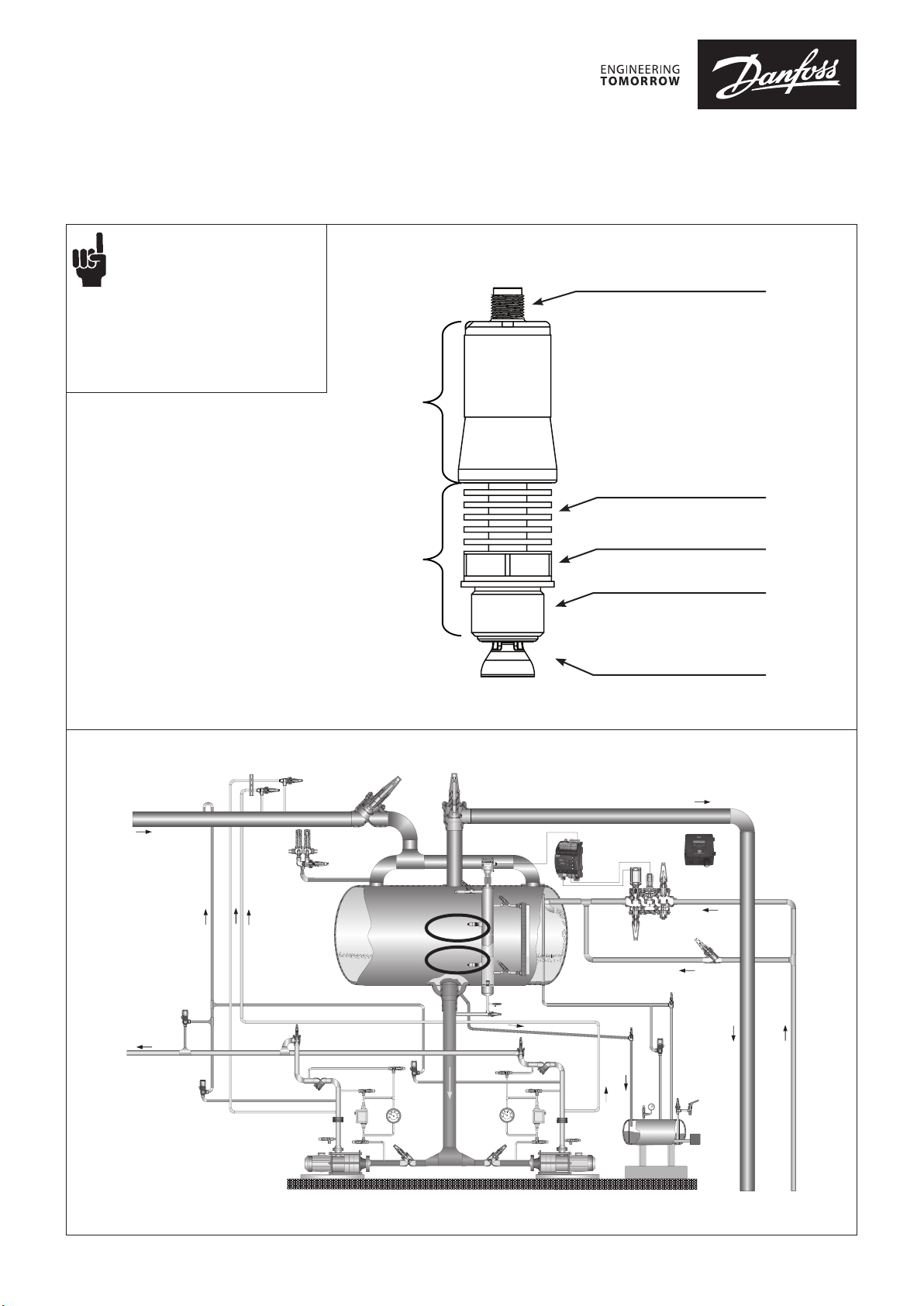

Installation guide/Quick start

Liquid Level Switch

Type LLS 4000 / LLS 4000U

Warning! This is a Class A device.

This device may cause radio

148R9650

interference in residential areas.

In case of interference, the operator

may be required to take

appropriate measures.

This instrument has to be mounted

on a metallic tank.

The device is intended to be used in

industrial areas.

