Page 1

Application guidelines

Danfoss scroll for refrigeration

LLZ013 to 034 with NI/VI/LI

Low temperature

50-60 Hz - R404A, R507

http://cc.danfoss.com

Page 2

Page 3

Content

GENERAL INFORMATION ........................ 4

PRODUCT INFORMATION ....................... 5

Features..................................................... 5

Overview ......................................................................5

Compressor model designation ............. 6

Nomenclature ............................................................6

Technical specications ........................... 7

50-60 Hz data .............................................................7

Dimensions ............................................. 10

Single compressors LLZ013-015-018 ...............10

Single compressors LLZ024 .................................11

Single compressors LLZ034 ...............................12

Electrical data, connections and wiring 14

Motor voltage ...........................................................14

Wiring connections ................................................ 14

IP rating .......................................................................15

Three phase electrical characteristics ............. 15

Motor protection.....................................................16

Approval and certicates ...................... 17

Pressure equipment directive ............................17

Low voltage directive ............................................ 17

Machines directive .................................................17

Internal free volume...............................................17

SYSTEM DESIGN ..................................... 18

Design piping ......................................... 18

General requirements ...........................................18

Design compressor mounting .............. 19

General requirements ...........................................19

Single compressor requirements ......................19

Manage sound and vibration ................ 20

Compressor sound radiation ............................. 20

Mechanical vibrations ...........................................21

Gas pulsation ............................................................21

Manage operating envelope ................. 22

Requirement ............................................................ 22

Evaluate the risk ...................................................... 24

Theory of Injection cycle ....................... 25

Theory of Vapor injection cycle ........................ 25

Theory of liquid injection cycle ........................ 25

TREV installation ..................................................... 26

Manage superheat ................................. 28

Requirement ............................................................ 28

Evaluate the risk ...................................................... 28

Test, criteria and solutions .................................. 28

Manage o cycle migration ................... 29

Requirement ............................................................ 29

Evaluate the risk ...................................................... 29

Test, criteria and solutions .................................. 29

Control logic ...........................................30

Safety control logic requirements ................... 30

Cycle rate limit requirements ............................ 30

Oil management logic recommendations ... 30

Defrost logic recommendations ...................... 30

Pump-down logic recommendations .............31

Provide power supply and electrical

protection ............................................... 32

Wiring information ................................................ 32

INTEGRATION INTO SYSTEMS ..............33

Reduce moisture in the system ............. 33

Requirements .......................................................... 33

Solutions ................................................................... 33

Assembly line procedure ....................... 34

Compressor storage .............................................. 34

Compressor holding charge .............................. 34

Handling ................................................................... 34

Piping assembly...................................................... 35

System pressure test and leak detection ...... 35

Vacuum evacuation and moisture removal 36

Refrigerant charging ............................................. 36

Dielectric strength and insulation resistance

tests ............................................................................. 36

Commissioning ....................................... 37

Preliminary check....................................................37

Initial start-up ...........................................................37

System monitoring .................................................37

Dismantle and disposal ......................... 38

ORDERING INFORMATION ................... 39

Packaging ............................................... 39

Ordering codes ....................................... 40

Accessories .............................................. 41

3FRCC.PC.039.A1.02

Page 4

General Information

PRODUCT INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION GENERAL INFORMATION

Danfoss scroll compressors are designed and

manufactured according to the state of the

art and to valid European and US regulations.

Particular emphasis has been placed on

safety and reliability. Related instructions are

highlighted with the following icons:

R

This icon indicates instructions to avoid

reliability risk.

This icon indicates instructions to avoid

safety risk.

You are strongly advised to follow these

instructions. For any deviation from the

guidelines, please contact Danfoss Technical

Support.

In any case, Danfoss accepts no liability as a result

of the improper integration of the compressor

into the unit by the system manufacturer.

4 FRCC.PC.039.A1.02

Page 5

Features

Overview Economized compressor: In the LLZ range of

Danfoss scroll compressor for refrigeration, LLZ,

with its unique scroll design and manufacturing

process exibility, oers a highly ecient solution

for demanding refrigeration applications.

This new family of refrigeration scroll

compressors includes 5 sizes of low temperature

scroll compressors designed for commercial

refrigeration applications. These compressors are

engineered for refrigeration and oer cooling

capacity from 5 to 12 kW (4 to 10 HP) at common

voltages and frequencies as well as any of the

common refrigerants (R404A / R507).

refrigeration scrolls, the compressors can work

with the economizer line activated, named as

economized compressor; or with the economizer

line disabled, named as standard compressor. The

economized compressor has been developed to

provide improved performance and an enlarged

operating envelope in refrigeration applications.

The economized compressor system presents

benets over standard refrigeration compressor

systems of equivalent horse power due to the

following:

• Capacity improvement: The capacity is

improved without increasing compressor

displacement, as it is increased by further

increasing system sub cooling with a

heat exchanger acting as an economizer

(connected to the compressor economizer

line). Furthermore a smaller economized

compressor can be used to achieve the same

capacity as a larger standard compressor,

leading to cost advantages.

• Eciency improvement: With a suitable sized

heat exchanger, the eciency improves

due to the fact that the gain in capacity is

greater than the increase in power that the

compressor consumes.

GENERAL INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION PRODUCT INFORMATION

• Enlarged operating envelope: The injection

of vapour through the economizer line

will reduce the discharge temperature and

therefore enlarge the operating envelope

based on the same suction status.

Standard compressor with liquid injection: The

standard compressor can also connect with a

liquid valve to reduce the discharge temperature

and enlarge the envelope.

• Enlarged operating envelope: The liquid

injection of refrigerant into the compressor

will ash and absorb heat from the

compressed gas and scroll set leading to

cooling of the discharge gas, thus keeping

the discharge gas temperature within safe

limits. The enlarged operating envelope is

therefore based on the same suction status.

5FRCC.PC.039.A1.02

Page 6

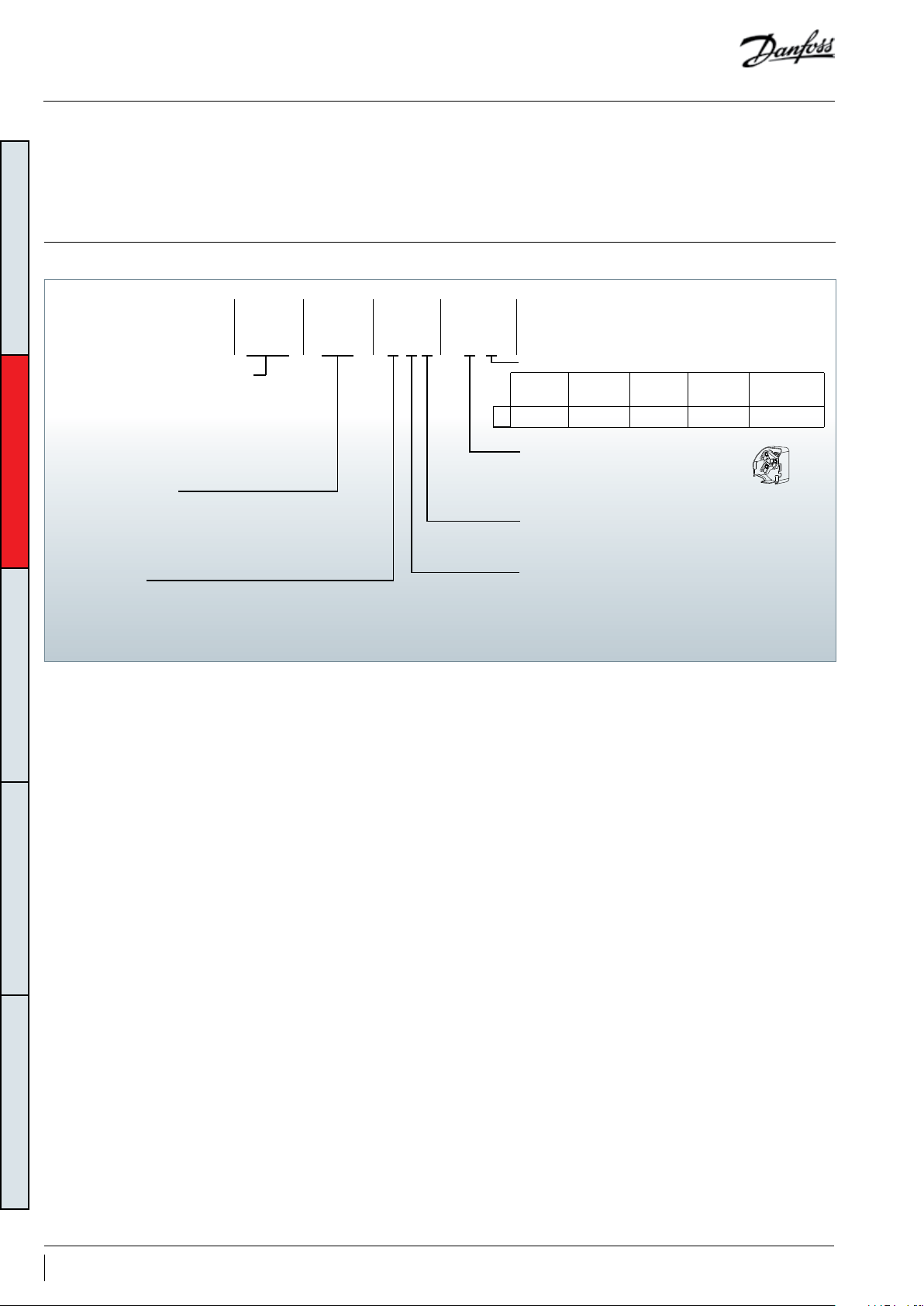

Compressor model designation

Nomenclature

GENERAL INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION PRODUCT INFORMATION

Family, Refrigerant & lubricant

LLZ: low temperature refrigeration,

R404A, R507 & PVE lubricant

Nominal capacity

In thousand Btu/h at 60 Hz,

ARI, LBP conditions

Model variation

T: design optimised for refrigeration

Danfoss scroll compressor LLZ for R404A, R507

is available as single compressor and can be

assembled in manifolding combinations.

Type FeaturesMotorSize

LLZ Q 9T 4 L

013

9

The example below presents the compressor

nomenclature which equals the technical

reference as shown on the compressor

nameplate. Code numbers for ordering are listed

section “Ordering information and packaging”.

