Page 1

Service Kit Instructions

Series 40 - M46

Load Control Field Conversion Kit Installation Instructions

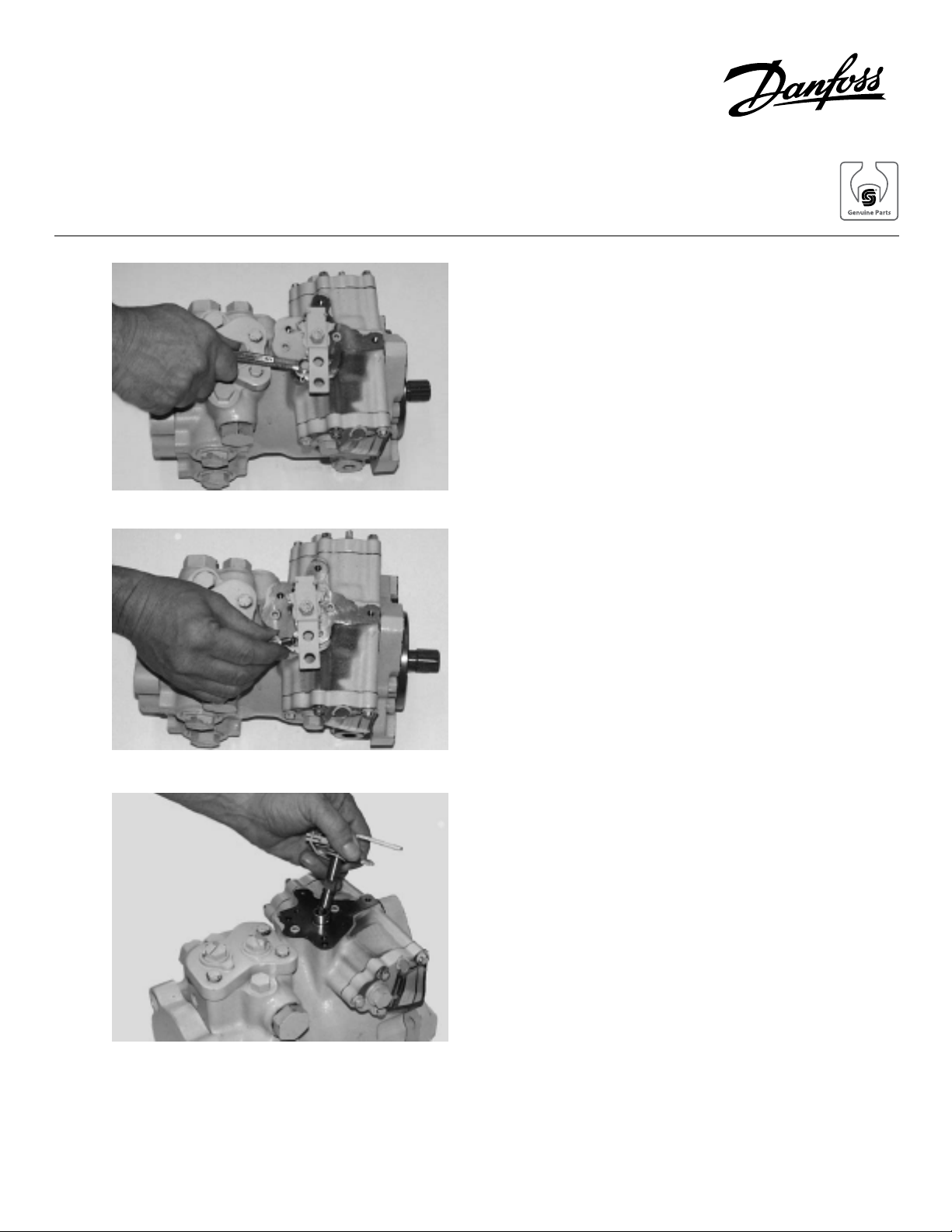

With the pump controller facing upward loosen the screw or

flange head screw retaining the neutral bracket to the

housing using a 7/16” or 3/8” wrench.

Remove the screw and washer or flange head screw from

the housing.

Remove the MDC spool assembly from the housing.

