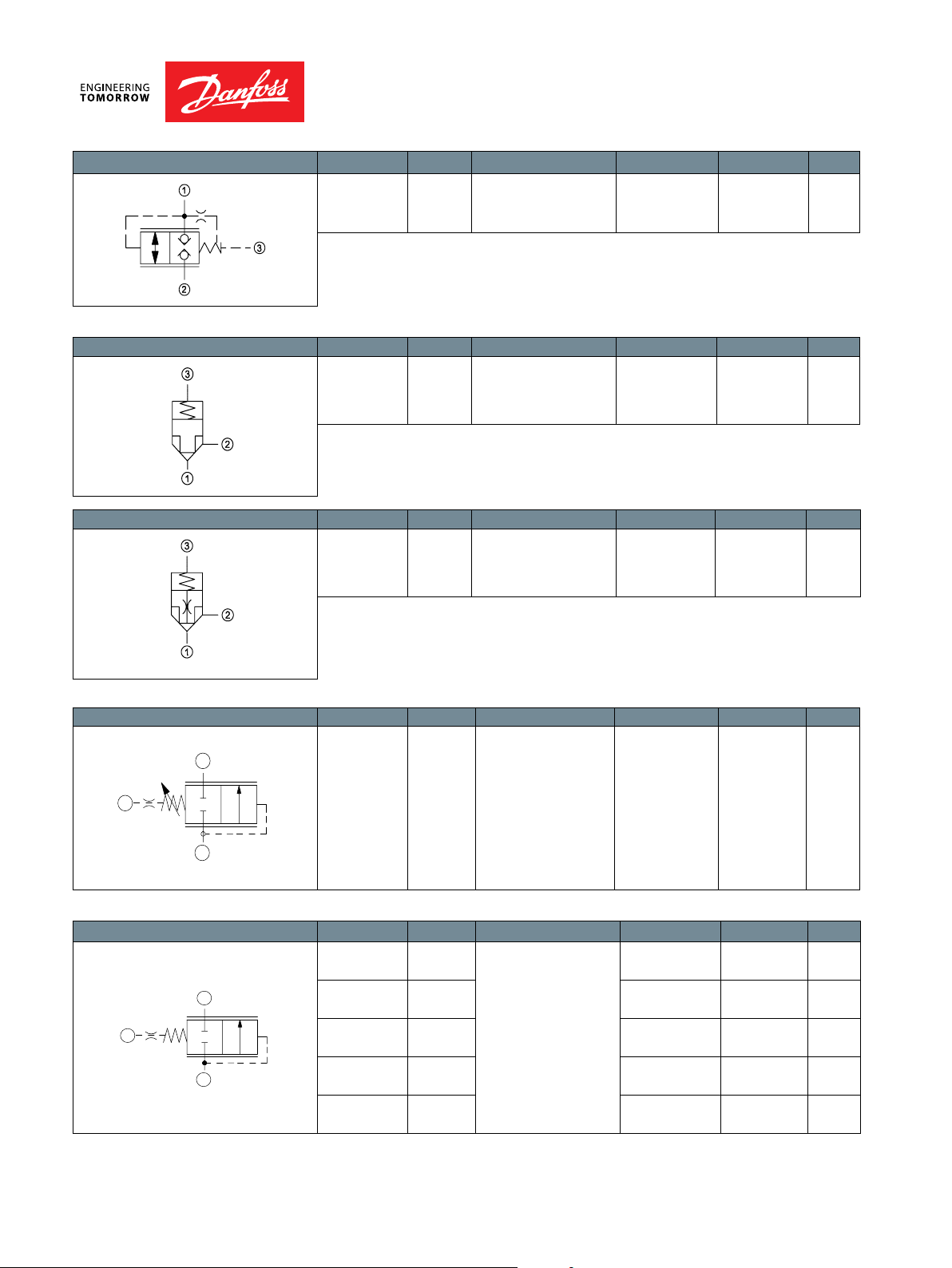

Quick Reference

Logic Element, Poppet Type

Logic Element, Poppet Type Model No. Cavity Description Flow* Pressure Page

Logic Element, Poppet Type Model No. Cavity Description Flow* Pressure Page

Quick Reference

Model No. Cavity Description Flow* Pressure Page

VLP 12/P2 NCS12/3 Logic Element Poppet,

Double Blocking Closed,

Vent to Open

VLP 12/A5 NCS12/3 Logic Element Poppet,

Normally Closed,

Pilot to Close

VLP 12/C2 NCS12/3 Logic Element Poppet,

Normally Closed,

Vent to Open

160 l/min

[42 US gal/min]

160 l/min

[42 US gal/min]

160 l/min

[42 US gal/min]

315 bar

[4500 psi]

315 bar

[4500 psi]

315 bar

[4500 psi]

LE - 11

LE - 13

LE - 15

Logic Element, Spool Type Model No. Cavity Description Flow* Pressure Page

HLEA10-CPC SDC10-3S Logic Element,

Normally Closed,

Pilot to Close

Logic Element, Spool Type Model No. Cavity Description Flow* Pressure Page

CP700-1 SDC10-3 Logic Element,

Normally Closed,

HLE10-CPC SDC10-3S 80 l/min

CP701-1 CP12-3S 150 l/min

CP702-1 SDC16-3S 190 l/min

LE20-CPC CP20-3S 340 l/min

* Flow ratings are based on a pressure drop of 7 bar [100 psi] unless otherwise noted. They are for comparison purposes only.

BC332375783111en-000101 • February 2020

Pilot to Close

80 l/min

[21 US gal/min]

50 l/min

[13 US gal/min]

[21.1 US gal/min]

[40 US gal/min]

[50 US gal/min]]

[90 US gal/min

350 bar

[5075 psi]

210 bar

[3045 psi]

350 bar

[5075 psi]

350 bar

[5075 psi]

210 bar

[3045 psi]

210 bar

[3045 psi]

LE - 17

LE - 19

LE - 21

LE - 23

LE - 25

LE - 27

LE - 1

Page 2

Logic Elements Technical Information

3

2

1

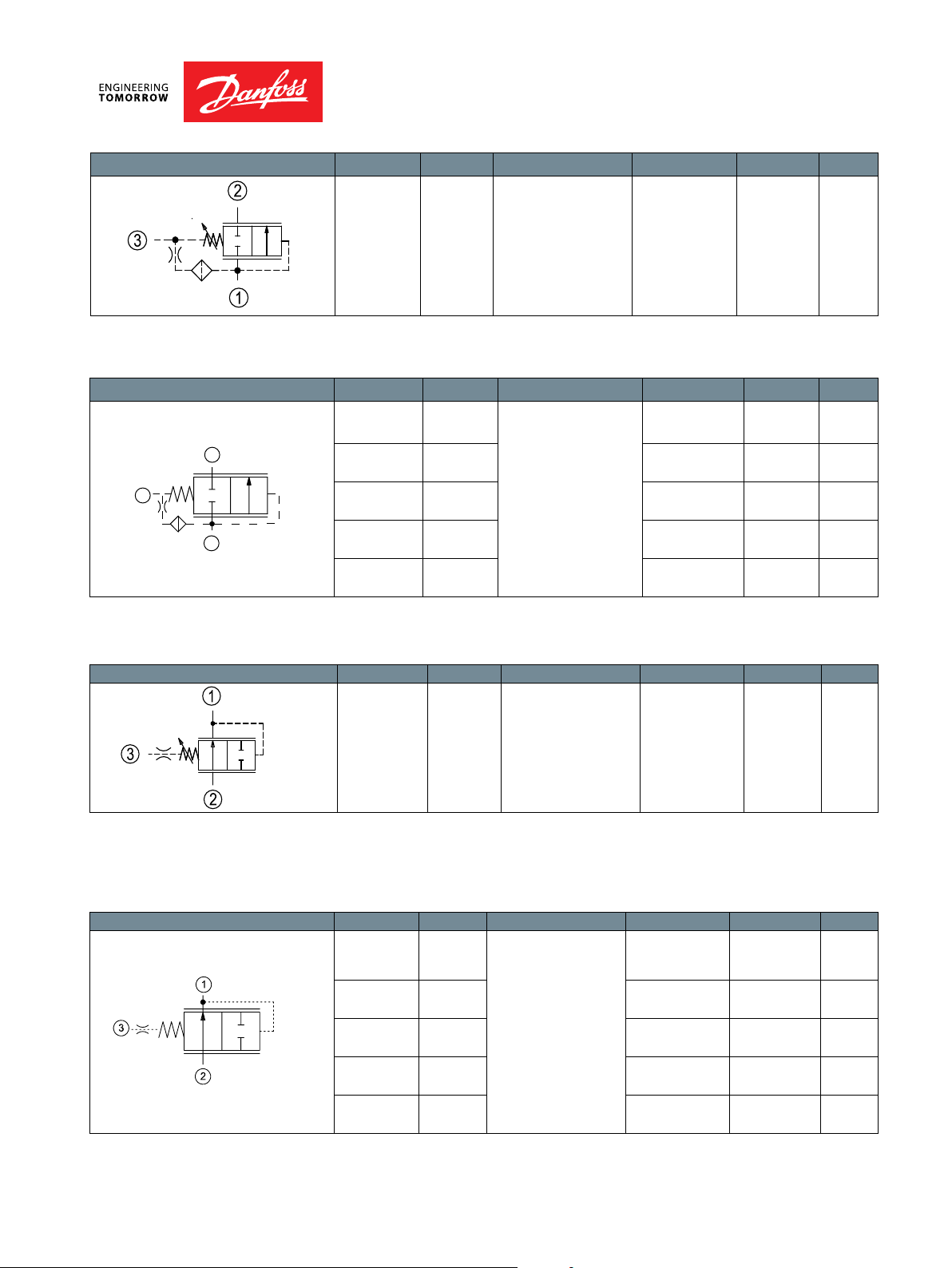

Quick Reference

Logic Element, Spool Type Model No. Cavity Description Flow* Pressure Page

HLEA10-CVO SDC10-3S Logic Element,

Normally Closed,

Vent to Open

80 l/min

[21 US gal/min]

350 bar

[5075 psi]

LE - 29

Logic Element, Spool Type

Logic Element, Spool Type Model No. Cavity Description Flow* Pressure Page

Model No. Cavity Description Flow* Pressure Page

CP700-2 SDC10-3 Logic Element,

Normally Closed,

HLE10-CVO SDC10-3S 80 l/min

CP701-2 CP12-3S 150 l/min

CP702-2 SDC16-3S 190 l/min

CP703-2 CP20-3S 340 l/min

HLEA10-OPO SDC10-3S Logic Element,

Vent to Open

Normally Open,

Pilot to Open

50 l/min

[13 US gal/min]

[21.1 US gal/min]

[40 US gal/min]

[50 US gal/min]

[90 US gal/min]

60 l/min

[16 US gal/min]

210 bar

[3045 psi]

350 bar

[5075 psi]

350 bar

[5075 psi]

210 bar

[3045 psi]

210 bar

[3045 psi]

350 bar

[5075 psi]

LE - 31

LE - 33

LE - 35

LE - 37

LE - 39

LE - 41

Quick Reference

Logic Element, Spool Type Model No. Cavity Description Flow* Pressure Page

CP700-4 SDC10-3 Logic Element,

Normally Open,

HLE10-OPO SDC10-3S 60 l/min

CP701-4 CP12-3S 75 l/min

CP702-4 SDC16-3S 114 l/min

CP703-4 CP20-3S 200 l/min

* Flow ratings are based on a pressure drop of 7 bar [100 psi] unless otherwise noted. They are for comparison purposes only.

BC332375783111en-000101 • February 2020

Pilot to Open

40 l/min

[11 US gal/min]

[15.8 US gal/min]

[20 US gal/min]

[30 US gal/min]

[53 US gal/min]

210 bar

[3045 psi]

350bar

[5075 psi]

350 bar

[5075 psi]

210 bar

[3045 psi]

210 bar

[3045 psi]

LE - 43

LE - 45

LE - 47

LE - 49

LE - 51

LE - 2

Page 3

Logic Elements Technical Information

3

214

3

2

1

3

2

4

1

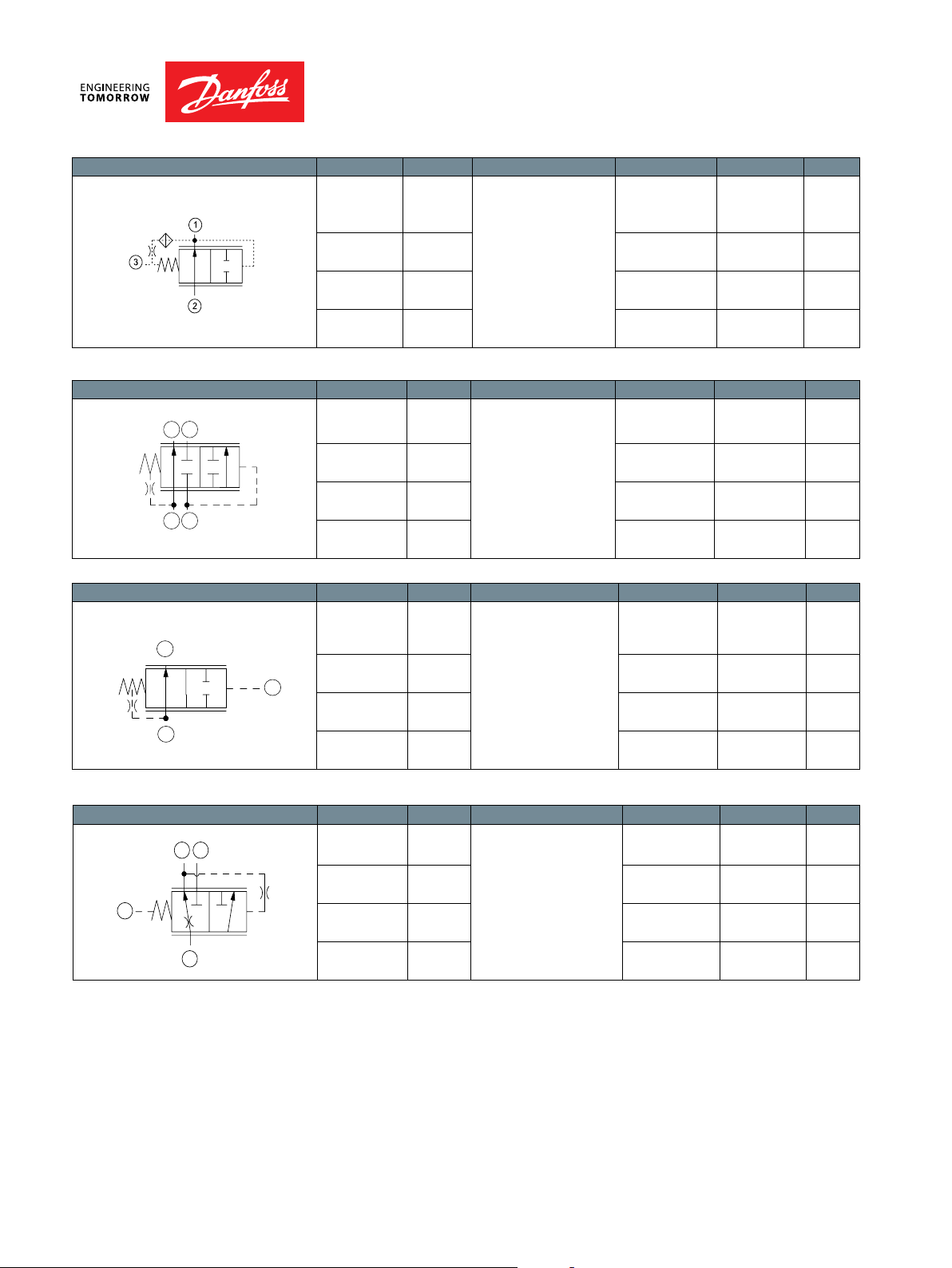

Quick Reference

Logic Element, Spool Type Model No. Cavity Description Flow* Pressure Page

CP700-3 SDC10-3 Logic Element,

Normally Open,

HLE10-OVC SDC10-3S 60 l/min

CP701-3 CP12-3S 80 l/min

CP702-3 SDC16-3S 115 l/min

Pressure Compensator Model No. Cavity Description Flow* Pressure Page

CP310-4 SDC10-4 Pressure Compensator,

CP311-4 CP12-4 60 l/min

CP312-4 CP16-4 130 l/min

CP313-4 SDC20-4 340 l/min

Vent to Close

Flow Control,

Priority

40 l/min

[11 US gal/min]

[15.8 US gal/min]

[21 US gal/min]

[30 US gal/min]

40 l/min

[11 US gal/min]

[16 US gal/min]

[34 US gal/min]

[90 US gal/min]

210 bar

[3045 psi]

350 bar

[5075 psi]

350 bar

[5075 psi]

210 bar

[3045 psi]

210 bar

[3045 psi]

210 bar

[3045 psi]

210 bar

[3045 psi]

210 bar

[3045 psi]

LE - 53

LE - 55

LE - 57

LE - 59

LE - 61

LE - 63

LE - 65

LE - 67

Quick Reference

Pressure Compensator Model No. Cavity Description Flow* Pressure Page

CP300-4 SDC10-3 Pressure Compensator,

Flow Control,

CP301-4 CP12-3 90 l/min

CP302-4 SDC16-3 130 l/min

CP303-4 SDC20-3 284 l/min

Restrictive

40 l/min

[11 US gal/min]

[24 US gal/min]

[34 US gal/min]

[75 US gal/min]

210 bar

[3045 psi]

210 bar

[3045 psi]

210 bar

[3045 psi]

210 bar

[3045 psi]

LE - 69

LE - 71

LE - 73

LE - 75

Pressure Compensator Model No. Cavity Description Flow* Pressure Page

CP310-6 SDC10-4 Pressure Compensator,

Load Sense,

PC12-LPS CP12-4 75 l/min

PC16-LPS CP16-4 125 l/min

CP313-6 SDC20-4 200 l/min

* Flow ratings are based on a pressure drop of 7 bar [100 psi] unless otherwise noted. They are for comparison purposes only.

BC332375783111en-000101 • February 2020

Priority,

Static

40 l/min

[11 US gal/min]

[20 US gal/min]

[30 US gal/min]

[53 US gal/min]

210 bar

[3045 psi]

210 bar

[3045 psi]

210 bar

[3045psi]

210 bar

[3045 psi]

LE - 77

LE - 79

LE - 81

LE - 83

LE - 3

Page 4

Logic Elements Technical Information

1

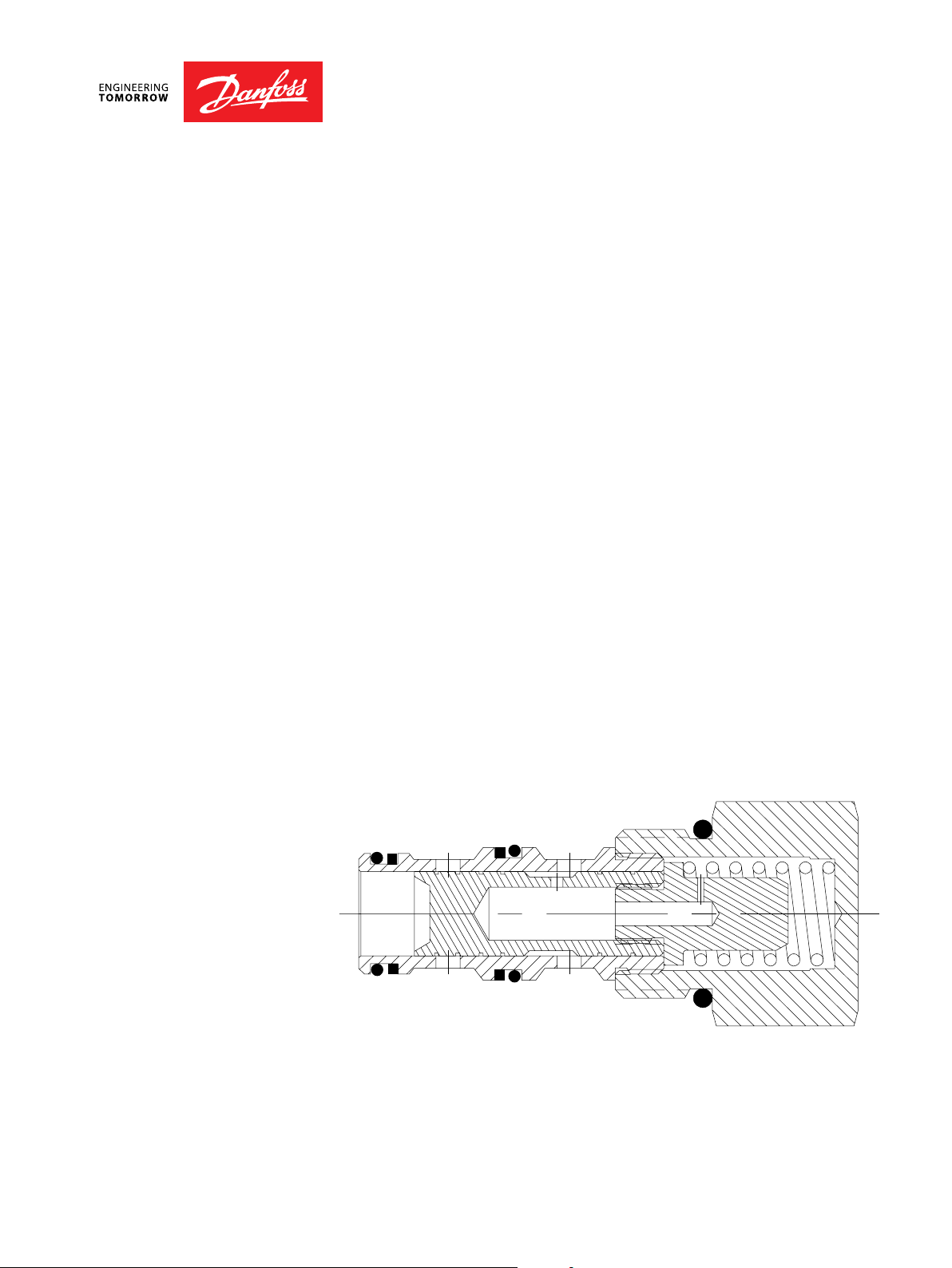

Application Notes

OVERVIEW Logic Elements are multi-purpose devices. These valves, when used with other cartridge

valves, can create a wide variety of circuits for control of pressure, ow, and direction.

Dierential sensing valves

SPRING BIASED,

NORMALLY CLOSED,

DIFFERENTIAL SENSING

VALVES

Spring-biased, normally-closed dierential sensing valves include: CP700-1, HLE10-CPC,

HLEA10-CPC, CP701-1, and CP702-1. These valves are normally closed and will modulate

based on the spring control pressure, inlet pressure at port 1, and pilot pressure at port 3.