Other features

Oil sight

glass

Threaded

Tubing and electrical connections

Q: rotolock connections, screw terminals

Motor protection

L: internal motor protection

Motor voltage code

2: 200-220V/3~/50 Hz & 208-230V/3~/60 Hz

4: 380-415V/3~/50 Hz & 460V/3~/60 Hz

9: 380V/3~/60 Hz

Oil

equalisation

None Schrader None

Oil

drain

LP gauge

port

equalisation

Gas

port

None

6 FRCC.PC.039.A1.02

Page 7

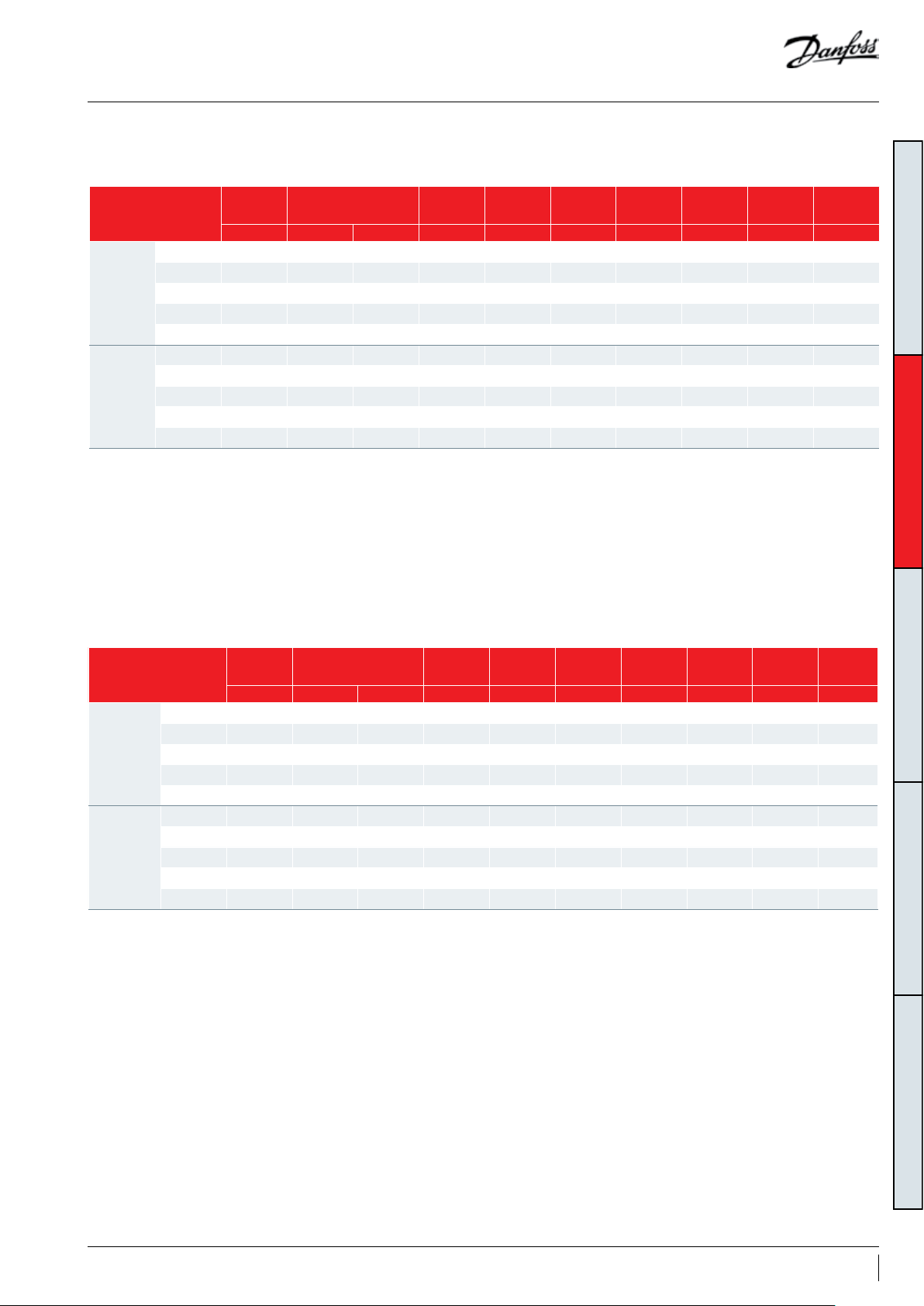

Technical specications

50-60 Hz data

Model with activated economizer line only

Models

Refrigerant

Nominal

tons 60 Hz

TR W Btu/h W W/W Btu/h/W cm

Nominal cooling

capacity

Power

input

COP E.E.R.

Swept

volume

Displace-

ment

3

/rev m3/h dm

Oil charge

3

Net weight

LL Z013 4 4044 138 02 3 011 1.34 4.57 67. 4 11.7 1.62 42

LL Z015 5 4840 16519 3511 1.38 4.71 83.5 14. 5 1.62 42

50 Hz

R404A/507*

LLZ018 6 5766 19679 4041 1.43 4.88 97. 6 17 1.62 43

LLZ024 8 7242 24717 4994 1.45 4.95 120 .2 20.9 2.51 46

LLZ034 10 9907 33812 6597 1.50 5.12 168.7 29.4 2.51 51

LL Z013 4 4863 16597 3482 1.40 4.78 67.4 14.2 1.62 42

LL Z015 5 5778 19720 415 8 1.39 4.74 83.5 17.5 1.62 42

60 Hz

R404A/507*

LLZ018 6 6905 23567 4739 1.46 4.98 97.6 20.5 1.62 43

LLZ024 8 8555 29198 5784 1.48 5.05 120. 2 25.3 2.51 46

LLZ034 10 12 041 4109 6 7807 1.54 5.26 168.7 35.4 2. 51 51

Displacement at nominal speed: 2900 rpm at 50 Hz, 3500 rpm at 60 Hz

Net weight with oil charge

TR: Ton of Refrigeration, Standard rating conditions: EN12900 Evaporating temperature: -35 °C Superheat: 10 K

EER: Energy Eciency Ratio Refrigerant: R404A* Condensing temperature: 40 °C Subcooling: 5 K

COP: Coecient Of Performance Economizer SH: 5 K Economizer ΔT: 5K

All of the compressor performance test after run-in 72h

*R507 performance data are nearly identical to R404A performance data

Subject to modication without prior notication.

Data given for motor code 4 compressor, for full data details and capacity tables refer to Online Datasheet Generator: www.danfoss.com/odsg

Model without activated economizer line, without liquid injection

kg

GENERAL INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION PRODUCT INFORMATION

Models

Refrigerant

Nominal

tons 60 Hz

TR W Btu/h W W/W Btu/h/W cm

Nominal cooling

capacity

Power

input

COP E.E.R.

Swept

volume

Displace-

ment

3

/rev m3/h dm

Oil charge

3

LL Z013 4 2417 8249 2366 1.02 3.48 67.4 11. 7 1.62 42

LL Z015 5 2937 10024 2776 1.06 3.62 83.5 14.5 1.62 42

50 Hz

R404A/R507*

LLZ018 6 3453 117 85 3150 1.10 3.75 97. 6 17 1.62 43

LLZ024 8 4 411 15055 3957 1.11 3.79 120.2 20.9 2.51 46

LLZ034 10 6051 20652 5458 1.11 3.79 168 .7 29.4 2.51 51

LL Z013 4 2896 9884 2774 1.04 3.55 67.4 14.2 1.62 42

LL Z015 5 3552 1212 3 3307 1.07 3.65 83.5 17.5 1.62 42

60 Hz

R404A/R507*

LLZ018 6 4228 1443 0 3799 1.11 3.79 97. 6 20.5 1. 62 43

LLZ024 8 5278 18014 4 611 1.14 3.89 120.2 25.3 2. 51 46

LLZ034 10 740 4 25270 6157 1.20 4.10 168.7 35.4 2.51 51

Displacement at nominal speed: 2900 rpm at 50 Hz, 3500 rpm at 60 Hz

Net weight with oil charge

TR: Ton of Refrigeration, Standard rating conditions: EN12900 Evaporating temperature: -35 °C Superheat: 10 K

EER: Energy Eciency Ratio Refrigerant: R404A* Condensing temperature: 40 °C Subcooling: 0 K

COP: Coecient Of Performance

All of the compressor performance test after run-in 72h

*R507 performance data are nearly identical to R404A performance data

Subject to modication without prior notication.

Data given for motor code 4 compressor, for full data details and capacity tables refer to Online Datasheet Generator: www.danfoss.com/odsg

Net weight

kg

7FRCC.PC.039.A1.02

Page 8

Technical specications

50-60 Hz data

Model with activated economizer line only

Models

Refrigerant

Nominal

tons 60 Hz

TR W Btu/h W W/W Btu/h/W cm

Nominal cooling

capacity

Power

input

COP E.E.R.

Swept

volume

Displace-

ment

3

/rev m3/h dm

Oil charge

LL Z013 4 4819 16447 3087 1.56 5. 32 6 7.4 11.7 1.62 42

LL Z015 5 5713 19498 3595 1.59 5.43 83.5 14.5 1.62 42

50 Hz

R404A

GENERAL INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION PRODUCT INFORMATION

LLZ018 6 6806 23229 4137 1.64 5.60 97. 6 17 1.62 43

LLZ024 8 8548 29174 5113 1.67 5.70 120.2 20.9 2.51 46

LLZ034 10 11624 39672 6805 1.71 5.84 168.7 29.4 2.51 51

LL Z013 4 5776 19713 3573 1.62 5.53 67. 4 14.2 1.62 42

LL Z015 5 6821 23280 4266 1.60 5.46 83.5 17. 5 1.62 42

60 Hz

R404A

LLZ018 6 8152 27823 48 61 1.68 5.73 97. 6 20.5 1.62 43

LLZ024 8 10100 34471 5934 1.70 5.80 120. 2 25.3 2. 51 46

LLZ034 10 14028 47877 8055 1.74 5.94 168.7 35.4 2.51 51

Displacement at nominal speed: 2900 rpm at 50 Hz, 3500 rpm at 60 Hz

Net weight with oil charge

TR: Ton of Refrigeration, Standard rating conditions: ARI Evaporating temperature: -31.7 °C Superheat: 50 K

EER: Energy Eciency Ratio Refrigerant: R404A* Condensing temperature: 40.6 °C Subcooling: 5 K

COP: Coecient Of Performance Economizer SH: 5 K Economizer ΔT: 5K

All of the compressor performance test after run-in 72h

*R507 performance data are nearly identical to R404A performance data

Subject to modication without prior notication.

Data given for motor code 4 compressor, for full data details and capacity tables refer to Online Datasheet Generator: www.danfoss.com/odsg

Model without activated economizer line, without liquid injection

3

Net weight

kg

Models

Refrigerant

Nominal

tons 60 Hz

TR W Btu/h W W/W Btu/h/W cm

Nominal cooling

capacity

Power

input

COP E.E.R.

Swept

volume

Displace-

ment

3

/rev m3/h dm

Oil charge

3

Net weight

LL Z013 4 3213 10966 2507 1.28 4.37 67. 4 11. 7 1.62 42

LL Z015 5 3898 133 04 2949 1.32 4. 51 83.5 14.5 1.62 42

50 Hz

R404A

LLZ018 6 4583 15642 3346 1.37 4.68 97.6 17 1.62 43

LLZ024 8 5854 19980 4204 1.39 4.74 120 .2 20.9 2. 51 46

LLZ034 10 7991 27273 5772 1.38 4.71 168 .7 29.4 2.51 51

LL Z013 4 3857 13164 2938 1. 31 4.47 67.4 14.2 1.62 42

LL Z015 5 4718 16102 3507 1.35 4. 61 83.5 17. 5 1.62 42

60 Hz

R404A

LLZ018 6 5616 19167 4028 1.39 4.74 97. 6 20.5 1.62 43

LLZ024 8 7 011 23928 4889 1.43 4.88 120. 2 25.3 2.51 46

LLZ034 10 9791 33416 6616 1.48 5.05 168.7 35.4 2.51 51

Displacement at nominal speed: 2900 rpm at 50 Hz, 3500 rpm at 60 Hz

Net weight with oil charge

TR: Ton of Refrigeration, Standard rating conditions: ARI Evaporating temperature: -31.7 °C Superheat: 50 K

EER: Energy Eciency Ratio Refrigerant: R404A* Condensing temperature: 40.6 °C Subcooling: 0 K

COP: Coecient Of Performance

All of the compressor performance test after run-in 72h

*R507 performance data are nearly identical to R404A performance data

Subject to modication without prior notication.

Data given for motor code 4 compressor, for full data details and capacity tables refer to Online Datasheet Generator: www.danfoss.com/odsg

kg

8 FRCC.PC.039.A1.02

Page 9

Technical specications

50-60 Hz data

Model with liquid injection only

Models

Refrigerant

Nominal

tons 60 Hz

TR W Btu/h W W/W Btu/h/W cm

Nominal cooling

capacity

Power

input

COP E.E.R.

Swept

volume

Displace-

ment

3

/rev m3/h dm

Oil charge

3

Net weight

LL Z013 4 2255 7694 2285 0.99 3.38 6 7.4 11 .7 1.62 42

LL Z015 5 2 814 9601 2811 1.00 3.41 83.5 14.5 1.62 42

50 Hz

R404A/507*

LLZ018 6 3307 112 83 3247 1.02 3.48 9 7.6 17 1.62 43

LLZ024 8 4086 13941 4016 1.02 3.47 120. 2 20.9 2.51 46

LLZ034 10 5807 19 813 5619 1.03 3. 53 168.7 29.4 2.51 51

LL Z013 4 2754 9397 2750 1. 00 3.41 67.4 14.2 1.62 42

LL Z015 5 3407 116 25 3355 1.02 3.46 83.5 17.5 1.62 42

60 Hz

R404A/507*

LLZ018 6 4031 13754 3809 1. 06 3.61 97.6 20.5 1.62 43

LLZ024 8 5024 17142 4703 1.07 3.64 120. 2 25.3 2 .51 46

LLZ034 10 7154 24409 6383 1.12 3.82 168.7 35.4 2.51 51

Displacement at nominal speed: 2900 rpm at 50 Hz, 3500 rpm at 60 Hz

Net weight with oil charge

TR: Ton of Refrigeration, Standard rating conditions: EN12900 Evaporating temperature: -35 °C Superheat: 10 K

EER: Energy Eciency Ratio Refrigerant: R404A* Condensing temperature: 40 °C Subcooling: 0 K

COP: Coecient Of Performance

All of the compressor performance test after run-in 72h

*R507 performance data are nearly identical to R404A performance data

Subject to modication without prior notication.

Data given for motor code 4 compressor, for full data details and capacity tables refer to Online Datasheet Generator: www.danfoss.com/odsg

All of these performance data base on using the injection valve: Sporlan Y1037-1/2-230-3/8ODFX3/8ODF

Model with liquid injection only

kg

GENERAL INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION PRODUCT INFORMATION

Models

Refrigerant

Nominal

tons 60 Hz

TR W Btu/h W W/W Btu/h/W cm

Nominal cooling

capacity

Power

input

COP E.E.R.