M12 male Electrical

148R9650

connector

Heat sink (do not cover)

Hexagon 32 mm

Process connection

Mechanical part Electronic part

G ¾” or ¾” NPT

Fig. 1

BSV

BSV

SVA

SFA

+DSV

SVA

FIA

SNV

SCA-X

Liquid sensing part

SVA

SNV

RT

260A

SNV

BSV

LLG

LLS 4000

LLS 4000

SVA

SVA

AKS 4100

LLG

SCA-X

SNV

SVA

260A

EKE

347

ICF 25-6-5A

FIA

SNV

RT

SNV

SVA

BSV

SNV

SNV

SVA

SVA

GD

REG

QDV

15

SVA

SVA

Fig. 2

© Danfoss | DCS (ms) | 2020.05 AN317523977313en-000201 | 1

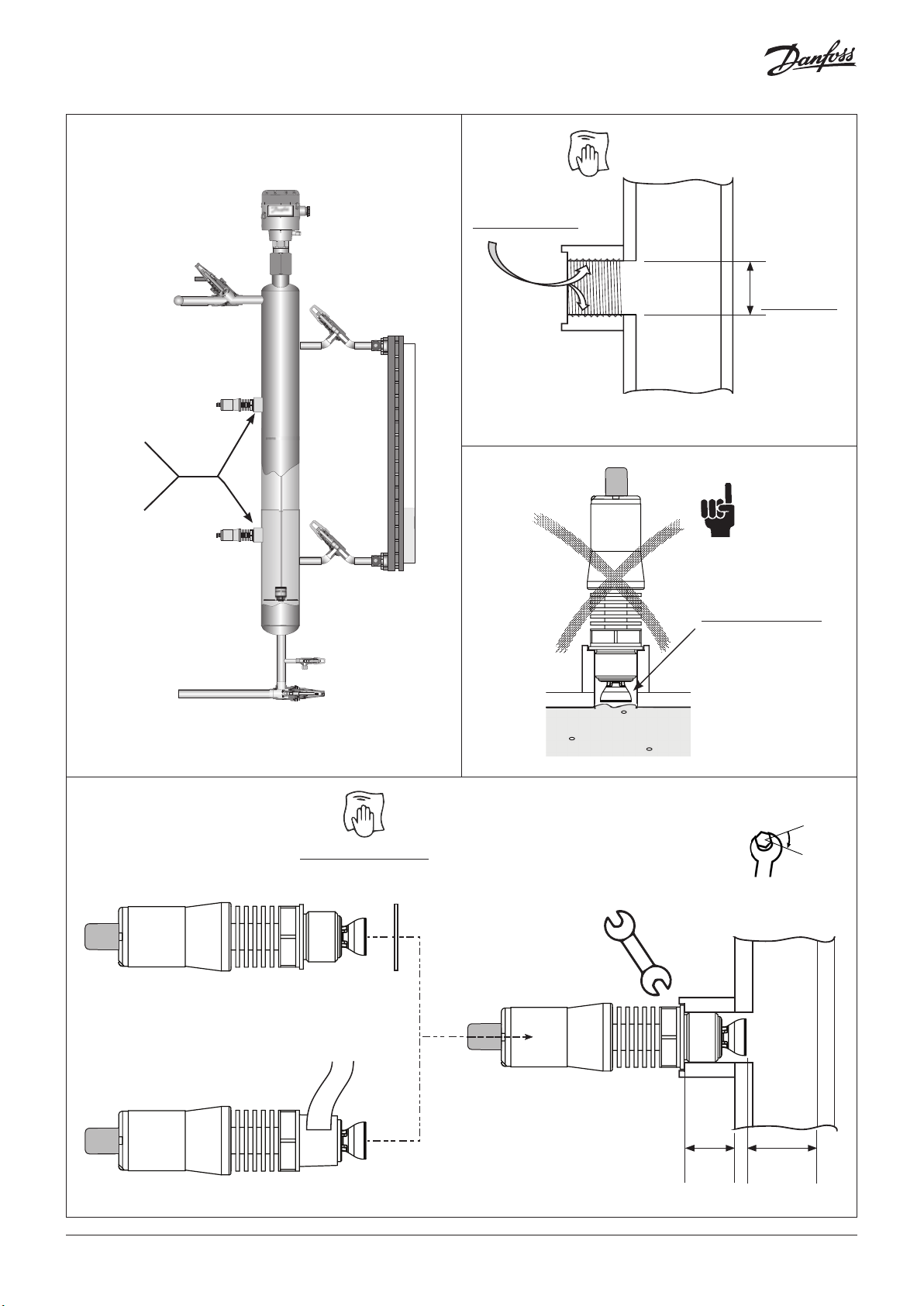

LLS 4000

45°

Weld connector

G ¾”

LLS 4000U

Weld connector

NPT ¾”

Note:

Horizontal installation

Recommended

Weld connector

Clean for particles

uninterrupted

hole size

no reduction

Fig. 4

Note:

Vertical or inclined

installation not

recommended:

Risk of Gas Pockets

Fig. 3 Fig. 5

Torque (LLS 4000 only):

10 Nm/7.4 lb ft pre-tightening + 45 degrees

clockwise rotation

Fig. 6

LLS 4000

LLS 4000U

Clean joining surfaces

Alu-gasket

G ¾”