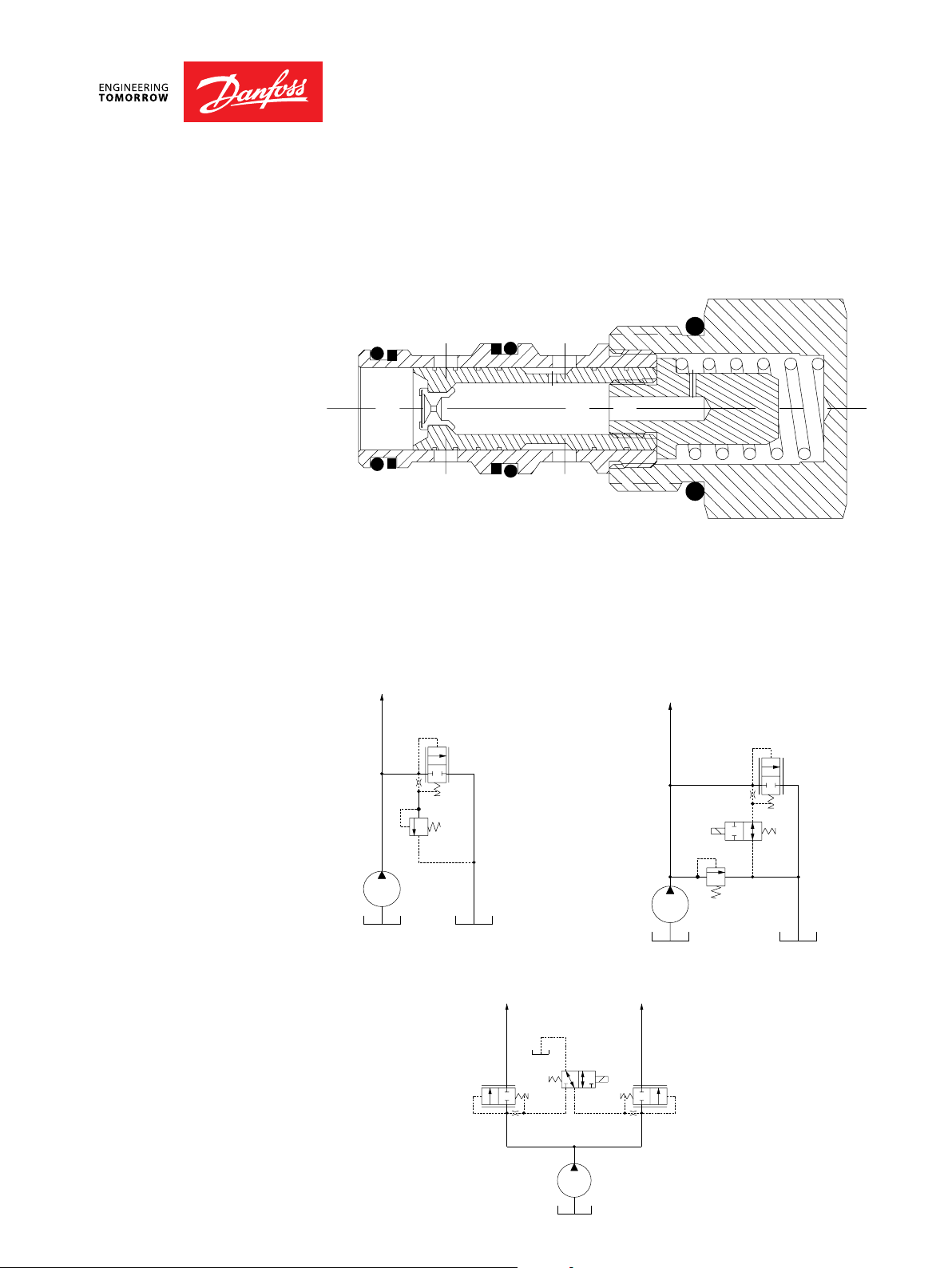

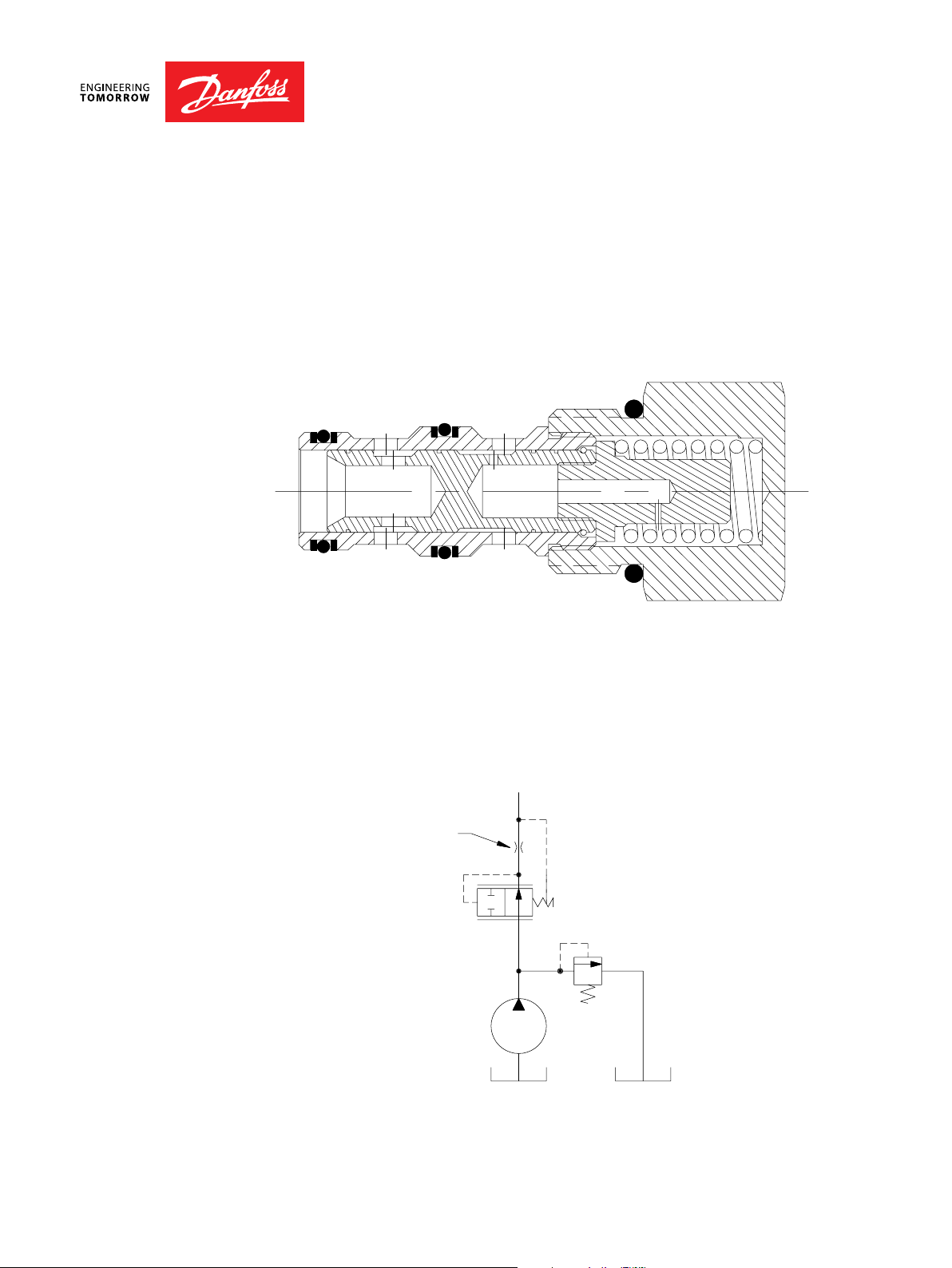

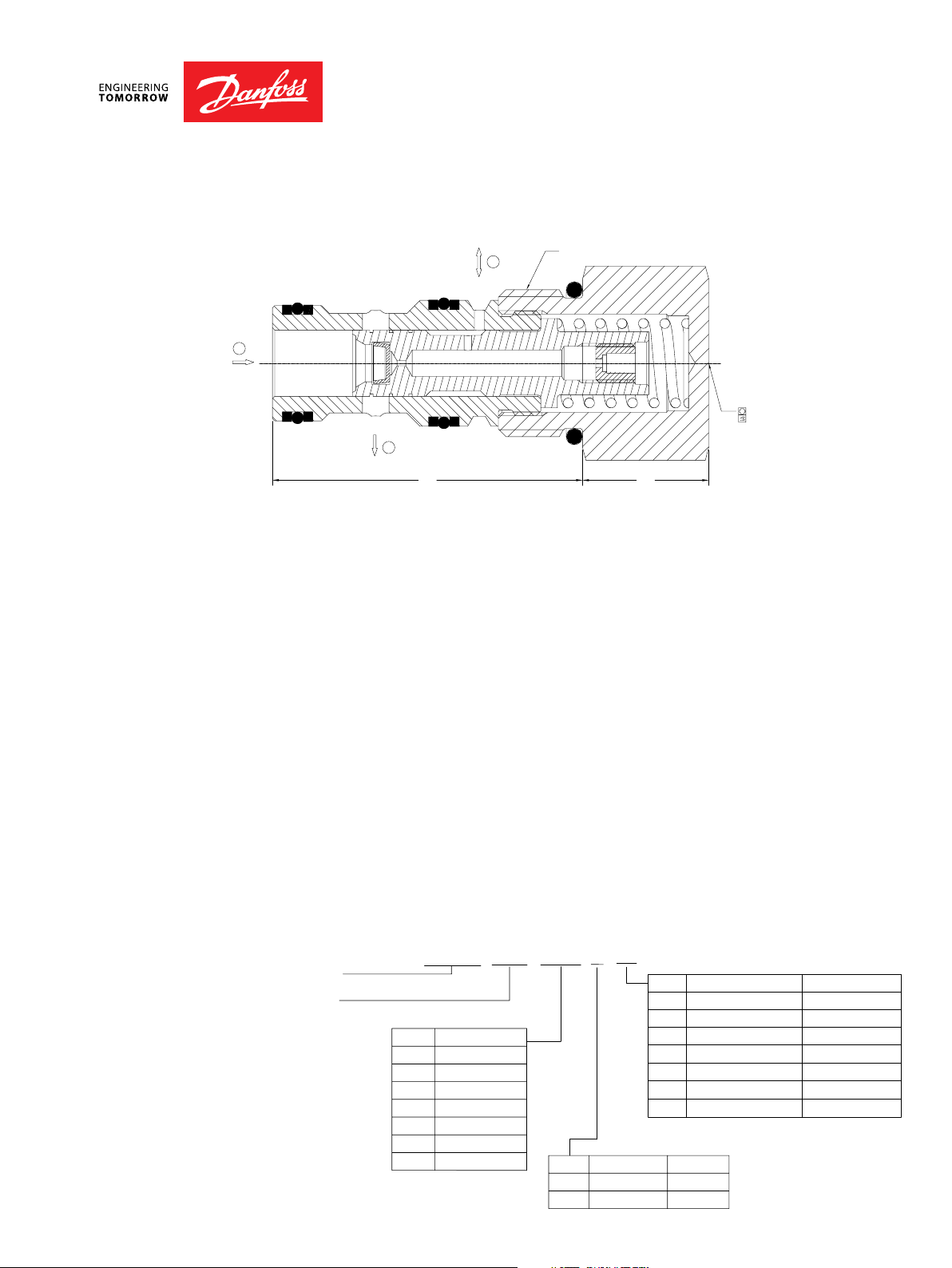

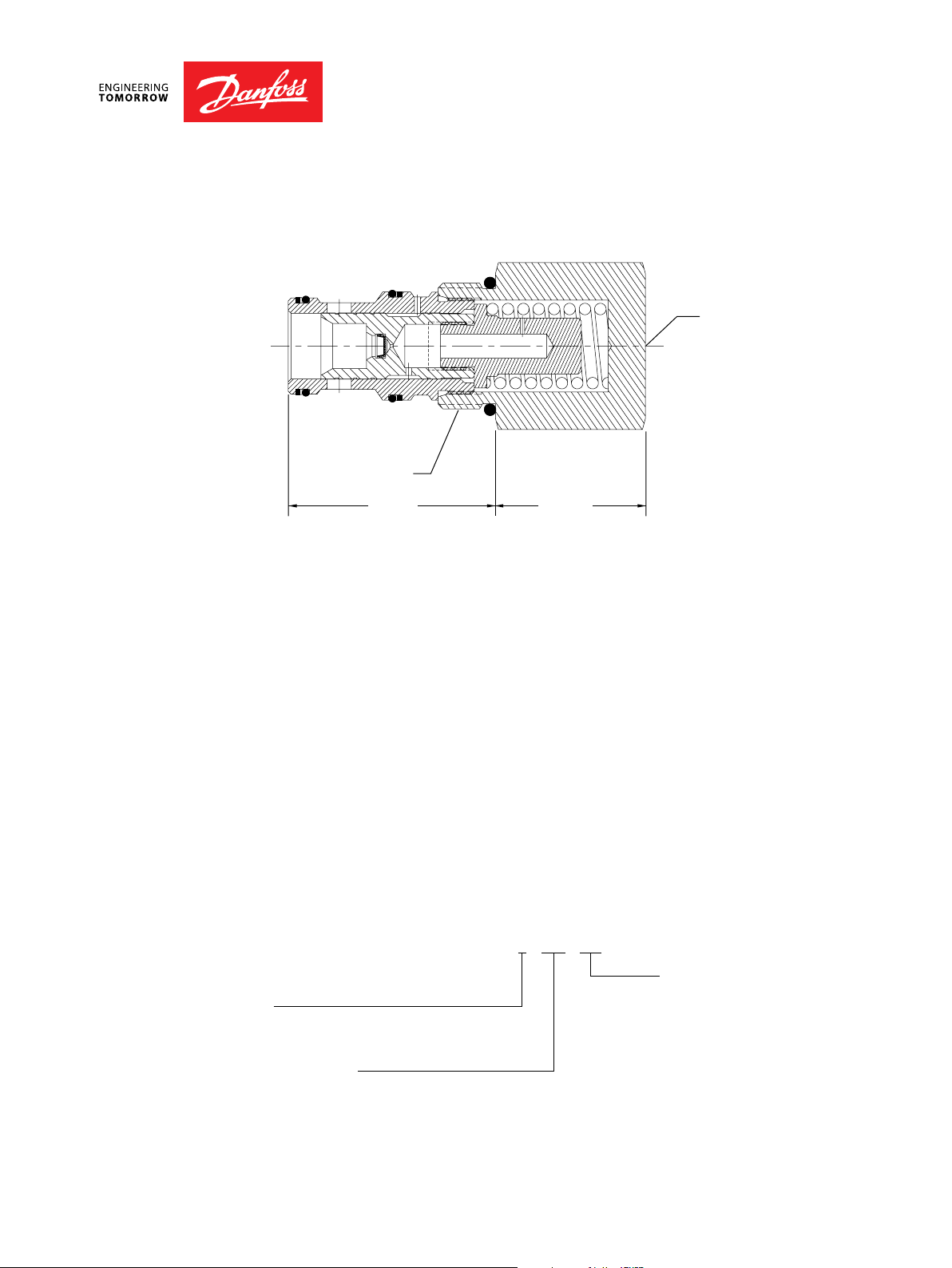

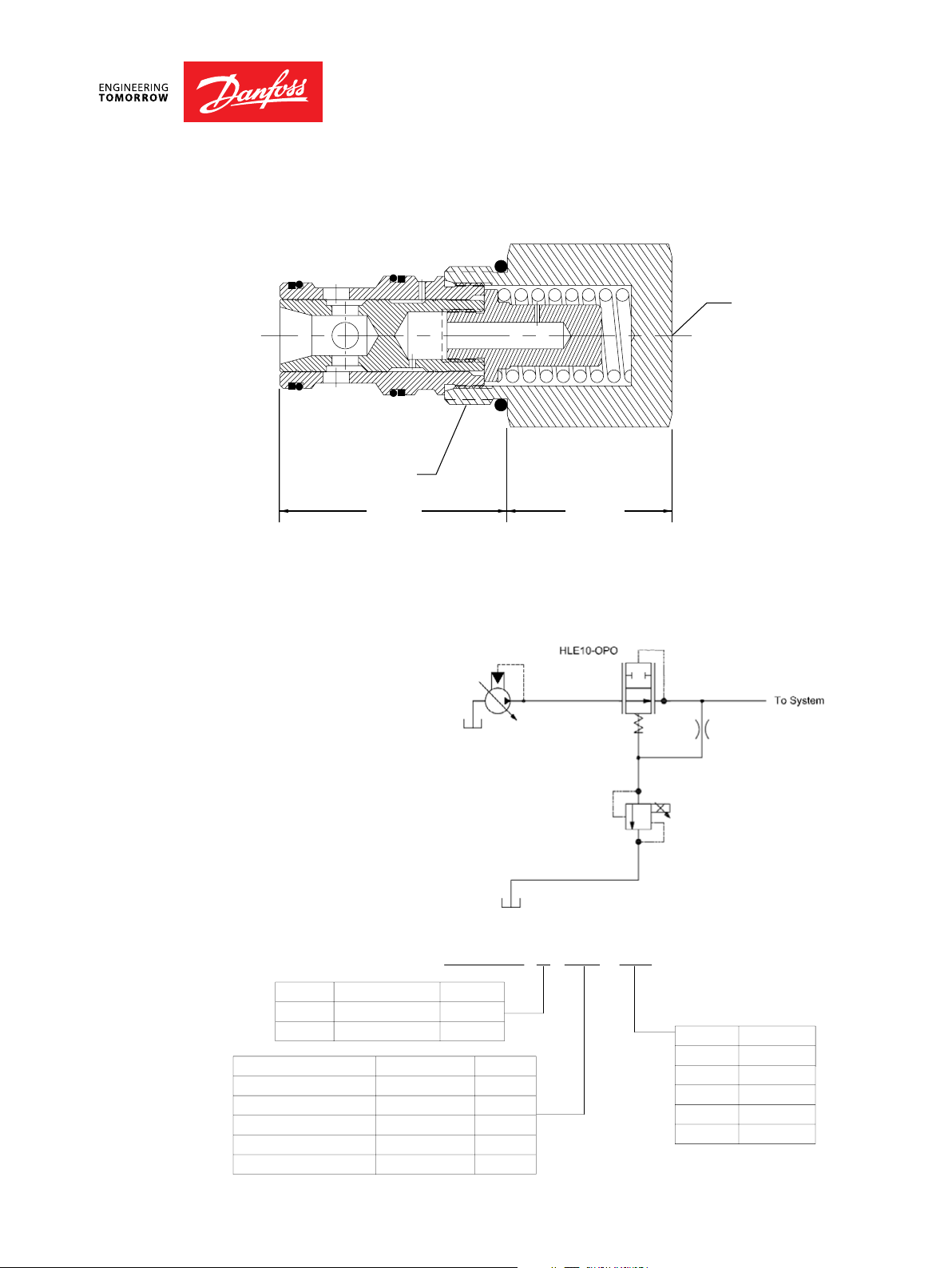

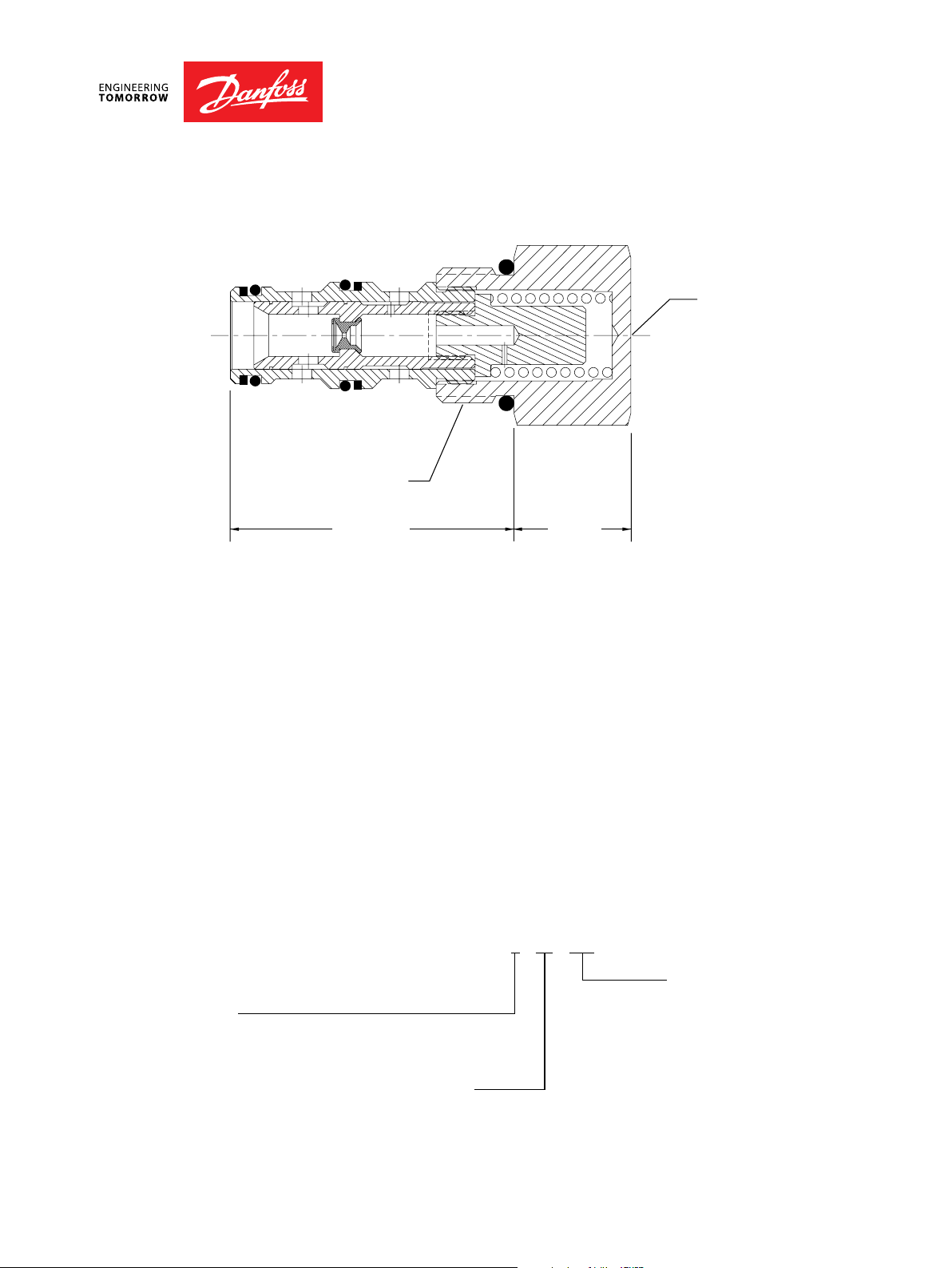

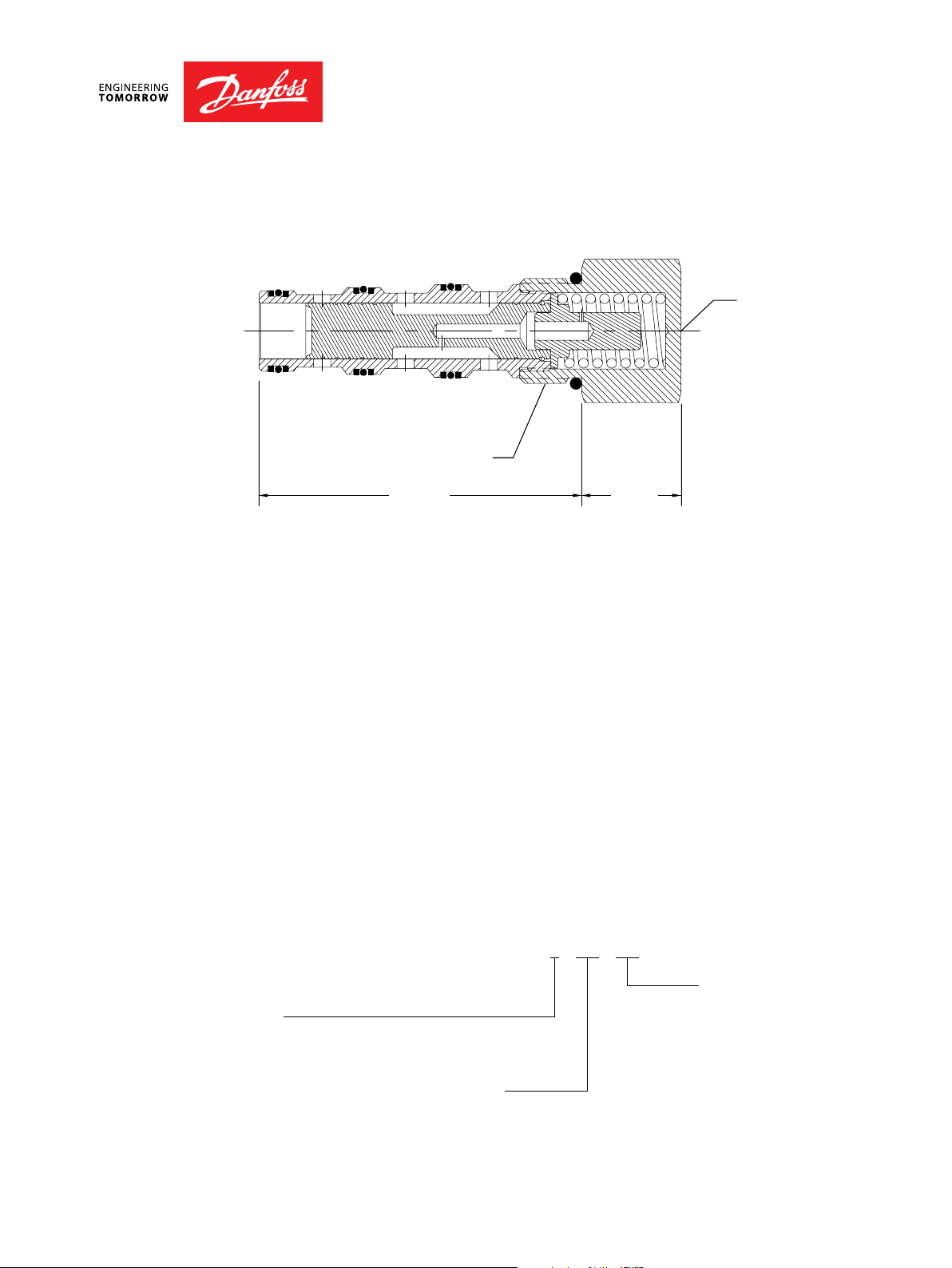

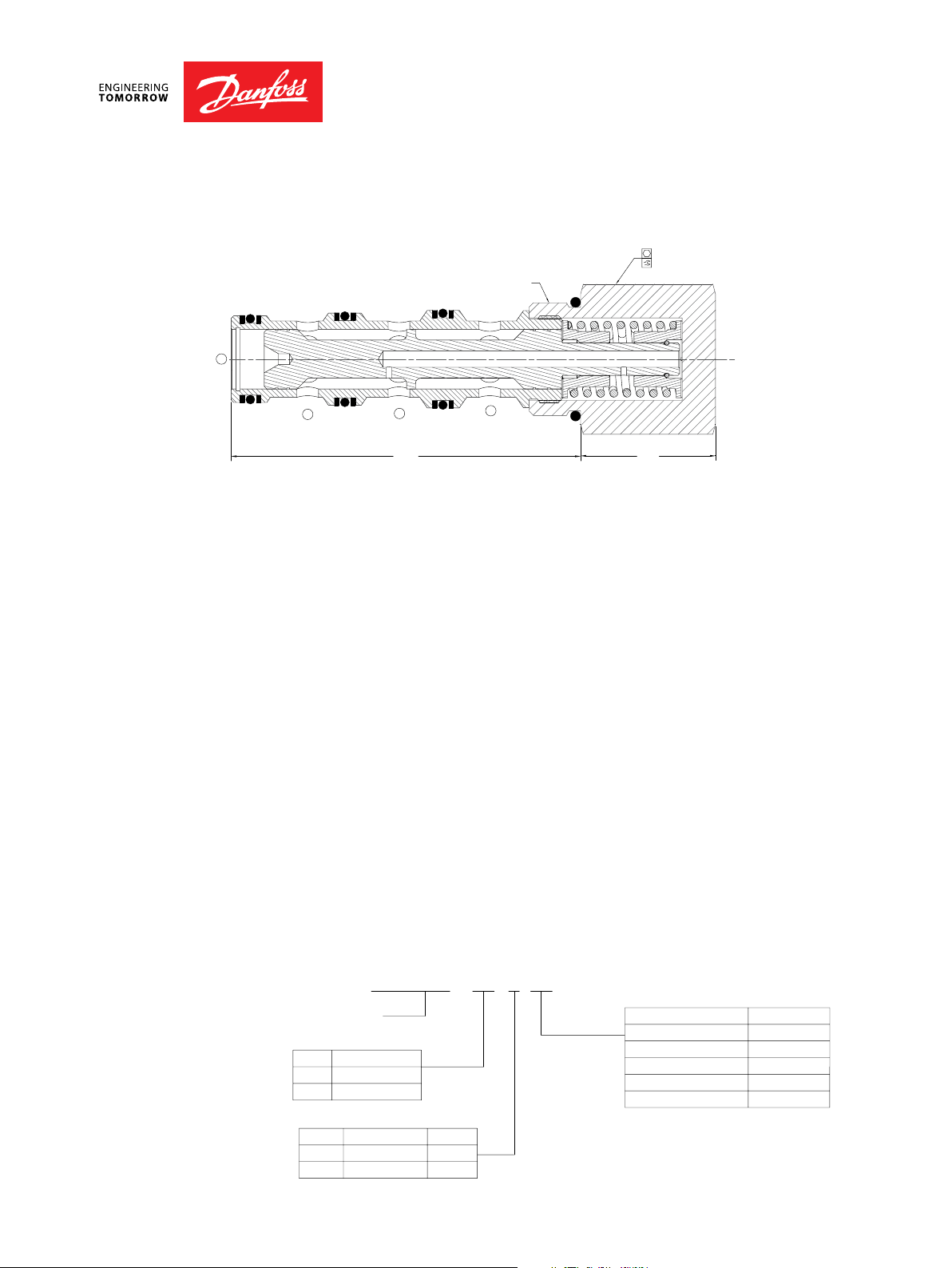

Spring biased, normally closed, dierential sensing valve cross section

23

Application Notes

BC332375783111en-000101 • February 2020

LE - 4

Page 5

Logic Elements Technical Information

Application Notes

Application Notes

SPRING BIASED,

NORMALLY CLOSED,

DIFFERENTIAL SENSING

VALVES

(continued)

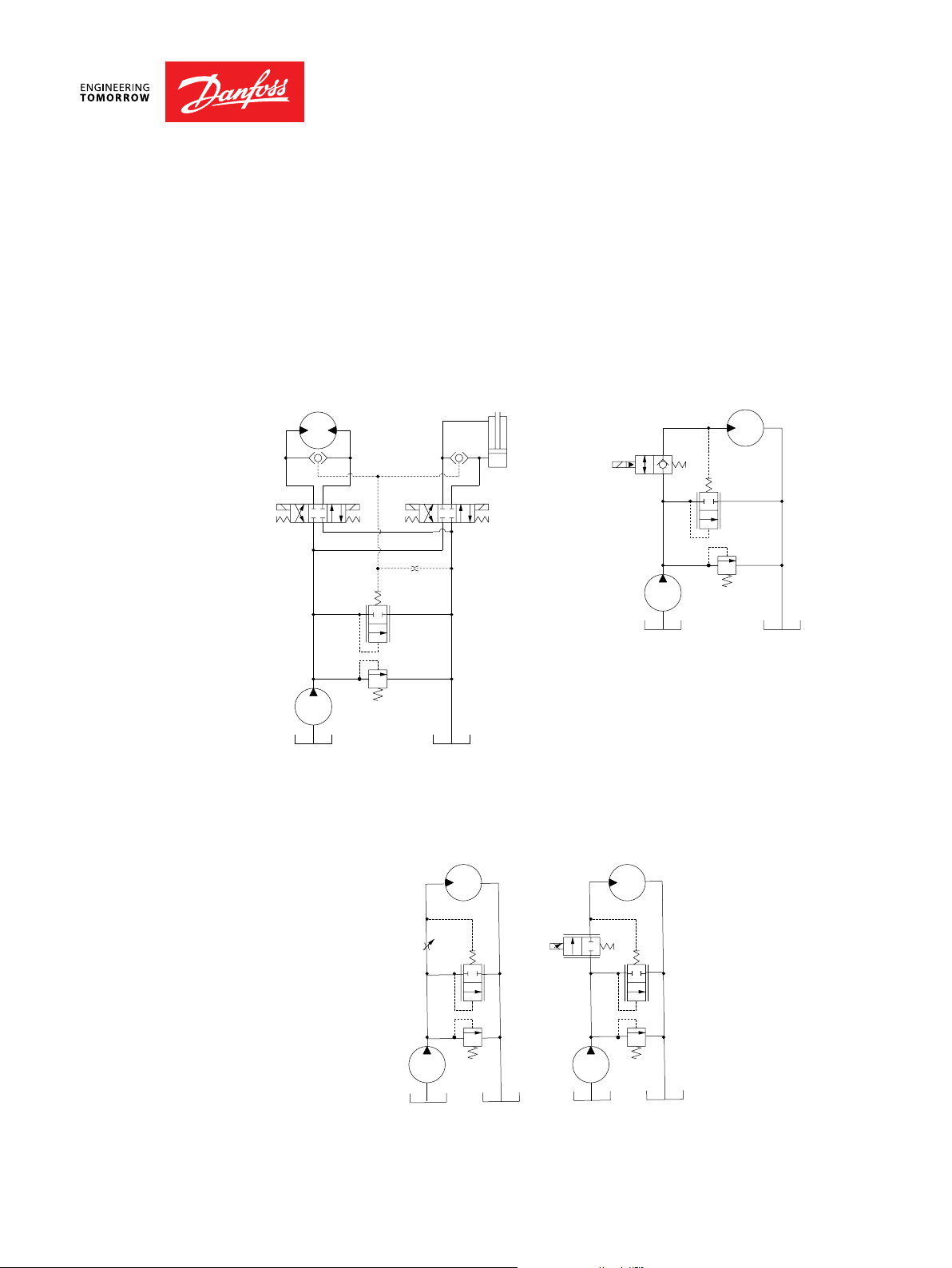

Common applications

· Load-sensing for a xeddisplacement pump with single or

multiple actuators.

· Bypass-type pressure-compensated

ow control.

Multiple actuator load sensing

Single actuator load sensing

BC332375783111en-000101 • February 2020

Bypass ow control

Manual Proportional

LE - 5

Page 6

Logic Elements Technical Information

To system

AT

Application Notes

SPRING BIASED,

NORMALLY CLOSED,

VENT TO OPEN

DIFFERENTIAL SENSING

VALVES

Spring-biased, normally-closed, vent-to-open dierential sensing valves include: CP700-2, HLE10CVO, HLEA10-CVO, CP701-2, and CP702-2. These valves are normally closed and will modulate

based on the spring control pressure, inlet pressure at port 1, and pilot pressure at port 3.

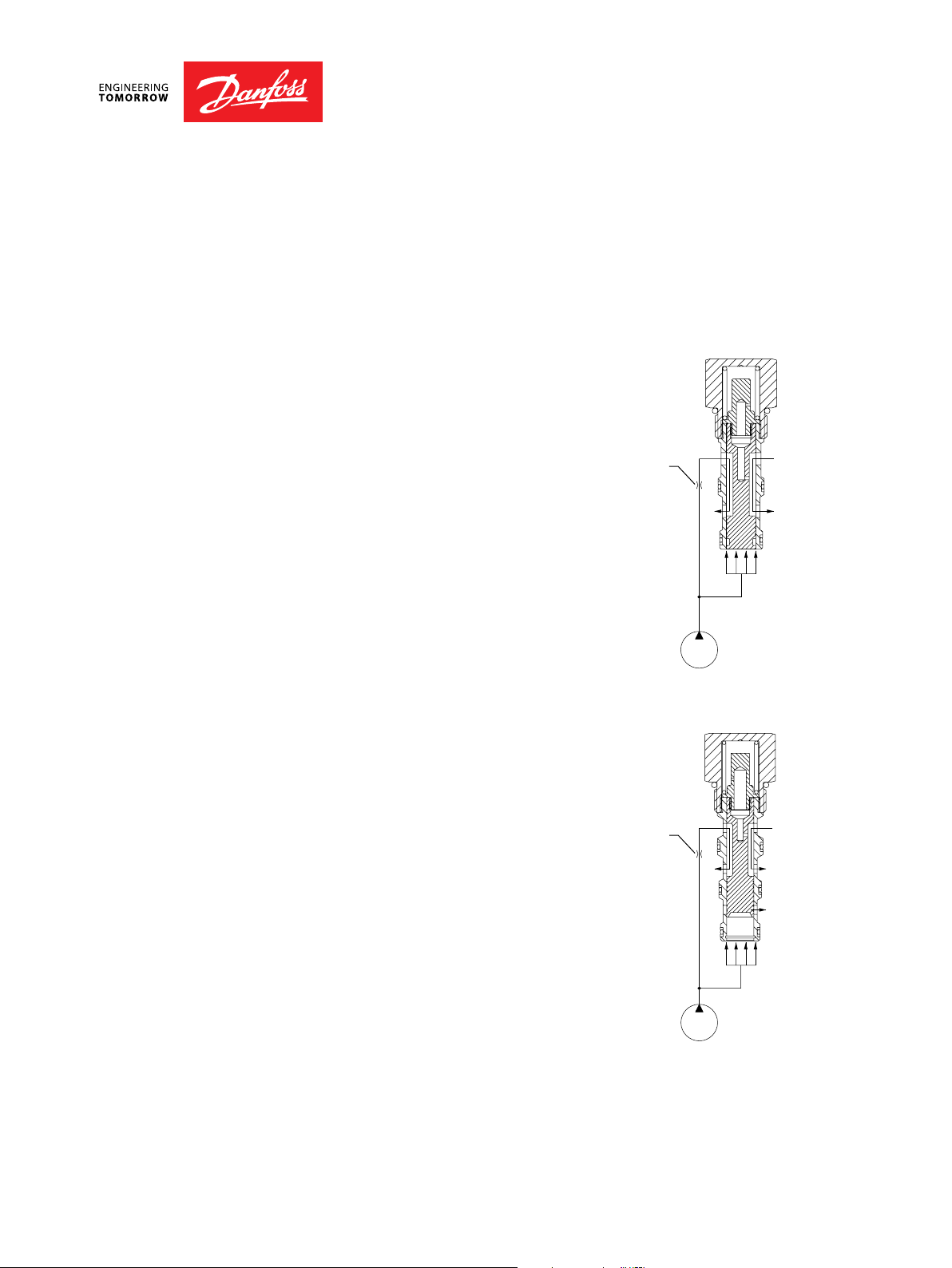

Spring biased, normally closed, vent to open dierential sensing valve

1

23

Common applications include:

· Pump unloading.

· Pilot-operated relief valve.

· Selector circuit.

Pilot-operated relief valve

Pump unloading

To system

Application Notes

BC332375783111en-000101 • February 2020

Selector valve

To circuit

o circuit B

LE - 6

Page 7

Logic Elements Technical Information

Application Notes

Application Notes

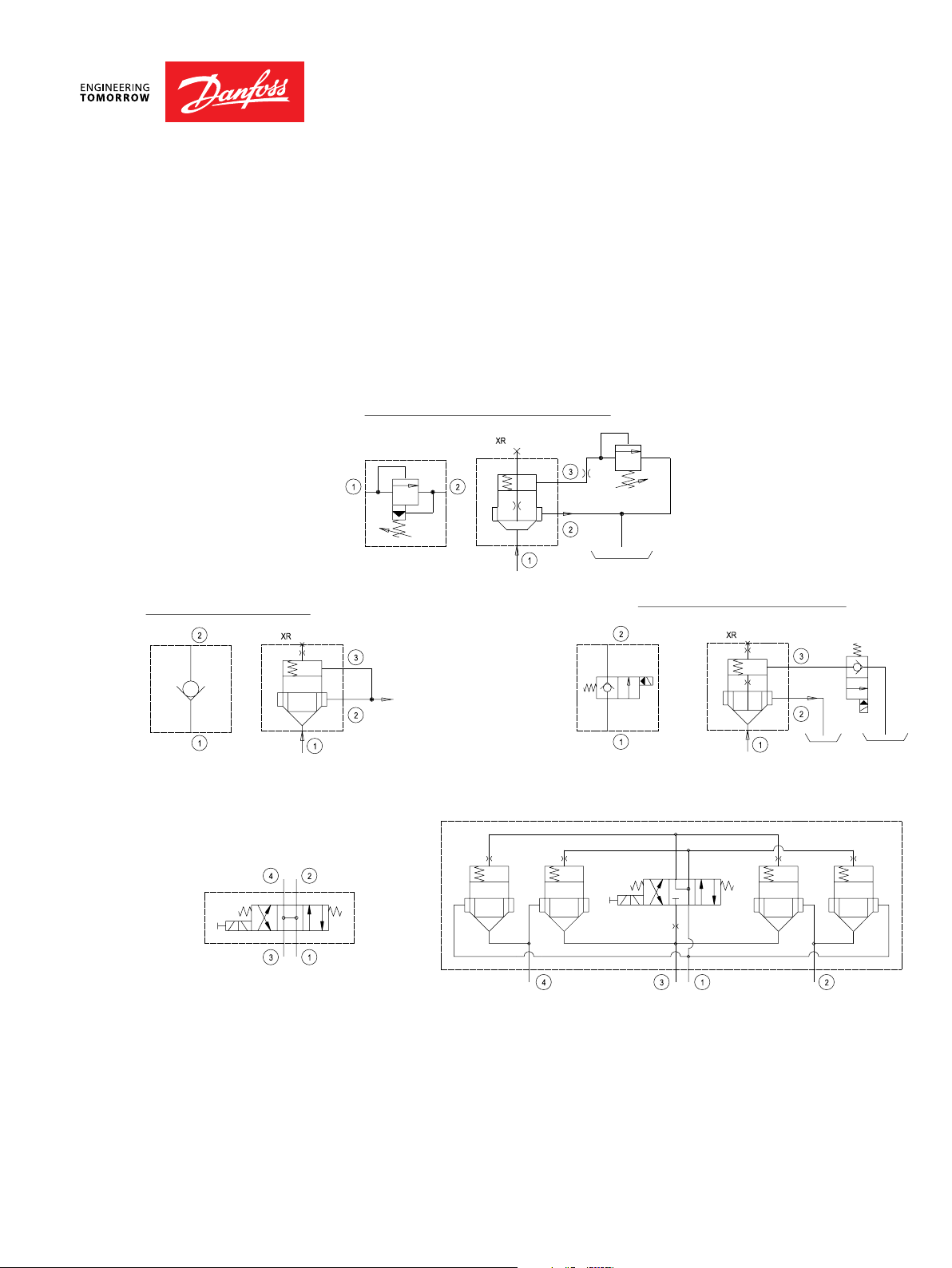

LOGIC ELEMENT

POPPETTYPE

CIRCUIT EXAMPLES

CHECK VALVE VLP /A5

Poppet-type logic elements provide a multitude of hydraulic circuit options, as illustrated in

the circuit examples below. These poppet designs provide low-leakage and are commonly

piloted. to provide the needed functionality, as a pressure relief, check valve, directional valve,

or ow control.

PRESSURE RELIEF VALVE VLP /P2

DIRECTIONAL VALVE VLP /C2

4-3 WAY ON-OFF VALVES VLP/A5

BC332375783111en-000101 • February 2020

LE - 7

Page 8

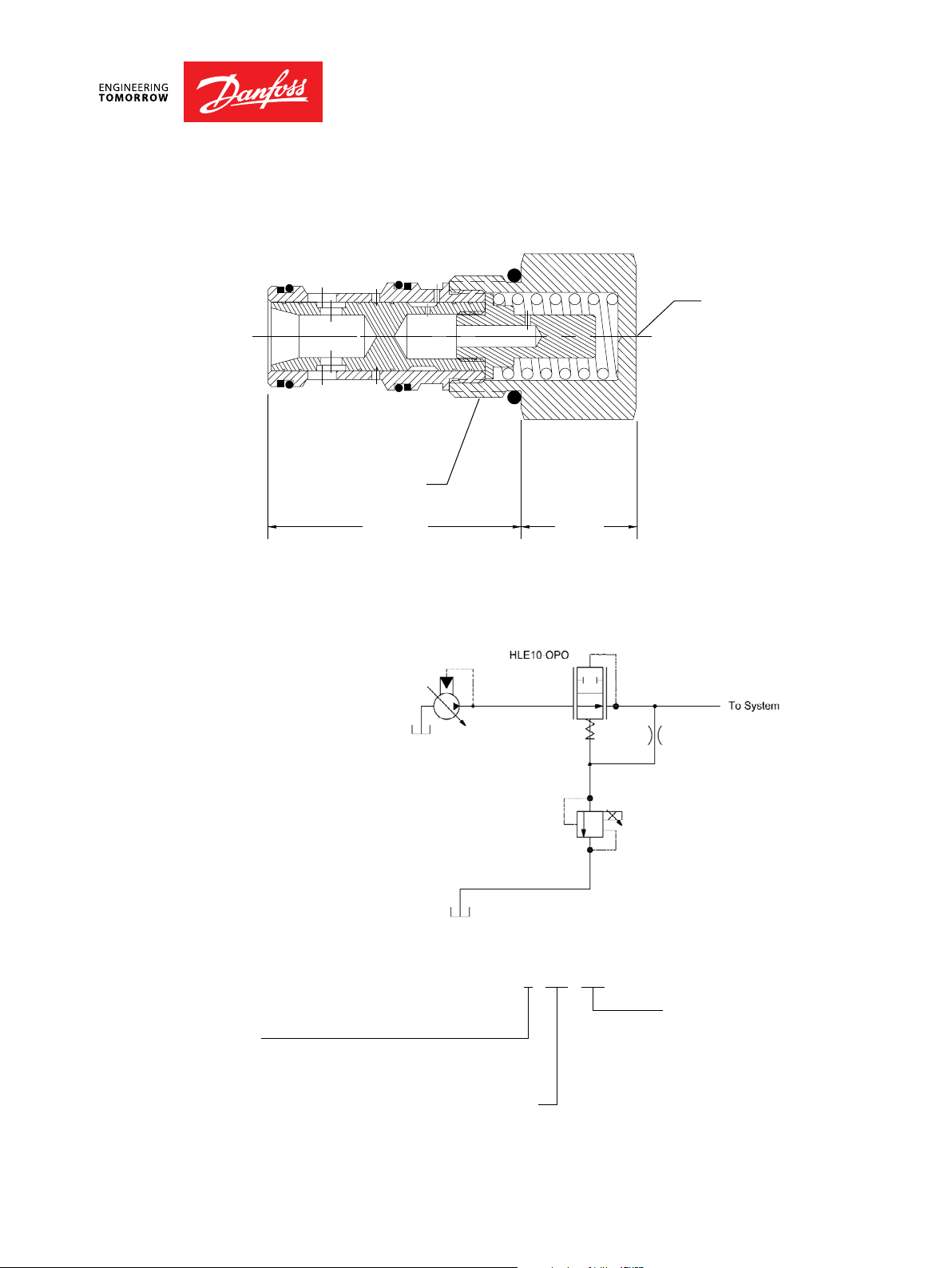

Logic Elements Technical Information

To System

Application Notes

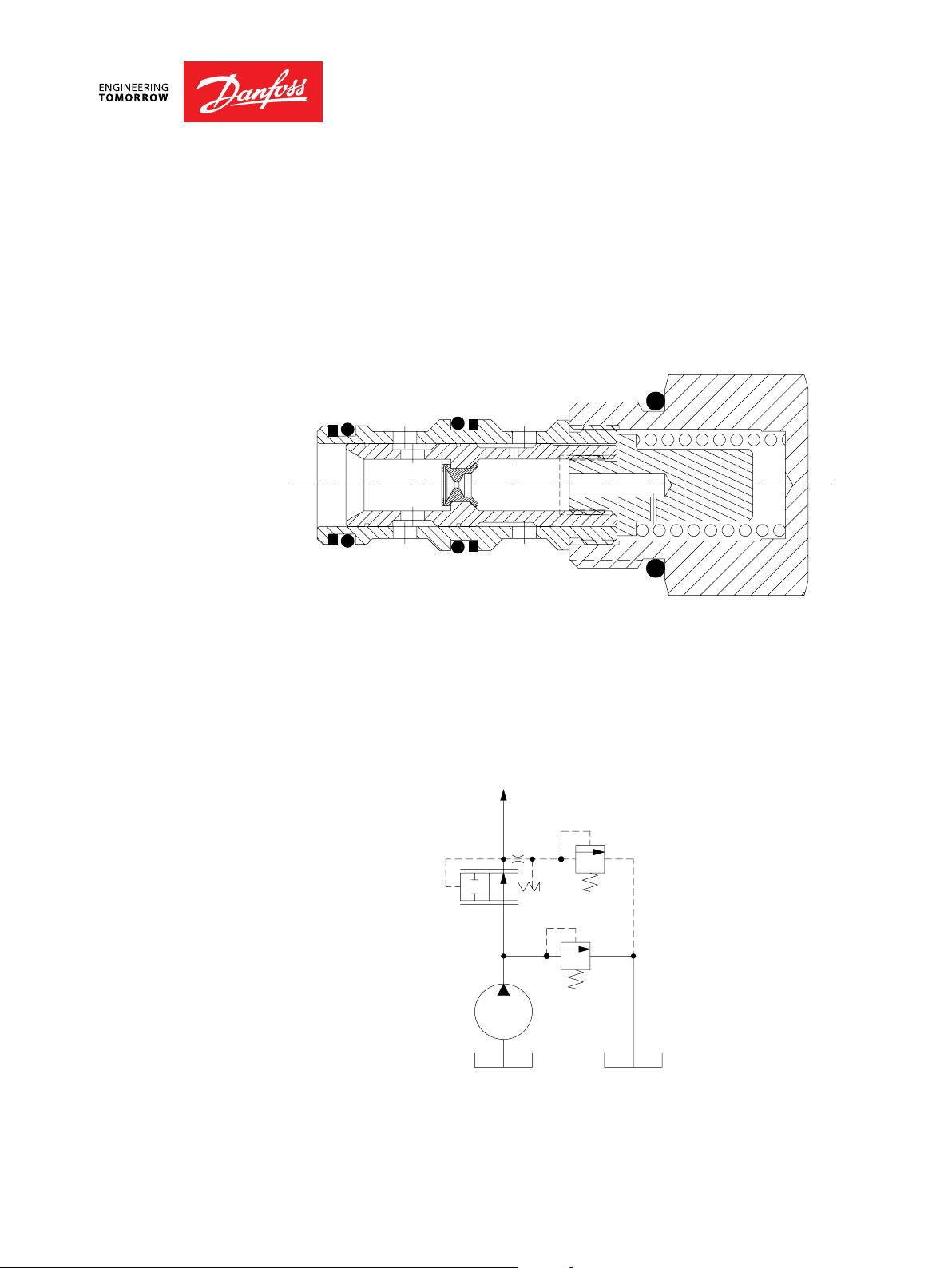

SPRING BIASED,

NORMALLY OPEN,

VENT TO CLOSE,

DIFFERENTIAL SENSING

VALVES

Spring-biased, normally-open, vent-to-close dierential sensing valves include:

CP700-3, CP701-3, and CP702-3. These valves are normally open and will modulate

based on spring control pressure, outlet pressure at port 1, and pilot pressure at

port 3. One application for this valve is to create a high-ow pressure reducing valve

when using a small relief valve (like CP208-1), or a proportional relief valve (like

PRV08-DAC) as a pilot element.