Swept

volume

Displace-

ment

3

/rev m3/h dm

Oil charge

3

Net weight

LL Z013 4 3027 10341 2403 1.26 4.30 6 7.4 11. 7 1.62 42

LL Z015 5 3777 12887 2957 1.28 4.36 83.5 14.5 1.62 42

50 Hz

R404A/507*

LLZ018 6 4439 15146 3 415 1.30 4.44 9 7.6 17 1.62 43

LLZ024 8 5450 18595 4225 1. 29 4.40 120.2 20.9 2.51 46

LLZ034 10 7 746 26429 5912 1. 31 4.47 168.7 29.4 2.51 51

LL Z013 4 3694 12604 2896 1.28 4.35 6 7.4 14. 2 1.62 42

LL Z015 5 4569 16688 3533 1.29 4.41 83.5 17.5 1.62 42

60 Hz

R404A/507*

LLZ018 6 5406 18445 4 011 1. 35 4.60 97.6 20.5 1. 62 43

LLZ024 8 6691 22830 4956 1.35 4.60 120.2 25.3 2.51 46

LLZ034 10 9528 32510 6727 1.41 4.83 168.7 35.4 2.51 51

Displacement at nominal speed: 2900 rpm at 50 Hz, 3500 rpm at 60 Hz

Net weight with oil charge

TR: Ton of Refrigeration, Standard rating conditions: ARI Evaporating temperature: -31.7 °C Superheat: 50 K

EER: Energy Eciency Ratio Refrigerant: R404A* Condensing temperature: 40.6 °C Subcooling: 0 K

COP: Coecient Of Performance

All of the compressor performance test after run-in 72h

*R507 performance data are nearly identical to R404A performance data

Subject to modication without prior notication.

Data given for motor code 4 compressor, for full data details and capacity tables refer to Online Datasheet Generator: www.danfoss.com/odsg

All of these performance data base on using the injection valve: Sporlan Y1037-1/2-230-3/8ODFX3/8ODF

kg

9FRCC.PC.039.A1.02

Page 10

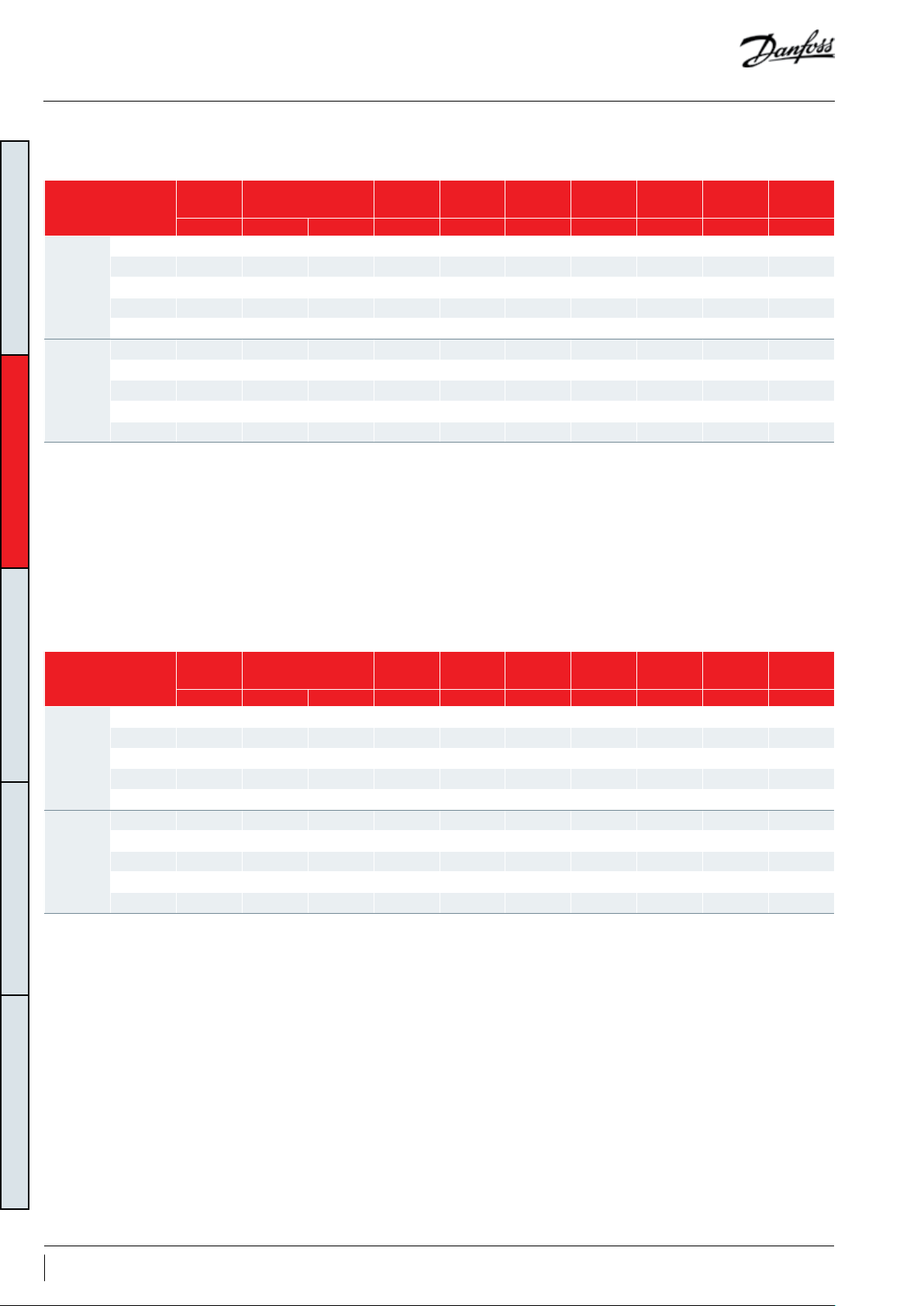

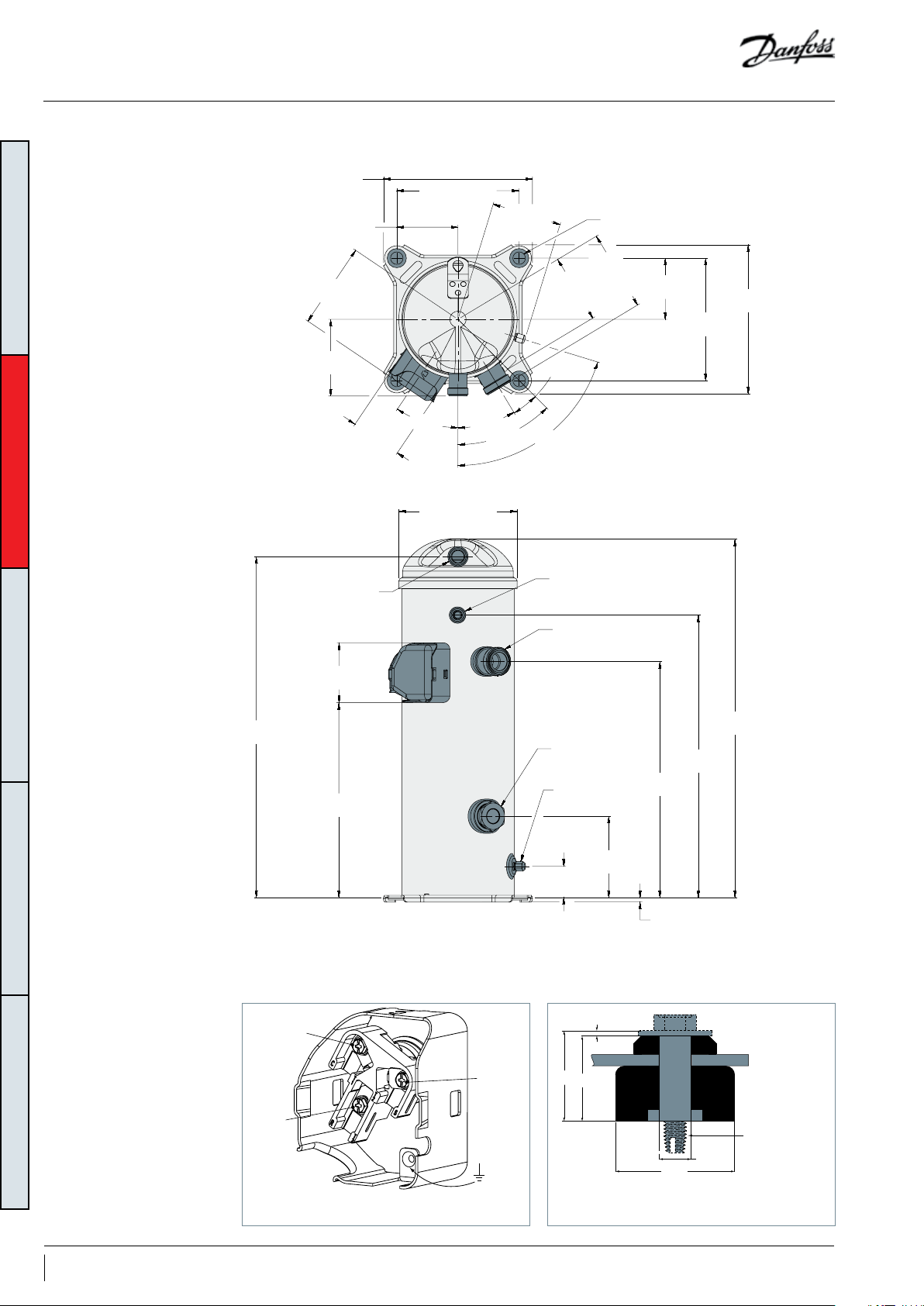

Dimensions

231.9

451

7.2

Single compressors

LLZ013-015-018

95.3

231.9

190.25 - 190.75

1°

Schrader valve

and cover

95.3

GENERAL INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION PRODUCT INFORMATION

133

108.8

Schrader

119.3

78.5 - 80.5

Discharge line

Ø1.00" - 14UN (2A)

92 - 94

34°

31°

45°±2°

124.9

suction

106.4

line

sight

glass

190.25 - 190.75

Injection line

Ø1.00" - 14UN (2A)

Suction line

Ø1.25" - 12UN (2A)

478.2

238.4

C

T₁

R

T₃

Ring connect screw terminals

C terminal box type

Sight glass

86.4

374.5

302.2

Mounting grommetTerminal box

1.7

S

T₂

41

29.5

Ø 41

Recommended torque for

mounting bolts: 11 Nm (±1 Nm)