Teflon (PTFE) tape

NPT ¾”

32 mm

max

45 mm

1.8 in

min

25 mm

1 in

© Danfoss | DCS (ms) | 2020.052 | AN317523977313en-000201

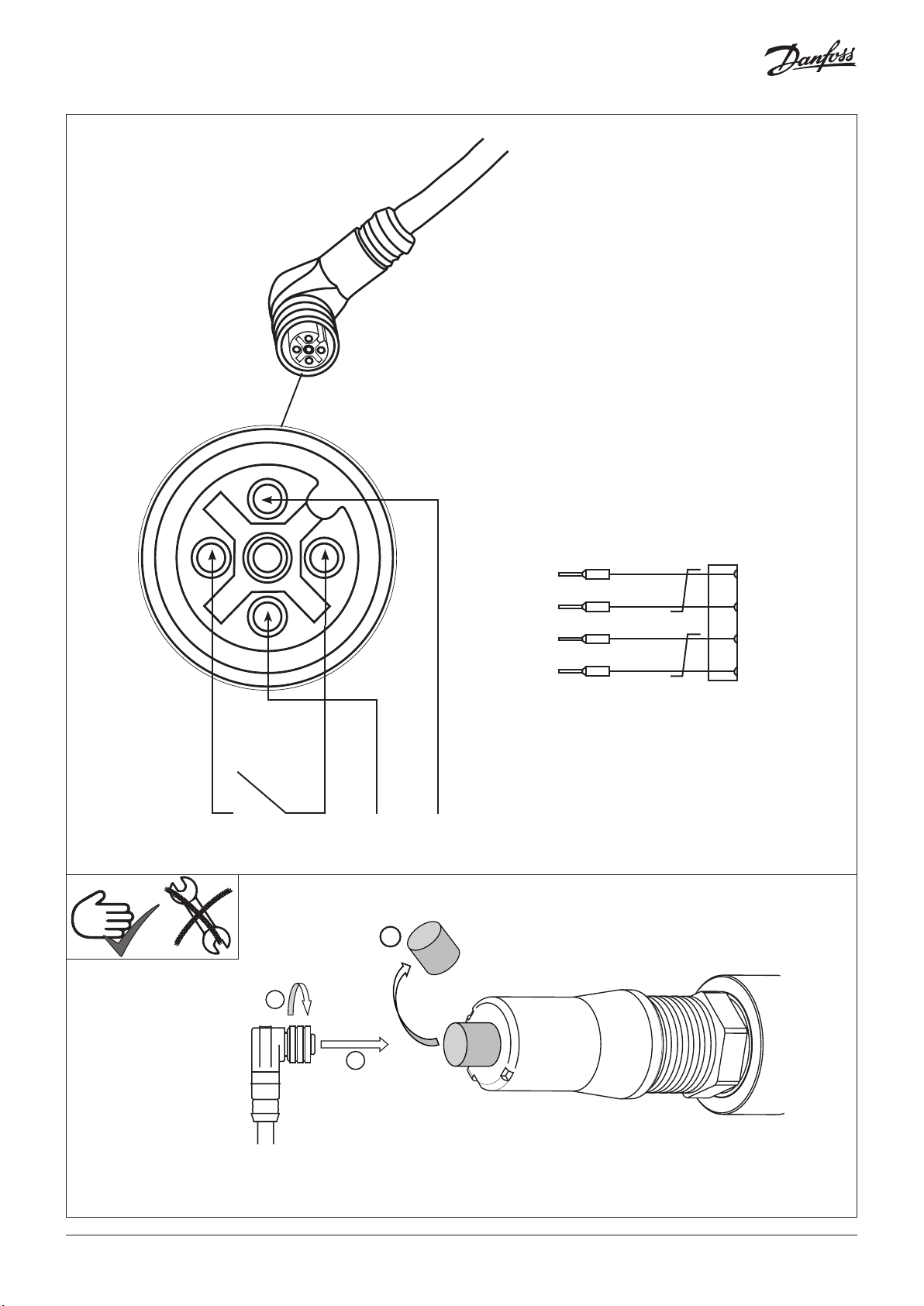

Cable with M12 female connector

1

Color code M12 cable

Fig. 7

4

3

Black

Relay: 30 V DC

200 mA

Hand-tighten clockwise

3

Red

2

Green

White

Black

1

2

3

4

Danfoss M12 cables

Green

- White

+ Red

034G7073, M12 cable female x 2 meter

034G7074, M12 cable female x 8 meter

Cables not included with LLS 4000/4000U

24 V DC +/- 25%

1

2

Note: Fasten the wire approx. 100 mm

from the LLS

Fig. 8

© Danfoss | DCS (ms) | 2020.05 AN317523977313en-000201 | 3

Red light LED

Yellow light LED

Fig. 9

High Level

sensor

High Level

sensor

Low Level

sensor

Low Level

sensor

Level

Open at no

Liquid

(Normally

Open)*

1)

Green light LED

Closed at no

Liquid

(Normally

Closed)*

SIL2 fixed

configuration

2)

Voltage

connected

Green LED Yel low LED Red LED

Level detection

LLS 4000/4000U

Fault

Voltage supply

outside

spec.