Spring biased, normally open, vent to close, dierential sensing valve

1

23

Common applications:

Pilot-operated pressure reducing valve

Application Notes

BC332375783111en-000101 • February 2020

LE - 8

Page 9

Logic Elements Technical Information

Regulated flow

Control

Orifice

Application Notes

Application Notes

SPRING BIASED,

NORMALLY OPEN,

DIFFERENTIAL SENSING

VALVES

Spring-biased, normally-open dierential sensing valves include: CP700-4, CP701-4,

HLE10-OPO, HLEA10-OPO and CP702-4. These valves are normally open and will

modulate based on spring control pressure, outlet pressure at port 1, and pilot

pressure at port 3. One application for this valve is as a pressure compensator

when used with a xed or adjustable orice to create a pressure-compensated ow

control.

Spring biased, normally open, dierential sensing valve

1

23

Common applications:

Pressure compensator

BC332375783111en-000101 • February 2020

LE - 9

Page 10

Logic Elements Technical Information

Application Notes

PRESSURE

COMPENSATING,

DIFFERENTIAL SENSING

VALVES

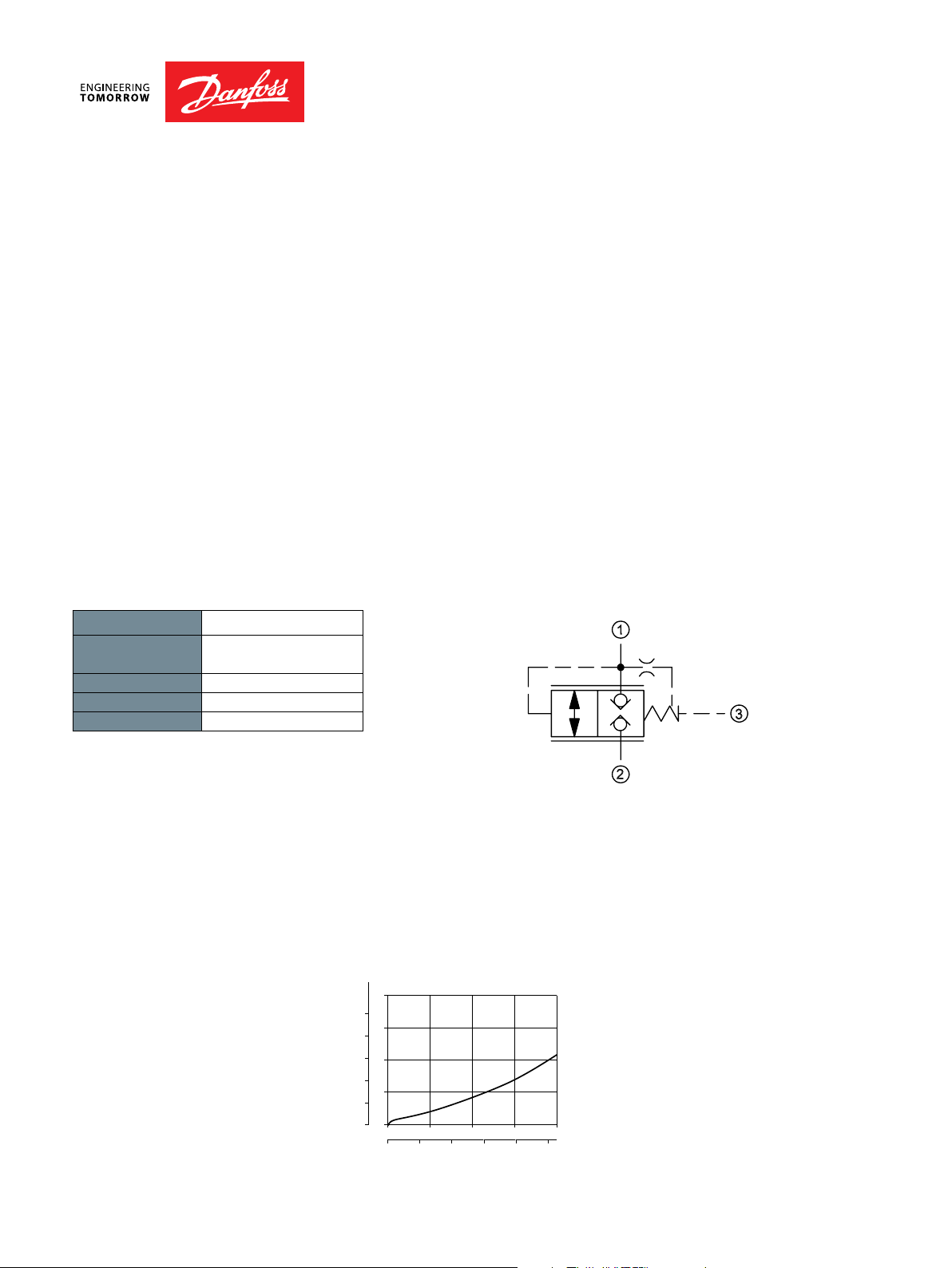

Pressure compensators oer the circuit designer capability to add pressure

compensation to any xed or variable orice. This ensures that ow, and resulting

actuator speed, are maintained regardless of system and working pressures. Note that

a pressure compensator is required when using Danfoss ICS direct-acting proportional

ow controls; see Proportional valve application notes for more information.

Restrictive-type

Restrictive-type pressure compensators

Restrictive-type pressure compensator

operation

are three-ported valves that work in

series with a xed or variable control

orice. The pressure compensator is

located downstream of the orice and

is spring-biased to an open position as

shown. The spool “senses” the pressure

on either side of the control orice

Control orifice

and will vary it’s restriction in order to

maintain a constant pressure dierential

Regulated flow

across the control orice, hence

maintaining a constant ow rate.

SUMMARY

Priority-type

Priority-type pressure compensators are

Priority-type pressure compensator

operation

four-ported valves that work in series

with a xed or variable control orice.

As with the restrictive-type valves, these

valves maintain a constant pressure

dierential across the control orice.

However, rather than restricting ow

when the dierential pressure becomes

too high, the priority-type pressure

Control orifice

Regulated flow

compensators open a fourth bypass port

for all ow in excess of that demanded

Bypass flow

by the control orice. Note that if the

bypass port is blocked, the valve will

function as a restrictive-type pressure

compensator.

All of these circuits are particularly eective to control high ows while using small (e.g.

8 series) solenoid and relief valves as pilot elements. The above examples are typical

circuits but are by no means the only applications for these valves. Eective use of

dierential sensing valves is a key to designing cost-eective circuits, and is limited only

by the imagination of the designer.

Application Notes

BC332375783111en-000101 • February 2020

LE - 10

Page 11

Logic Elements Technical Information

pressure drop

05

Pressure

Poppet Type, Double-Blocking

VLP 12/P2

OPERATION

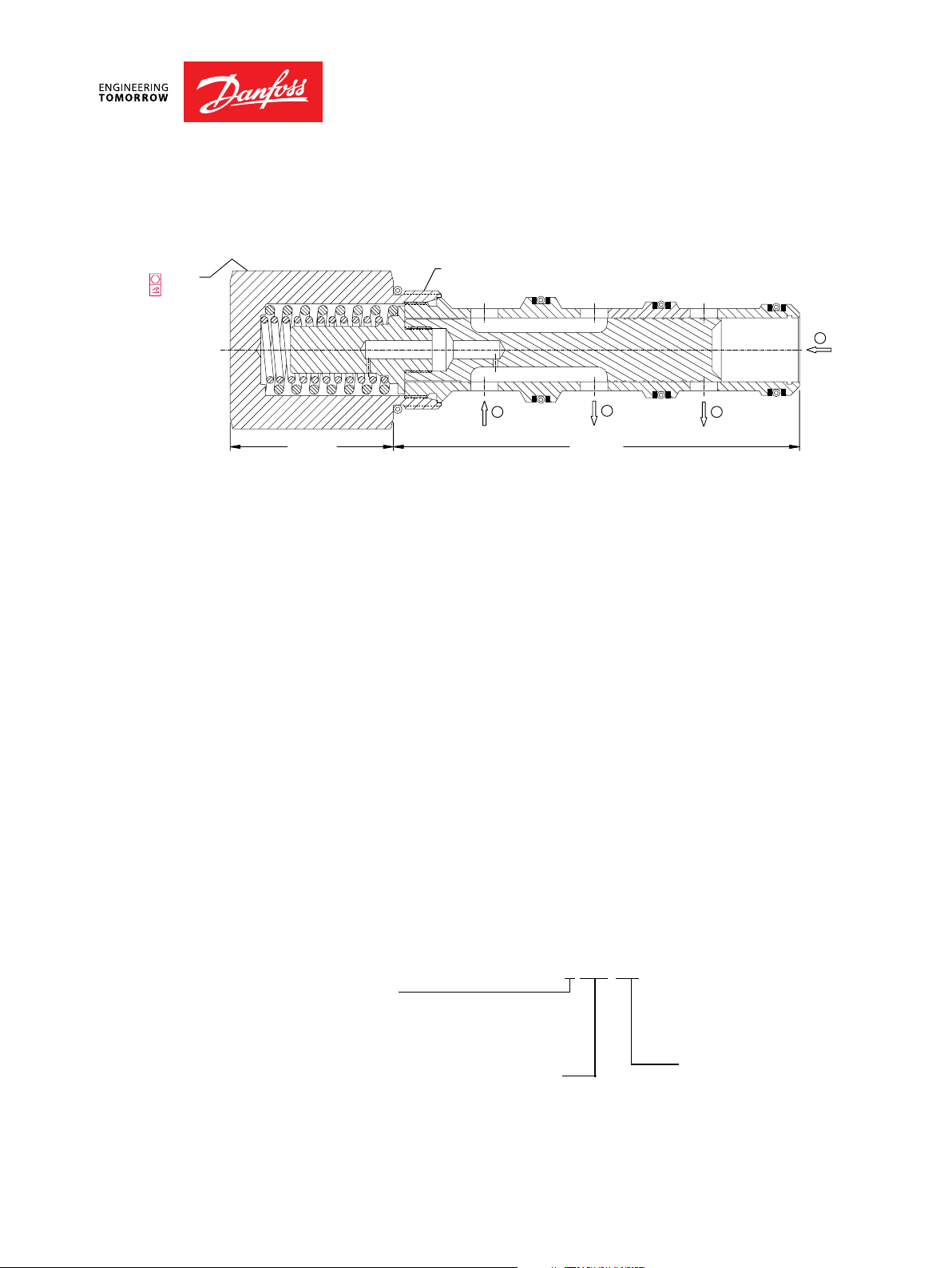

The VLP 12/P2 is a metric 12-size, normally-closed, vent-to-open, poppet-type,

double-blocking, spring biased dierential-sensing logic element. It will provide

on/o ow control from 1 to 2 based on the spring control pressure, inlet

pressure at port 1, and pilot pressure at port 3.

APPLICATION

The valve provides on/o, leakage-free control in both directions, suitable for use as a

high ow relief valve when used with a relief valve to pilot. Common applications include:

pump unloading, pilot-operated relief valve, sequence valve and selector circuit. Eective

use of logic elements is a key to designing cost-eective circuits, and is limited only by the

imagination of the designer.

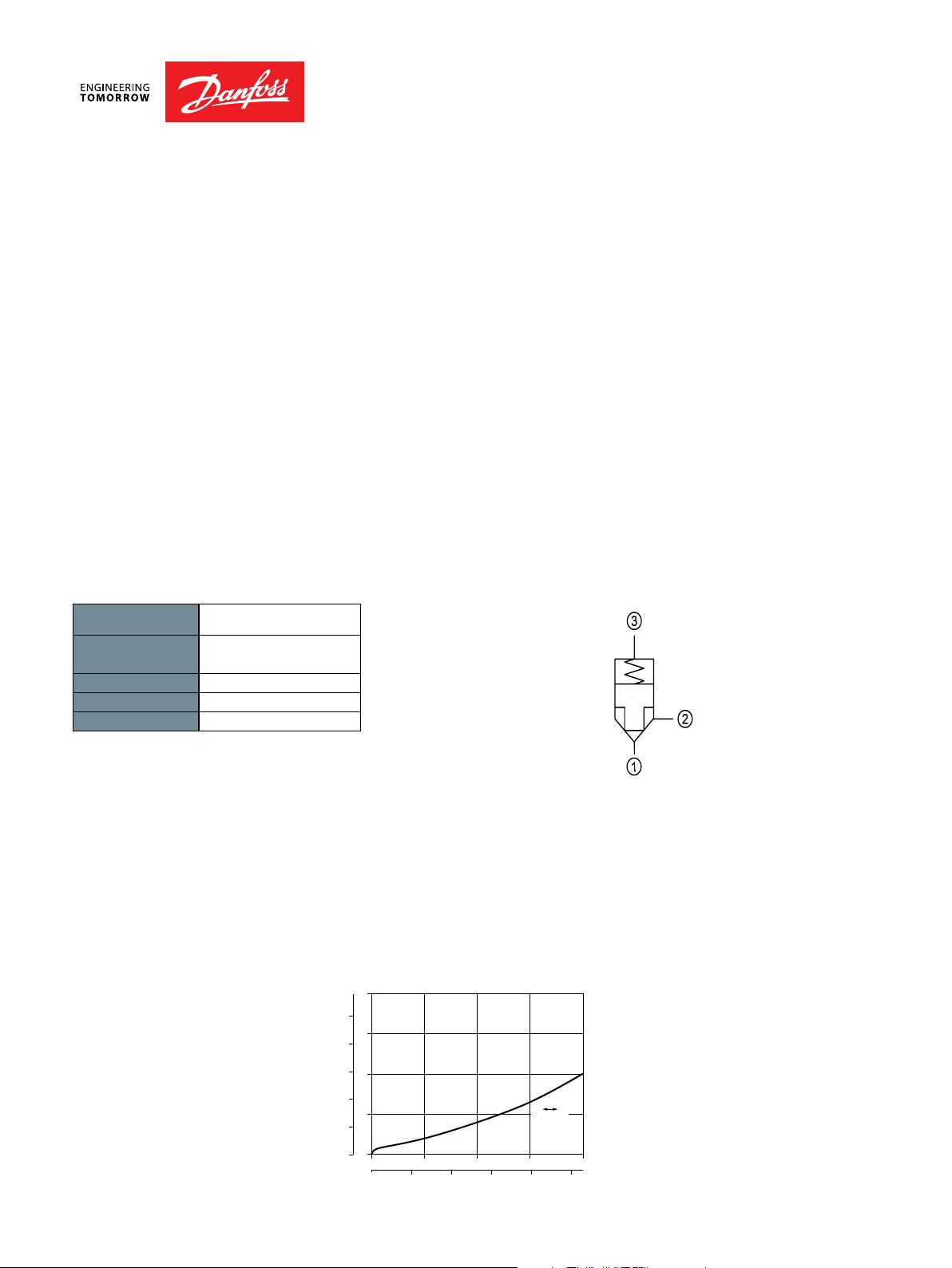

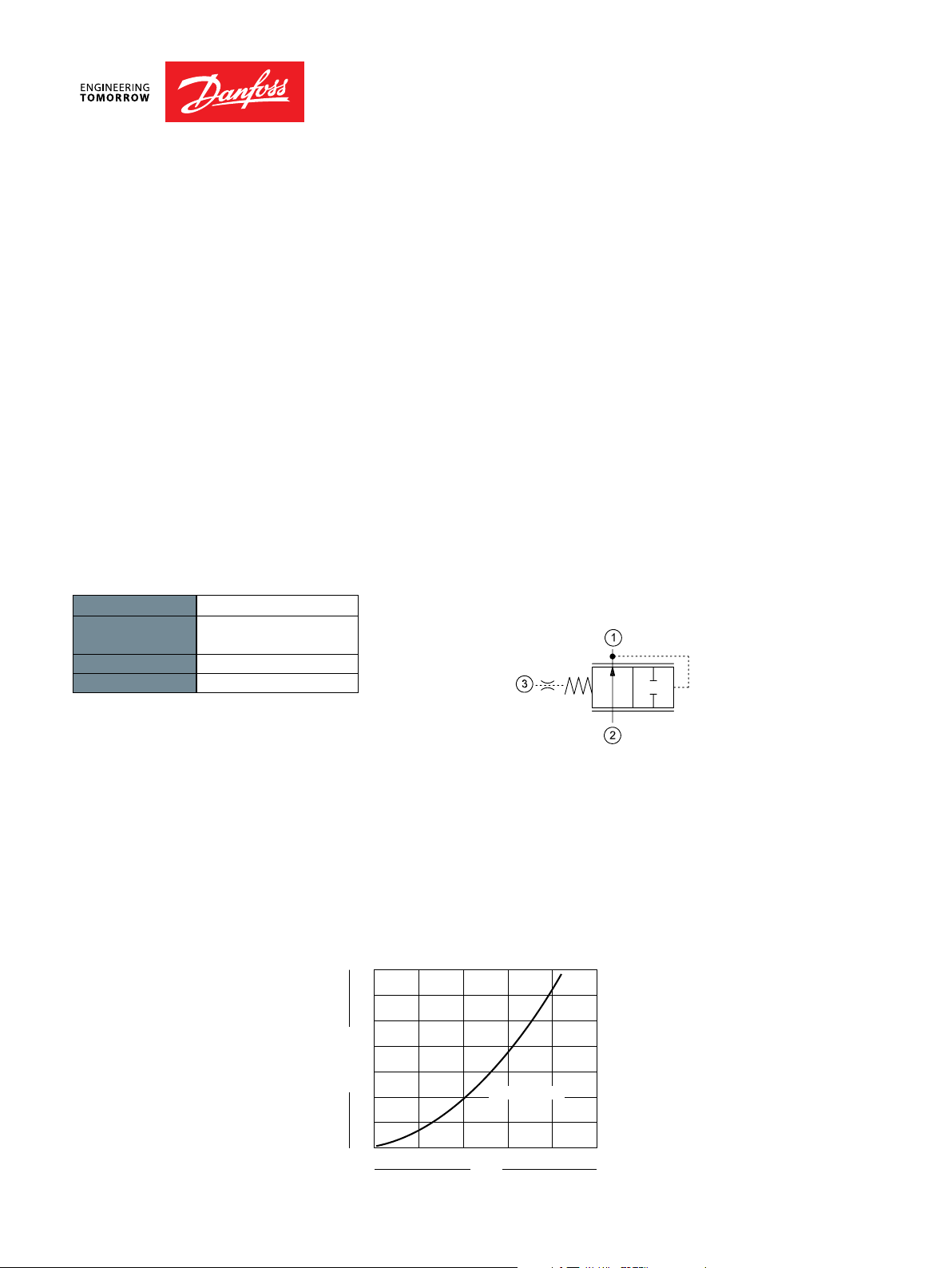

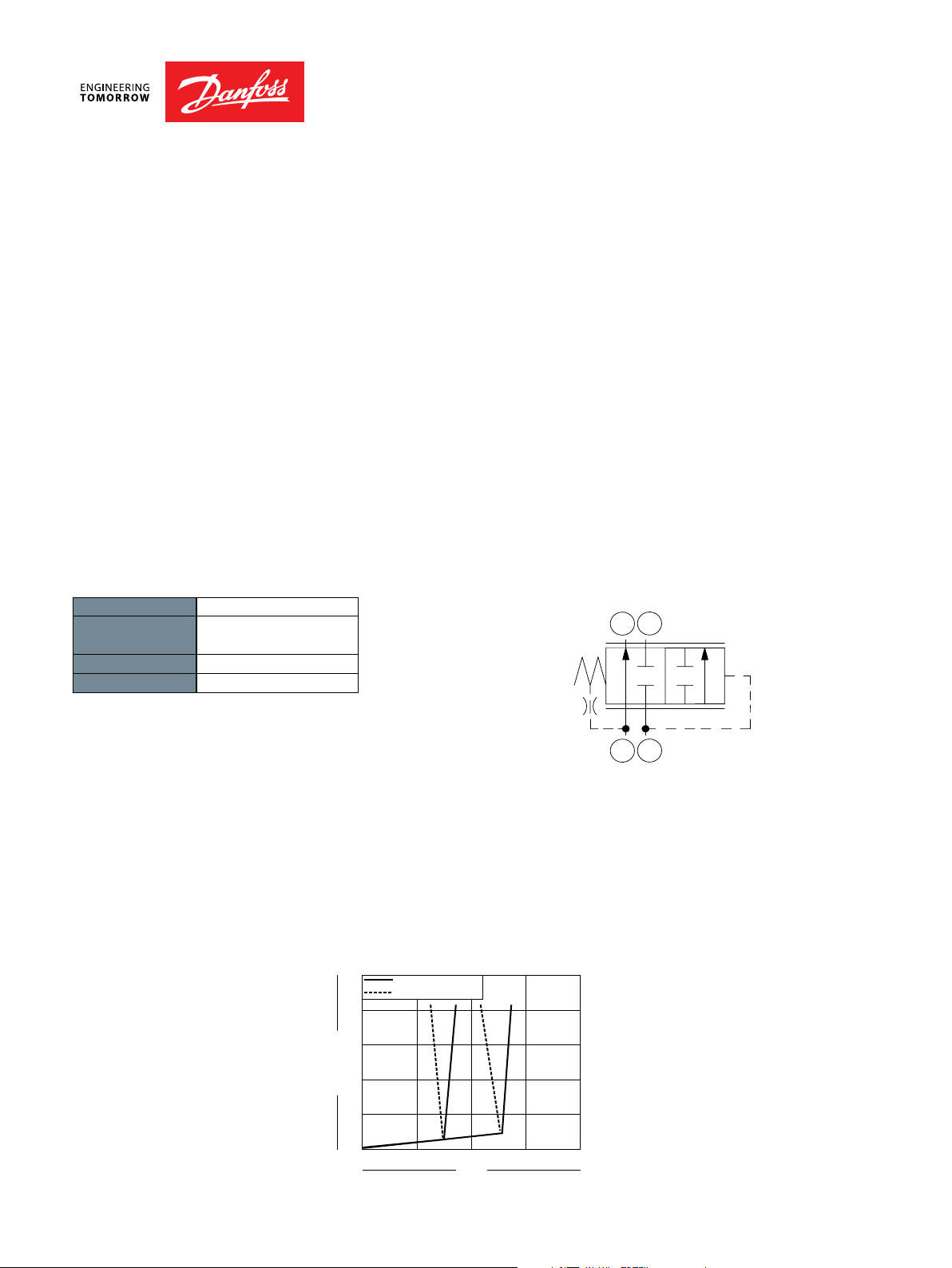

SPECIFICATION

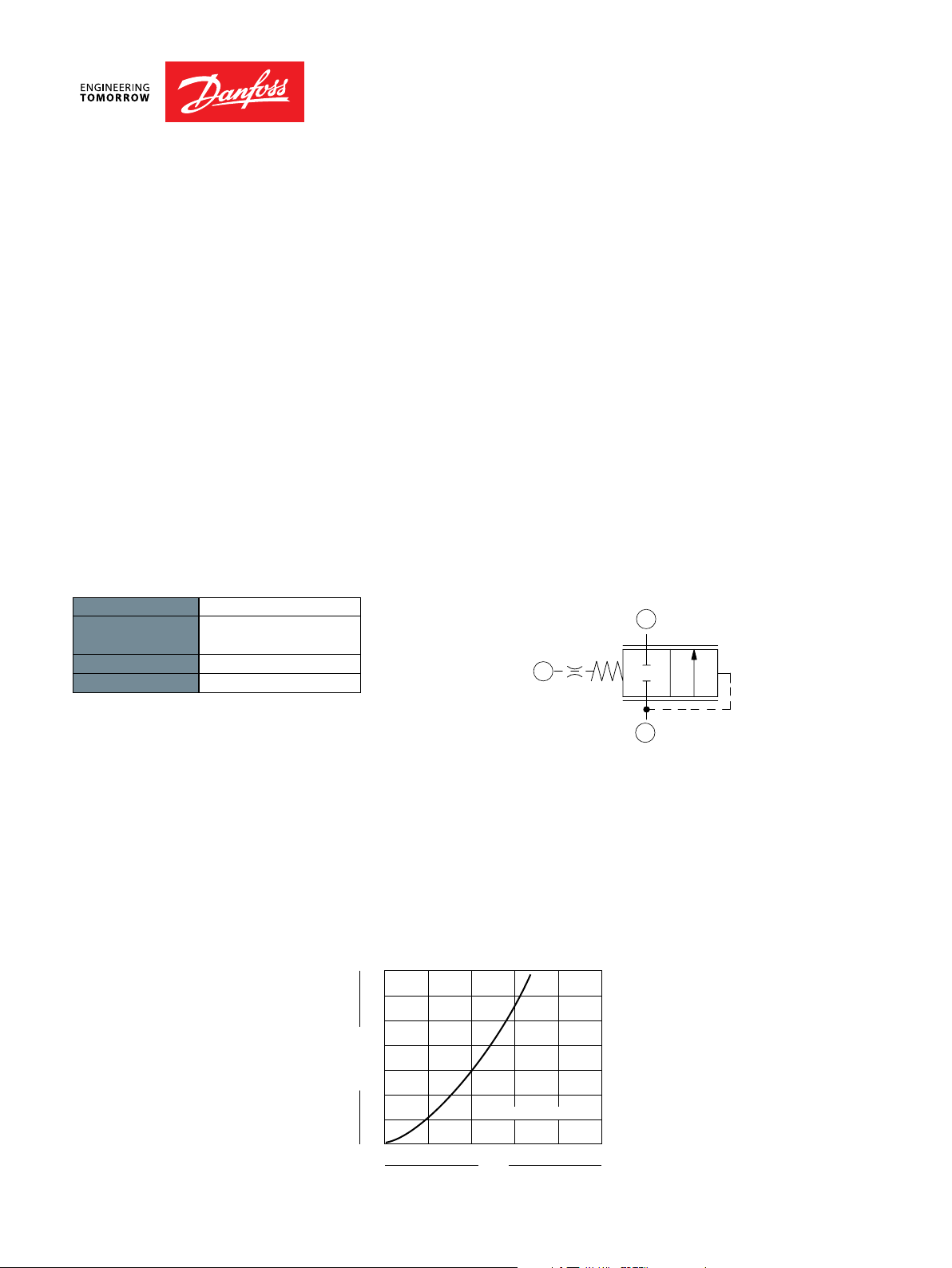

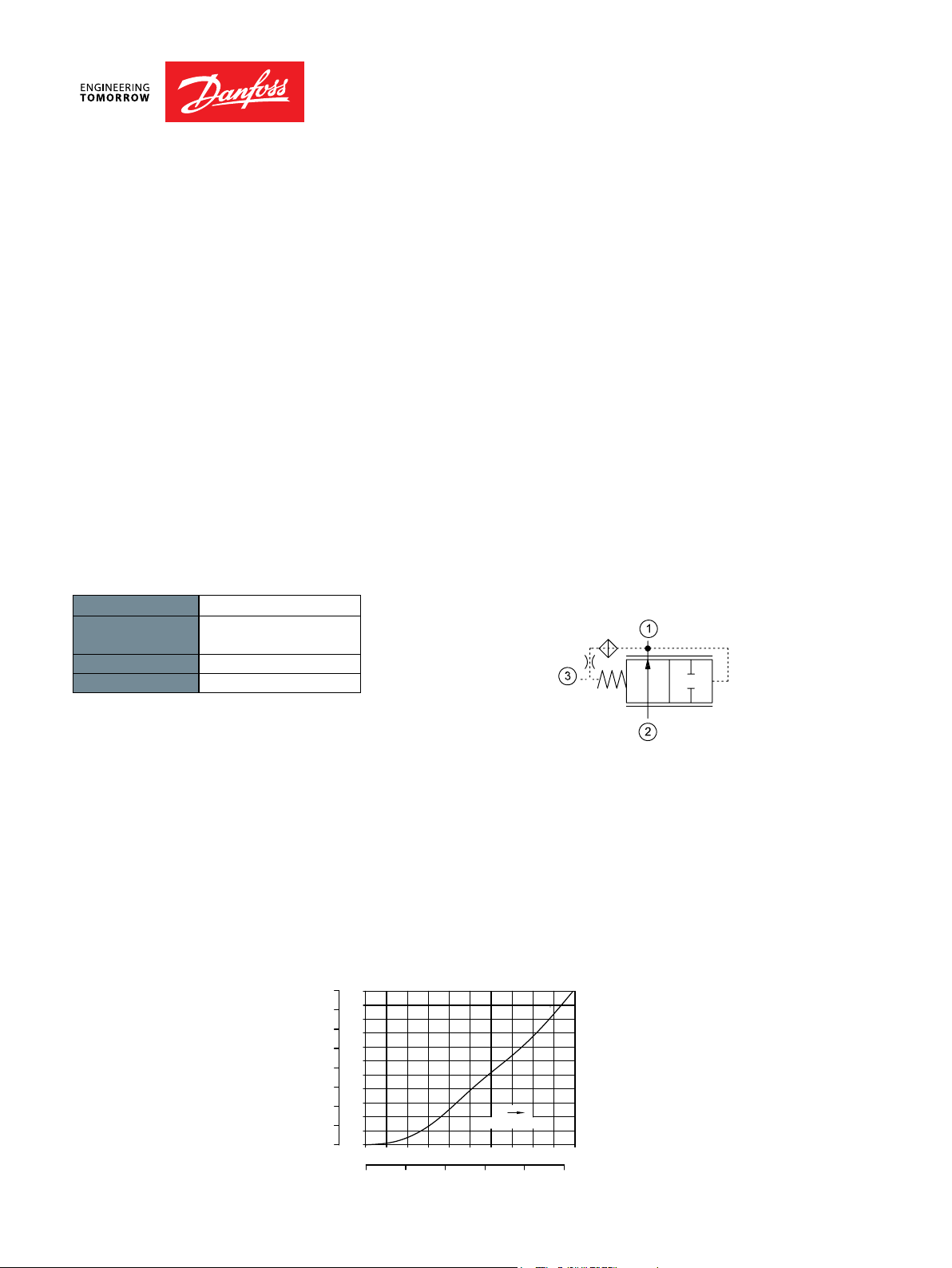

SCHEMATIC

Rated pressure 315 bar [4500 psi]

Rated ow at 7 bar

[100 psi]

160 l/min

[42 US gal/min]

Weight 0.30 kg [0.66 lb]

Cavity NCS12/3

Bias spring 2 bar [29 psi]

PERFORMANCE CURVE

Theoretical performance

psi

bar

26 cSt [125 SUS] hyd.oil @ 20° C [68° F]

20

250

15

200

150

10

100

5

50

0

0

050 100 150 200

l/min

US gal/min

0102

flow

04030

BC332375783111en-000101 • February 2020

LE - 11

Page 12

Logic Elements Technical Information

[2.48]

[0.57]

VLP 12/P2 - B - SE8S -V

Other housings available

Poppet Type, Double-Blocking

VLP 12/P2

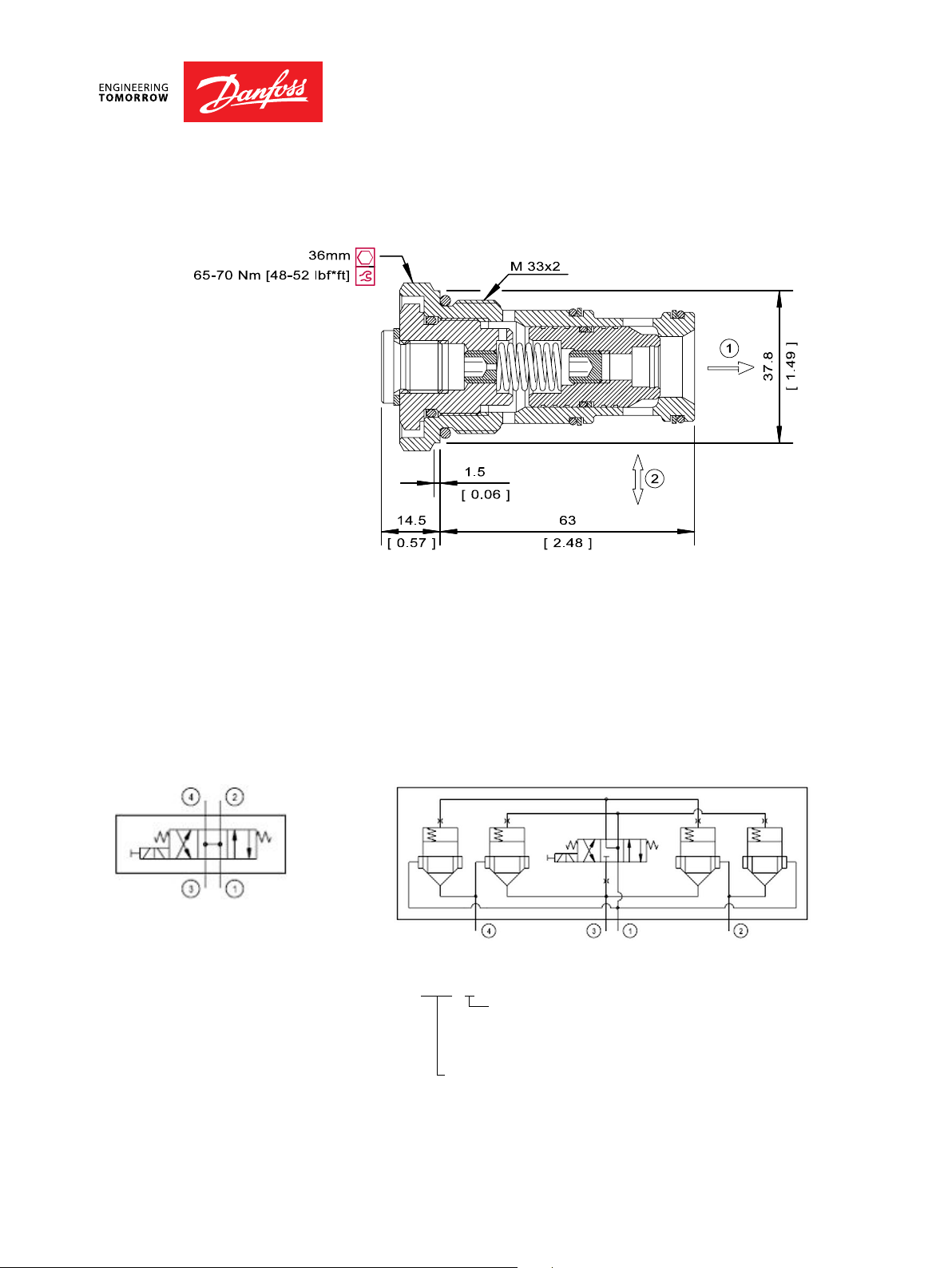

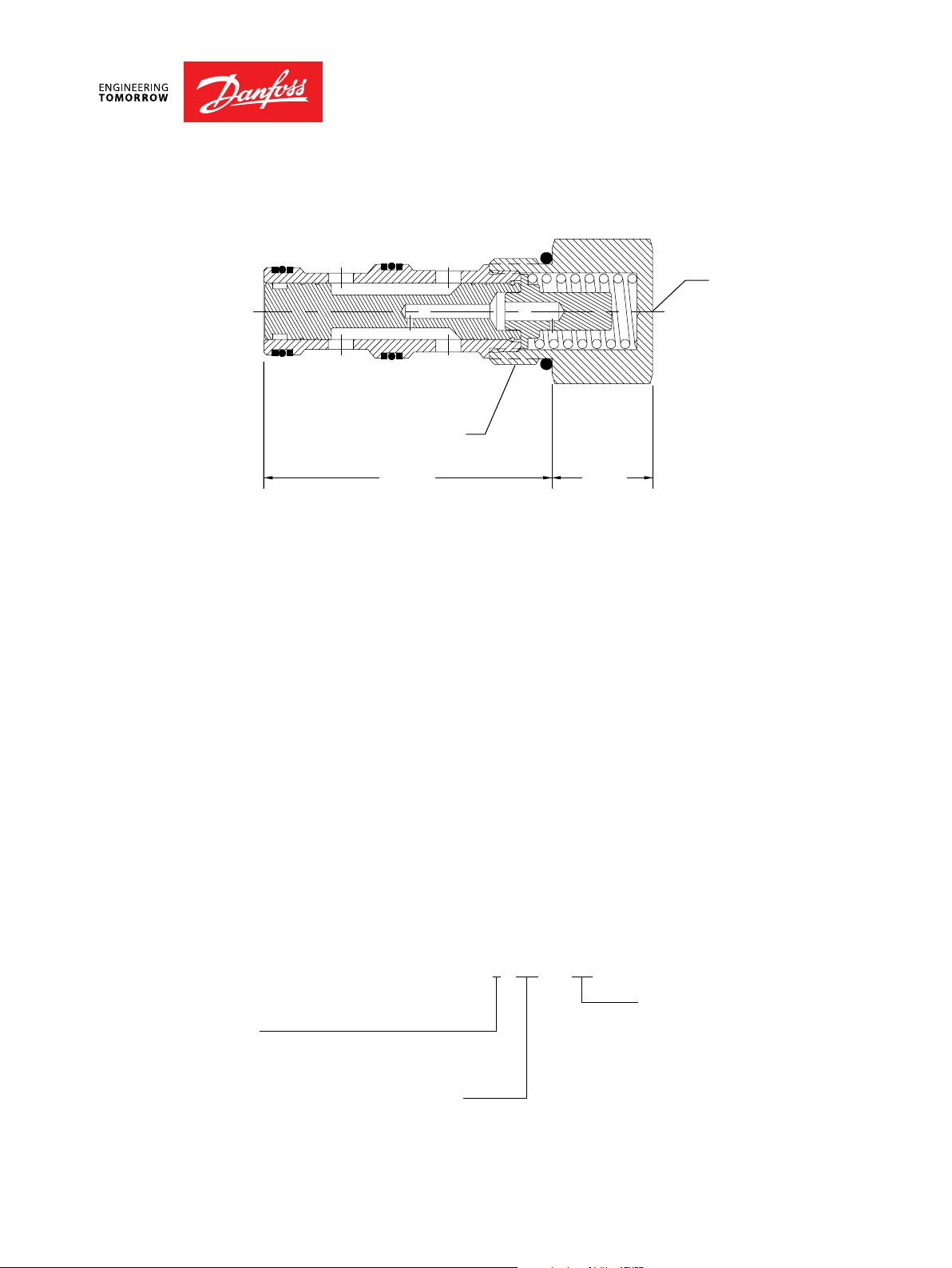

DIMENSION

mm [in]