Ø11

5/16" - 18 UNC

self tapping

10 FRCC.PC.039.A1.02

Page 11

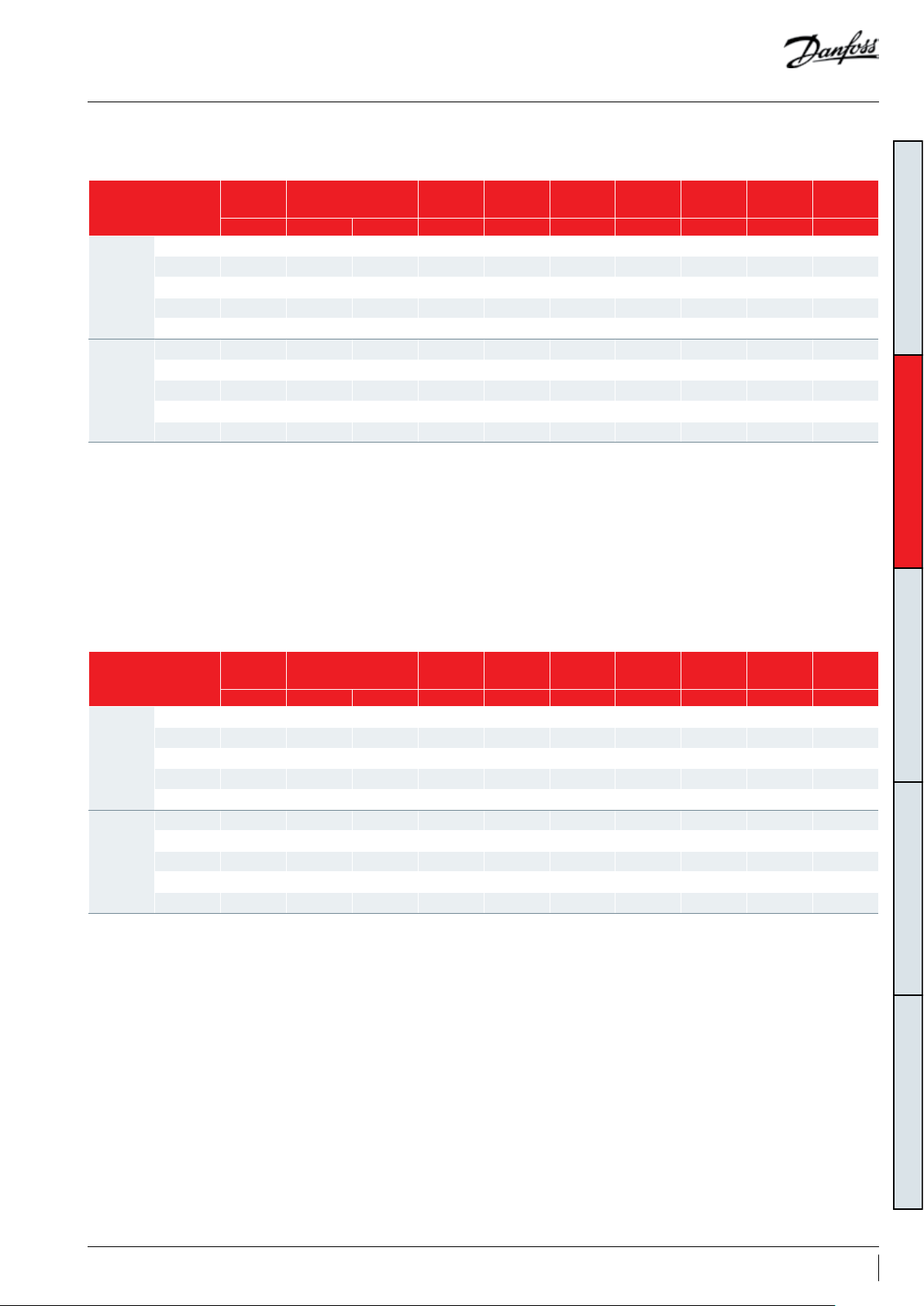

Dimensions

Single compressors

LLZ024

133

119.3

95.25

231.9

190.25-190.75

108.8

4x Ø19.0 - 20.0

106.4

sight

glass

14°±2°

124.9

suction

line

95.25

190.25-

190.75

231.9

GENERAL INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION PRODUCT INFORMATION

Discharge line

Ø1.25" - 12UN (2A)

92.0-94.0

505.5

278.4

78.5-80.5

34°

31°

45°±2°

Ø183.14-185.14

73°

Injection line

Ø1.00" - 14UN (2A)

Suction line

Ø1.75" - 12UN (2A)

Sight glass

Schrader valve

and cover

7.2

48.4

532.7

414.5

342.2

126.4

C

T₁

R

T₃

Ring connect screw terminals

C terminal box type

Mounting grommetTerminal box

1.7

S

T₂

41

29.5

Ø 41

Recommended torque for

mounting bolts: 11 Nm (±1 Nm)

Ø11

5/16" - 18 UNC

self tapping

11FRCC.PC.039.A1.02

Page 12

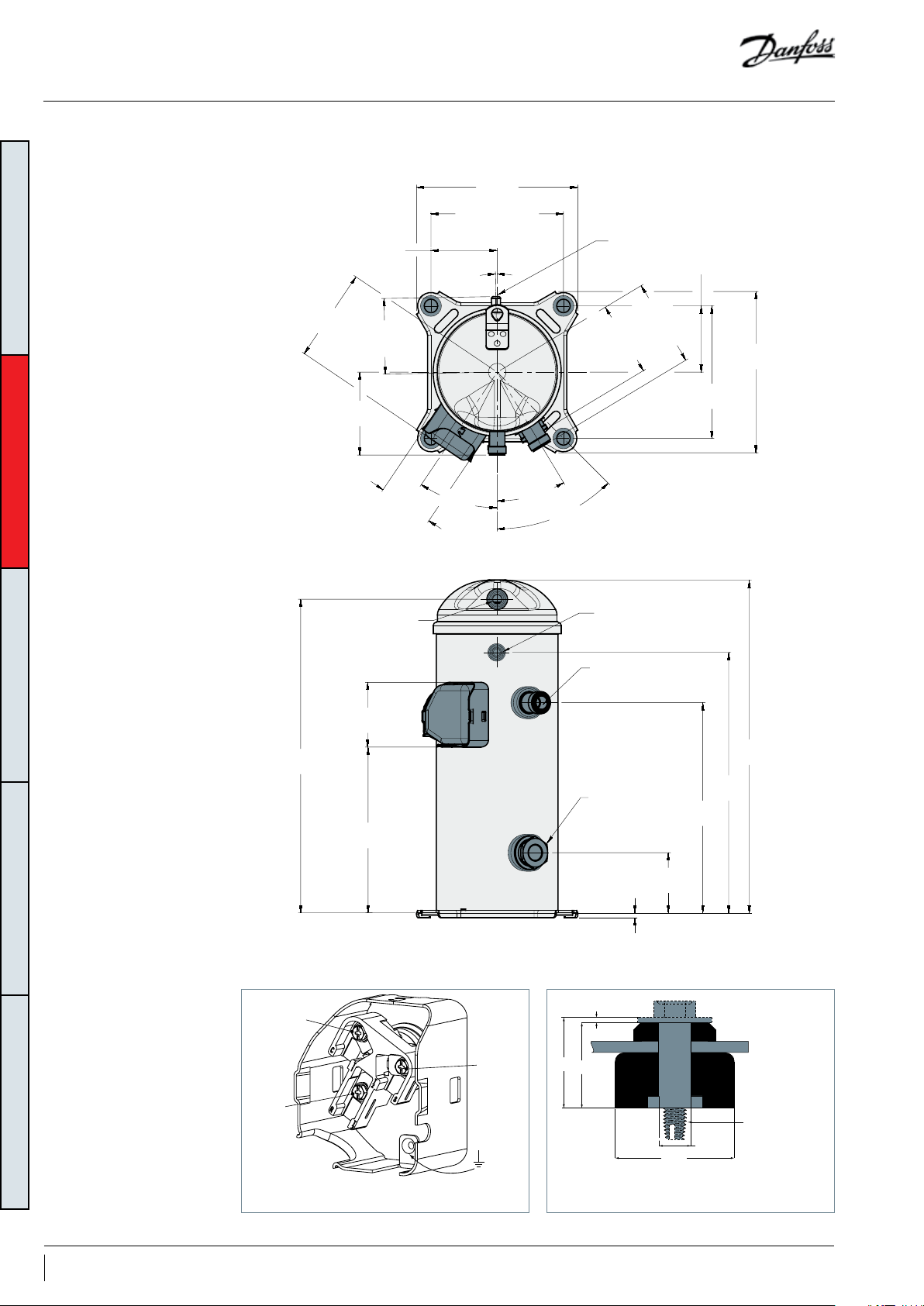

Dimensions

7.2

530.5

231.9

Single compressors

LLZ034

GENERAL INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION PRODUCT INFORMATION

133

95.25

190.25 - 190.75

108.8

Schrader

106.4

sight

glass

4x Ø19 - 20

124.9

suction

line

95.25

231.9

190.25 - 190.75

119.3

78.5 - 80.5

Discharge line

Ø1.25" - 14UN (2A)

92 - 94

303.4

34°

183.14 - 185.14

31°

45°±2°

14°±2°

73°

Injection line

Ø1.00" - 14UN (2A)

Suction line

Ø1.75" - 12UN (2A)

Sight glass

Schrader valve

and cover

557.7

439.5

367.2

12 FRCC.PC.039.A1.02

C

T₁

R

T₃

Ring connect screw terminals

C terminal box type

126.4

48.4

Mounting grommetTerminal box

1.7

S

T₂

41

29.5

Ø 41

Recommended torque for

mounting bolts: 11 Nm (±1 Nm)