LLS 4000/4000U

fault**

Green LED ON Yellow LED ON Red LED ON

* Configuration dependent. Non-SIL2 fully configurable. SIL2 fixed configuration and only applicable for High Level sensor

** For failure types please connect the device to the Bluetooth App, enter fault state mode, and read the failure type

*** Fault can be detected at any detected level, ie. 2 or all 3 lights on

Not recommended in these applications because

1) A High Level Alarm may not be registered at a power failure

2) A Low Level Alarm may not be registered at a power failure

–

–

***

Green LED Flashing.

LLS 4000/4000U

connected to

Bluetooth device

© Danfoss | DCS (ms) | 2020.054 | AN317523977313en-000201

General specifications

Electrical data

24 V DC +/-25%, 80 mA

Supply

Relay (Solid state)

Mechanical Data

Max. medium viscosity 5000 cps

Max. working pressure 65 bar (943 psi)

Ambient temperature range -40 °C to +65 °C (-40 °F to +149 °F)

Medium temperature range -50 °C to +120 °C (-58 °F to +248 °F)

Operating environment Pollution degree 3, altitude 2000 max., outdoor use

Connection type G ¾ in. or NPT ¾ in.

Weight 350 g (0.77 lbs.)

Approved media

Refrigerants

Standard power supply of type: SELV (Separated Extra Low Voltage)

with current limit of max. 8A.

Max 30 V DC, 200 mA.

Same power supply as to supply can be used.

Observe:

In applications with request for SIL2, another separate SELV power

supply may be needed.

Max. cycles: 1.000.000

R717/NH (Ammonia): -50 °C to +105 °C (-58 °F to +221 °F)

R22: -50 °C to +86 °C (-58 °F to +187 °F)

R404A: -50 °C to +63 °C (-58 °F to +145 °F)

R410A: -50 °C to +61 °C (-58 °F to +142 °F)

R134A: -50 °C to +91 °C (-58 °F to +196 °F)

© Danfoss | DCS (ms) | 2020.05 AN317523977313en-000201 | 5

3/4 NPT

5.6

M12x1

M12x1

71,3 2

142,4

2.80.78

Fig. 10

36

H32

34

20 15

G3/4

1.4

H32

0.6

19,5

0.77

LLS 4000 (mm) LLS 4000U (in)

© Danfoss | DCS (ms) | 2020.056 | AN317523977313en-000201

LLS Bluetooth app download

1

2

3

download

Search

Danfoss

4

LLS 4000

ABCDEFGHIJKL

LL S______

1

2

3

LL S______ _

4 5 6

Configuration

LLS 4000

Pin code: 0000

© Danfoss | DCS (ms) | 2020.05 AN317523977313en-000201 | 7

Configurable

Configuration continued

LLS 00 7

7

8

Password: 12131400

In Service menu a unique

password for Service menu

can be entered.

- Go to menu upper right

- Go login

- Go to settings

- Go to Service Password

- Enter new Service Password

Read and apply safety instructions contained in product documentation.

Direct current.

General warnings/precautions

- Every use that is not described in this guide is considered incorrect and is not authorized by the manufacturer.

- The LLS device should only be used with approved media listed under General specifications. Use with other medias must be

validated by Danfoss before installation.

- Verify that the installation and operating conditions of the device respects those specified in this guide, especially concerning

the supply voltage and environmental conditions.

- All service and maintenance operations must be performed by qualified personnel.

- Installation must comply with local standards and legislation.

- Before carrying out any maintenance operations on the device, disconnect the device from the main power supply.

- Before unscrewing the LLS device from the pipe or tank ensure that pipe or tank is empty and not under pressure.

- Liability for injury or damage caused by incorrect use of the device lies solely with the user.

- Depending on the application, the metallic part of the instrument may be hot or cold.

- If media detection or non-detection by the level switch could generate a hazard the SIL version and specific instructions described

in the safety manual (periodic proof test) should be used. The SIL safety manual can be downloaded from Danfoss web site or by

scanning the QR code below.

For further documents (Data sheet, SIL2 safety manual etc.) scan this QR code:

Danfoss A/S, 6430 Nordborg, Denmark

www.danfoss.com

22

© Danfoss | DCS (ms) | 2020.058 | AN317523977313en-000201

Loading...

Loading...