EXAMPLE CIRCUITS

38 mm

64-70N m

[47-52 lbf ft]

14.5

Cross-sectional view

M33x 2

3

2

1

63.0

ORDERING

INFORMATION

BC332375783111en-000101 • February 2020

Seals Seal kit

V=Viton 230000360

Omit =Buna-N230000130

Housing and portsHousing P/N

00 =No Housing No Housing

SE1/2 = AL,1/2 BSP NCS12/3-SE-1/2

SE3/4 = AL,3/4 BSP NCS12/3-SE-3/4

SE8S = AL, #8 SAE NCS12/3-SE-8S

SE12S = AL, #12SAE NCS12/3-SE-12S

LE - 12

Page 13

Logic Elements Technical Information

Pressure drop

Pressur

e

Poppet Type

VLP 12/A5

OPERATION

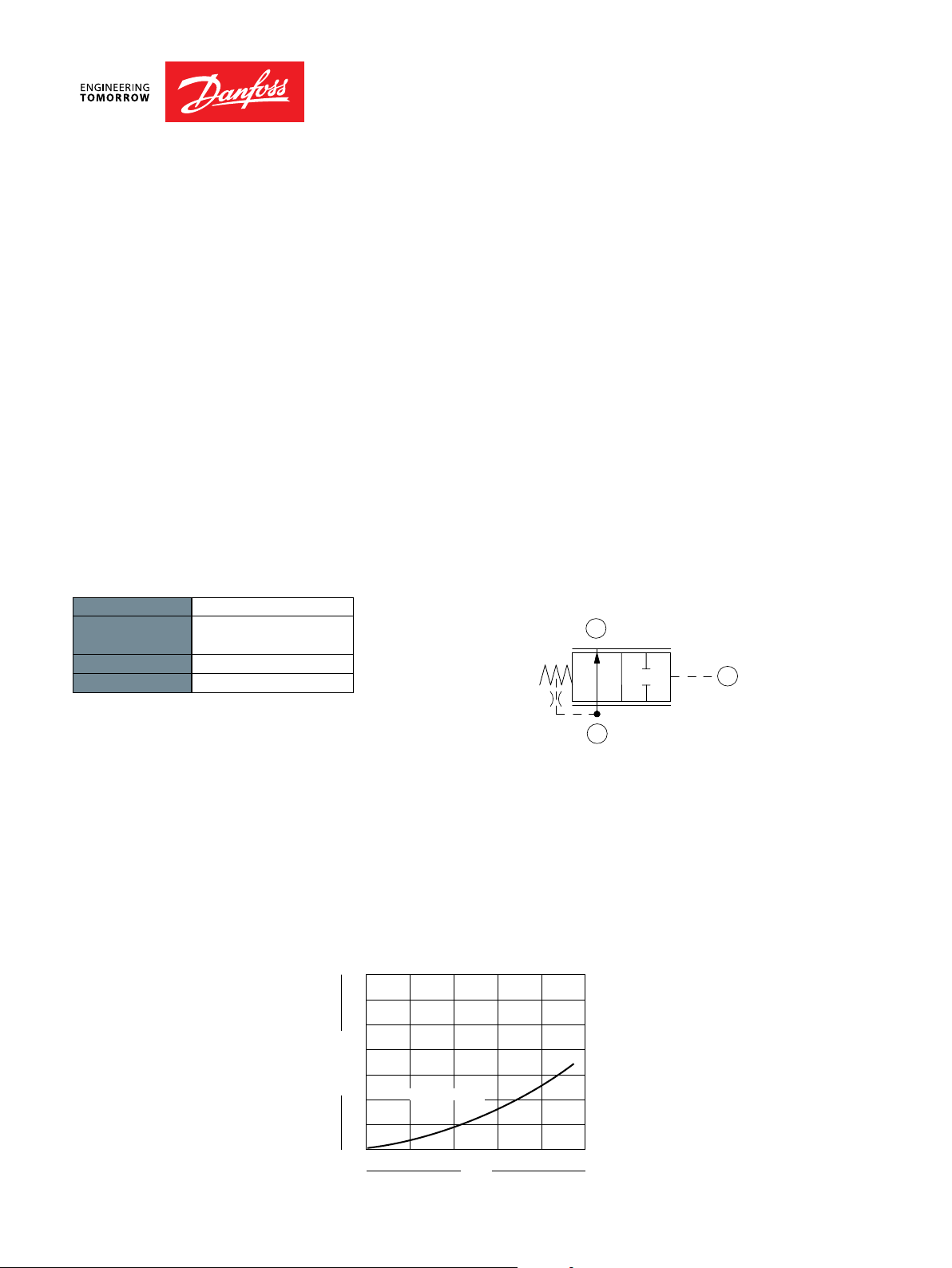

The VLP 12/A5 is a metric 12-size, normally-closed, pilot-to-close,

poppet-type, spring biased dierential-sensing logic element. It will

provide on/o ow control from 1 to 2 based on the spring control

pressure, inlet pressure at port 1, and pilot pressure at port 3.

APPLICATION

The valve provides on/o, leakage-free control, suitable for use as a

high ow check valve when piloted with a small check valve; or a high

ow directional valve when piloted with a directional solenoid valve,

using four VLP 12/A5 valves. Eective use of logic elements is a key to

designing cost-eective circuits, and is limited only by the imagination

of the designer.

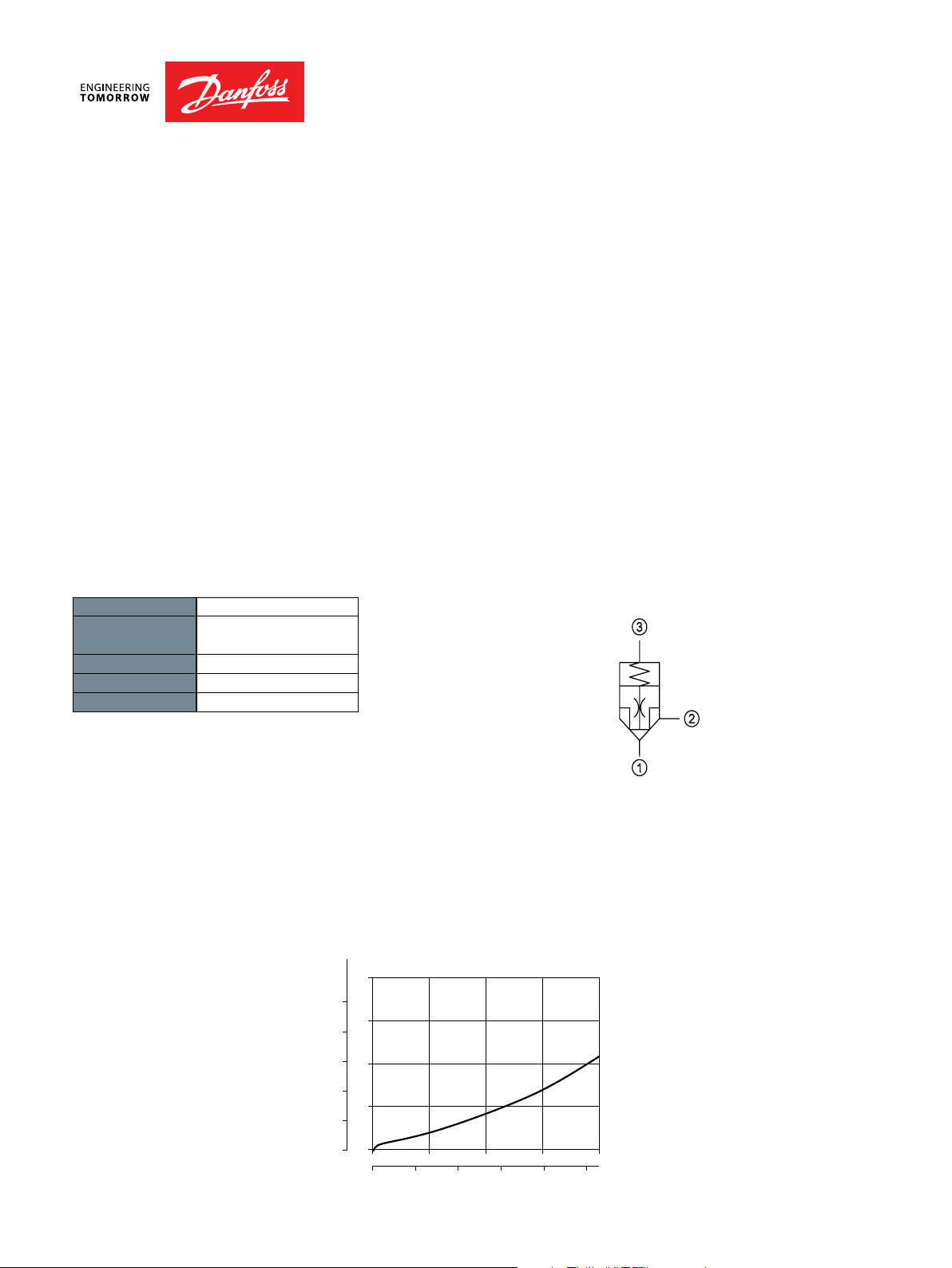

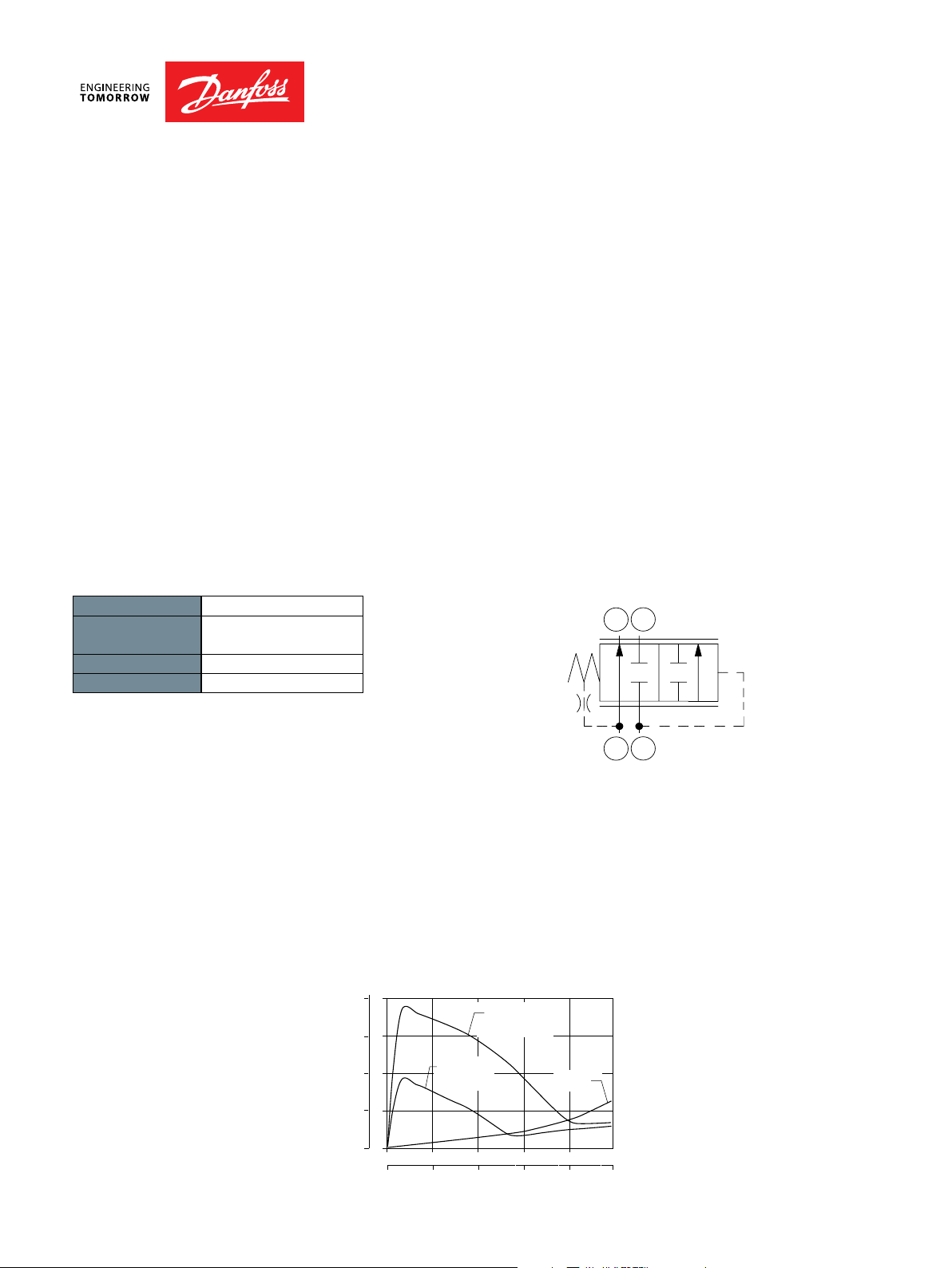

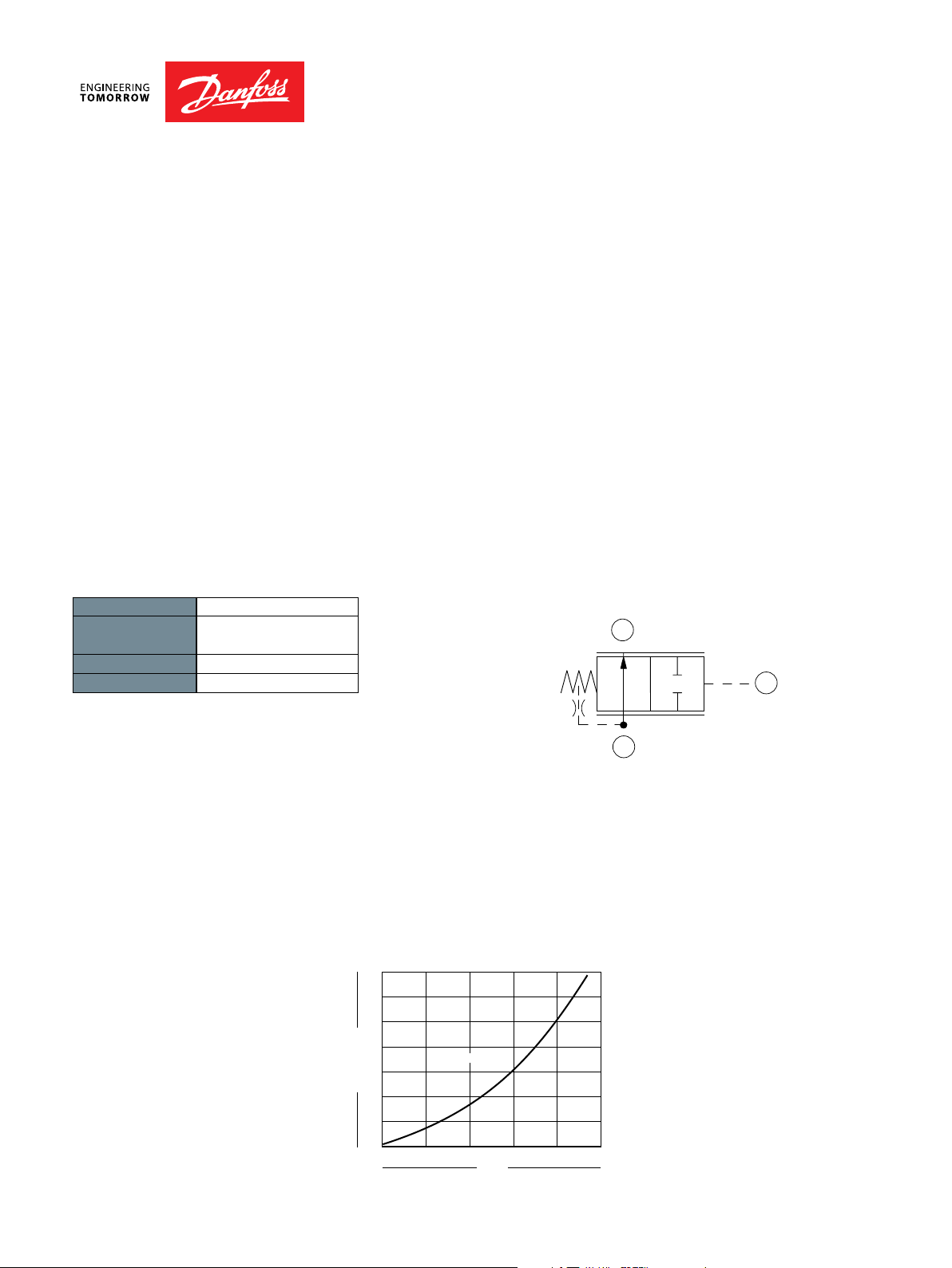

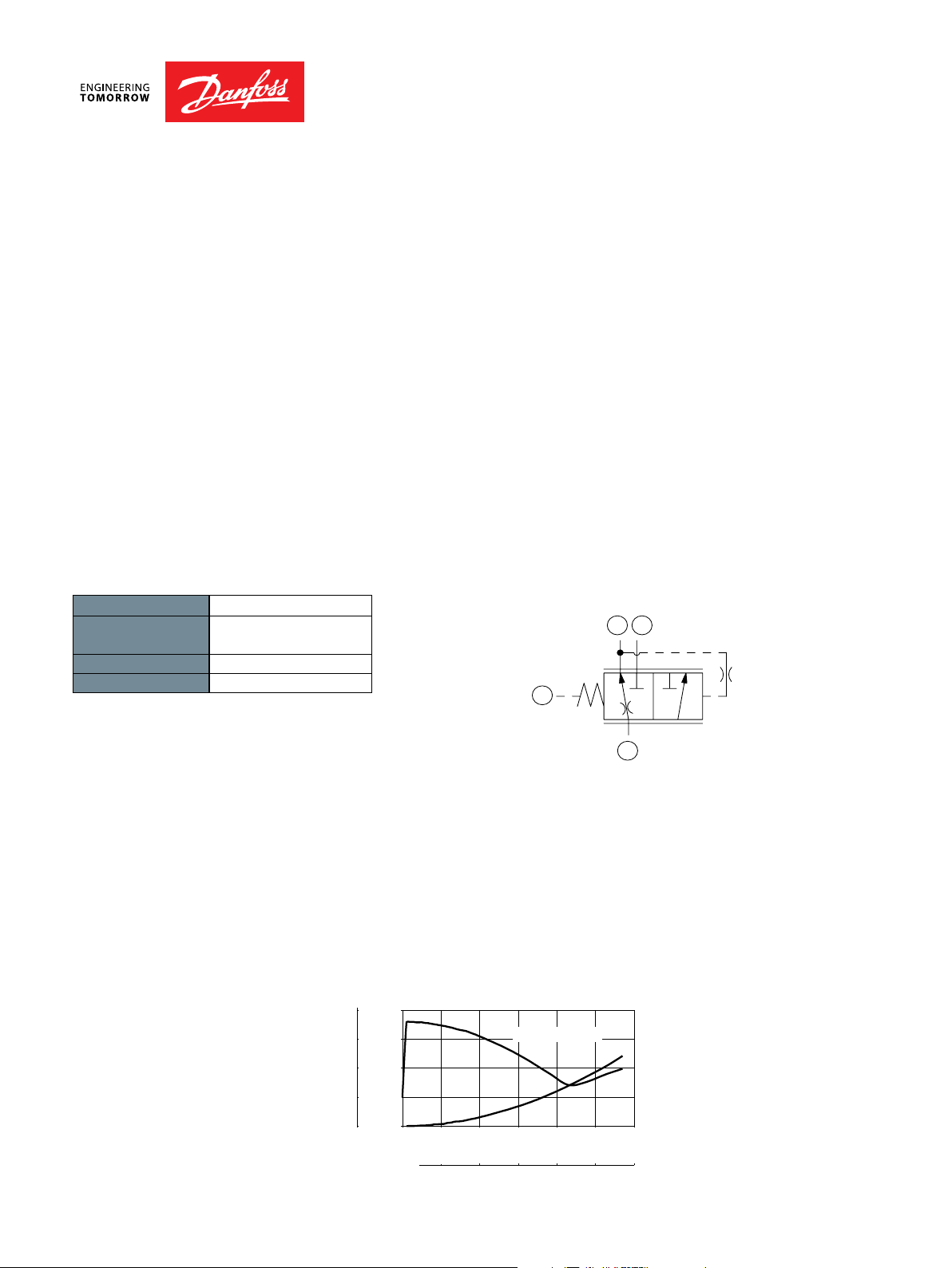

SPECIFICATION

Rated pressure 315 bar [4500 psi]

Rated ow at 7 bar

[100 psi]

Weight 0.30 kg [0.66 lb]

Cavity NCS12/3

Bias spring 2 bar [29 psi]

160 l/min

[42 US gal/min]

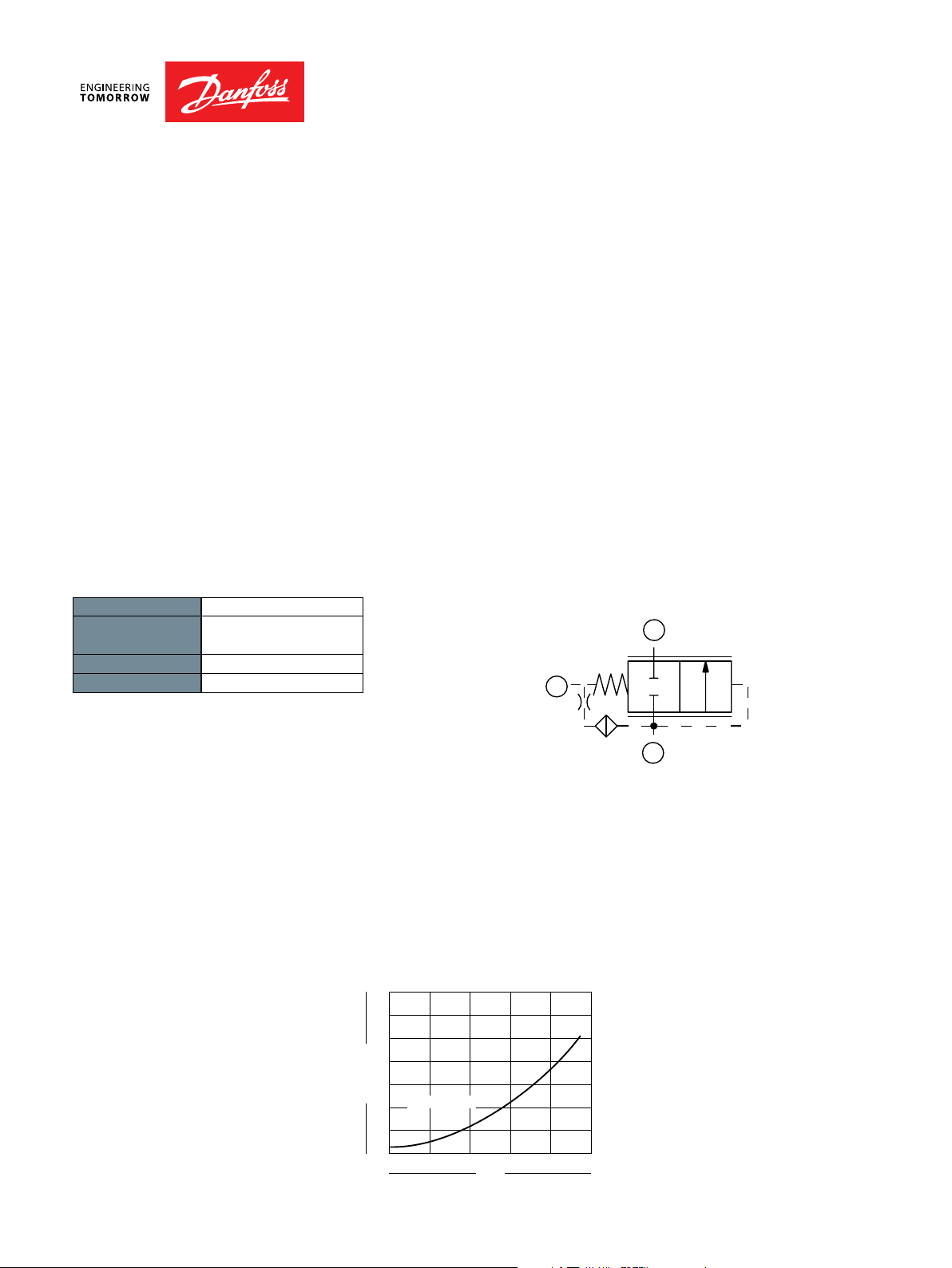

PERFORMANCE CURVE

Theoretical performance

bar

psi

250

200

26 cSt [125 SUS] hyd.oil @ 20° C[68°F]

20

15

SCHEMATIC

150

10

100

5

50

0

0

US gal/min

BC332375783111en-000101 • February 2020

l/min

10 20 504030

50 100 150

flow

1

P103 834E

2

200

LE - 13

Page 14

Logic Elements Technical Information

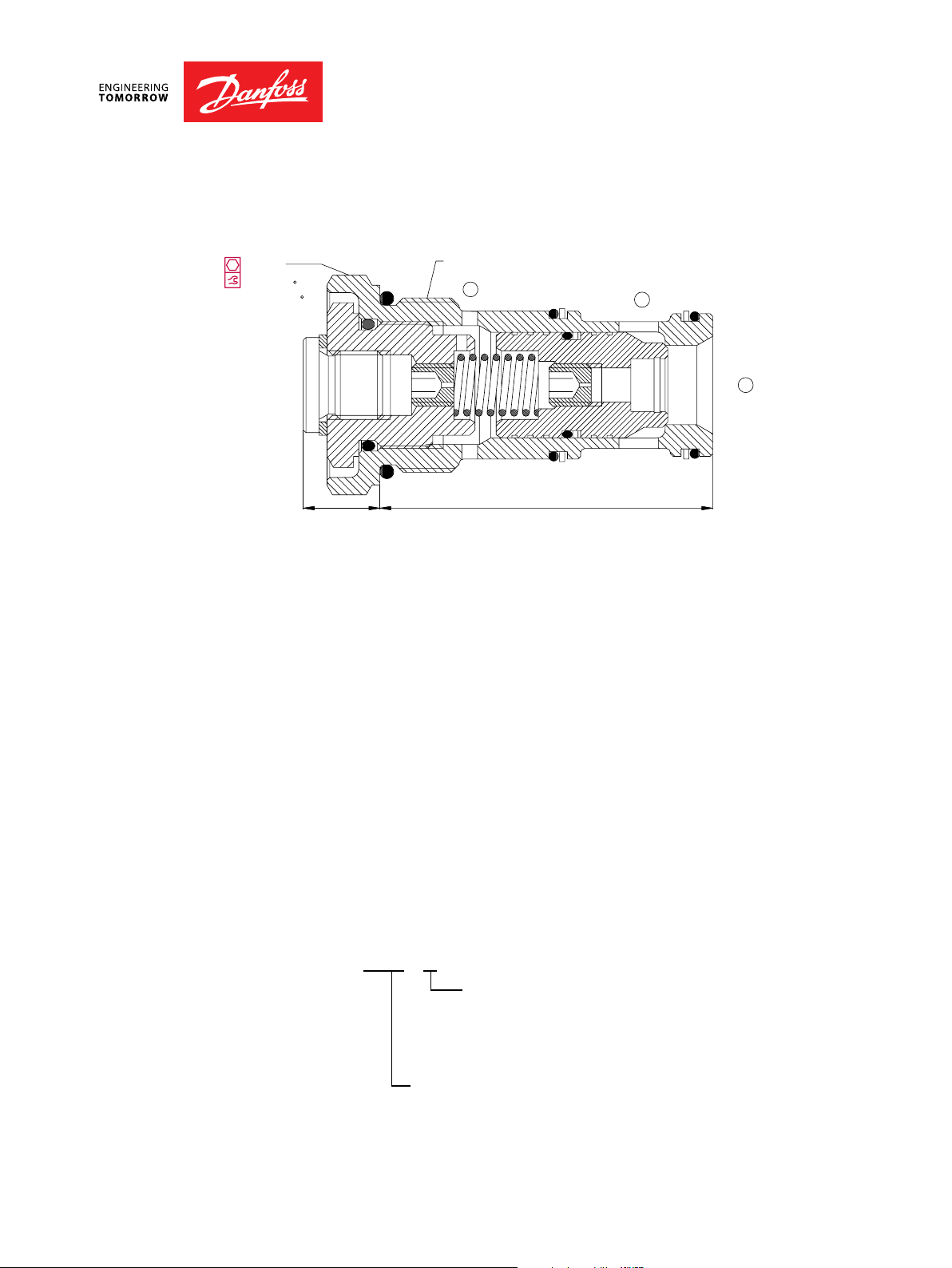

Poppet Type

VLP 12/A5

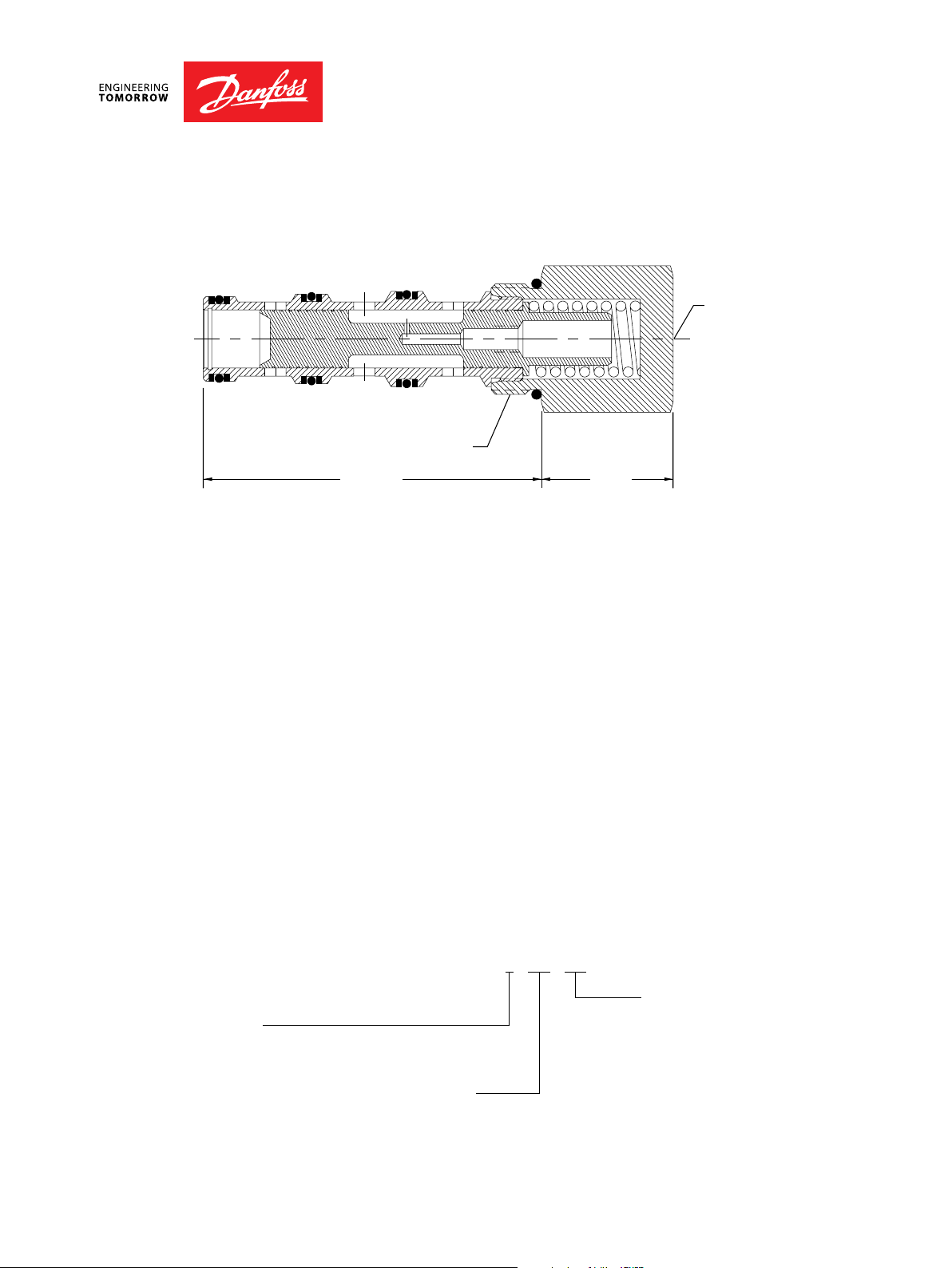

DIMENSION

mm [in]

EXAMPLE CIRCUITS

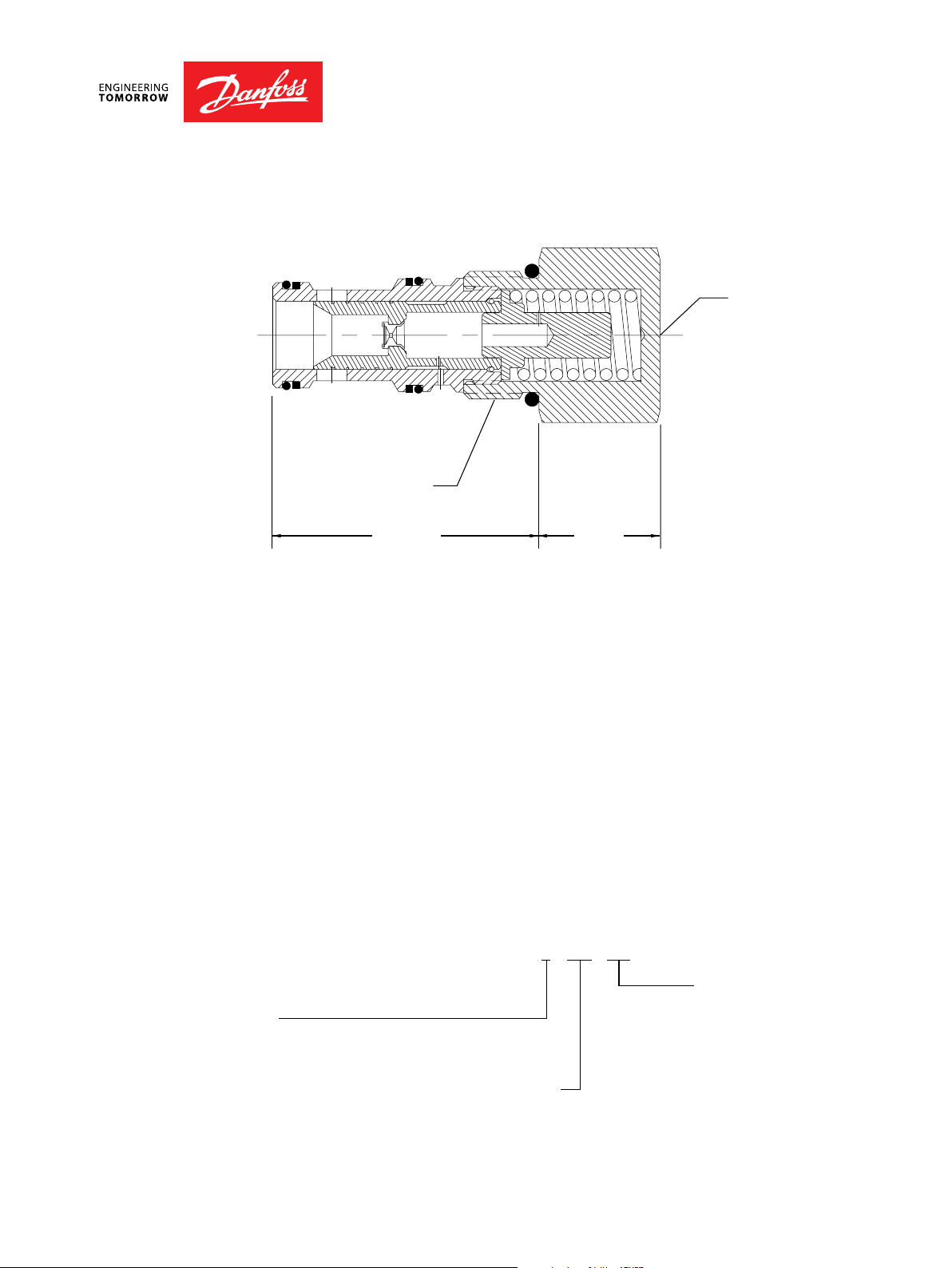

Cross-sectional view

Check Valve

4-3 Way On-O Valve

=

ORDERING

INFORMATION

VLP 12/A5 - B - SE8S -V

BC332375783111en-000101 • February 2020

Seals Seal kit

V=Viton 230000360

Omit =Buna-N230000130

Housing and portsHousing P/N

00 =No Housing No Housing

SE1/2 = AL,1/2 BSP NCS12/3-SE-1/2

SE3/4 = AL,3/4 BSP NCS12/3-SE-3/4

SE8S = AL, #8 SAE NCS12/3-SE-8S

SE12S = AL, #12SAE NCS12/3-SE-12S

Other housings available

LE - 14

Page 15

Logic Elements Technical Information

pressure drop

flow

Poppet Type

VLP 12/C2

OPERATION

The VLP 12/C2 is a metric 12-size, normally-closed, vent-to-open, poppettype, spring biased dierential-sensing logic element. It will provide on/

o ow control from 1 to 2 based on the spring control pressure, inlet

pressure at port 1, and pilot pressure at port 3.