Ø11

5/16" - 18 UNC

self tapping

Page 13

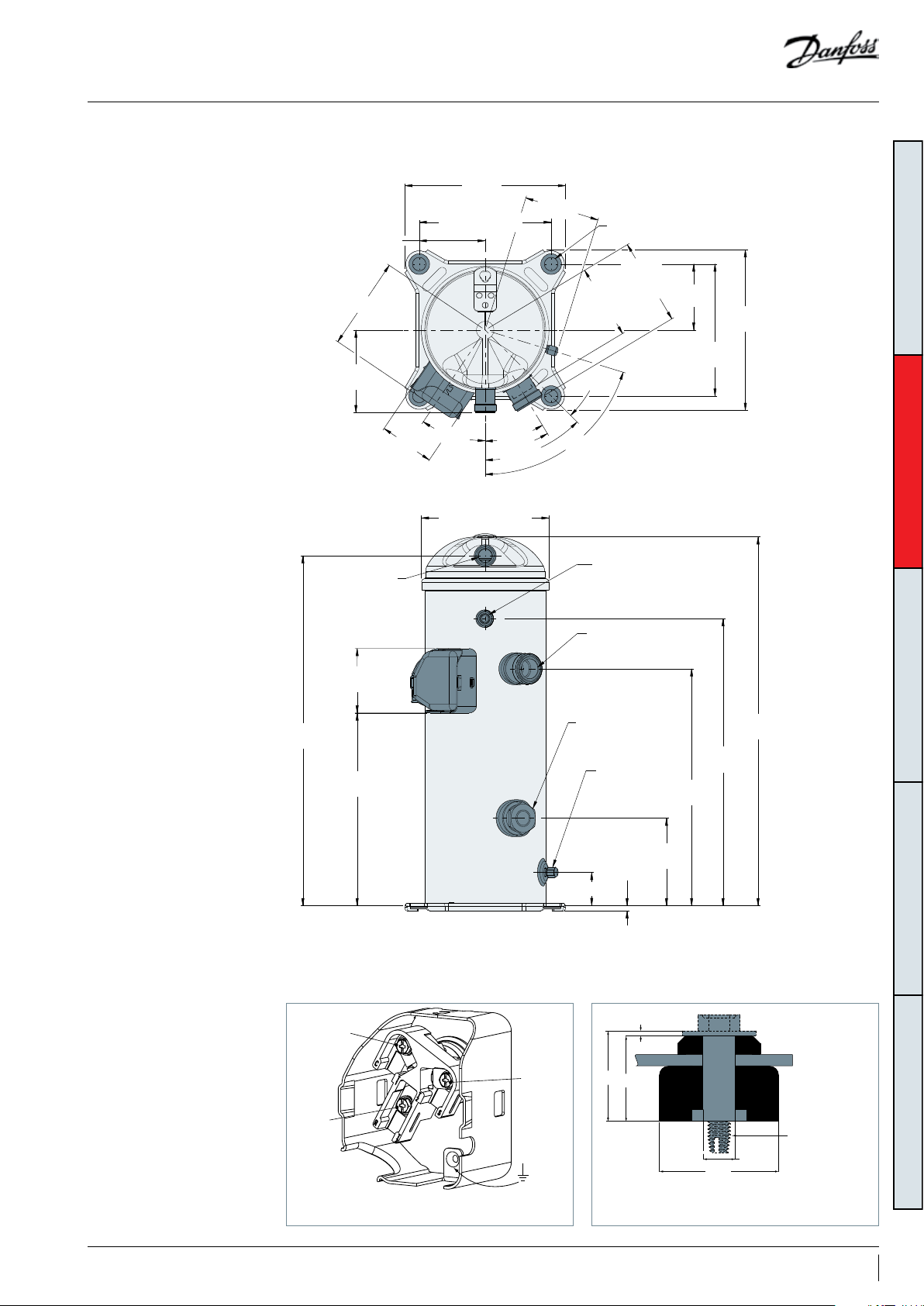

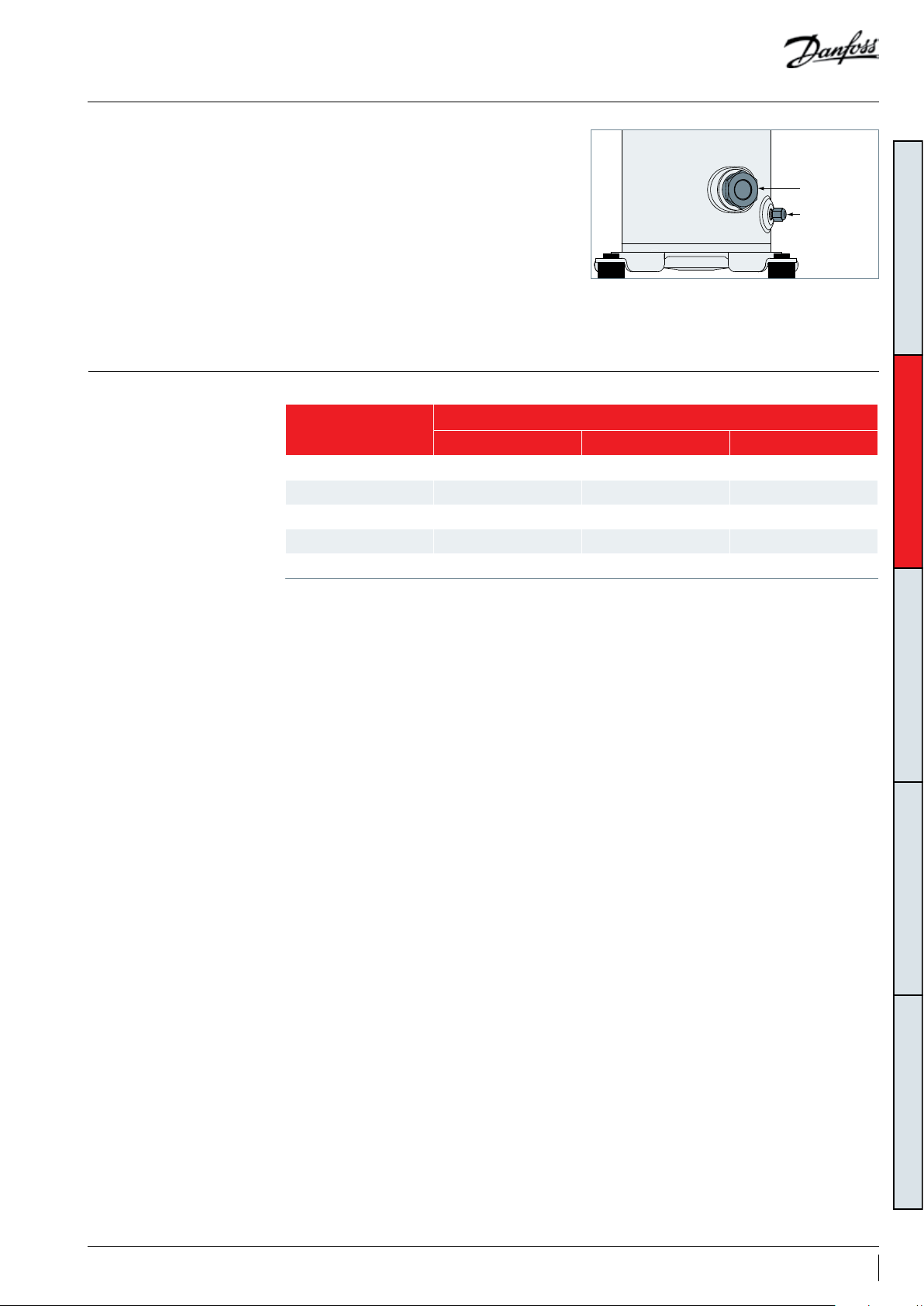

Dimensions

Oil sight glass

Schrader

Suction and discharge

connections

LLZ scroll compressors come equipped with a

threaded oil sight glass with 1"1/8 - 18 UNEF

connection. It can be used for a visual check

of the oil amount and condition or it may be

replaced by an accessory oil management device.

The oil level must be visible in the sight glass

during operation.

The oil ll and drain connection and gauge port

is a 1/4" male are connector incorporating a

schrader valve.

LLZ scroll compressors are factory delivered with rotolock connections only.

Compressor Models

Suction Fitting (in) Discharge Fitting (in) Injection Fitting (in)

LZL013 1"1/4 1" 1"

LL Z015 1"1/4 1" 1"

LLZ018 1"1/4 1" 1"

LLZ024 1"3/4 1"1/4 1"

LLZ034 1"3/4 1"1/4 1"

Rotolock Sizes

Oil sight glass

Schrader valve

and cap

GENERAL INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION PRODUCT INFORMATION

13FRCC.PC.039.A1.02

Page 14

Electrical data, connections and wiring

Danfoss scroll compressors LLZ are available in 3 dierent motor voltages as listed below.Motor voltage

GENERAL INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION PRODUCT INFORMATION

Motor voltage code Code 2 Code 4 Code 9

Nominal voltage 200-220V-3 ph 380-415V - 3 ph -

50 Hz

Voltage range 180 -242V* 342-457 V

Nominal voltage 208-230V-3 ph 460V - 3 ph 380V -3 ph

60 Hz

Voltage range 187-253V* 414-5 06 V 342-418V

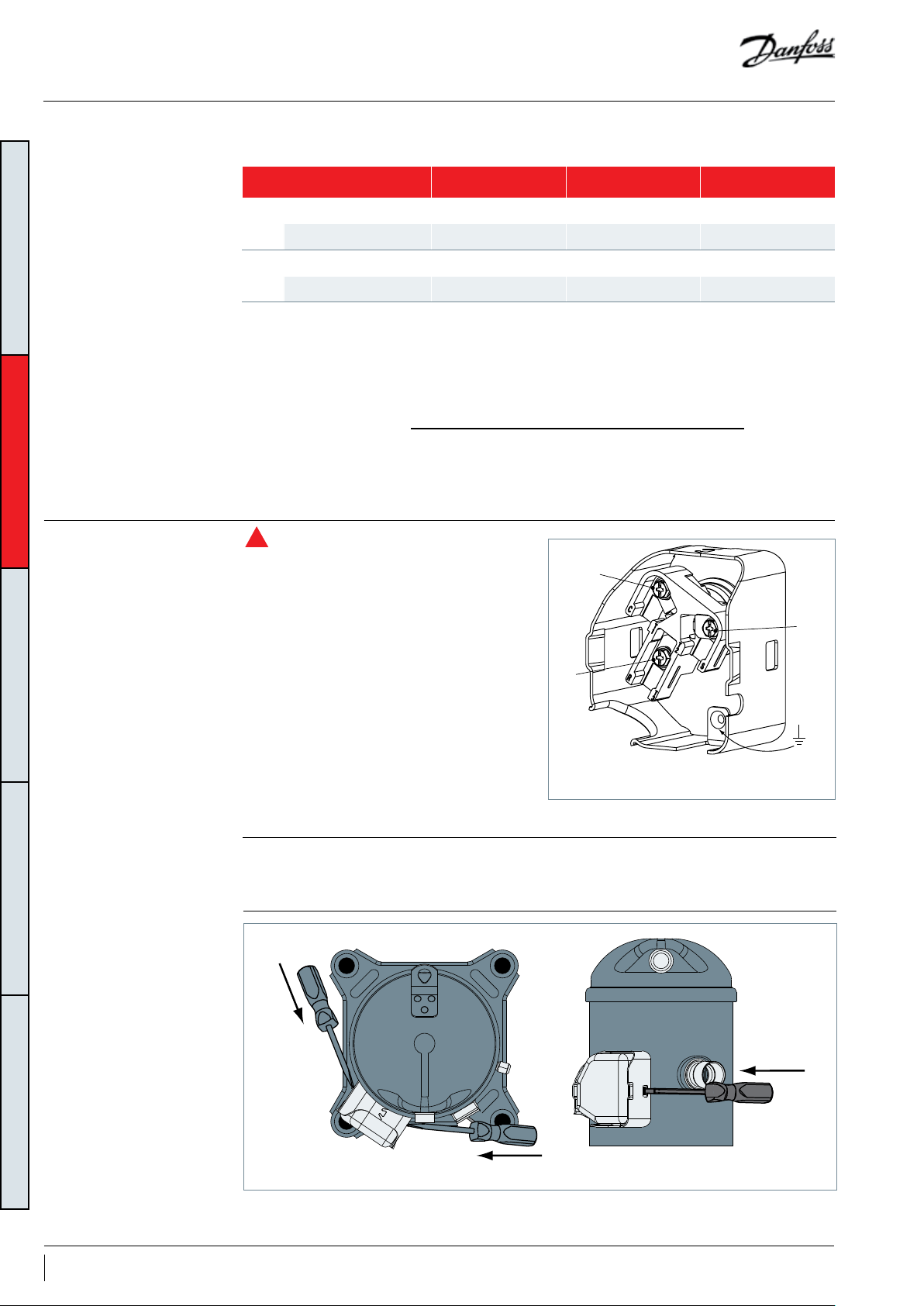

Wiring connections

The maximum allowable voltage imbalance is

2%. Voltage imbalance causes high amperage

over one or several phases, which in turn leads to

% voltage

imbalance

Vavg = Mean voltage of phases 1, 2, 3.

V1-2 = Voltage between phases 1 and 2.

Danfoss scroll compressors LLZ will only

R

= x 100

| Vavg - V1-2 | + | Vavg - V1-3 | + | Vavg - V2-3 |

compress gas while rotating counter-clockwise

(when viewed from the compressor top).

Three-phase motors will start and run in either

direction, depending on the phase angles of

the supplied power. Care must be taken during

installation to ensure that the compressor

operates in the correct direction (see “Phase

sequence and reverse rotation protection”).

The drawings hereafter show electrical terminal

labelling and should be used as a reference

when wiring the compressor. For three phase

applications, the terminals are labelled T1, T2, and

T3. . For single-phase applications the terminals

are labelled C (common), S (start), and R (run).

overheating and possible motor damage. Voltage

imbalance is given by the formula:

2 x Vavg

V1-3 = Voltage between phases 1 and 3.

V2-3 = Voltage between phases 2 and 3.

C

T1

S

T2

R

T3

Ring connect screw terminals

C terminal box type

Terminal cover mounting

Terminal cover removal

14 FRCC.PC.039.A1.02

The terminal cover and gasket should be installed

prior to operation of the compressor. Respect the

"up" marking on gasket and cover and ensure

push

push

that the two outside tabs of the cover engage the

terminal box.

push

Page 15

Electrical data, connections and wiring

IP rating

Three phase electrical

characteristics

The compressor terminal box IP rating according to CEI 529 is IP22 for all models. IP ratings is only valid

when correctly sized cable glands of the IP rating is applied.

First numeral, level of protection against contact and foreign objects

2 - Protection against object size over 12.5 mm (ngers of similar)

Second numeral, level of protection against water

2 - Protection against dripping water when tilted up to 15°

The IP rating can be upgraded to IP54 with an accessory kit (see section “Accessories”).

Max. operating

current with

economizer

Winding

resistance

Compressor model

Motor voltage code 2

200-220 V / 3 / 50Hz

208-230 V / 3 / 60Hz

Motor voltage code 4

380-415/3ph/50Hz

460V/3ph/60Hz

Motor voltage code 9

380V/3ph/60Hz

LRA MCC

A A A A Ω

LL Z013 123 .0 25.0 16.4 20.0 0.60

LL Z015 180.0 29.0 18.9 23.0 0.50

LLZ018 184. 0 31.0 24.1 29.4 0.43

LLZ024 190 .0 40.0 28.4 34.7 0.37

LLZ034 250.0 50.0 42.4 44.7 0.29

LL Z013 62.0 12.0 8.0 9.8 2.30

LL Z015 88.5 15. 0 9.8 12.0 1.69

LLZ018 90.0 15.0 11.8 14.4 1.61

LLZ024 95.0 21.0 15. 0 18 .3 1.4 8

LLZ034 150. 0 26.0 19.1 22.7 0.84

LL Z013 81.0 14.0 9.4 11.8 1.49

LL Z015 81.0 17.0 11. 3 14.2 1.49

LLZ018 106.0 20.0 13.7 16. 5 1.13

LLZ024 135 .0 21.0 17.1 19. 4 0.93

LLZ034 155.0 29.6 22.9 25.5 0.63

Max. operating

current

GENERAL INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION PRODUCT INFORMATION

15FRCC.PC.039.A1.02

Page 16

Electrical data, connections and wiring

LRA (Locked Rotor Amp)

MCC (Maximum Continuous

Current)

GENERAL INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION PRODUCT INFORMATION

Max. operating Current

Winding resistance

Locked Rotor Amp value is the higher average

current as measured on mechanically blocked

compressor tested under nominal voltage. The

LRA value can be used as rough estimation for

The MCC is the current at which the motor

protection trips under maximum load and

low voltage conditions. This MCC value is the

maximum at which the compressor can be

operated in transient conditions and out of

The max. operating current is the current when

the compressors operate at maximum load

conditions and 10% below nominal voltage

(+15°C evaporating temperature and +68°C

Winding resistance is the resistance between

phases at 25°C (resistance value +/- 7%).

Winding resistance is generally low and it

requires adapted tools for precise measurement.

Use a digital ohm-meter, a "4 wires" method and

measure under stabilised ambient temperature.