© Danfoss, 2013 BLN-10193 • Rev AA • September 2013 1

Page 2

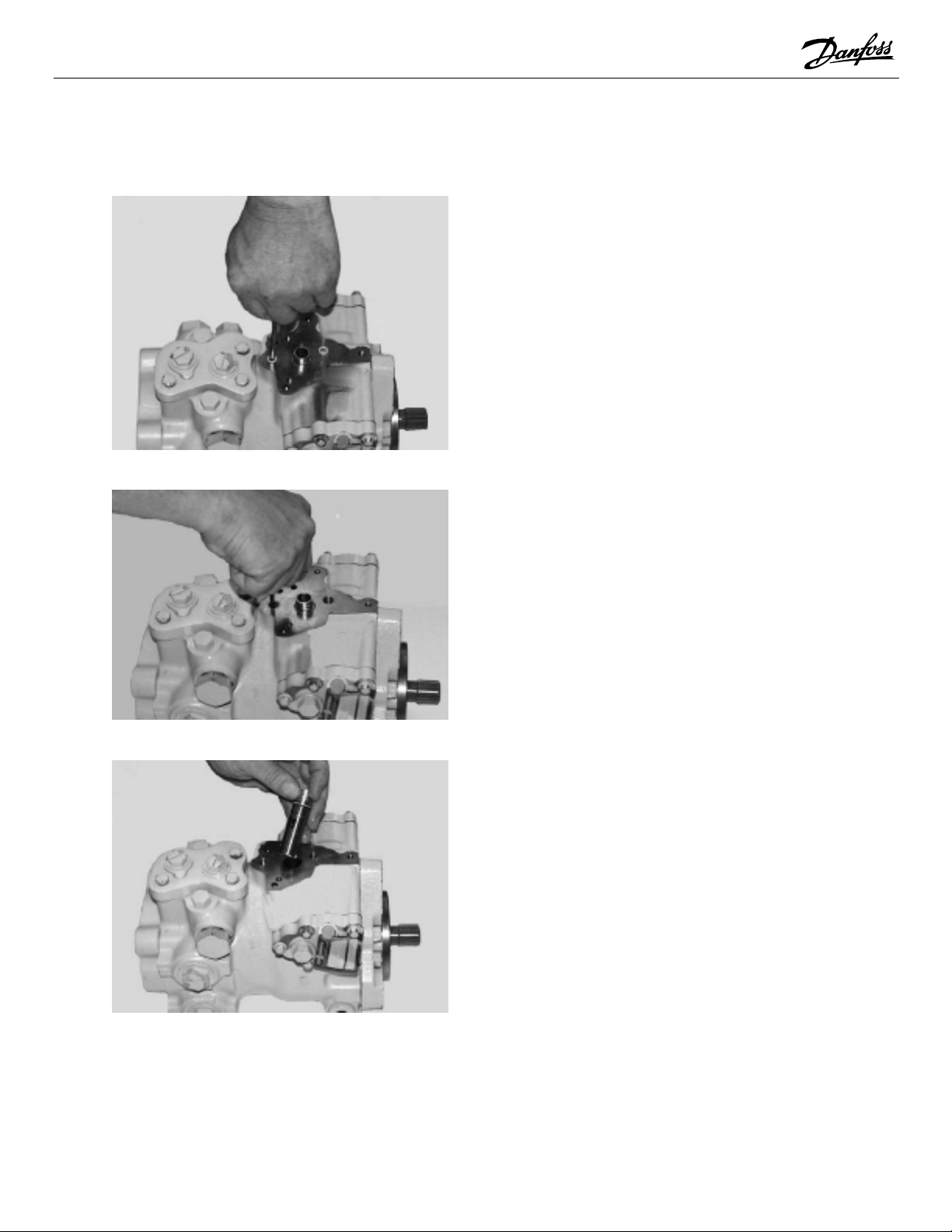

Remove the 2 plugs on both sides of the control sleeve.

On pumps with date code 86-14 or below, remove the

control inlet using a 9/16 in. hex wrench. On pumps with

dates code above 86-14, use a 3/16 in. internal hex wrench.

Remove control inlet orifice.

Remove the control sleeve from the unit by carefully

gripping the end of the sleeve with pliers and pulling out.

© Danfoss, 2013 BLN-10193 • Rev AA • September 2013 2

Page 3

S L O T

Install screened orifice. Torque to 2 to 3 Nm [20 to 30 lbf •in]

Align the new control sleeve so its slot will engage the

swashplate feedback pin.

FEED BACK PIN

Swashplate feedback pin.

© Danfoss, 2013 BLN-10193 • Rev AA • September 2013 3

Page 4

Carefully push the control sleeve all the way down by hand.

Using petroleum jelly to retain them, make sure all O-rings

are in place on the bottom side of the EDC.

Carefully install the EDC onto the pump.

© Danfoss, 2013 BLN-10193 • Rev AA • September 2013 4

Page 5

Install the 4 mounting screws.

Torque screws to 13-14 Nm [10 to 12 lbs•ft]

© Danfoss, 2013 BLN-10193 • Rev AA • September 2013 5

Page 6

Stamp information on new tag.

STAMP NEW MODELS NUMBERS

IN THIS AREA

“M46-20578”

STAMP THE DATE THE EDC

WAS INSTALLED

IN THIS AREA

STAMP COMPLETE ORIGINAL

SERIAL NUMBER IN THIS AREA

Loosen and remove retaining screw with tag attached.

Combine old and new tags.

Install screw with tags in place and torque screw to 15 - 18

Nm [11-13 lbf•ft].

© Danfoss, 2013 BLN-10193 • Rev AA • September 2013 6

Page 7

Electrical Displacement Control (EDC) Neutral

Adjustment

Remove the electrical connector at the EDC. Install a 0 to

300 PSI (0 to 21 BAR) gauge in each servo port.

Warning

The following procedure may require the

vehicle/machine to be disabled (wheels raised off

the ground, work function disconnected, ect.)

while performing the procedure in order to prevent injury to the technician and bystanders.

Start the prime mover and slowly accelerate to normal

operating RPM.

Loosen lock nut with 1/2” wrench and slowly rotate the

neutral adjustment screw, with 5/32” internal hex wrench,

until the pressure is equal on both servo gages.

Slowly rotate the neutral adjust screw until one of the servo

gauges starts to increase in pressure.

Noting the amount of rotation, slowly rotate the neutral

adjust screw in the opposite direction until the other servo

gauge begins to increase in pressure.

Turn the neutral adjust screw back one-half the amount

noted above. Hold the neutral adjust screw and torque the

lock nut to 25 to 30 lbs•in. (2.8 to 3.4 Nm).

Stop the prime mover. Connect the control input. Remove

the servo pressure gauges. Return the machine to normal

operating condition. Restart prime mover and assure that

hydrostatic system is in neutral.

© Danfoss, 2013 BLN-10193 • Rev AA • September 2013 7

Loading...

Loading...