APPLICATION

The valve provides on/o, leakage-free control, suitable for use as a high ow

relief valve when piloted with a relief valve or a high ow unloading solenoid

when piloted with a small solenoid valve. Common applications include: pump

unloading, pilot-operated relief valve, sequence valve and selector circuit.

Eective use of logic elements is a key to designing cost-eective circuits, and is

limited only by the imagination of the designer.

SPECIFICATION

Rated pressure 315 bar [4500 psi]

Rated ow at 7 bar

[100 psi]

Weight 0.30 kg [0.66 lb]

Cavity NCS12/3

Bias spring 2 bar [29 psi]

160 l/min

[42 US gal/min]

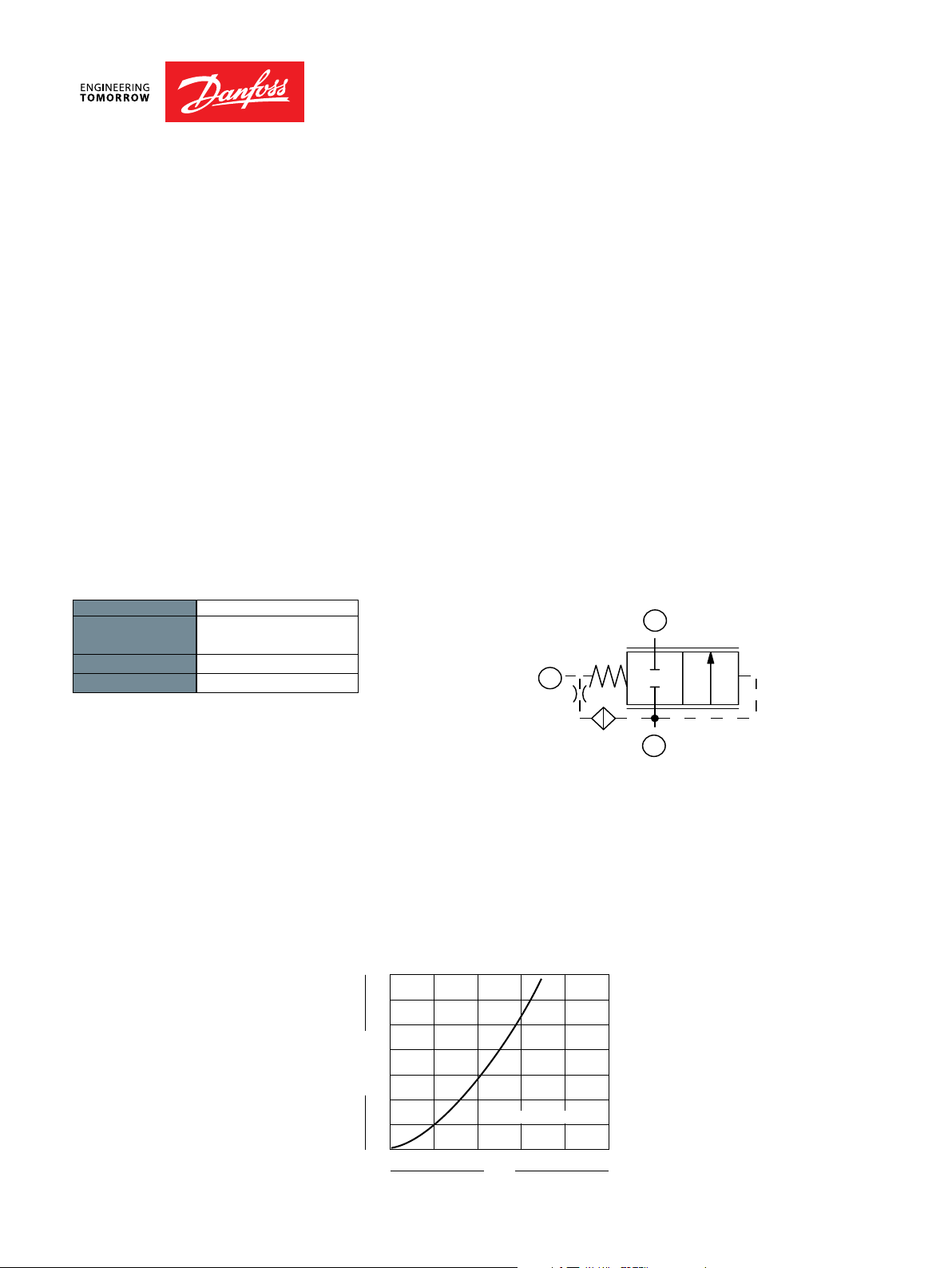

PERFORMANCE CURVE

SCHEMATIC

Theoretical performance

psi

bar

20

250

15

e

200

26 cSt [125 SUS] hyd.oil @ 20° C [68° F]

150

pressur

10

100

5

50

0

0

l/min

US gal/min

BC332375783111en-000101 • February 2020

050 100 150 200

01020504030

LE - 15

Page 16

Logic Elements Technical Information

VLP 12/C2 - B - SE8S -V

Other housings available

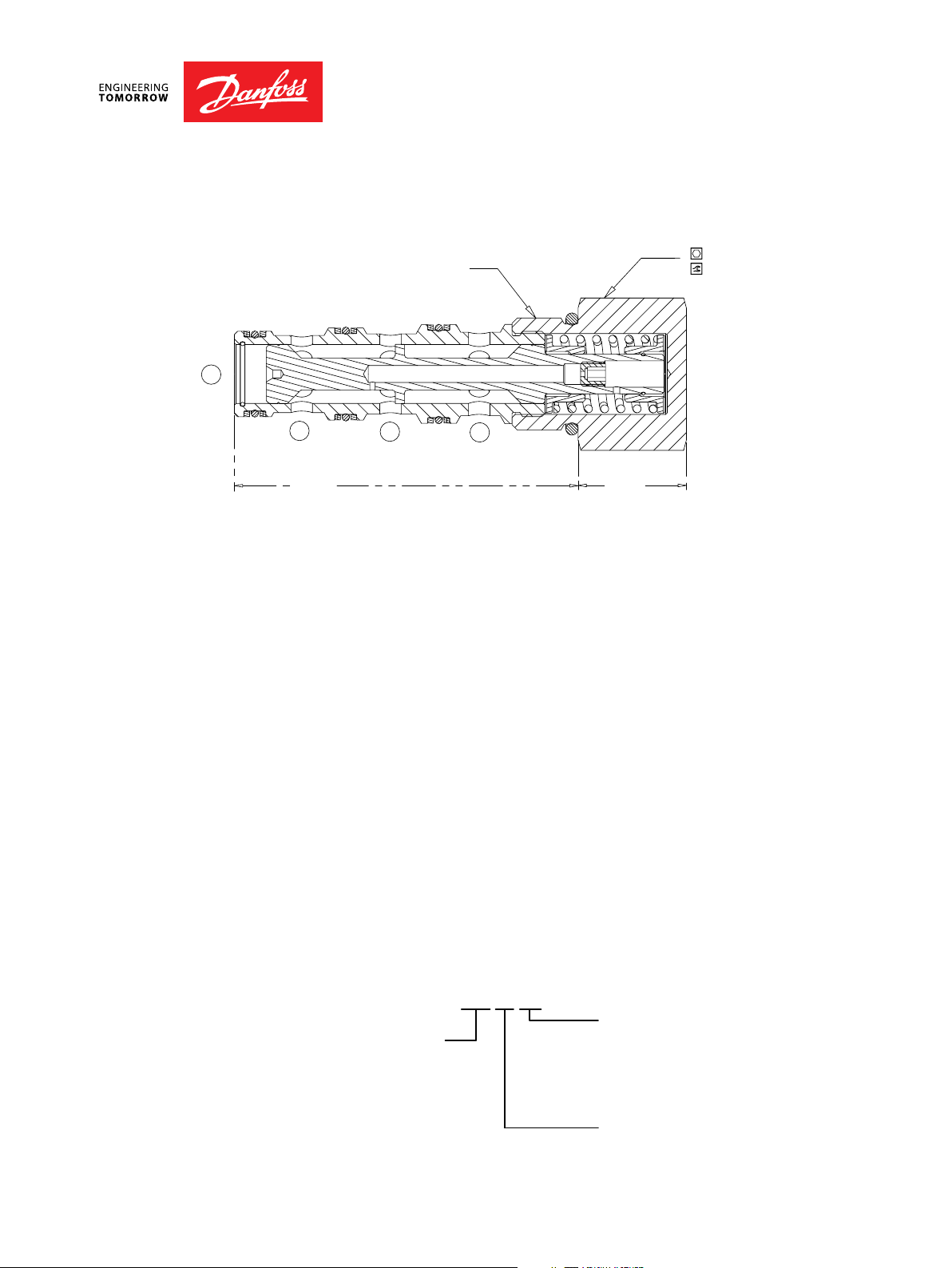

Poppet Type

VLP 12/C2

DIMENSION

mm [in]

EXAMPLE CIRCUITS

38 mm

64-70N m

[47-52 lbf ft]

14.5

[0.57]

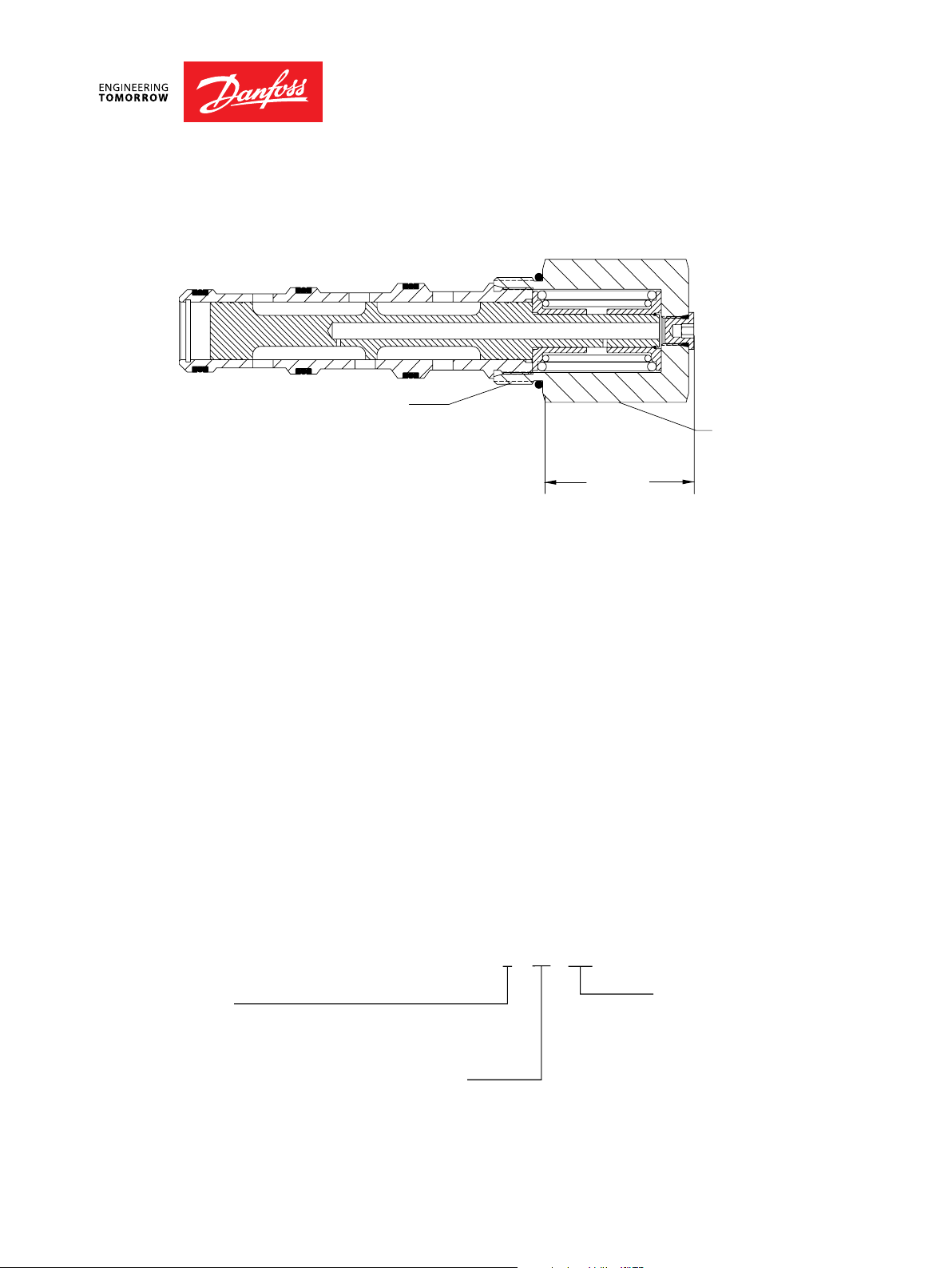

Cross-sectional view

M33x2

3

2

1

63.0

[2.48]

ORDERING

INFORMATION

BC332375783111en-000101 • February 2020

Seals Seal kit

V=Viton 230000360

Omit =Buna-N230000130

Housing and portsHousing P/N

00 =No Housing No Housing

SE1/2 = AL,1/2 BSP NCS12/3-SE-1/2

SE3/4 = AL,3/4 BSP NCS12/3-SE-3/4

SE8S = AL, #8 SAE NCS12/3-SE-8S

SE12S = AL, #12SAE NCS12/3-SE-12S

LE - 16

Page 17

Logic Elements Technical Information

3

2

1

Spool Type

HLEA10-CPC

OPERATION

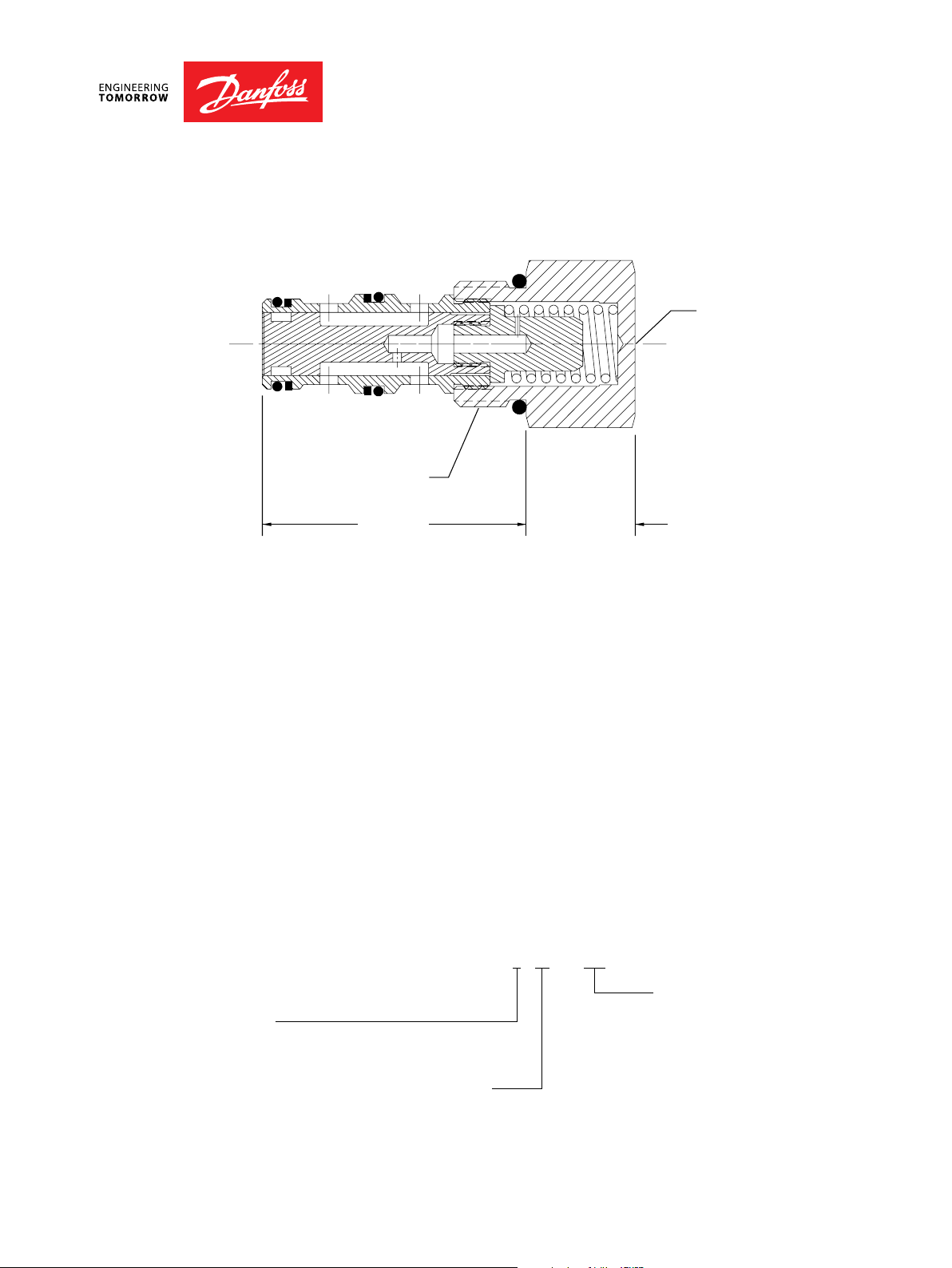

The HLEA10-CPC is a 10-size, high pressure, normally-closed,

pilot-to-close, spring biased dierential-sensing logic

element that includes an adjustable compensator feature. It

will modulate ow from 1 to 2 based on the spring control

pressure, inlet pressure at port 1, and pilot pressure at port 3.

APPLICATION

Common applications include load-sensing bypass compensator for a xed displacement

pump with single or multiple actuators as well as bypass-type pressure-compensated ow

control. Eective use of logic elements is a key to designing cost-eective circuits, and is

limited only by the imagination of the designer.

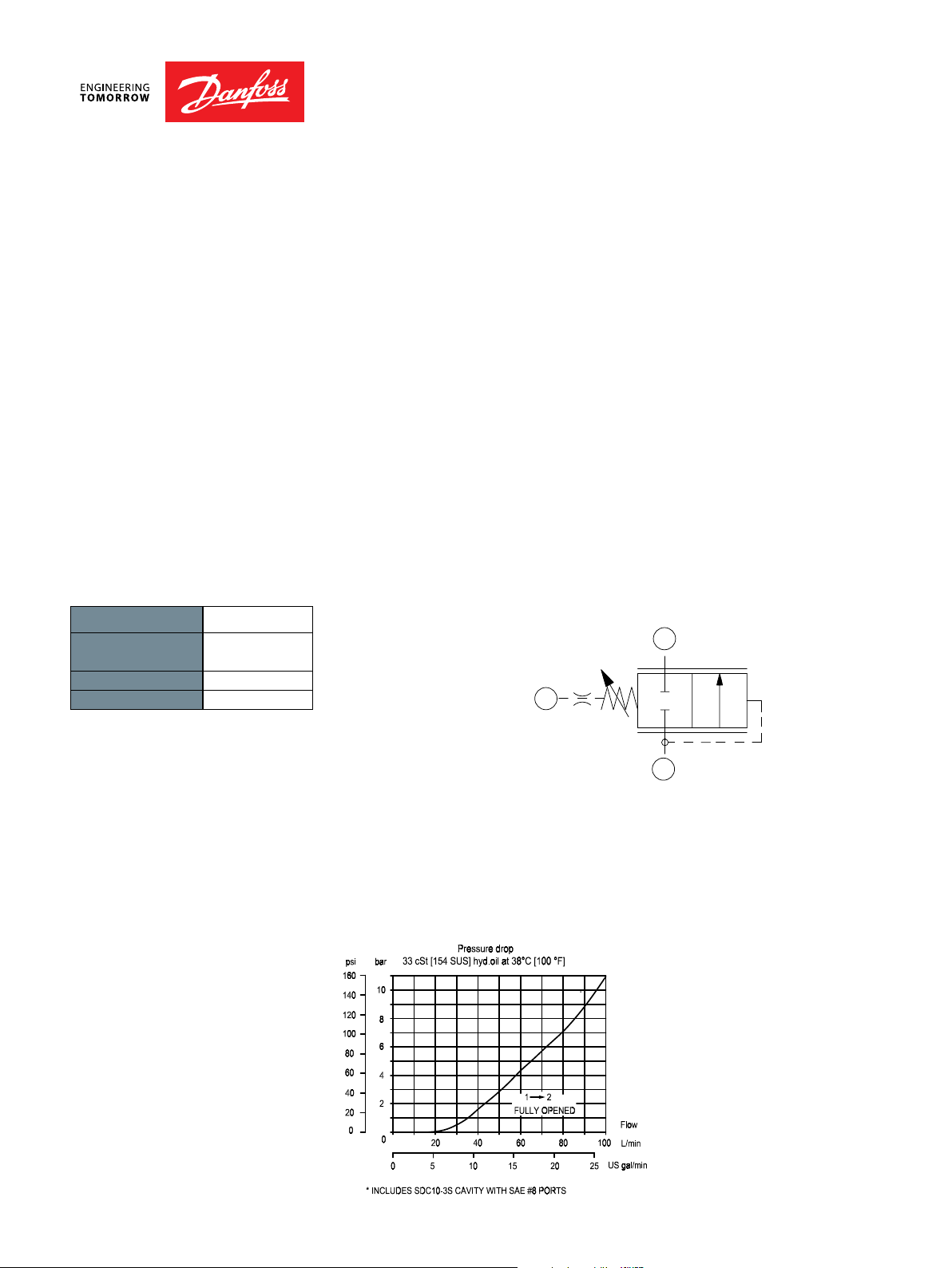

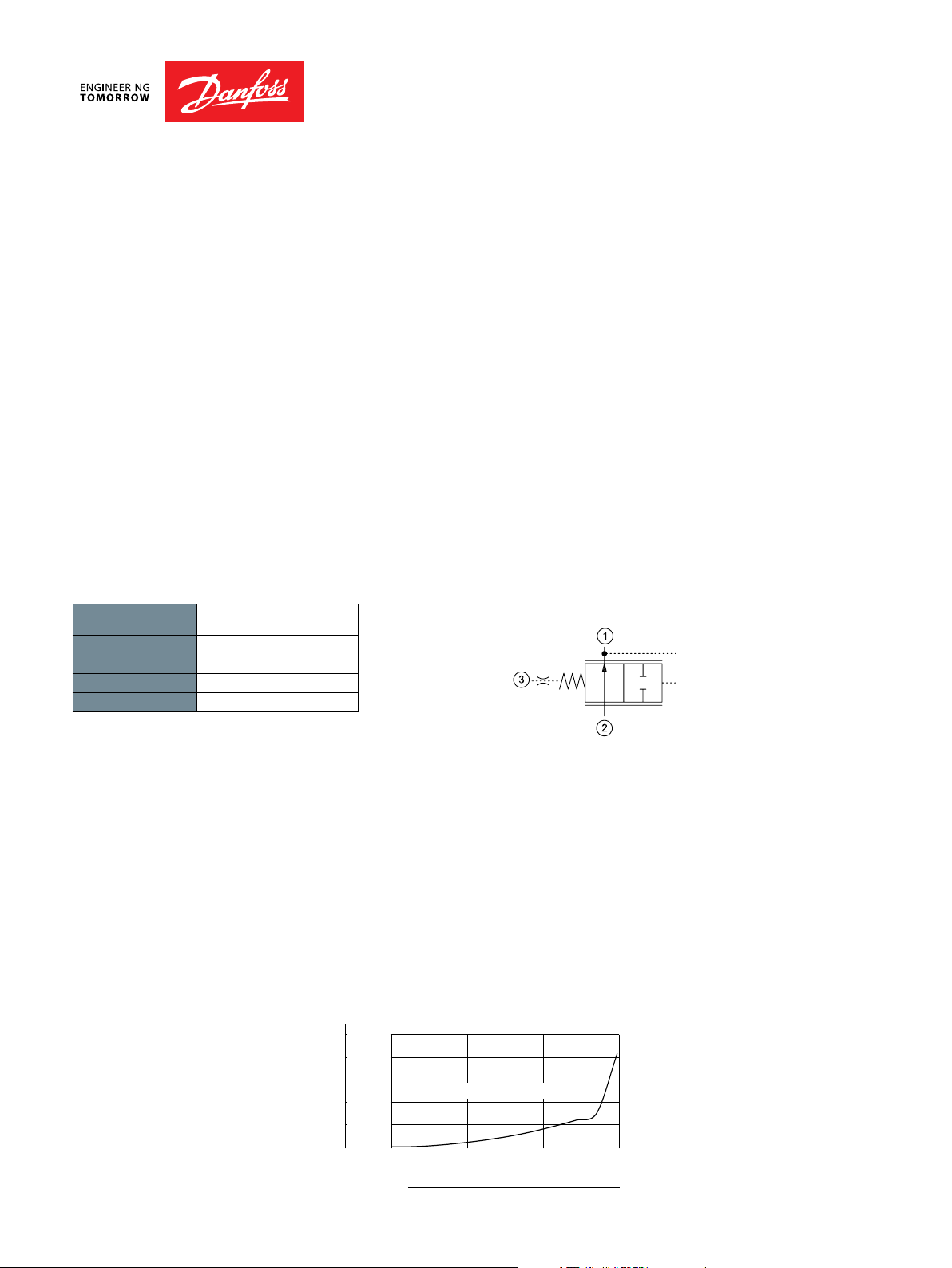

SPECIFICATION

Rated Pressure* 350 bar [5075 psi]

Rated Flow at 7 bar

[100 psi]

Weight 0.29 kg [0.64 lbs]

Cavity SDC10-3S

* Rated Pressure based on NFPA fatigue test standards (at 1 Million Cycles).

80 l/min

[21.1 US gal/min]

PERFORMANCE CURVE

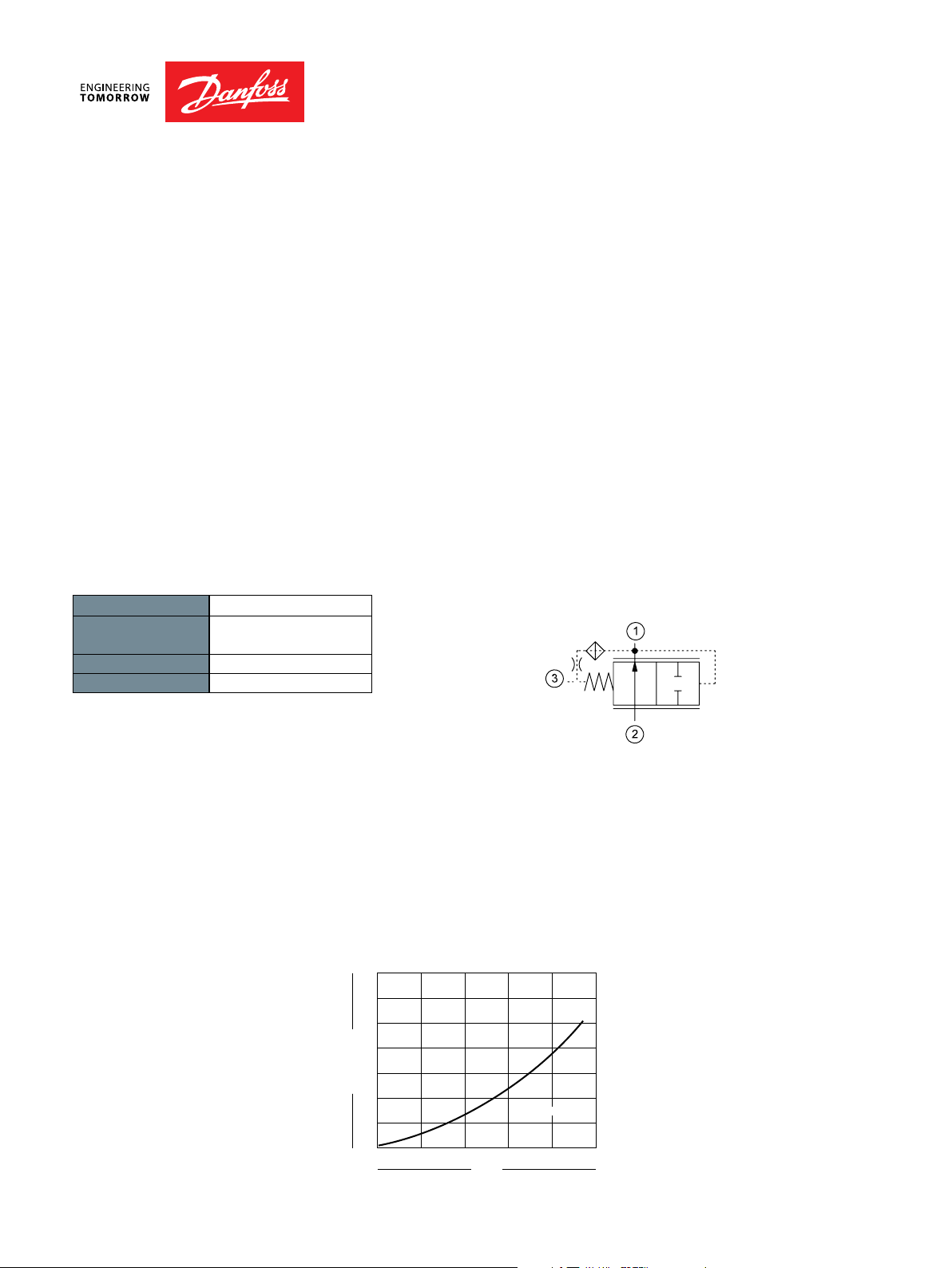

SCHEMATIC

Theoretical Performance

BC332375783111en-000101 • February 2020

LE - 17

Page 18

Logic Elements Technical Information

Spool Type

HLEA10-CPC

DIMENSION

mm [in]

1

EXAMPLE CIRCUITS

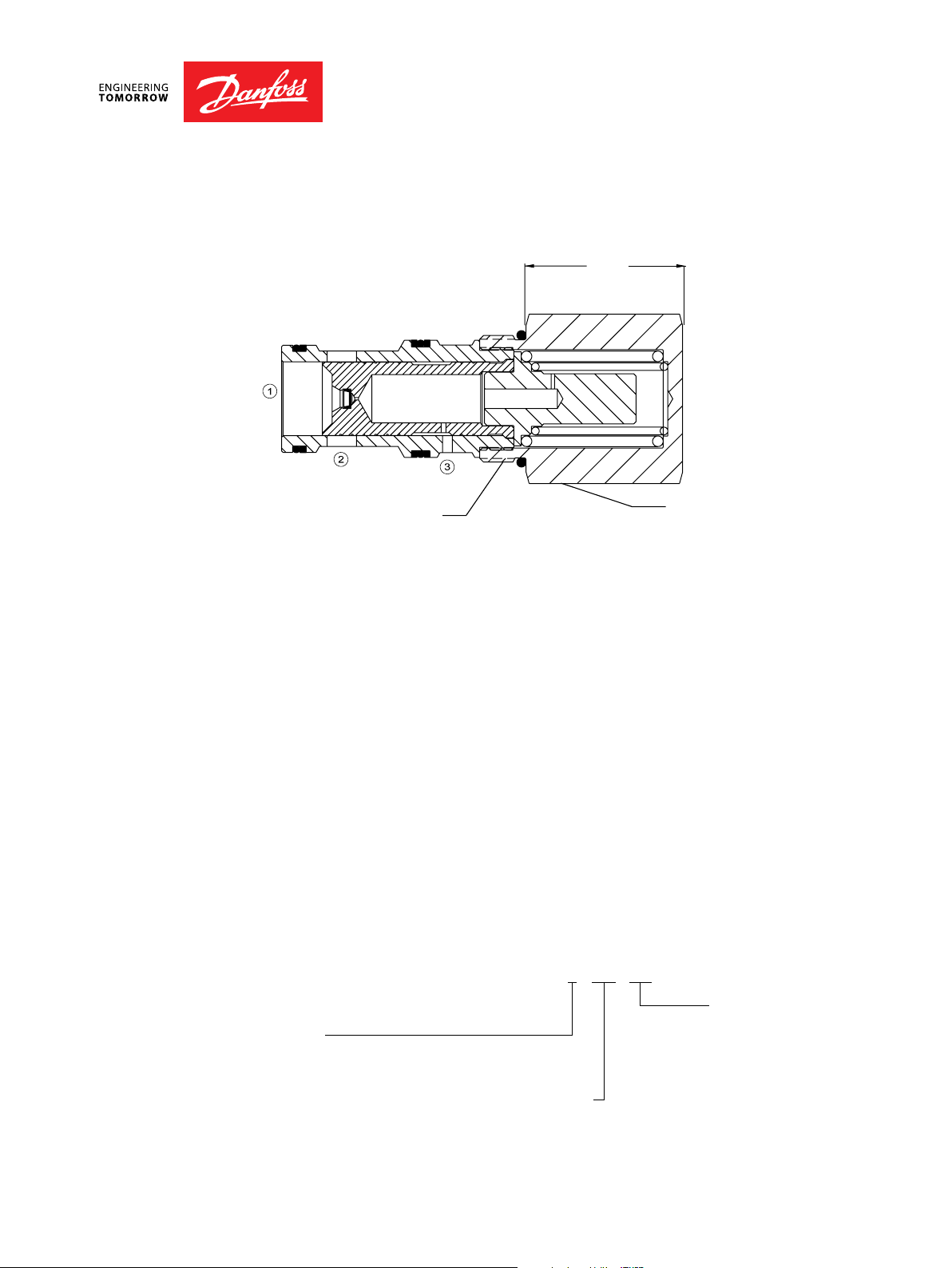

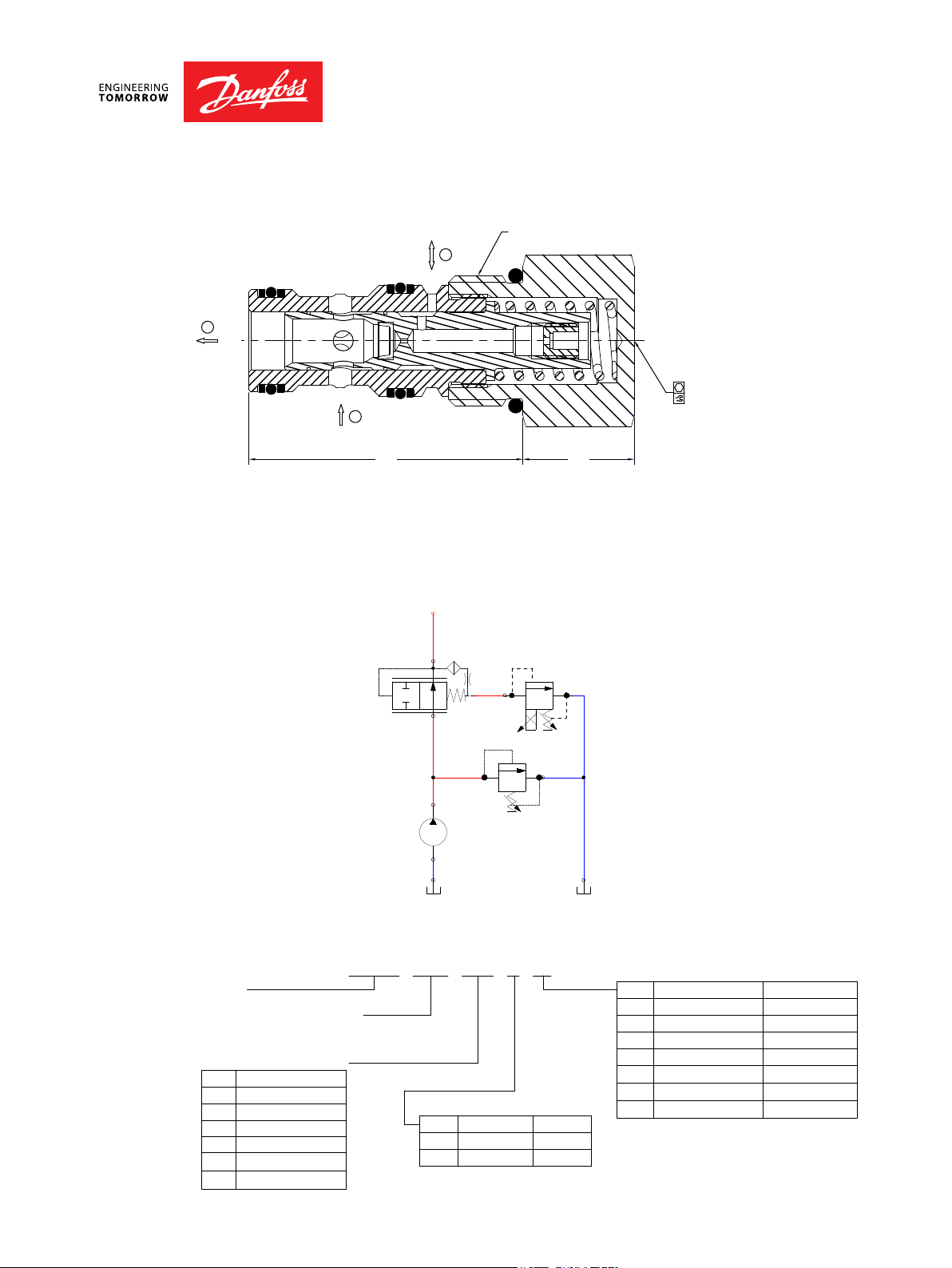

Cross-sectional view

7/8-14 UNF

25.4 mm [1.00]

68-75 Nm

3

[50-55 lbf*ft]

2

46.8

[1.84]

19.1 mm [.75]

4.1-5.4 Nm

[36-48 lbf*in]

80.0 MAX

[3.15]

6.4 mm [.25]

Double Acng Cylinder with Proporonal Speed

Control, Unloading Valve and Circuit Relief

ORDERING

INFORMATION

BC332375783111en-000101 • February 2020

Proporonal Bypass Flow Control

Dump and Relief Valve for a Fixed Pump

LE - 18

Page 19

Logic Elements Technical Information

Spool Type

CP700-1

OPERATION

The CP700-1 is a 10-size, normally-closed, pilot-to-close, spool-type,

spring biased dierential-sensing logic element. It will modulate

ow from 1 to 2 based on the spring control pressure, inlet pressure

at port 1, and pilot pressure at port 3.