Winding resistance varies strongly with winding

temperature. If the compressor is stabilised

at a dierent value than 25°C, the measured

resistance must be corrected using the following

formula:

the starting current. However in most cases, the

real starting current will be lower. A soft starter

can be applied to reduce starting current.

the application envelope. Above this value, the

overload or external electronic module will cutout the compressor to protect the motor.

condensing temperature). Max Oper. A can be

used to select cables and contactors. In normal

operation, the compressor current consumption

is always less than the Max Oper. A. value.

a + t

R

= R

tamb

25°C

a + t

t

: reference temperature = 25°C

25°C

t

: temperature during measurement (°C)

amb

R

: winding resistance at 25°C

25°C

R

: winding resistance at tamb

amb

amb

_______

25°C

Coecient a = 234.5

Motor protection

Phase sequence and reverse

rotation protection

Danfoss scroll compressors LLZ are equipped

with an internal line break protector mounted

on the motor windings. The protector is an

automatic reset device, containing a snap action

bimetal switch.

Internal protectors respond to over-current and

overheating. They are designed to interrupt

The compressor will only operate properly in a

single direction. Use a phase meter to establish

the phase orders and connect line phases L1, L2

and L3 to terminals T1, T2 and T3, respectively.

For three-phase compressors, the motor will run

equally well in both directions. Reverse rotation

results in excessive noise; no pressure dierential

between suction and discharge; and suction

line warming rather than immediate cooling. A

Motor current under a variety of fault conditions,

such as failure to start, running overload, and fan

failure.

If the internal overload protector trips out, it must

cool down to about 60°C to reset. Depending on

ambient temperature, this may take up to several

hours.

service technician should be present at initial

start-up to verify that supply power is properly

phased and that compressor and auxiliaries are

rotating in the correct direction.

Phase monitors are required for LLZ compressors.

The selected phase monitor should lock out the

compressor from operation in reverse.

16 FRCC.PC.039.A1.02

Page 17

Approval and certicates

Pressure equipment

directive 97/23/EC

Low voltage directive

2006/95/EC

Machines directive

2006/42/EC

LLZ scroll compressors comply with the following

approvals and certicates.

CE 0062 or CE 0038 or CE0871

(European Directive)

UL

(Underwriters Laboratories)

Other approvals / certicates Contact Danfoss

*LVD compliant without Annex AA

Products LLZ013-034

Refrigerating uids Group 2

Category PED I

Evaluation module no scope

Products LLZ013-034

Declaration of conformity

ref. Low voltage Directive 2006/95/EC

Products LLZ013-034

Manufacturer’s declaration of incorporation ref.

Machines Directive 2006/42/EC

Certicates are listed on the product datasheets:

http://www.danfoss.com/odsg

All LLZ models

All LLZ models

Contact Danfoss

Contact Danfoss

GENERAL INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION PRODUCT INFORMATION

Internal free volume

Products Internal free volume at LP side without oil (litre)

LLZ013-015-018 4.74

LLZ024-034 5.95

17FRCC.PC.039.A1.02

Page 18

Design piping

U-trap, as short as possible

U-trap

General requirements Proper piping practices should be employed to:

1. Ensure adequate oil return, even under

minimum load conditions (refrigerant speed,

piping slopes…). For validation tests see section

“Manage oil in the circuit”.

GENERAL INFORMATIONPRODUCT INFORMATIONINTEGRATION INTO SYSTEMORDERING INFORMATION SYSTEM DESIGN

max. 4 m

max. 4 m

g.1

0.5% slope,

4 m/s or more

U-trap, as short as possible

8 to 12 m/s

0.5% slope,

4 m/s or more

Evaporator

To condenser

U-trap

2. Avoid condensed liquid refrigerant from

draining back to the compressor when stopped

(discharge piping upper loop). For validation

tests see section “Manage o cycle migration”.

General recommendations are described in the

gures below:

g. 2

HP

Upper loop

Condenser

LP

3D exibility

3. Piping should be designed with adequate

three-dimensional exibility to avoid excess

vibration. It should not be in contact with the

surrounding structure, unless a proper tubing

mount has been installed. For more information

on noise and vibration, see section on: “Sound

and vibration management”.

18 FRCC.PC.039.A1.02

Page 19

Design compressor mounting

General requirements

Single compressor

requirements

Compressors used in single application must be

mounted with exible grommets

Compressors used in parallel application must be

mounted with rigid mounting spacers onto rails

LLZ compressors are delivered with exible

grommets, accessory mounting kit.

Mounting grommet

1.7

41

29.5

5/16" - 18 UNC

Ø11

Ø 41

Recommended torque for

mounting bolts: 11 Nm (±1 Nm)

self tapping

and the manifold assembly must be mounted

with exible grommets onto frame.

During operation, maximum inclination from the

vertical plane must not exceed 3 degrees.

The grommets must be compressed until contact

between the at washer and the steel mounting

sleeve is established. The required bolt size for

the LLZ013-034 compressors is M8*45mm. This

bolt must be tightened to a torque of 11 Nm.

GENERAL INFORMATIONPRODUCT INFORMATIONINTEGRATION INTO SYSTEMORDERING INFORMATION SYSTEM DESIGN

19FRCC.PC.039.A1.02

Page 20

Manage sound and vibration

Compressor sound

radiation

GENERAL INFORMATIONPRODUCT INFORMATIONINTEGRATION INTO SYSTEMORDERING INFORMATION SYSTEM DESIGN

Typical sounds and vibrations in systems can be

broken down into the following three categories:

• Sound radiation (through air)

• Mechanical vibrations (through parts and

• Gas pulsation (through refrigerant)

The following sections focus on the causes and

methods of mitigation for each of the above

sources.

structure)

For sound radiating from the compressors,

the emission path is air and the sound waves

are travelling directly from the machine in all

directions.

Sound levels are as follows:

• For compressors running alone:

50 Hz 60 Hz

Compressor model

LL Z013 78 8 80 8 12 0Z5052

LL Z015 80 8 83 8 120Z5052

LLZ018 83 10 84 10 120Z505 2

LLZ024 85 10 86 10 120Z5053

LLZ034 85 8 86 8 120Z5 055

Sound power and attenuation are given at ARI LBP conditions, measured in free space

Attenuation given with acoustic hood

Materials are UL approved and RoHS compliant

Sound power

dB(A)

Attenuation

dBA

Sound power

dB(A)

Attenuation

dBA

Acoustic hood

code number

LLZ scroll compressors have a unique discharge

valve design that minimizes stopping noise. This

results in very low shutdown sound.

Note: During compressor shut down, a short

reverse rotation sound is generated. The duration

of this sound depends on pressure dierence at

shut down and should be less than 3 seconds.

This phenomenon has no impact on compressor

reliability.

Mitigations methods:

We can consider two means to reduce

compressors sound radiations:

1. Acoustic hoods are quick and easy to install

and do not increase the overall size of the

compressors to a great extent. Acoustic hoods

are available from Danfoss as accessories. Refer

to table above for sound levels, attenuation and

code numbers.

2. Use of sound-insulation materials on the inside

of unit panels is also an eective means to reduce

radiation.

20 FRCC.PC.039.A1.02

Page 21

Manage sound and vibration

Mechanical vibrations

Gas pulsation

Vibration isolation constitutes the primary

method for controlling structural vibration. LLZ

scroll compressors are designed to produce

minimal vibration during operations. The use of

rubber isolators on the compressor base plate or

on the frame of a manifolded unit is very eective

in reducing vibration being transmitted from the

compressor(s) to the unit. Rubber grommets are

supplied with all LLZ scroll compressors.

Once the supplied rubber grommets have

been properly mounted, vibration transmitted

from the compressor base plate to the unit

are held to a strict minimum. In addition, it is

The LLZ scroll compressors have been designed

and tested to ensure that gas pulsation has

been minimized for the most commonly

encountered refrigeration pressure ratio. On

installations where the pressure ratio lies beyond

the typical range, testing should be conducted

under all expected conditions and operating

congurations to ensure that minimum gas

pulsation is present.

extremely important that the frame supporting

the mounted compressor be of sucient mass

and stiness to help dampen any residual

vibration potentially transmitted to the frame.

The tubing should be designed so as to both

reduce the transmission of vibrations to other

structures and withstand vibration without

incurring any damage. Tubing should also be

designed for three-dimensional exibility. For

more information on piping design, please see

the section entitled “Essential piping design

considerations”.

Mitigations methods:

If an unacceptable level is identied, a discharge

muer with the appropriate resonant volume

and mass can be installed.

GENERAL INFORMATIONPRODUCT INFORMATIONINTEGRATION INTO SYSTEMORDERING INFORMATION SYSTEM DESIGN

21FRCC.PC.039.A1.02

Page 22

Manage operating envelope

Saturated discharge temperature (°C)

Saturated suction temperature (°C)

RGT 18.3°C

SH 20K

LLZ No Injection Operating Envelope (R404A/R507)

-45 -40 -35 -30 -25 -20 -15 -10 -5

5

0

10

15

20

25

30

35

40

45

50

55

60

65

Saturated discharge temperature (°C)

Saturated suction temperature (°C)

RGT 18.3°C

LLZ with economizer Operating Envelope (R404A/R507)

-45 -40 -35 -30 -25 -20 -15 -10 -5

5

0

10

15

20

25

30

35

40

45

50

55

60

65

Requirement

GENERAL INFORMATIONPRODUCT INFORMATIONINTEGRATION INTO SYSTEMORDERING INFORMATION SYSTEM DESIGN

R

The operating envelope for LLZ scroll

compressors is given in the gures below and

Steady-state operation envelope is valid for a

suction superheat high than 5K

guarantees reliable operations of the compressor

for steady-state and operation.

LLZ compressor operating envelop are dierence with refrigerant and with/with out injection. The

detail as following.

LLZ Compressor with R404A/R507, code2/4/9, Non Injection

LLZ Compressor with R404A/R507, code2/4/9, with economizer line

22 FRCC.PC.039.A1.02

Page 23

Saturated discharge temperature (°C)

Saturated suction temperature (°C)

20°C RGT No LI

20°C RGT+LI

30K SH+LI

LLZ Liquid Injection Operating Envelope (R404A/R507)

-45 -40 -35 -30 -25 -20 -15 -10 -5

5

0

10

15

20

25

30

35

40

45

50

55

60

65

Manage operating envelope

LLZ Compressor with R404A/R507, code2/4/9, with liquid injection(LI)

GENERAL INFORMATIONPRODUCT INFORMATIONINTEGRATION INTO SYSTEMORDERING INFORMATION SYSTEM DESIGN

Pressure settings R404A/R507

Working range high side bar(g) 5. 94 -27. 74

Working range low side bar(g) 0.33-3.34

Maximum high pressure safety switch setting bar(g) 29.7

Minimum low pressure safety switch setting bar(g) 0.15

Minimum low pressure pump-down switch setting bar(g) 0.33

R

LP and HP safety switches must never

be bypassed nor delayed and must stop all the

compressors.

HP safety switch must be manual reset

Depending on application operating envelope,

you must dene HP and LP limits within

operating envelope and pressure setting table

above.

For LLZ compressors, the external Discharge

Gas Temperature protection (DGT) is required

if the high and low pressure switch settings do

not protect the compressor against operations

beyond its specic application envelope.

The discharge gas thermostat accessory kit (code

7750009) includes all components required

for installation as shown on the right. DGT

installation must respect below requirements:

When caused low by LP safety switch, limit the

number of auto-restart to maximum 5 times

within 12 hours.

• The thermostat must be attached to the

discharge line within 150 mm from the

compressor discharge port and must be

thermally insulated and tightly xed on the

pipe.

• The DGT should be set to open at a discharge

gas temperature of 135°C.

Thermostat

Discharge line

Insulation

Bracket

23FRCC.PC.039.A1.02

Page 24

Manage operating envelope

Evaluate the risk We consider two types of operating envelope

management:

GENERAL INFORMATIONPRODUCT INFORMATIONINTEGRATION INTO SYSTEMORDERING INFORMATION SYSTEM DESIGN

Basic:

• HP and LP switch

• MOP (Max Operating Pressure) ensured by expansion

device

• Condensing pressure control

• (DGT integrated)

HP switch setting

DGT (integrated)

MOP

LP switch setting

Condensing pressure control

Advanced:

• HP and LP sensor

• Operating envelope limits (permanent and transient)

integrated into control logic

• (DGT integrated)

No additional test are required

24 FRCC.PC.039.A1.02

Page 25

Theory of Injection cycle

Theory of Vapor injection

cycle

Economizer system conguration

The below schematic shows a system

conguration with a heat exchanger acting as an

economizer for economized cycle (12345671).

The economizer is used to provide subcooling

to the refrigerant leaving the condenser before

it enters into the evaporator. This subcooling

process provides an increased capacity gain for

P

P

i

the system. Meanwhile, another small amount of

refrigerant leaving the condenser goes through

the expansion device and is then evaporated and

superheated. The superheated refrigerant is then

injected into the mid-compression cycle of the

compressor and compressed together with the

suction ow. The injected vapour also provides

cooling and therefore lowers the disch arge

temperature.

Economizer cycle 12345671

6

7

1

m+i

5

i

m

4

3

2

h

GENERAL INFORMATIONPRODUCT INFORMATIONINTEGRATION INTO SYSTEMORDERING INFORMATION SYSTEM DESIGN

Theory of liquid injection

cycle

Liquid injection system conguration

The below schematic shows a system

conguration with a liquid injection

cycle(1234561). The liquid refrigerant is injected

into scroll pocket, the injected liquid will ash

and absorb heat from compressed gas and

scroll set then cooling the discharge gas, keep

discharge gas temperature within safe limits.

Liquid injection is achieved by utilization of a

Discharge Temperature Responsive Expansion

Valve. The same valve can be used for all LLZ

models with R404A. The valve can regulates

the injection mass ow according to discharge

temperature.

An additional solenoid valve has to be installed

in case of power shortage to prevent from liquid

injection.

For the liquid injection system to be eective,

a minimum of 5°K sub cooled liquid at the at

the injection valve inlet is required. To prevent

a partial or full blockage at the injection port

caused through shavings, foreign bodies etc a

lter should be installed in the liquid line prior to

the injection valve inlet.

Liquid injection cycle 1234561

25FRCC.PC.039.A1.02

Page 26

Theory of Injection cycle

TREV installation o Recommended TREV : Sporlan

Y1037-1/2-230-3/8ODFX3/8ODF

o Liquid injection special accessories:

• Thermal insulator 1pc

• Rotolock sleeve 1" to 3/8" injection

connection 1pc

• Gasket o-ring 1pc

o Sleeve solder and valve location

GENERAL INFORMATIONPRODUCT INFORMATIONINTEGRATION INTO SYSTEMORDERING INFORMATION SYSTEM DESIGN

Insert nut rst , solder sleeve with valve outlet

pipe (Figure A) ; It is not necessary to disassemble

the TREV when soldering to the connecting lines.

Figure A Rotolock tting

Any of the commonly used types of solders or

brazing materials,e.g., 95-5, Sil-Fos, Easy-Flo,

Phos-Copper, Stay Brite 8 or equivalents may

be used for copper to copper connections. It

is important, however, regardless of the solder

used, to direct the ame away from the valve

body. As an extra precaution, a wet cloth may be

wrapped around the body during the soldering

operation. Screw the nut with compressor

injection tting (Figure A/gureB) ;Valve position

should be 30°to 45°with compressor center axis

,the nut screw torque is 80±10NM.

Figure B Valve location

26 FRCC.PC.039.A1.02

Page 27

Theory of Injection cycle

o Bulb location (Figure C)

• Good thermal contact between the bulb and

discharge line is essential. Before assembly,

make sure the pipe and bulb surface is clean,

remove oil and impurities. We recommend to

add thermal Conductive Adhesive or silver paint

at the contact surface .

• Strapping the sensing bulb as close to the

compressor discharge valve as possible, not to

Figure C Bulb location

exceed 20cm.Strap the center of the bulb with

discharge pipe, the screw force should be taken

care, otherwise the bulb will be deformed, the

setting will be changed.

• The control temperature of the valve may be

slightly higher due to the cooling eects of

ambient temperature on the sensing bulb.

Therefore, insulating the bulb with insulator is

mandatory. Remove the paper surface, align the

cut with clamp, wrap around bulb.

GENERAL INFORMATIONPRODUCT INFORMATIONINTEGRATION INTO SYSTEMORDERING INFORMATION SYSTEM DESIGN

* Others refer to Sporlan SD-168 “Installation & eld service instructions” delivered with valve.

27FRCC.PC.039.A1.02

Page 28

Manage superheat

Requirement

GENERAL INFORMATIONPRODUCT INFORMATIONINTEGRATION INTO SYSTEMORDERING INFORMATION SYSTEM DESIGN

Evaluate the risk

During normal operation, refrigerant enters

the compressor as a superheated vapor. Liquid

ood back occurs when a part of the refrigerant

entering the compressor is still in liquid state.

In steady state conditions,

• suction superheat must be higher than 5K

• Discharge superheat must be higher than 15K

• Oil superheat must be higher than 10K

Discharge temperature sensor must be placed

onto the discharge tting and be insulated.

Oil temperature sensor must be placed between

oil sight glass and compressor baseplate and be

insulated.

Use the tables below in relation with the system

charge and the application to quickly evaluate

the risk and potential tests to perform.

BELOW charge limit ABOVE charge limit

No test or additional safeties required Liquid ood back test

Liquid ood back can cause oil dilution and, in

extreme situations lead to liquid slugging that

can damage compression parts.

In transient conditions,

• Discharge superheat must be higher than 5K

• Oil superheat must be higher than 10K

Charge limit is dened in table below:

Models Refrigerant charge limit (kg)

Single

LLZ013-015-018 4.54

LLZ024-034 7.26

Test, criteria and solutions

Tes t Purpose Test condition Pass criteria Solutions

Liquid ood back testing must be

carried out under expansion valve

threshold operating conditions: a

high pressure ratio and minimum

Liquid ood

back test

Defrost test

Steady-state

Transient

Check liquid

oodback

during defrost

cycle

evaporator load (A).

A

Tests must be carried out with most

unfavorable conditions :

• fan staging,

• compressor staging

• …

Defrost test must be carried out in

the most unfavorable condition (at

0°C evaporating temperature)

Oil superheat>10K

Steady-state discharge

superheat>15K

Oil superheat>10K

Transient discharge superheat >5K

Oil superheat>10K

Transient discharge superheat >5K

1. Check expansion valve selection

and setting

2. Add a suction accumulator*

1. Check expansion valve selection

and setting.

-For Thermostatic expansion valve

(TXV) check bulb position...

-For Electronic expansion valve

(EXV) check measurement chain and

PID....

2. Add a suction accumulator*

In refrigeration system, there are

dierent defrost method, such as

electric method. (for more details

see “Control Logic”).

*Suction accumulator oers protection by trapping the liquid refrigerant upstream from the compressor. The accumulator should be sized at least 50 % of

the total system charge. Suction accumulator dimensions can impact oil return (gas velocity, oil return hole size…), therefore oil return has to be checked

according to section “Manage oil in the circuit”.

28 FRCC.PC.039.A1.02

Page 29

Manage o cycle migration

Requirement

Evaluate the risk

Test, criteria and solutions

R

O -cycle refrigerant migration happens:

• when the compressor is located at the coldest

part of the installation, refrigerant vapor

condenses in the compressor.

• or directly in liquid-phase by gravity.

Amount of liquid refrigerant in the compressors

must not overpass the charge limit (refer to

charge limit table in section “Manage superheat”)

Use the table below in relation with the system

charge (refer to charge limit table in section

“Manage superheat”) and the application to

BELOW cHargE Limit aBOV E cHargE Limit

Non split No test or additional safeties required

Since each installation is unique, no test can fully evaluate o-cycle migration, therefore

Split

the following safeties are required:

• Belt type crankcase heater *

• Liquid Line Solenoid Valve**+ pump-down cycle***

When the compressor starts running again, the

refrigerant diluted in the oil generates poor

lubrication conditions. In extreme situations,

this leads to liquid slugging that can damage

compression parts.

GENERAL INFORMATIONPRODUCT INFORMATIONINTEGRATION INTO SYSTEMORDERING INFORMATION SYSTEM DESIGN

quickly dene necessary safeties to implement

and test to perform:

• Belt type crank case heater *

• Migration test

• (External Non-Return Valve)

Tes t N° Purpose Test condition Pass criteria Solutions

Migration test

Check that

there is no

migration of

refrigerant into

the compressor

(either liquid

or vapour

condensating)

Energize CCH*.

Stabilize the non-running system at

a pressure equivalent to 5°C .

Raise the system pressure

equivalent to 20°C. When saturated

condensing temperature reaches

20°C then start the unit.

Oil temperature sensor must be placed between

oil sight glass and compressor baseplate and be

insulated.

*Crank case heater (CCH)

The blet type sump heaters are designed

to protect the compressor against o-cycle

migration of refrigerant.

Additional heater power or thermal insulation

might be needed in case of ambient temperature

below -5°C and a wind speed above 5m/second.

The heater must be energized whenever all the

When all compressors are idle:

• Check in liquid line sight glass that

there is no liquid refrigerant transfer

• Oil superheat must be >10K during

o-cycle

After compressors has started:

• Oil superheat must remain >10K

It is recommended that the heater be turned on

for a minimum of 12 hours prior to starting the

compressor.

**Liquid line solenoid valve (LLSV)

A LLSV is used to isolate the liquid charge

on the condenser side, thereby preventing

against charge transfer to the compressor

during o -cycles. The quantity of refrigerant

on the low-pressure side of the system can be

further reduced by using a pump-down cycle in

association with the LLSV.

1. Check bulb position, tightness of

expansion device,

2. add LLSV**

3. add pump down cycle***

4. Check Crank case heater eciency

compressors are o.

Crank case heater accessories are available from

Danfoss (see section “Accessories”).

***Pump-down cycle

By decreasing pressure in the sump, pump down:

• evacuates refrigerant from oil

• set the sump saturating pressure much

lower than ambiance temperature and due

Optimum

location area

to that, avoid refrigerant condensation in the

compressor.

Pump-down must be set heigher than 0.33Bar(g)

for R404a.

For more details on pump-down cycle see

section “Control Logic”.

29FRCC.PC.039.A1.02

Page 30

Control logic

T

Safety control logic

requirements

HP switch

LP safety switch

GENERAL INFORMATIONPRODUCT INFORMATIONINTEGRATION INTO SYSTEMORDERING INFORMATION SYSTEM DESIGN

Electronic module (Motor

protection, DGT)

Tripping conditions Re-start conditions

Value Time Value Time

See Pressure settings table

from section “Manage

operating envelope”

Contact M1-M2 opened

Immediate, no delay.

No by- pass

Conditions back to normal.

Switch closed again

Manual reset

Maximum 5 auto reset during

a period of 12 hours, then

manual reset.

Maximum 5 auto reset during

a period of 12 hours, then

manual reset.

Cycle rate limit

requirements

Oil management logic

recommendations

Danfoss requires a minimum compressor running

time of 2 minutes to ensure proper oil return and

sucient motor cooling.

Additionally, compressor service life is based on a

maximum of 12 starts per hour.

~

KA

A1

H

T T

A2

TH

KA

~

A2 A3A1

180 s

In some cases, oil management can be enhanced

by control logic:

• If oil return test failed, a function can be

integrated in control to run all compressors

simultaneously during one minute every hour

in order to boost oil return. Time and delay can

be ne-tuned by oil return test N°1 in section

“Manage oil in the circuit”. During oil boost, pay

special attention to superheat management to

avoid liquid ood back and foaming.

Therefore, to guarantee these 2 requirements,

a three-minute (180- sec) time out is

recommended.

• If after running long time in full load, oil

unbalance appears, then a function can be in

control to stop all compressors in manifold

during one minute every two hours in order

to balance oil between compressors. Time and

delay can be ne-tuned by Oil balancing test

N°2 in section “Manage oil in the circuit”.

Defrost logic

recommendations

30 FRCC.PC.039.A1.02

In refrigeration system applications, there

are dierent defrost methods, such as electric

heating defrost, hot gas bypass defrost, reversible

defrost etc. For the systems which use hot gas

bypass or reversible defrost method, suction

accumulator is necessary as a result of the

possibility of a substantial quantity of liquid

refrigerant remaining in the evaporator.

This liquid refrigerant can then return to the

compressor, either ooding the sump or as

a dynamic liquid slug when the cycle switch

back to normal cooling operations. Sustained

and repeated liquid slugging and ooding can

seriously impair the oil’s ability to lubricate the

compressor bearings. In such cases a suction

accumulator is a must.

Page 31

Control logic

Pump-down logic

recommendations

Pump-down cycle: Once the system has reached

its set point and is about to shut o, the LLSV

on the liquid line closes. The compressor then

pumps the majority of the refrigerant charge into

the high pressure side before the system stops on

the low pressure pump-down switch. This step

reduces the amount of charge on the low side in

order to prevent o-cycle migration.

A pump-down cycle represents one of the most

eective ways to protect against the

o-cycle migration of refrigerant; however it is

only convenient to apply on application with

thermostatic control.

Rack application with pressostatic control can use

timer delay to empty the evaporators before the

stop. Time should be carefully set to not interfere

with the low safety pressure switch.

For low pressure pump-down switch settings,

refer to section “High and low pressure

protection”. For suggested wiring diagrams,

please see section “Wiring diagram”.