APPLICATION

Common applications include load-sensing bypass compensator for a xed

displacement pump with single or multiple actuators as well as bypass-type

pressure-compensated ow control. Eective use of logic elements is a key to

designing cost-eective circuits, and is limited only by the imagination of the

designer.

SPECIFICATION

Rated pressure 210 bar [3045 psi]

Rated ow at 7 bar

[100 psi]

Weight 0.12 kg [0.27 lb]

Cavity SDC10-3

50 l/min

[13 US gal/min]

PERFORMANCE CURVE

psi bar

203

174

145

116

87

Press ure drop

58

29

Theoretical performance

154 SUS (33 cSt) hyd. oil @ 100° F (38° C)

14

12

10

8

6

4

2

Fully opened

SCHEMATIC

2

3

1

BC332375783111en-000101 • February 2020

0

40 60 80 100

20L/min

5.3US gal/min

Flow

10.6 15.9 21.1 26.4

LE - 19

Page 20

Logic Elements Technical Information

[1.82]

[0.75]

Spool Type

CP700-1

DIMENSION

mm [in]

1

EXAMPLE CIRCUITS

Cross-sectional view

23

7/8-14 UNF

46.2

19.1

h 1.00 in

41-47 N.m

t

[30-35 lbf.ft]

Double Acng Cylinder with Proporonal Speed

Control, Unloading Valve and Circuit Relief

ORDERING

INFORMATION

Seals

B=Buna-N 120027

V=Viton 120028

Housing and portsHousing P/N

0=No Housing No Housing

SE3B=AL,3/8 BSP SDC10-3-SE-3B

SE4B=AL, 1/2 BSP SDC10-3-SE-4B

6S = AL, #6 SAE CP10-3-6S

8S = AL, #8 SAE CP10-3-8S

Other housings available

BC332375783111en-000101 • February 2020

Proporonal Bypass Flow Control

CP700-1-B-8S-080

Seal kit

Dump and Relief Valve for a Fixed Pump

Differential

Control

Pressure

bar[psi]

040=2.8[40]

080=5.5[80]

110=7.6[110]

150=10.3 [150]

190=13.1 [190]

LE - 20

Page 21

Logic Elements Technical Information

Spool Type

HLE10-CPC

OPERATION

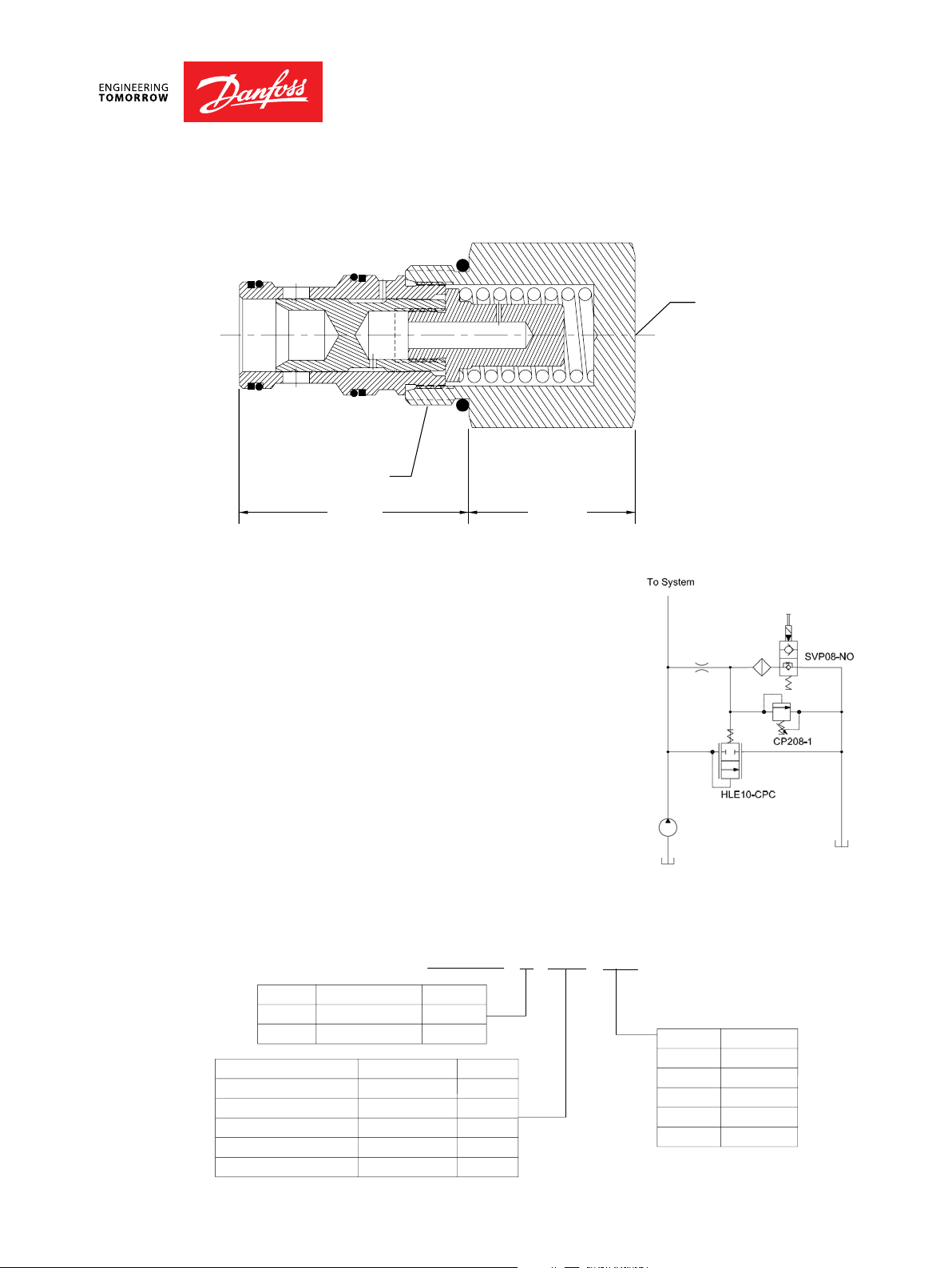

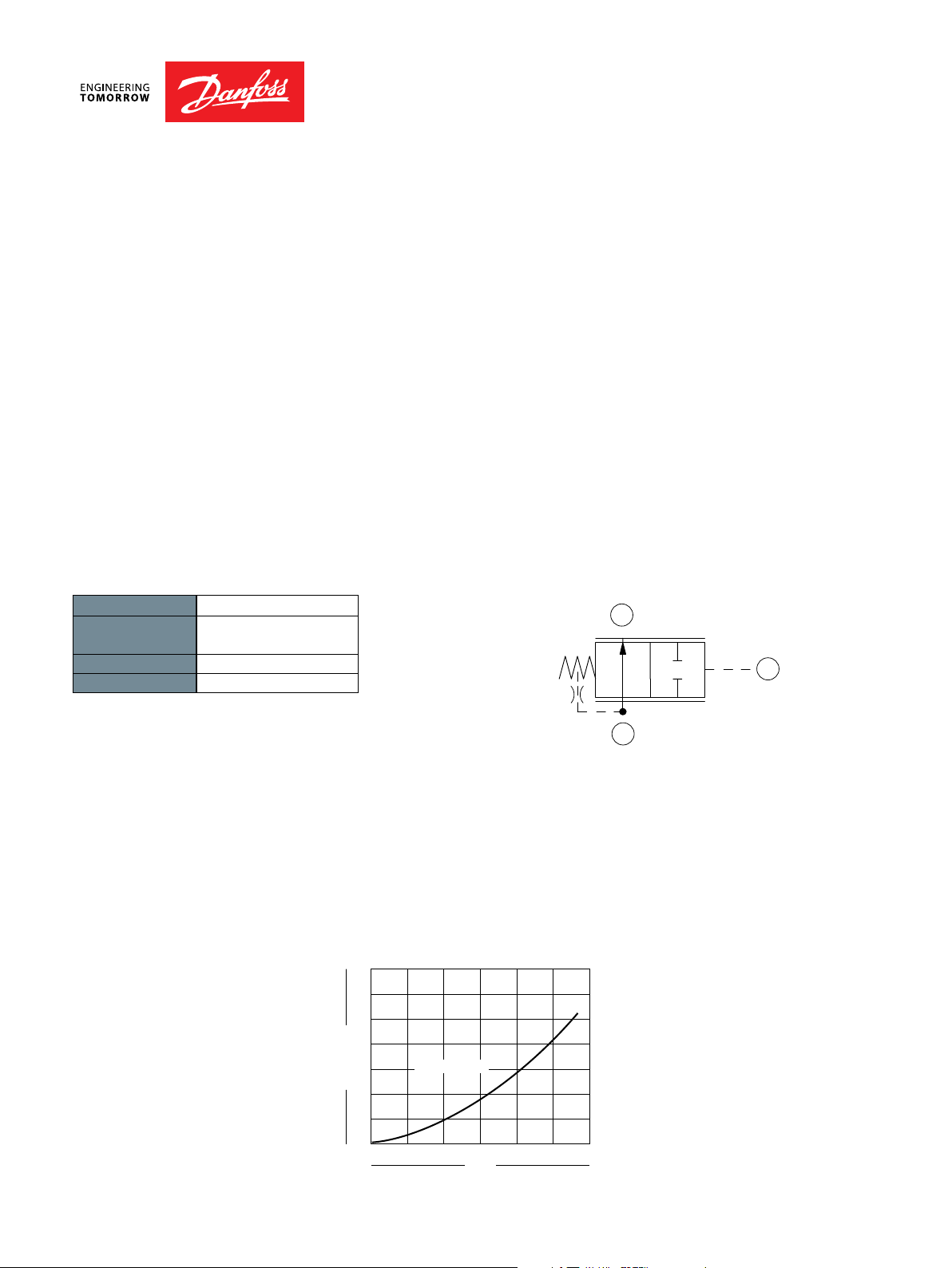

The HLE10-CPC is a 10-size, high pressure, normally-closed, pilot-toclose, spool-type, spring biased dierential-sensing logic element. It

will modulate ow from 1 to 2 based on the spring control pressure,

inlet pressure at port 1, and pilot pressure at port 3.

APPLICATION

Common applications include load-sensing bypass compensator

for a xed displacement pump with single or multiple actuators

as well as bypass-type pressure-compensated ow control. Eective

use of logic elements is a key to designing cost-eective circuits,

and is limited only by the imagination of the designer

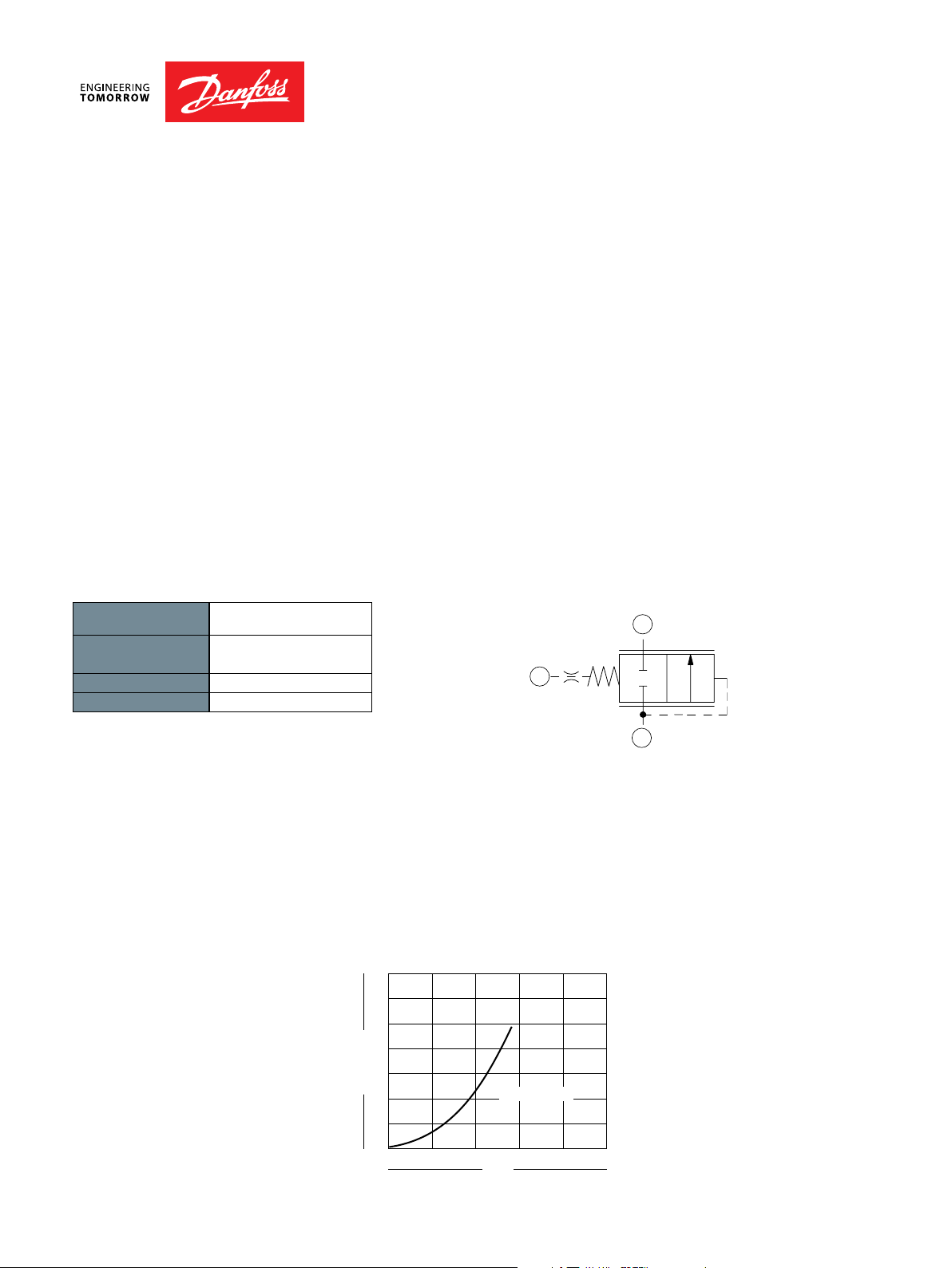

HLE10-CPC

SPECIFICATION

Rated Pressure* 350 bar [5075 psi]

Rated Flow at 7 bar

[100 psi]

Weight 0.14 kg [0.31 lbs]

Cavity SDC10-3S

* Rated Pressure based on NFPA fatigue test standards (at 1 Million Cycles).

80 l/min

[21.1 US gal/min]

PERFORMANCE CURVE

SCHEMATIC

Theoretical Performance

BC332375783111en-000101 • February 2020

LE - 21

Page 22

Logic Elements Technical Information

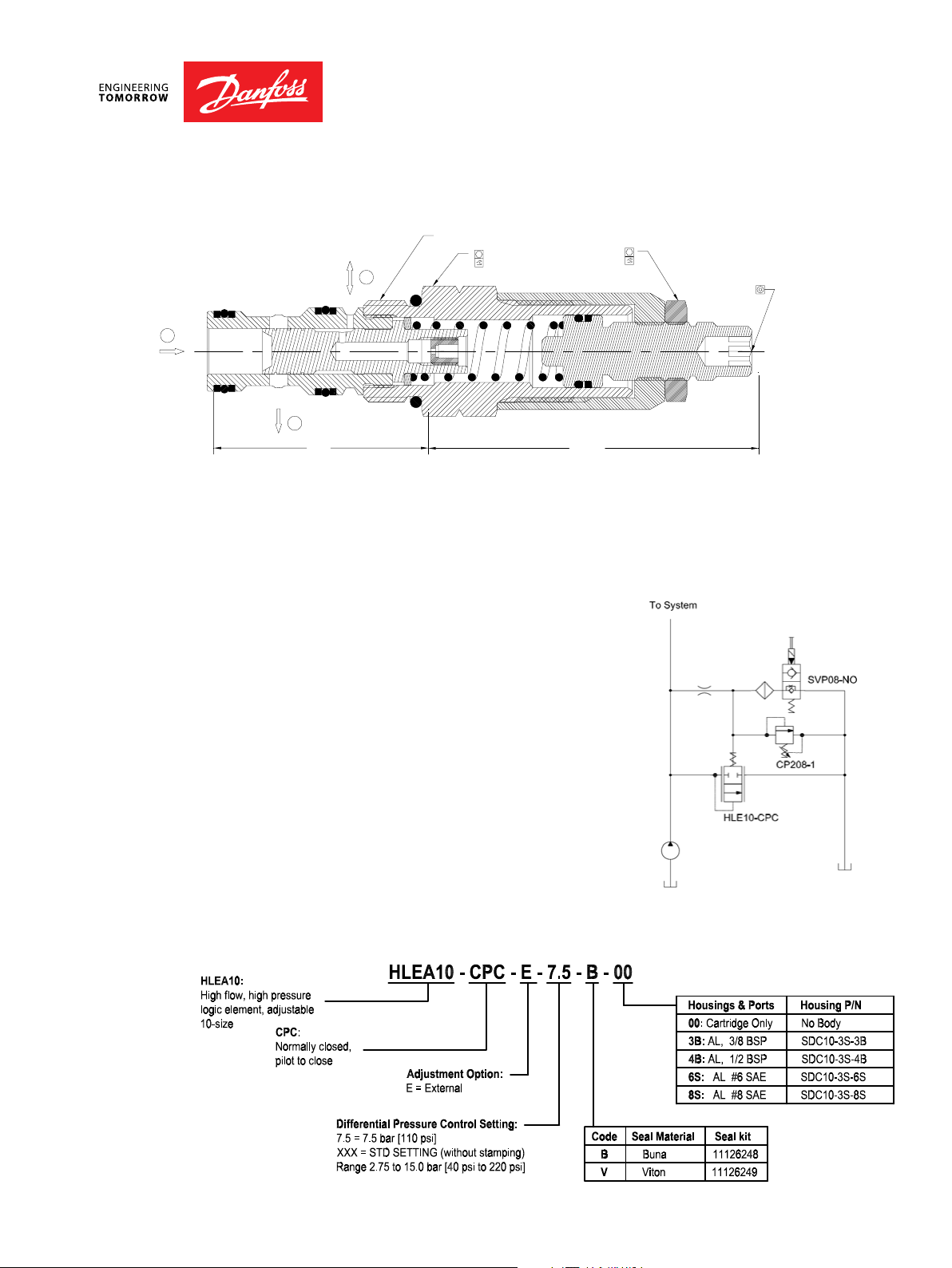

HLE10 - CPC - 2.75 - B - 00

Code Seal Material Seal kit

B Buna 11126248

V Viton 11126249

HLE10: High pressure,

logic element, 10-size

CPC: Normally closed,

pilot to close

Description

2.75 bar [40 psi]

5.5 bar [80 psi]

7.5 bar [110 psi]

10.0 bar [150 psi]

13.0 bar [190 psi]

15.0 bar [220 psi]

Differential Pressure Control

Code

2.75

5.5

7.5

10.0

13.0

15.0

Ports and Material Housing P/N

Cartridge Only No Body

AL, #6 SAE SDC10-3S-6S

AL, #8 SAE SDC10-3S-8S

AL, 3/8 BSP SDC10-3S-3B

AL, 1/2 BSP SDC10-3S-4B

STEEL, #6 SAE SDC10-3S-S6S

STEEL, #8 SAE SDC10-3S-S8S

Code

00

6S

8S

3B

4B

S6S

S8S

Housings

*** Aluminum bodies are for use in lower pressure applications only

[less than 210 bar (3000 psi)].

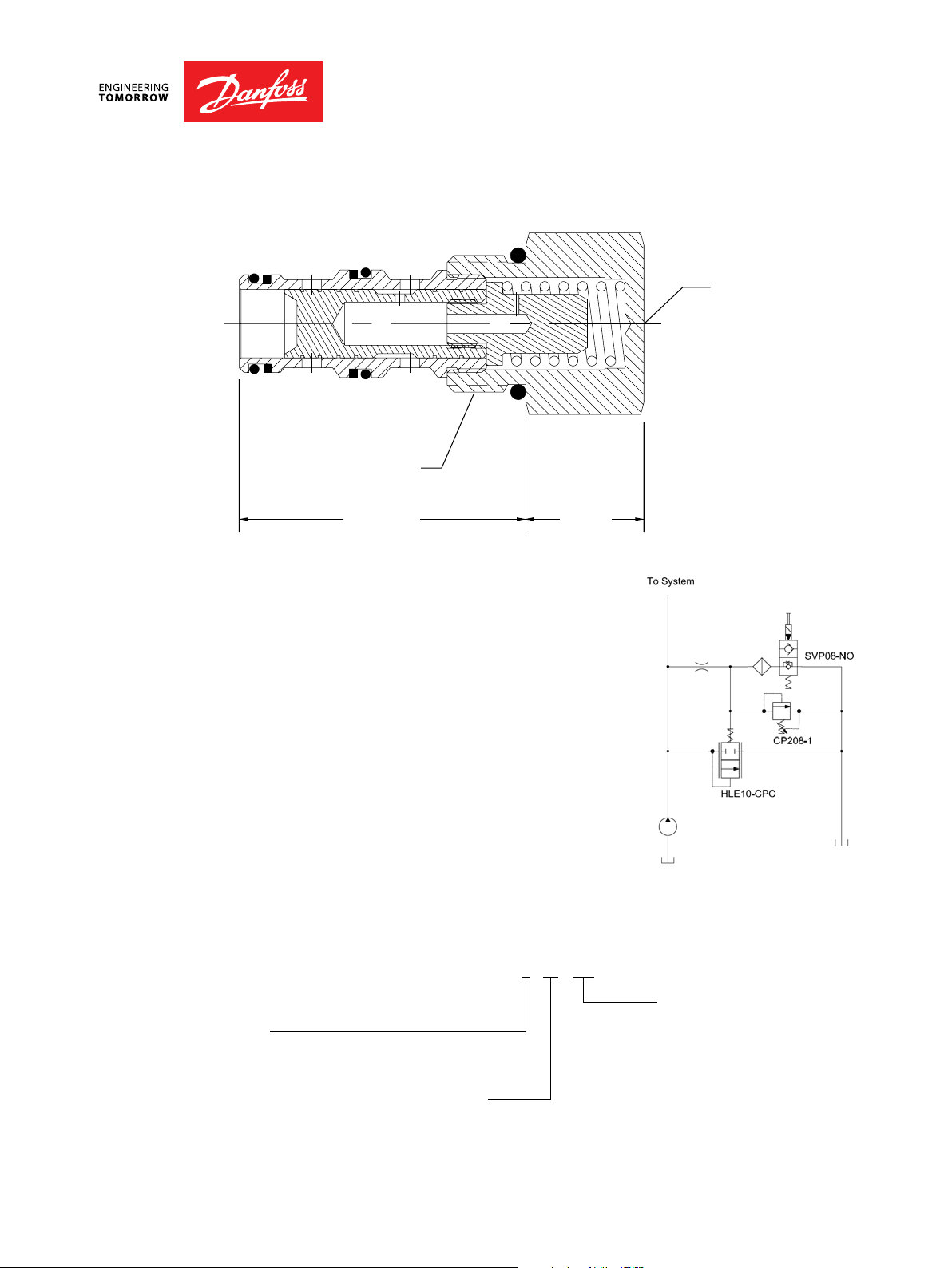

Spool Type

HLE10-CPC

DIMENSION

1

EXAMPLE CIRCUITS

Cross-sectional view

3

2

46.8

[1.84]

7/8-14 UNF

19.1

[0.75]

25.4 mm [1.00]

68-75 Nm

[50-55 lbf*ft]

Double Acng Cylinder with Proporonal Speed

Control, Unloading Valve and Circuit Relief

ORDERING

INFORMATION

BC332375783111en-000101 • February 2020

Proporonal Bypass Flow Control

Dump and Relief Valve for a Fixed Pump

LE - 22

Page 23

Logic Elements Technical Information

11

14

17

20

8

Spool Type

CP701-1

OPERATION

The CP701-1 is a 12-size, normally-closed, pilot-toclose, spool-type,, spring biased dierential-sensing logic element. It will

modulate ow from 1 to 2 based on the spring control pressure, inlet

pressure at port 1, and pilot pressure at port 3.

APPLICATION

Common applications include load-sensing bypass compensator for a

xed displacement pump with single or multiple actuators as well as

bypass-type pressure-compensated ow control. Eective use of logic

elements is a key to designing cost-eective circuits, and is limited only

by the imagination of the designer.

SPECIFICATION

SCHEMATIC

Rated pressure* 350 bar [5075 psi]

Rated ow at 7 bar

[100 psi]

150 l/min

[40 US gal/min]

2

Weight 0.26 kg [0.57 lb]

Cavity CP12-3S

* Rated Pressure based on NFPA fatigue test standards (at 1 Million Cycles).

3

1

PERFORMANCE CURVE

psi bar

87

58

29

Theoretical performance

154 SUS (33 cSt) hyd. oil @ 100° F (38° C)

14

3

12

4

10

5

8

6

6

Press ure drop

4

2

Pressure drop

Fully opened

BC332375783111en-000101 • February 2020

0

40L/min

80 120 160 200

10.6US gal/min

Flow

21.1 31.7 42.3 52.

LE - 23

Page 24

Logic Elements Technical Information

[2.20]

[1.00]

Spool Type

CP701-1

DIMENSION

mm [in]

1

EXAMPLE CIRCUITS

Cross-sectional view

2

1-1/16-12 UN

55.9

ht1.25 in

68-75 N.m

[50-55 lbf.ft]

3

25.4

Double Acng Cylinder with

Proporonal Speed Control,

Unloading Valve and Circuit Relief

ORDERING

INFORMATION

Seals

B=Buna-N 120335

V=Viton 120336

0=No housing No housing

4B = AL,1/2 BSP CP12-3S-4B/2B = 1/4 BSP

6B = AL,3/4 BSP CP12-3S-6B/2B = 1/4 BSP

= #10 SAE CP12-3S-10S/4S = #4 SAE

= #12 SAE CP12-3S-12S/4S = #4 SAE

rtsHousing P/N Pilot port

AL,

AL,

BC332375783111en-000101 • February 2020

Proporonal Bypass Flow Control

CP701-1-B-12S-080

Seal kit

Dump and Relief Valve for a Fixed Pump

Differential

Control

Pressure

bar[psi]

030=2.1[30]

050=3.5[50]

080=5.5[80]

100=6.9[100]

150=10.3 [150]

170 = 11.7 [170]

LE - 24

Page 25

Logic Elements Technical Information

154 SUS (33 cSt) hyd. oil @ 100° F (38° C)

11

14

17

20

Spool Type

CP702-1

OPERATION

The CP702-1 is a 16-size, normally-closed, pilot-to-close, spool-type,,

spring biased dierential-sensing logic element. It will modulate ow

from 1 to 2 based on the spring control pressure, inlet pressure at

port 1, and pilot pressure at port 3.

APPLICATION

Common applications include load-sensing bypass compensator for a

xed displacement pump with single or multiple actuators as well as

bypass-type pressure-compensated ow control. Eective use of logic

elements is a key to designing cost-eective circuits, and is limited only

by the imagination of the designer.

SPECIFICATION

Rated pressure 210 bar [3045 psi]

Rated ow at 7 bar

[100 psi]

Weight 0.38 kg [0.83 lb]

190 l/min

[50 US gal/min]

SCHEMATIC

2

3

Cavity SDC16-3S

1

Theoretical performance

PERFORMANCE CURVE

psi bar

3

4

5

6

87

Press ure drop

58

29

14

12

10

8

6

4

2

Fully opened

BC332375783111en-000101 • February 2020

0

80L/min

160 240 320 400

21.1US gal/min

Flow

42.3 63.4 84.5 105.7

LE - 25

Page 26

Logic Elements Technical Information

CP702-1

Differential Control Pressure

Spool Type

CP702-1

DIMENSION

mm [in]

1

EXAMPLE CIRCUITS

Cross-sectional view

23

1-5/16-12 UN

54.6

[2.15]

ht1.50 in

122-136 N.m

[90-100 lbf.ft]

39.6

[1.56]

CP702-1

Double Acng Cylinder with Proporonal Speed

Control, Unloading Valve and Circuit Relief

ORDERING

INFORMATION

Seal Option

Code Seal Material Seal kit

B Buna 120033

V Viton 120034

Housings & Ports

0: Cartridge Only

6B: 3/4 BSP, AL

8B: 1 BSP, AL

12S: #12 SAE, AL

16S: #16 SAE, AL

Other Housings available

Housing P/N

No Housing

CP16-3S-6B/2B

CP16-3S-8B/2B

CP16-3S-12S/4S

CP16-3S-16S/4S

BC332375783111en-000101 • February 2020

Proporonal Bypass Flow Control

-

B

16S

-

Pilot port

1/4 BSP

1/4 BSP

#4 SAE

#4 SAE

-

Dump and Relief Valve for a Fixed Pump

080

Code

040

080

110

150

190

bar [psi]

2.8 [40]

5.5 [80]

7.6 [110]

10.3 [150]

13.1 [190]

LE - 26

Page 27

Logic Elements Technical Information

US gal/min

100

120

140

160

Logic Elements Catalog

Spool Type

LE20-CPC

OPERATION

The LE20-CPC is a 20-size, normally-closed, pilot-to-close, spool-type,, spring

biased dierential-sensing logic element. It will modulate ow from 1 to

2 based on the spring control pressure, inlet pressure at port 1, and pilot

pressure at port 3.

APPLICATION

Common applications include load-sensing bypass compensator for a xed

displacement pump with single or multiple actuators as well as bypass-type

pressure-compensated ow control. Eective use of logic elements is a key to

designing cost-eective circuits, and is limited only by the imagination of the

designer.

SPECIFICATION

Rated pressure 210 bar [3045 psi]

Rated ow at 7 bar

[100 psi]

340 l/min

[90 US gal/min]

Weight 1.19 kg [2.62 lb]

Cavity CP20-3S

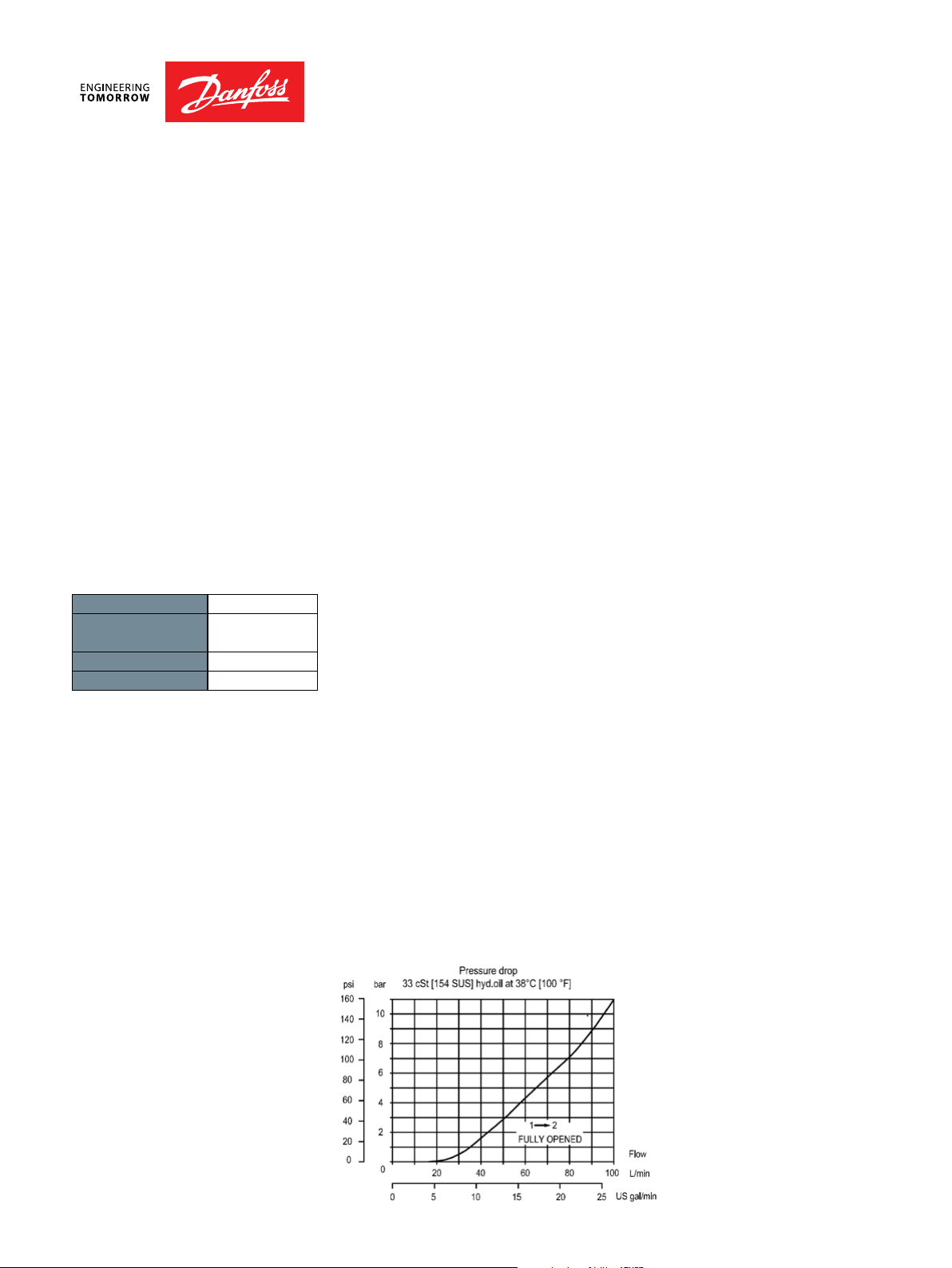

PERFORMANCE CURVE

Theoretical performance

bar

psi

10

8

6

80

60

4

40

2

20

0

0

0

BC332375783111en-000101 • February 2020

3

Pressure drop

33 cSt [154 SUS] hyd.oil at 38°C [100 °F]

1

2

FULLY OPENED

80

20

160

40 80

320

240

60 100

SCHEMATIC

2

1

Flow

400

L/min

LE - 27

Page 28

Logic Elements Technical Information

Spool Type

LE20-CPC

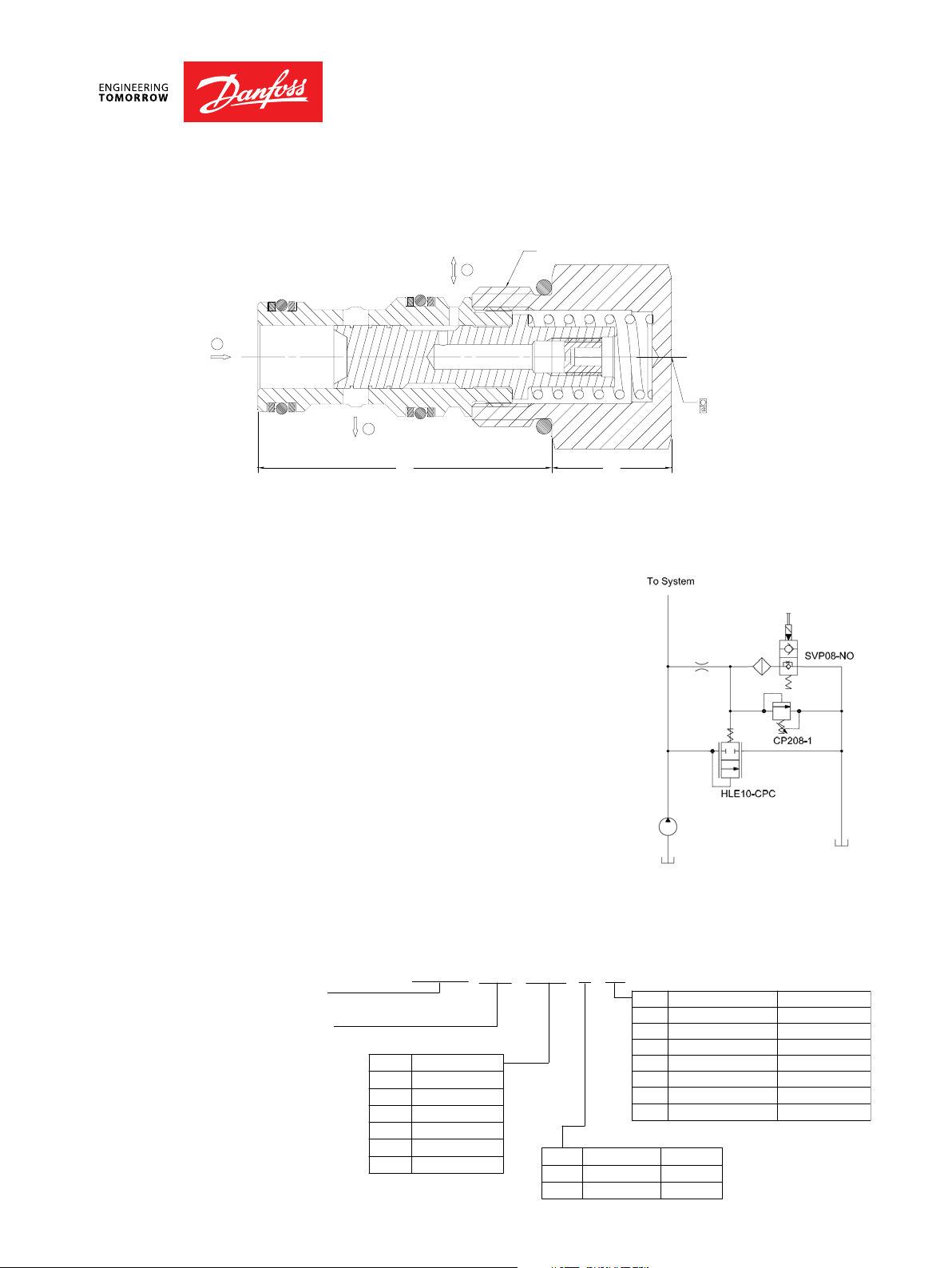

DIMENSION

mm [in]

1

EXAMPLE CIRCUITS

79.30

[3.12]

Cross-sectional view

1.875 in.

1-5/8-12 UN

217-231 Nm [160-170 lbf-ft]

2

3

56.62

[2.23]

LE20-CPC

Double Acng Cylinder with Proporonal Speed

Control, Unloading Valve and Circuit Relief

ORDERING

INFORMATION

LE20-CPC-5.5-B-00

Logic Element,

20 Size Cavity

Normally Closed,

Pilot-to-Close

Differential Control Pressure

5.5 = 5.5 bar [80 psi]

7.0 = 7 bar [100 psi]

10.0 = 10.0 bar [150 psi]

15.0 = 15.0 bar [218 psi]

BC332375783111en-000101 • February 2020

Proporonal Bypass Flow Control

Housing and ports

00 = No Housing

8B = Al, 1 BSP

10B = Al, 1-1/4 BSP

16S = Al, #16 SAE

20S = Al, #20 SAE

Seals Seal Kit

B = Buna-N 120380

V = Viton 120381

Dump and Relief Valve for a Fixed Pump

Housing Part #

No Housing

CP20-3S-8B/2B

CP20-3S-10B/2B

CP20-3S-16S/4S

CP20-3S-20S/4S

Pilot Port

1/4 BSP

1/4 BSP

#4 SAE

#4 SAE

LE - 28

Page 29

Logic Elements Technical Information

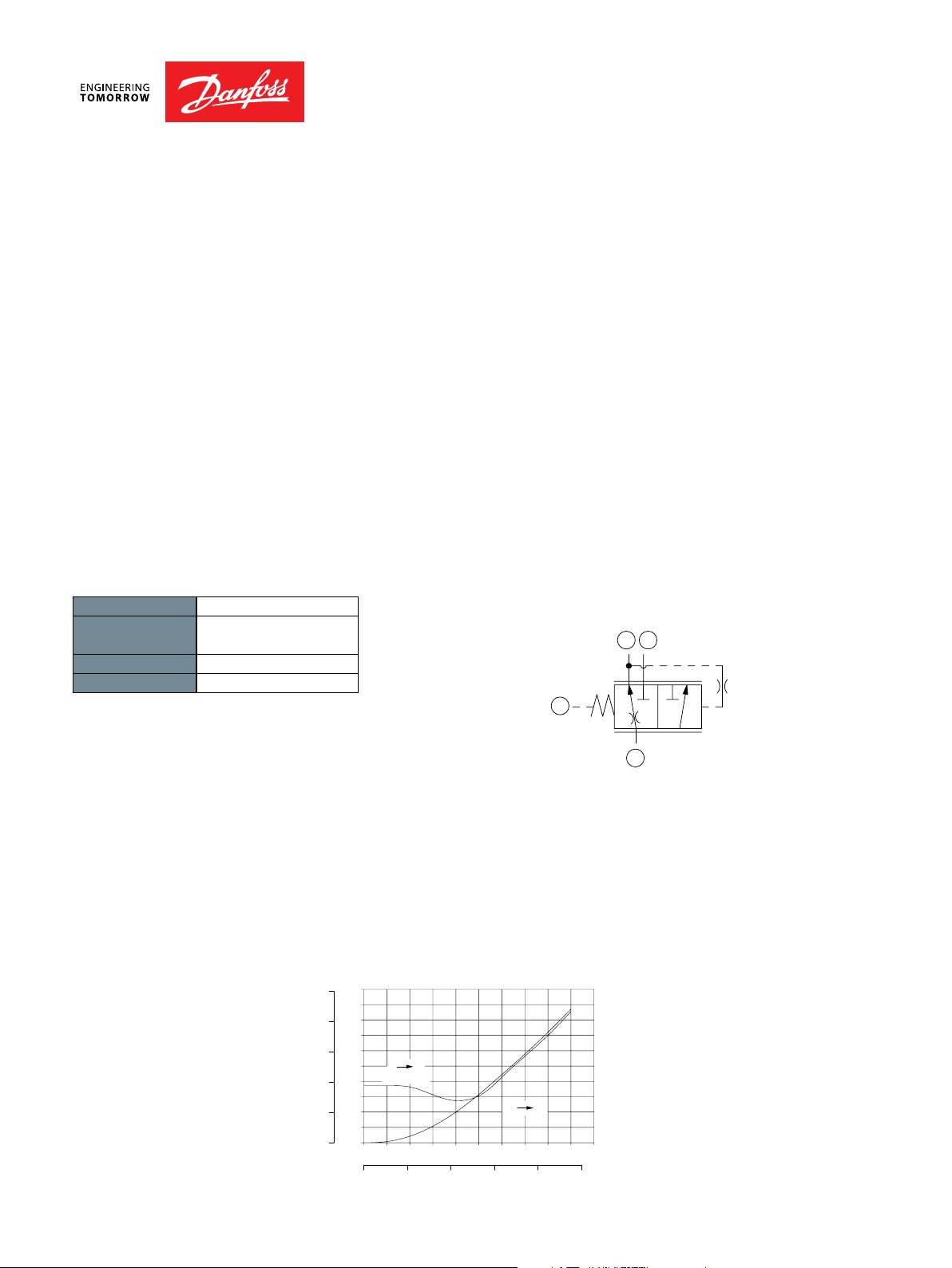

Spool Type

HLEA10-CVO

OPERATION

The HLEA10-CVO is a 10-size, high pressure, normally

closed, vent-to-open, spring-biased dierential-sensing

logic element that includes an adjustable compensator

feature. It will modulate ow from 1 to 2 based on the

spring control pressure, inlet pressure at port 1, and

pilot pressure at port 3.

APPLICATION

Common applications include: pump unloading, pilot-operated relief valve (mechanical or proportional),

sequence valve and selector circuit. The adjustability of the HLEA10 allows the operator to change the

compensator setting of the logic element, ranging from 2.75 to 15.2 bar (40 to 220 psi). This is especially

helpful when ne tuning the applications, providing exibility to the operator and allowing for machine

optimization

SPECIFICATION

Rated pressure* 350 bar [5075 psi]

Rated ow at 7 bar

[100 psi]

Weight 0.29 kg [0.64 lb]

Cavity SDC10-3S

*Rated Pressure based on NFPA fatigue test

standards (at 1 Million Cycles).

80l/min

[21 US gal/min]

PERFORMANCE CURVE

SCHEMATIC

Theoretical performance

BC332375783111en-000101 • February 2020

LE - 29

Page 30

Logic Elements Technical Information

AT

Logic Elements Catalog

Spool Type

HLEA10-CVO

DIMENSION

mm [in]

1

EXAMPLE CIRCUITS

2

46.8

[1.84]

Cross-sectional view

7/8-14 UNF

3

To system

25.4 mm [1.00]

68-75 Nm

[50-55 lbf*ft]

19.1 mm [.75]

4.1-5.4 Nm

[36-48 lbf*in]

80.0 MAX

[3.15]

To circuit

6.4 mm [.25]

o circuit B

ORDERING

INFORMATION

BC332375783111en-000101 • February 2020

Pump unloading Selector valve

LE - 30

Page 31

Logic Elements Technical Information

154 SUS (33 cSt) hyd. oil @ 100° F (38° C)

2

0

29

psi bar

Press ure drop

20L/min

Flow

5.3US gal/min

4

6

8

10

12

14

58

87

40 60 80 100

10.6 15.9 21.1 26.4

Fully opened

Spool Type

CP700-2

OPERATION

The CP700-2 is a 10-size, normally closed, vent-to-open, springbiased dierential-sensing logic element. It will modulate ow

from 1 to 2 based on the spring control pressure, inlet pressure at

port 1, and pilot pressure at port 3.

APPLICATION

Common applications include: pump unloading, pilot-operated

relief valve (mechanical or proportional), sequence valve and

selector circuit. Eective use of logic elements is a key to designing

cost-eective circuits, and is limited only by the imagination of the

designer.

SPECIFICATION

Rated pressure 210 bar [3045 psi]

Rated ow at 7 bar

[100 psi]

Weight 0.13 kg [0.28 lb]

Cavity SDC10-3

50 l/min

[13 US gal/min]

PERFORMANCE CURVE

BC332375783111en-000101 • February 2020

SCHEMATIC

2

3

1

Theoretical performance

LE - 31

Page 32

Logic Elements Technical Information

Spool Type

CP700-2

DIMENSION

mm [in]

1

EXAMPLE CIRCUITS

Cross-sectional view

23

7/8-14 UNF

46.2

[1.82]

ht1.00 in

41-47 N.m

[30-35 lbf.ft]

19.1

[0.75]

CP700-2

ORDERING

INFORMATION

Seals

B=Buna-N 120027

V=Viton 120028

Housing and ports Housing P/N

0=No Housing No Housing

SE3B = AL,3/8 BSP SDC10-3-SE-3B

SE4B = AL, 1/2 BSP SDC10-3-SE-4B

6S = AL, #6 SAE CP10-3-6S

8S = AL, #8 SAE CP10-3-8S

Other housings available

BC332375783111en-000101 • February 2020

Seal kit

CP70

0-2-B-

8S

080

Di erential

Control

Pressure

bar[psi]

040=2.8[40]

080=5.5[80]

110=7.6[110]

150=10.3[150]

190=11.7[190]

LE - 32

Page 33

Logic Elements Technical Information

Spool Type

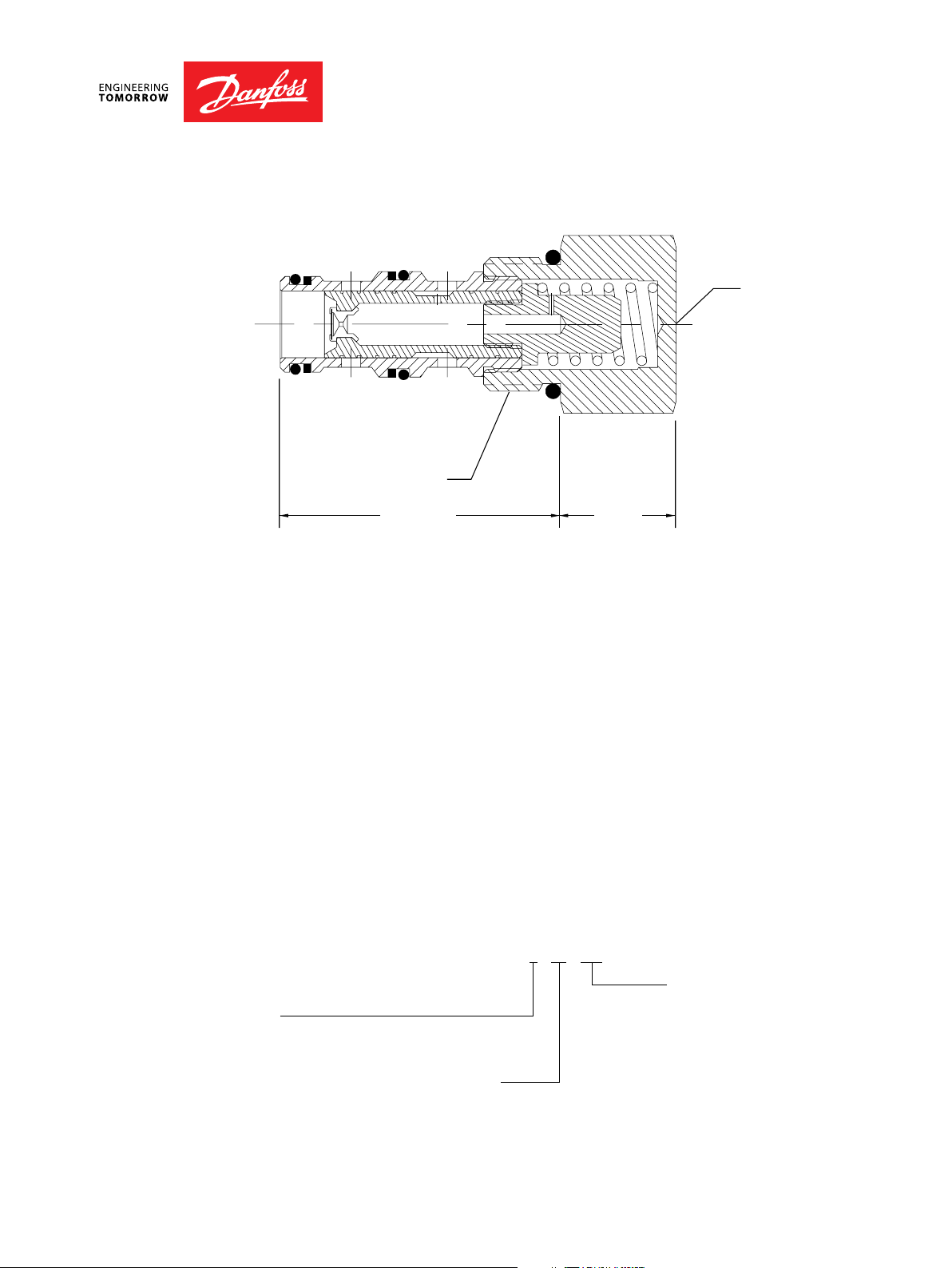

HLE10-CVO

OPERATION

The HLE10-CVO is a 10-size, high pressure, normally closed,

vent-to-open, spring-biased dierential-sensing logic element.

It will modulate ow from 1 to 2 based on the spring control

pressure, inlet pressure at port 1, and pilot pressure at port 3.

APPLICATION

Common applications include: pump unloading, pilot-operated

relief valve (mechanical or proportional), sequence valve and

selector circuit. Eective use of logic elements is a key to designing

cost-eective circuits, and is limited only by the imagination of the

designer.

SPECIFICATION

Rated Pressure* 350 bar [5075 psi]

Rated Flow at 7 bar

[100 psi]

Weight 0.14 kg [0.31 lbs]

Cavity SDC10-3S

* Rated Pressure based on NFPA fatigue test standards (at 1 Million Cycles).

80 l/min

[21.1 US gal/min]

PERFORMANCE CURVE

SCHEMATIC

Theoretical performance

BC332375783111en-000101 • February 2020

LE - 33

Page 34

Logic Elements Technical Information

HLE10

-

CVO

- 2.75 -

B

-

00

Spool Type

HLE10-CVO

DIMENSION

mm [in]

EXAMPLE CIRCUITS

Theoretical performance

3

1

2

46.8

[1.84]

7/8-14 UNF

19.1

[0.75]

25.4 mm [1.00]

68-75 Nm

[50-55 lbf*ft]

ORDERING

INFORMATION

HLE10: High pressure,

logic element, 10-size

CVO: Normally closed,

vent to open

BC332375783111en-000101 • February 2020

Differential Pressure Control

Code

Description

2.75

2.75 bar [40 psi]

5.5

5.5 bar [80 psi]

7.5

7.5 bar [110 psi]

10.0

10.0 bar [150 psi]

13.0

13.0 bar [190 psi]

15.0

15.0 bar [220 psi]

18.0

18.0 bar [260 psi]

Housings

Code

Ports and Material Housing P/N

00

Cartridge Only No Body

6S

AL, #6 SAE SDC10-3S-6S

8S

AL, #8 SAE SDC10-3S-8S

3B

AL, 3/8 BSP SDC10-3S-3B

AL, 1/2 BSP SDC10-3S-4B

4B

STEEL, #6 SAE SDC10-3S-S6S

S6S

STEEL, #8 SAE SDC10-3S-S8S

S8S

*** Aluminum bodies are for use in lower pressure applications only

[less than 210 bar (3000 psi)].

Code Seal Material Seal kit

B Buna 11126248

V Viton 11126249

LE - 34

Page 35

Logic Elements Technical Information

3

2

1

Spool Type

CP701-2

OPERATION

The CP701-2 is a 12-size, normally closed, vent-to-open, spring-biased

dierential-sensing logic element. It will modulate ow from 1 to 2 based

on the spring control pressure, inlet pressure at port 1, and pilot pressure

at port 3.

APPLICATION

Common applications include: pump unloading, pilot-operated relief

valve (mechanical or proportional), sequence valve and selector circuit.

Eective use of logic elements is a key to designing cost-eective circuits,

and is limited only by the imagination of the designer.

SPECIFICATION

Rated pressure* 350 bar [5075 psi]

Rated ow at 7 bar

[100 psi]

Weight 0.26 kg [0.57 lb]

Cavity CP12-3S

* Rated Pressure based on NFPA fatigue test standards (at 1 Million Cycles).

PERFORMANCE CURVE

150 l/min

[40 US gal/min]

Theoretical performance

psi bar

203

14

174

12

145

10

116

8

87

6

Press ure drop

58

4

2

29

SCHEMATIC

154 SUS (33 cSt) hyd. oil @ 100° F (38° C)

Fully opened

BC332375783111en-000101 • February 2020

0

80 120 160 200

40L/min

10.6US gal/min

Flow

21.1 31.7 42.3 52.8

LE - 35

Page 36

Logic Elements Technical Information

100]

[150]

Housing and po

other housings

Spool Type

CP701-2

DIMENSION

mm [in]

1

EXAMPLE CIRCUITS

2

1-1/16-12 UN

Cross-sectional view

3

55.9

[2.20]

ht1.25 in

68-75 N.m

[50-55 lbf.ft]

25.4

[1.00]

CP701-2

ORDERING

INFORMATION

Seals

B=Buna-N 120335

V=Viton 120336

0=No housing No houisng

4B = AL, 1/2 BSP CP12-3S-4B/2B=1/4 BSP

6B = AL, 3/4 BSP CP12-3S-6B/2B=1/4 BSP

10S =#10 SAE CP12-3S-10S/4S =#4 SAE

12S =#12 SAE CP12-3S-12S/4S =#4 SAE

rtsHousing P/N Pilot port

AL,

AL,

available

BC332375783111en-000101 • February 2020

CP701-2-B-12S -080

Seal kit

Differential

Control

Pressure

bar[psi]

030=2.1[30]

050=3.5[50]

080=5.5[80]

100=6.9[

150=10.3

LE - 36

Page 37

Logic Elements Technical Information

11

14

17

20

3

2

1

Spool Type

CP702-2

OPERATION

The CP702-2 is a 16-size, normally closed, vent-to-open, springbiased dierential-sensing logic element. It will modulate ow from

1 to 2 based on the spring control pressure, inlet pressure at port 1,

and pilot pressure at port 3.

APPLICATION

Common applications include: pump unloading, pilot-operated

relief valve (mechanical or proportional), sequence valve and

selector circuit. Eective use of logic elements is a key to designing

cost-eective circuits, and is limited only by the imagination of the

designer.

SPECIFICATION

Rated pressure 210 bar [3045 psi]

Rated ow at 7 bar

[100 psi]

Weight 0.38 kg [0.83 lb]

Cavity SDC16-3S

190 l/min

[50 US gal/min]

SCHEMATIC

Theoretical performance

PERFORMANCE CURVE

psi bar

3

4

5

6

87

58

29

154 SUS (33 cSt) hyd. oil @ 100° F (38° C)

14

12

10

8

6

Press ure drop

4

2

Fully opened

BC332375783111en-000101 • February 2020

0

80L/min

160 240 320 400

21.1US gal/min

Flow

42.3 63.4 84.5 105.7

LE - 37

Page 38

DIMENSION

Logic Elements Technical Information

Spool Type

CP702-2

Cross-sectional viewmm [in]

h 1.50 in

122-136 N.m

1

23

1-5/16-12 UN

54.6

[2.15]

39.6

[1.56]

t

[90-100 lbf.ft]

EXAMPLE CIRCUITS

ORDERING

INFORMATION

CP702-2-B-16S -080

Seals

B=Buna-N 120033

V=Viton 120034

Housing and ports

0= No housing No housing

6B = AL, 3/4 BSP CP16-3S-6B/2B

8B = AL, 1 BSP CP16-3S-8B/2B =

12S = AL, #12 SAE CP16-3S-12S/4S = #4 SAE

16S =#16 SAE CP16-3S-12S/4S = #4 SAE

Other housings available

AL,

Seal kit

Housing P/N Pilot port

= 1/4 BSP

1/4 BSP

Differential

Control

Pressure

bar[psi]

040=2.8[40]

080=5.5[80]

110=7.6[110]

150=10.3 [150]

170=11.7 [170]

BC332375783111en-000101 • February 2020

LE - 38

Page 39

Logic Elements Technical Information

US gal/min

100

120

140

160

3

2

1

Spool Type

CP703-2

OPERATION

OPERATION

The CP703-2 is a 20-size, normally closed, vent-to-open, springbiased dierential-sensing logic element. It will modulate ow

from 1 to 2 based on the spring control pressure, inlet pressure

at port 1, and pilot pressure at port 3.

APPLICATION

Common applications include: pump unloading, pilot-operated

relief valve (mechanical or proportional), sequence valve

and selector circuit. Eective use of logic elements is a key

to designing cost-eective circuits, and is limited only by the

imagination of the designer.

SPECIFICATION

Rated pressure 210 bar [3045 psi]

Rated ow at 7 bar

[100 psi]

340 l/min

[90 US gal/min]

Weight 1.18 kg [2.60 lb]

Cavity CP20-3S

PERFORMANCE CURVE

psi

80

60

40

20

0

BC332375783111en-000101 • February 2020

Theoretical performance

Pressure drop

33 cSt [154 SUS] hyd.oil at 38°C [100 °F]

bar

10

8

6

4

2

0

80

160

0

20

40 80

1

FULLY OPENED

240

60 100

SCHEMATIC

2

Flow

320

400

L/min

LE - 39

Page 40

DIMENSION

50.8

[160 - 170 lbf.ft]

Housing and po

other housings

mm [in]

Logic Elements Technical Information

Spool Type

CP703-2

Cross-sectional view

[2.00]

EXAMPLE CIRCUITS

ORDERING

INFORMATION

1 5/8 - 12 UN THD.

CP703-2-B-16S -080

h 1.88 in

217 - 231 N.m

t

CP703-2

Seals

B=Buna-N 120380

V=Viton 120381

0=No housing No housing

8B = AL, 1 BSP CP20-3S-8B/2B = 1/4 BSP

10B = AL, 1-1/4 BSP CP20-3S-10B/2B = 1/4 BSP

16S =#16 SAE CP20-3S-16S/4S = #4 SAE

20S =#20 SAE CP20-3S-20S/4S = #4 SAE

rtsHousing P/N Pilot port

AL,

AL,

available

BC332375783111en-000101 • February 2020

Seal kit

Differential control

pressure

bar[psi]

050=3.4[50]

080=5.5[80]

100=6.9[100]

130=9.0[130]

150=10.3 [150]

LE - 40

Page 41

Logic Elements Technical Information

Spool Type

HLEA10-OPO

OPERATION

OPERATION

The HLEA10-OPO is a 10-size, high pressure, normally open,

pilot-to-open, spring-biased dierential-sensing logic

element that includes an adjustable compensator feature. It

will modulate ow from 2 to 1 based on the spring control

pressure, outlet pressure at port 1, and pilot pressure at port 3.

APPLICATION

The adjustability of the HLEA10 allows the operator to change the compensator setting of the logic element,

ranging from 2.75 to 15.2 bar (40 to 220 psi). This is especially helpful when ne tuning the applications,

providing exibility to the operator and allowing for machine optimization.

SPECIFICATION

Rated pressure 350 bar [5075 psi]

Rated ow at 7 bar

[100 psi]

Weight 0.29 kg [0.64 lb]

Cavity SDC10-3S

PERFORMANCE CURVE

PERFORMANCE

60 l/min

[16 US gal/min]

SCHEMATIC

Theoretical performance

BC332375783111en-000101 • February 2020

LE - 41

Page 42

Logic Elements Technical Information

Spool Type

HLEA10-OPO

DIMENSION

mm [in]

1

EXAMPLE CIRCUITS

2

46.8

[1.84]

Cross-sectional view

7/8-14 UNF

3

25.4 mm [1.00]

68-75 Nm

[50-55 lbf*ft]

19.1 mm [.75]

4.1-5.4 Nm

[36-48 lbf*in]

80.0 MAX

[3.15]

6.4 mm [.25]

ORDERING

INFORMATION

Compensated Bi-directional Flow Control

HLEA10-OPO

Proportional Pressure Reducing Valve

BC332375783111en-000101 • February 2020

LE - 42

Page 43

Logic Elements Technical Information

9

Spool Type

CP700-4

OPERATION

OPERATION

The CP700-4 is a 10-size, normally open, pilot-to-open, springbiased dierential-sensing logic element. It will modulate ow

from 2 to 1 based on the spring control pressure, outlet pressure

at port 1, and pilot pressure at port 3.

APPLICATION

Common applications include: pre-compensator for proportional

directional control or ow controls, as well as a pressure control

valve. A common application for this valve is as a pressure

compensator when applied with a xed, or adjustable orice to

create a pressure-compensated ow control. This ensures that

ow rate, and resulting actuator speed is maintained regardless

of pressure drop across the control orice. Eective use of logic

elements is a key to designing cost-eective circuits, and is limited

only by the imagination of the designer.

SPECIFICATION

Rated pressure 210 bar [3045 psi]

Rated ow at 7 bar

[100 psi]

Weight 0.13 kg [0.28 lb]

Cavity SDC10-3

40 l/min

[11 US gal/min]

PERFORMANCE CURVE

Theoretical performance

psi bar

203

174

145

116

87

58

29

154 SUS (33 cSt) hyd. oil @ 100° F (38° C)

14

12

10

8

6

Press ure drop

4

2

SCHEMATIC

Fully opened

BC332375783111en-000101 • February 2020

0

20 30 40 50 60

10L/min

2.6US gal/min

Flow

5.3 7.9 10.6 13.2 15.

LE - 43

Page 44

Logic Elements Technical Information

Spool Type

CP700-4

DIMENSION

mm [in]

1

EXAMPLE CIRCUITS

Compensated Circuit Proportional Pressure Reducing

Cross-sectional view

23

7/8-14 UNF

46.2

[1.82]

19.1

[0.75]

h 1.00 in

41-47 N.m

t

[30-35 lbf.ft]

ORDERING

INFORMATION

Seals

B=Buna-N 120009

V=Viton 120010

Housing and portsHousing P/N

0=No Housing No Housing

SE3B=AL,3/8 BSP SDC10-3-SE-3B

SE4B=AL, 1/2 BSP SDC10-3-SE-4B

6S = AL, #6 SAE CP10-3-6S

8S = AL, #8 SAE CP10-3-8S

Other housings available

BC332375783111en-000101 • February 2020

CP700-4-B-8S-080

Seal kit

Differential

Control

Pressure

bar[psi]

040=2.8[40]

080=5.5[80]

110=7.6[110]

150=10.3 [150]

200=13.8 [200]

LE - 44

Page 45

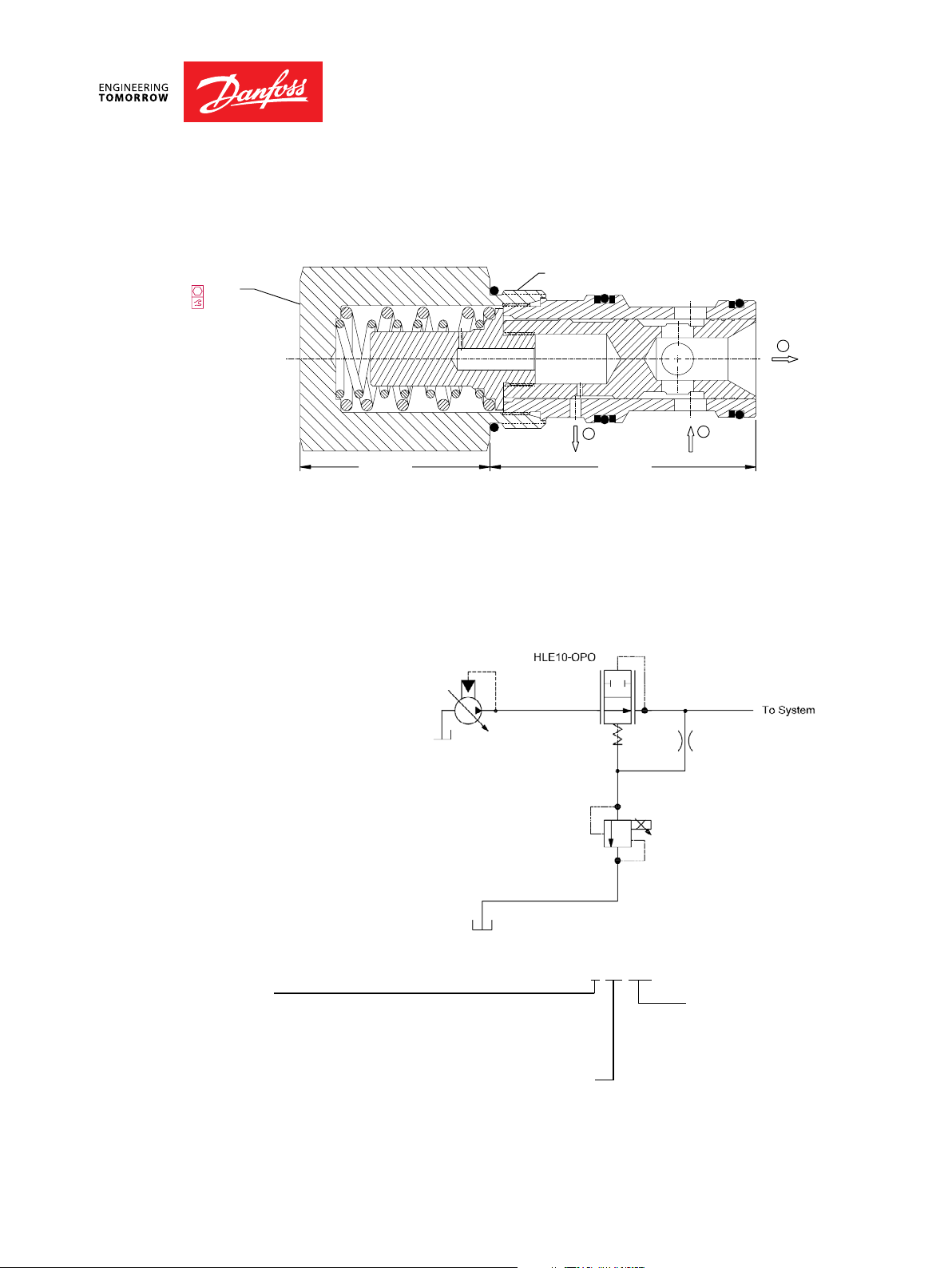

Logic Elements Technical Information

Spool Type

HLE10-OPO

OPERATION

OPERATION

The HLE10-OPO is a 10-size, high pressure, normally open, pilot-to-open,

spring-biased dierential-sensing logic element. It will modulate ow

from 2 to 1 based on the spring control pressure, outlet pressure at port

1, and pilot pressure at port 3. The HLE10-OPO technically replaces the

CP700-4L, but cavities are not interchangeable.

APPLICATION

Common applications include: as a pre-compensator for proportional

directional control or ow controls, as well as a pressure control valve.

A common application for this valve is as a pressure compensator

when applied with a xed, or adjustable orice to create a

pressure-compensated ow control. This ensures that ow rate,

and resulting actuator speed is maintained regardless of pressure drop across the control orice. Eective use of logic

elements is a key to designing cost-eective circuits, and is limited only by the imagination of the designer.

SPECIFICATION

Rated Pressure* 350 bar [5075 psi]

Rated Flow at 7 bar

[100 psi]

Weight 0.14 kg [0.31 lbs]

Cavity SDC10-3S

* Rated Pressure based on NFPA fatigue test standards (at 1 Million Cycles).

60 l/min

[15.8 US gal/min]

Theoretical performance

PERFORMANCE CURVE

SCHEMATIC

BC332375783111en-000101 • February 2020

LE - 45

Page 46

Logic Elements Technical Information

Spool Type

HLE10-OPO

DIMENSION

mm [in]

EXAMPLE CIRCUITS

Cross-sectional view

7/8-14 UNF

3

1

68-75 Nm

2

46.8

[1.84]

19.1

[0.75]

[50-55 lbf*ft]

ORDERING

INFORMATION

Compensated Bi-directional Flow Control

Proportional Pressure Reducing Valve

*** Aluminum bodies are for use in lower pressure applications only

[less than 210 bar (3000 psi)].

HLE10-OPO

BC332375783111en-000101 • February 2020

LE - 46

Page 47

Logic Elements Technical Information

5.3US gal/min

10.6 15.9 21.1 26.4

Spool Type

CP701-4

OPERATION

OPERATION

The CP701-4 is a 12-size, normally open, pilot-to-open, springbiased dierential-sensing logic element. It will modulate ow

from 2 to 1 based on the spring control pressure, outlet pressure at

port 1, and pilot pressure at port 3.

APPLICATION

Common applications include: pre-compensator for proportional

directional control or ow controls, as well as a pressure control valve.

A common application for this valve is as a pressure compensator

when applied with a xed, or adjustable orice to create a pressurecompensated ow control. This ensures that ow rate, and resulting

actuator speed is maintained regardless of pressure drop across the

control orice. Eective use of logic elements is a key to designing

cost-eective circuits, and is limited only by the imagination of the

designer.

SPECIFICATION

Rated pressure* 350 bar [5075 psi]

Rated ow at 7 bar

[100 psi]

Weight 0.26 kg [0.57 lb]

Cavity CP12-3S

* Rated Pressure based on NFPA fatigue test standards (at 1 Million Cycles).

75 l/min

[20 US gal/min]

Theoretical performance

PERFORMANCE CURVE

psi bar

203

174

145

116

87

Press ure drop

58

29

14

12

10

8

6

4

2

SCHEMATIC

154 SUS (33 cSt) hyd. oil @ 100° F (38° C)

Fully opened

BC332375783111en-000101 • February 2020

0

40 60 80 100

20L/min

Flow

LE - 47

Page 48

DIMENSION

[2.20]

[1.00]

Housing and po

mm [in]

Logic Elements Technical Information

Spool Type

CP701-4

Cross-sectional view

h 1.25 in

68-75 N.m

t

1

[50-55 lbf.ft]

EXAMPLE CIRCUITS

Compensated Circuit

2

1-1/16-12 UN

55.9

3

25.4

Proportional Pressure Reducing

CP701-4

ORDERING

INFORMATION

Seals

B=Buna-N 120335

V=Viton 120336

0=No housing No houisng

4B = AL, 1/2 BSP CP12-3S-4B/2B = 1/4 BSP

6B = AL, 3/4 BSP CP12-3S-6B/2B = 1/4 BSP

10S =#10 SAE CP12-3S-10S/4S = #4 SAE

12S =#12 SAE CP12-3S-12S/4S = #4 SAE

rtsHousing P/N Pilot port

AL,

AL,

BC332375783111en-000101 • February 2020

Seal kit

CP701-4-B-12S -080

Differential

Control

Pressure

bar[psi]

030=2.1[30]

050=3.5[50]

080=5.5[80]

100=6.9[100]

150=10.3 [150]

LE - 48

Page 49

Logic Elements Technical Information

154 SUS (33 cSt) hyd. oil @ 100° F (38° C)

Spool Type

CP702-4

OPERATION

The CP702-4 is a 16-size, normally open, pilot-to-open, spring-biased

dierential-sensing logic element. It will modulate ow from 2 to 1 based

on the spring control pressure, outlet pressure at port 1, and pilot pressure

at port 3.