Under certain conditions, the internal valve may

not completely seal, and due to the refrigerant

back ow the compressor might restart during

pump-down applications. Repeated short cycling

can result in a compressor breakdown. It is

recommended to install an external magnetic

check valve (such as Danfoss Part No. 120Z5046)

close to the compressor’s discharge connector so

the discharge volume is minimized.

A magnetic check valve is recommended for

this as it oers the best solution regarding

minimal required and maximal pressure drop

over the wide application envelope of the LLZ

scroll compressors. If a Danfoss NRV check valve

is applied it has to be carefully selected for the

specic operation conditions of the individual

system.

Tests for pump down cycle approval:

• As the pump-down switch setting is inside the

application envelope, tests should be carried

out to check unexpected cut-out during

transient conditions (i.e. defrost - cold starting).

When unwanted cut-outs occur, the low

pressure pump-down switch can be delayed. In

this case a low pressure safety switch without

any delay timer is mandatory.

• While the thermostat is o, the number of

pressure switch resets should be limited to

avoid short cycling of the compressor. Use

dedicated wiring and an additional relay which

allows for one shot pump-down.

GENERAL INFORMATIONPRODUCT INFORMATIONINTEGRATION INTO SYSTEMORDERING INFORMATION SYSTEM DESIGN

31FRCC.PC.039.A1.02

Page 32

Provide power supply and electrical protection

Wiring information

GENERAL INFORMATIONPRODUCT INFORMATIONINTEGRATION INTO SYSTEMORDERING INFORMATION SYSTEM DESIGN

Requirements:

• An additional external overload protection is

still advisable for either alarm or manual reset.

For overload setting, take the max current

• Provide separate electrical supply for the

heaters so that they remain energized even

when the machine is out of service (e.g.

seasonal shutdown).

you can face on the application and add

10%. Setting must always be lower than Max

Operating Current (see table…)

The wiring diagrams below are examples for a

safe and reliable compressor wiring:

• HP safety switch and DGT must be wired in the

safety chain. Other safety devices such as LP can

be either hardware or software managed.

The wiring diagrams below are examples for a safe and reliable compressor wiring:

Compressor model LLZ 013 - 015 - 018 - 024 - 034

CONTROL CIRCUIT

KM

F1F1

KA KA

PM

KA

KS

L1 L3 L2

Q1

KM

Control device.............................................TH

Optional short cycle timer (3 mins) .180 s

Control relay.................................................KA

Liquid Line Solenoid valve..................LLSV

Compressor contactor.............................KM

Phase monitor............................................PM

Safety lock out relay...................................KS

Pump-down control low

pressure switch............................................LP

High pressure safety switch..................HPs

Fused disconnect.......................................Q1

Fuses................................................................F1

Compressor motor.......................................M

Discharge gas thermostat....................DGT

A1

KM

KS

LP

KA

A3

180 s

A2

TH

KS

LLSV KS

T1

HPs

DGT

T2

T3

M

Wiring diagram with pump-down cycle

Note:

For LLZ phase monitors are mandatory. The selected phase monitor should lock out the compressor from operation in reverse.

32 FRCC.PC.039.A1.02

Page 33

Reduce moisture in the system

Requirements

Solutions

Excessive air and moisture

• can increase condensing pressure and cause

excessively high discharge temperatures.

• can create acid giving rise to copper platting.

• can destroy the lubricating properties of the oil.

LLZ compressors are delivered with < 100 ppm

moisture level.

To achieve this requirement, a properly sized

and type of drier is required. Important selection

criteria’s include:

• driers water content capacity,

• system refrigeration capacity,

• system refrigerant charge.

All these phenomena can reduce service life

and cause mechanical and electrical compressor

failure.

At the time of commissioning, system moisture

content may be up to 100 ppm. During

operation, the lter drier must reduce this to a

level between 20 and 50 ppm.

For new installations with LLZ compressors with

polyolester oil, Danfoss recommends using the

Danfoss DML (100% molecular sieve) solid core

lter drier.

GENERAL INFORMATIONPRODUCT INFORMATIONSYSTEM DESIGNORDERING INFORMATION INTEGRATION INTO SYSTEM

33FRCC.PC.039.A1.02

Page 34

Assembly line procedure

Compressor storage

Compressor holding

charge

GENERAL INFORMATIONPRODUCT INFORMATIONSYSTEM DESIGNORDERING INFORMATION INTEGRATION INTO SYSTEM

Handling

HEAVY

Store the compressor not exposed to rain,

corrosive or ammable atmosphere between

-35°C and 70°C when charged with nitrogen.

Each compressor is shipped with a nominal dry

nitrogen holding charge between 0.4 and 0.7 bar

and is sealed with elastomer plugs.

R

Respect the following sequence:

• Remove the nitrogen holding charge via the

suction schrader valve to avoid an oil mist blow

out.

R

Compressor handling

LLZ Compressors are provided with a lifting

lug. This lug should always be used to lift the

compressor.

Once the compressor is installed, the lifting

lug should never be used to lift the complete

• Remove the suction plug rst and the discharge

plug afterwards to avoid discharge check valve

gets stuck in open position.

An opened compressor must not be exposed to

air for more than 20 minutes to avoid moisture is

captured by the PVE oil.

installation. The compressor must be handled

with caution in the vertical position, with a

maximum inclination of 15° from vertical.

do not lift

manually

34 FRCC.PC.039.A1.02

Page 35

Assembly line procedure

Piping assembly Good practices for piping assembly is a pre-requisite to ensure compressor service life.

System cleanliness

Circuit contamination possible cause: Requirement:

Brazing and welding oxides During brazing, ow nitrogen through the system

Filings and particles from the removal of burrs in

pipe-work

Moisture and air

Remove any particles and burrs generated by tube

cutting and hole drilling

Use only clean and dehydrated refrigeration grade

copper tubing

Opened compressor must not be exposed to air more

than 20 minutes to avoid moisture captured by POE oil

GENERAL INFORMATIONPRODUCT INFORMATIONSYSTEM DESIGNORDERING INFORMATION INTEGRATION INTO SYSTEM

Brazing procedure:

• Brazing operations must be performed by

qualied personnel.

• Make sure that no electrical wiring is connected

to the compressor.

• To prevent compressor shell and electrical box

overheating, use a heat shield and/or a heatabsorbent compound.

• Clean up connections with degreasing agent

• Flow nitrogen through the compressor.

• Use ux in paste or ux coated brazing rod.

R

Before eventual un-brazing of the

compressor or any system component, the

refrigerant charge must be removed.

• Use brazing rod with a minimum of 5% silver

content.

• It is recommended to use double-tipped torch

using acetylene to ensure a uniform heating of

connection.

• For discharge connections brazing time should

be less than 2 minutes to avoid NRVI damages

if any.

• To enhance the resistance to rust, a varnish on

the connection is recommended.

heat shield

A

C

B

System pressure test and

leak detection

The compressor has been strength tested

and leak proof tested (<3g/year) at the factory.

For system tests:

• Pressurize the system on HP side rst then LP

side.

• Do not exceed the following pressures:

• Always use an inert gas such as Nitrogen or

Helium.

Maximum compressor test pressures

Maximum compressor test pressure high side (HP) 31.1 bar (g)

Maximum compressor test pressure low side (LP) 31.1 bar (g)

35FRCC.PC.039.A1.02

Page 36

Assembly line procedure

Vacuum evacuation and

moisture removal

Refrigerant charging

GENERAL INFORMATIONPRODUCT INFORMATIONSYSTEM DESIGNORDERING INFORMATION INTEGRATION INTO SYSTEM

Dielectric strength and

insulation resistance tests

Requirements:

• Never use the compressor to evacuate the

system.

• Connect a vacuum pump to both the LP and HP

sides.

• Evacuate the system to a pressure of 500 μm Hg

(0.67 mbar) absolute.

R

Initial charge:

• For the initial charge, the compressor must not

run.

• Charge refrigerant as close as possible to the

nominal system charge.

• This initial charging operation must be done in

liquid phase between the condenser outlet and

the lter drier.

The tests are performed on each compressor at

the factory between each phase and ground.

• Dielectric strength test is done with a high

potential voltage (hi-pot) of 2Un +1000V AC

at least, and leakage current must be less than

5 mA. Additional tests of this type are not

recommended as it may reduce motor lifetime.

Nevertheless, if such a test is necessary, it must

be performed at a lower voltage.

Recommendations:

• Energized heaters improve moisture removal.

• Alternate vacuum phases and break vacuum.

with Nitrogen to improve moisture removal.

For more detailed information see “Vacuum

pump-down and dehydration procedure”

TI-026-0302.

If needed, a complement of charge can be done:

• In liquid phase while compressor is running by

slowly throttling liquid in.

• On the low pressure side, as far away as possible

from the compressor suction connection.

• Never bypass safety low pressure switch.

For more detailed information see

“Recommended refrigerant system charging

practice“ FRCC.EN.050.

• Insulation resistance is measured with a 500 V

DC megohm tester and must be higher than 1

megohm.

• The presence of refrigerant around the

motor windings will result in lower resistance

values to ground and higher leakage current

readings. Such readings do not indicate a faulty

compressor. To prevent this, the system can be

rst operated briey to distribute refrigerant.

Do not use a megohm meter nor apply

R

power to the compressor while it is under

vacuum as this may cause internal damage.

36 FRCC.PC.039.A1.02

Page 37

Commissioning

Preliminary check

Initial start-up

System monitoring

Check electrical power supply:

• Phase order: For LLZ compressors equipped

with an electronic module, reverse rotation will

be automatically detected. For more details refer

to section “Motor protection”.

• Surface sump heaters must be energized at least

6 hours in advance to remove refrigerant.

• A quicker start-up is possible by “jogging” the

compressor to evacuate refrigerant. Start the

The system must be monitored after initial

startup for a minimum of 60 minutes to ensure

proper operating characteristics such as:

• Correct superheat and subcooling.

• Current draw of individual compressors within

acceptable values (max operating current).

• No abnormal vibrations and noise.

• Correct oil level.

• Voltage and voltage unbalance within tolerance:

For more details refer to section “Motor voltage”.

compressor for 1 second, then wait for 1 to 2

minutes. After 3 or 4 jogs the compressor can

be started. This operation must be repeated for

each compressor individually.

If Oil Top-up is needed, it must be done while the

compressor is idle. Use the schrader connector

or any other accessible connector on the

compressor suction line. Always use original

Danfoss POE oil 160SZ from new cans.

For more detailed information see “Lubricants

lling in instructions for Danfoss Commercial

Compressors” TI 2-025-0402.

GENERAL INFORMATIONPRODUCT INFORMATIONSYSTEM DESIGNORDERING INFORMATION INTEGRATION INTO SYSTEM

37FRCC.PC.039.A1.02

Page 38

Dismantle and disposal

GENERAL INFORMATIONPRODUCT INFORMATIONSYSTEM DESIGNORDERING INFORMATION INTEGRATION INTO SYSTEM

Danfoss recommends that compressors and compressor oil should be recycled by a

suitable company at its site.

38 FRCC.PC.039.A1.02

Page 39

Packaging

Single pack

Industrial pack

Compressors are packed individually in a

cardboard box. They can be ordered in any

quantity. Minimum ordering quantity = 1.

Compressor model

LL Z013 116 9 965 730 460

LL Z015 1169 965 718 460

LLZ018 1169 965 718 468

LLZ024 116 9 965 775 495

LLZ034 1169 965 817 544

Note : Here including 9 single pack compressors

Length

(mm)

Compressors are not packed individually but

are shipped all together on one pallet. They

can be ordered in quantities of full pallets only,

Compressor model Nbr*

As far as possible, Danfoss will ship the boxes on

full pallets of 9 compressors according below

table.

Width

(mm)

Height

(mm)

multiples of 12 compressors, according below

table.

Length

(mm)

Width

(mm)

Height

(mm)

Gross

weight

(kg)

Gross

weight

(kg)

Static

stacking

pallets

GENERAL INFORMATIONPRODUCT INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION

LL Z013 12 1170 815 665 538 4

LL Z015 12 1170 815 750 538 4

LLZ018 12 1170 815 750 550 4

LLZ024 12 1170 815 720 586 4

LLZ034 12 1170 815 817 651 4

39FRCC.PC.039.A1.02

Page 40

Ordering codes

Compressor code numbers

Single pack

GENERAL INFORMATIONPRODUCT INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION

Compressor

model

LL Z013 T Q 9 121L9519 121L9517 121L9531

LL Z015 T Q 9 121L9515 121L9513 121L9529

LLZ018 T Q 9 121L9511 121L9509 121L9527

LLz024 T Q 9 121L9507 121L9505 121L9525

LLZ034 T Q 9 121L9523* 121L9521 121L9533*