APPLICATION

Common applications include: pre-compensator for proportional directional

control or ow controls, as well as a pressure control valve. A common application

for this valve is as a pressure compensator when applied with a xed, or adjustable

orice to create a pressure-compensated ow control. This ensures that ow rate,

and resulting actuator speed is maintained regardless of pressure drop across the

control orice. Eective use of logic elements is a key to designing cost-eective

circuits, and is limited only by the imagination of the designer.

SPECIFICATION

Rated pressure 210 bar [3045 psi]

Rated ow at 7 bar

[100 psi]

Weight 0.38 kg [0.83 lb]

Cavity SDC16-3S

114 l/min

[30 US gal/min]

PERFORMANCE CURVE

psi bar

203

174

145

116

87

Press ure drop

58

29

Theoretical performance

14

12

10

8

6

4

2

SCHEMATIC

Fully opened

0

BC332375783111en-000101 • February 2020

80 120 160 200

40L/min

10.6US gal/min

Flow

21.1 31.7 42.3 52.8

LE - 49

Page 50

Logic Elements Technical Information

CP702- 4 - B

-

16S

-

Differential Control Pressure

Spool Type

CP702-4

DIMENSION

mm [in]

1

EXAMPLE CIRCUITS

Compensated Circuit

Cross-sectional view

23

1-5/16-12 UN

54.6

[2.15]

39.6

[1.56]

Proportional Pressure Reducing

h 1.50 in

122-136 N.m

t

[90-100 lbf.ft]

CP702-4

ORDERING

INFORMATION

Seal Option

Code Seal Material Seal kit

B Buna 120033

V Viton 120034

Housings & Ports

0: Cartridge Only

6B: 3/4 BSP, AL

8B: 1 BSP, AL

12S: #12 SAE, AL

16S: #16 SAE, AL

Other Housings available

BC332375783111en-000101 • February 2020

Housing P/N

No Housing

CP16-3S-6B/2B

CP16-3S-8B/2B

CP16-3S-12S/4S

CP16-3S-16S/4S

Pilot port

1/4 BSP

1/4 BSP

#4 SAE

#4 SAE

080

Code

040

080

110

150

190

bar [psi]

2.8 [40]

5.5 [80]

7.6 [110]

10.3 [150]

13.1 [190]

LE - 50

Page 51

Logic Elements Technical Information

Pressure Drop

33 cSt[154 SUS] hyd.oil@38°C[100° F]

12174

218 15

131 9

87 6

44 3

00

psi bar

18 37 55

US gal/min

210140700

l/min

2to1with 5.5 bar (80 psi) spring

Spool Type

CP703-4

OPERATION

The CP703-4 is a 20-size, normally open, pilot-to-open, springbiased dierential-sensing logic element. It will modulate ow from

2 to 1 based on the spring control pressure, outlet pressure at port

1, and pilot pressure at port 3.

APPLICATION

Common applications include: pre-compensator for proportional

directional control or ow controls, as well as a pressure control valve.

A common application for this valve is as a pressure compensator when

applied with a xed, or adjustable orice to create a pressure-compensated

ow control. This ensures that ow rate, and resulting actuator speed is

maintained regardless of pressure drop across the control orice. Eective

use of logic elements is a key to designing cost-eective circuits, and is

limited only by the imagination of the designer.

SPECIFICATION

Rated pressure 210 bar [3045 psi]

Rated ow at 7 bar

[100 psi]

Weight 1.18 kg [2.60 lb]

Cavity CP20-3S

200 l/min

[53 US gal/min]

PERFORMANCE CURVE

BC332375783111en-000101 • February 2020

SCHEMATIC

Theoretical performance

LE - 51

Page 52

DIMENSION

100]

130]

]

Housing and po

other housings

mm [in]

Logic Elements Technical Information

Spool Type

CP703-4

Cross-sectional view

1.88 in

217-231 N•m

[160-170 lbf•ft]

56.7 [2.23]

1 5/8 -12 UN

3

79.4 [3.13]

EXAMPLE CIRCUITS

Compensated Circuit Proportional Pressure Reducing

1

2

ORDERING

INFORMATION

BC332375783111en-000101 • February 2020

CP703-4-B-8B-050

Seals

Seal kit

B=Buna-N 120380

V=Viton 120381

rtsHousing P/N Pilot port

0=No housing No houisng

8B = AL, 1 BSP CP20-3S-8B/2B = 1/4 BSP

10B = AL, 1-1/4 BSP CP20-3S-10B/2B = 1/4 BSP

16S =#16 SAE CP20-3S-16S/4S =#4 SAE

20S =#20 SAE CP20-3S-20S/4S =#4 SAE

AL,

AL,

available

Differential

Control

Pressure

bar[psi]

050=3.5[50]

080=5.5[80]

100=6.9[

130=9.0[

150=10.3 [150

LE - 52

Page 53

Logic Elements Technical Information

Spool Type

CP700-3

OPERATION

The CP700-3 is a 10-size, normally open, pilot-to-close, springbiased dierential-sensing logic element. It will modulate ow from

2 to 1 based on the spring control pressure, outlet pressure at port

1, and pilot pressure at port 3.

APPLICATION

Common applications include: high-ow pressure reducing valve

when using a small relief valve (like CP208-1), or a proportional

relief valve (like PRV08-DAC) as a pilot element. Eective use of logic

elements is a key to designing cost-eective circuits, and is limited

only by the imagination of the designer.

SPECIFICATION

Rated pressure 210 bar [3045 psi]

Rated ow at 7 bar

[100 psi]

Weight 0.13 kg [0.28 lb]

Cavity SDC10-3

40 l/min

[11 US gal/min]

PERFORMANCE CURVE

Theoretical performance

psi bar

203

174

145

116

87

58

29

154 SUS (33 cSt) hyd. oil @ 100° F (38° C)

14

12

10

8

6

Press ure drop

4

2

Fully opened

SCHEMATIC

BC332375783111en-000101 • February 2020

0

20 30 40 50 60

10L/min

2.6US gal/min

Flow

5.3 7.9 10.6 13.2 15.9

LE - 53

Page 54

Logic Elements Technical Information

Seals

110]

[150]

[200]

Housing and po

SE3B

SE4B

Other housings available

Spool Type

CP700-3

DIMENSION

mm [in]

1

EXAMPLE CIRCUITS

Cross-sectional view

23

7/8-14 UNF

46.2

[1.82]

ht1.00 in

41-47 N.m

[30-35 lbf.ft]

19.1

[0.75]

ORDERING

INFORMATION

BC332375783111en-000101 • February 2020

CP700-3-B-8S-080

Seal kit

B=Buna-N 120027

V=Viton 120028

rtsHousing P/N

0=No Housing No Housing

= AL,3/8 BSP SDC10-3-SE-3B

= AL, 1/2 BSP SDC10-3-SE-4B

6S = AL, #6 SAE CP10-3-6S

8S = AL, #8 SAE CP10-3-8S

Differential

Control

Pressure

bar[psi]

040=2.8[40]

080=5.5[80]

110=7.6[

150=10.3

200=13.8

LE - 54

Page 55

Logic Elements Technical Information

US gal/min

100

120

140

160

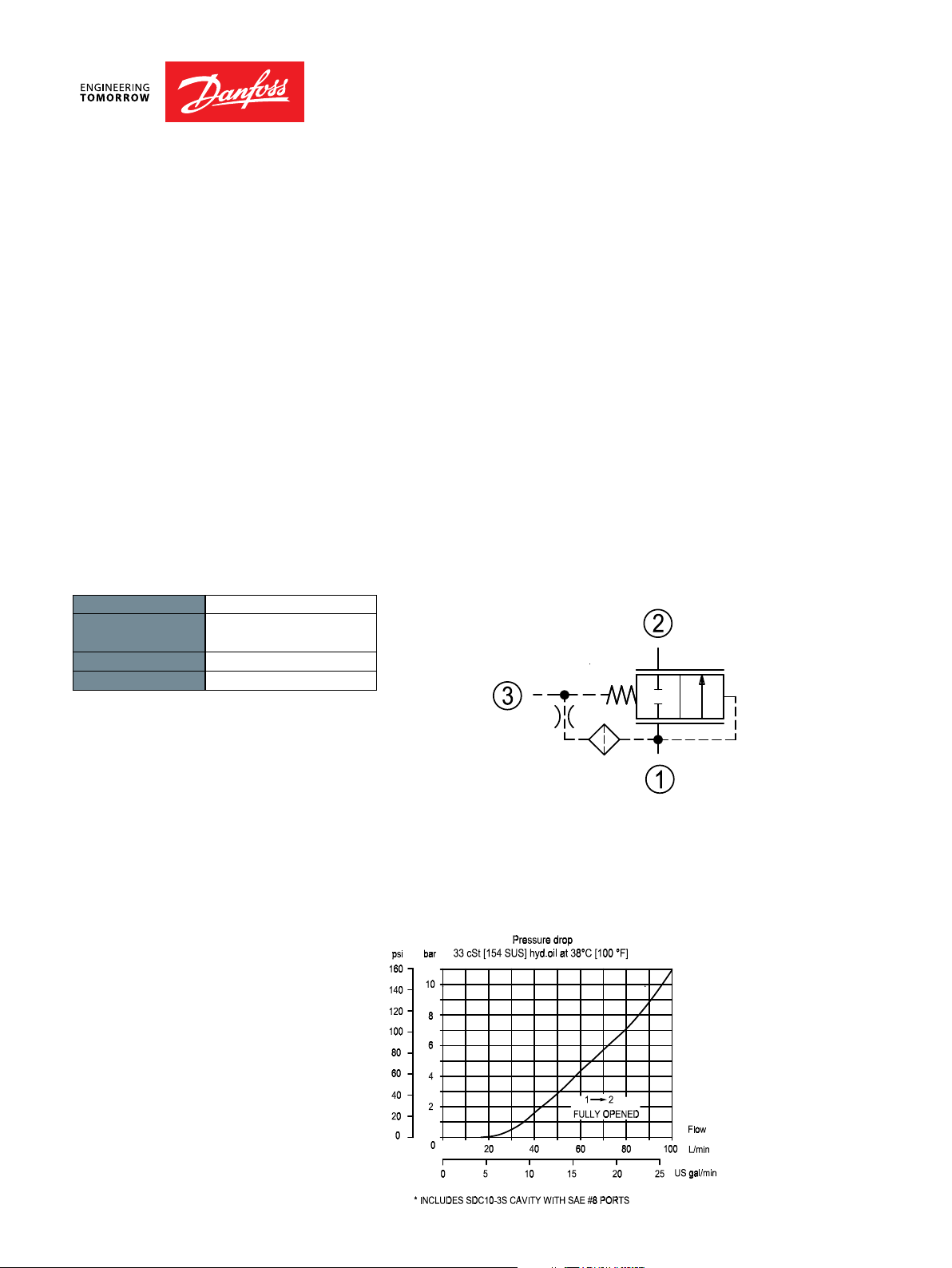

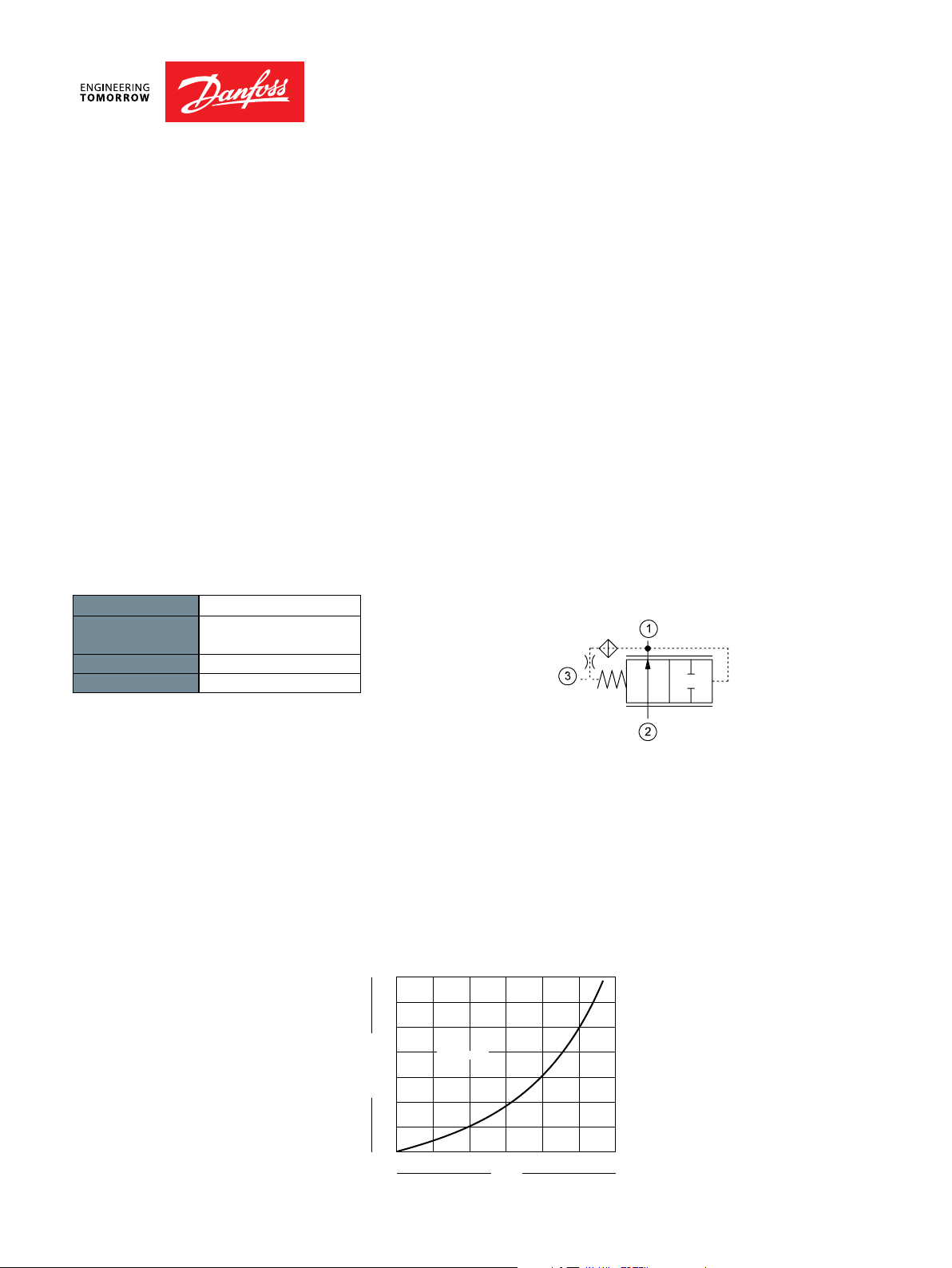

Spool Type

HLE10-OVC

OPERATION

The HLE10-OVC is a 10-size, normally open, vent-to-close, springbiased dierential-sensing logic element. It will modulate ow from

2 to 1 based on the spring control pressure, outlet pressure at port

1, and pilot pressure at port 3.

APPLICATION

Common applications include: high-ow pressure reducing valve

when using a small relief valve (like CP208-1), or a proportional

relief valve (like PRV08-DAC) as a pilot element. Eective use of logic

elements is a key to designing cost-eective circuits, and is limited

only by the imagination of the designer.

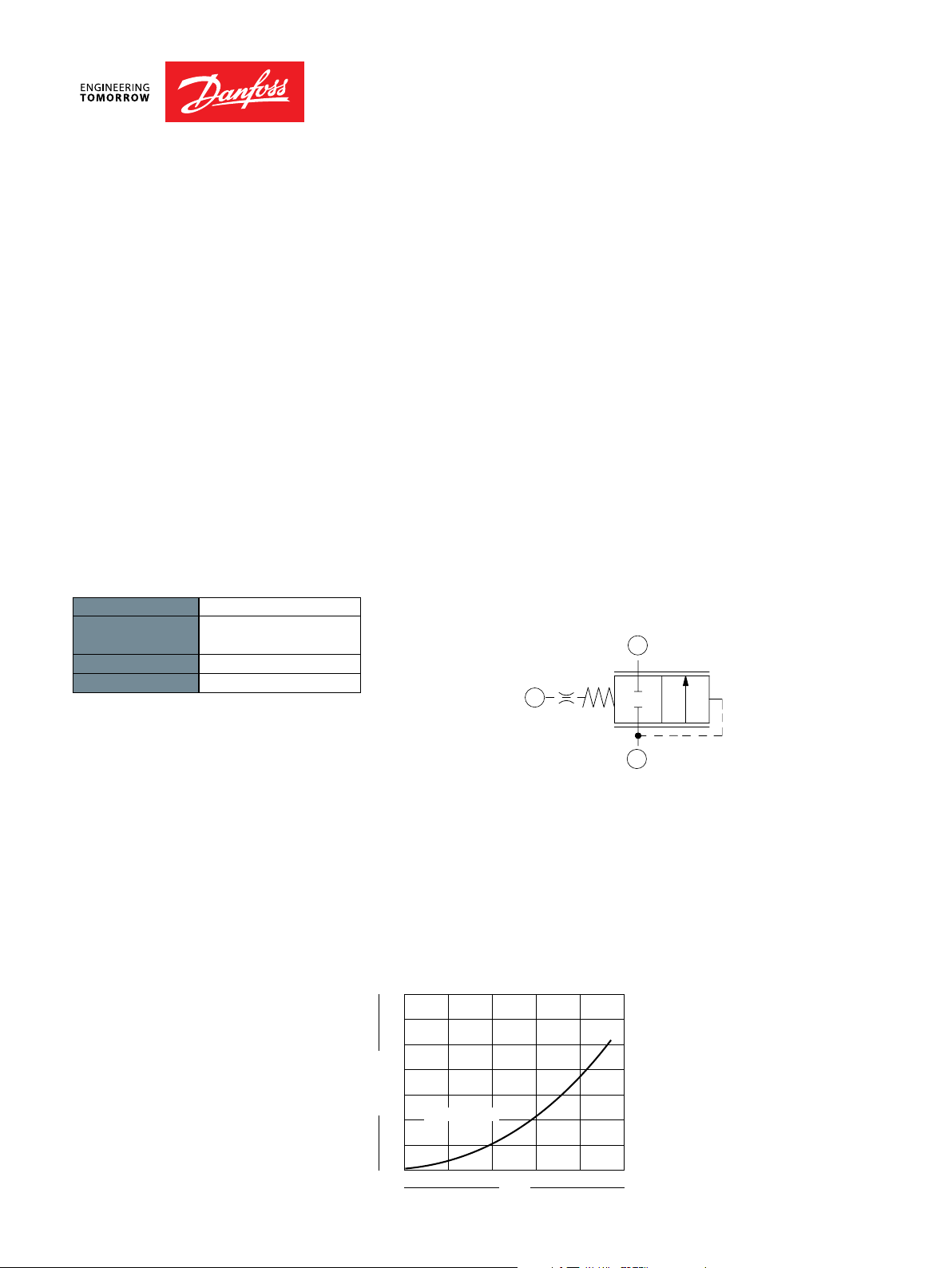

SPECIFICATION

Rated pressure* 350 bar [5075 psi]

Rated ow at 7 bar

[100 psi]

60 l/min

[15.8 US gal/min]

Weight 0.14 kg [0.31 lb]

Cavity SDC10-3S

* Rated Pressure based on NFPA fatigue test standards (at 1 Million Cycles).

Theoretical performance

PERFORMANCE CURVE

Pressure drop

bar

psi

80

60

40

20

0

33 cSt [154 SUS] hyd.oil at 38°C [100 °F]

10

8

6

4

2

0

16

4

0

2

FULLY OPENED

12 20

8 16

SCHEMATIC

1

Flow

80

644832

L/min

BC332375783111en-000101 • February 2020

LE - 55

Page 56

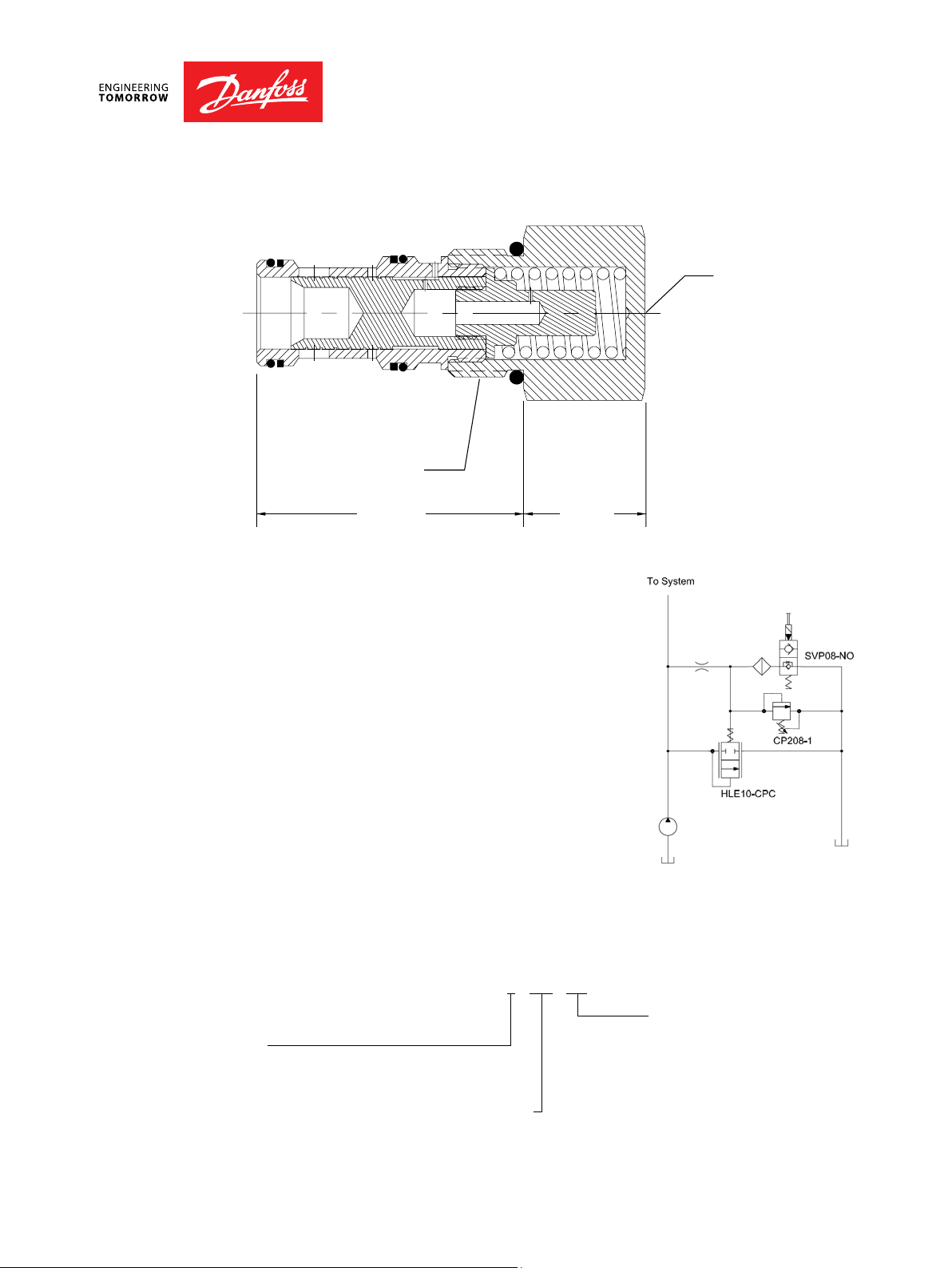

Logic Elements Technical Information

46.8

[1.84]

19.1

[0.75]

25.4 mm [1.00]

68-75 Nm

[50-55 lbf*ft]

7/8-14 UNF

2

1

3

Spool Type

HLE10-OVC

DIMENSION

mm [in]

EXAMPLE CIRCUITS

Cross-sectional view

Pilot-Operated Pressure Reducing Valve

ORDERING

INFORMATION

HLE10:

High pressure,

logic element, 10-size

Differential Control Pressure

Code Pressure

2.75 2.75 bar [40 psi]

BC332375783111en-000101 • February 2020

5.5 5.5 bar [80 psi]

7.5 7.5 bar [110 psi]

10.0 10.0 bar [150 psi]

14.0 14.0 bar [200 psi]

19.0 19.0 bar [225 psi]

HLE10 - OVC - 2.75 - B - 00

OVC:

Normally open,

vent to close

Seals

Code Seal Material Seal kit

B Buna 11126248

V Viton 11126249

Housings

Code

Ports and Material Housing P/N

00

Cartridge Only No Body

6S

AL, #6 SAE SDC10-3S-6S

8S

AL, #8 SAE SDC10-3S-8S

3B

AL, 3/8 BSP SDC10-3S-3B

4B

AL, 1/2 BSP SDC10-3S-4B

STEEL, #6 SAE SDC10-3S-S6S

S6S

STEEL, #8 SAE SDC10-3S-S8S

S8S

*** Aluminum bodies are for use in lower pressure applications only

[less than 210 bar (3000 psi)].

LE - 56

Page 57

Logic Elements Technical Information

Spool Type

CP701-3

OPERATION

The CP701-3 is a 12-size, normally open, pilot-to-close, springbiased dierential-sensing logic element. It will modulate

ow from 2 to 1 based on the spring control pressure, outlet

pressure at port 1, and pilot pressure at port 3.

APPLICATION

Common applications include: high-ow pressure reducing valve

when using a small relief valve (like CP208-1), or a proportional

relief valve (like PRV08-DAC) as a pilot element. Eective use of logic

elements is a key to designing cost-eective circuits, and is limited

only by the imagination of the designer.

SPECIFICATION

Rated pressure* 350 bar [5075 psi]

Rated ow at 7 bar

[100 psi]

Weight 0.26 kg [0.57 lb]

Cavity CP12-3S

* Rated Pressure based on NFPA fatigue test standards (at 1 Million Cycles).

80 l/min

[21 US gal/min]

Theoretical performance

PERFORMANCE CURVE

psi bar

203

174

145

116

87

58

29

154 SUS (33 cSt) hyd. oil @ 100° F (38° C)

14

12

10

8

6

Press ure drop

4

2

SCHEMATIC

Fully opened

BC332375783111en-000101 • February 2020

0

40 60 80 100

20L/min

5.3US gal/min

Flow

10.6 15.9 21.1 26.4

LE - 57

Page 58

DIMENSION

[2.20]

[1.00]

100]

[150]

Housing and po

mm [in]

Logic Elements Technical Information

Spool Type

CP701-3

Cross-sectional view

h 1.25 in

68-75 N.m

t

1

[50-55 lbf.ft]

EXAMPLE CIRCUITS

2

1-1/16-12 UN

55.9

3

25.4

CP701-3

ORDERING

INFORMATION

Seals

B=Buna-N 120335

V=Viton 120336

0=No housing No housing

4B = AL, 1/2 BSP CP12-3S-4B/2B = 1/4 BSP

6B = AL, 3/4 BSP CP12-3S-6B/2B = 1/4 BSP

10S =#10 SAE CP12-3S-10S/4S = #4 SAE

12S =#12 SAE CP12-3S-12S/4S = #4 SAE

rtsHousing P/N Pilot port

AL,

AL,

BC332375783111en-000101 • February 2020

CP701-3-B-12S -080

Seal kit

Differential

Control

Pressure

bar[psi]

030=2.1[30]

050=3.5[50]

080=5.5[80]

100=6.9[

150=10.3

LE - 58

Page 59

Logic Elements Technical Information

8

Spool Type

CP702-3

OPERATION

The CP702-3 is a 16-size, normally open, pilot-to-close, spring-biased

dierential-sensing logic element. It will modulate ow from 2 to 1

based on the spring control pressure, outlet pressure at port 1, and

pilot pressure at port 3.

APPLICATION

Common applications include: high-ow pressure reducing valve when

using a small relief valve (like CP208-1), or a proportional relief valve (like

PRV08-DAC) as a pilot element. Eective use of logic elements is a key to

designing cost-eective circuits, and is limited only by the imagination of

the designer.

SPECIFICATION

Rated pressure 210 bar [3045 psi]

Rated ow at 7 bar

[100 psi]

Weight 0.38 kg [0.83 lb]

Cavity SDC16-3S

115 l/min

[30 US gal/min]

PERFORMANCE CURVE

Theoretical performance

psi bar

203

174

145

116

87

58

29

154 SUS (33 cSt) hyd. oil @ 100° F (38° C)

14

12

10

8

6

Press ure drop

4

2

SCHEMATIC

Fully opened

BC332375783111en-000101 • February 2020

0

10.6US gal/min

80 120 160 200

40L/min

Flow

21.1 31.7 42.3 52.

LE - 59

Page 60

DIMENSION

[2.15]

[1.00]

mm [in]

Logic Elements Technical Information

Spool Type

CP702-3

Cross-sectional view

h 1.50 in

122-136 N.m

t

1

[90-100 lbf.ft]

EXAMPLE CIRCUITS

2

1-5/16-12 UN

54.6

3

25.4

CP702-3

ORDERING

INFORMATION

Seal Option

Code Seal Material Seal kit

B Buna 120033

V Viton 120034

Housings & Ports

0: Cartridge Only

6B: 3/4 BSP, AL

8B: 1 BSP, AL

12S: #12 SAE, AL

16S: #16 SAE, AL

Other Housings available

BC332375783111en-000101 • February 2020

CP702-3 - B - 16S - 080

Housing P/N

No Housing

CP16-3S-6B/2B

CP16-3S-8B/2B

CP16-3S-12S/4S

CP16-3S-16S/4S

Pilot port

1/4 BSP

1/4 BSP

#4 SAE

#4 SAE

Differential Control Pressure

Code

040

080

110

150

190

bar [psi]

2.8 [40]

5.5 [80]

7.6 [110]

10.3 [150]

13.1 [190]

LE - 60

Page 61

Logic Elements Technical Information

1,450

2,176

2,901

3,626

10.6

3

2

4

1

Pressure Compensator

CP310-4

OPERATION

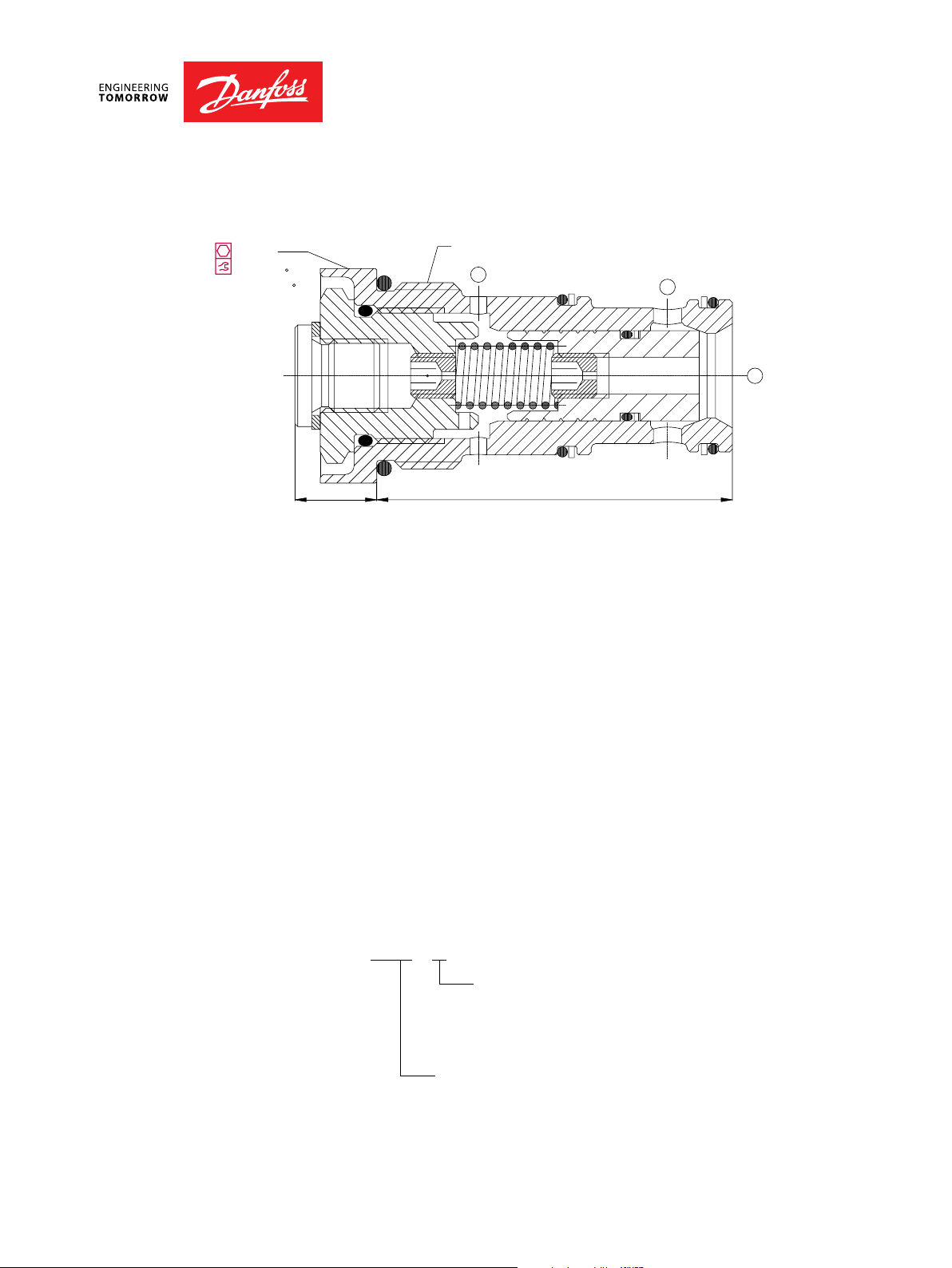

The CP310-4 is a 10-size, ow control, priority type pressure compensator. Priority-type pressure

compensators are four-ported valves that work in series with a xed or variable control orice. As with

the restrictive-type valves, these valves maintain a constant pressure dierential across the control

orice. However, rather than restricting ow when the dierential pressure becomes too high, the

priority-type pressure compensators open a fourth bypass port for all ow in excess of that demanded

by the control orice. Note that if the bypass port is blocked, the valve will function as a restrictive-type

pressure compensator.

APPLICATION

Common applications include any circuit that requires compensated priority ow going to one

actuator (for example, steering or charge pressure to a hydrostatic pump), and a the remaining going

to a secondary function (for example, a fan motor). Pressure compensators oer the circuit designer

capability to add pressure compensation to any xed or variable orice. This ensures that ow, and

resulting actuator speed, are maintained regardless of system and working pressures

SPECIFICATION

Rated pressure 210 bar [3045 psi]

Rated ow at 7 bar

[100 psi]

Weight 0.15 kg [0.32 lb]

Cavity SDC10-4

40 l/min

[11 US gal/min]

PERFORMANCE CURVE

Theoretical performance

psi bar

154 SUS (33 cSt) hyd. oil @ 100° F (38° C)

250

200

150

regulated pressure

secondary pressure

SCHEMATIC

100

Press ure

50

725

BC332375783111en-000101 • February 2020

0

8L/min

16 24 32 40

Flow

4.26.3 8.5

2.1US gal/min

LE - 61

Page 62

DIMENSION

CP310-4-B-8S-080

110]

[150]

[190]

mm [in]

Logic Elements Technical Information

Pressure Compensator

CP310-4

Cross-sectional view

ht1.00 in

1

41-47 N.m

[30-35 lbf.ft]

23

7/8-14 UNF

62.5

[2.46]

4

19.1

[0.75]

EXAMPLE CIRCUITS

Priority-type Pressure Compensator operation Post-Compensated Proportional Priority Flow Control

ORDERING

INFORMATION

Seals

B=Buna-N 120023

V=Viton 120024

Housing and portsHousing P/N

0=No Housing No Housing

L3B = AL,3/8 BSP SDC10-4-L-3B

L4B = AL, 1/2 BSP SDC10-4-L-4B

6S = AL, #6 SAE CP10-4-6S

8S = AL, #8 SAE CP10-4-8S

Other housings available

BC332375783111en-000101 • February 2020

Seal kit

Differential

Control

Pressure

bar[psi]

040=2.8[40]

080=5.5[80]

110=7.6[

150=10.3

190=13.1

LE - 62

Page 63

Logic Elements Technical Information

1,450

2,176

2,901

3,626

21.1

3

2

4

1

Pressure Compensator

CP311-4

OPERATION

The CP311-4 is a 12-size, ow control, priority type pressure compensator. Priority-type pressure compensators

are four-ported valves that work in series with a xed or variable control orice. As with the restrictive-type

valves, these valves maintain a constant pressure dierential across the control orice. However, rather than

restricting ow when the dierential pressure becomes too high, the priority-type pressure compensators